A solid-phase combustion synthesis method for preparing porous metal monolithic profiles

A technology for porous metal and profiles, which is applied in the field of preparation of porous metal profiles, can solve the problems of easy foaming, difficulty in forming porous metal strips, rapid gas generation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

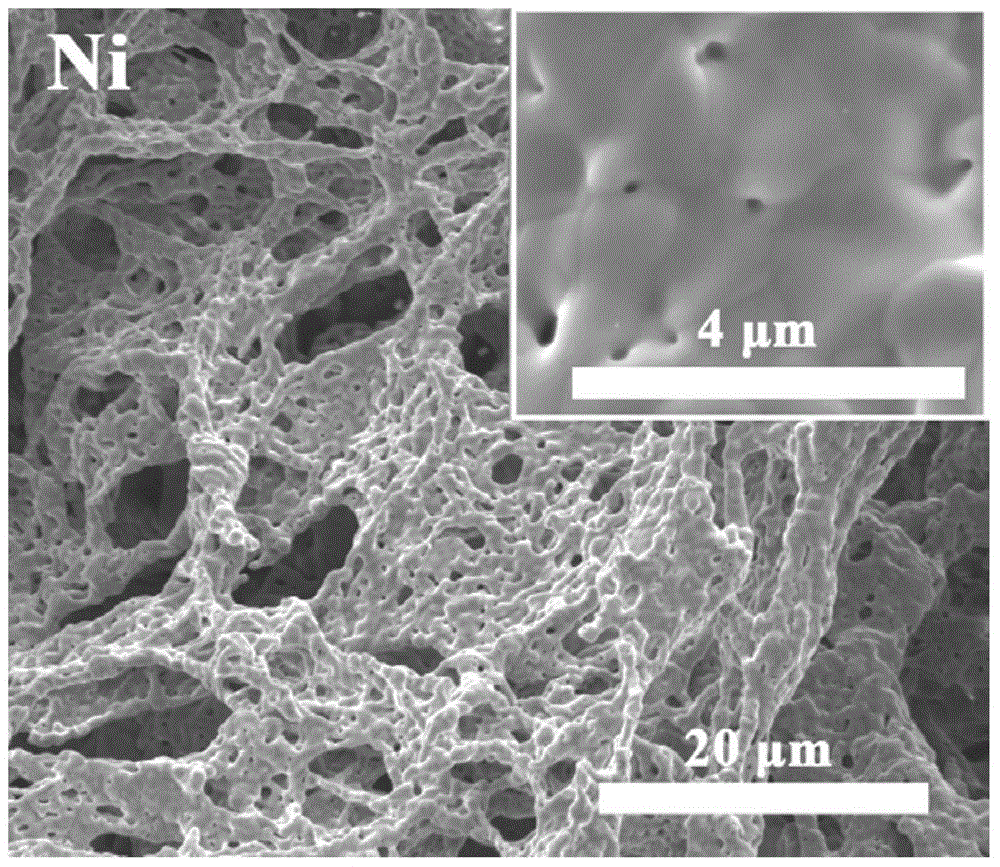

[0020] Porous nickel monolithic profiles were prepared as follows:

[0021] Step 1: Dissolve glycine and nickel nitrate in water at a molar ratio of 1.5:1, stir to form a uniform solution; evaporate water at 100°C to form a high-viscosity transparent colloidal precursor, and then place the colloidal precursor in vacuum, Dry at 200°C to obtain a molecular-level mixed solid complex precursor containing less crystal water.

[0022] Step 2: Grind the solid precursor obtained in the first step into a powder in a glove box filled with air dried at 100°C, and place the powder precursor in a cylindrical mold with d=16mm under a pressure of 10MPa Next, mechanically compact the powder into a cylindrical green body.

[0023] Step 3: After removing the mold, use an electric heating tungsten wire to partially ignite the green body prepared in the second step in the air, so that the solid precursor is self-propagating and fired into an integral nanoporous nickel integral profile in one ste...

Embodiment 2

[0026] After the third step in Example 1, the porous nickel monolithic profile is placed in a heat treatment device filled with a hydrogen atmosphere for reduction heat treatment to remove impurity elements such as C, N, and O in the nickel metal.

Embodiment 3

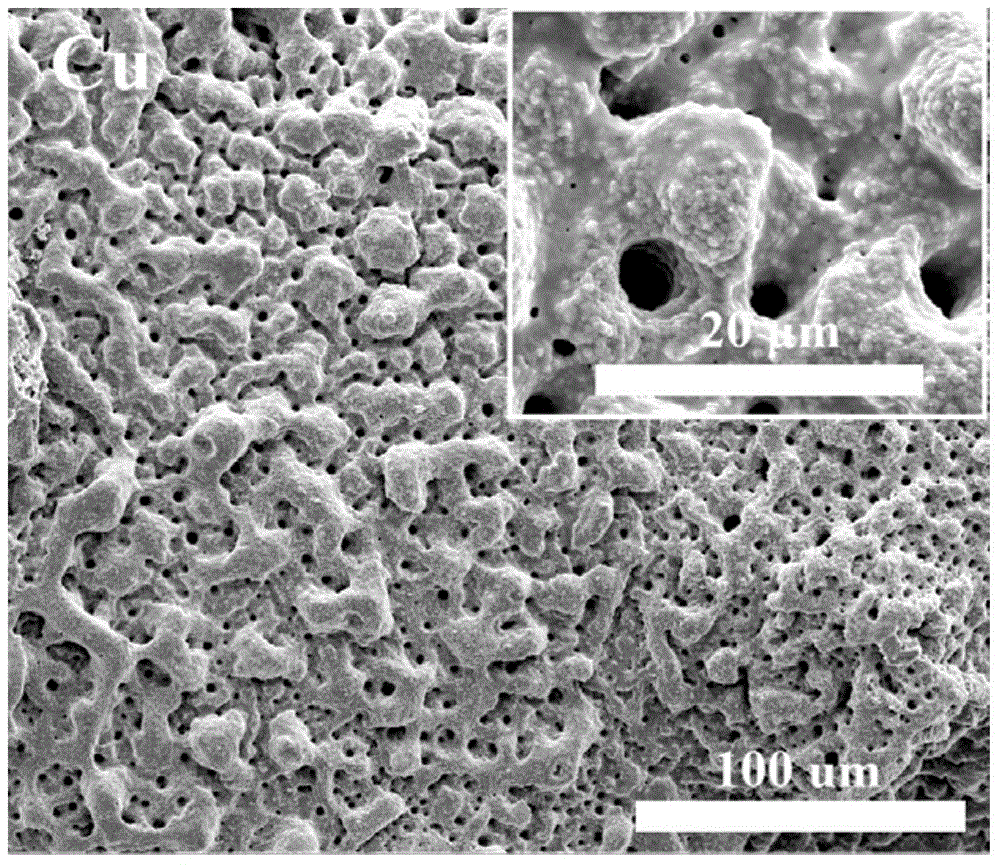

[0028] The preparation process is basically the same as in Example 1, but copper nitrate and citric acid are used as raw materials, and the molar ratio of citric acid to copper sulfate is 3:1 to prepare a porous copper integral profile. The microscopic morphology of the monolithic porous copper prepared by the above steps is as follows: figure 1 As shown, it is interlaced bands distributed with graded pores,

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com