A large-scale continuous and stable production equipment and method for black phosphorus

A technology for stable production and black phosphorus, applied in the preparation of phosphorus, chemical instruments and methods, products, etc., can solve the problems of high cost and low production efficiency, and achieve the effect of improving yield, production efficiency and output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

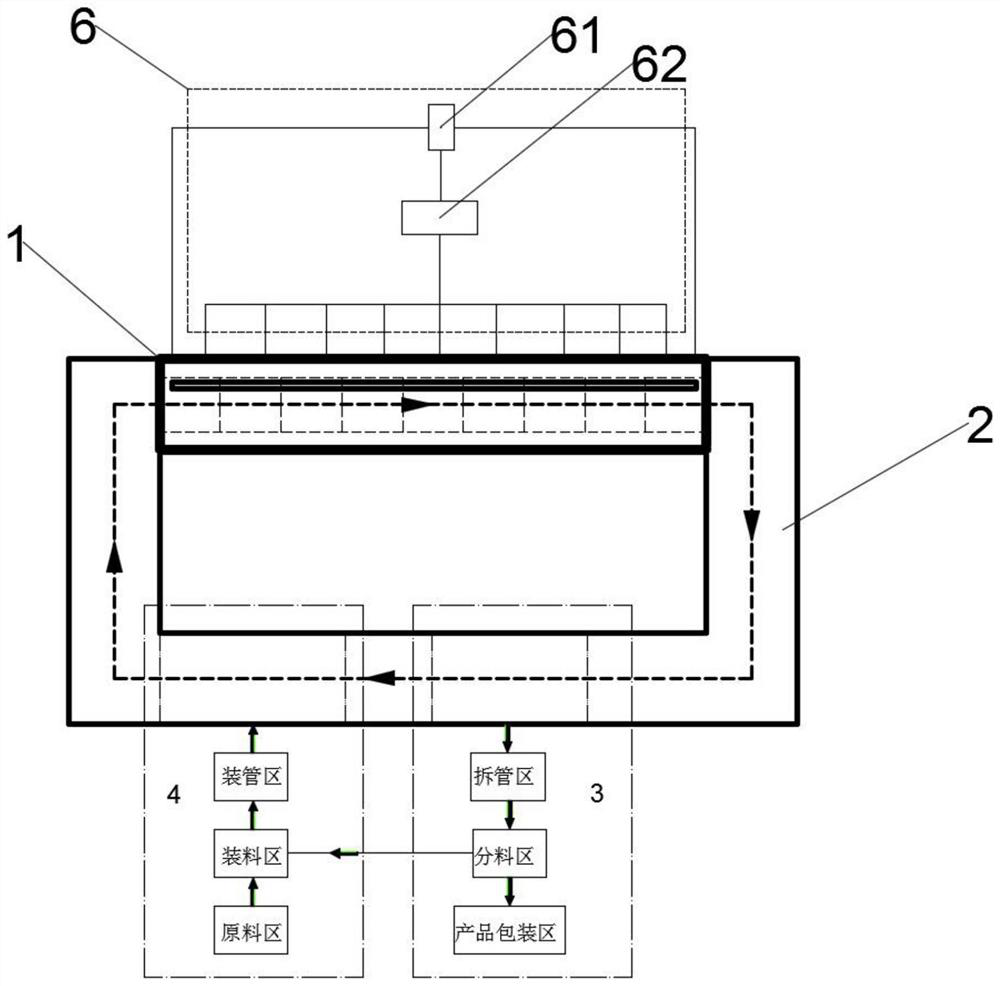

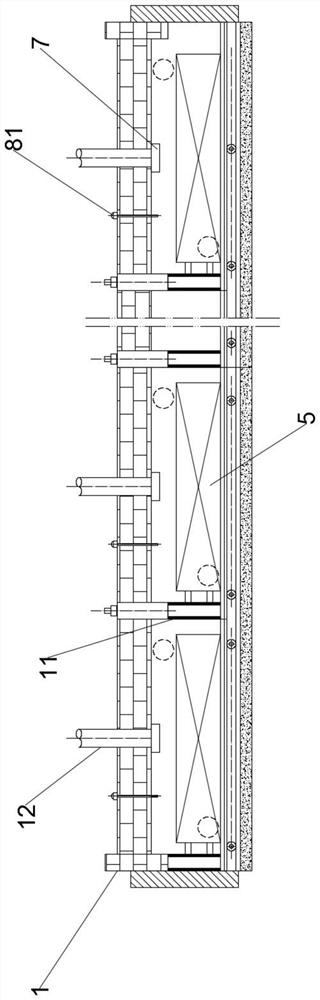

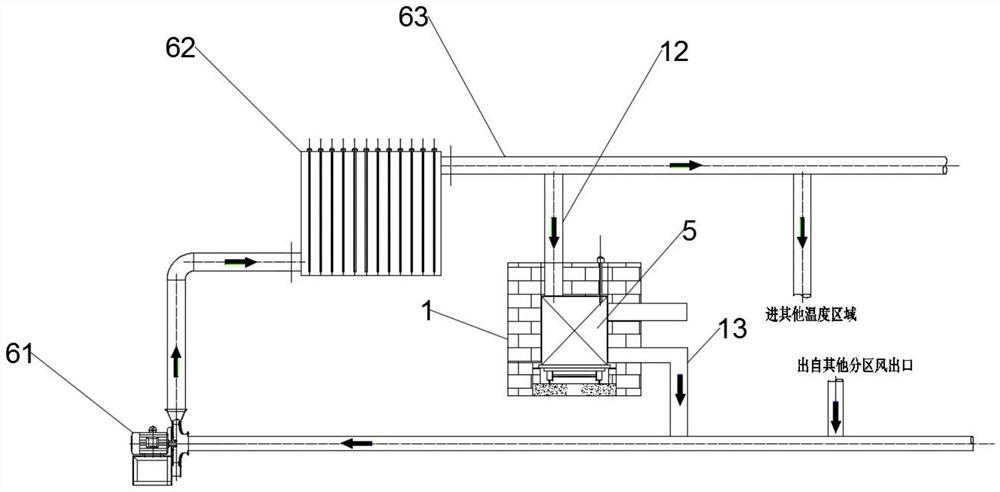

Method used

Image

Examples

Embodiment 1

[0064] Adopt equipment and production method of the present invention to carry out the production of black phosphorus, heater 62 adopts the mode of burning oil; The ratio of raw material is: red phosphorus: tin: iodine=8:1.5:1; Dolly 5 is in tunnel kiln 1 9 The time of staying in different temperature zones in turn is 0.5h. The heating method of burning oil, the temperature of the middle kiln area will rise rapidly, while the temperature of the kiln areas at both ends will rise slowly, the heat conduction is poor, and the temperature of each kiln area is not easy to control; it is not conducive to the growth of black phosphorus, and the yield is low ( Productivity is 85%), the black phosphorus particle diameter that obtains is uneven, and size difference is bigger, and the ratio of qualified product black phosphorus reaches 80% higher, and high-quality black phosphorus is less.

Embodiment 2

[0066] Adopt equipment and production method of the present invention to carry out the production of black phosphorus, but do not comprise spiral turbulent flow inlet device 7, heater 62 adopts microwave heating mode; The ratio of raw material is: red phosphorus: tin: iodine=9:1.8:15; The time for the trolley 5 to stay in the nine different temperature zones of the tunnel kiln 1 is 1 hour. The present embodiment does not include the spiral turbulent air inlet device 7, the temperature in the tunnel kiln is not uniform, the temperature is unstable, and the obtained black phosphorus particle size is not uniform, which has a certain influence on the yield (yield rate is 75%), and the qualified product is black phosphorus. The proportion of phosphorus is higher at 85%, with less premium black phosphorus.

Embodiment 3

[0068] Adopt equipment and production method of the present invention to carry out the production of black phosphorus, heater 62 adopts electric heating heating mode; The ratio of raw material is: red phosphorus: tin: iodine=10:2:3; Dolly is in 9 different temperature zones of tunnel kiln The time of successive residence was 2 hours. The temperature control is more accurate by means of electric heating. The length of the large-sized black phosphorus prepared can reach 14cm, the yield is high, reaching 95%, and the particle size is relatively uniform. Phosphorus accounts for more than 60% of qualified black phosphorus.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com