Gunpowder for realizing deep well deep bumming and fracturing

A technology for blasting fracturing and gunpowder, applied in the direction of explosives, etc., can solve the problems of difficult to press formation with high fracture pressure, unsuitable gas generating agent, low energy of double-base gunpowder, etc. The effect of action time and slow burn rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The gunpowder of this embodiment includes solid gunpowder and liquid gunpowder, the mass ratio of the solid gunpowder and liquid gunpowder is 1:10.8, and the formula composition of the solid gunpowder and the liquid gunpowder is shown in Table 1.

[0026] Table 1 The formula composition of embodiment 1 solid gunpowder and liquid gunpowder

[0027]

[0028] The preparation method of the solid gunpowder of this embodiment is as follows: weigh each raw material according to the formula composition of the solid gunpowder, place the raw materials in a mixer and mix for 80 minutes, select a mold according to the shape and size of the gunpowder column to be prepared, and then mix the powder The raw materials are vacuum casted and molded, and then placed in a 70°C oven for curing for 5 days after being pressure-preserved and degassed to obtain a solid gunpowder column. The gunpowder column is hollow cylindrical, with an inner diameter of 25mm, an outer diameter of 85mm, and a...

Embodiment 2

[0037] This embodiment is the same as embodiment 1, wherein the difference is: the binder is polyurethane, or nitrocellulose and polyurethane, and the plasticizer is one of nitroglycerin, triacetin and pentaerythritol tetranitrate Or three, or nitroglycerin and pentaerythritol tetranitrate, or triacetin and pentaerythritol tetranitrate, the oxidizer in the solid gunpowder is ammonium nitrate, or ammonium perchlorate and ammonium nitrate, and the metal burning agent is magnesium powder , or aluminum powder and magnesium powder, the high-energy additive is RDX or Octogen, the stabilizer is 2-nitrodiphenylamine, and the catalyst is copper salicylate, rysooctanoic acid cuprous or carbon black; the liquid The oxidant in the gunpowder is ammonium perchlorate, or ammonium perchlorate and ammonium nitrate, and the burning agent is one, three or four of diethylene glycol, glycerin, urea and hexamethamine, or two Two of ethylene glycol, glycerin and urotropine, or a mixture of diethylen...

Embodiment 3

[0039] The gunpowder of this embodiment includes solid gunpowder and liquid gunpowder, the mass ratio of the solid gunpowder and liquid gunpowder is 1:9.6, and the formula composition of the solid gunpowder and the liquid gunpowder is shown in Table 2.

[0040] The formula composition of table 2 embodiment 3 solid gunpowder and liquid gunpowder

[0041]

[0042] The preparation methods of the solid gunpowder and the liquid gunpowder of this embodiment are all the same as in Example 1.

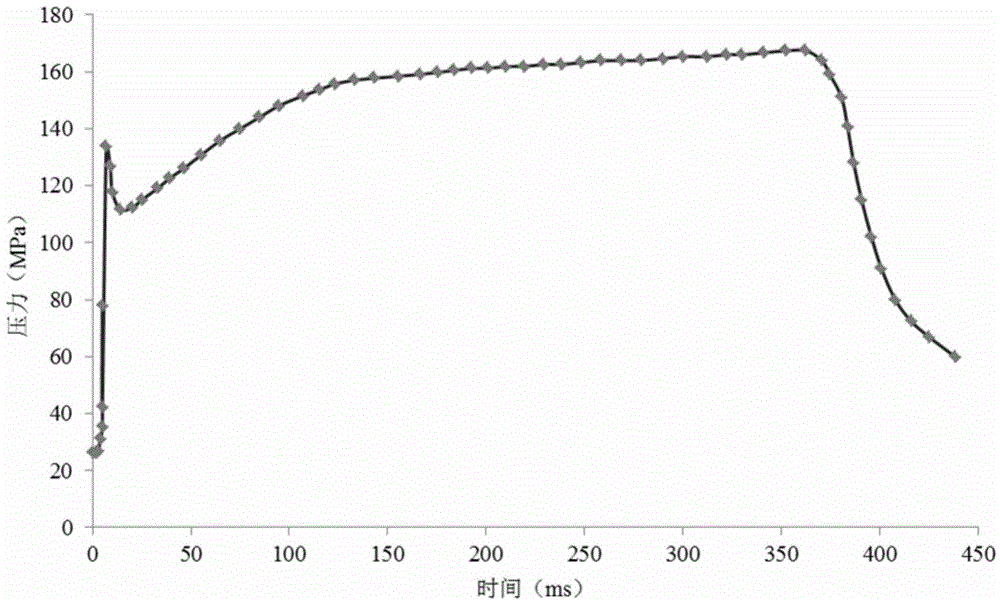

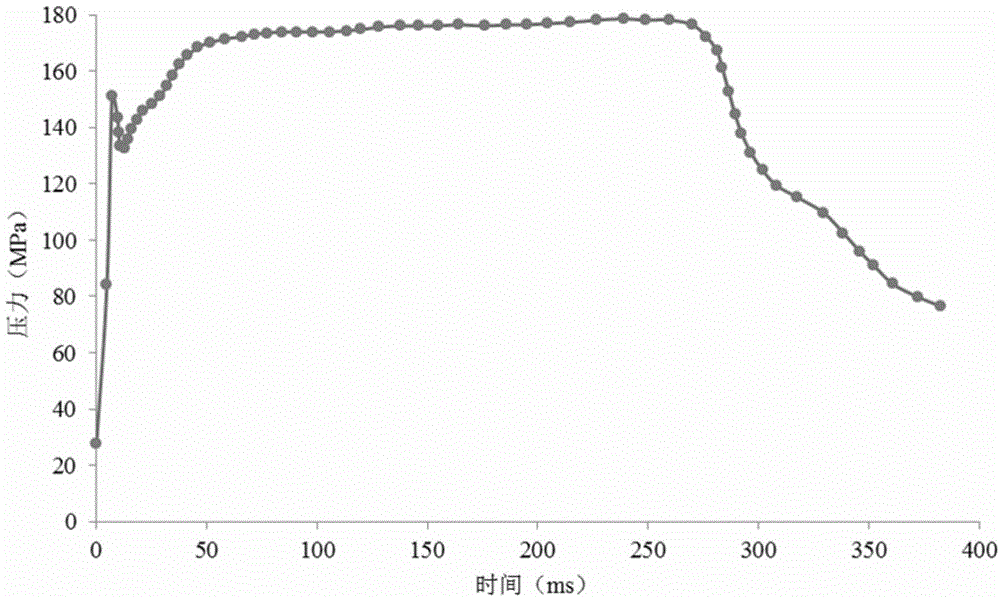

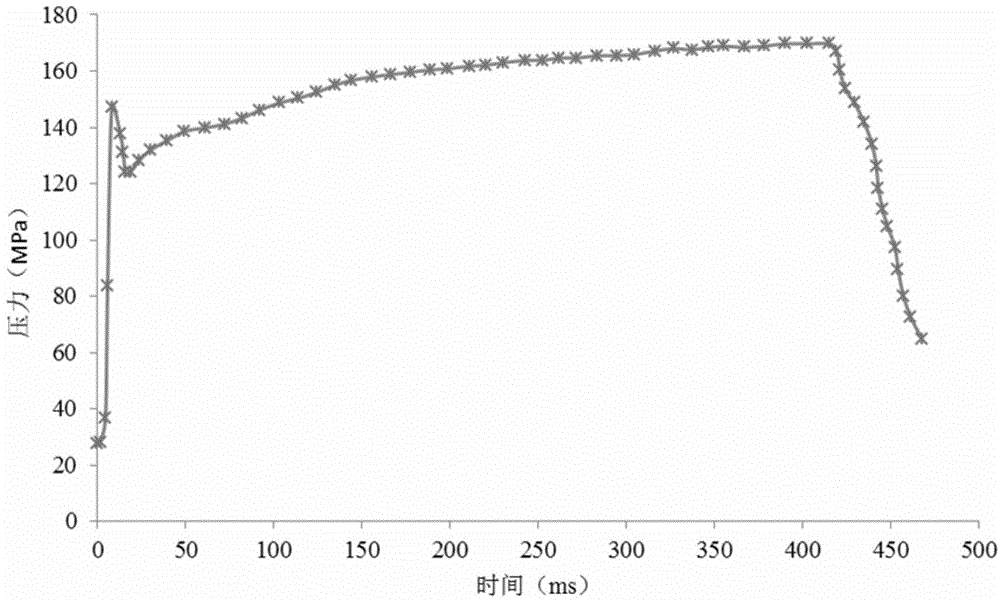

[0043] The gunpowder performance of the present embodiment is detected, and the results are as follows:

[0044] Peak pressure: under the airtight explosive device, the solid powder is 178.6MPa, and the liquid powder is 129.8MPa;

[0045] Burning rate and pressure index: under the airtight detonator 6.89MPa, the burning rate of solid propellant is 8.28mm / s, the pressure index is 0.418, the burning rate of liquid propellant is 2.52mm / s, and the pressure index is 0.203;

[0046] Temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com