Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1555results about How to "Easy to troubleshoot" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

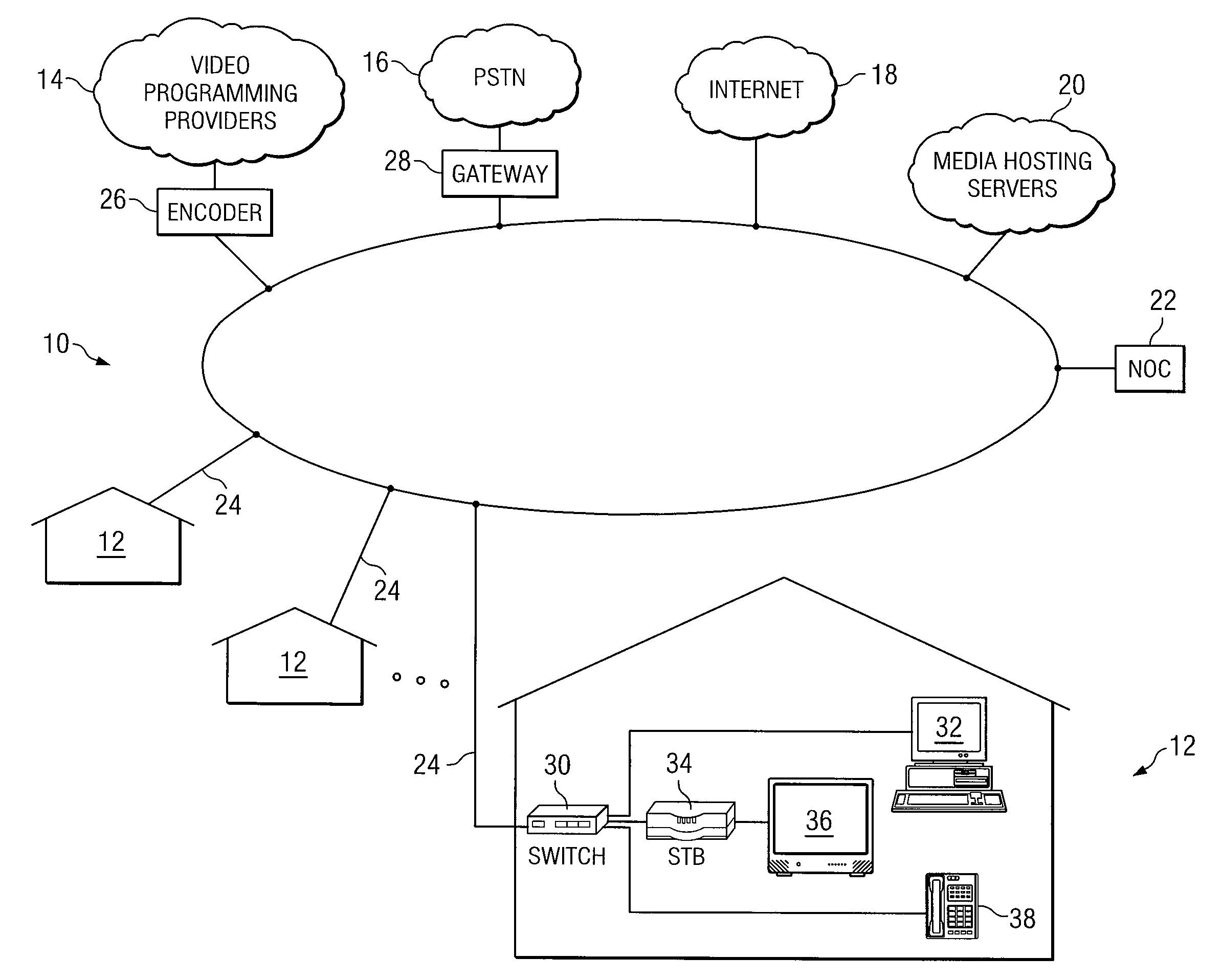

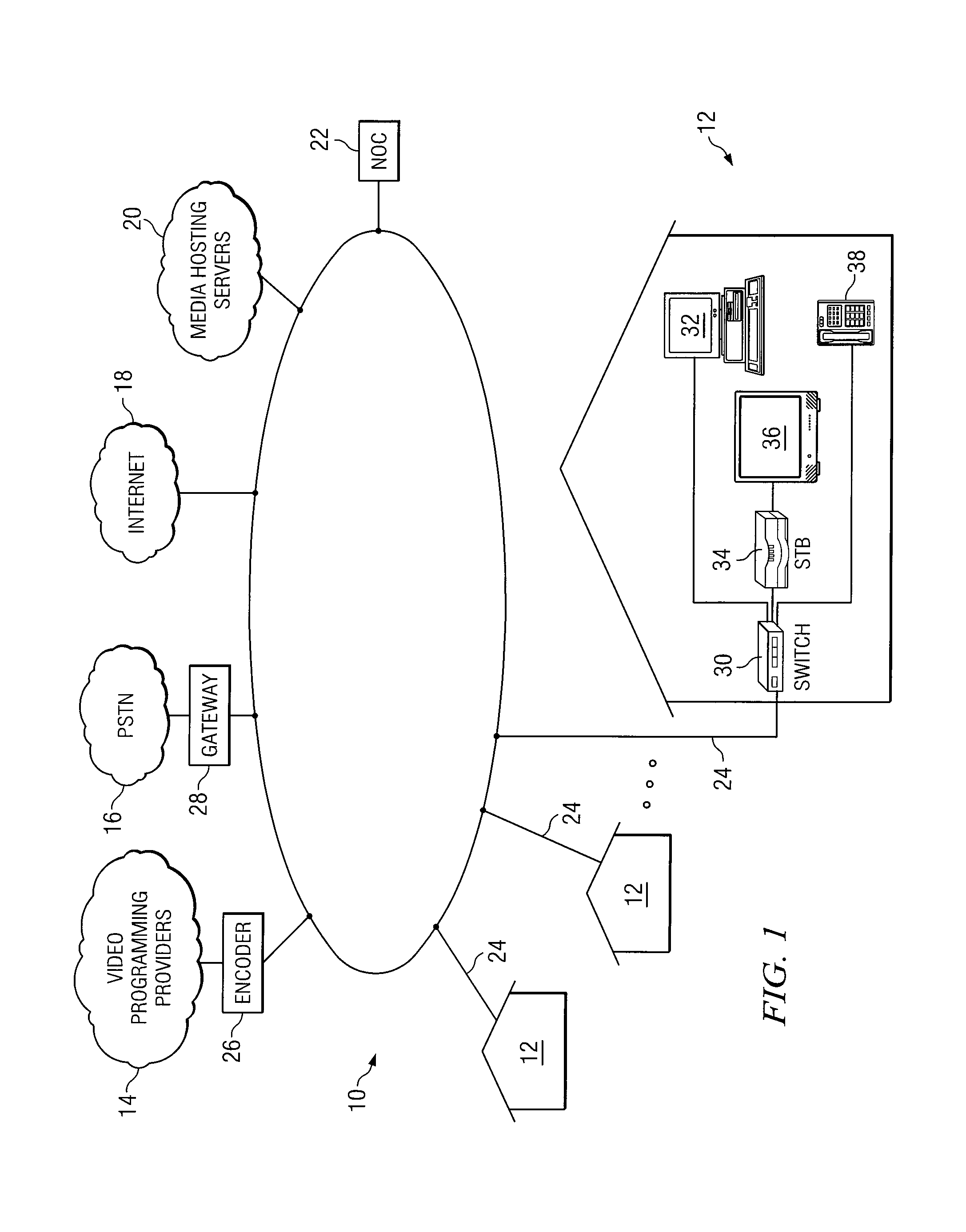

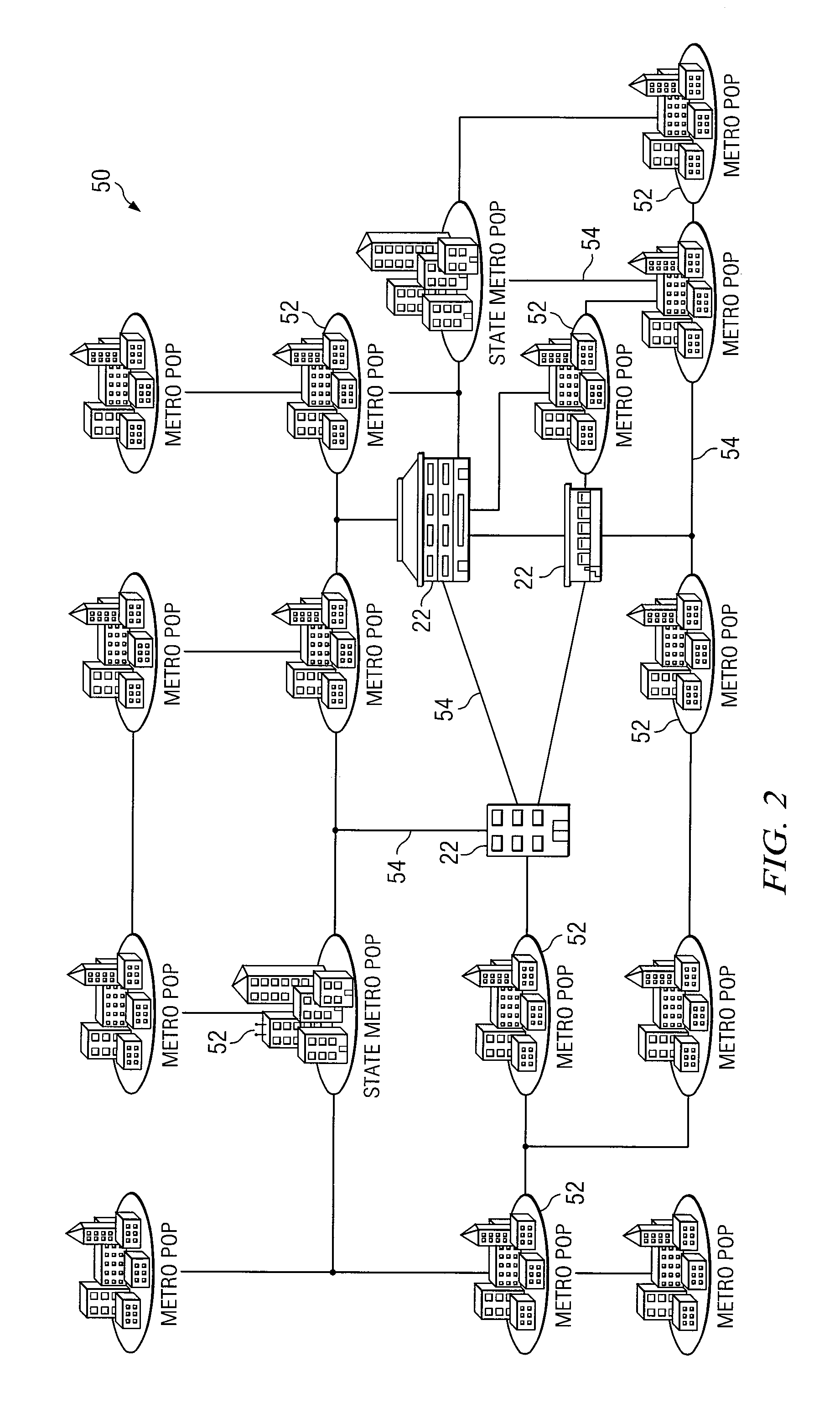

System and method for providing integrated voice, video and data to customer premises over a single network

InactiveUS7075919B1Easy to troubleshootEnhanced fault-toleranceTime-division multiplexData switching by path configurationData contentTelephone network

A method for providing integrated voice, video, and data content in an integrated service offering to one or more customer premises includes receiving television programming from a programming source, receiving data from a data network, and receiving telephone communications from a telephone network. The method further includes placing the television programming, data, and telephone communications in a common format for integrated communication over a single network infrastructure using a common communication protocol. In addition, the method includes communicating the integrated television programming, data, and telephone communications in the common format over the single network infrastructure using the common communication protocol to one or more customer premises to provide the integrated service offering.

Owner:CISCO TECH INC

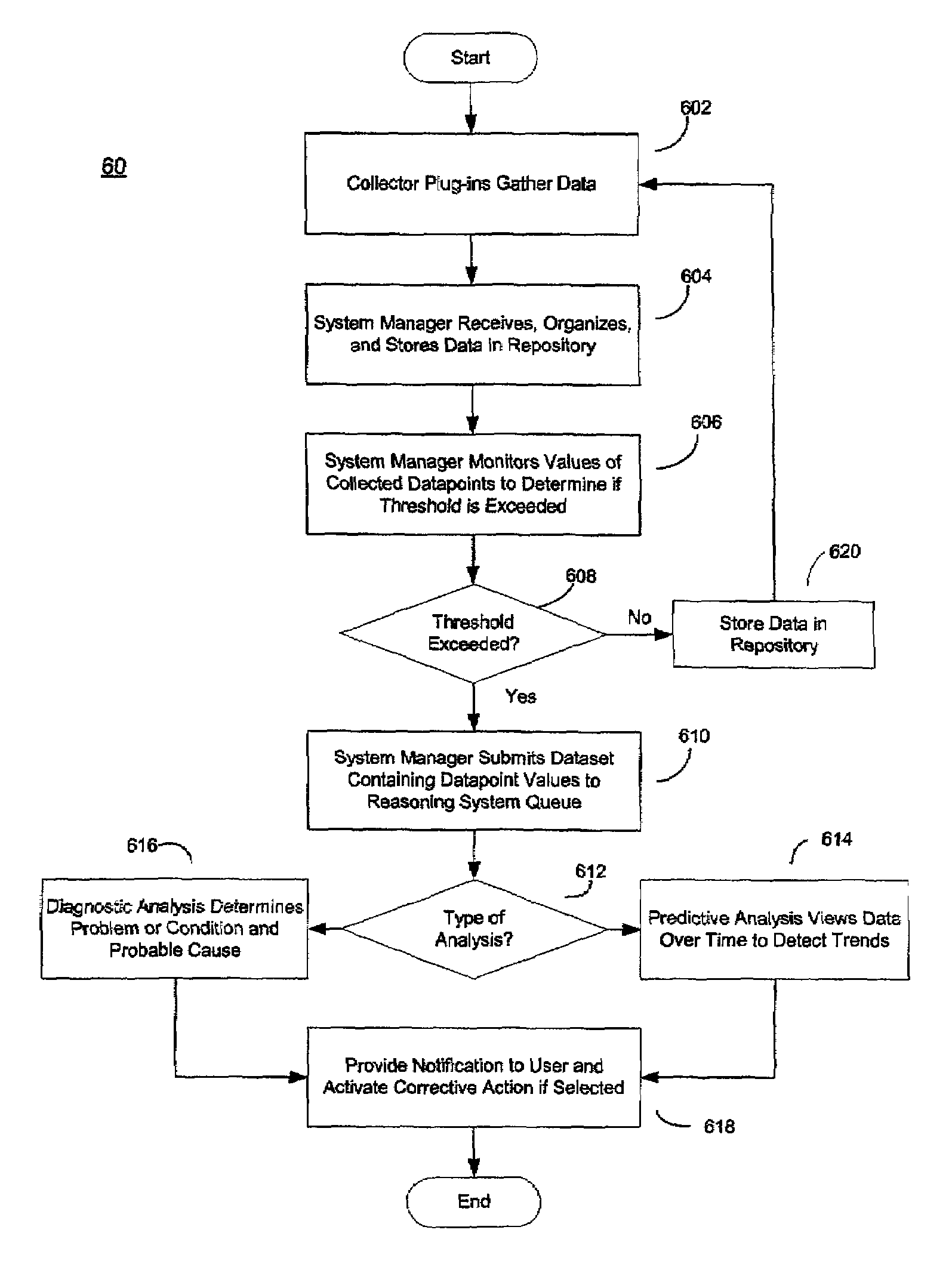

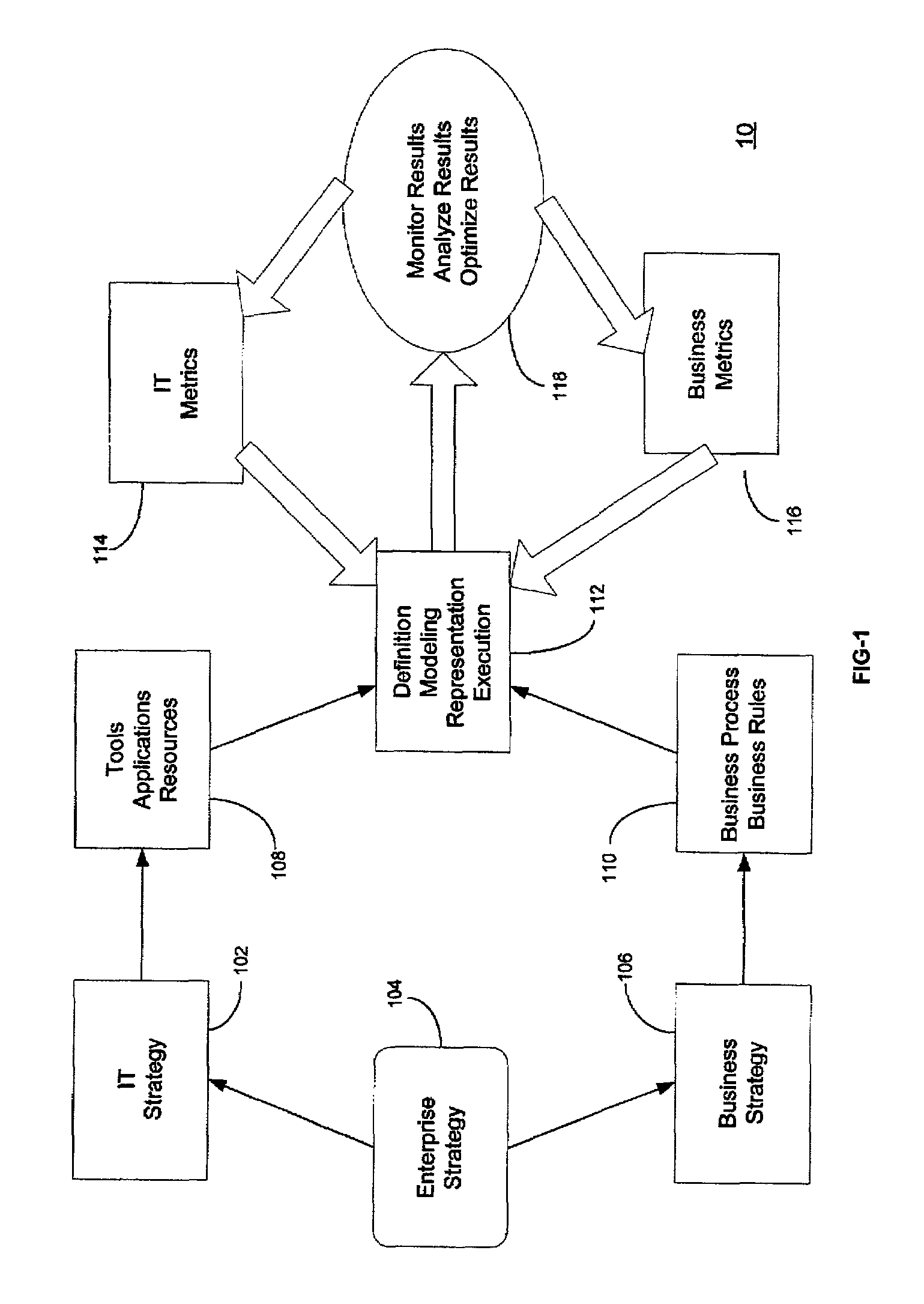

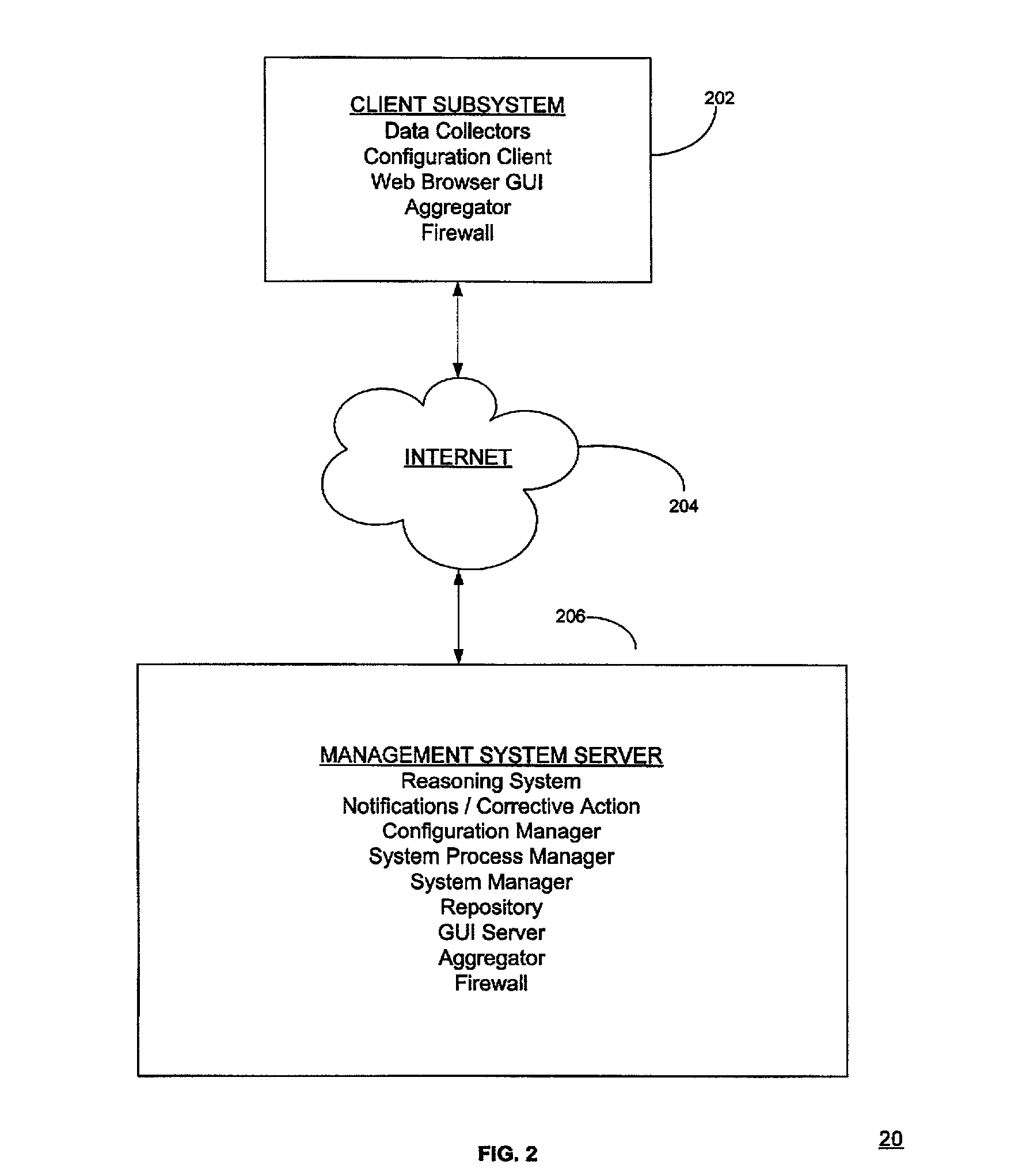

System and method for business systems transactions and infrastructure management

InactiveUS7065566B2Increase costImprove performanceDigital computer detailsBuying/selling/leasing transactionsSecure communicationCollection system

The system and method for business systems transactions and infrastructure management includes a client side collection system and a server side system having the capability to communicate with the other over a secure communication path. The collection system extracts transaction and infrastructure data from a business system and transmits the extracted data to the management server over a secure communication path. The management server receives the extracted data over the secure communication path, compares it to threshold analyzes the data that exceed threshold values, and notifies a user of the results of the analysis. The management server also has the capability to activate corrective scripts in the client business system and to reconfigure the client business system.

Owner:CA TECH INC

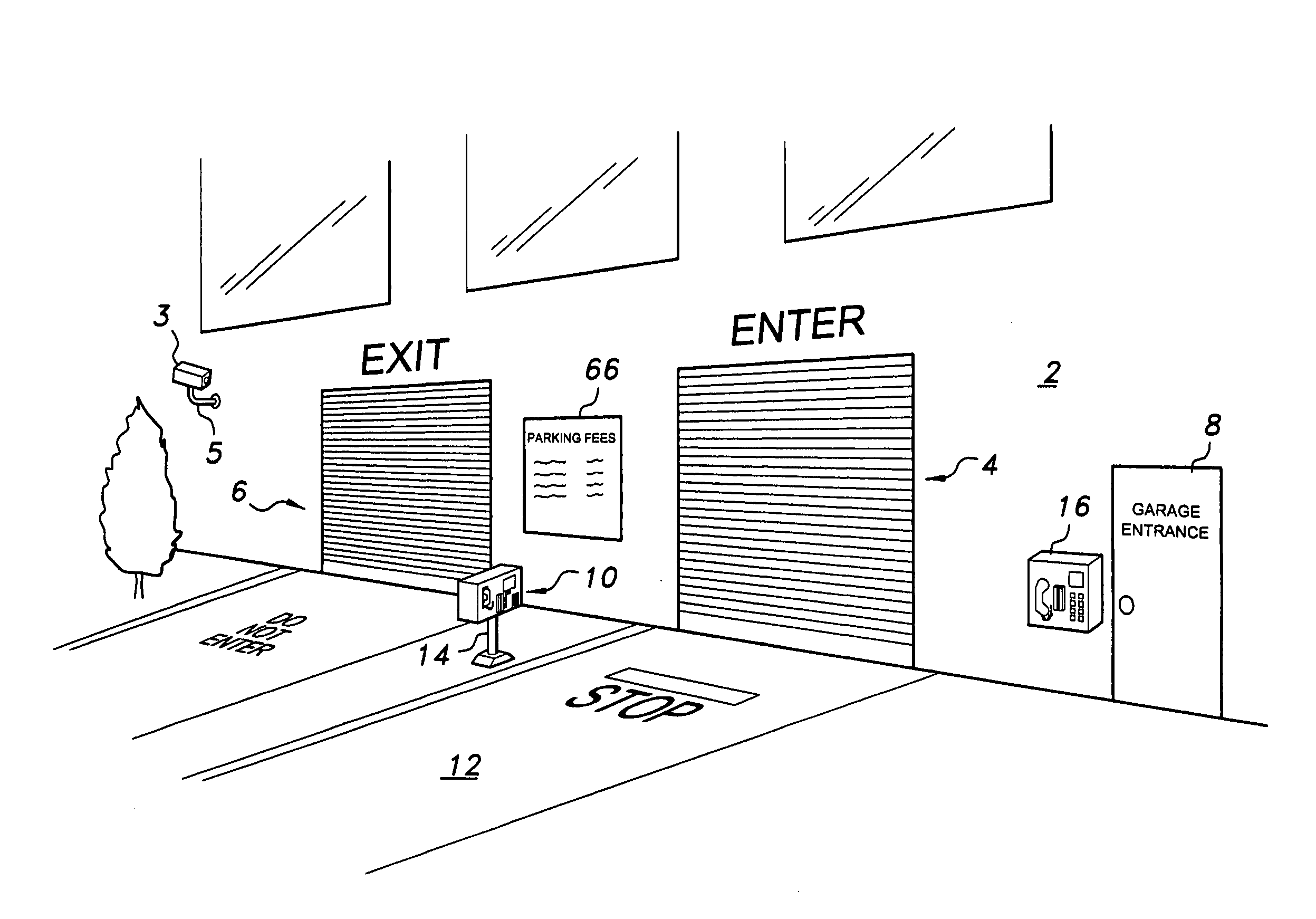

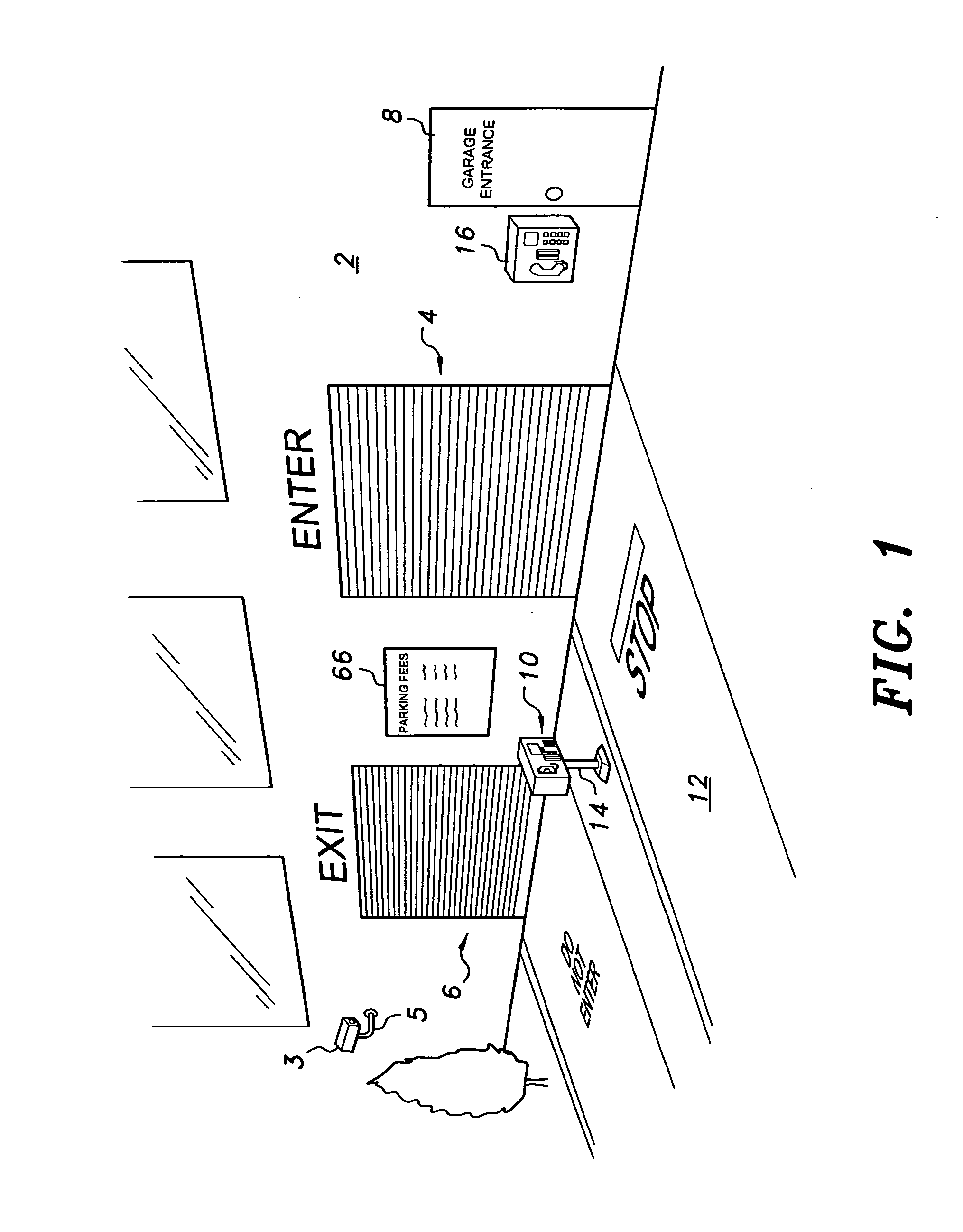

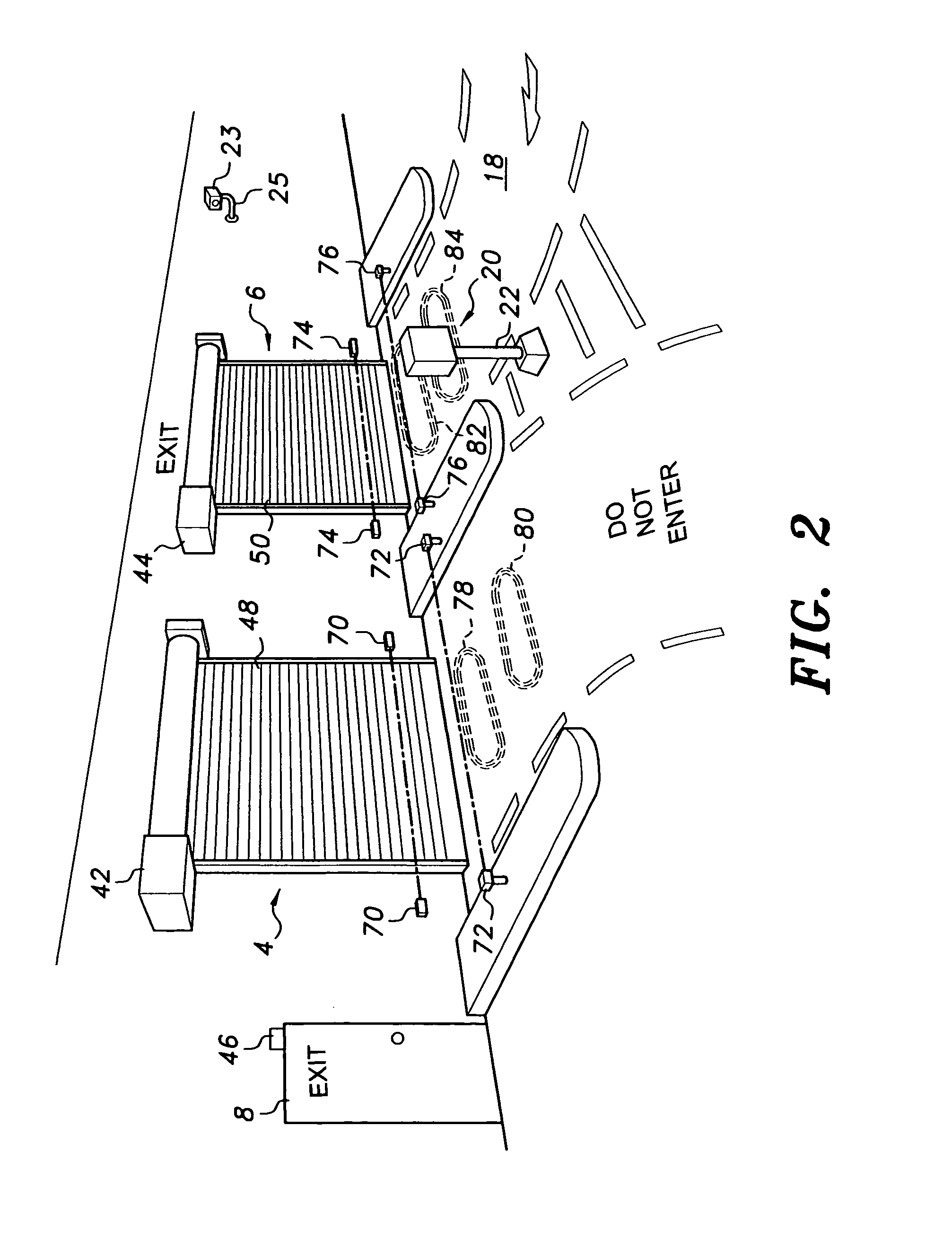

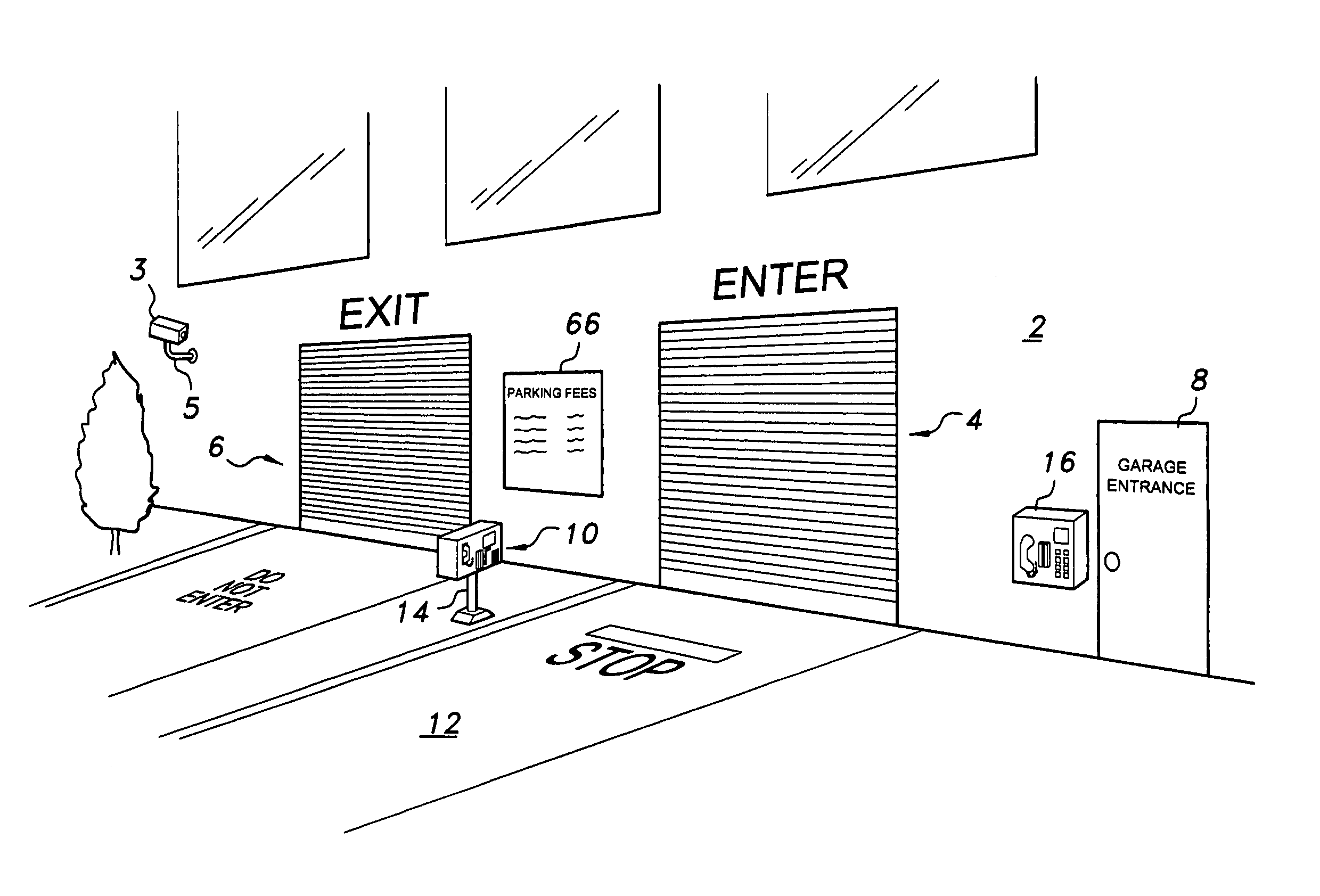

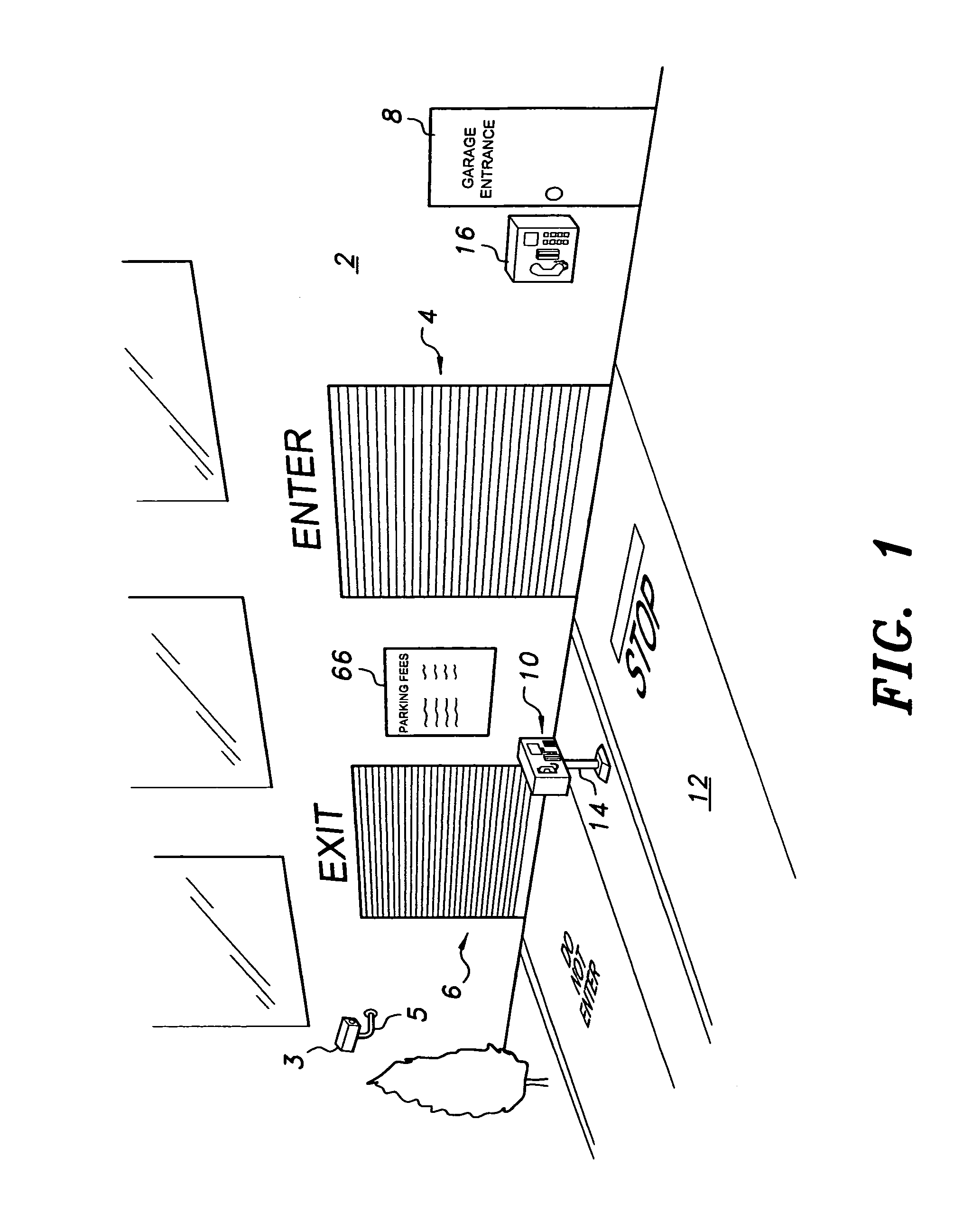

Virtual attendant system and parking management system

InactiveUS20130117078A1Increase valueAccurate assessmentProgramme controlTicket-issuing apparatusDocumentation procedureWaiters/waitresses

A control and management system for defined areas, employs a card reader, vehicle sensing loop detectors and electric eyes, entrance door sensors and operators, truck securement devices, cameras, a control system with memory, and a wireless connection or internet / intranet connection, is provided to produce event log documentation. The event information is readily accessible by management or supervisory personnel, to see all of the recorded information concerning a specified event. Thus, an event can be readily reconstructed after the fact, using all available sensors and other information relevant to a manager or supervisor. An alert can be issued whenever an abnormal or unauthorized event occurs during operations. A QR code reader can be provided which communicates with the system to enable a person carrying the cell phone to scan QR codes at specified locations or on specified items or vehicles.

Owner:WEIK III MARTIN HERMAN +2

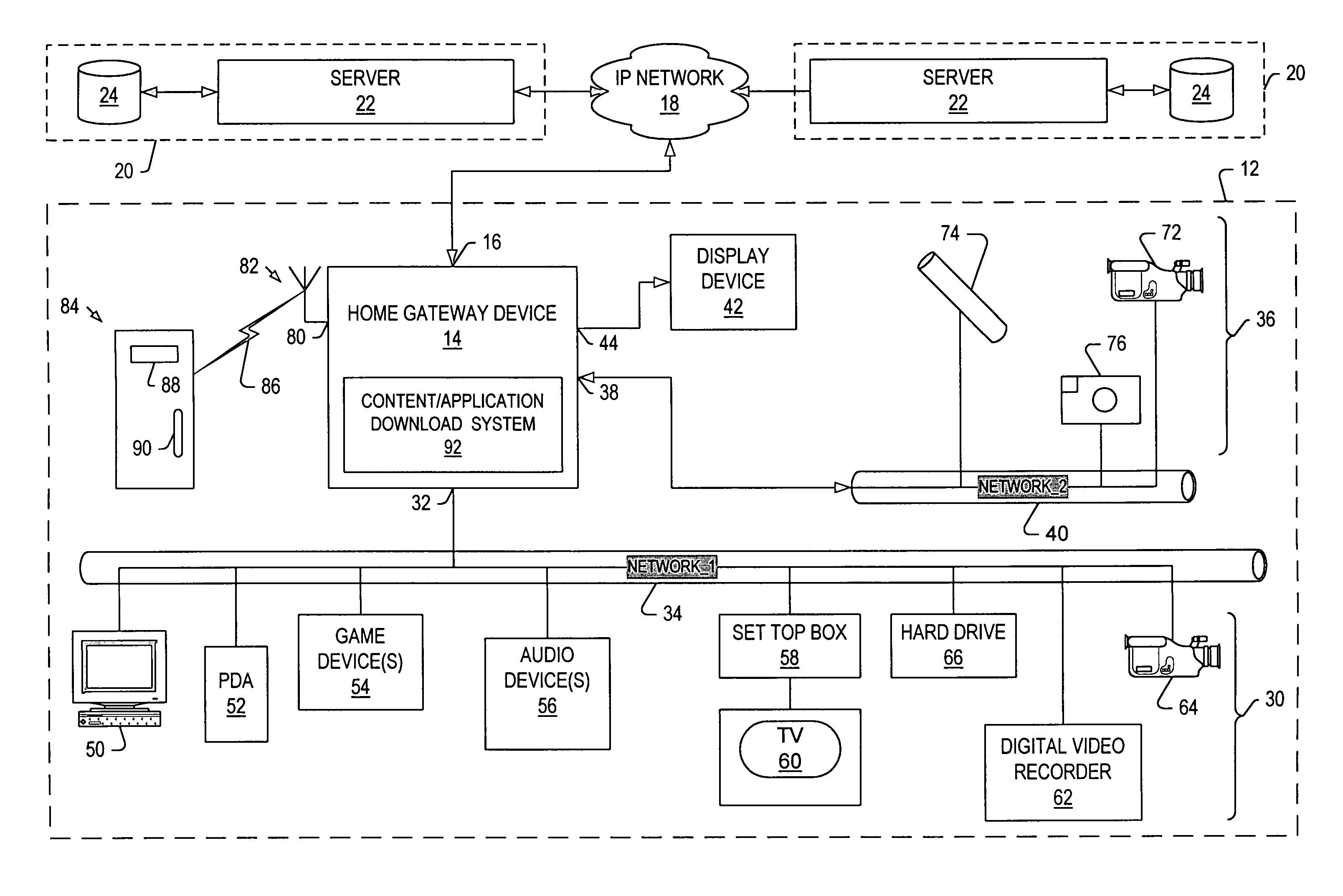

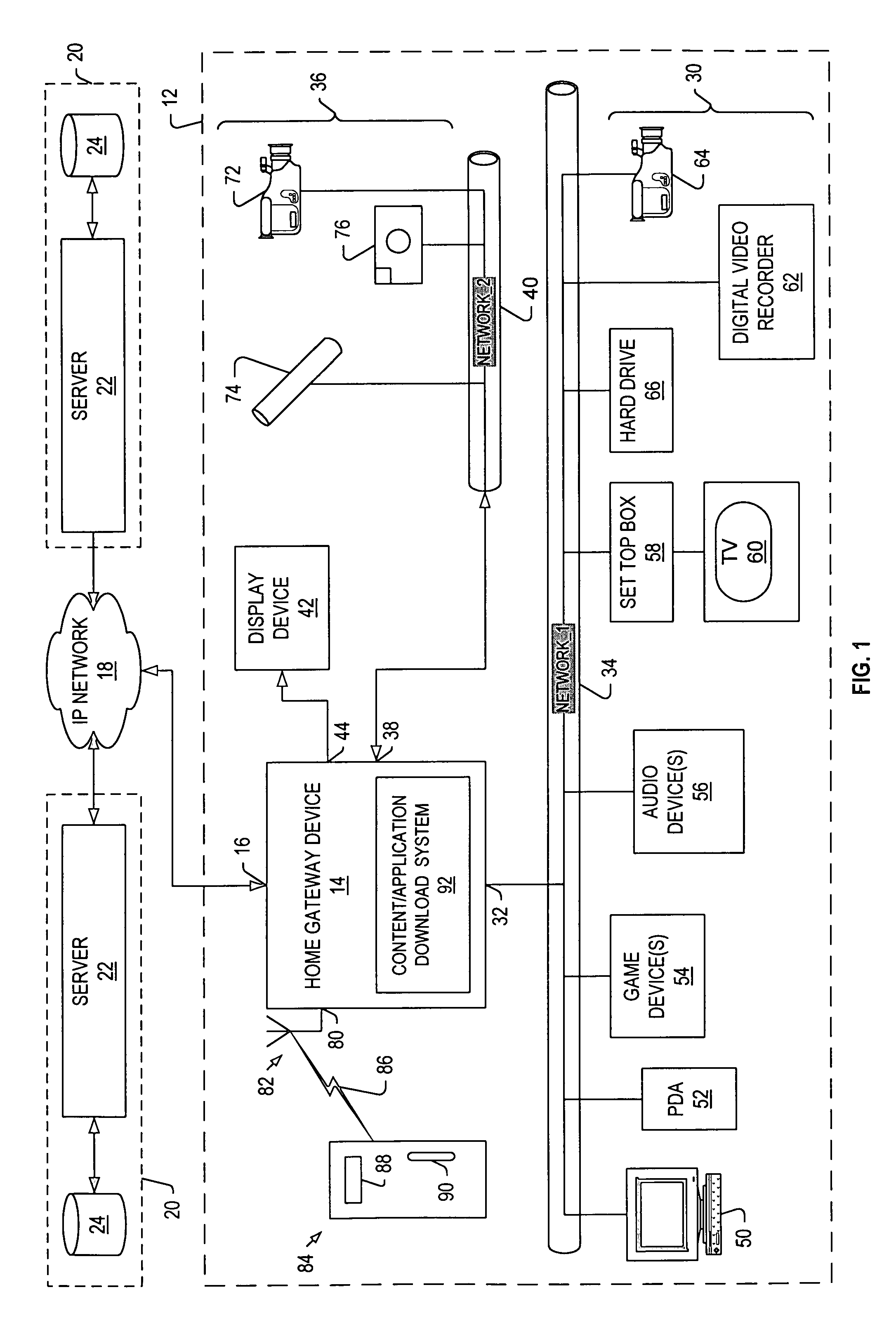

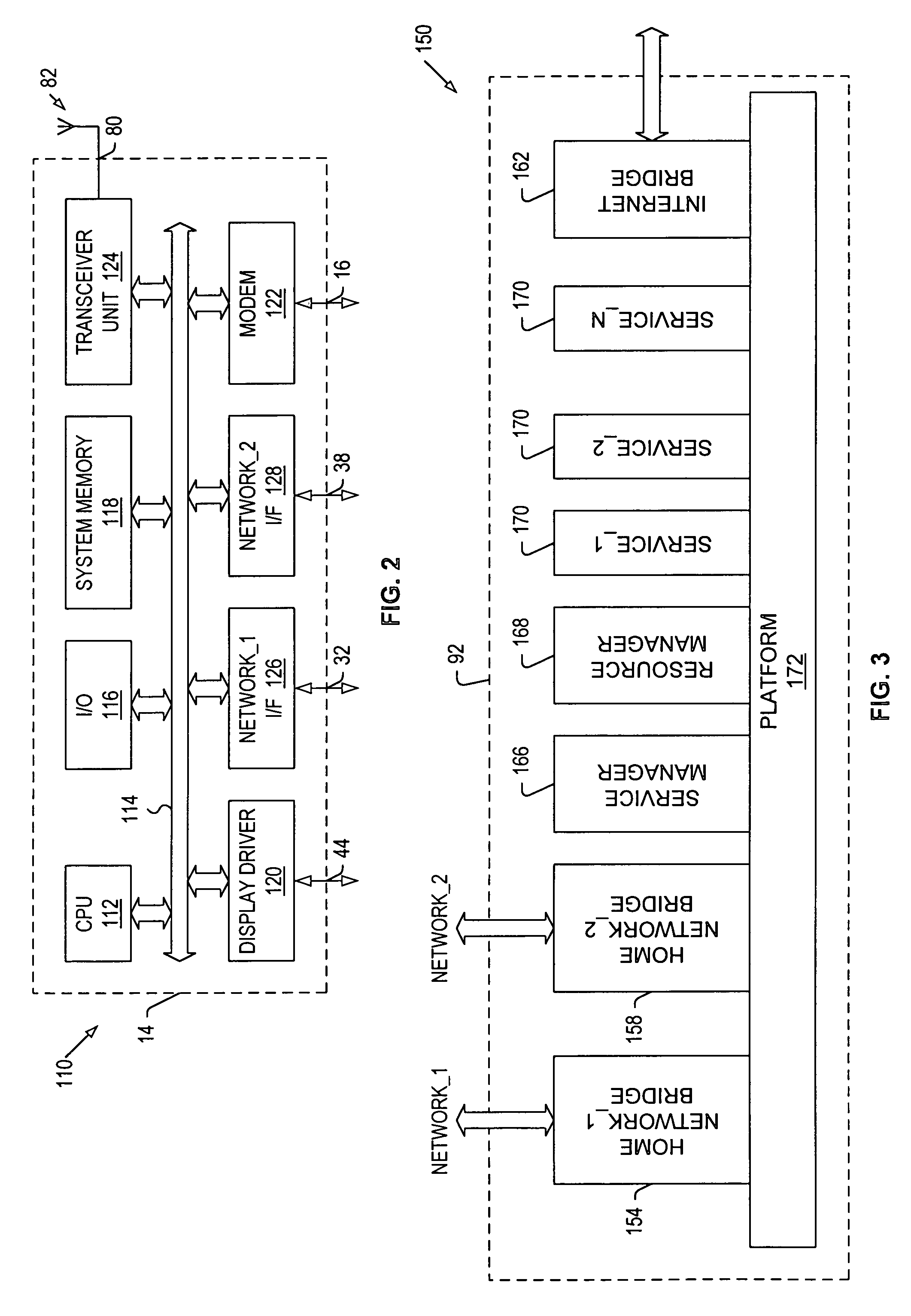

Remote manual, maintenance, and diagnostic services for networked electronic devices

InactiveUS7260597B1Easy to troubleshootData augmentationData processing applicationsError detection/correctionNetworked systemThe Internet

A process is provided for identifying and managing support service applications associated with consumer electronic devices. The process is executed by a gateway device communicatively coupled with each of the electronic devices via a home network, the gateway device being operative to access the Internet and being communicatively coupled with a display unit. The process includes the steps of: determining device ID information associated with a selected one of the electronic devices for which a support service application is required; providing the device ID information to a selected server computing system via the Internet; downloading a support service application associated with the selected device from the selected server computing system; and executing the downloaded support service application at the gateway device to provide a remote interactive support service process for the selected device. The support service may include a remote interactive manual service providing educational instructions to a user of the home network system regarding operation of a selected device, a remote interactive maintenance / diagnostic service for instructing a home network system user in solving maintenance problems associated with a selected device, or a combination remote interactive manual / maintenance / diagnostic service.

Owner:SONY CORP +1

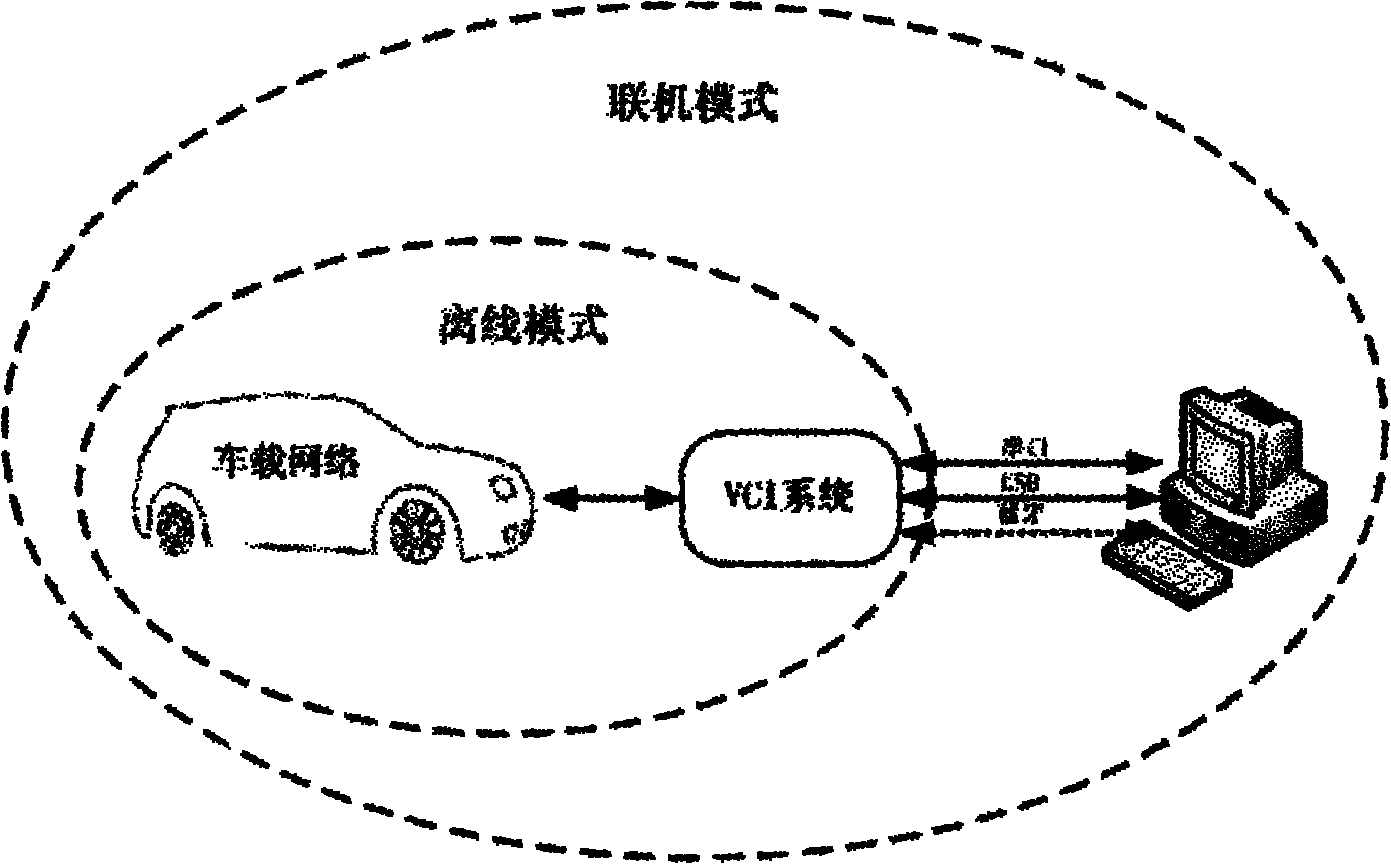

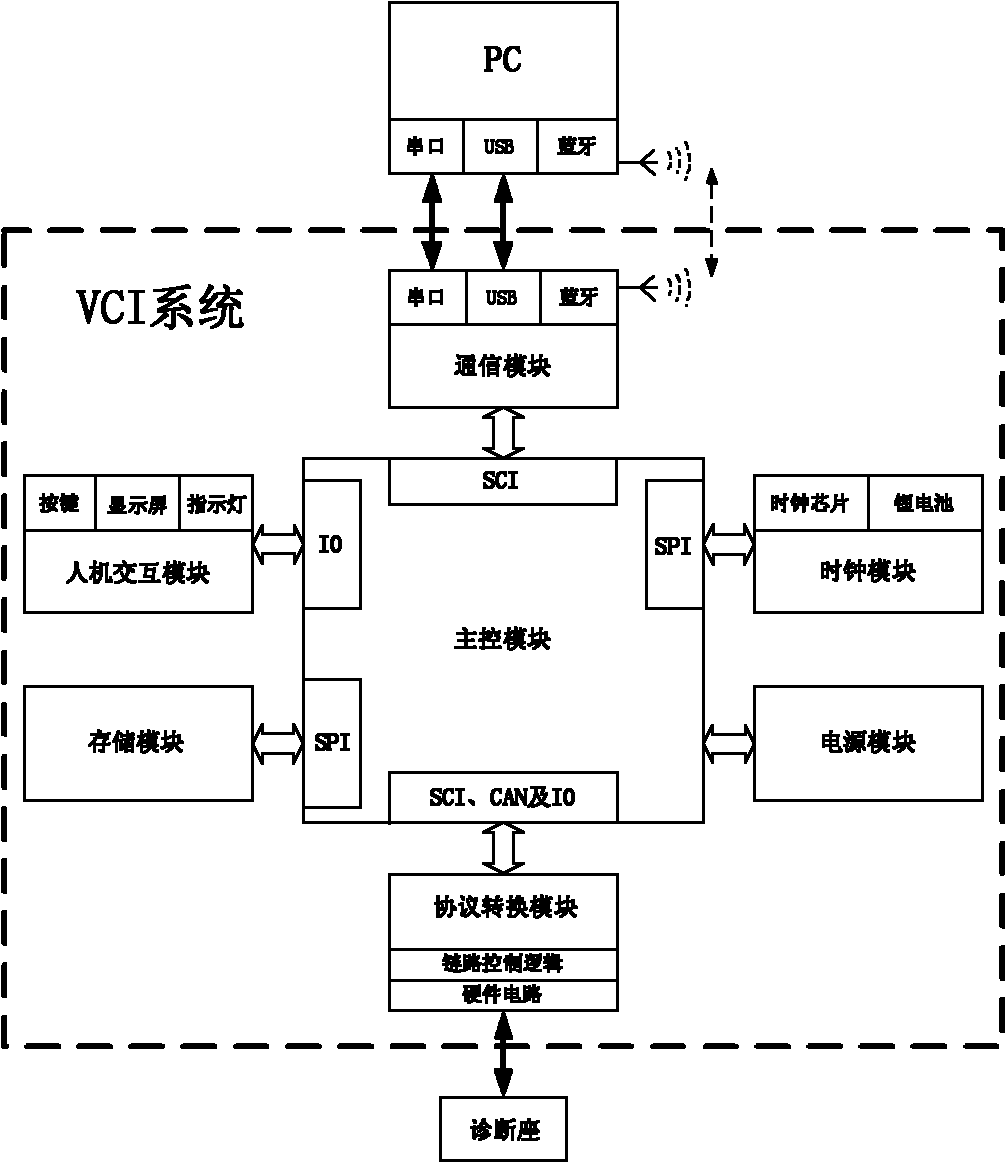

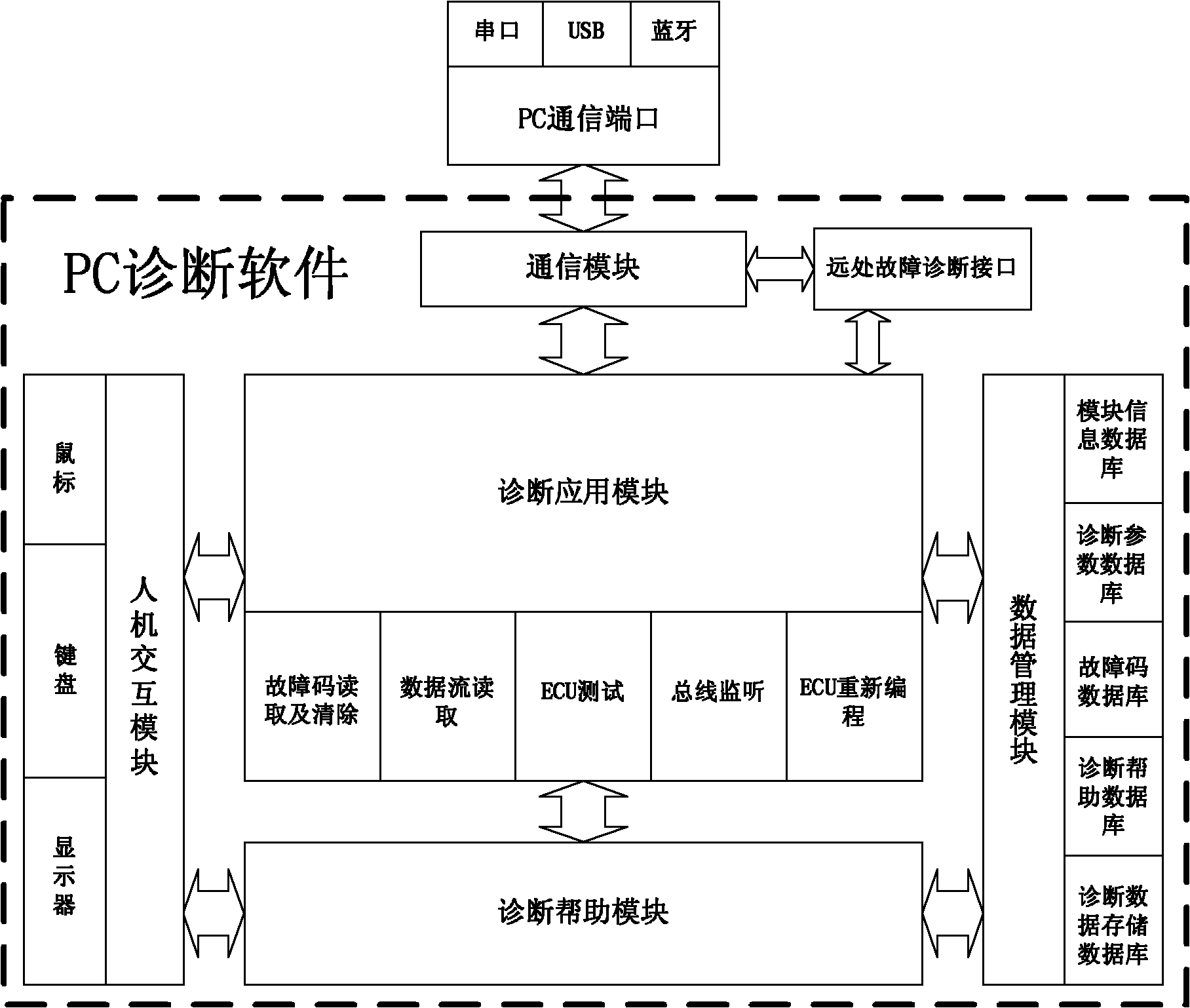

Multifunctional comprehensive type electric control automobile fault diagnosis system

ActiveCN102073319ARealize wireless data communicationEasy to troubleshootElectric testing/monitoringCommunication interfaceDiagnostic data

The invention relates to a multifunctional comprehensive type electric control automobile fault diagnosis system. The multifunctional comprehensive type electric control automobile fault diagnosis system comprises a vehicle-mounted network, a vehicle communication interface (VCI) system and personal computer (PC) diagnosis software. The system comprises two working modes: an off-line mode and an on-line mode. Under the off-line mode, the VCI system is connected with the vehicle-mounted network; fault diagnosis of a plurality of protocols and different module types is realized by the VCI system; functions of reading a fault code, removing the fault code, reading a frozen frame, reading a data stream and reading module information are realized; a diagnosis result is displayed by a liquid crystal display screen; and a function of storing diagnosis data is achieved. Under the on-line mode, the VCI system is connected with the vehicle-mounted network; the PC diagnosis software is connectedwith the VCI system; and the fault diagnosis of the plurality of protocols is realized. Besides the functions provided by a diagnosis protocol, a diagnosis application module also provides functions of monitoring data of the vehicle-mounted network and generating a diagnosis result report.

Owner:WUHAN UNIV OF TECH +1

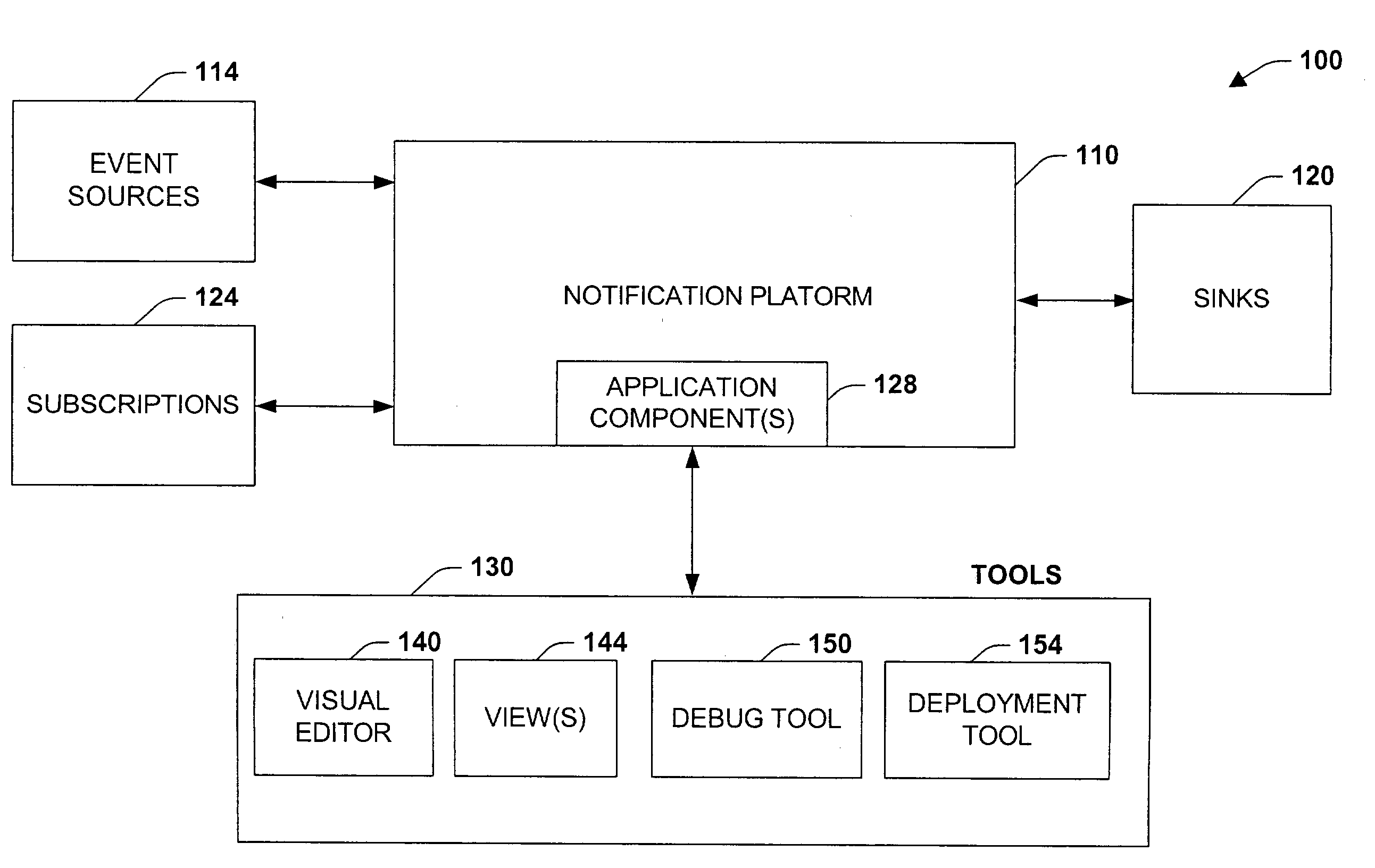

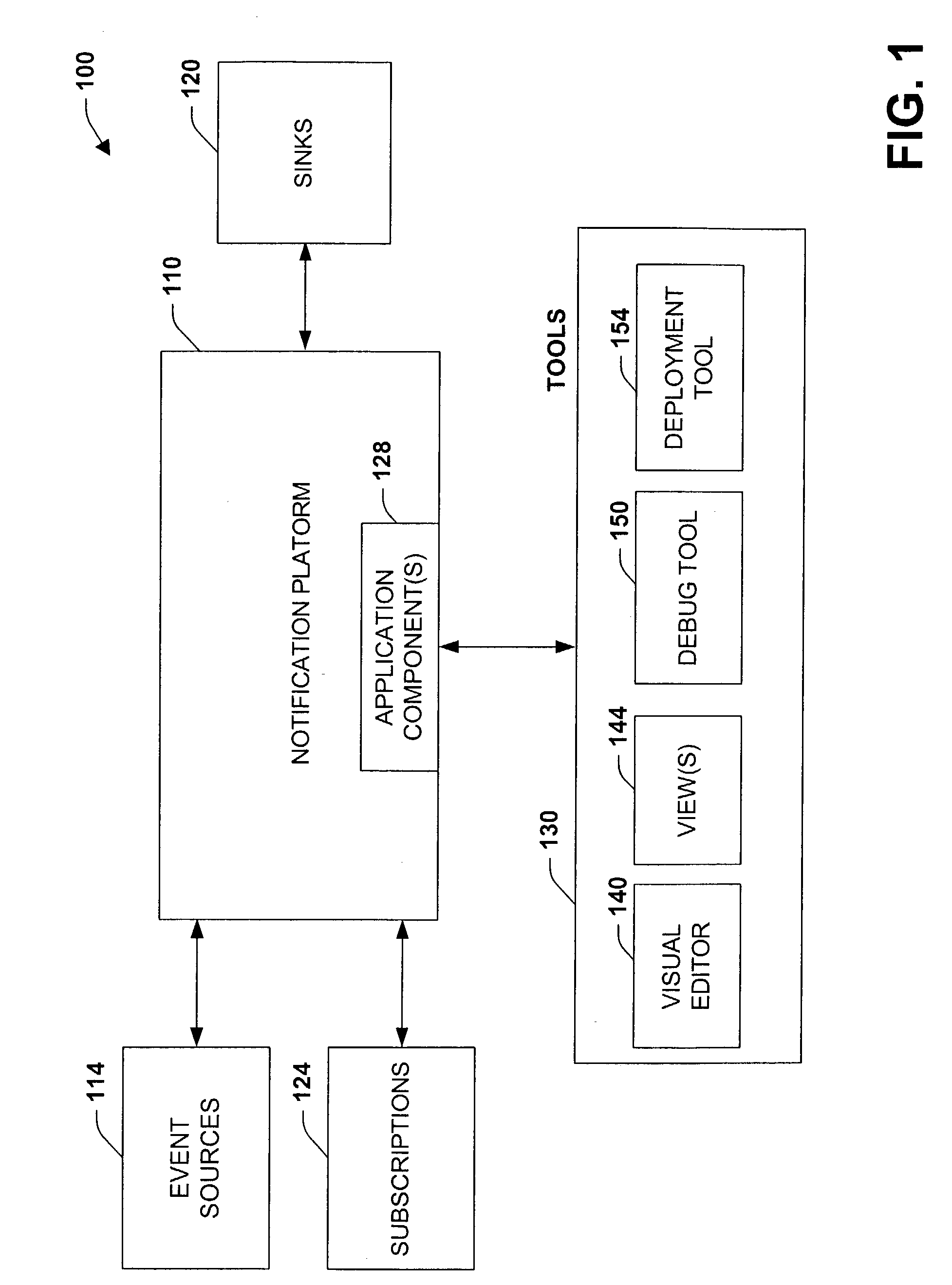

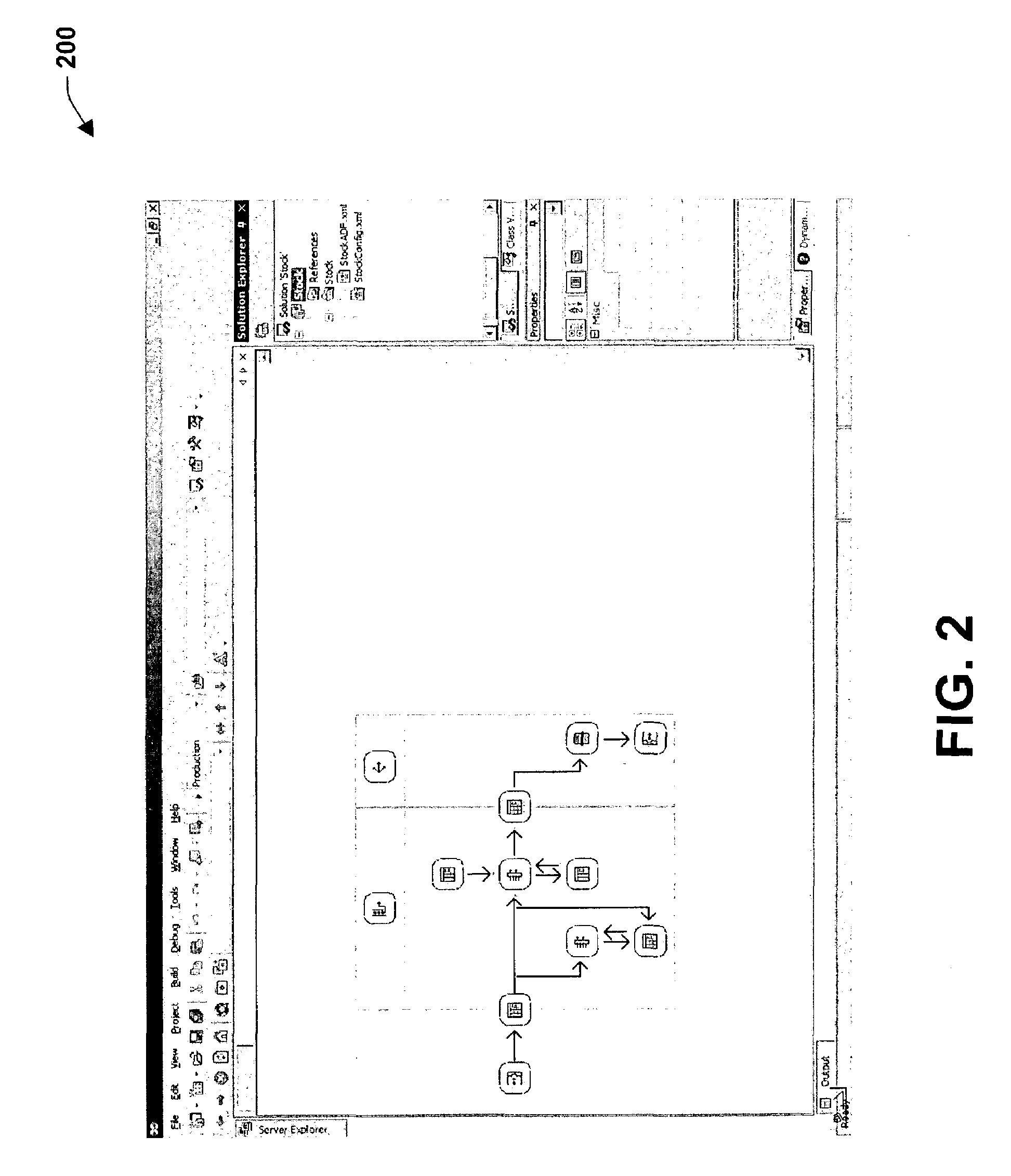

User interface system and methods for providing notification(s)

InactiveUS7360202B1Facilitates efficient design and debug and management and deploymentImprove development experienceData processing applicationsDigital data processing detailsSoftware engineeringApplication software

The present invention relates to a system and methodology to facilitate development, debug, and deployment of a notification platform application. This includes providing various editor and display tools that interact with diverse components of the application in the context of a dynamic framework and development environment adapted to the nuances of the components. Visual displays and interfaces are provided that depict the various components of an application along with the relationships between the components. Developers are then directed though the components of the application in a visual manner, wherein various editors can be invoked to design a portion of the application relating to the selected component. Other aspects include providing a debug environment for troubleshooting a notification application along with deployment options to install and execute the application.

Owner:MICROSOFT TECH LICENSING LLC

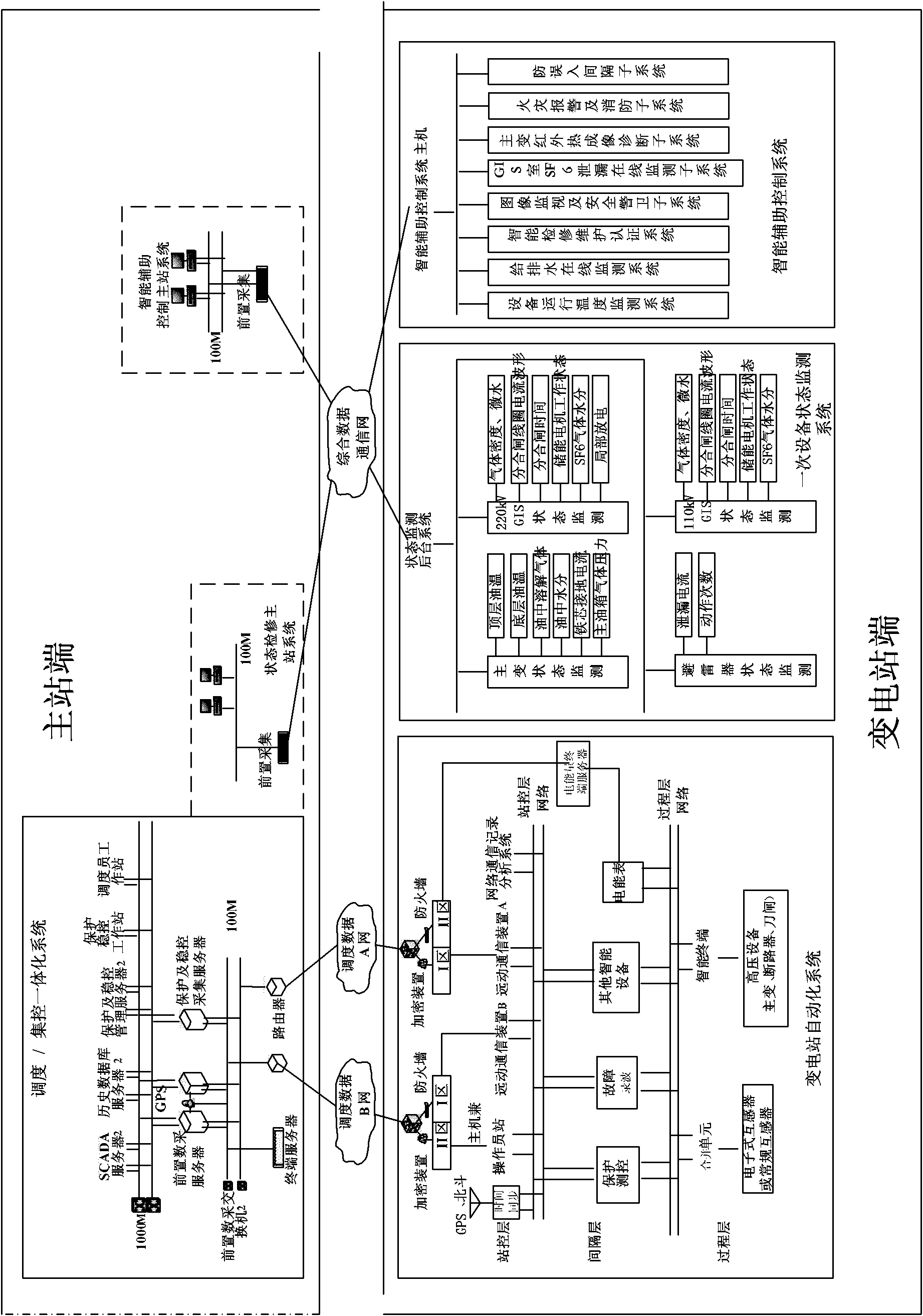

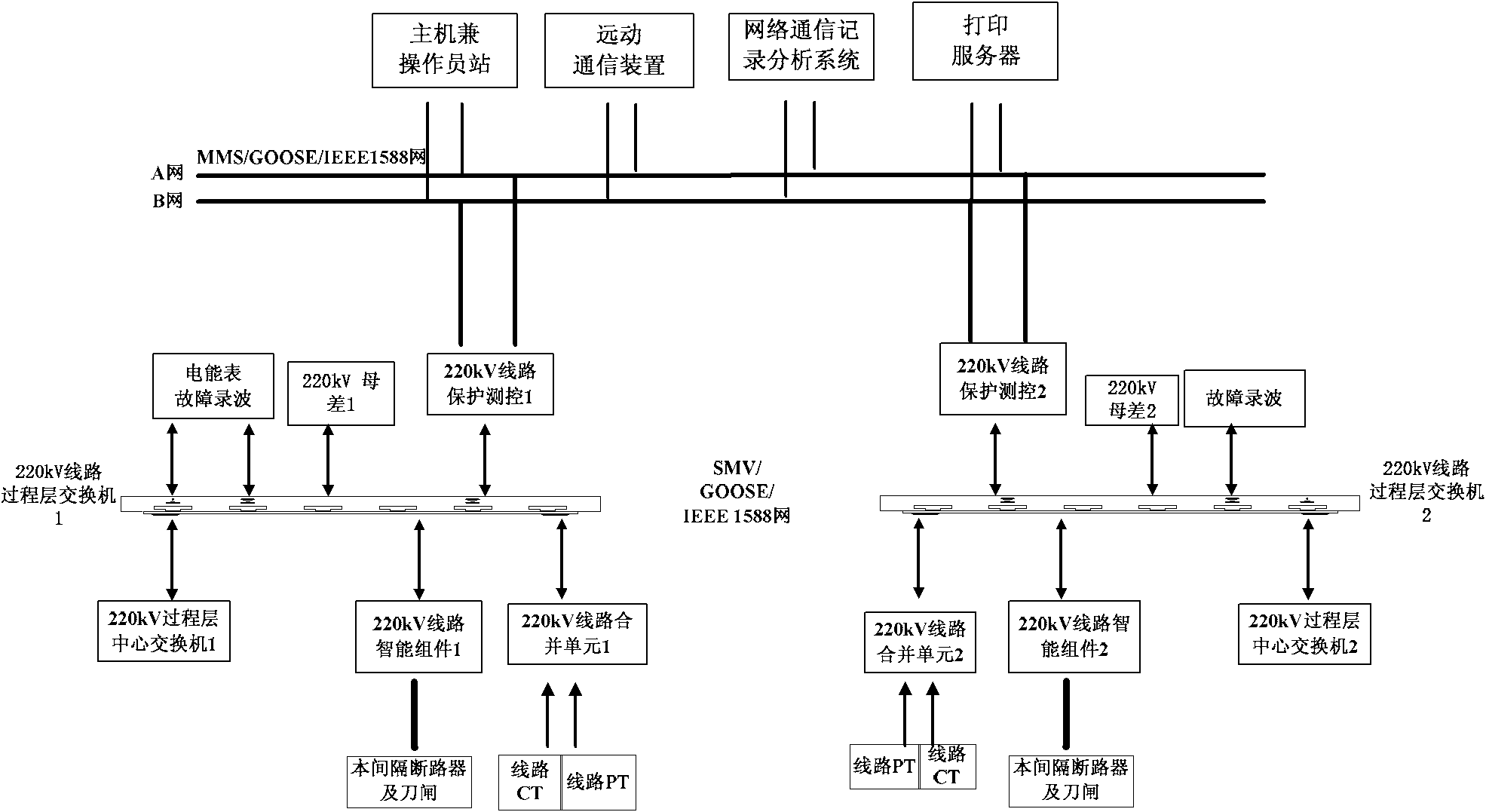

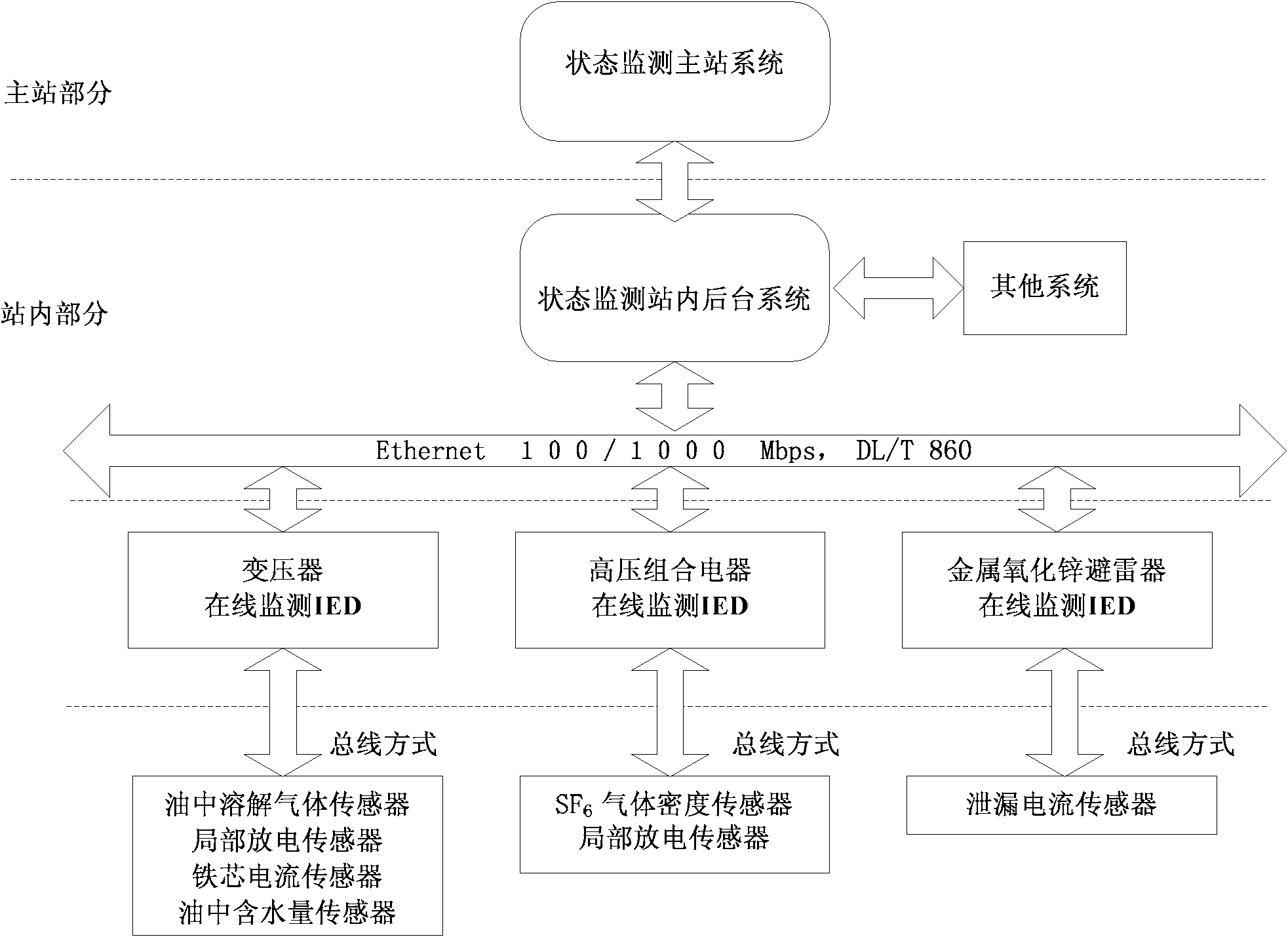

Intelligent substation based on sensor, communication network and expert system

InactiveCN102122844ARealize functionRealize online monitoringCircuit arrangementsInformation technology support systemThe InternetCapacitive voltage divider

The invention discloses an intelligent substation based on sensors, a communication network and an expert system. The intelligent substation comprises a substation automation system, a primary equipment condition monitoring system and an intelligent auxiliary control system. The intelligent substation is characterized in that the real-time data of equipment operation are acquired by additionally installing various sensors, the IEC61850 standard is utilized to realize information modeling of the sensor data, a communication network is utilized to build a physical channel for information transmission, and advanced application of the substation automation system and intelligent monitoring and linkage of the primary equipment condition monitoring and auxiliary systems are realized by a background expert system, thus realizing intelligent operation and patrol functions of the substation; the sensors include an all-fiber electronic current transformer, a capacitive voltage divider type electronic voltage transformer, a primary equipment condition monitoring sensor and an internet sensor with an auxiliary system things; and the advanced application of the substation automation system includes sequential control, equipment condition visualization, intelligent alarm, distributed condition estimation, substitution function and the like. Intelligent operation and patrol functions of the substation can be realized.

Owner:CEEC JIANGSU ELECTRIC POWER DESIGN INST +2

Virtual attendant system and parking management system

InactiveUS8831970B2Increase valueAccurate assessmentTicket-issuing apparatusHand manipulated computer devicesDocumentation procedureControl system

A control and management system for defined areas, employs a card reader, vehicle sensing loop detectors and electric eyes, entrance door sensors and operators, truck securement devices, cameras, a control system with memory, and a wireless connection or internet / intranet connection, is provided to produce event log documentation. The event information is readily accessible by management or supervisory personnel, to see all of the recorded information concerning a specified event. Thus, an event can be readily reconstructed after the fact, using all available sensors and other information relevant to a manager or supervisor. An alert can be issued whenever an abnormal or unauthorized event occurs during operations. A QR code reader can be provided which communicates with the system to enable a person carrying the cell phone to scan QR codes at specified locations or on specified items or vehicles.

Owner:WEIK III MARTIN HERMAN +2

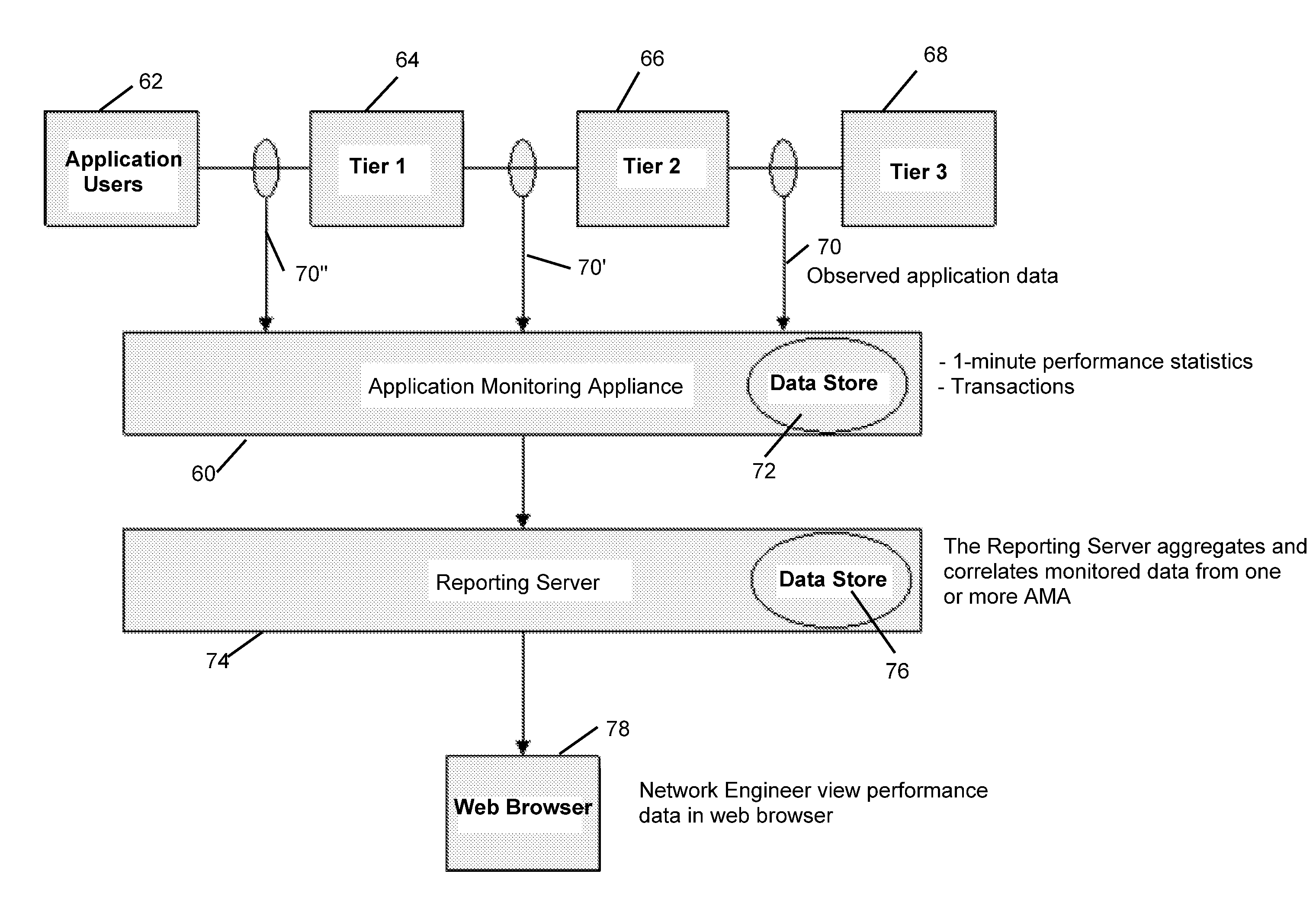

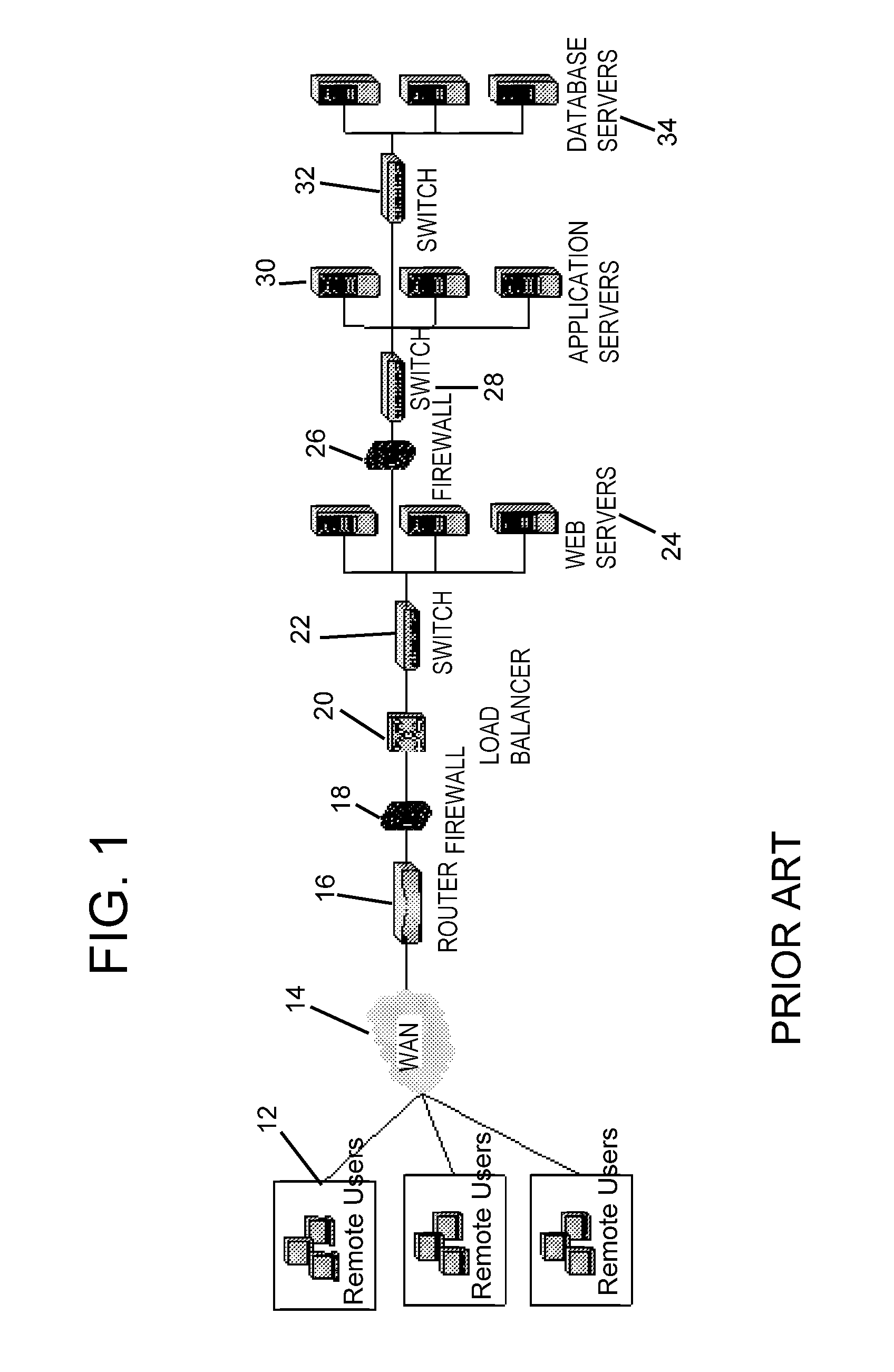

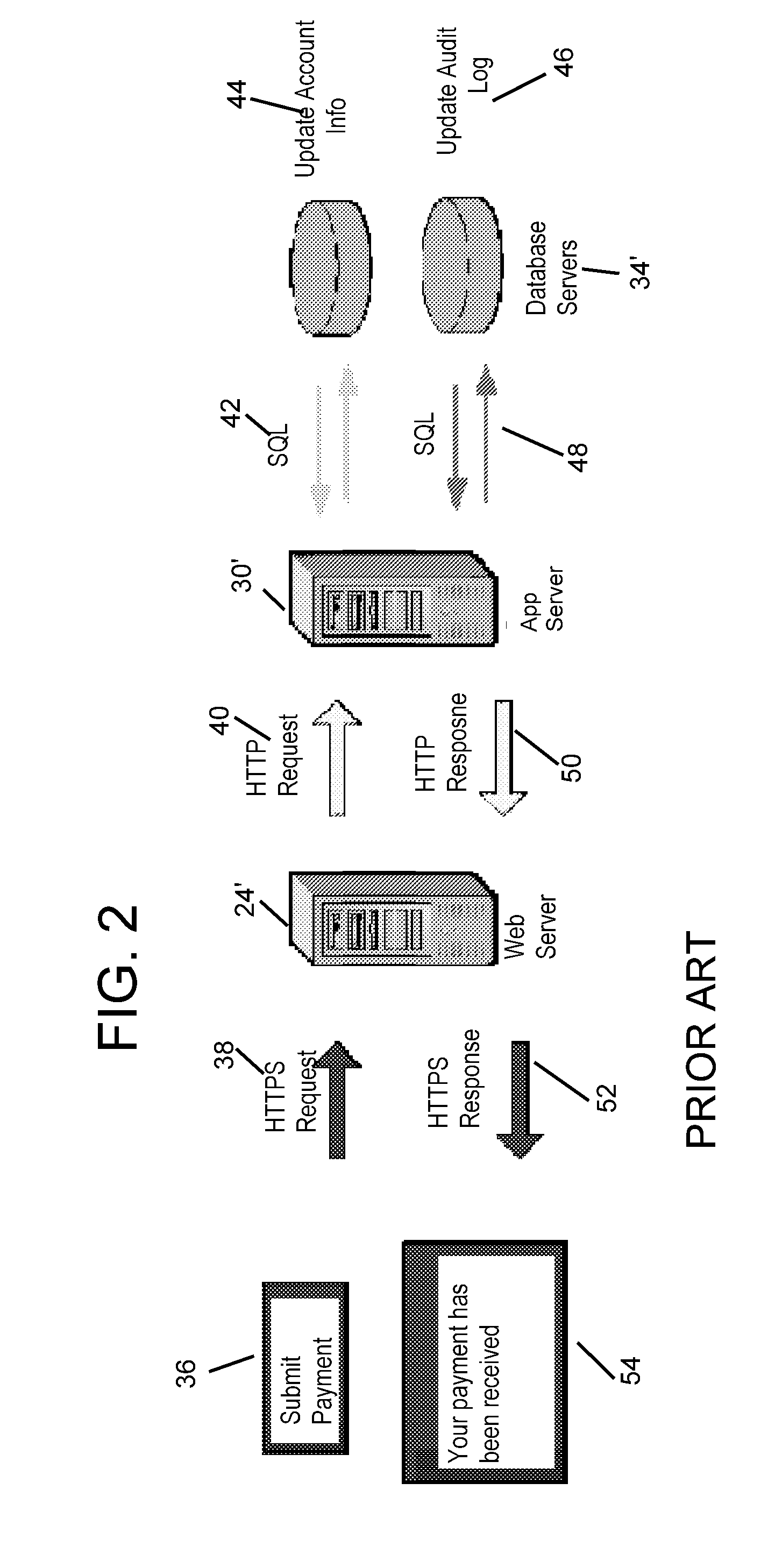

Method and apparatus for the continuous collection and correlation of application transactions across all tiers of an n-tier application

InactiveUS20100198909A1Easy to troubleshootSimple methodMultiple digital computer combinationsTransmissionDatabaseWeb browser

Method and apparatus for continuous collection and correlation of application transactions across multiple tiers of an N-tier application employs an application monitoring appliance that observes application data and stores transactions and statistics. A reporting server aggregates and correlates monitored data from the application monitoring appliance and provides access via a web browser for viewing by a network engineer.

Owner:JOHN FLUKE MFG CO INC

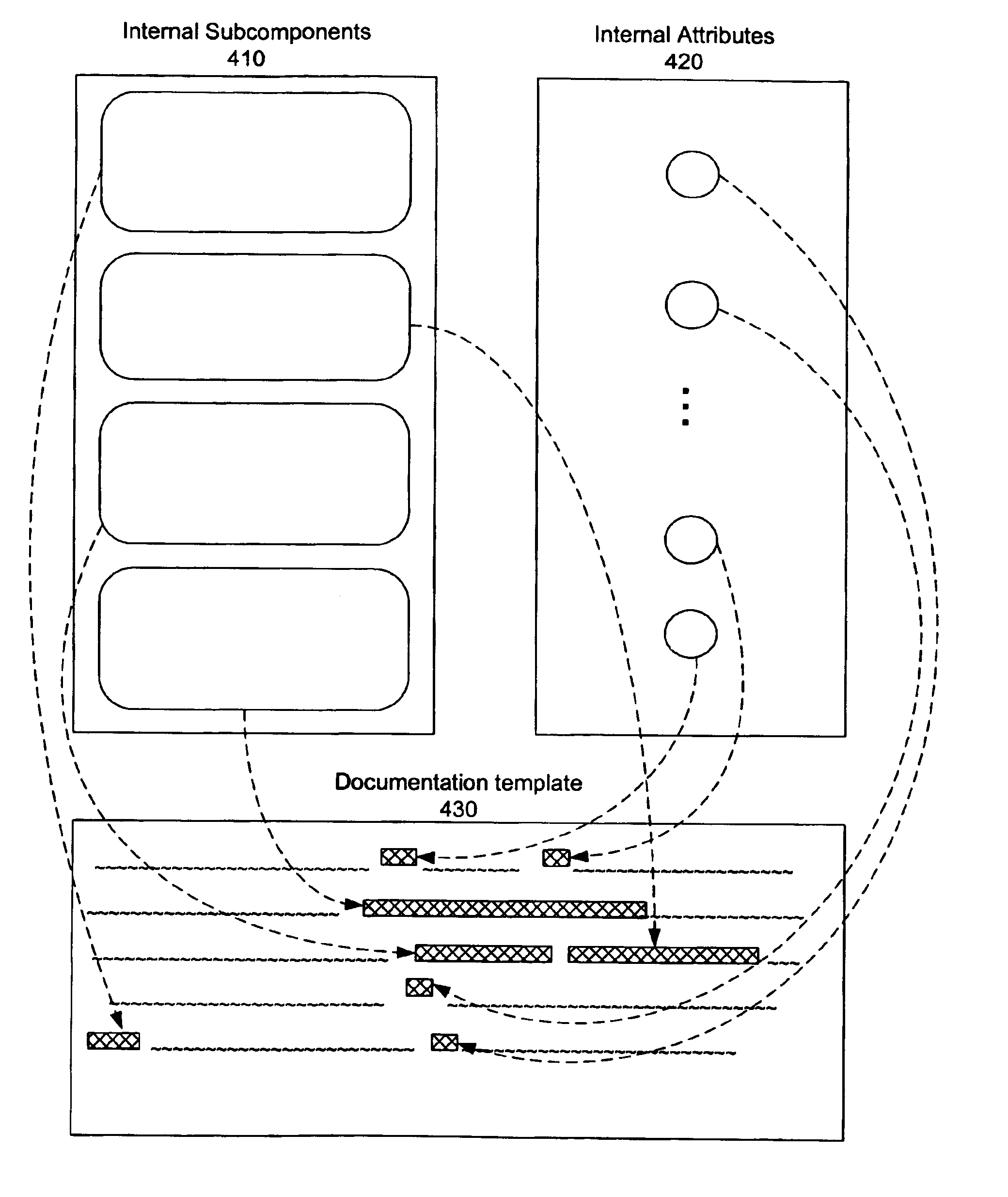

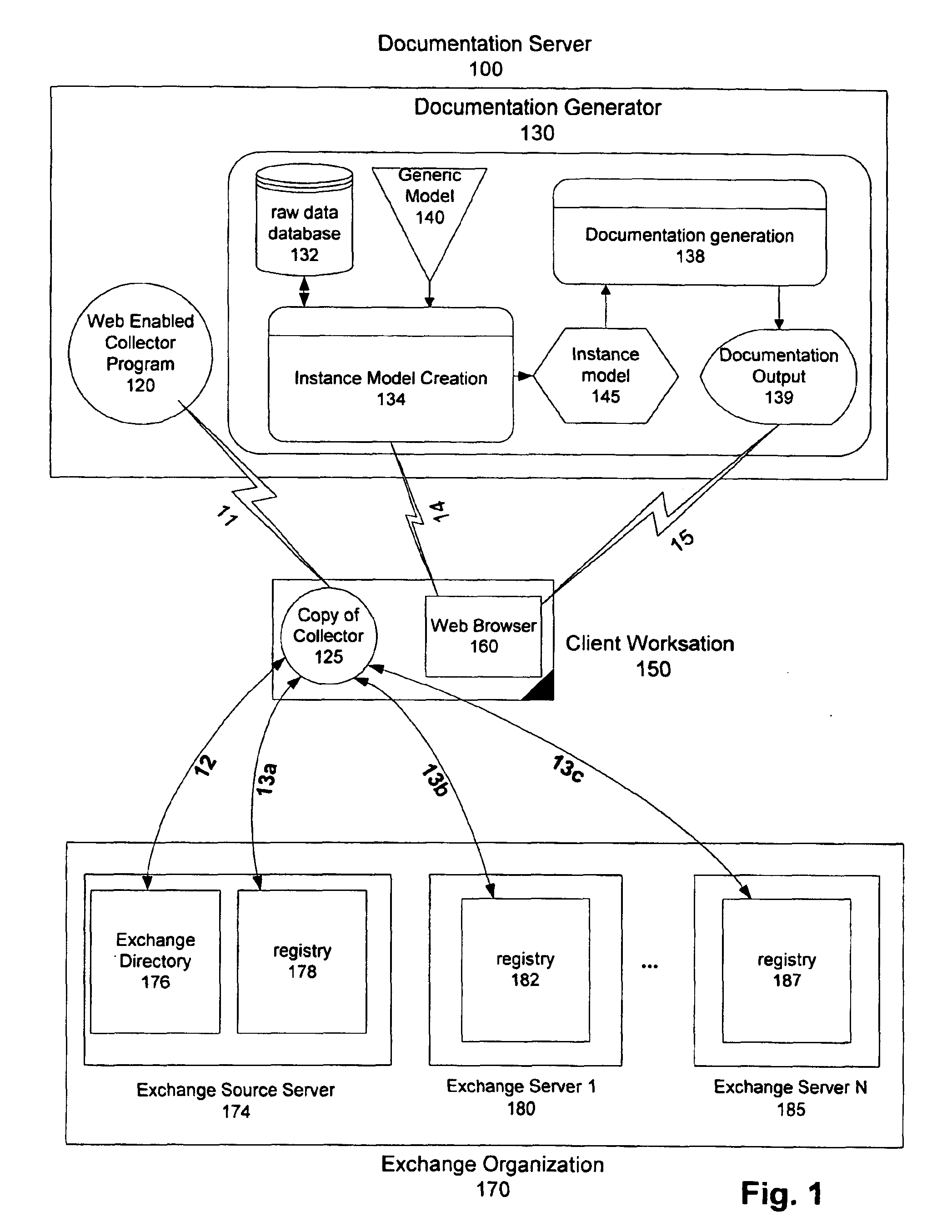

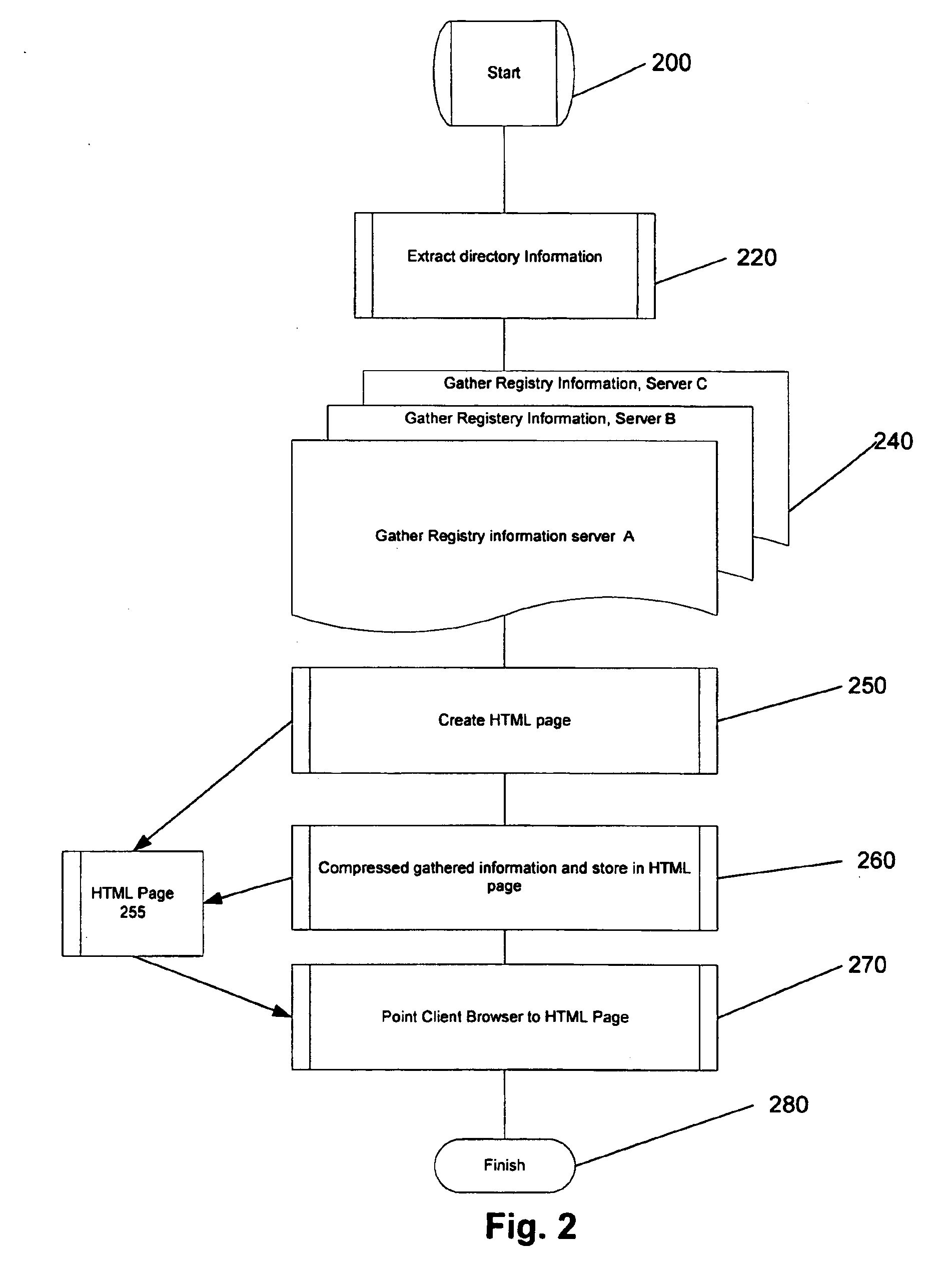

Automatic documentation of configurable systems by outputting explanatory information of configuration parameters in a narrative format and configuration parameters differences

InactiveUS6981207B1Fast and efficient checkingEasy flagging of error conditionDigital data processing detailsLogical operation testingDocumentation procedureApplication software

An automatic documentation generation and management system and method, for documenting configurable systems such as complex software applications and hardware systems is disclosed. The method retrieves configuration parameters from the configurable system and utilizes them to automatically generate an explanatory document specific to the configured system. The invention also discloses a documentation appliance system, which is a dedicated documentation server coupled to the configurable system via a communication network, preferably via an Intranet. In yet another alternative, the invention may be practiced by integrating code for automatic documentation generation within the configurable system program.

Owner:VERSATA

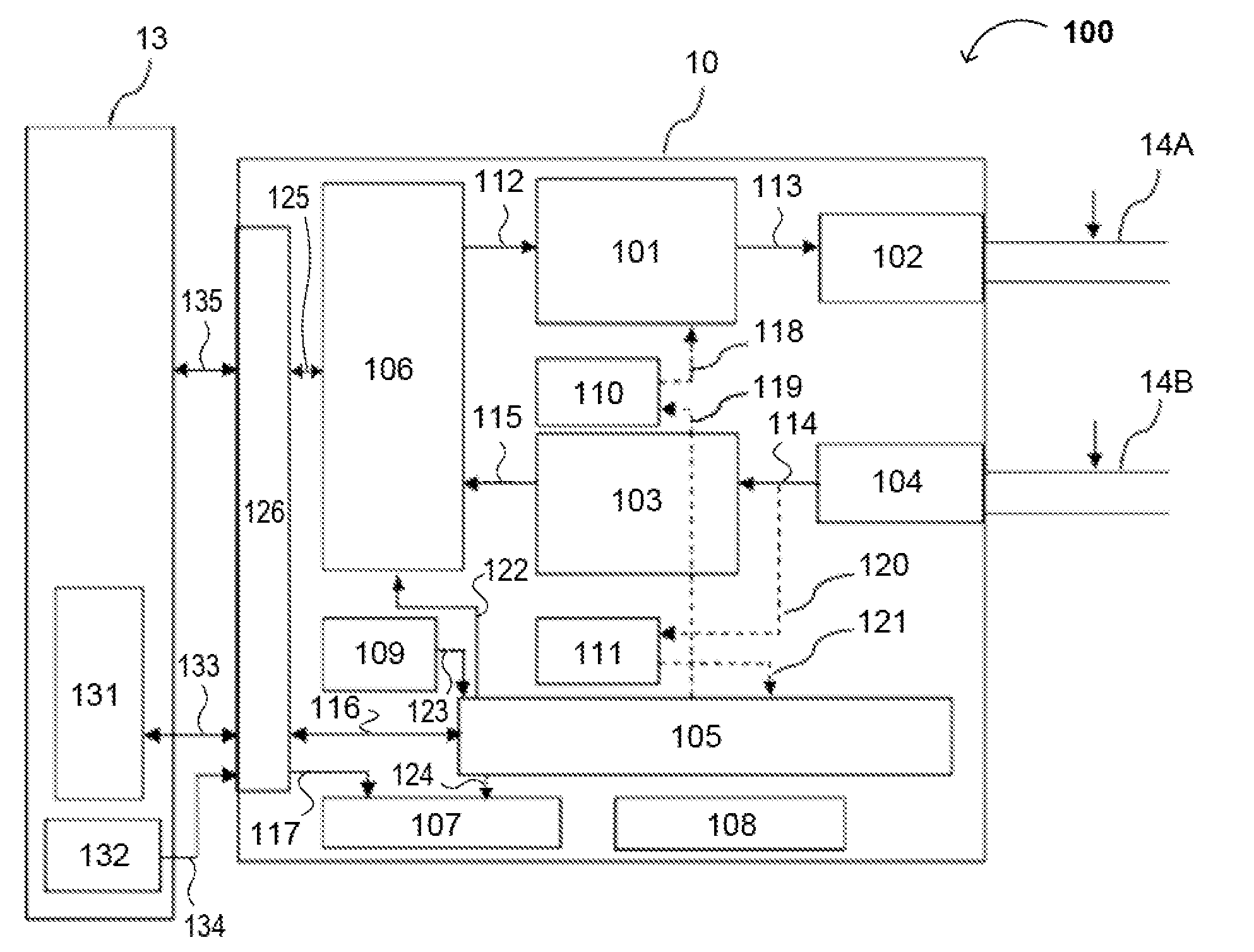

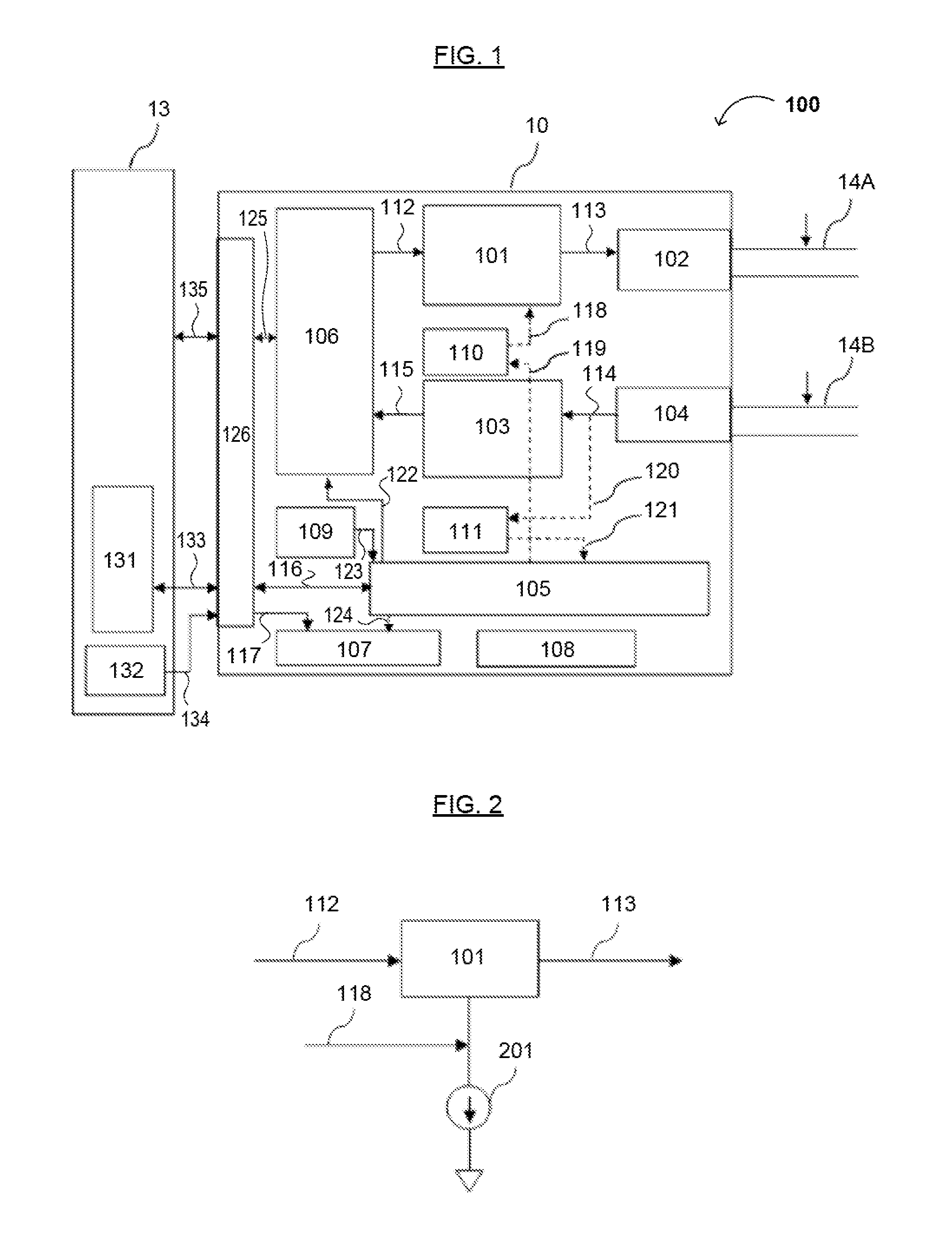

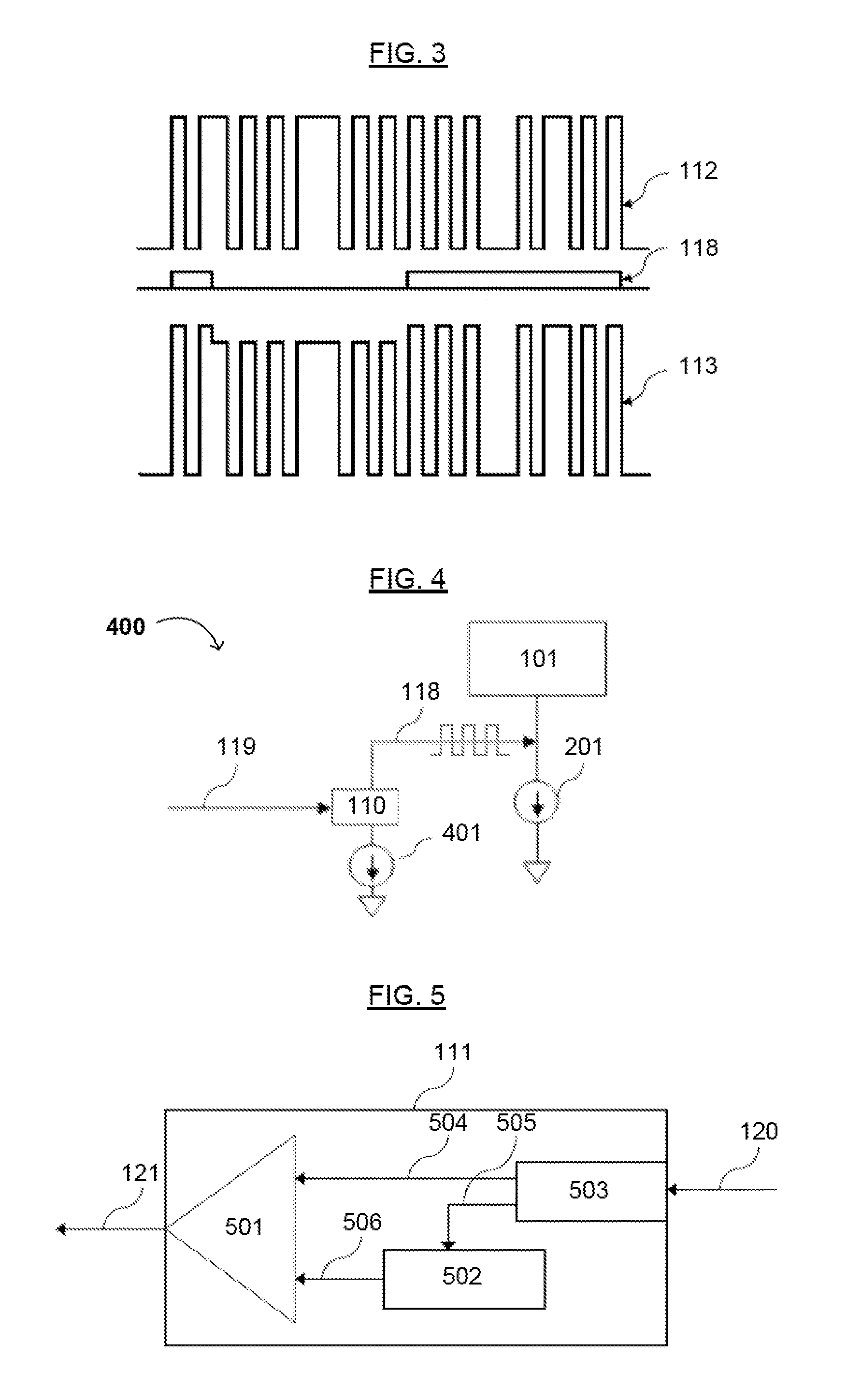

Circuits, Architectures, Apparatuses, Systems, and Methods for Merging of Management and Data Signals, and for Recovery of a Management Signal

ActiveUS20120170927A1Low costEasy to manageTransmission monitoringTransmission monitoring/testing/fault-measurement systemsManagement unitTransceiver

An optical and / or optoelectrical transceiver and system are disclosed that enable parallel transmission of data and management signals via an optical fiber without affecting data signal transmissions transmitted on the optical fiber. Furthermore, the present transceiver and system provide a fault diagnosis function for an optical fiber link. The transceiver and system generally comprise an interface, an intersecting transmission management unit, a driver, a management signal driving unit, an optical transmitter, an optical receiver, an amplifier, a management signal recovery unit, a management unit, and optionally, a power supply unit.

Owner:MAGNOLIA SOURCE CAYMAN

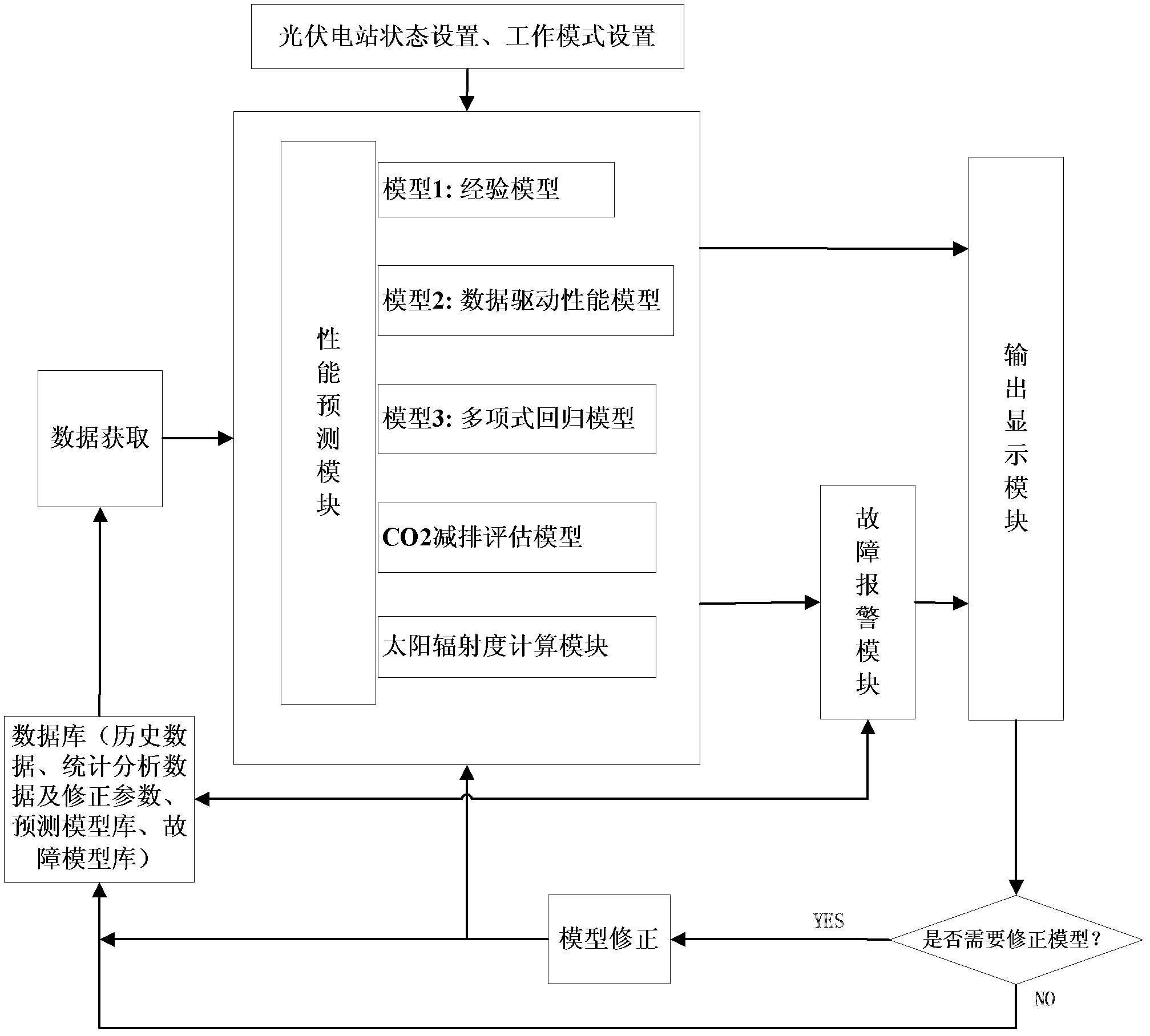

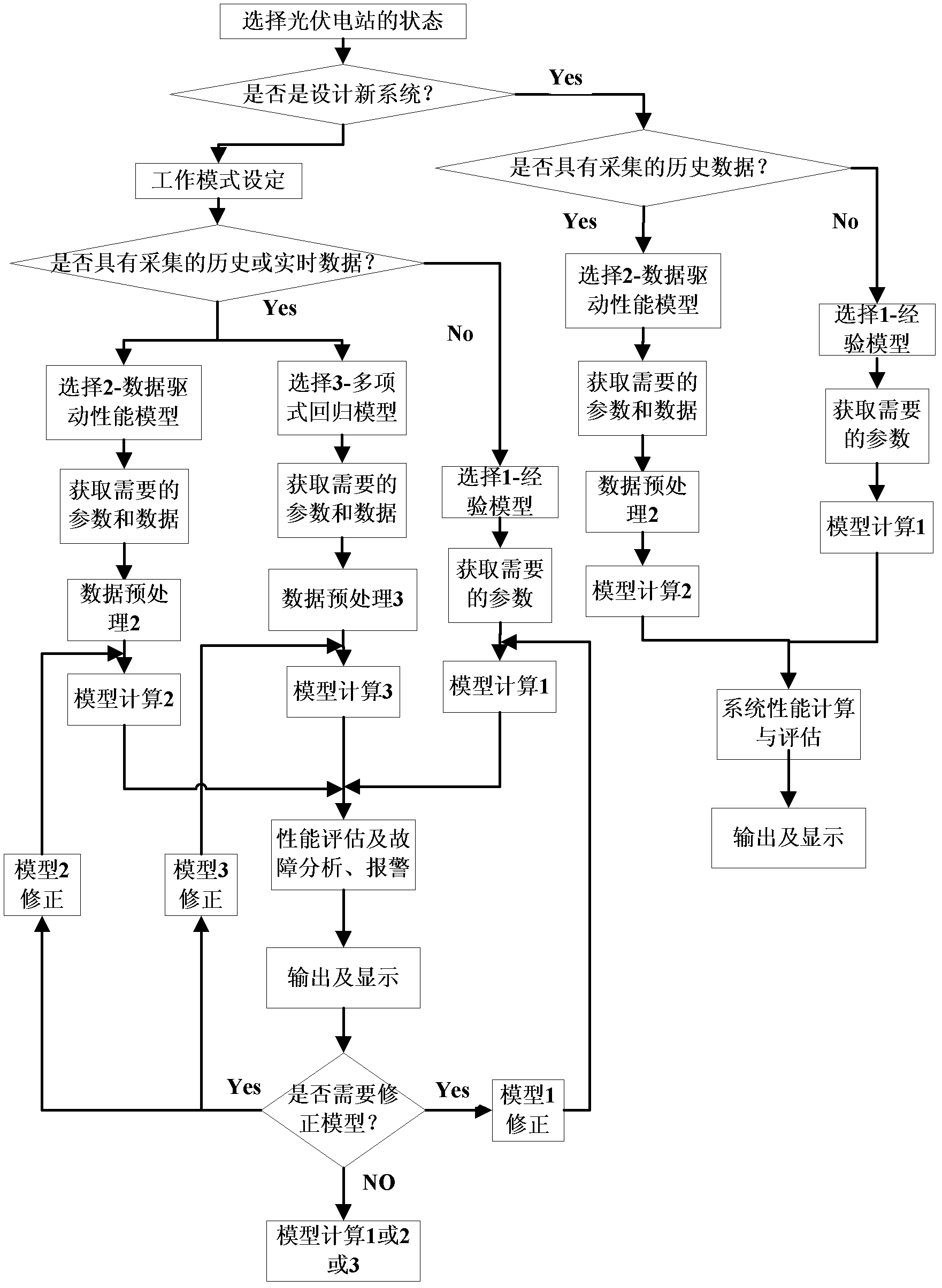

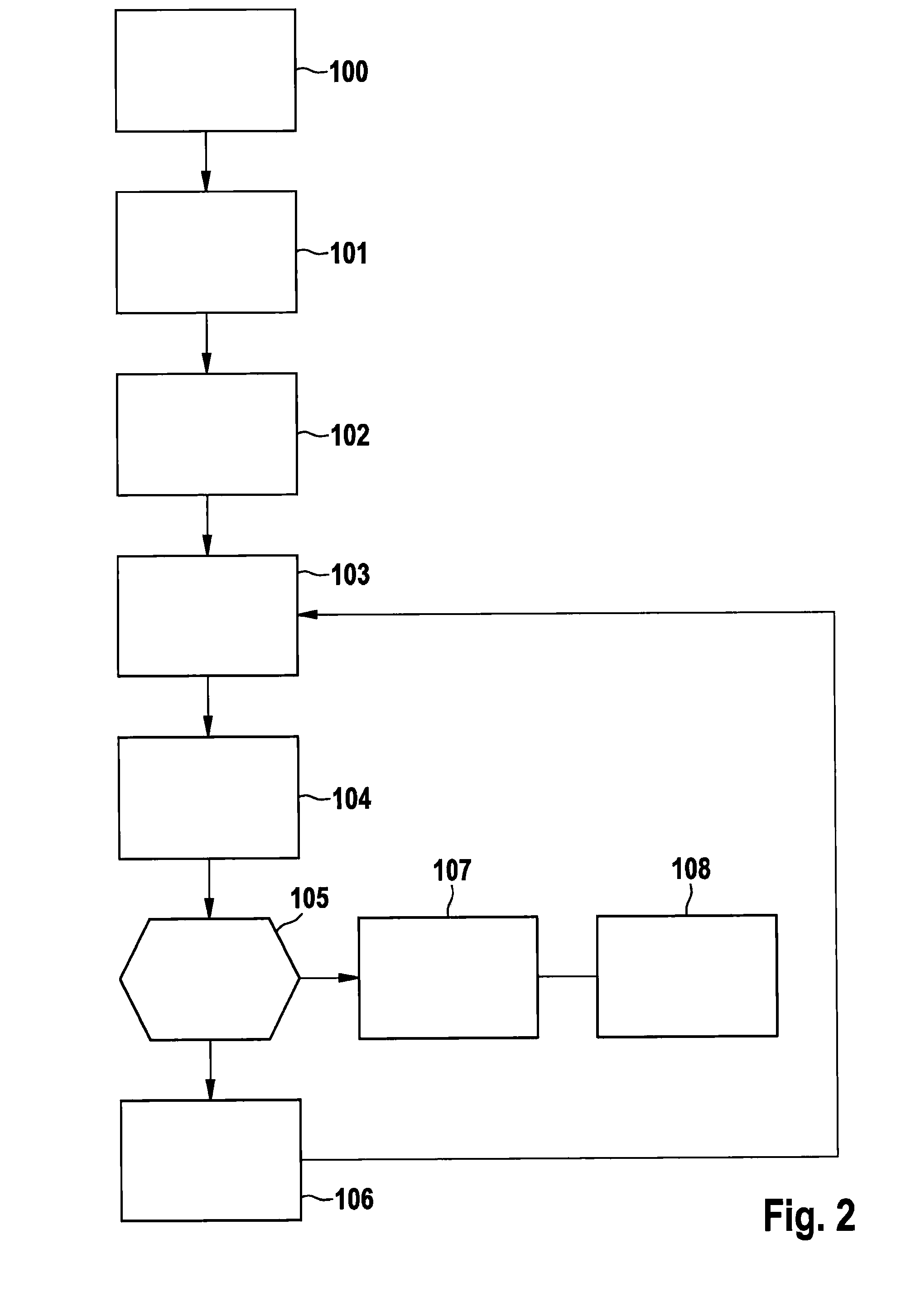

Performance prediction and fault alarm method for photovoltaic power station

InactiveCN102566435AImprove accuracyEasy to troubleshootAdaptive controlReal-time dataPolynomial regression model

The invention discloses a performance prediction and fault alarm method for a photovoltaic power station. The method comprises the following steps of: a, setting the station of the power station; b, setting the operation mode of the power station; c, judging whether required real-time data or historical data exists or not; d, predicting the performance of the power station through an experience model if the state in the step a is that a new photovoltaic power station is required to be designed and the required real-time data or historical data in the step c does not exist, and predicting the performance of the power station through a data drive performance model if the required real-time data or historical data in the step c exists; e, predicting the performance of the power station through the data drive performance model or a polynomial regression model if the photovoltaic power station in the step a is operated and the required real-time data or historical data in the step c exists, and predicting the performance of the power station through the experience model if the required real-time data or historical data in the step c does not exist; f, comparing actual performance with the predicted performance, and performing fault alarm; and g, correcting the models on line by a Kalman filtering method and returning to the step c, and otherwise, directly returning to the step e. By the method, solar energy resources can be utilized to the maximum extent, and power utilization cost can be reduced; and the accuracy of performance prediction and fault diagnosis is improved.

Owner:AUTOMATION RES & DESIGN INST OF METALLURGICAL IND

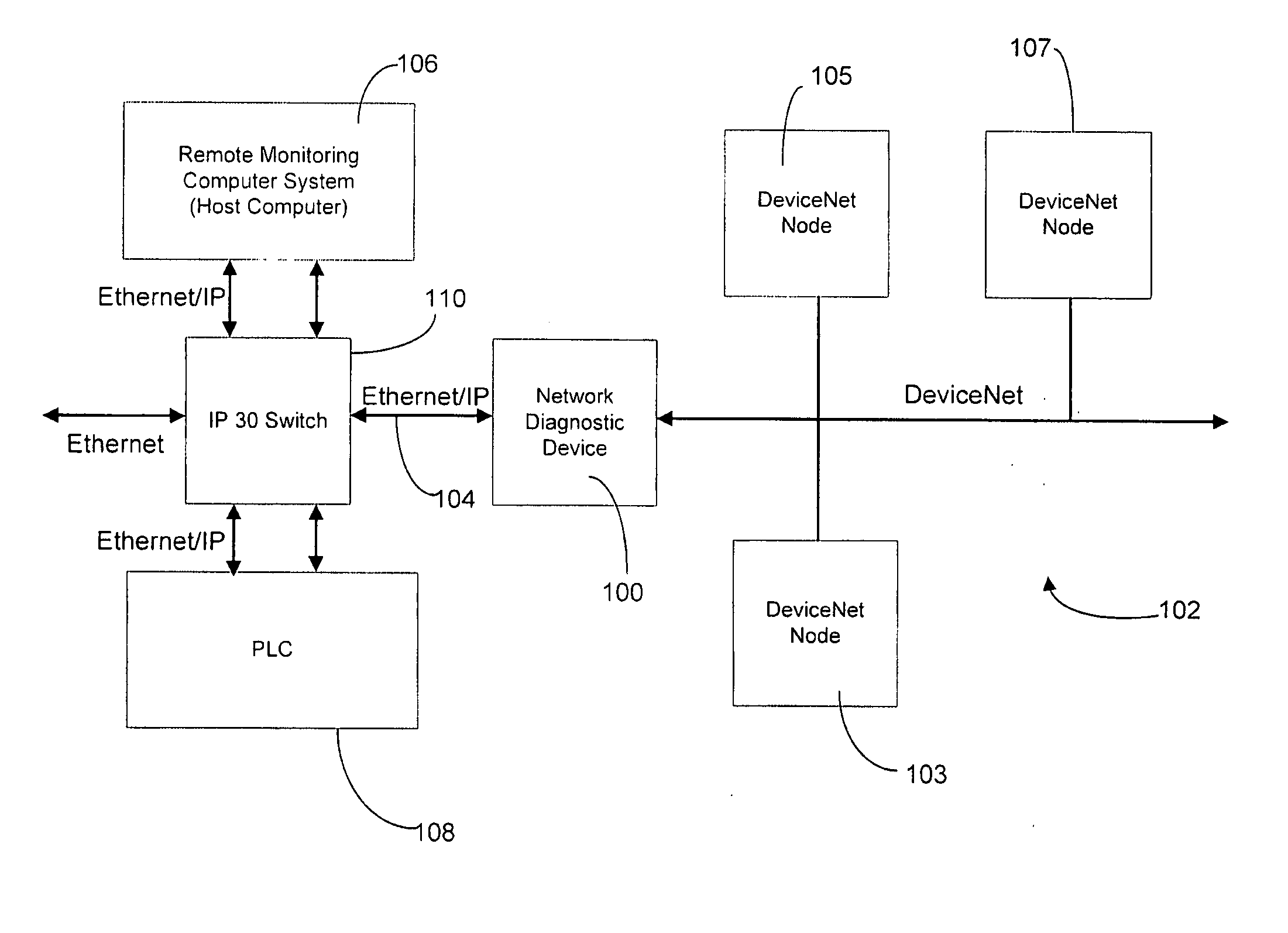

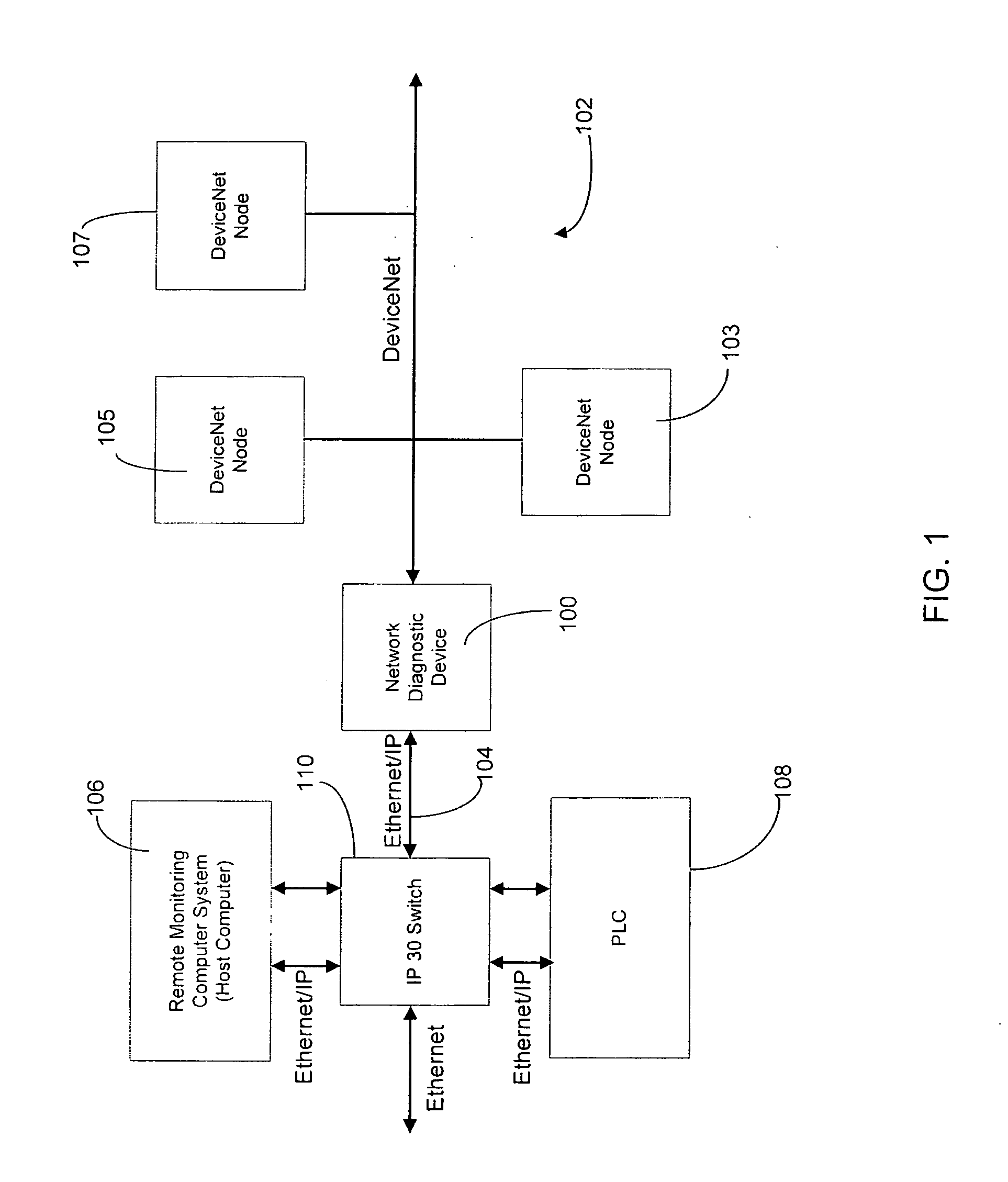

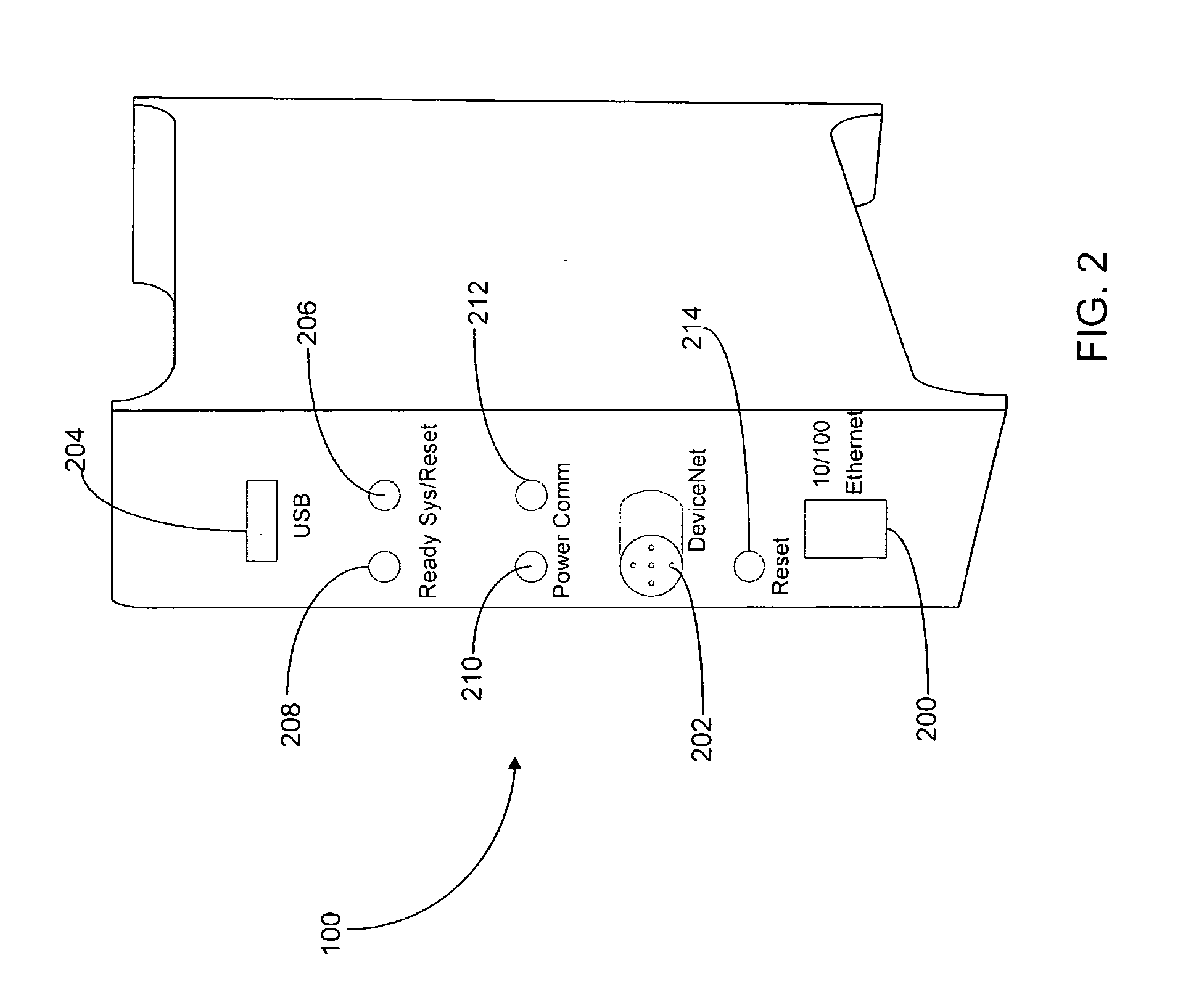

Microcontroller network diagnostic system

ActiveUS20100082805A1Easy to predictEasy to troubleshootDigital computer detailsElectric digital data processingMicrocontrollerArea network

A network diagnostic device is provided, which comprises a passive real-time measurement tool that is useful for, among other things, expediting fault identification, isolation, and repair of a communication network or bus. The device also facilitates prediction of failures by identifying marginal operating conditions. The device analyzes data flowing through the communication network, including through an analysis of variations in bit waveform shape carried by the network physical interconnect media. In one embodiment, an implementation of the network diagnostic device is particularly useful in a DeviceNet-compatible network or, more generally, a Controller Area Network (CAN). The device identifies faults by comparing measurements made on the actual DeviceNet bus with worst-case acceptable criteria. The device interfaces with a remote monitoring computer via an Ethernet compatible medium to display parsed bit-level waveforms, network warnings and errors, as well as an overall network health index.

Owner:WOODHEAD IND INC

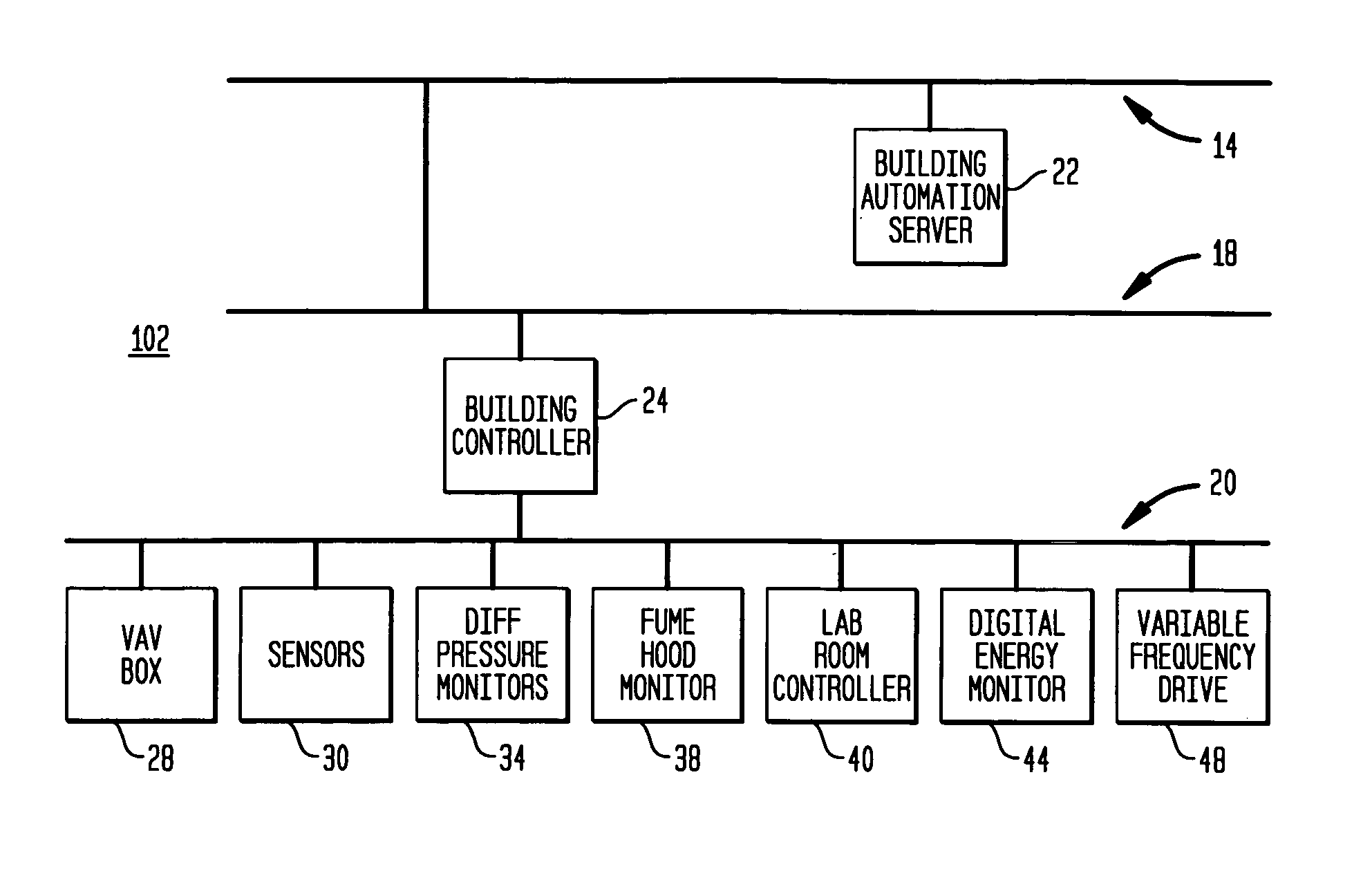

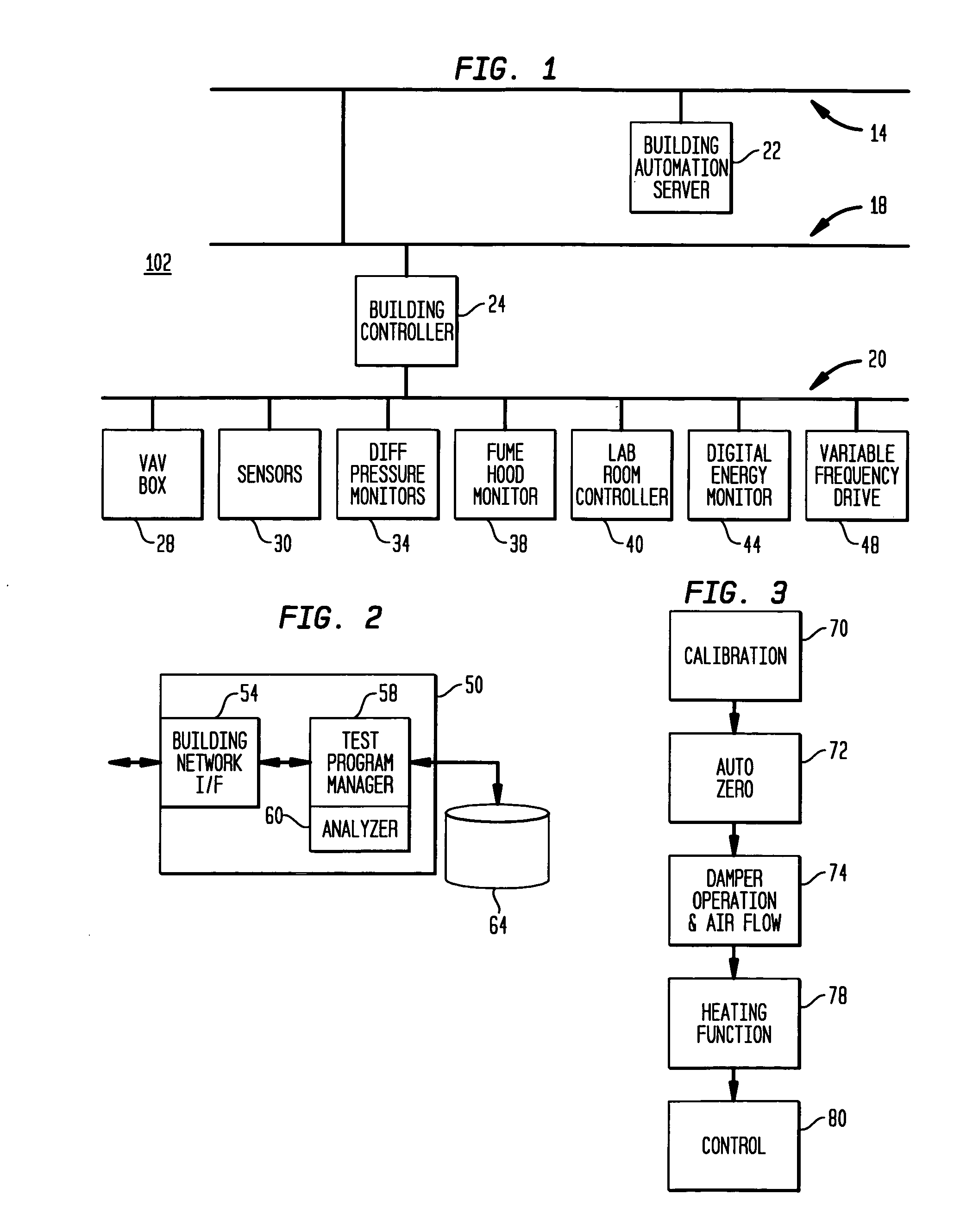

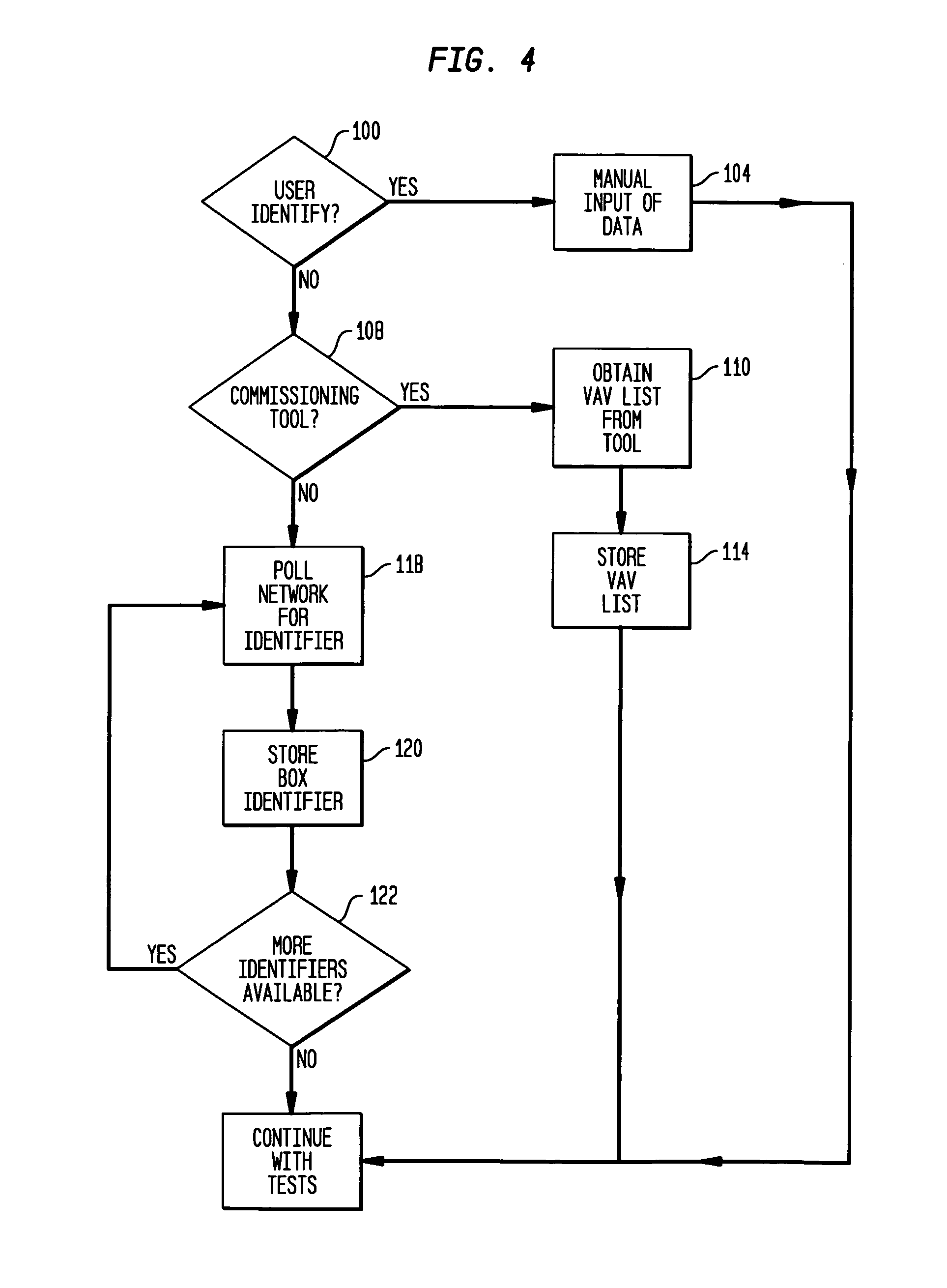

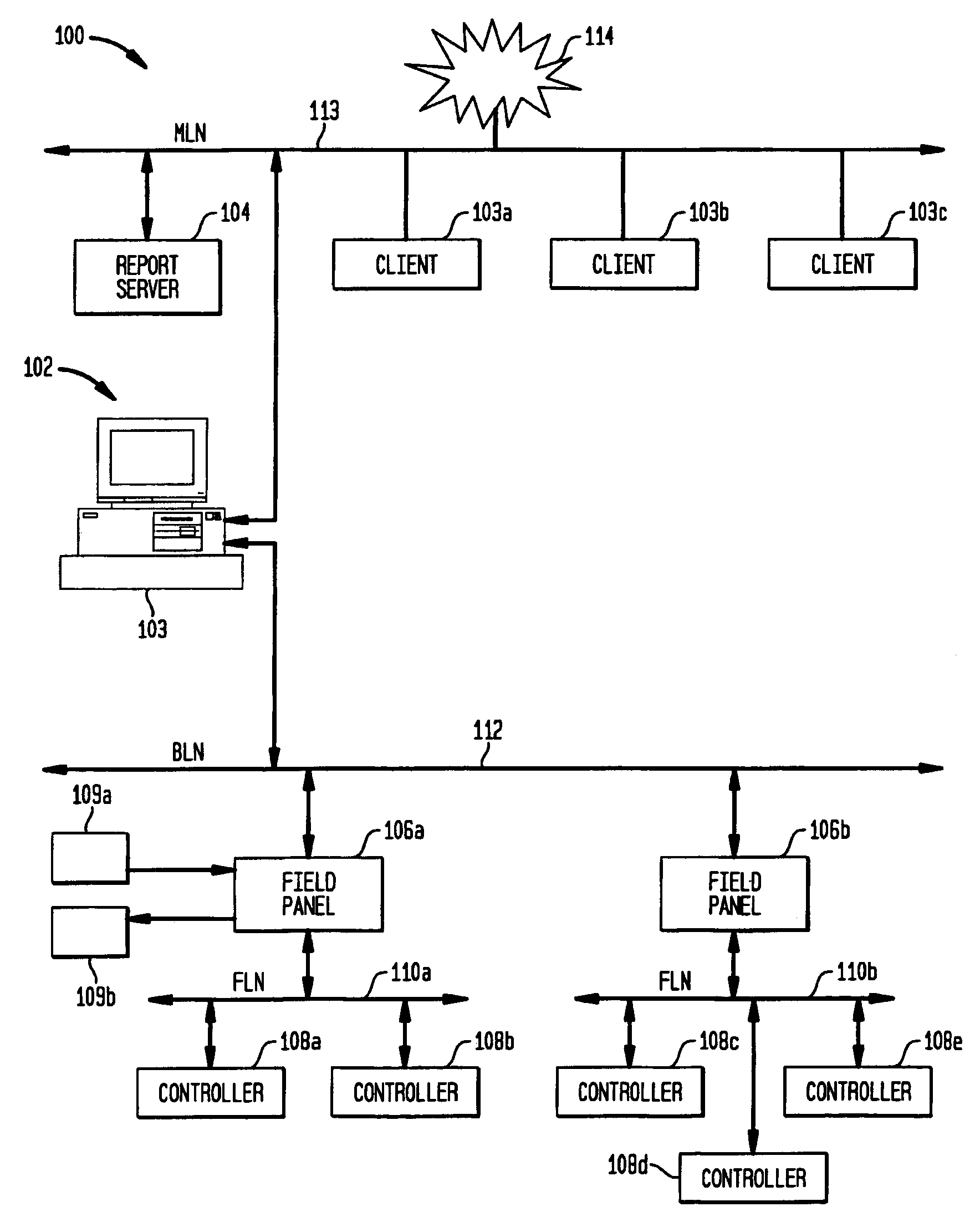

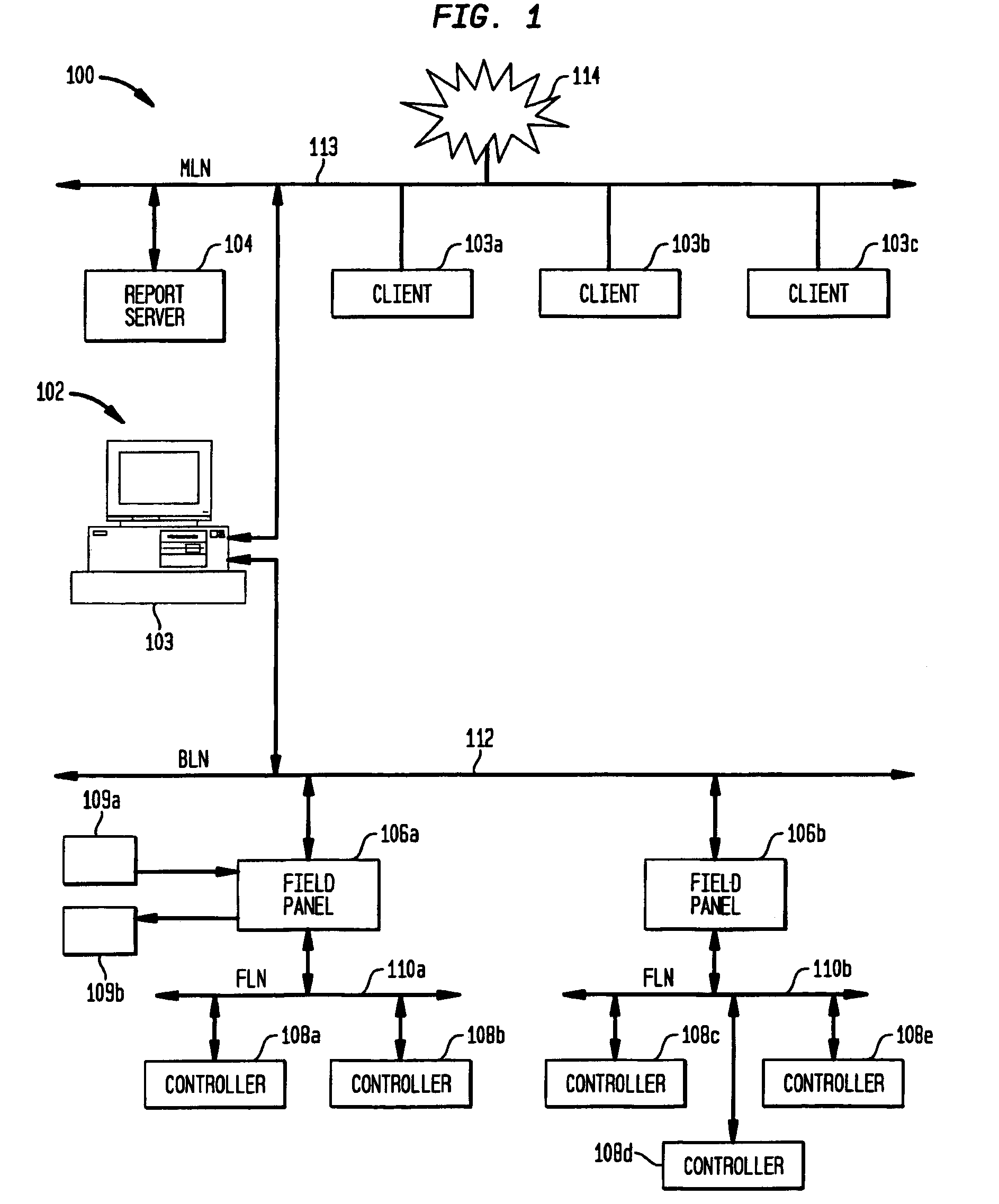

System and method for developing and processing building system control solutions

ActiveUS7177776B2Addressing slow performanceLow costProgramme controlMechanical apparatusTraffic volumeTest program

A test tool enables the testing of multiple variable air volume (VAV) boxes from a single location in a building environmental system. The test tool includes a building level network interface and a test program for sending a test parameter to a plurality of VAV boxes so that measurements of air flow characteristics may be obtained at the plurality of VAV boxes.

Owner:SIEMENS IND INC

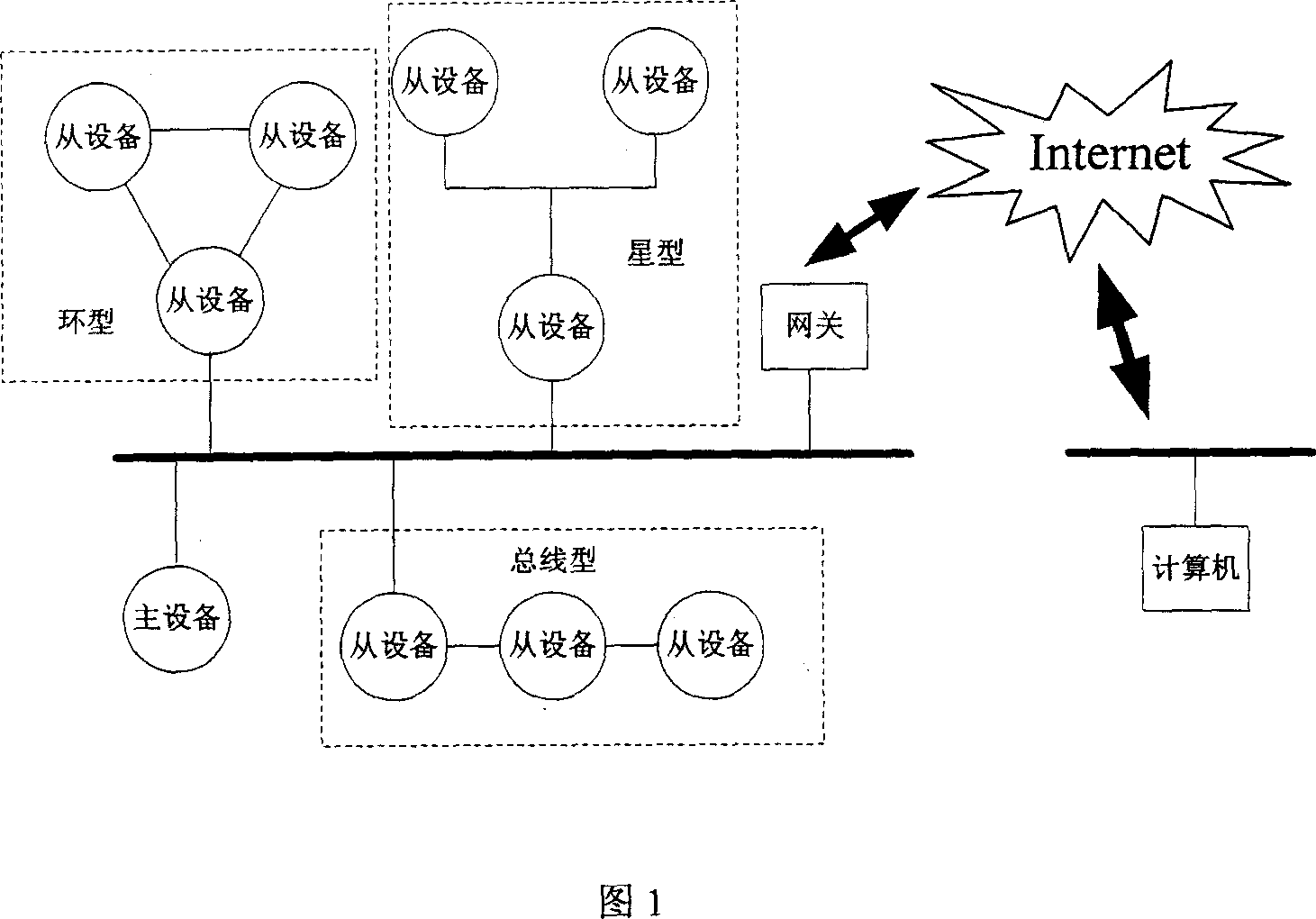

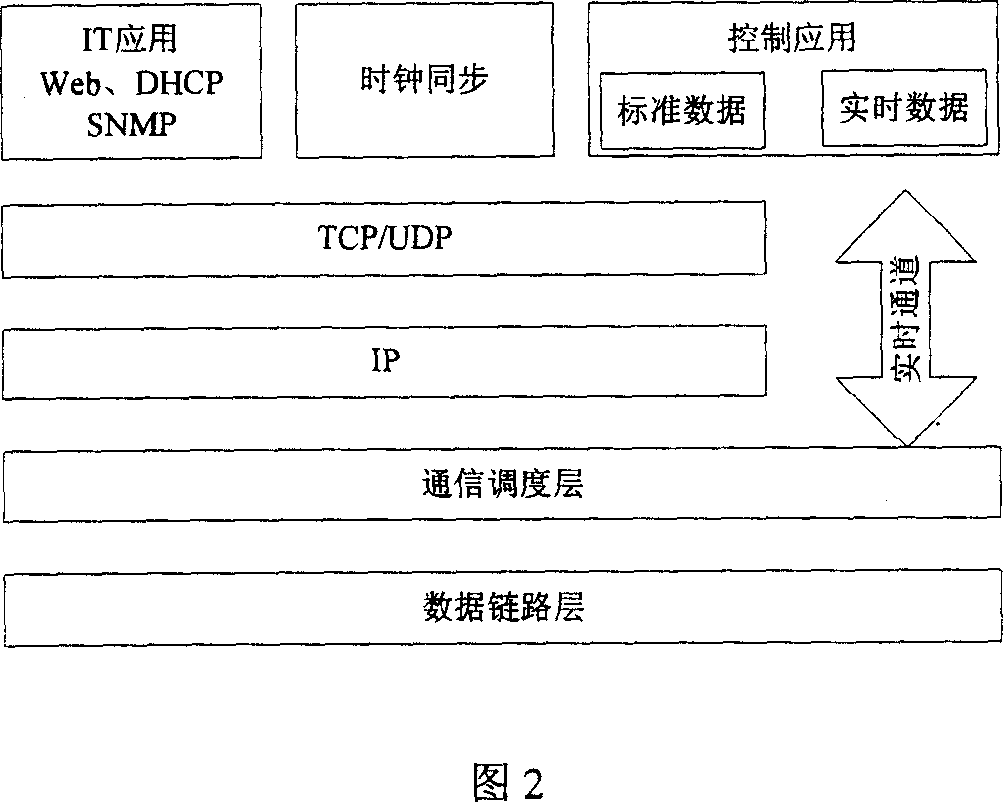

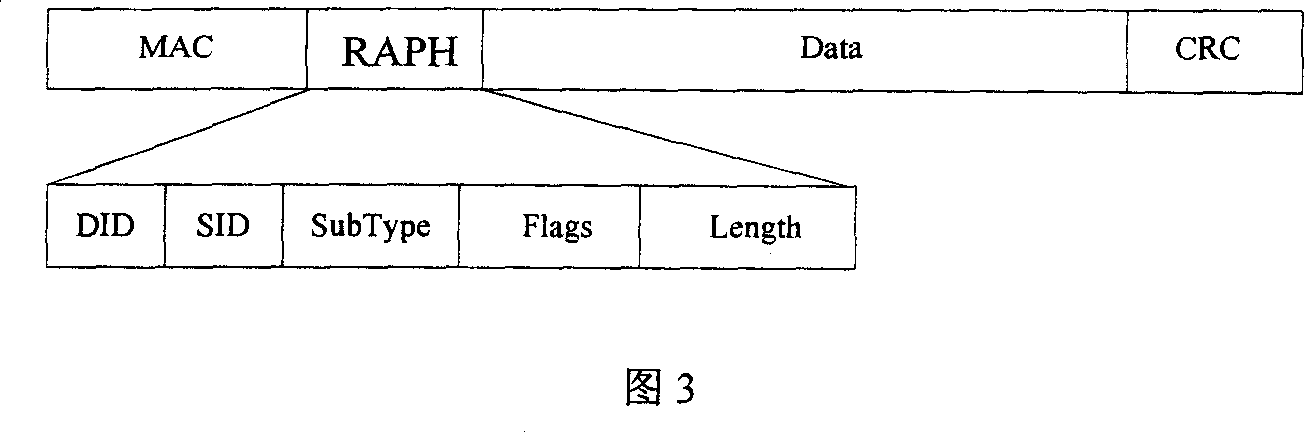

Method for determining realtime Ethernet tlecommunication

ActiveCN101075945ASatisfy real-timeFulfil requirementsData switching networksOriginal dataControl area

The method comprises: newly adding a communication scheduling layer into original data link layer of Ethernet; in relation to the standard channel using TCP / IP, newly adding a real time channel; according to the greatest common divisor of control cycle in the actual control area, using a three segmentation dividing principal to divide macro cycle into three time segmentations on time axis; the bus arbitration uses a approach of combining the distribution with the concentration, and uses a time slot distribution based scheduling approach to send the cyclic data relating to the realization of control function in the time segmentation, uses the centralized scheduling approach with priority controlling function to send the system data and non cyclic data in the time segmentation; all slave devices in the system keep the time consistence with the master device by using a clock synchronous algorithm; the logic addressing is made based on the device ID; realizing the real time Ethernet determinacy communication.

Owner:MICROCYBER CORP

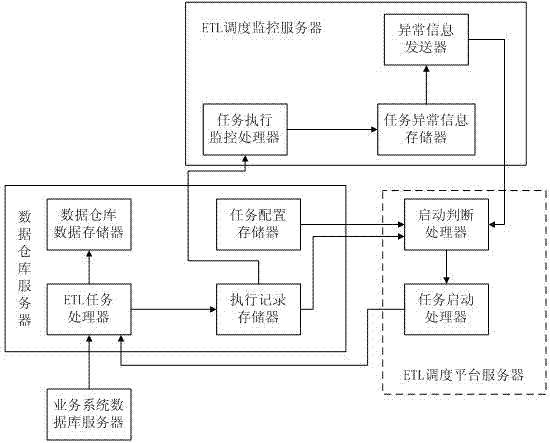

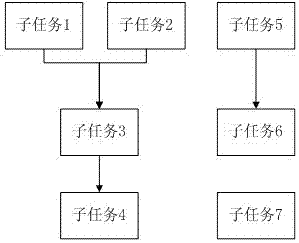

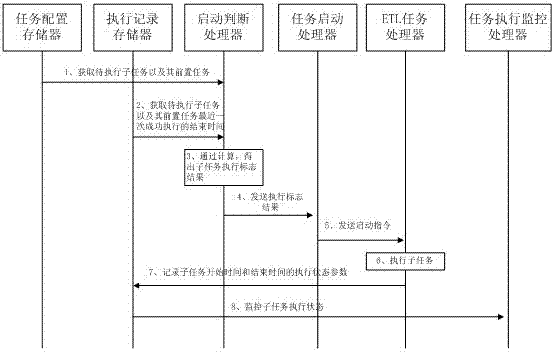

ETL (Extraction-Transformation-Loading) dispatching system and method for error-correction restarting and automatic-judgment starting

ActiveCN103034554AEasy to troubleshootReduce rescheduling task timeProgram initiation/switchingFault responseData warehouseDatabase server

The invention discloses an ETL (Extraction-Transformation-Loading) dispatching system and method for error-correction restarting and automatic-judgment starting. The ETL dispatching system structurally comprises a business system database server, a data warehouse server, an ETL dispatching and monitoring server and an ETL dispatching platform server. The ETL dispatching method disclosed by the invention comprises the following steps of: dividing a data warehouse ETL task into a plurality of subject tasks, wherein each subject task comprises a plurality of sub-tasks; configuring information according to a preset executing sequence and automatically judging the end time for successfully executing the pre-posed associated sub-tasks; executing follow-up sub-tasks, stopping the execution of the associated follow-up sub-tasks according to the sub-task correlation after the execution of the sub-tasks has exception faults, and recording the exceptional sub-tasks; and only processing the exceptional sub-tasks and the associated follow-up sub-tasks in a way of automatically restarting for many times. According to the ETL dispatching system and method disclosed by the invention, the problem that the follow-up sub-tasks are continuously executed when the pre-posed sub-tasks have faults in the ETL task dispatching is solved; the task executing efficiency is improved; the manual intervention is reduced; and the operation loss is reduced.

Owner:FOCUS TECH

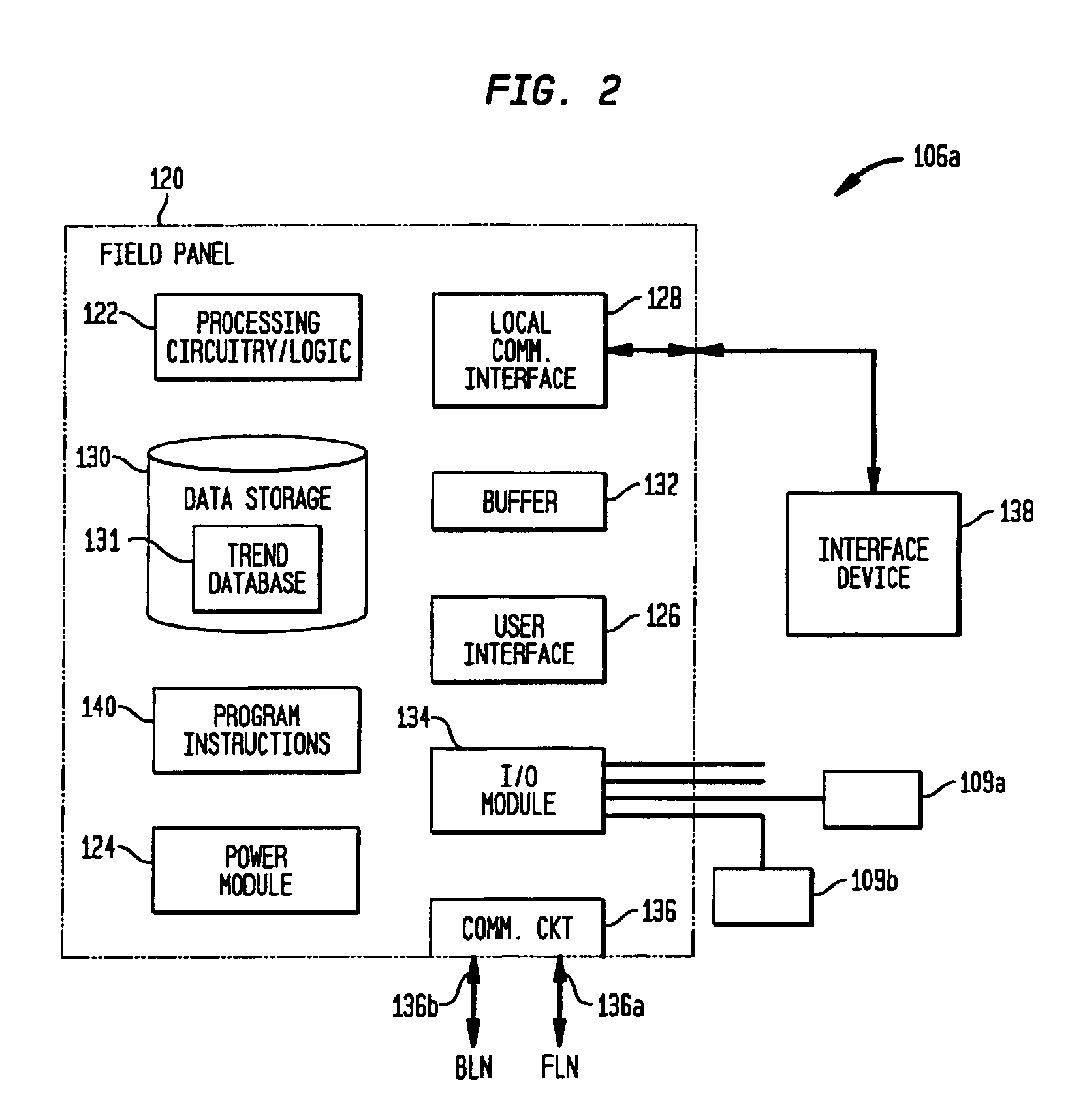

Field panel trending on event in a building control system

InactiveUS7110919B2Easy to troubleshootEliminates collectionTemperatue controlUser identity/authority verificationControl systemWorkstation

A building control system, such as an HVAC system, has a field unit incorporating a control panel (a field panel) with a local user interface allowing user selected parameters for collecting trend information when the system detects a change of value for a point in the system or a timed instruction in the memory of the field panel to begin collecting trend data for a point. The resulting trend data collected by the field panel can be uploaded to a workstation in the building control system, where the trend data can be formatted into a report, and then digitally authenticated.

Owner:SIEMENS IND INC

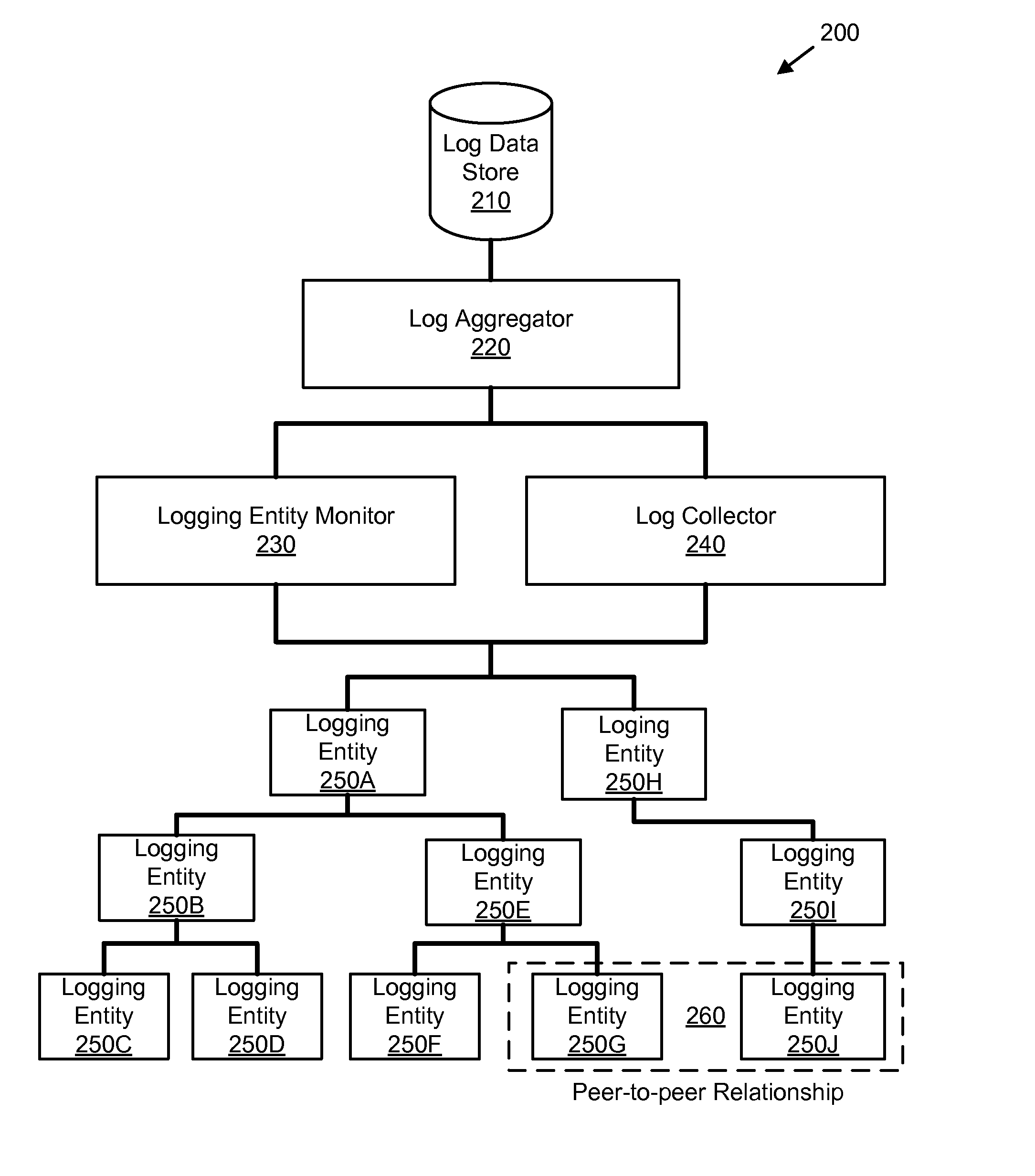

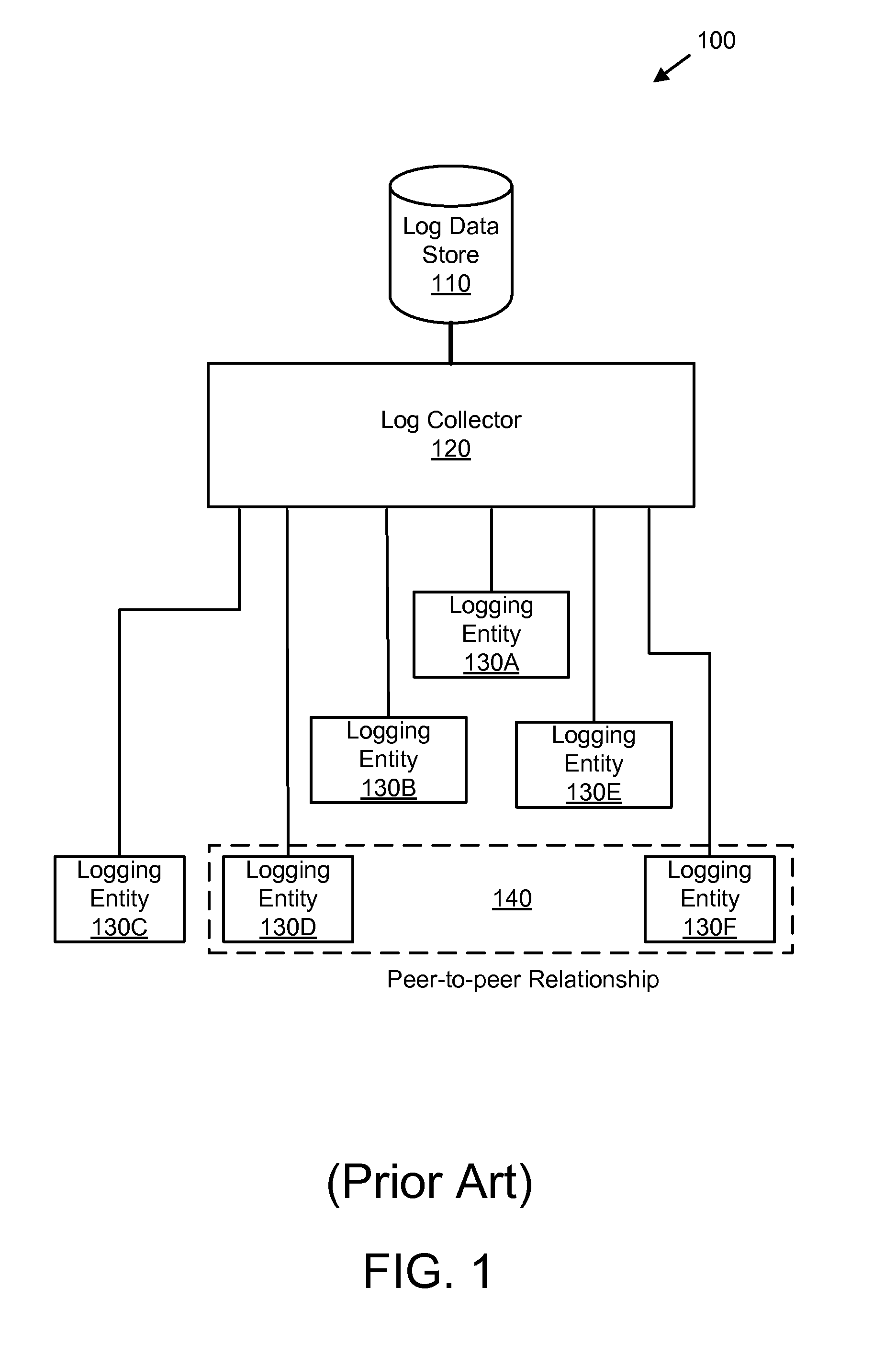

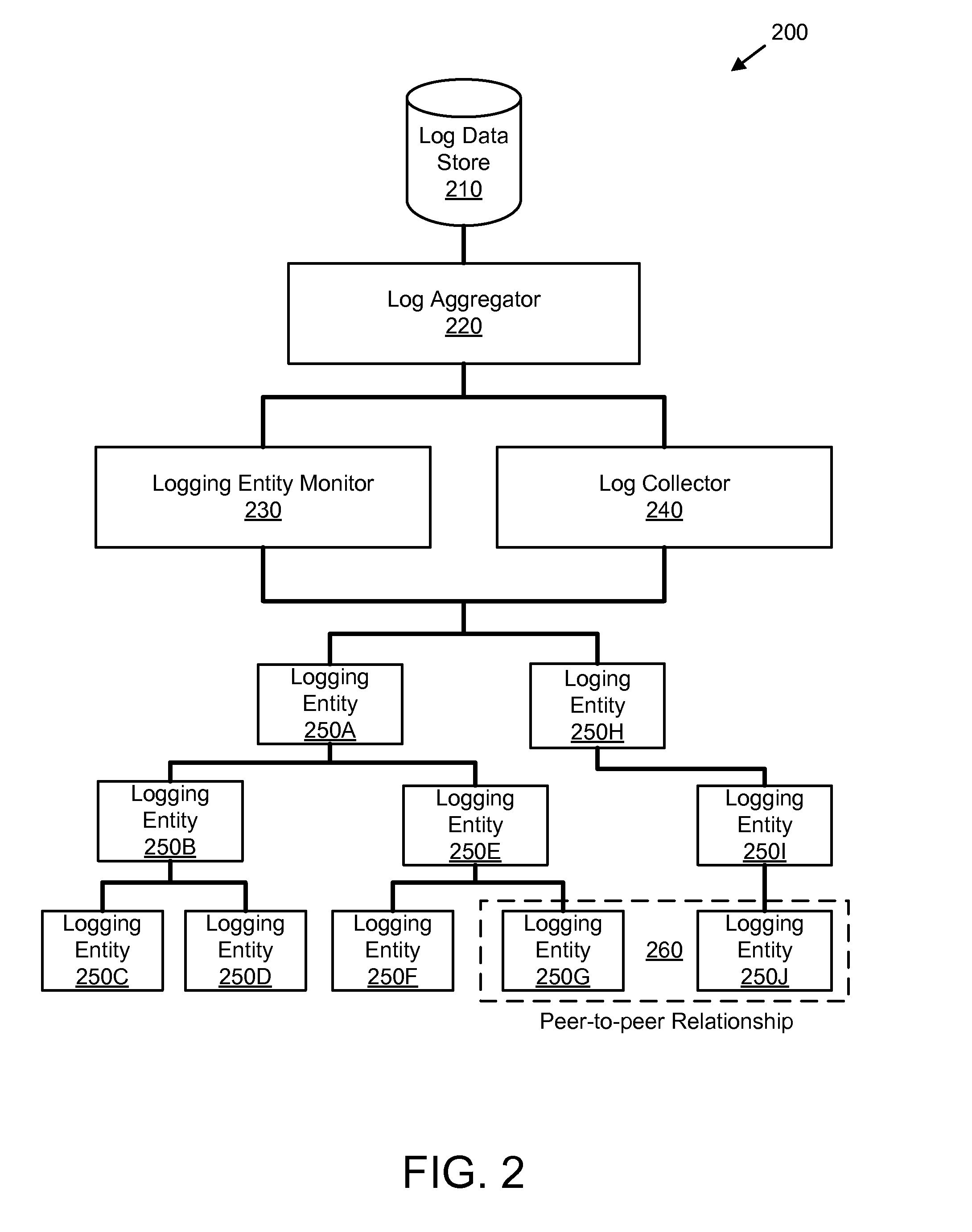

Distributed logging apparatus system and method

An apparatus, system, and method are disclosed for distributed logging. Operating entities and associations between operating entities are registered in a registry by a logging entity registrar. An event notification monitor recognizes operating errors in operating entities. An aggregation module aggregates operating logs from sets of associated entities, which are then stored by a log set recorder.

Owner:TWITTER INC

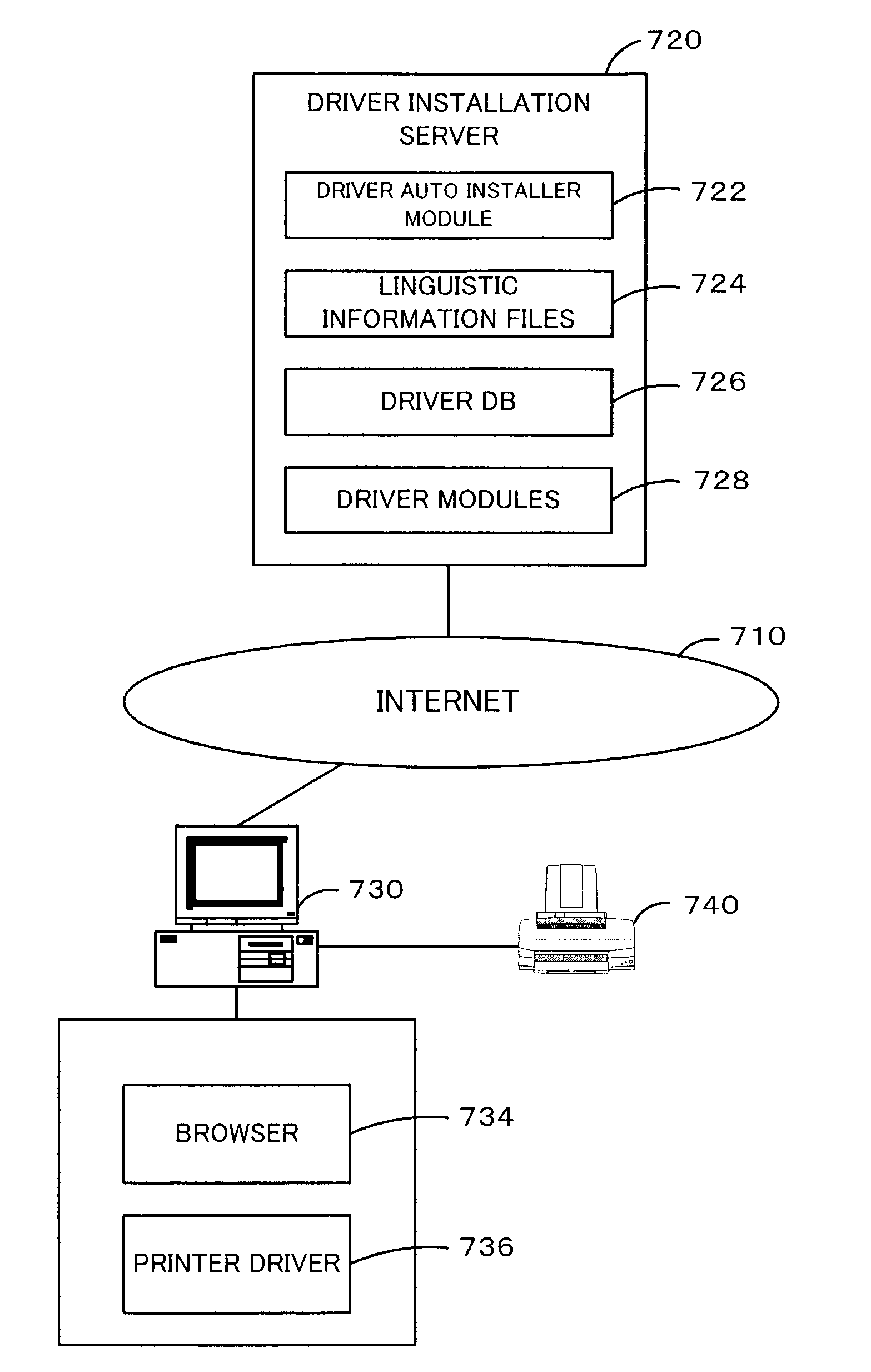

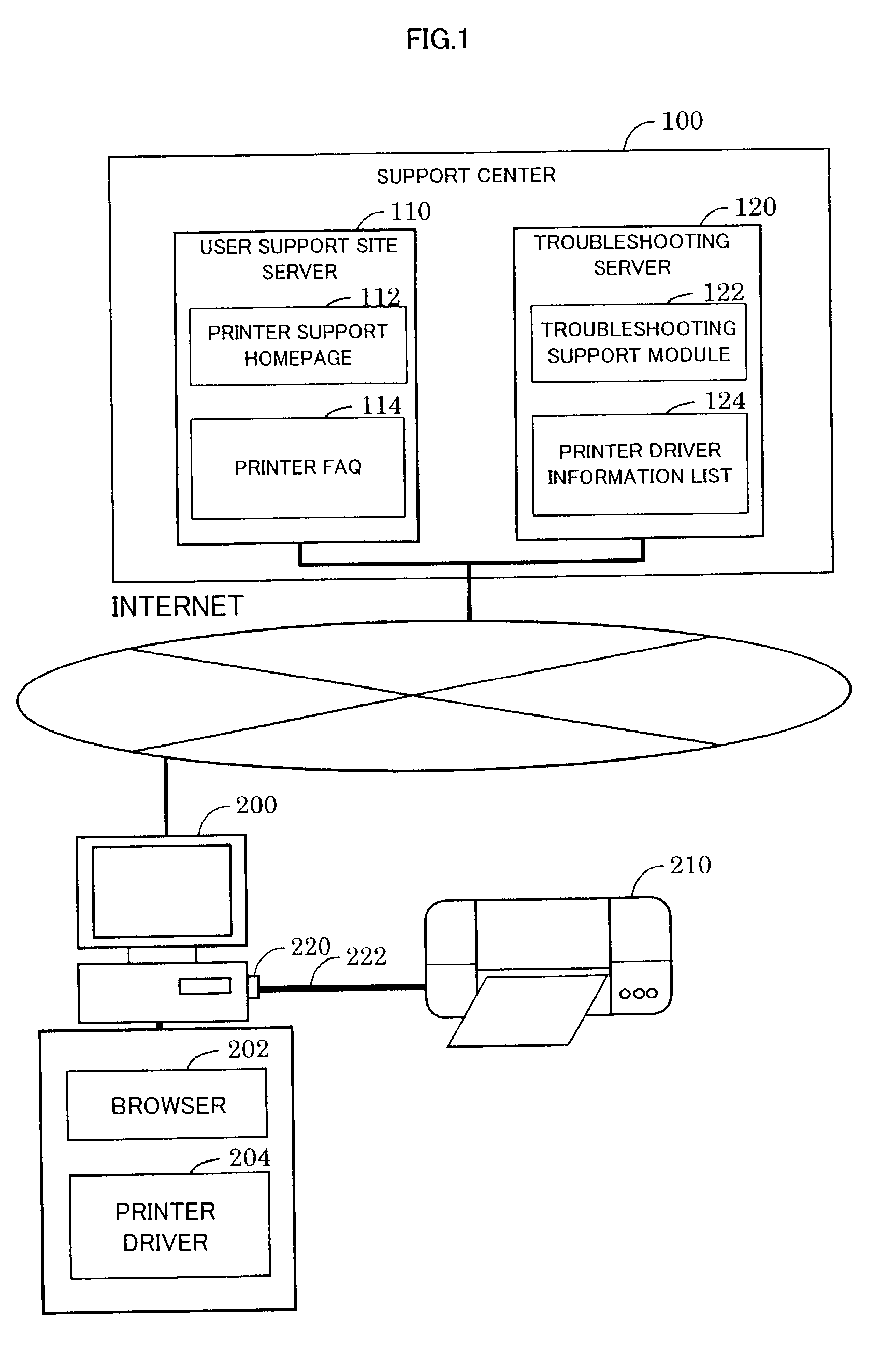

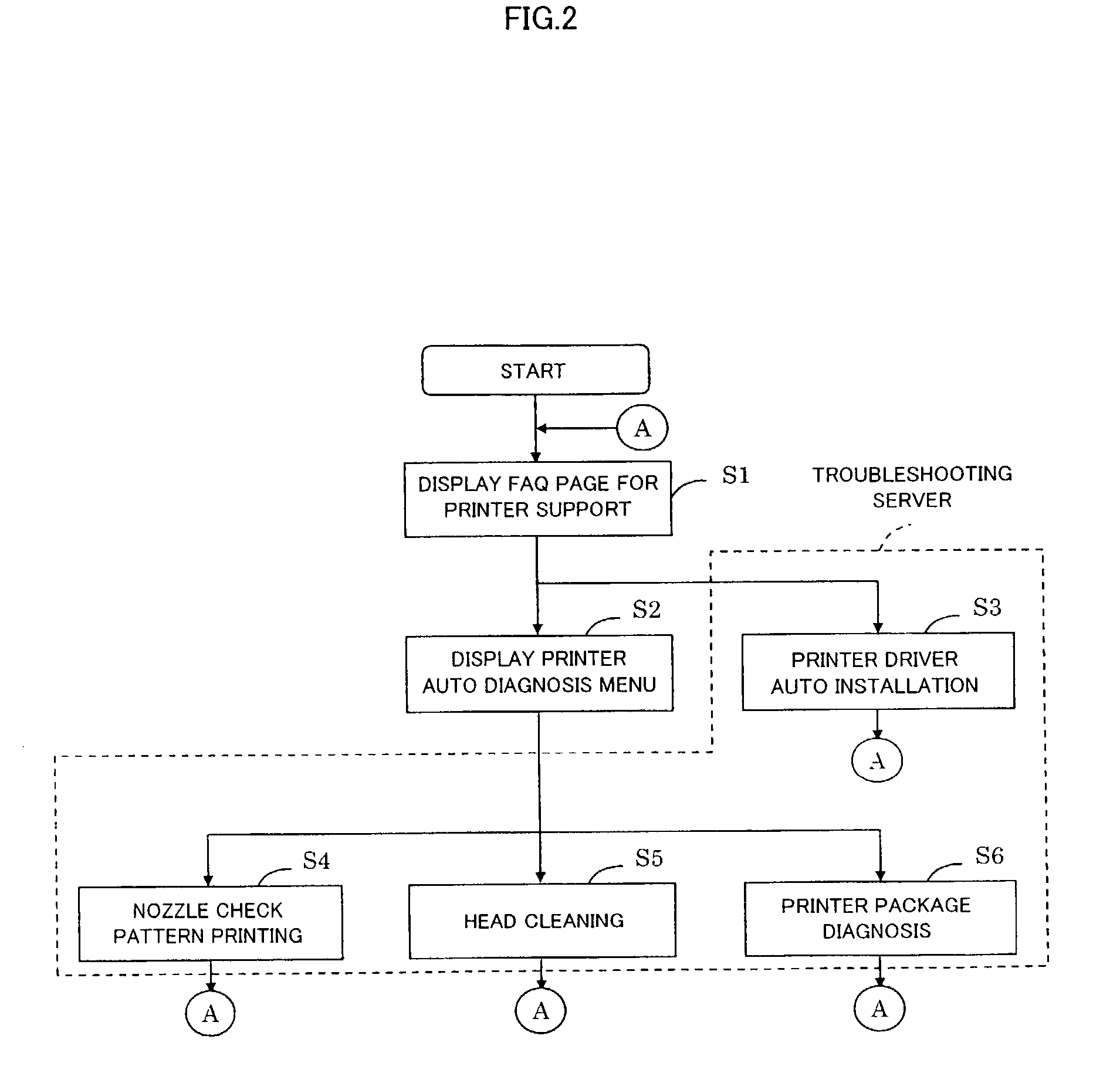

Network technique for troubleshooting

InactiveUS7284044B2Easy to troubleshootEasy to installNatural language data processingMultiple digital computer combinationsReal-time computingTroubleshooting

In response to a user's selection of a troubleshooting instruction element on a troubleshooting page displayed on a client 200 by a browser, the client 200 transmits a transfer request of a troubleshooting program to servers 110 and 120. The servers 110 and 120 transfer the troubleshooting program according to the transfer request. The troubleshooting program is automatically activated on the client 200 on completion of its download to the client 200, in order to execute a troubleshooting procedure.

Owner:SEIKO EPSON CORP

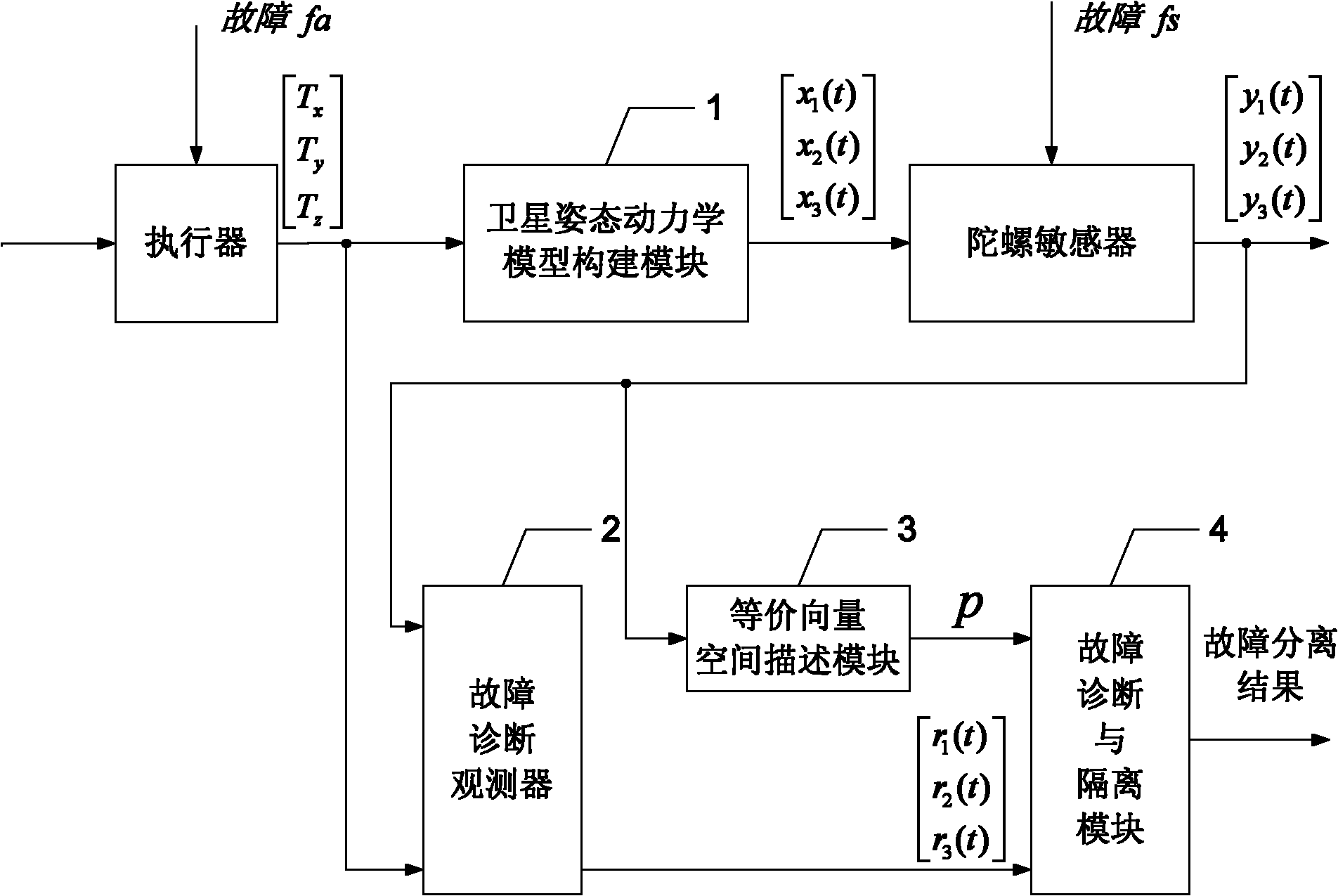

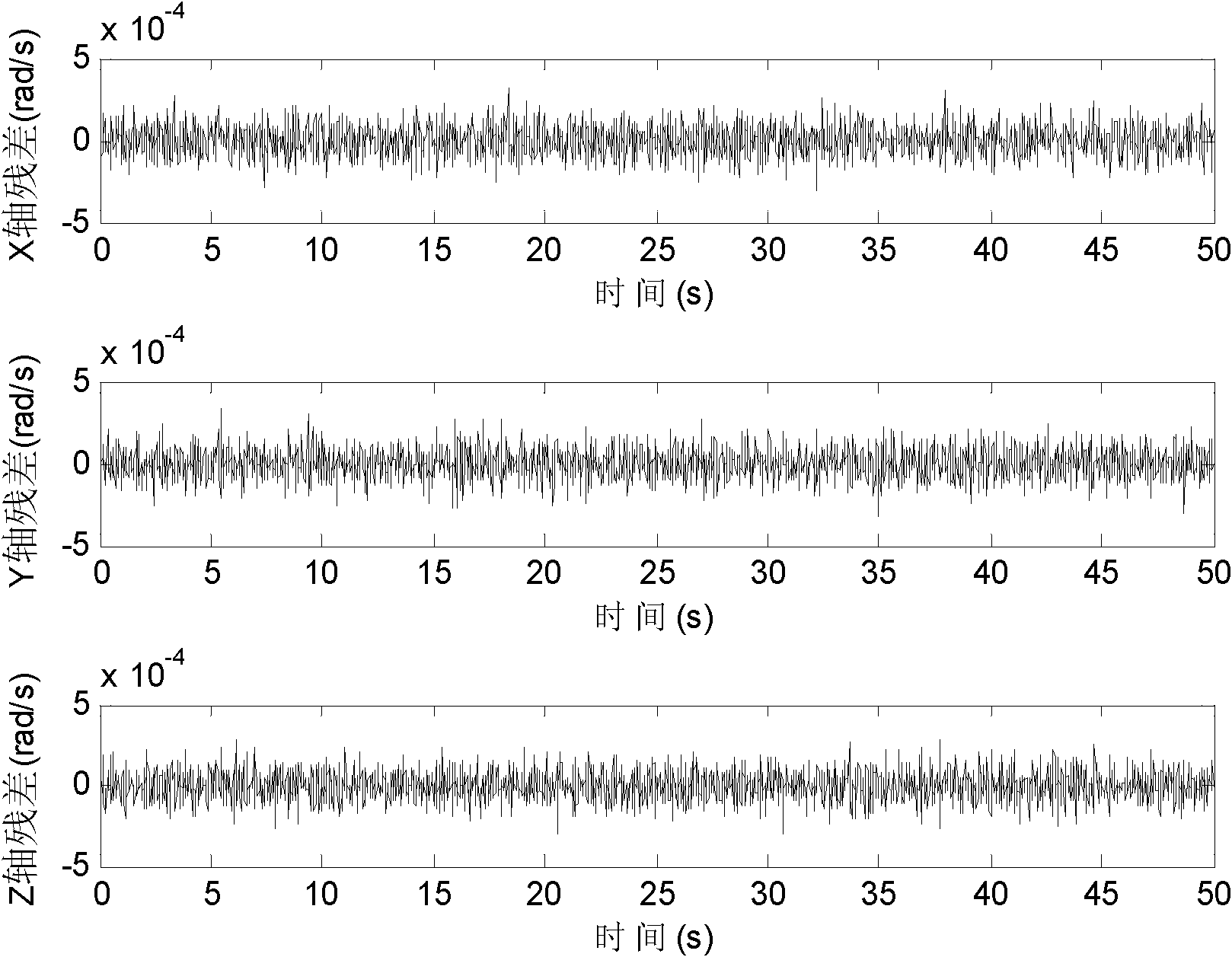

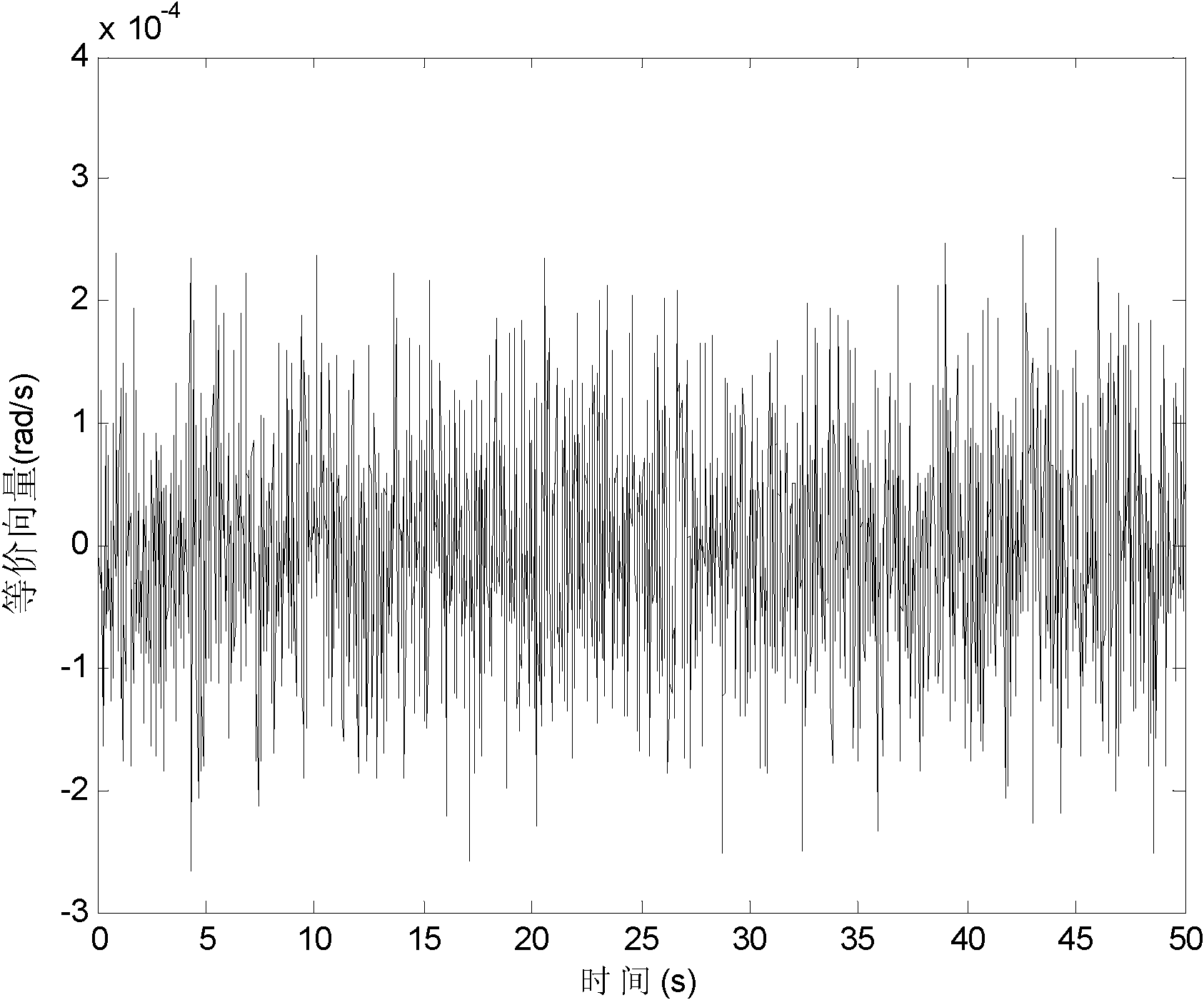

Satellite attitude control system failure diagnosis device and method based on state observer and equivalent space

ActiveCN102176159AImprove effectivenessImplement fault diagnosisElectric testing/monitoringState observerHardware complexity

The invention discloses a satellite attitude control system failure diagnosis device based on a state observer and an equivalent space and a satellite attitude control system failure diagnosis method based on the state observer and the equivalent space, which belong to the field of aerospace and aim to solve the problems of high hardware complexity, low control accuracy and low failure diagnosis algorithm effectiveness of the conventional failure diagnosis method. The method provided by the invention comprises the following steps that: 1, a failure diagnosis observer outputs a satellite triaxial angular rate residual according to output signals of an actuator and a gyro sensor; 2, an equivalent vector space description module constructs equivalent space descriptions of the gyro sensor according to the output signal of the gyro sensor, wherein an output equivalent vector p is used for judging whether the gyro sensor fails or not; and 3, a failure diagnosis and isolation module outputs a failure separation result indicating that the actuator or the gyro sensor fails according to the satellite triaxial angular rate residual obtained by the step 1 and the equivalent vector p obtained by the step 2, and further judges which axis of the failing part fails.

Owner:HARBIN INST OF TECH

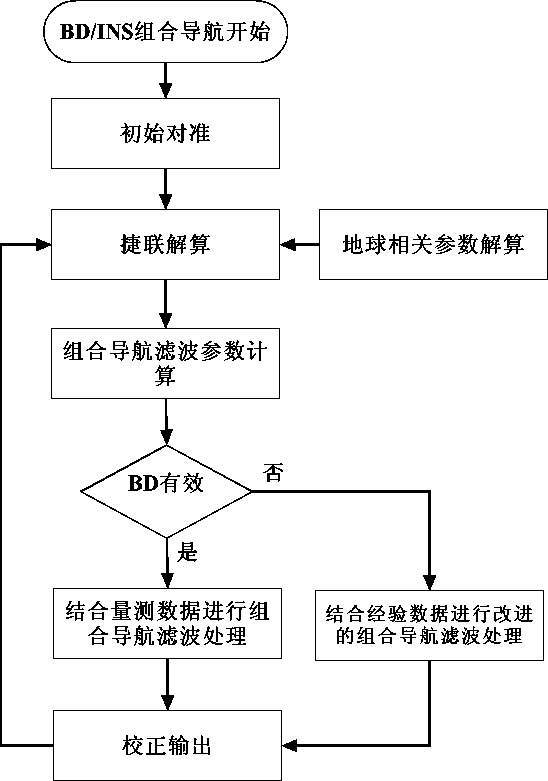

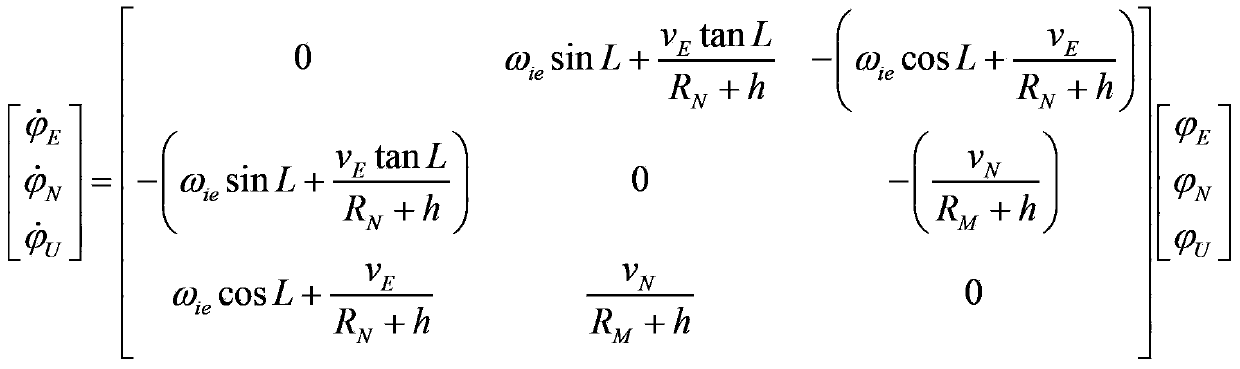

Strapdown inertial navigation system/global navigation satellite system combined based navigation filter system and method

ActiveCN104181574AHigh precisionFast convergenceNavigational calculation instrumentsSatellite radio beaconingNormal modeFilter system

The invention discloses a strapdown inertial navigation system(SINS) / global navigation satellite system (GNSS) combined navigation filter system comprising a primary binding module, an earth parameter calculation module, an initial alignment module, a strapdown inertial navigation calculation module, an improved filter algorithm parameter calculation module, a normal-mode combined navigation filtering module, a fault-mode combined navigation filtering module and a feedback correction output module. The improved filter algorithm parameter calculation module calculates a sate transition matrix, a system drive noise covariance matrix, and a measurement noise covariance matrix that are needed by an improved kalman filtering algorithem based on data provided by an SINS and a GNSS and transmits the information to the normal-mode combined navigation filtering module and the fault-mode combined navigation filtering module to carry out filtering calculation according to the result and a status flag. According to the invention, the combined navigation filtering algorithm is modularized, thereby obviously improving precision of the combined navigation and accelerating the convergence speed of the combined navigation filtering algorithm; and the kalman filtering divergence can be effectively inhibited.

Owner:CHENGDU GUOXING COMM

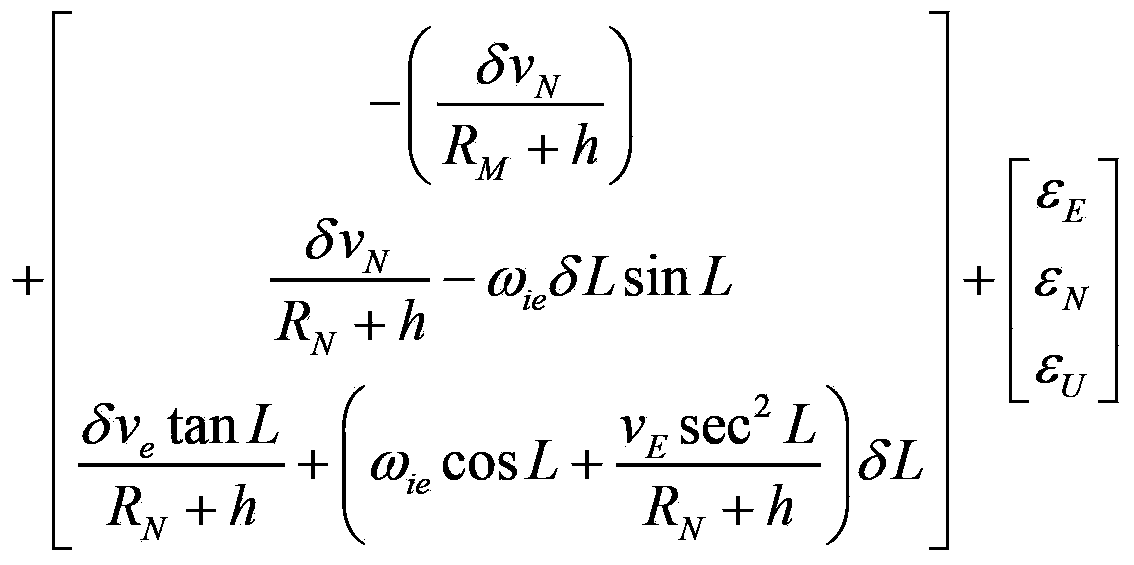

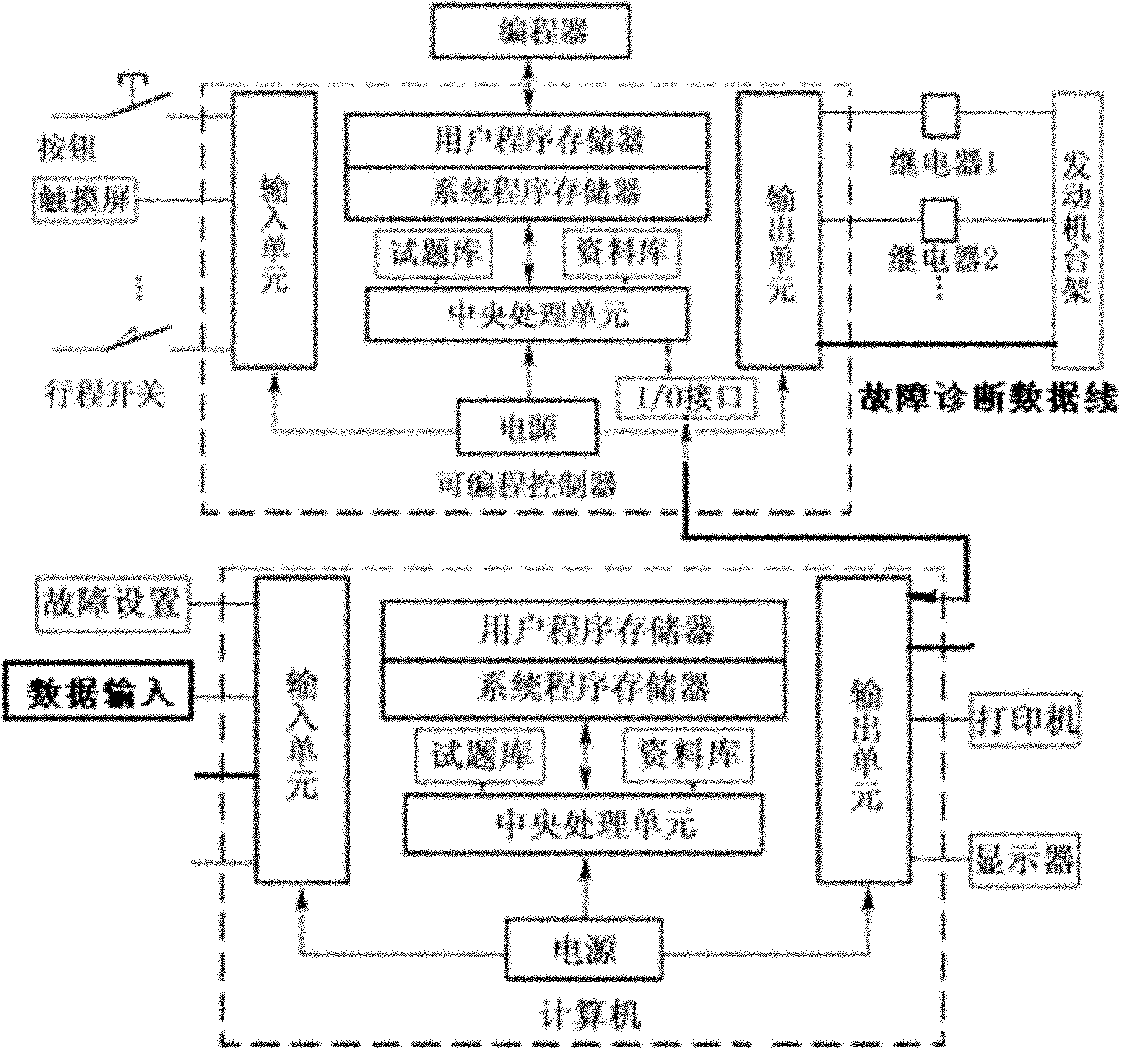

Vehicle failure intelligent setting, practical training and check-out system and realization method thereof

InactiveCN102117564AQuality improvementImprove efficiencyCosmonautic condition simulationsElectrical appliancesProgrammable logic controllerTest question

The invention discloses a vehicle failure intelligent setting, practical training and check-out system and a realization method thereof. The system comprises a test bench, a relay, a PLC (Programmable Logic Controller) and a touch screen, wherein the test bench is connected with the PLC through the relay; the system has a standalone edition mode and a network edition mode according to that whether the system is connected to the network or not; in the standalone edition, the PLC is directly connected with the touch screen; in the network edition, the system also comprises a computer which is connected with the touch screen and the PLC respectively, and the PLC is connected with the touch screen. The method is that a teacher can retrieve the test questions in an item pool through the touch screen or the computer and conduct failure setting on a vehicle on the test bench through the PLC and the relay; and a student can read the technical information in a data bank through the touch screen for conducting fault diagnosis and reporting the result to the PLC or the computer. The system and realization method can conduct intelligent failure setting, technical information storage and automatic scoring statistics, and improve practical training and check-out quality and efficiency.

Owner:广州市铭珠电控设备科技有限公司

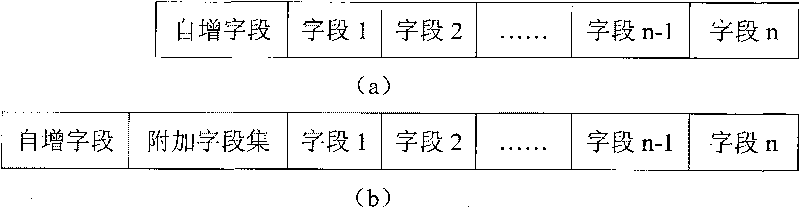

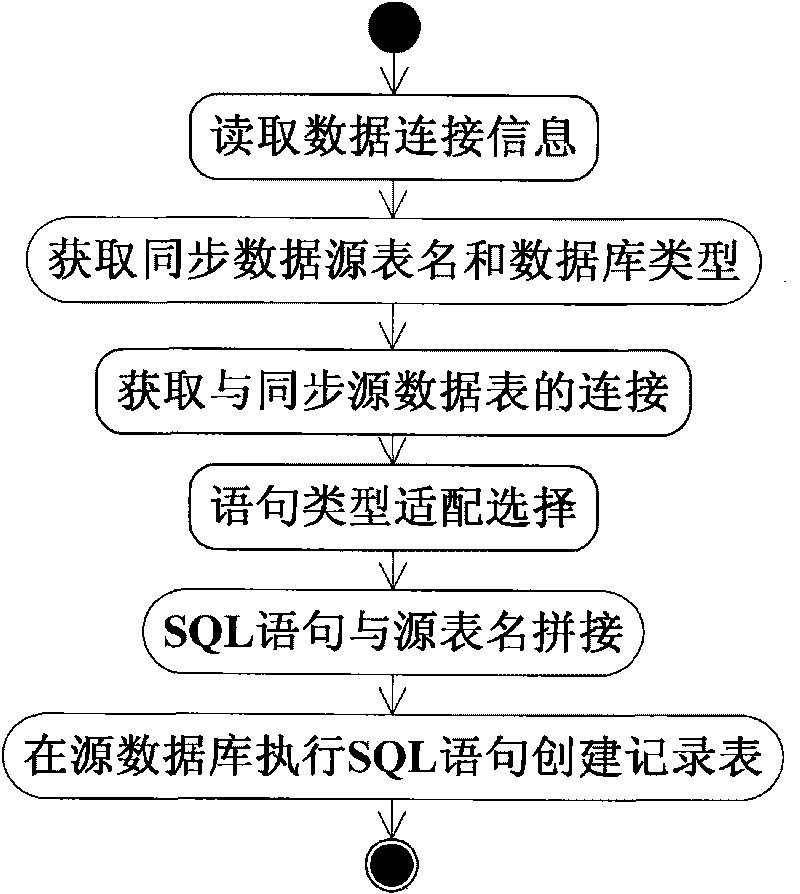

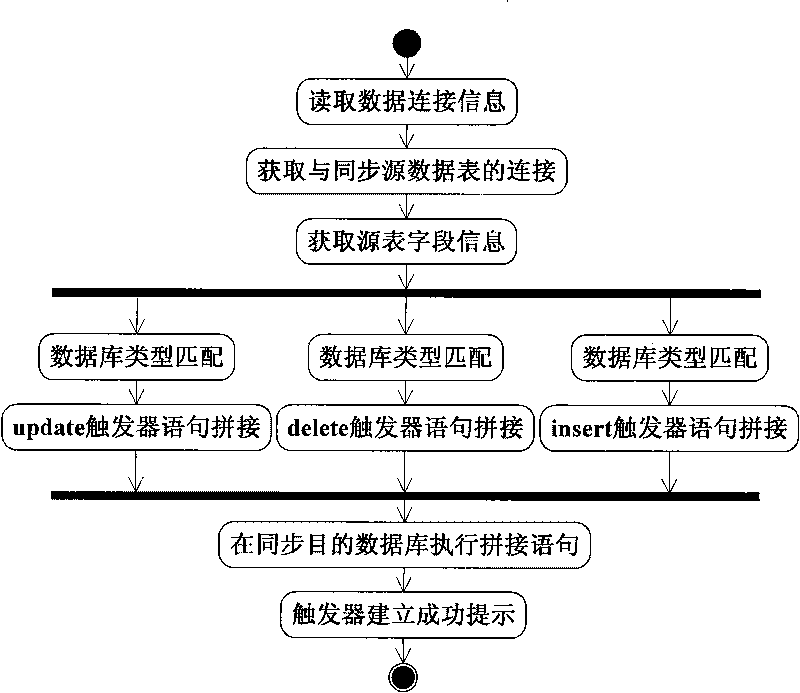

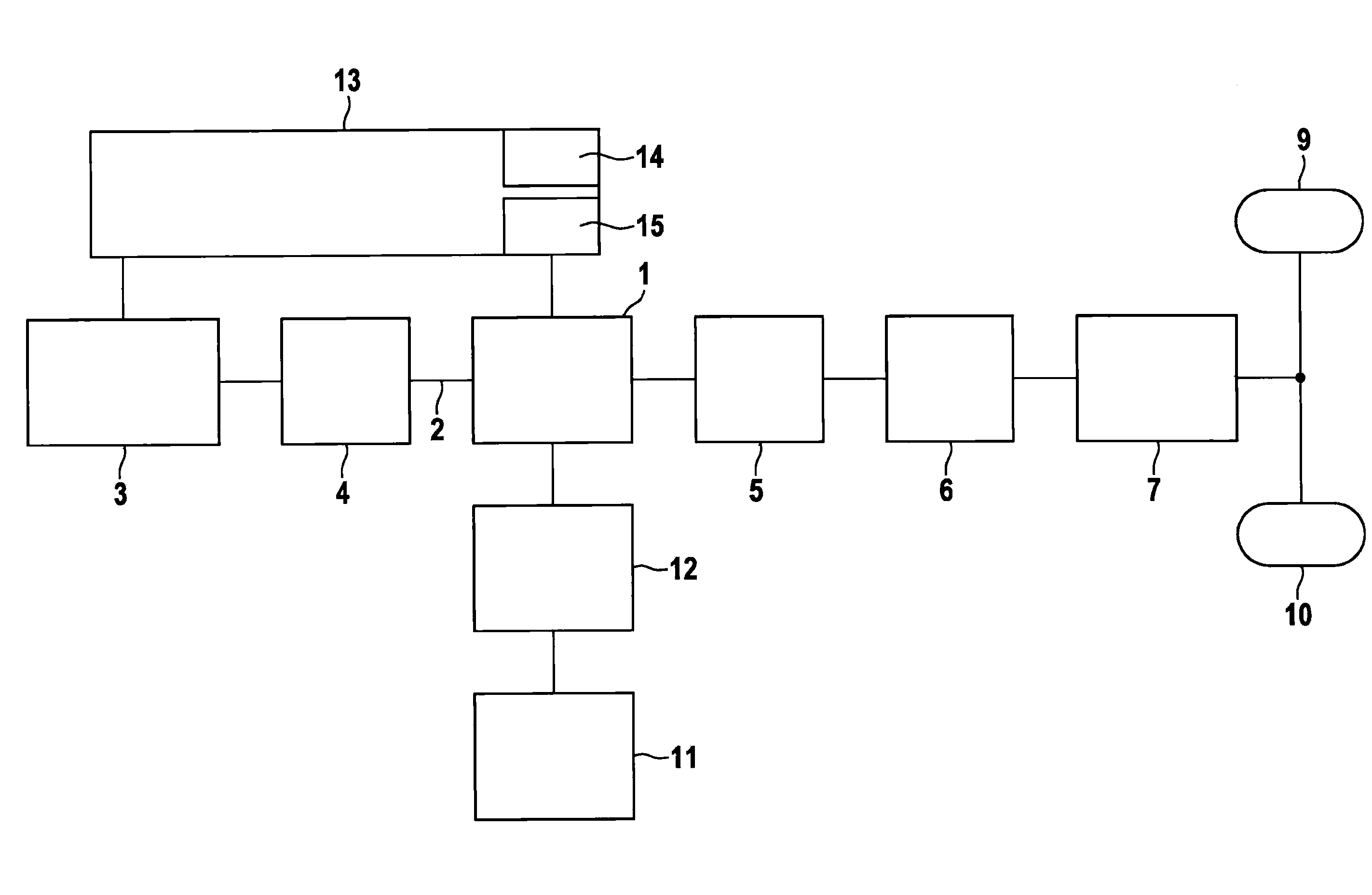

Method for migrating production data of weaving workshop

InactiveCN101706803AImprove efficiencyIntegrity guaranteedSpecial data processing applicationsReconfigurabilityData connection

The invention relates to a method for migrating production data of a weaving workshop, which comprises a central database, a central data sheet structure, a branch factory database and a branch factory data sheet structure and adopts the following steps: (1) system initialization; (2) data connection configuration, namely providing an editing function for data connection; (3) data synchronization, namely finishing the migration of the production data from the branch factory database to the central database; and (4) data recovery, namely, when a database system of a certain branch factory collapses and cannot operate normally due to an accident, utilizing a branch factory identification to extract the production data of a corresponding branch factory from the central database, recovering the production data to the database of the branch factory and ensuring the completeness of the branch factory data. The migrating method of the invention has the characteristics of reconfigurability, easy expansion, support for transmission resuming at break-point, incremental migration, periodic migration, and support for the data transmission between different databases.

Owner:TIANJIN POLYTECHNIC UNIV

Method and device for verifying a drive torque applied by an electric machine in a hybrid drive of a motor vehicle

ActiveUS20120303196A1Accurate torqueTested rapidly and easilyDigital data processing detailsElectric machinesCombustionElectric machine

A method for verifying a drive torque applied by an electric machine in a hybrid drive of a motor vehicle, the motor vehicle being propelled by the electric machine and / or an internal combustion engine, and it being checked if the drive torque applied by the electric machine is determined accurately. In order to ensure that the operating strategy is correctly implemented and a shift in load level in the power train functions reliably during operation of the motor vehicle, the drive torque applied by the electric machine is evaluated with regard to its accuracy, using a drag torque generated by the combustion engine during an overrun fuel cut off.

Owner:ROBERT BOSCH GMBH

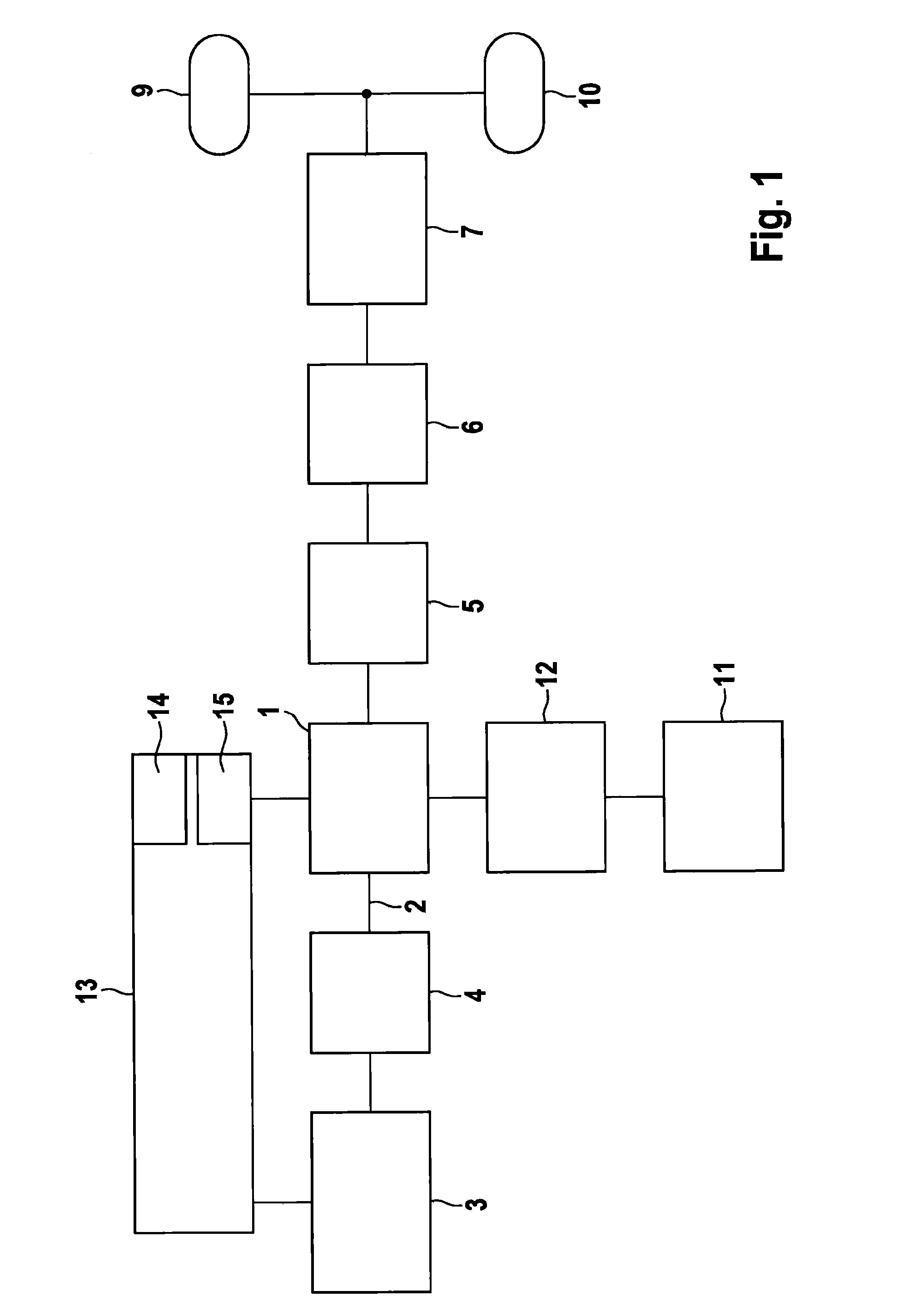

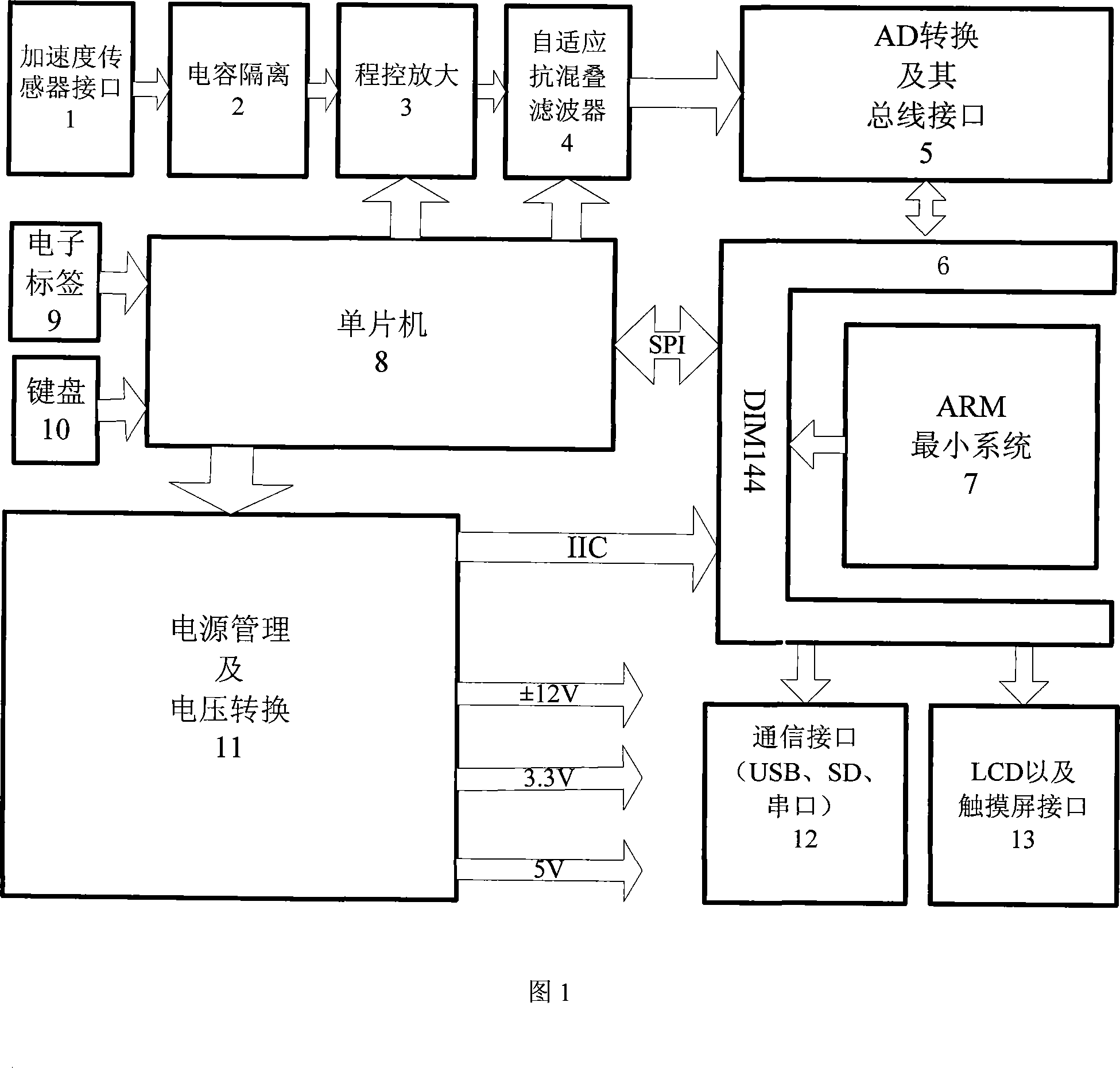

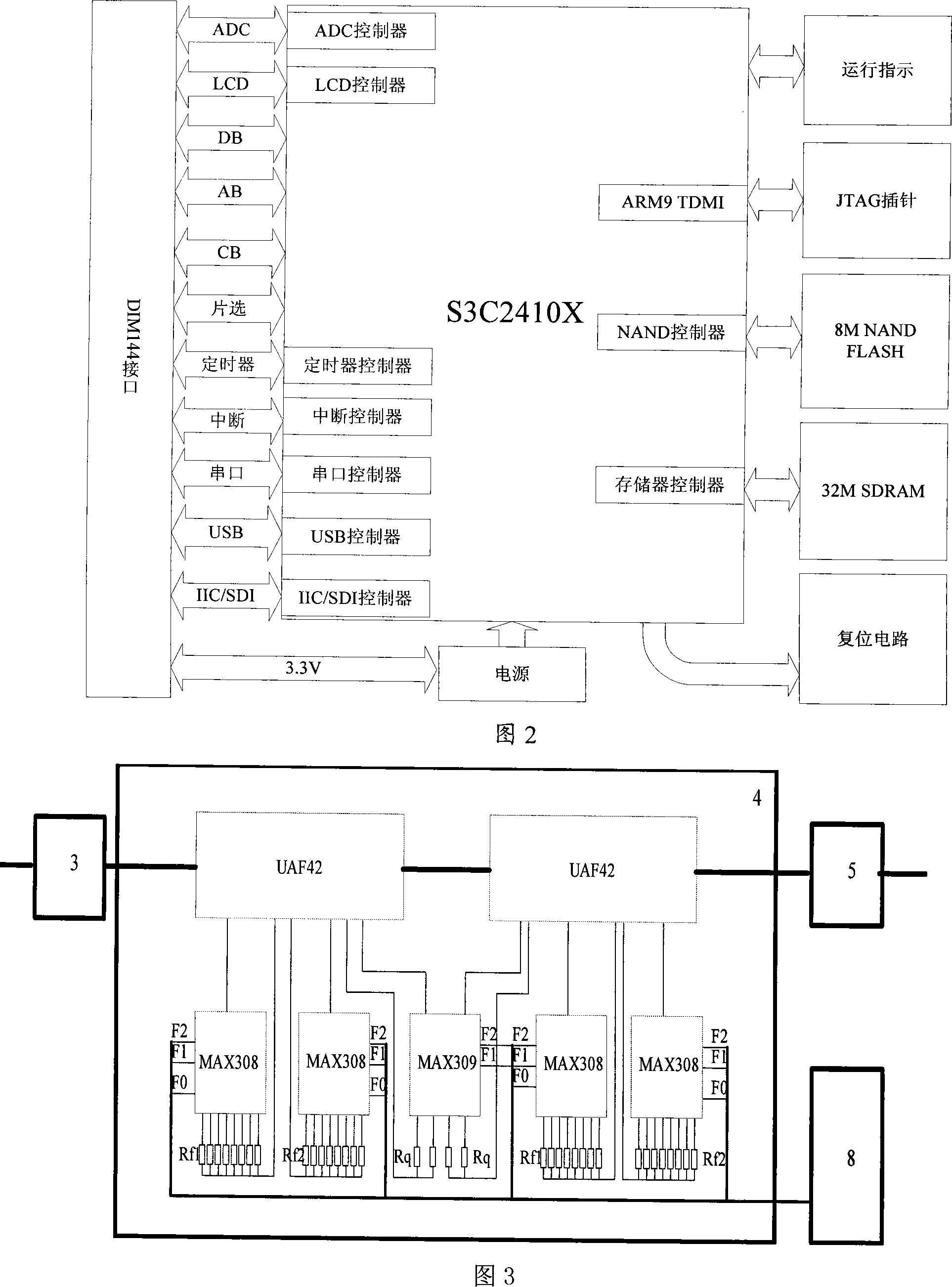

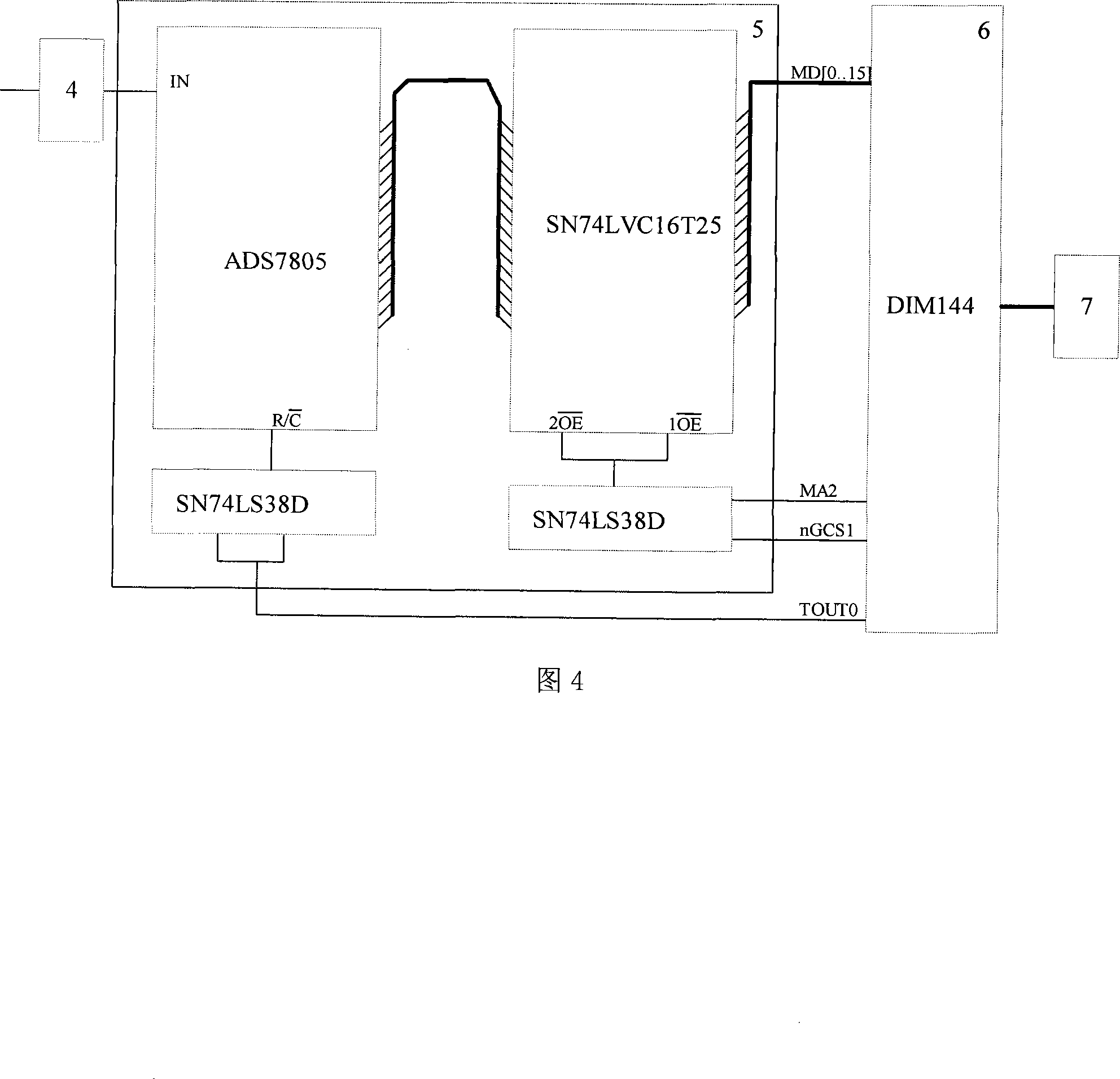

Portable vibration data collector and method based on embedded technology

InactiveCN101221422AStrong computing powerFriendly data analysis functionComputer controlSimulator controlCapacitanceMicrocontroller

The invention relates to the data acquisition and equipment fault diagnosis field, in particular to a portable vibration data acquisition device and a method based on embedded technology. The device comprises an acceleration transducer, an acceleration transducer interface module, a capacitance isolation module, a programmed control amplifying module, a self-adapting antialiasing filter, an AD converter and the bus interface of the converter which are connected in turn; moreover, the device also comprises an ARM minimum system, a DIM144 interface module, a singlechip as well as an electronic label module, a keyboard, a power source management and voltage conversion module which are connected with the singlechip; in addition, the programmed control amplifying module and the self-adapting antialiasing filter are also connected with a singlechip 8. The device communicates with an upper computer through a serial port to assign point inspection task, and transmits the sampling frequency in the point inspection task to the singlechip; moreover, the singlechip sets the lowpass cut-off frequency of the antialiasing filter according to the sampling frequency. With low power consumption, convenient operation and powerful data analysis function, the device has the characteristics of real time and accuracy.

Owner:BEIJING UNIV OF TECH

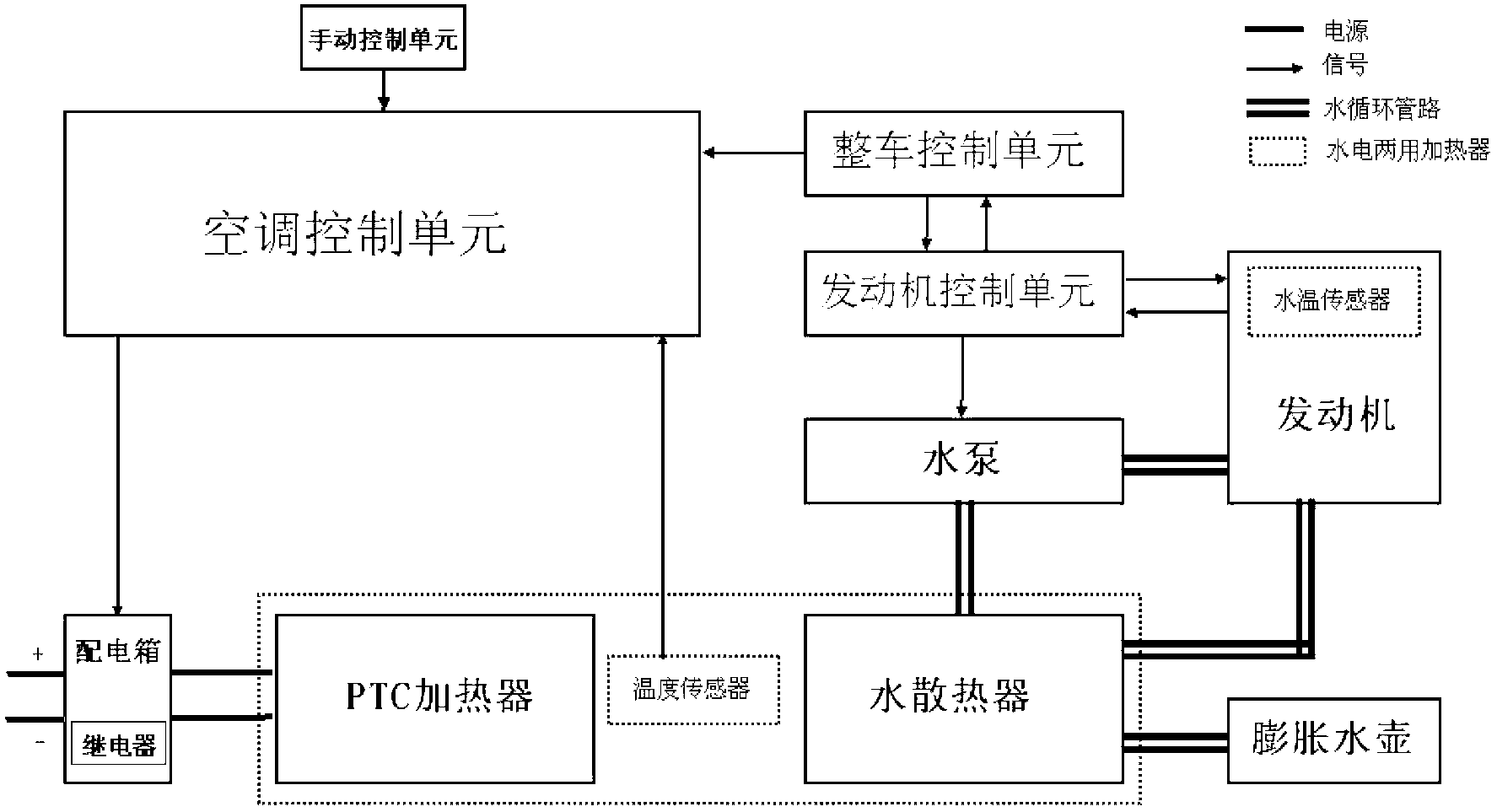

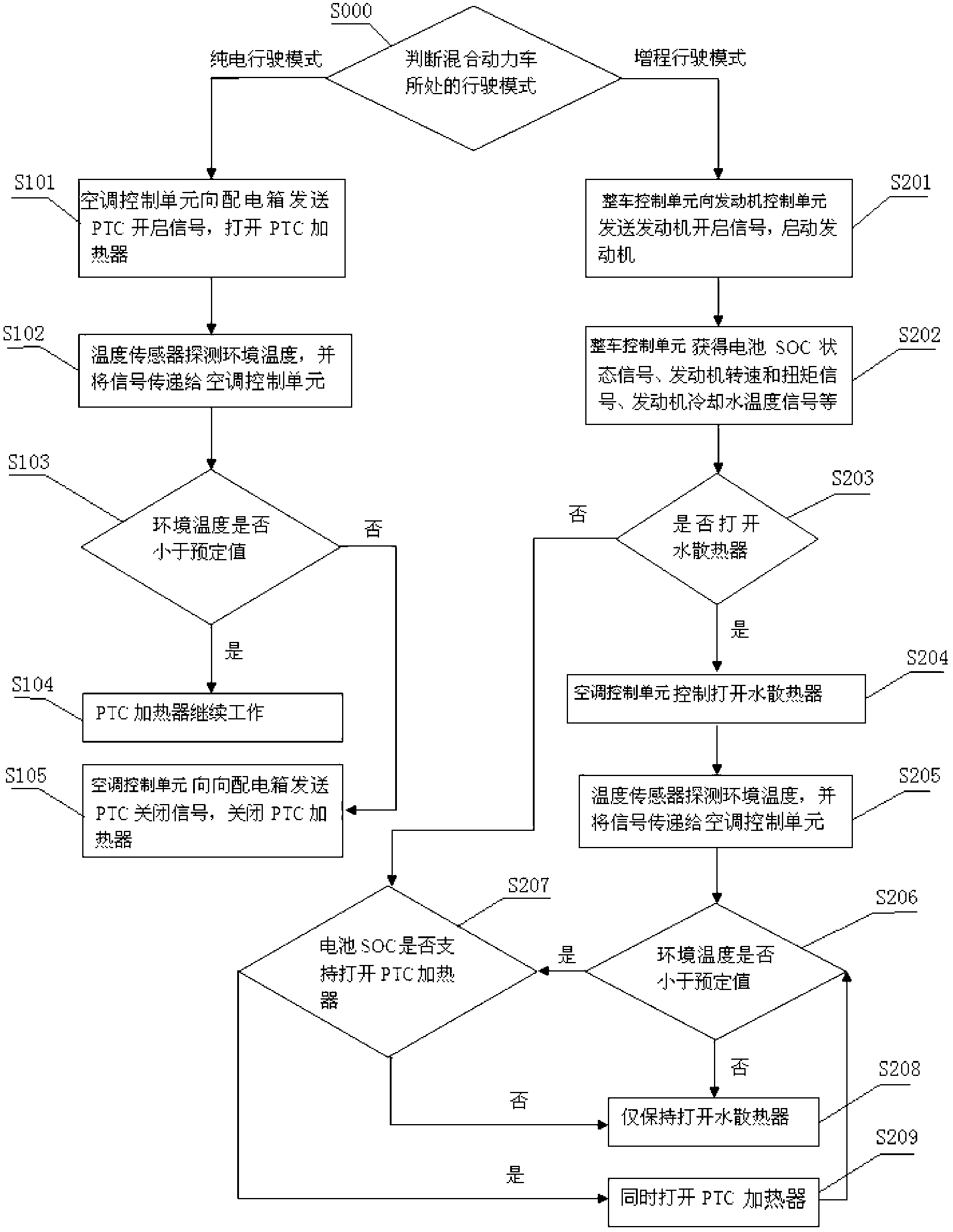

Hydropower dual-purpose heating system and control method of hybrid electric vehicle

ActiveCN103213473ASave energyFast heatingAir-treating devicesVehicle heating/cooling devicesElectric vehicleHydropower

The invention discloses a hydropower dual-purpose heating system of a hybrid electric vehicle. The hydropower dual-purpose heating system comprises a water radiator, an electric heater, an engine control unit, a temperature sensor, an entire vehicle control unit and an air conditioner control unit, wherein the water radiator is connected with an engine cooling water cycle; the engine control unit is used for controlling opening and closing of an engine; the temperature sensor is used for detecting ambient temperature; the entire vehicle control unit is used for monitoring the entire vehicle operation state; and the air conditioner control unit is used for controlling to turn on the water radiator according to a running mode signal and an engine working state signal of the entire vehicle control unit and an ambient temperature signal from the temperature sensor, and controlling to turn on the electric heater according to the running mode signal and a battery SOC (State of Charge) signal of the entire vehicle control unit and the ambient temperature signal from the temperature sensor. The invention also discloses a hydropower dual-purpose heating control method of the hybrid electric vehicle. According to the hydropower dual-purpose heating system and the hydropower dual-purpose heating control method, the consumtion ofelectric energy and fuel is optimized on the premise of guaranteeing a heating effect to reduce the energy consumption while a battery and engine cooling water are simultaneously used for heating.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

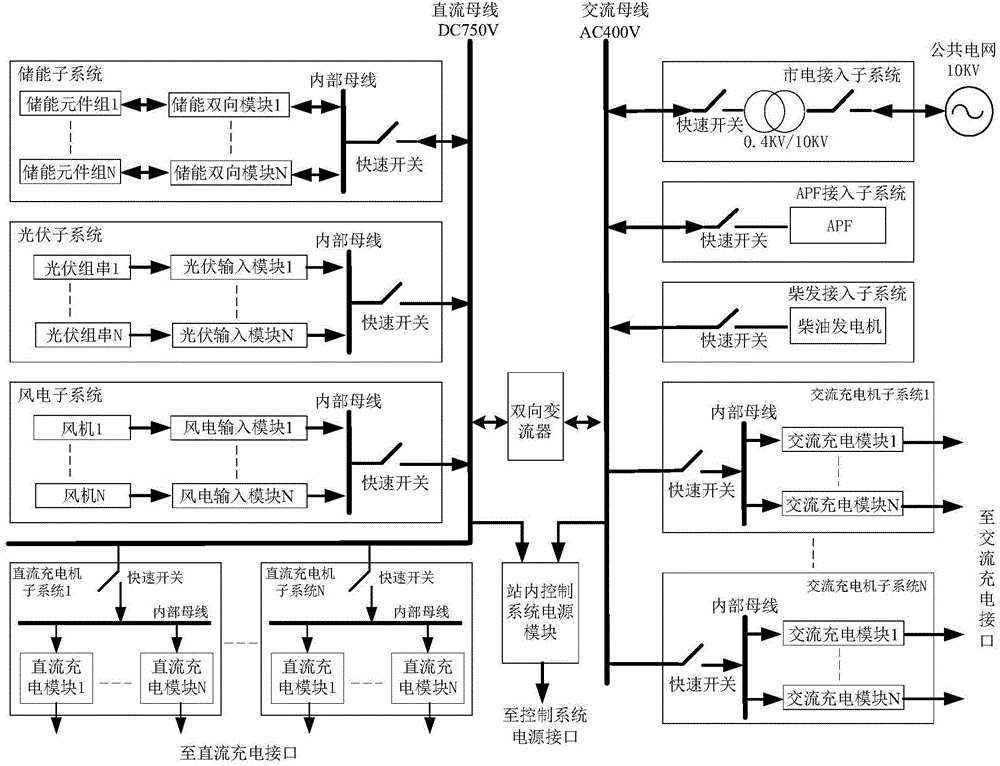

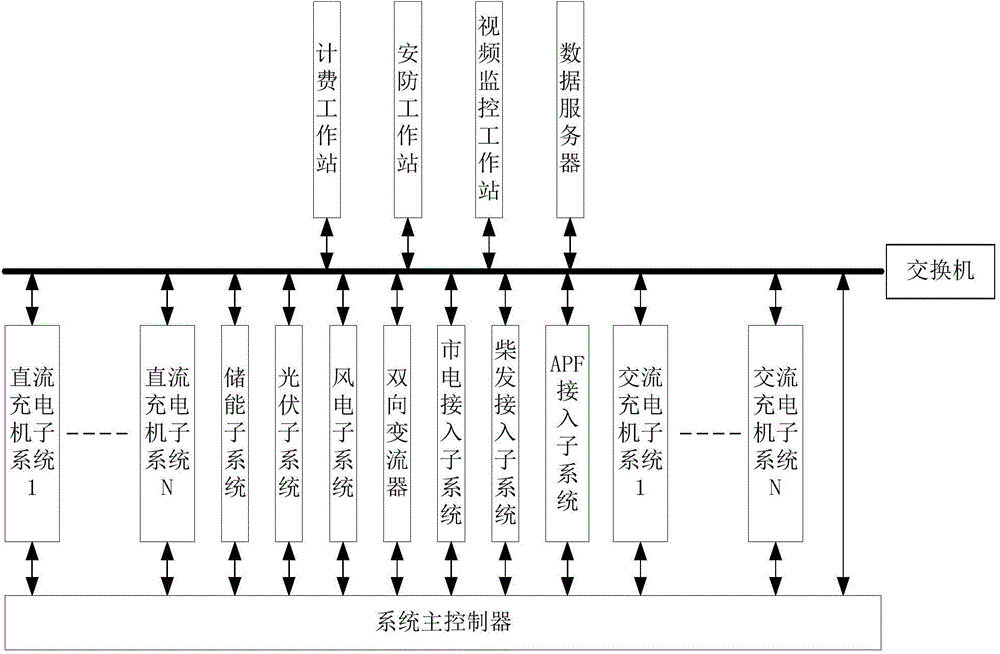

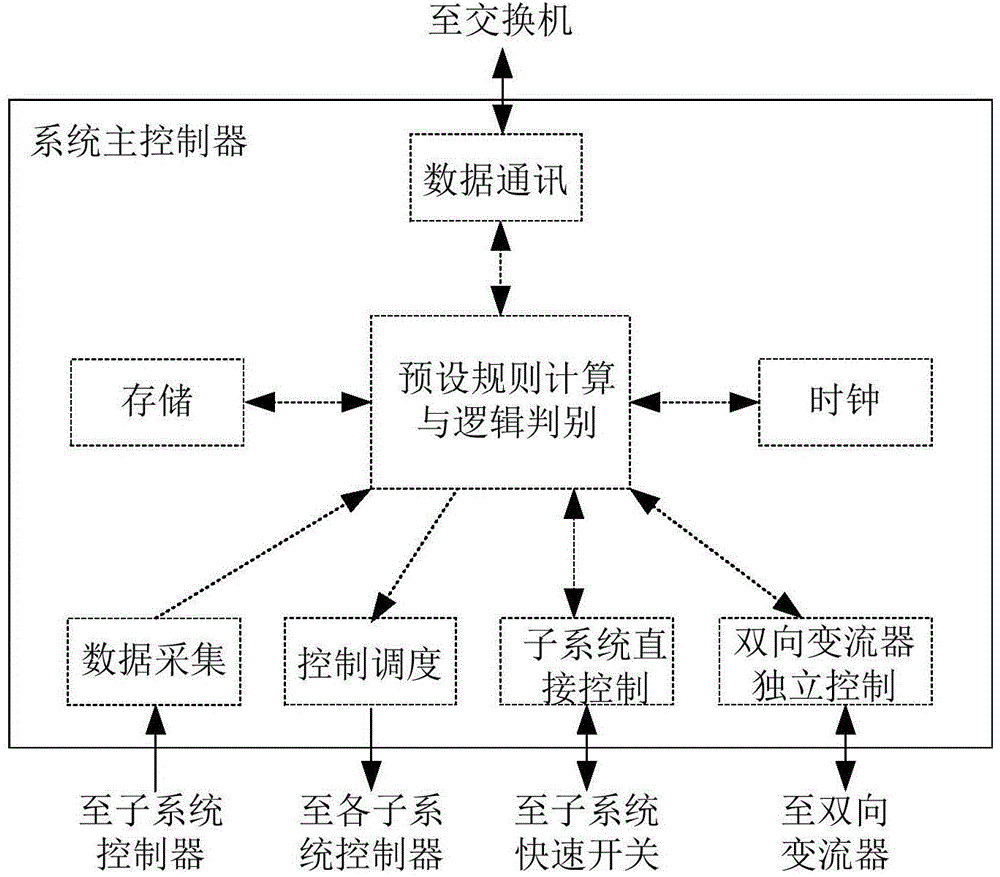

Electric vehicle charging station system based on AC/DC double bus

ActiveCN104600807AFlexible configurationImprove power supply reliabilitySingle network parallel feeding arrangementsMobile unit charging stationsElectricityElectronic systems

The invention provides an electric vehicle charging station system based on an AC / DC double bus. The electric vehicle charging station system based on the AC / DC double bus adopts a system framework of the AC / DC double bus, connection of the bus with multiple subsystems, modularization in each subsystem and dual data interaction channels, and has the complete function of the electric vehicle charging station system. The electric vehicle charging station system based on the AC / DC double bus takes a bidirectional converter as the core, the AC side of the bidirectional converter is connected with the AC bus, the DC side of the bidirectional converter is connected with the DC bus, and energy flows bi-directionally between the DC and AC buses through the bidirectional converter. The DC bus is connected with an energy storing subsystem, a photovoltaic subsystem, a wind power subsystem and a plurality of DC charger subsystems. The AC bus is connected with an electric supply access subsystem, an active power filter APF access subsystem, a diesel engine generator access subsystem and a plurality of AC charger subsystems. The quantities and the capacities of the AC charger subsystems and the DC charger subsystems can be flexibly selected according to actual needs. The electric vehicle charging station system based on the AC / DC double bus is flexible in configuration and high in power supply reliability, enables the electric vehicle charging station load to combine with new energy power generation, and realizes the sustainable and stable operation of the system.

Owner:BEIJING SIFANG JIBAO AUTOMATION

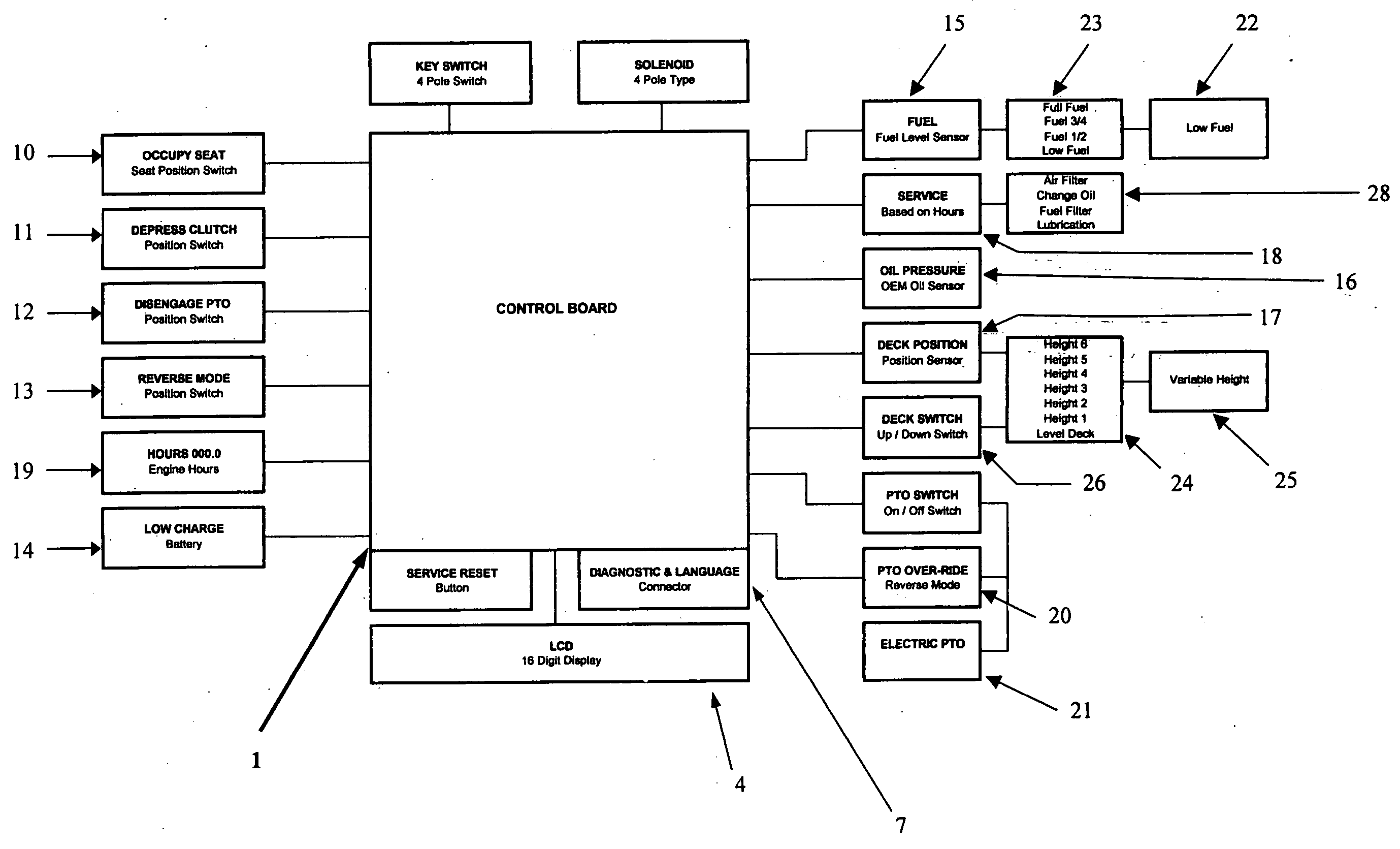

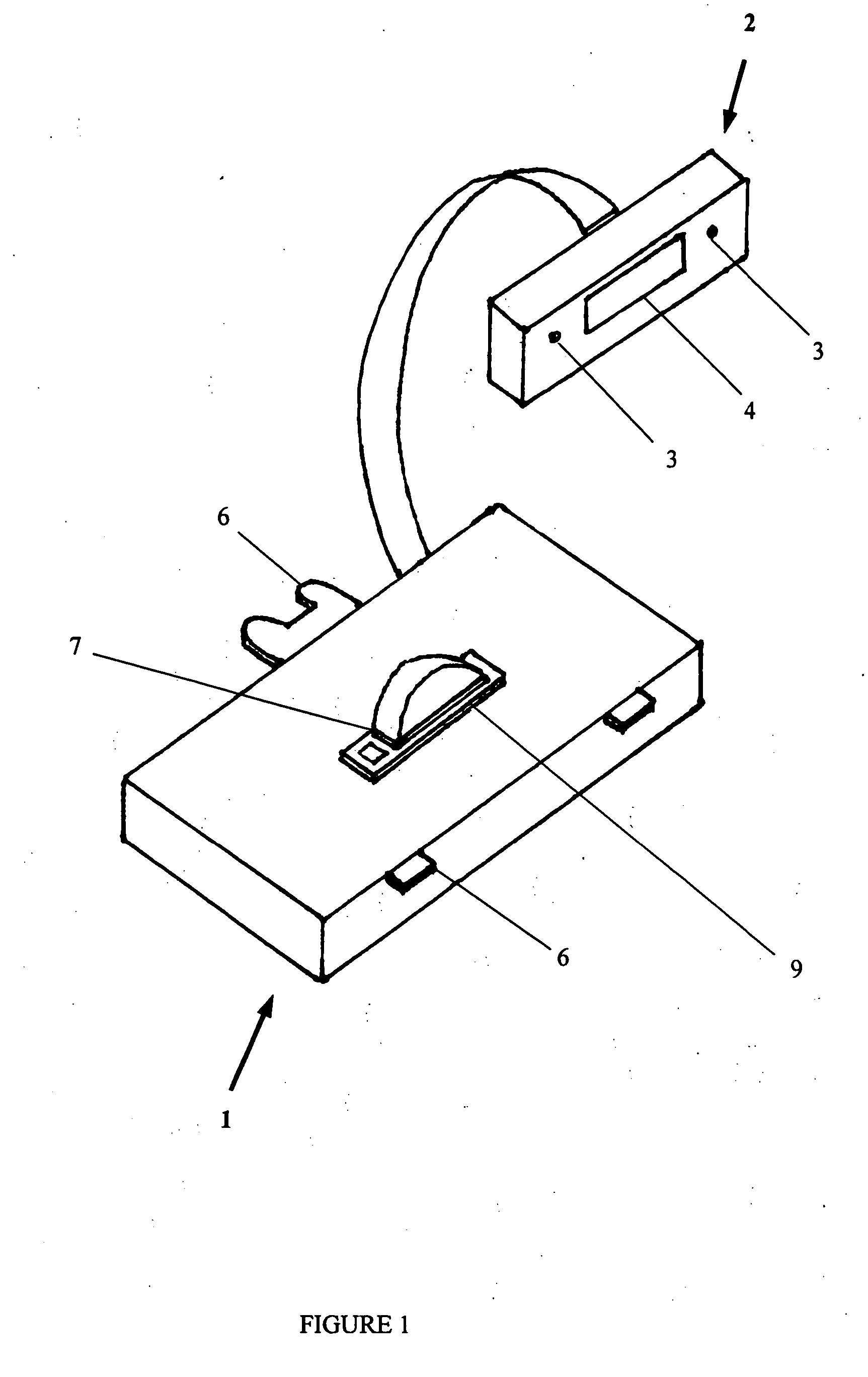

Electronic control module for mower

InactiveUS20060021312A1Reduce in quantityEasy to troubleshootMowersPicking devicesEmbedded systemMower

An electronic control module to monitor and control various functions and conditions of a mower, and to display information about such functions and conditions to the operator of the mower. Information is accepted from a variety of switches and sensors on the various components of the mower, and information about certain mower functions can be displayed by means of LEDs or a LCD on a display module, which may be integrated with the central control module.

Owner:BRANDON DENNIS +1

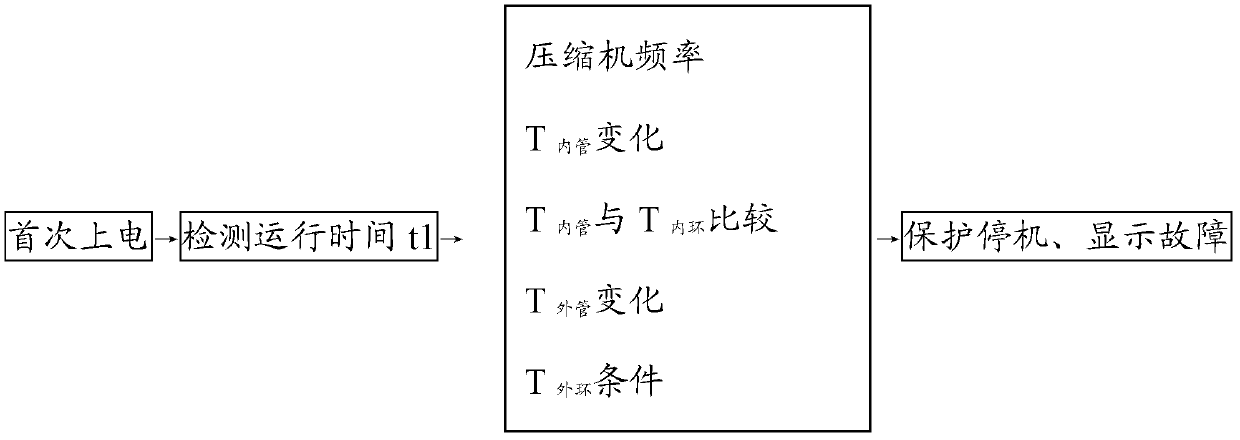

Air conditioner and refrigerant circulation abnormality protection control method for same

ActiveCN103375874AGuaranteed reliabilityAvoid damageSpace heating and ventilation safety systemsLighting and heating apparatusElectricityRemote control

The invention provides an air conditioner and a refrigerant circulation abnormality protection control method for the same. Under the condition of refrigerant circulation abnormalities caused by closing of a shut-off valve of the air conditioner, a controller protects a compressor timely to avoid undesirable operation and frequent on-off operation, various components of the air conditioner are protected against damage, and the reliability performance is improved. A refrigerant circulation abnormality protection control device of the air conditioner comprises a sampling module, a data processing module, an execution module and an output display module; once the data processing module determines that refrigerant circulation has abnormal faults, the execution module controls the air conditioner to conduct protective shutdown after receiving instructions of the data processing module; whether protective shutdown of the air conditioner occurs continuously for n times is judged, if protective shutdown of the air conditioner occurs continuously for n times, the execution module controls the air conditioner to be unable to resume operation automatically, and the operation can only be resumed through reenergizing or remote-control shutdown and starting-up; the output display module receives instructions of the data processing module or the execution module and controls a display device of an indoor unit of the air conditioner to display refrigerant circulation abnormality fault codes.

Owner:GREE ELECTRIC APPLIANCES INC

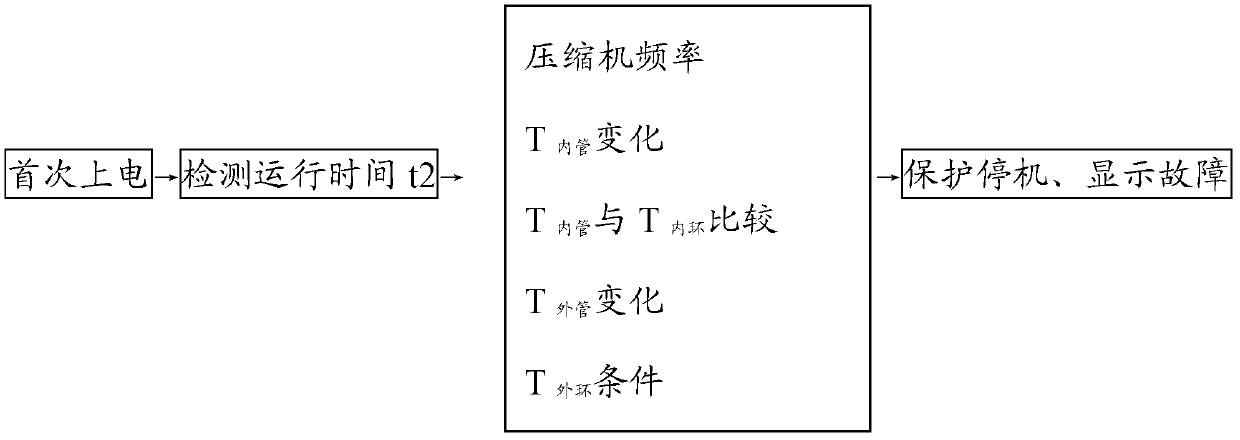

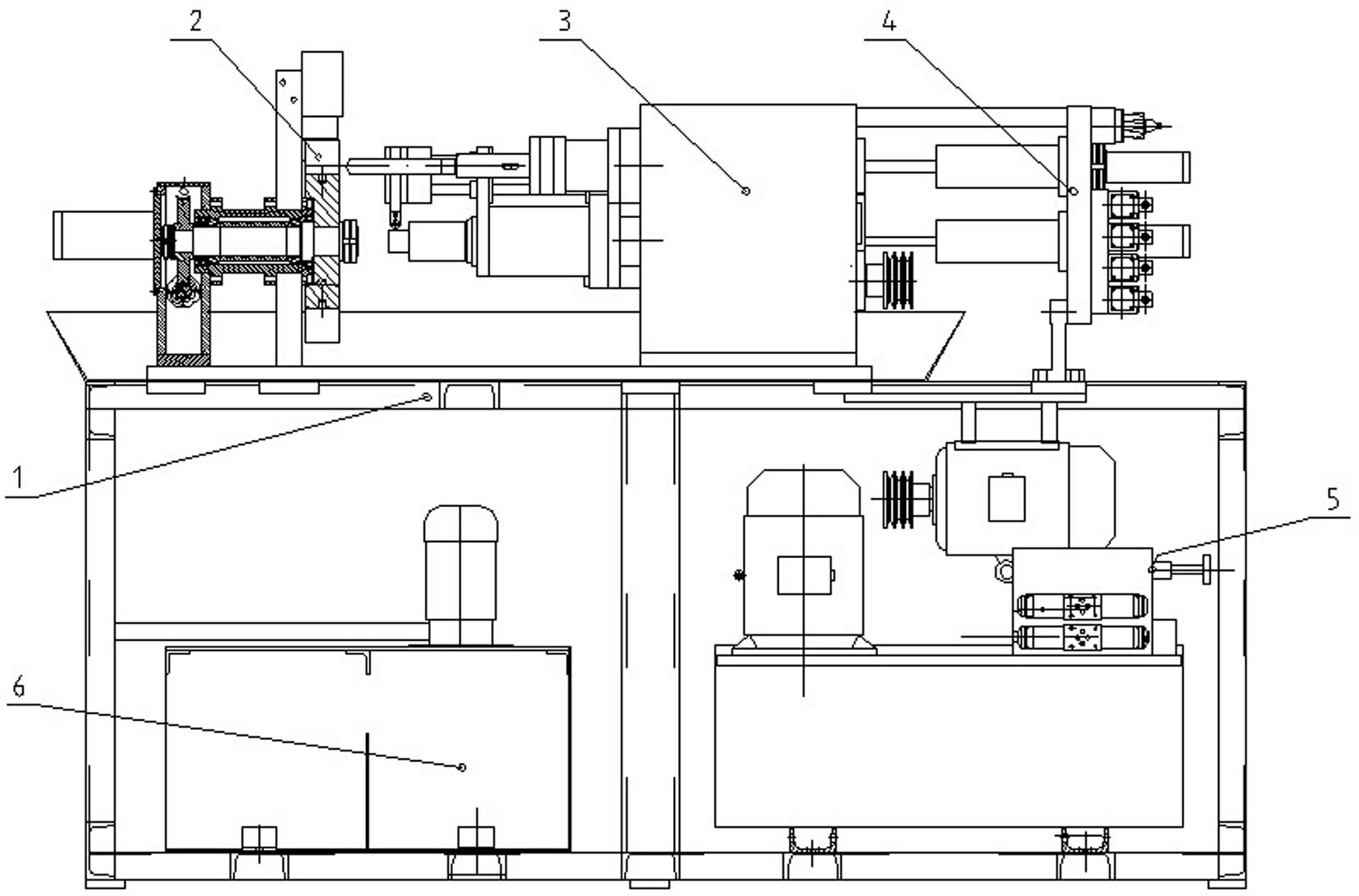

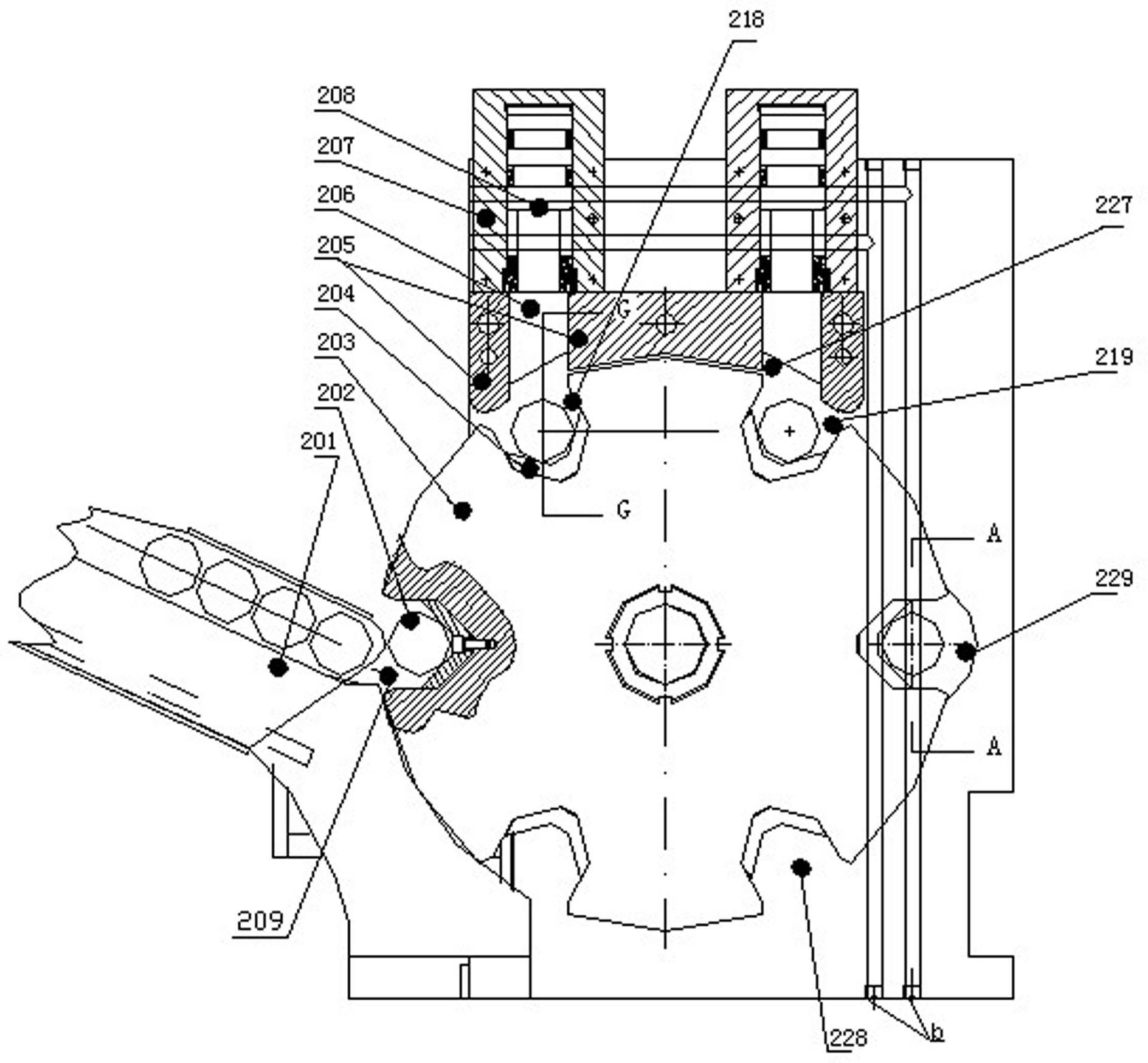

Metal-cutting machine tool for automatically machining steel reinforcement connection sleeve

InactiveCN102554623AReduce axial forceHigh thread precisionFeeding apparatusOther manufacturing equipments/toolsMachineProcess engineering

The invention relates to a metal-cutting machine tool for automatically machining a steel reinforcement connection sleeve, which comprises a machine frame, wherein a rotating table, a main spindle box and a hydraulic table are sequentially assembled at the upper part of the machine frame; and a hydraulic station and a cooling station are installed at the lower part of the machine frame. In the invention, independent processes of performing drilling, tapping and turning performed respectively by a corresponding independent machine in the traditional method are integrated into an automatic and continuous process, and the process from sleeve blank input to finished sleeve output is realized completely through automatic machining; therefore, work by multiple operators and multiple independent machines can be replaced, equipment, site and workers can be saved, work efficiency can be improved, and productive cost can be reduced; in the invention, the tubingless plate type integration oil cylinder technology is adopted, so that a large number of traditional externally-exposed oil tubes are saved, the structure is compact, the maintenance is convenient, an oil-way channel is short, and the oil current resistance and leakage are reduced; the metal-cutting machine provided by the invention is provided with a hydraulic control screw clutch and a rotary oil-cylinder friction plate clutch to realize rigid tapping, so that the axial force that a screw tap bears can be reduced, and the thread accuracy can be improved; in addition, a high-pressure gas and liquid atomizing cooling and chip-blowing technology is adopted.

Owner:唐衍洪

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com