Liquefied natural gas station

A technology for liquefied natural gas and gas filling station, which is applied in gas/liquid distribution and storage, equipment for loading into pressure vessels, container filling methods, etc. Reasonable and other issues, to achieve the effect of being conducive to fully automatic control, conducive to automatic control, and reducing natural gas consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Technical solution 1:

[0078] The liquid natural gas filling station is composed of storage tanks, pumps, filling machines, electric control systems, valves and pipelines. Its technical characteristics are:

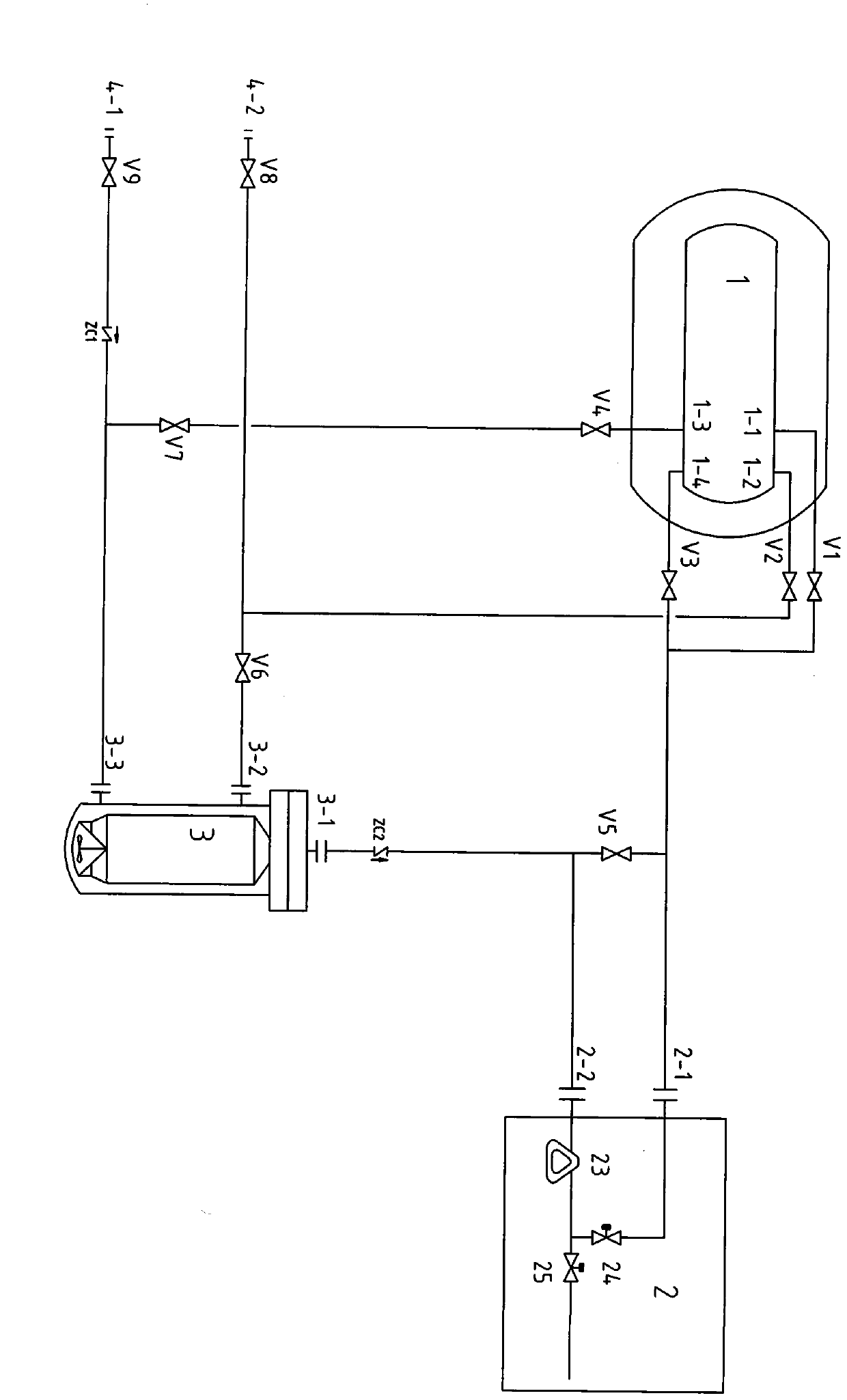

[0079] exist figure 1 Among them, option one:

[0080] (Transportation of LNG tank trucks) The unloading liquid phase port 4-1, the liquid inlet port 3-3 in the pump 3, and the bottom liquid phase liquid outlet port 1-3 in the storage tank 1 are connected through valves and pipelines (the connection form is Inverted "T"-shaped connection); the three form a connected circuit or pipeline, that is, LNG tanker unloading liquid phase port 4-1, valve V9, check valve ZC1, pump liquid inlet 3-3, storage tank 1 The pipeline consisting of the bottom liquid phase liquid outlet 1-3, valve V4, and valve V7;

[0081] (Transportation of LNG tank trucks) unloading gas phase port 4-2, gas return port 3-2 in pump 3, and upper gas phase port 1-2 in storage tank 1 are connected th...

Embodiment 2

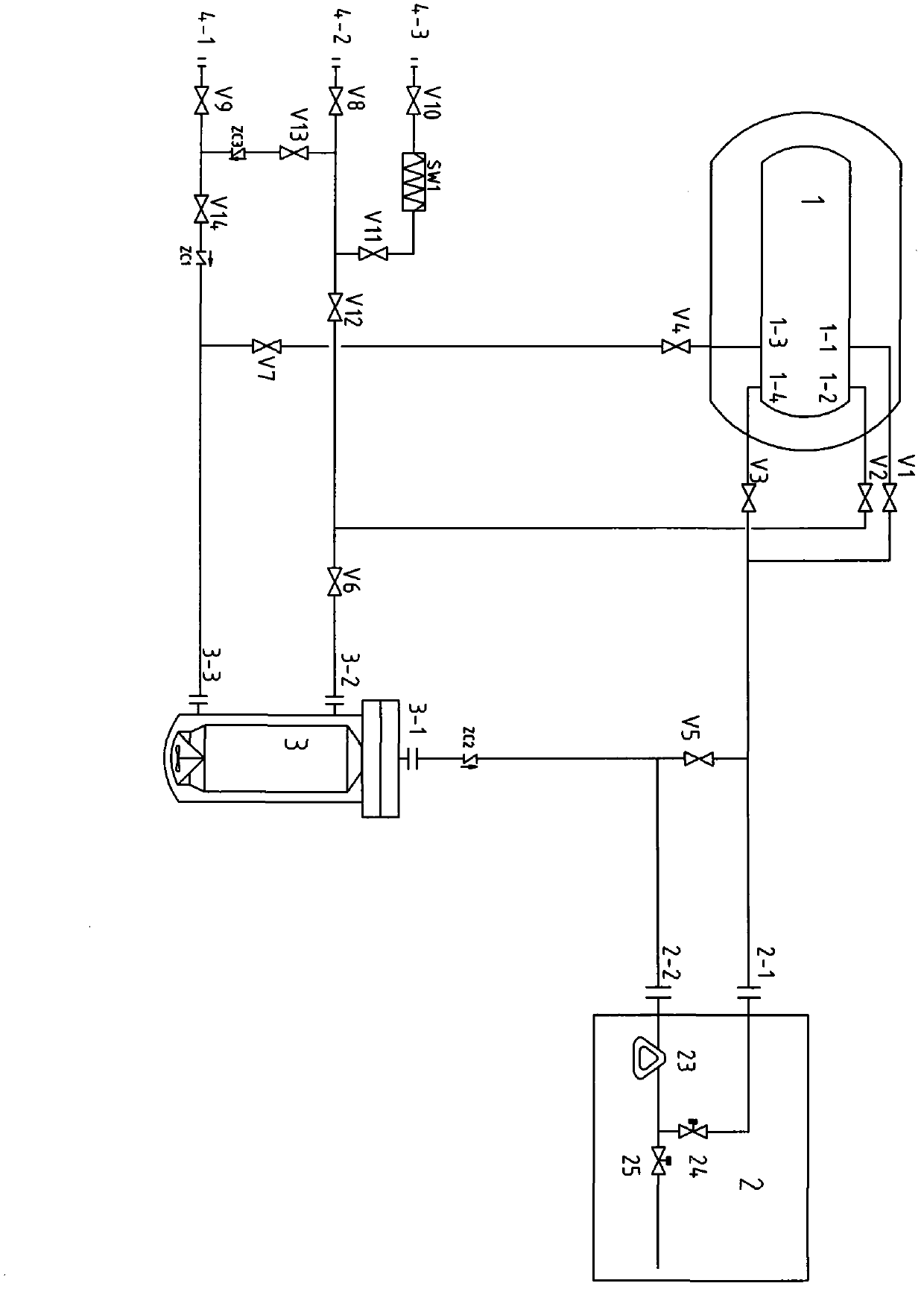

[0099] Add pipelines in Scheme 1 to expand applications, for example:

[0100] exist figure 2 In the middle, add 4-3 liquid phase, increase carburetor SW1, and parallel connection with unloading gas phase 4-2 pipeline, increase self-pressurized unloading function; it can also cooperate with pump unloading to increase the inlet pressure of the pump;

[0101] Between the unloading gas phase 4-2 pipeline and 4-1 liquid phase pipeline, add a valve and a check valve to achieve gas-liquid balance, let the BOG in the storage tank enter the tank car, and make the low temperature in the tank car unsaturated Liquid LNG liquefies BOG to reduce BOG emissions.

[0102] Unloading process steps:

[0103] The first method, air-gas balance self-pressurized unloading:

[0104] Close V6, V13, open V2, V12, V8, and balance the BOG in the storage tank and the BOG in the tank car first, that is, 1 storage tank→1-2→V2→V12→V8→4-2→inside the tank car;

[0105] After balancing, close V12, open V10...

Embodiment 3

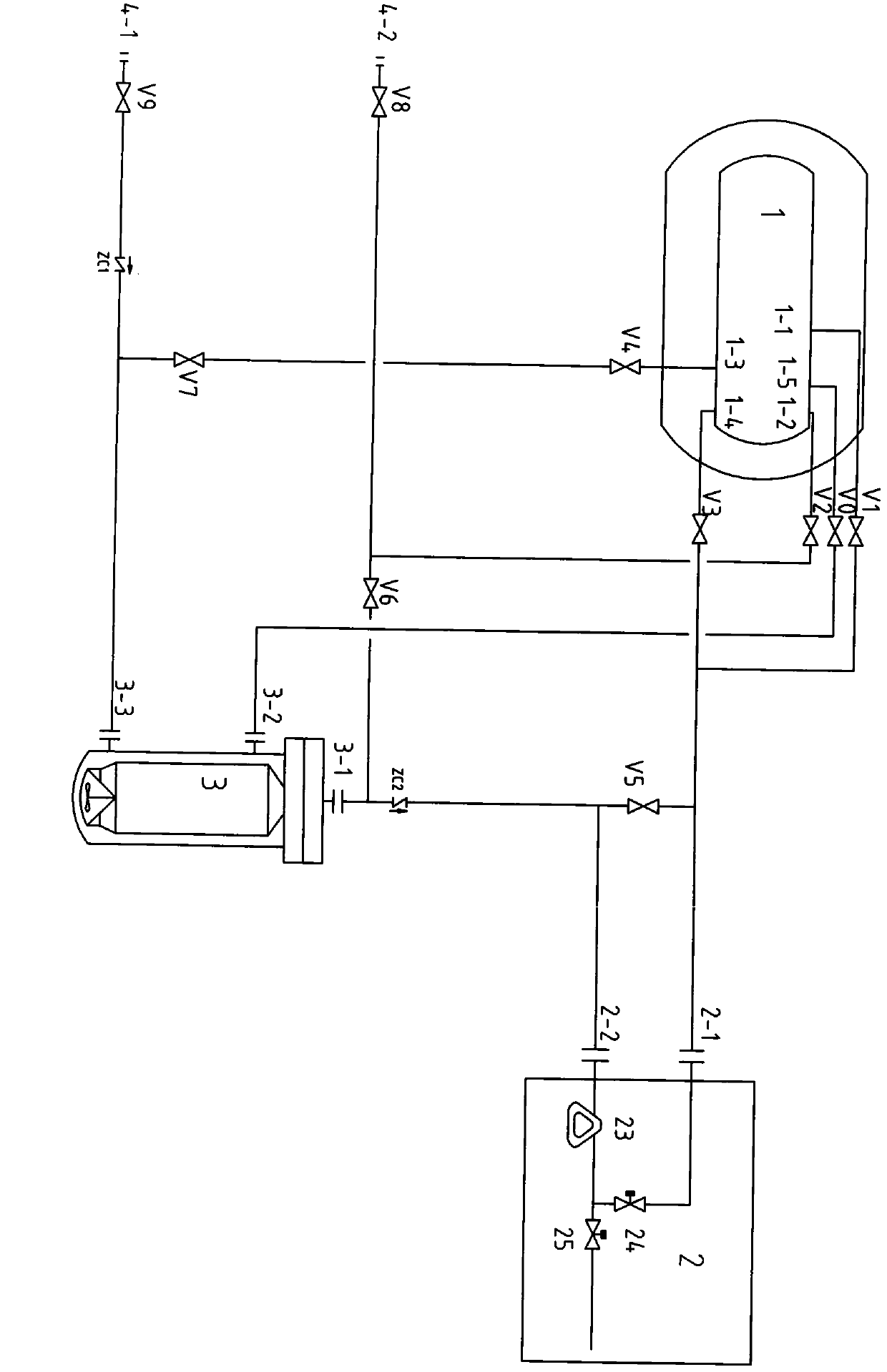

[0117] Technical solution 2:

[0118] The liquid natural gas filling station is composed of storage tanks, pumps, filling machines, electric control systems, valves and pipelines. Its technical characteristics are:

[0119] (Transportation of LNG tanker) Unloading liquid phase port 4-1, liquid inlet port 3-3 in pump 3, bottom liquid phase liquid outlet port 1-3 in storage tank 1 are directly connected by valves and pipelines (connection form Inverted "T"-shaped connection); that is, LNG tank truck unloading liquid phase port 4-1, valve V9, check valve ZC1, pump liquid inlet 3-3, bottom liquid phase liquid outlet 1 in storage tank 1 -3. The pipeline composed of valve V4 and valve V7;

[0120] (Transportation of LNG tanker) unloading gas phase port 4-2, liquid outlet 3-1 in pump 3, and upper gas phase port 1-2 in storage tank 1 are directly connected through valves and pipelines (the connection form is inverted " T" type word connection); that is (LNG tanker) unloading gas pha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com