Catalysis carbon-forming type flame-retardant composite material and preparation method thereof

A flame-retardant composite material and charcoal-forming technology, which is applied in the field of catalytic charcoal-forming flame-retardant composite materials and its preparation, can solve the problems of fast flame propagation speed, large release rate, environmental hazards, etc., and achieve reduction of combustible gas content, reduction of Good effect on burning speed and product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

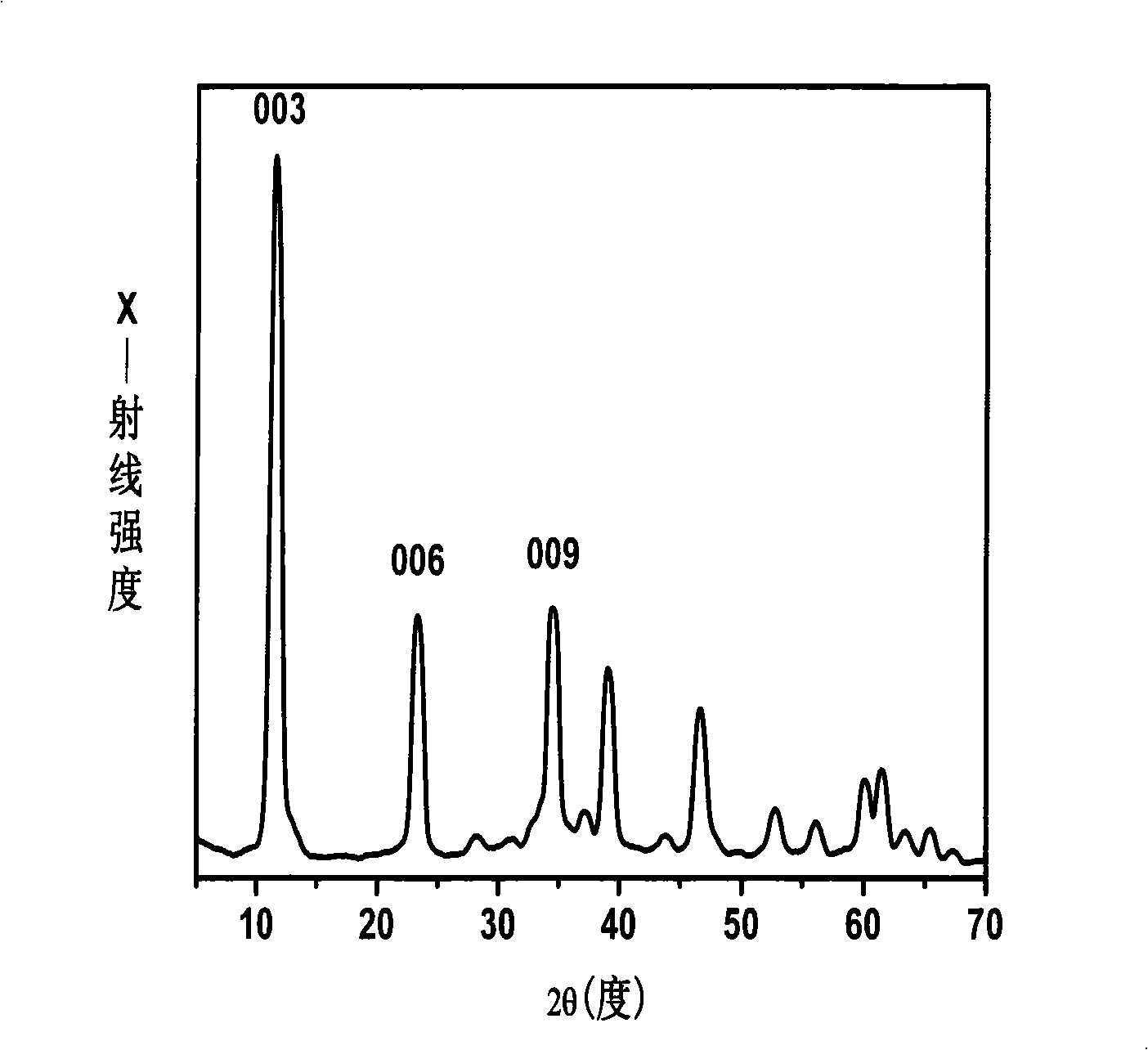

[0023] A: Hydrotalcite is prepared by nucleation crystallization / isolation method, the specific method is to weigh 174.48gNi(NO 3 ) 2 ·6H 2 O and 112.54g Al(NO 3 ) 3 9H 2 O was dissolved in deionized water to form a 750mL mixed salt solution, and 64.8g NaOH and 95.39g NaOH were weighed 2 CO 3 Dissolve in deionized water to make 750mL mixed alkali solution, add the two mixed solutions into the total back-mixed liquid membrane reactor at the same time, adjust the slit width between the rotor and stator of the reactor to be 2mm, the working voltage is 140V, and the rotor speed is 5000rpm , transfer the obtained mixed slurry to a three-necked flask, heat and stir, under nitrogen protection, reflux crystallization at 70°C for 6 hours, then fully wash with deionized water until the pH value is 7, and dry at 70°C for 12 hours to obtain Ni 2 Al-CO 3 - LDHs;

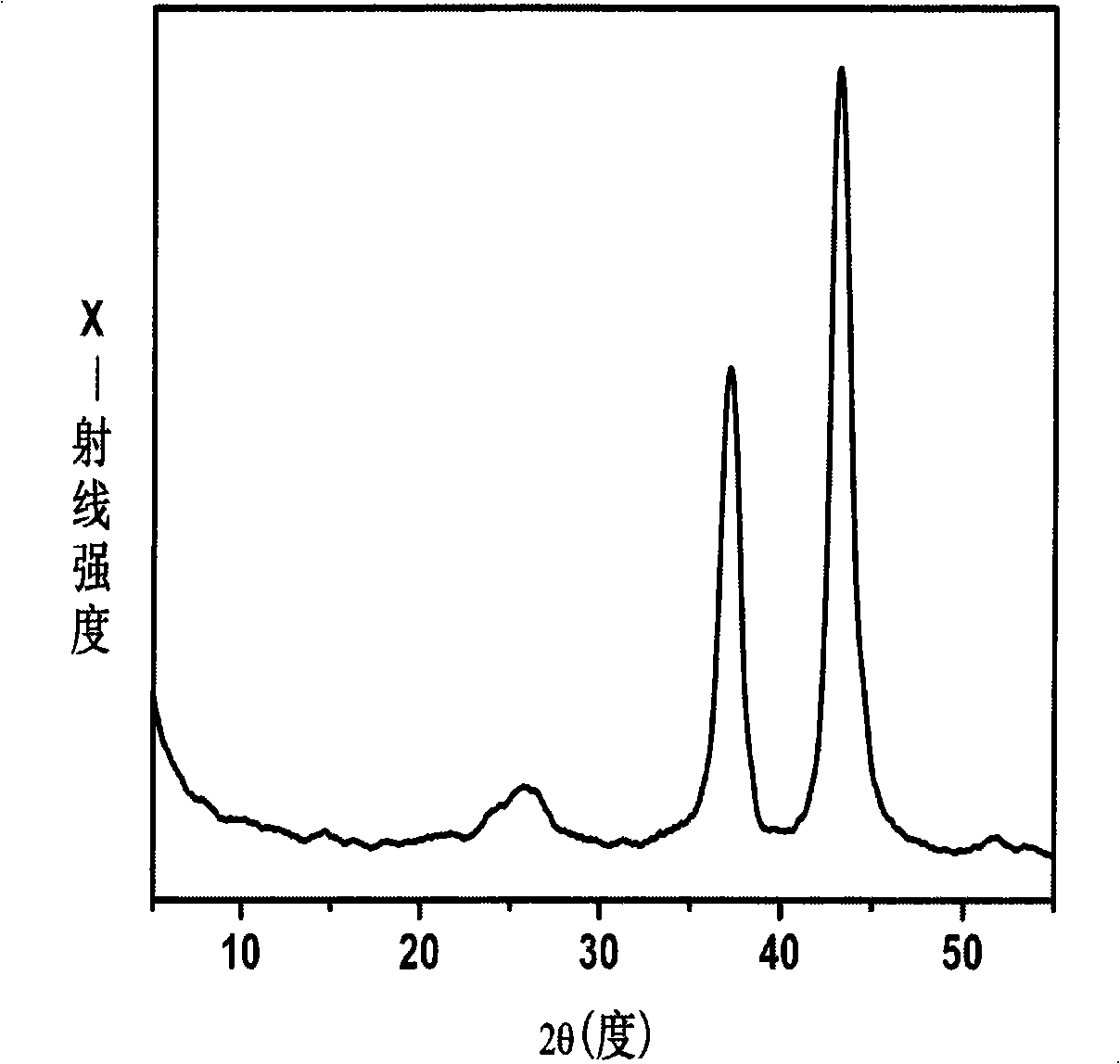

[0024] B: Weigh 60g of the hydrotalcite obtained in step A, then weigh 100g of polypropylene, and melt and blend it on ...

Embodiment 2

[0031] A: Weigh 174.48g Ni(NO 3 ) 2 ·6H 2 O and 75.96g Al(NO 3 ) 3 9H 2 O was dissolved in deionized water to make 750mL mixed salt solution; then weighed 51.36g NaOH and 63.59g NaOH 2 CO 3Dissolve in deionized water to make 750mL mixed alkali solution; add the above two mixed solutions into the total back-mixed liquid film reactor at the same time, adjust the slit width between the reactor rotor and the stator to be 2mm, the working voltage is 140V, and the rotor speed is 5000rpm, add the obtained mixed slurry into a three-necked flask, heat and stir, under nitrogen protection, keep the temperature of the mixed slurry in the bottle at 70°C for reflux crystallization for 6 hours, and obtain Ni 3 Al-CO 3 - LDHs;

[0032] B: Same as example 1;

[0033] C: Same as example 1.

Embodiment 3

[0035] A: Weigh 43.62g Ni(NO 3 ) 2 ·6H 2 O, 115.38g Mg(NO 3 ) 2 ·6H 2 O and 112.53gAl(NO 3 ) 3 9H 2 O was dissolved in deionized water to make 750mL mixed salt solution; then weighed 57.60g NaOH and 95.39g NaOH 2 CO 3 Dissolve in deionized water to make 750mL mixed alkali solution; add the above two mixed solutions into the total back-mixed liquid film reactor at the same time, adjust the slit width between the reactor rotor and the stator to be 2mm, the working voltage is 140V, and the rotor speed is 5000rpm, add the obtained mixed slurry into a three-necked flask, heat and stir, under nitrogen protection, keep the temperature of the mixed slurry in the bottle at 70°C for reflux crystallization for 6 hours, and obtain nickel-magnesium-aluminum hydrotalcite;

[0036] B: Same as example 1;

[0037] C: Same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com