Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

746results about How to "Raise the combustion temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

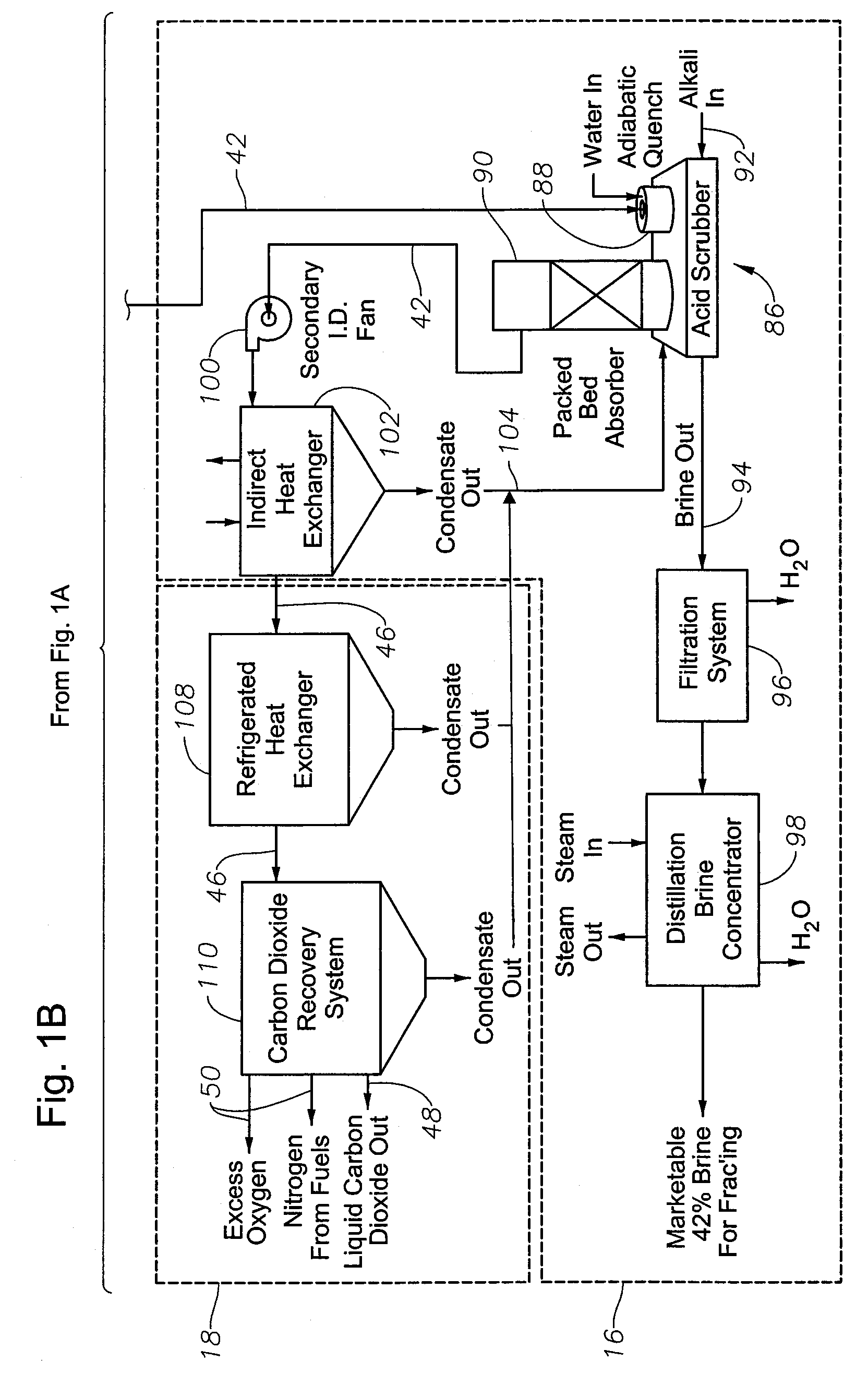

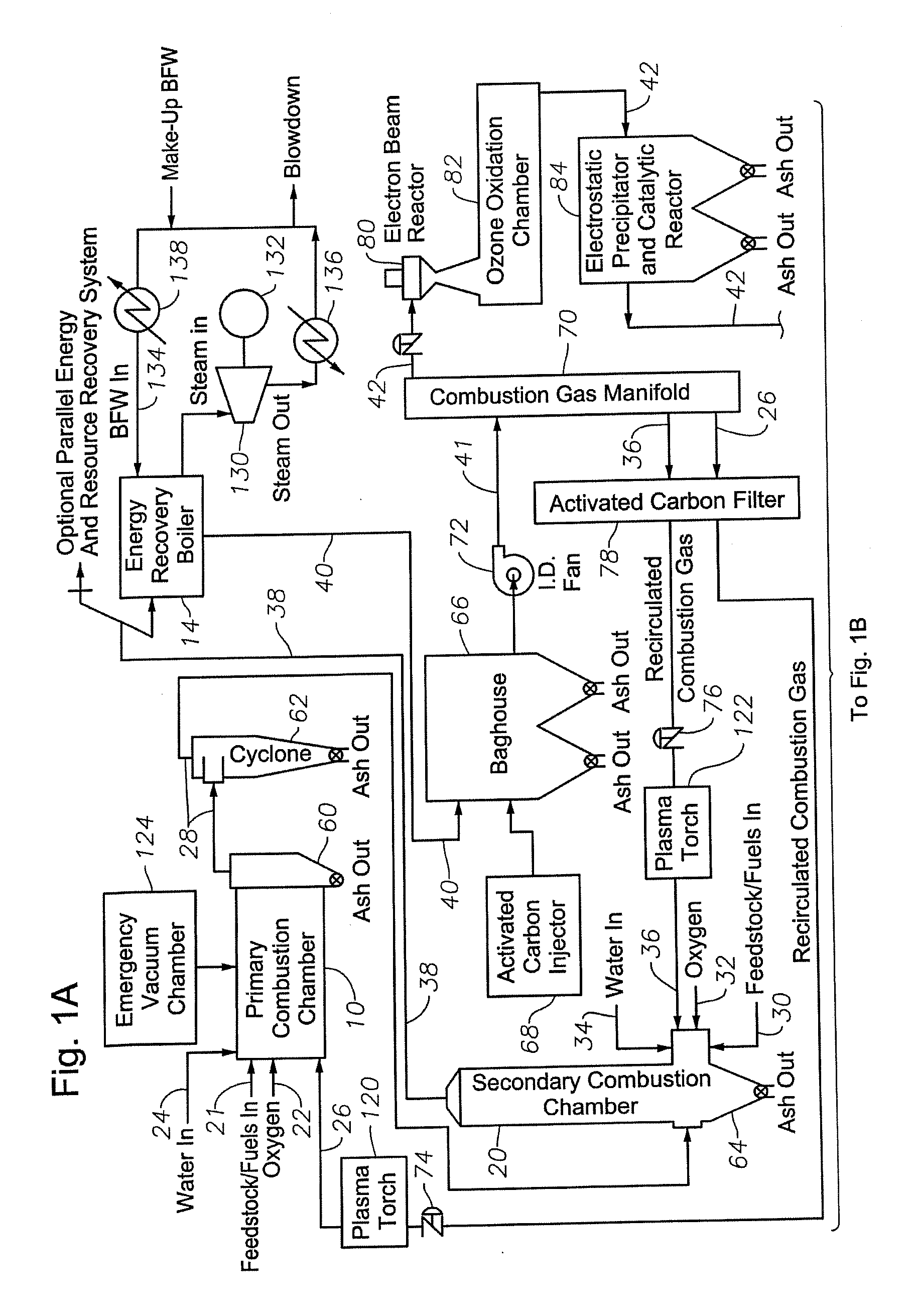

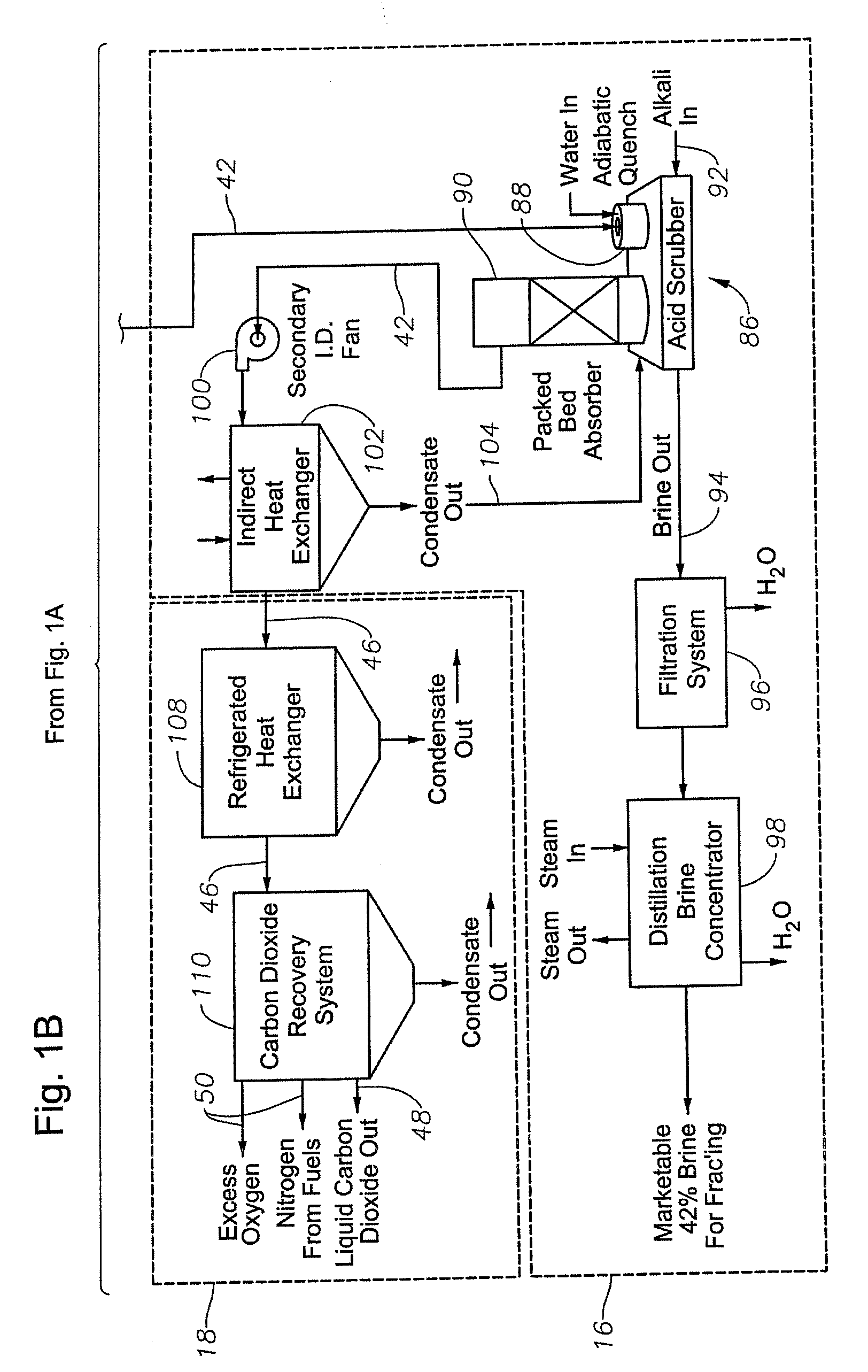

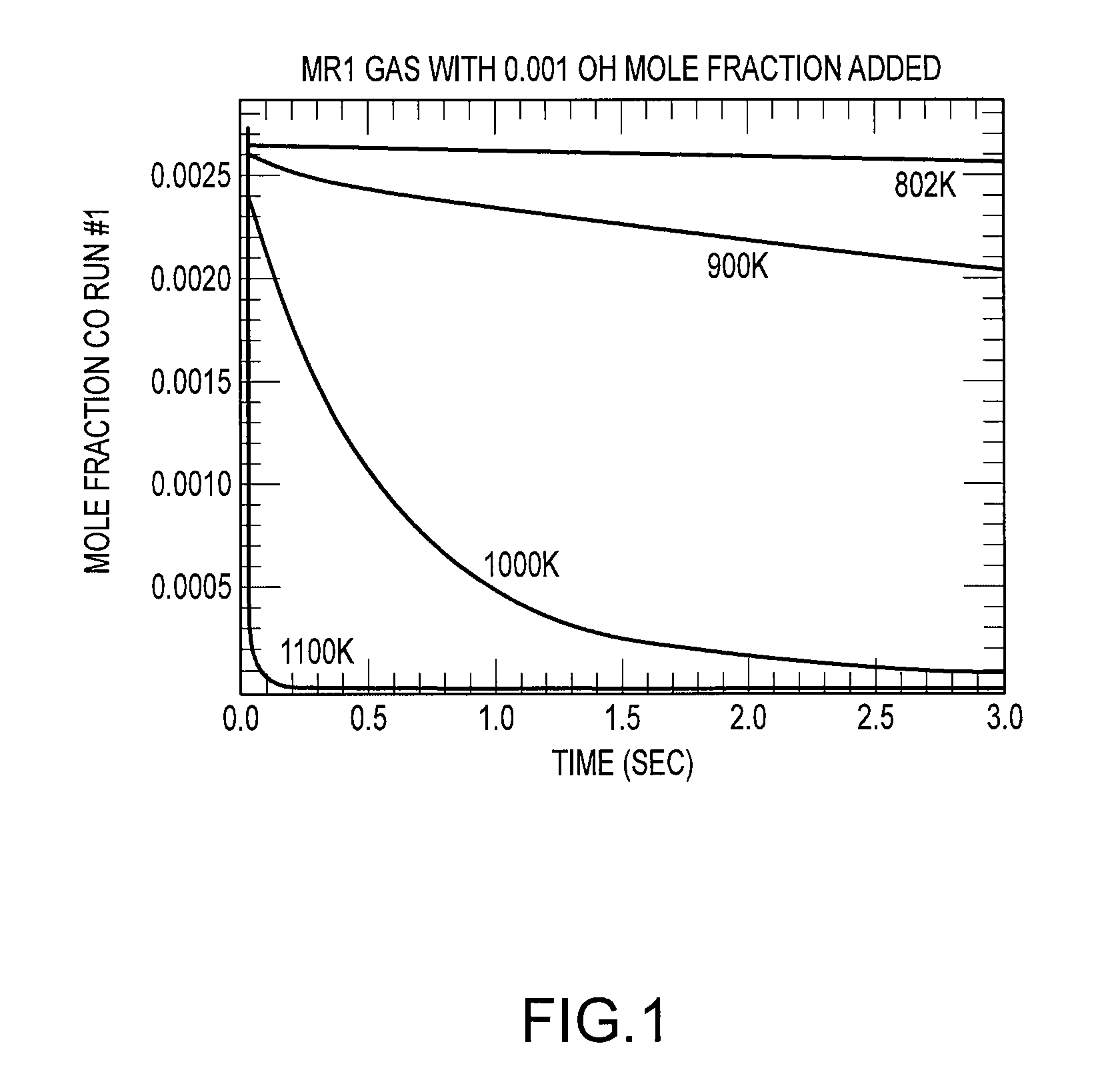

Reduced-emission gasification and oxidation of hydrocarbon materials for liquid fuel production

InactiveUS8038746B2Reduce system sizeHigh heat transfer rateHydrogenGas modification by gas mixingLiquid hydrocarbonsLiquid fuel

Owner:CLARK STEVE L

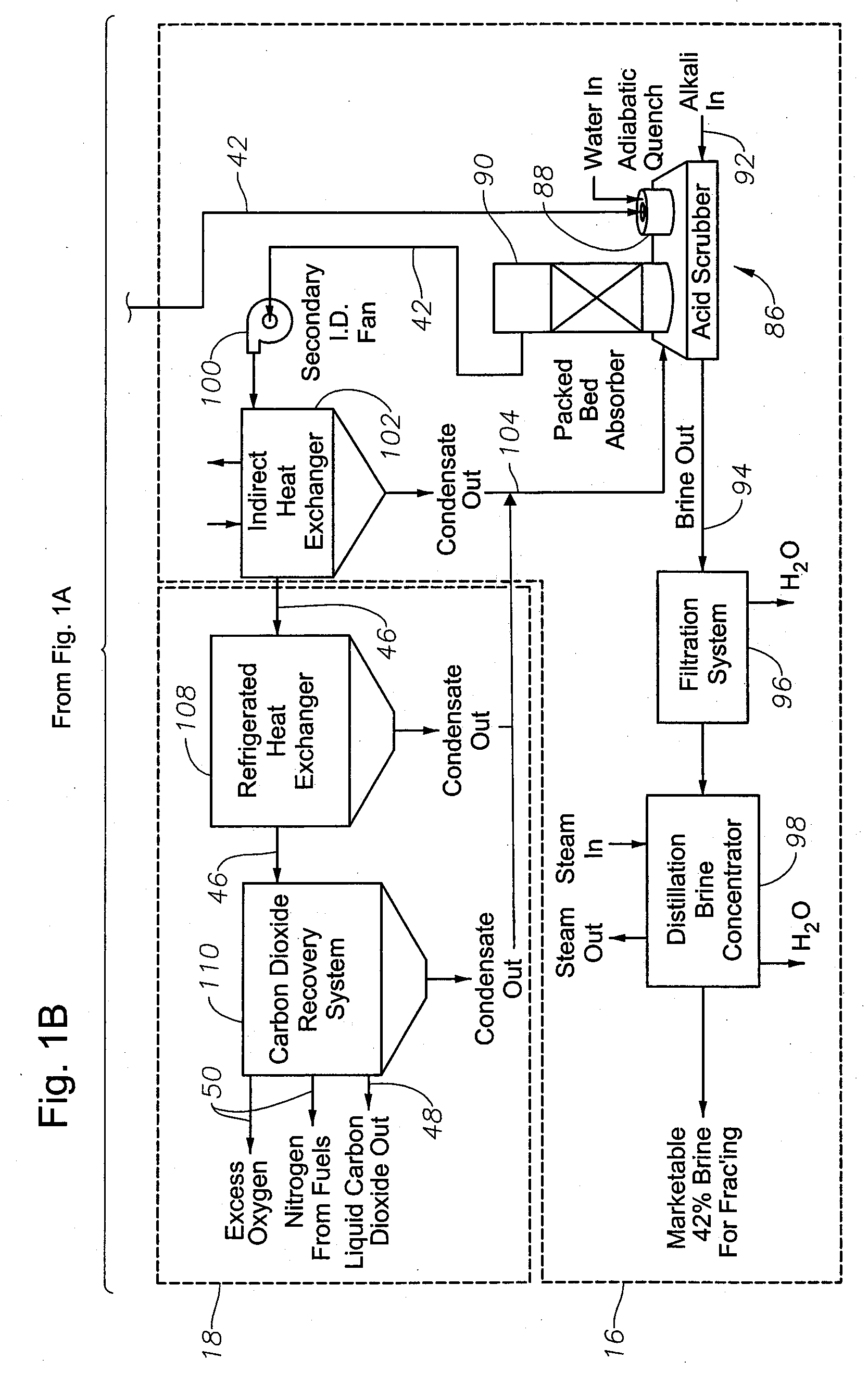

Reduced-Emission Gasification and Oxidation of Hydrocarbon Materials for Liquid Fuel Production

InactiveUS20080275278A1Reduce system sizeRaise the combustion temperatureGas modification by gas mixingLiquid hydrocarbon mixture productionThermal energyLiquid hydrocarbons

A system and process are disclosed for the controlled combustion of a wide variety of hydrocarbon feedstocks to produce thermal energy, liquid fuels, and other valuable products with little or no emissions. The hydrocarbon feeds, such as coal and biomass, are first gasified and then oxidized in a two-chamber system / process using pure oxygen rather than ambient air. A portion of the intermediate gases generated in the system / process are sent to a Fischer-Tropsch synthesis process for conversion into diesel fuel and other desired liquid hydrocarbons. The remaining intermediate gases are circulated and recycled through each of the gasification / oxidation chambers in order to maximize energy production. The energy produced through the system / process is used to generate steam and produce power through conventional steam turbine technology. In addition to the release of heat energy, the hydrocarbon fuels are oxidized to the pure product compounds of water and carbon dioxide, which are subsequently purified and marketed. The system / process minimizes environmental emissions.

Owner:CLARK STEVE L

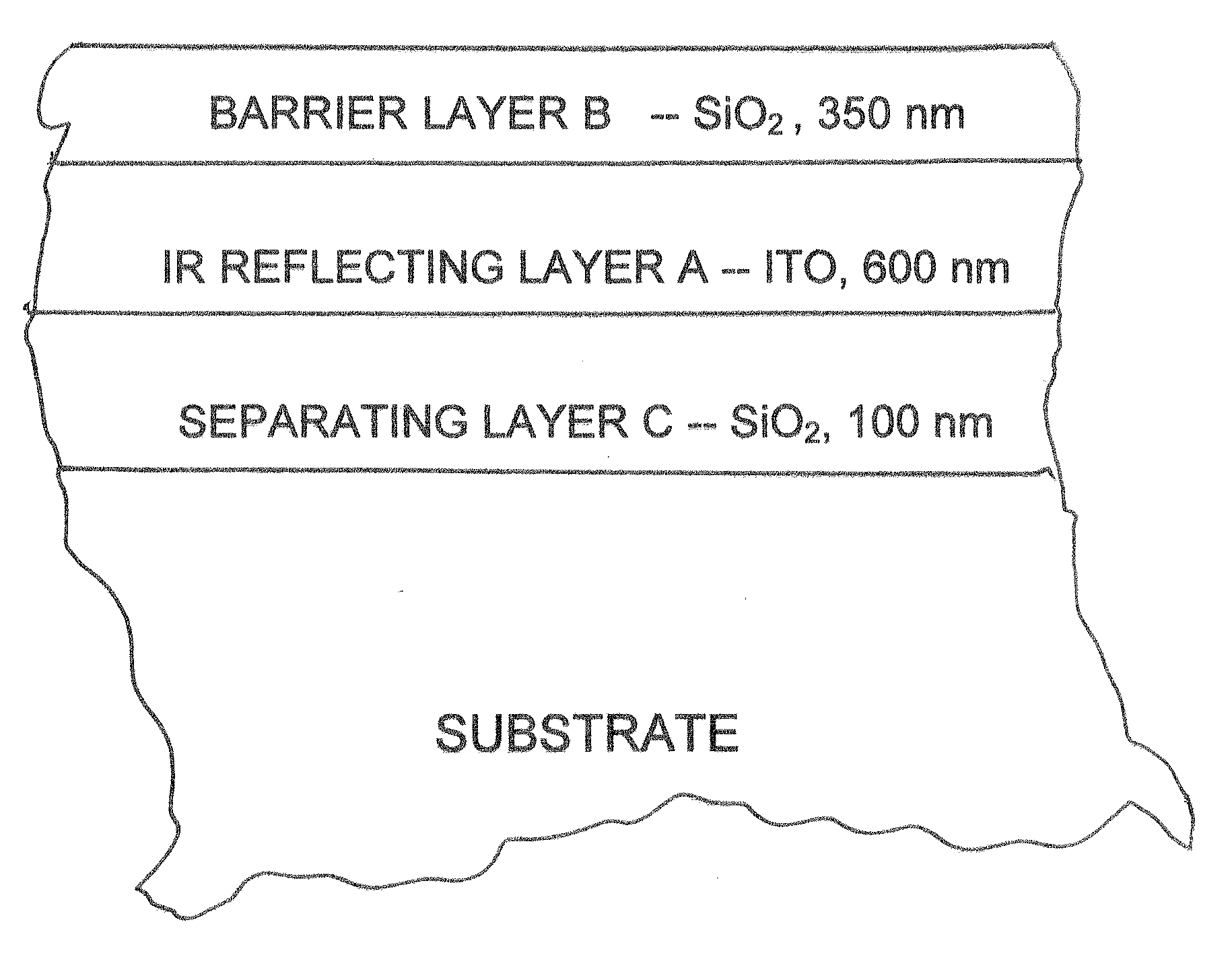

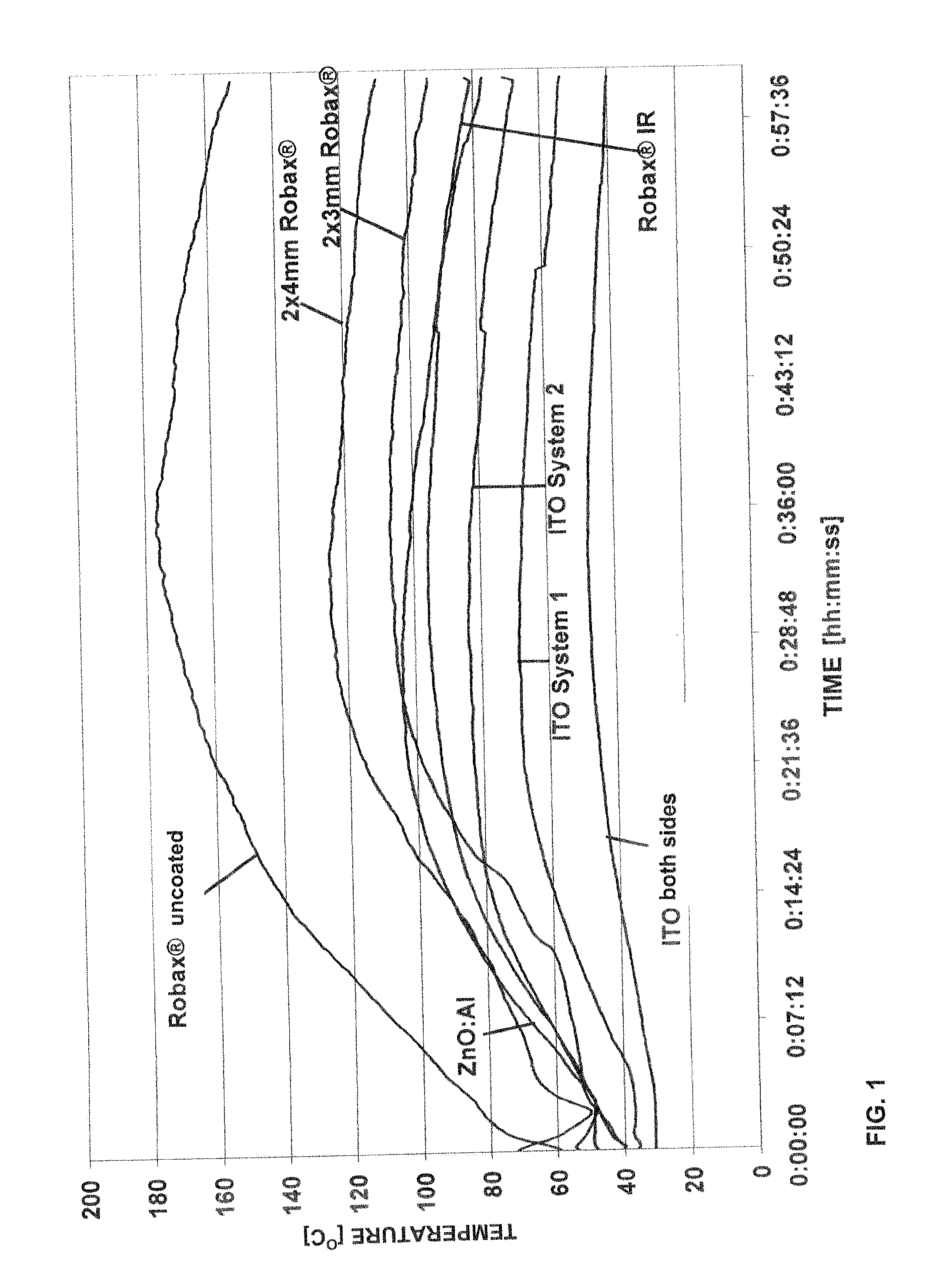

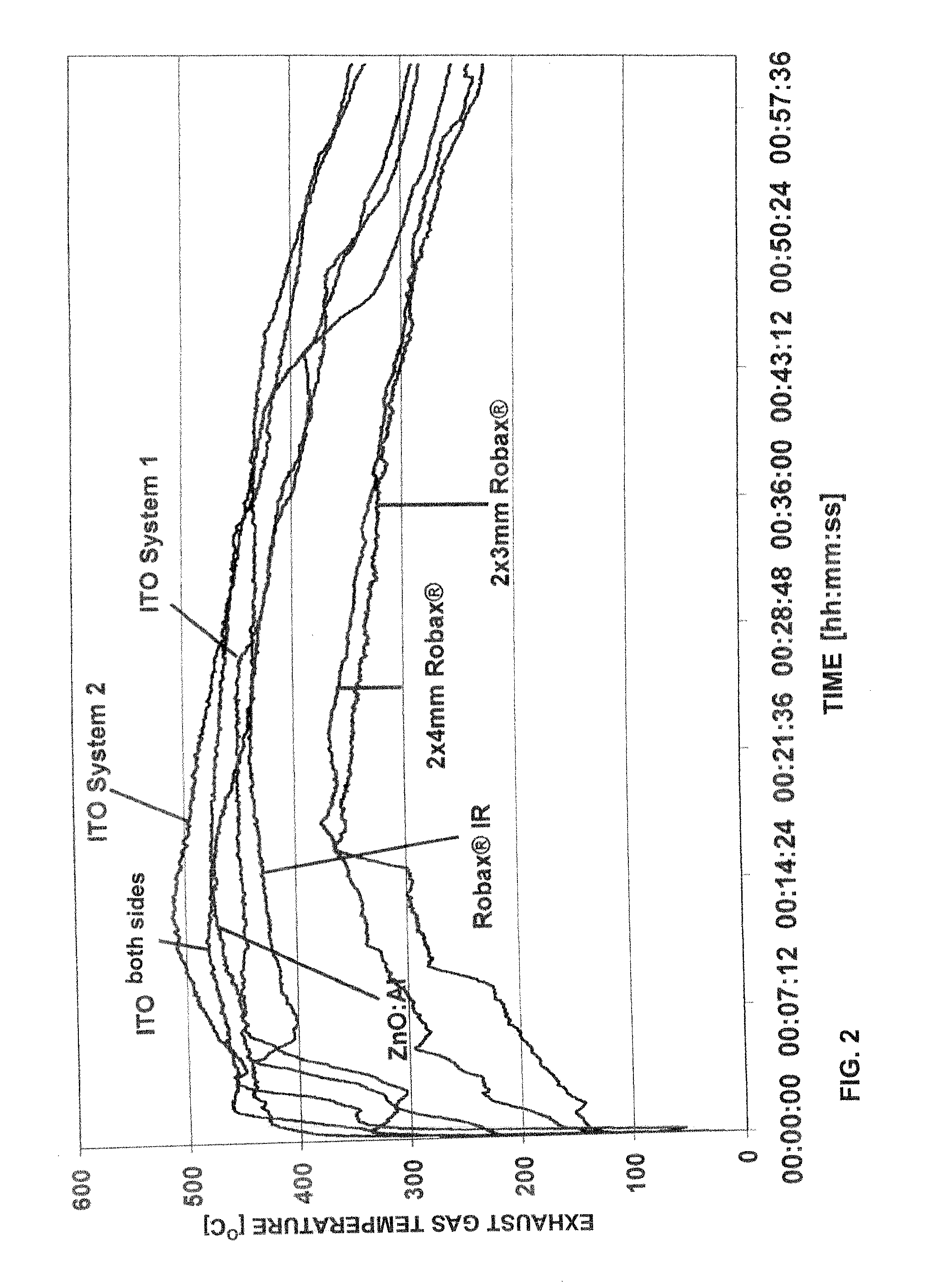

Arrangement for reflection of heat radiation, process of making same and uses of same

ActiveUS20090320824A1No agingReduce the temperatureSelf-cleaning stoves/rangesMirrorsThermal radiationOxide

The heat reflecting arrangement with an improved high heat resistance, e.g. 100 hours at 500° C., includes a substrate, a heat reflecting layer (A) on at least one side of the substrate, which contains indium tin oxide (ITO), and a barrier layer (B) that covers the heat reflecting layer (A), which contains a metal oxide and / or a metal nitride. A fireplace or baking oven with a viewing window having this layer system with the heat reflecting layer is also described. In addition a process for providing the heat reflecting arrangement is described.

Owner:SCHOTT AG +1

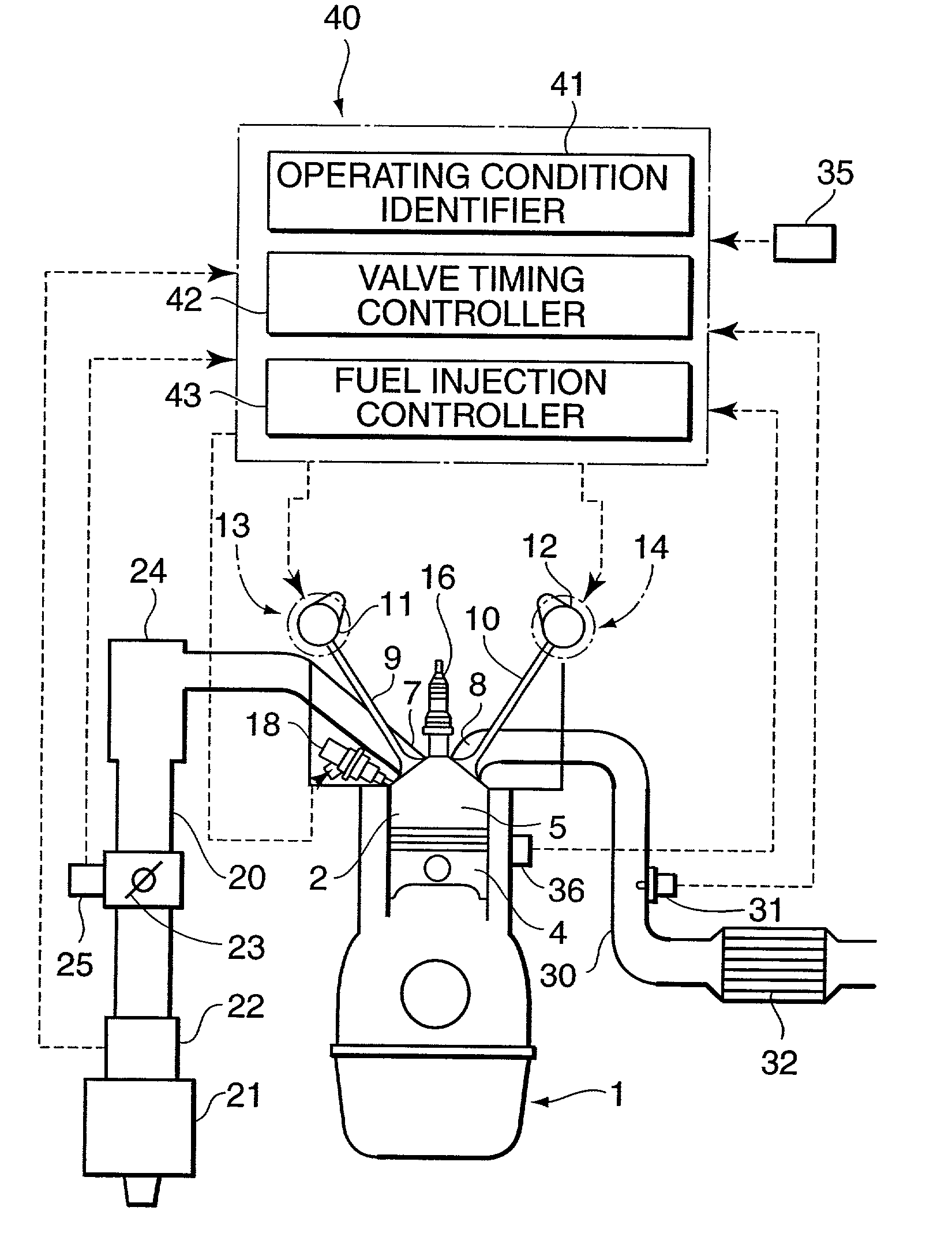

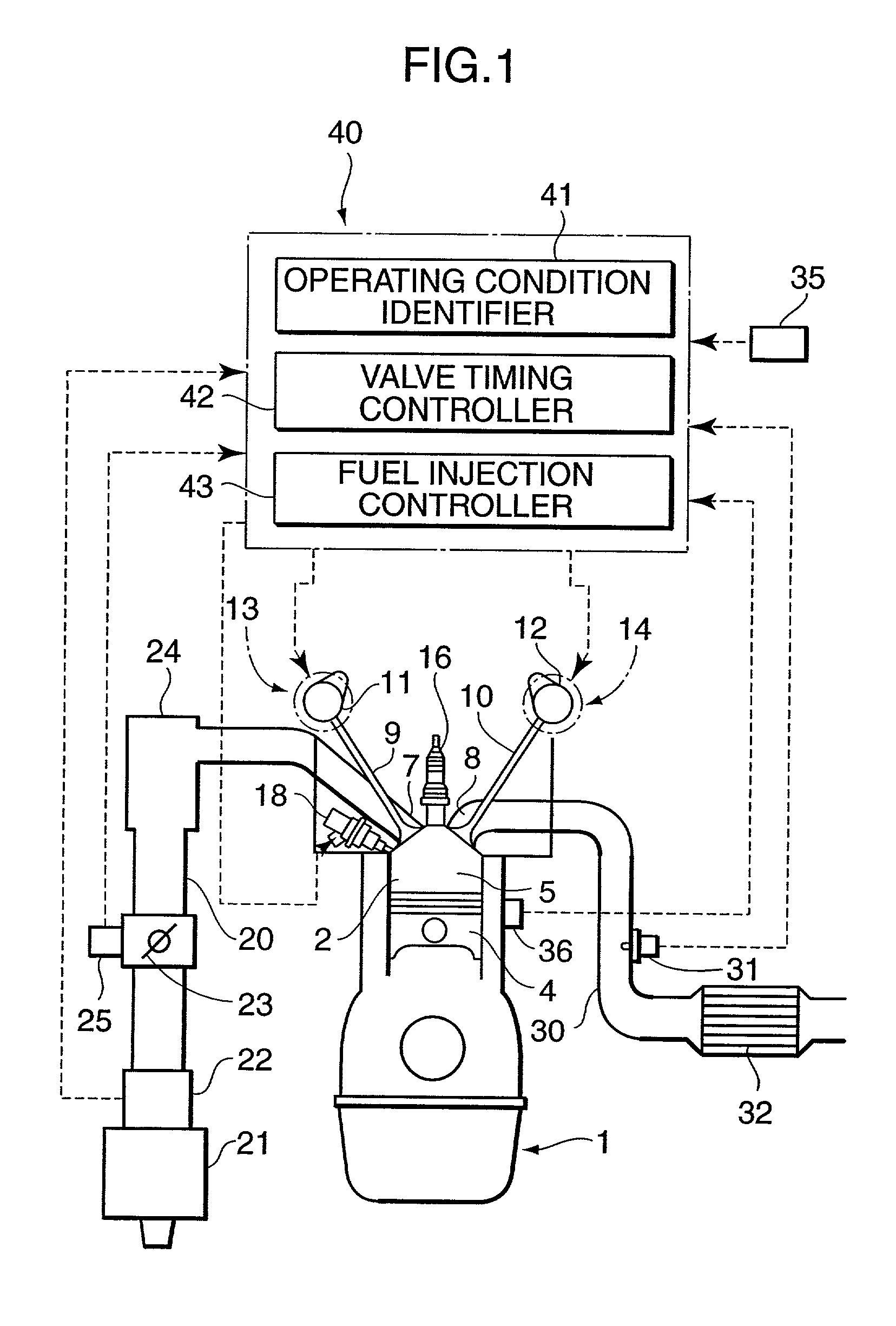

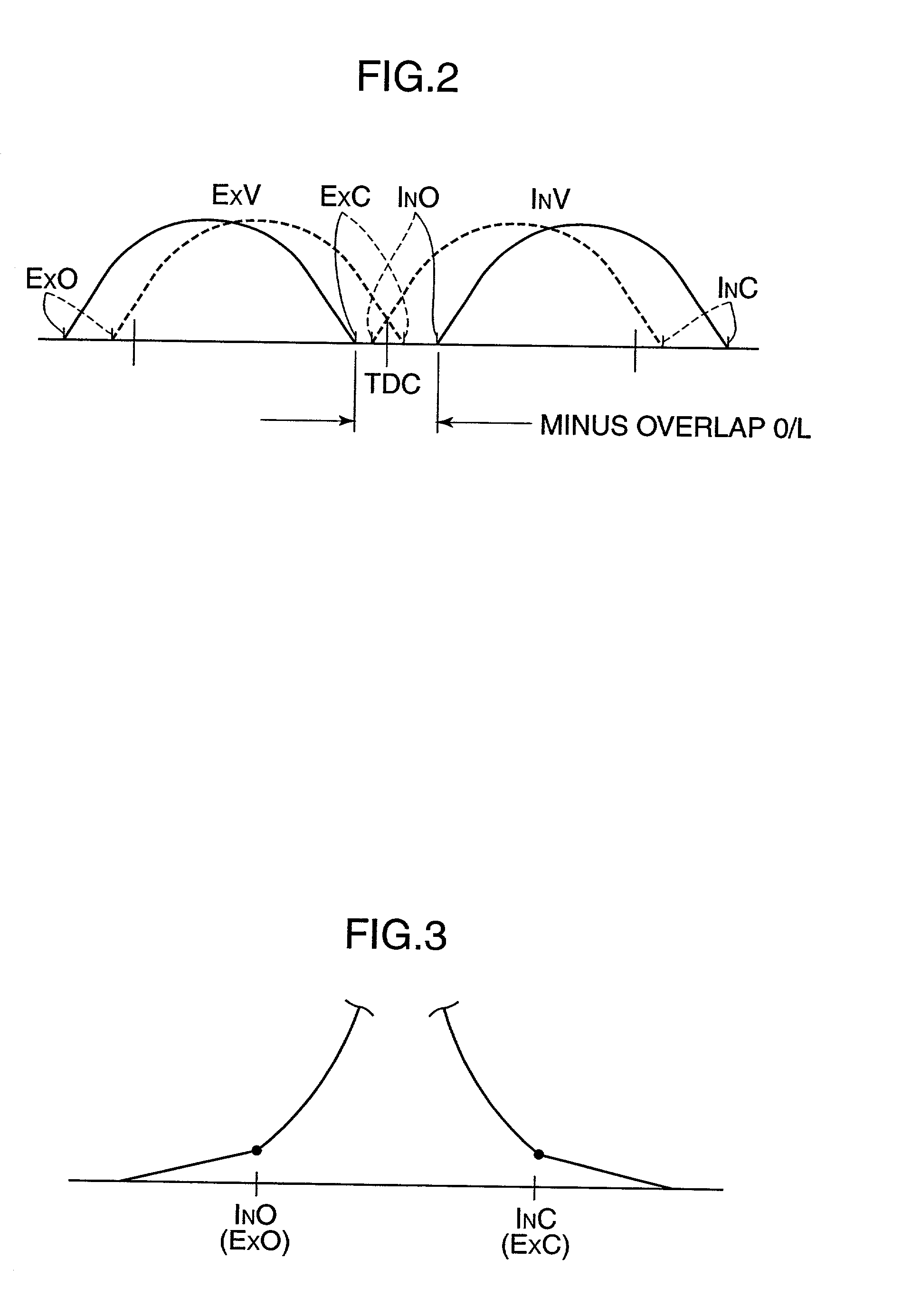

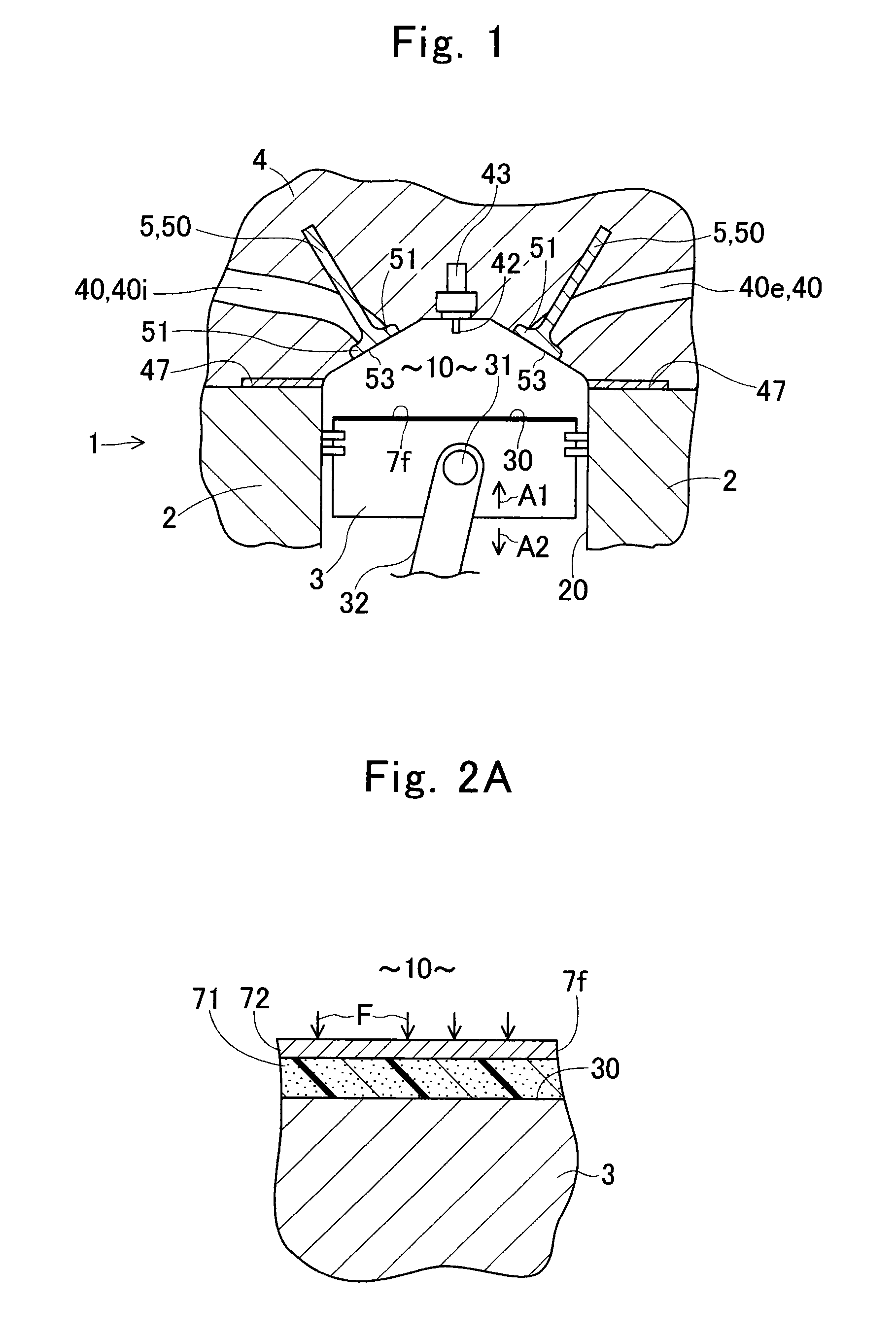

Automotive four-cycle engine

InactiveUS20020166536A1Improve engine performanceRaise the combustion temperatureValve arrangementsElectrical controlExhaust valveTop dead center

A four-cycle engine is provided with valve timing adjusters for adjusting opening and closing timing an and an exhaust valve. In medium- to high-speed ranges in medium- to high-load regions of the engine, a closing point (ExC) of the exhaust valve defined as a point of transfer from an acceleration portion to a constant speed portion on its valve lift characteristics curve is set to a point a specific period before an intake top dead center, and an opening point (InO) of the intake valve defined as a point of transfer from a constant speed portion to an acceleration portion on its valve lift characteristics curve is set to a point after the intake top dead center. In addition, the period from the closing point (ExC) of the exhaust valve to the opening point (InO) of the intake valve is made longer in the medium-speed range than in the high-speed range in the medium- to high-load regions of the engine.

Owner:MAZDA MOTOR CORP

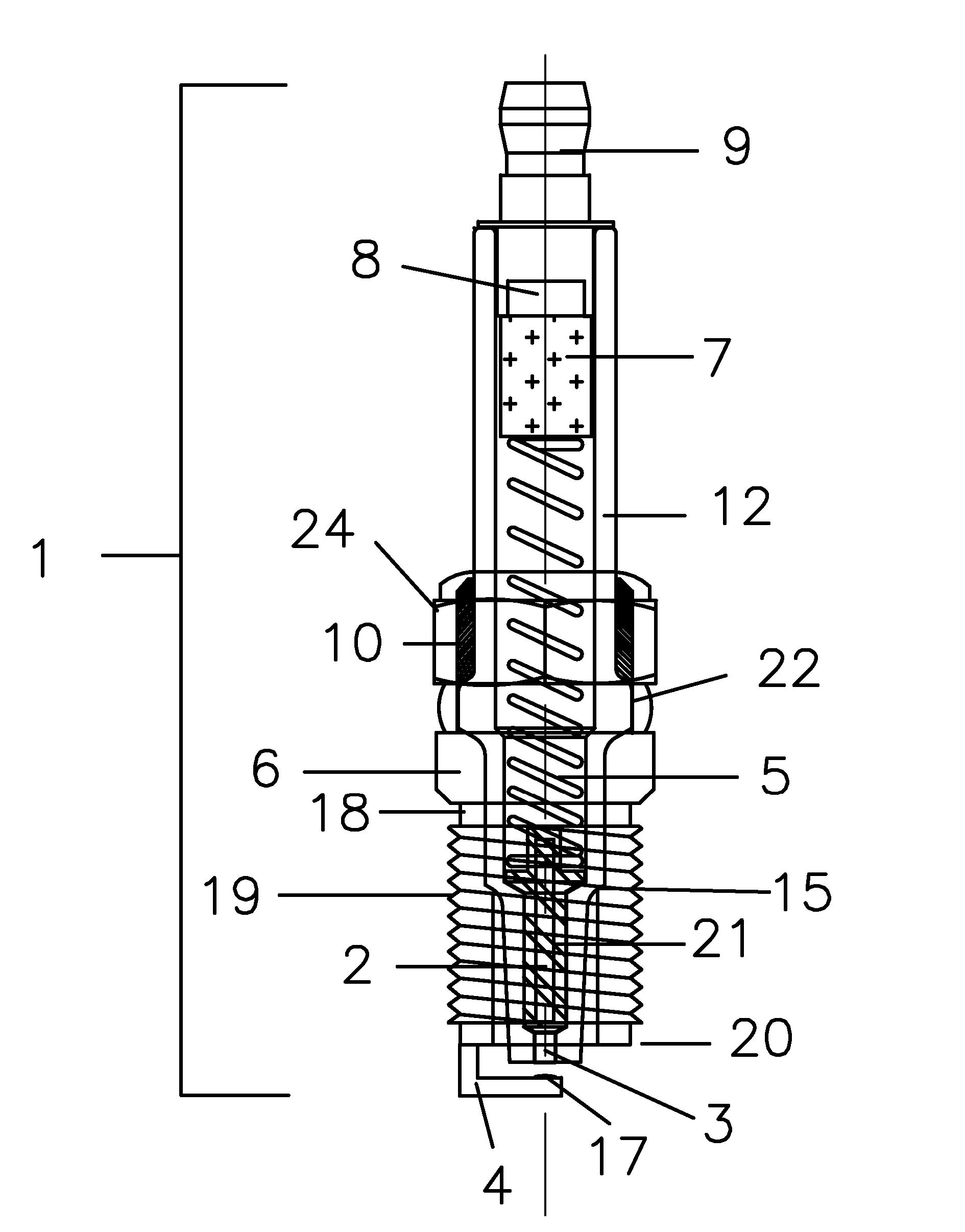

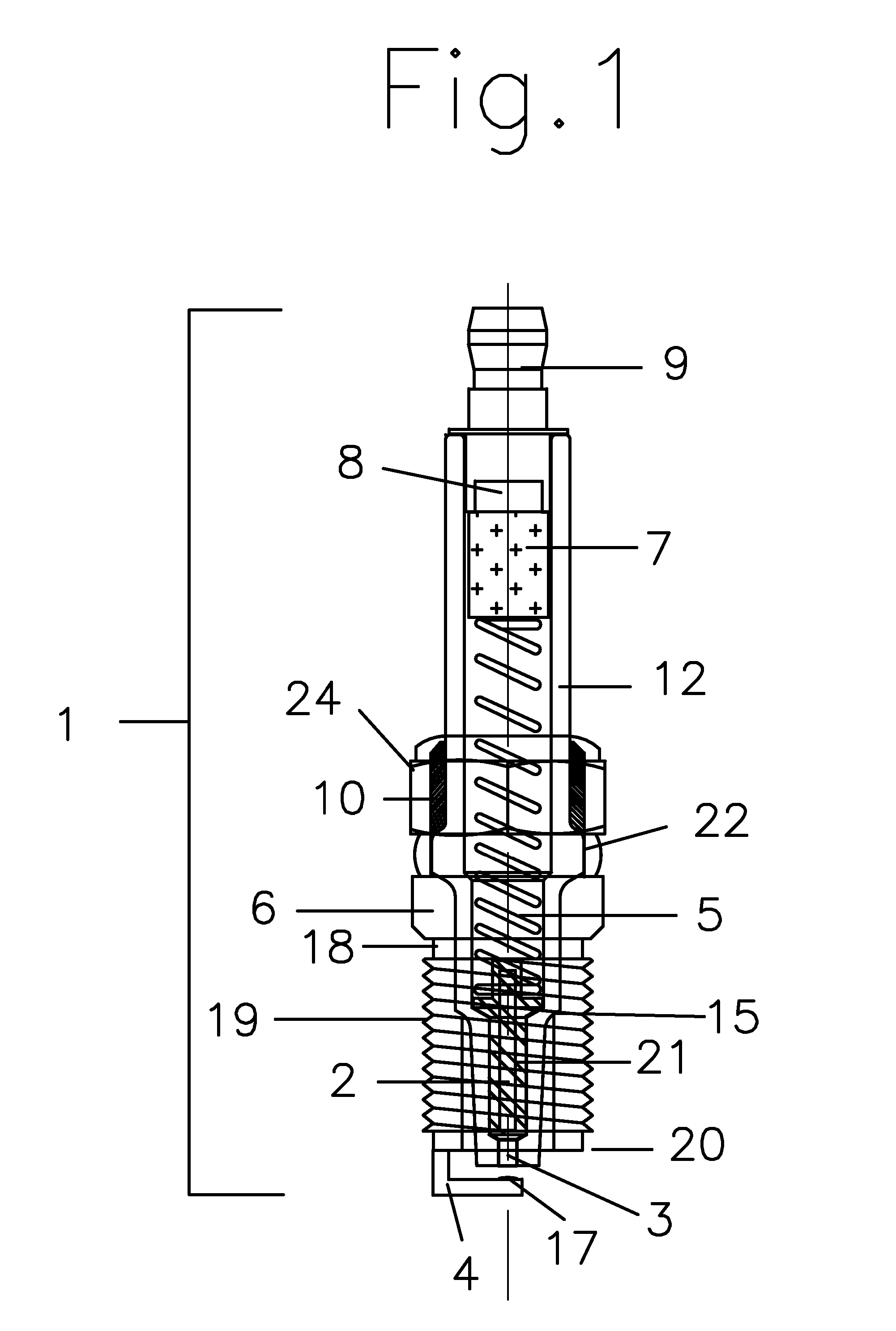

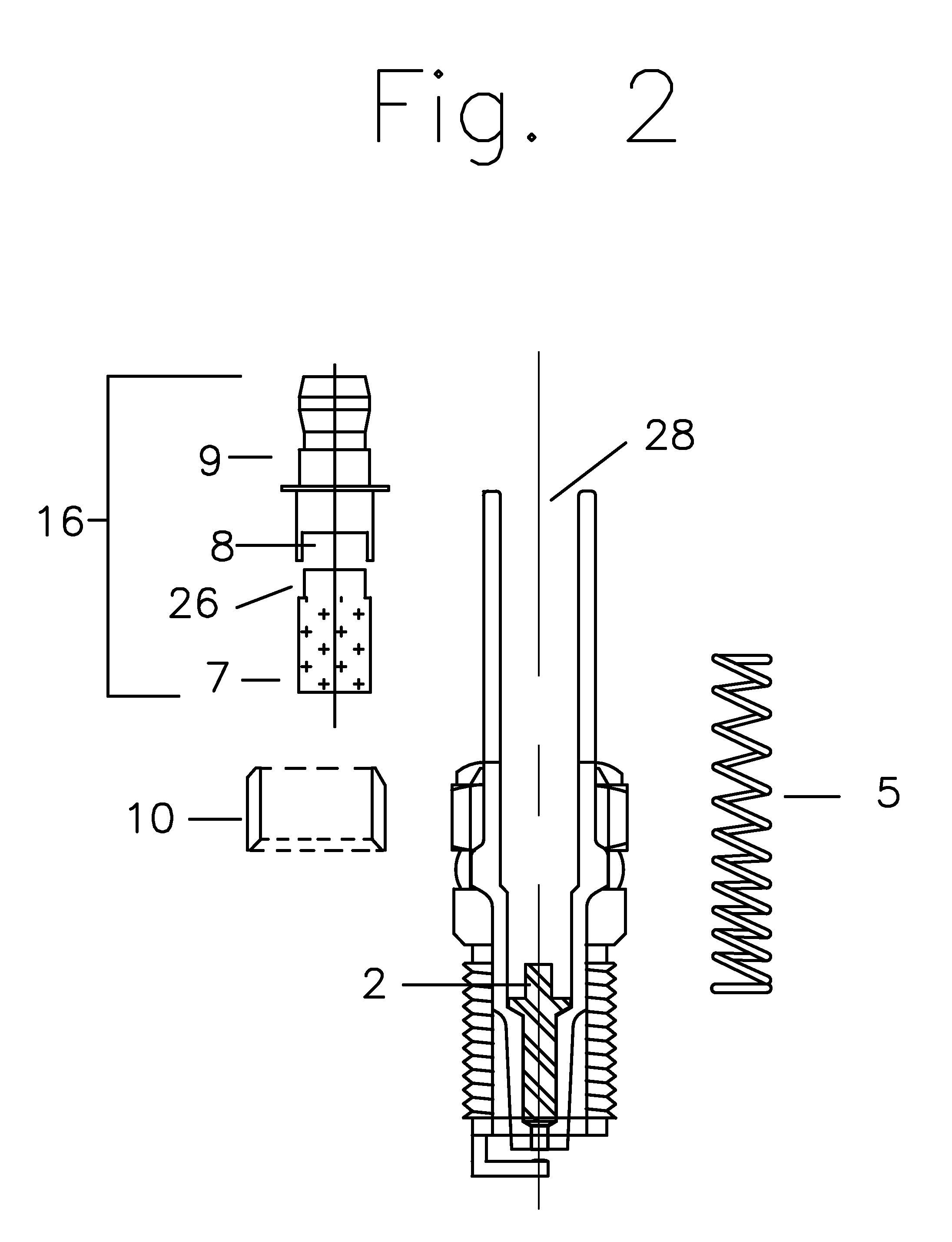

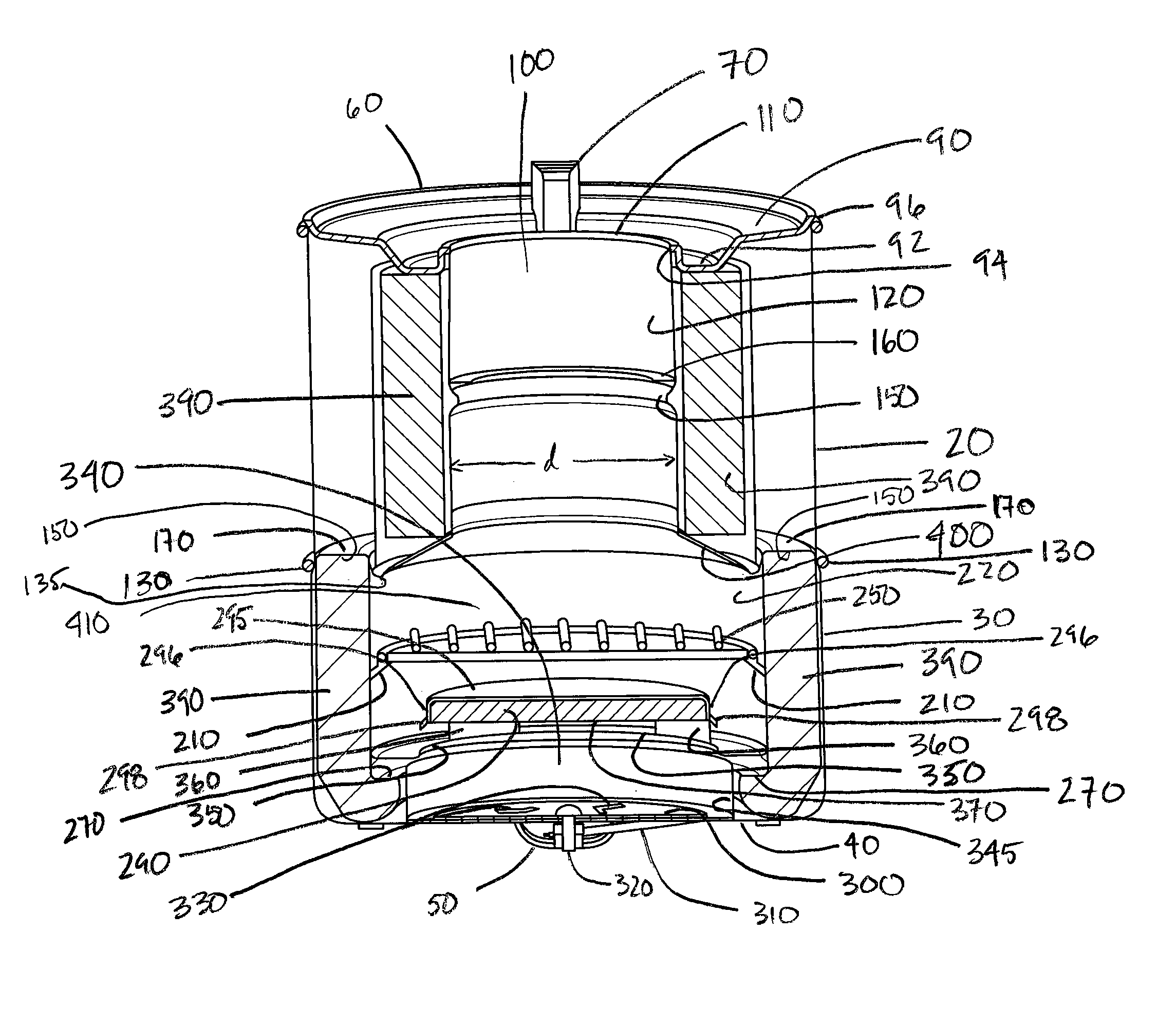

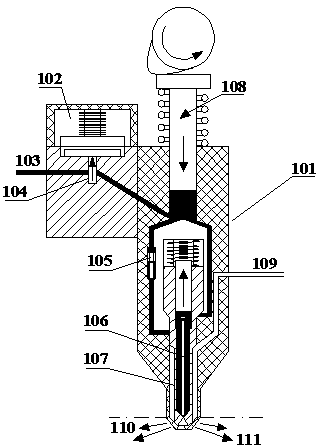

High power discharge fuel ignitor

ActiveUS20080018216A1Reduce erosionGreat cross sectionSpark gapsMachines/enginesElectricityCombustion

A spark-ignited, internal combustion engine ignition device to increase electrical transfer efficiency of the ignition by peaking the electrical power of the spark during the streamer phase of spark creation and improving combustion quality, incorporating an electrode design and materials to reduce electrode erosion due to high power discharge, an insulator provided with capacitive plates to peak the electrical current of the spark discharge, and concomitant methods.

Owner:PASSAIC RIVER CO INC

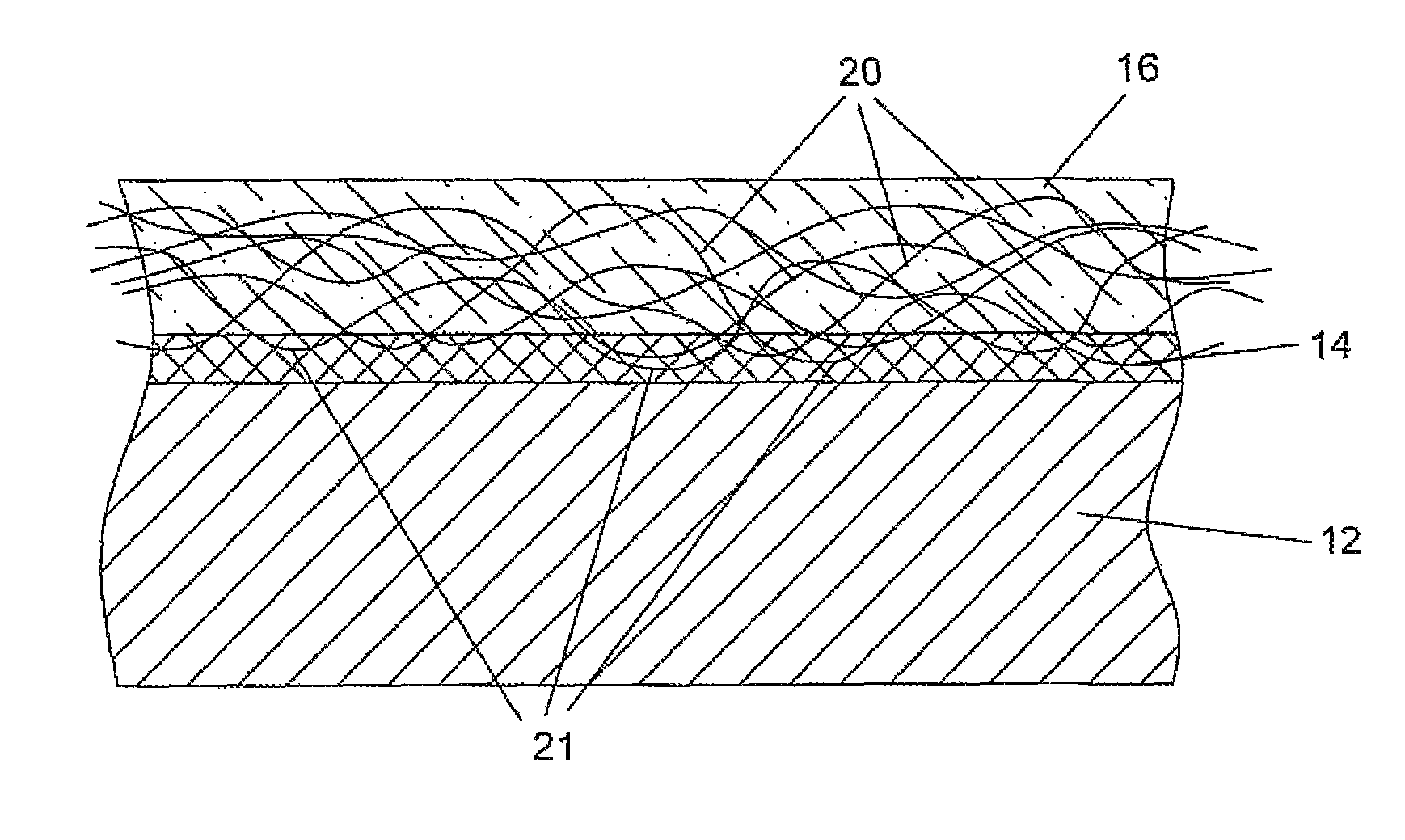

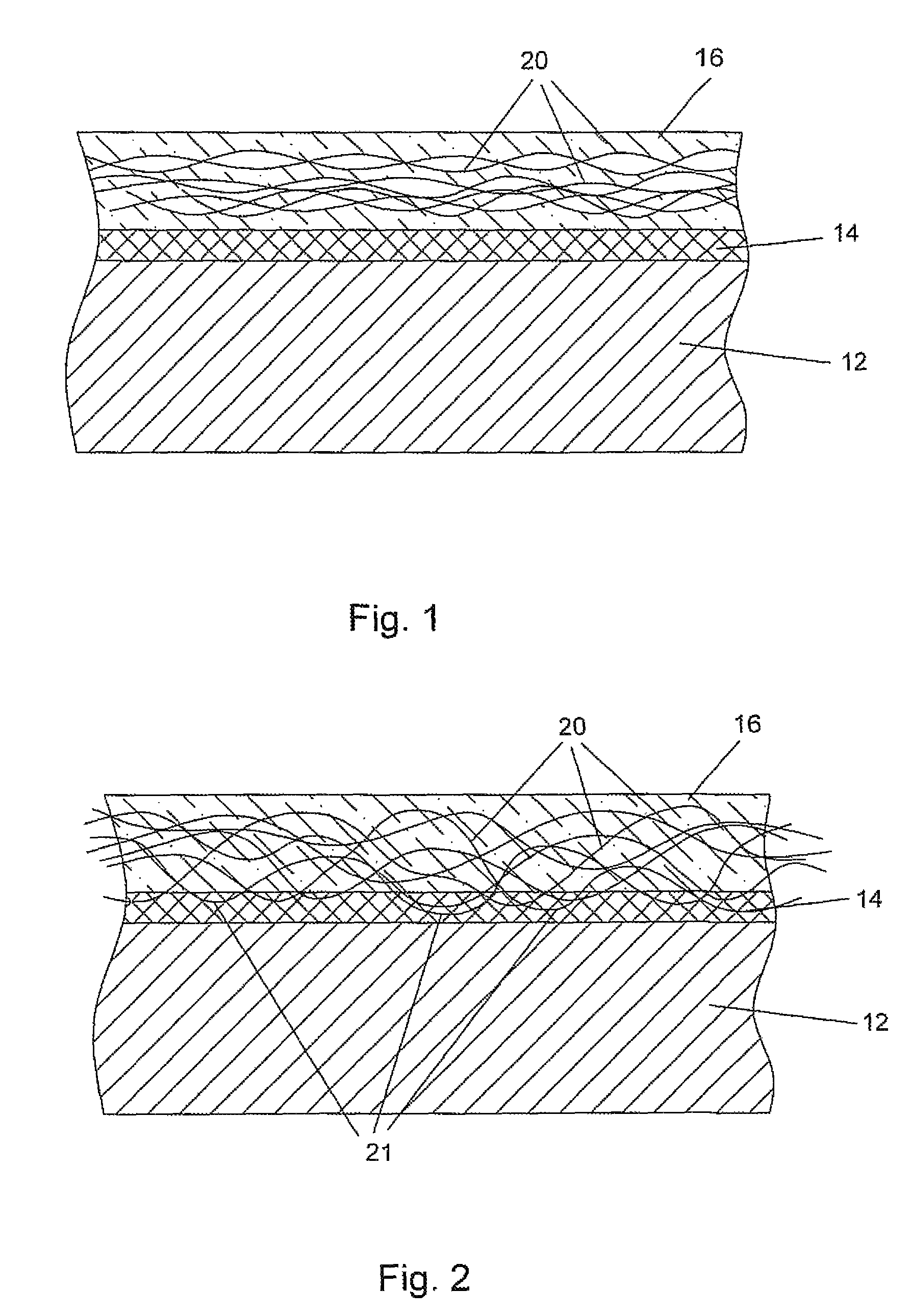

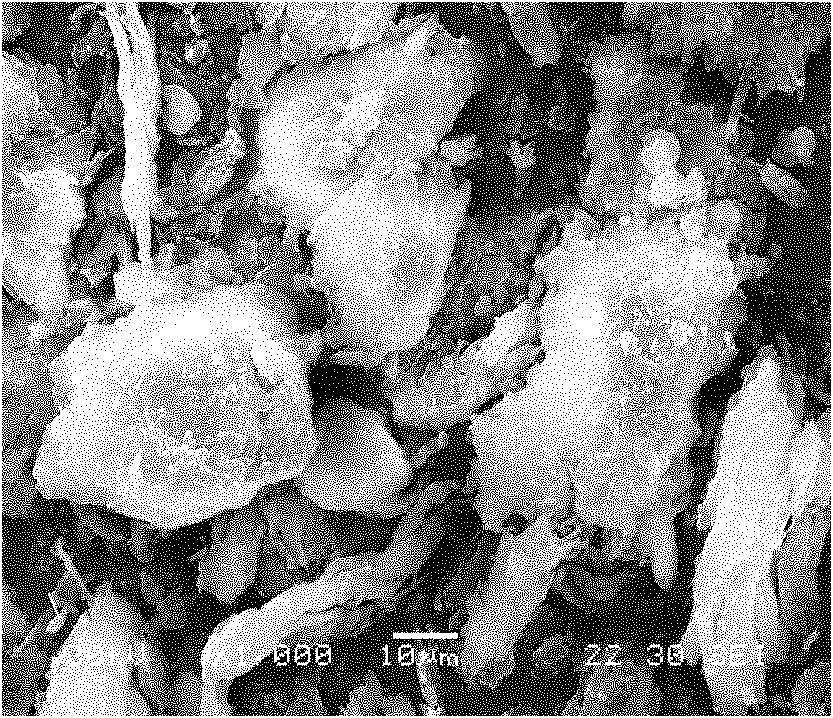

TBC with fibrous reinforcement

A substrate exposed to high temperatures, the substrate having a TBC layer that includes fibers of reinforcing material to add strength to the layer of TBC. The fibers are made from carbon nanotubes to withstand the high temperatures, and have a diameter of about 0.1 mm or less in order that a thin layer of TBC can completely cover and embed the fibers within the layer. A bond coat is applied to the substrate and the fibers are attached to the bond coat to limit the fibers from being pulled away from the substrate. The carbon nanotubes also provide for improved heat transfer through the TBC to improve the cooling capability of the TBC.

Owner:FLORIDA TURBINE TECH

High-efficiency industrial gas

InactiveCN101892102ARaise the combustion temperatureImprove combustion efficiencyGaseous fuelsGas flame welding apparatusIndustrial gasPropane gas

The invention discloses a high-efficiency industrial gas which comprises the raw materials: industrial propane gas with the purity higher than 95% (weight percent), and liquid-phase synergistic additive accounting for 0.3-1.0% (weight percent) of the industrial propane gas. By adding a little liquid-phase synergistic additive into the propane gas, the high-efficiency industrial gas remarkably improves the burning temperature and efficiency; meanwhile, the liquid-phase synergistic additive of the high-efficiency industrial gas has low corrosivity for a container and good volatility.

Owner:BEIJING DATONG HONGYE TECH DEV

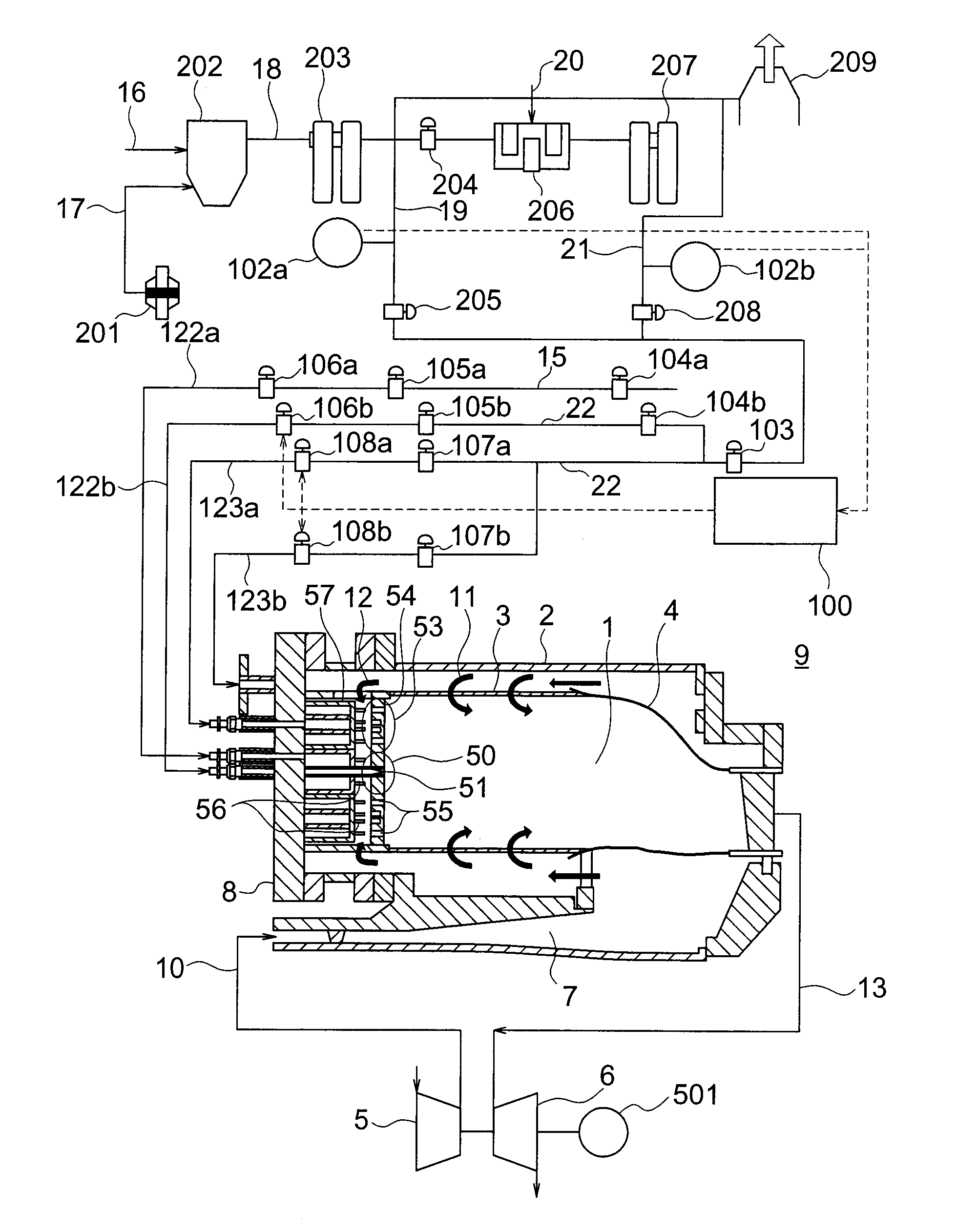

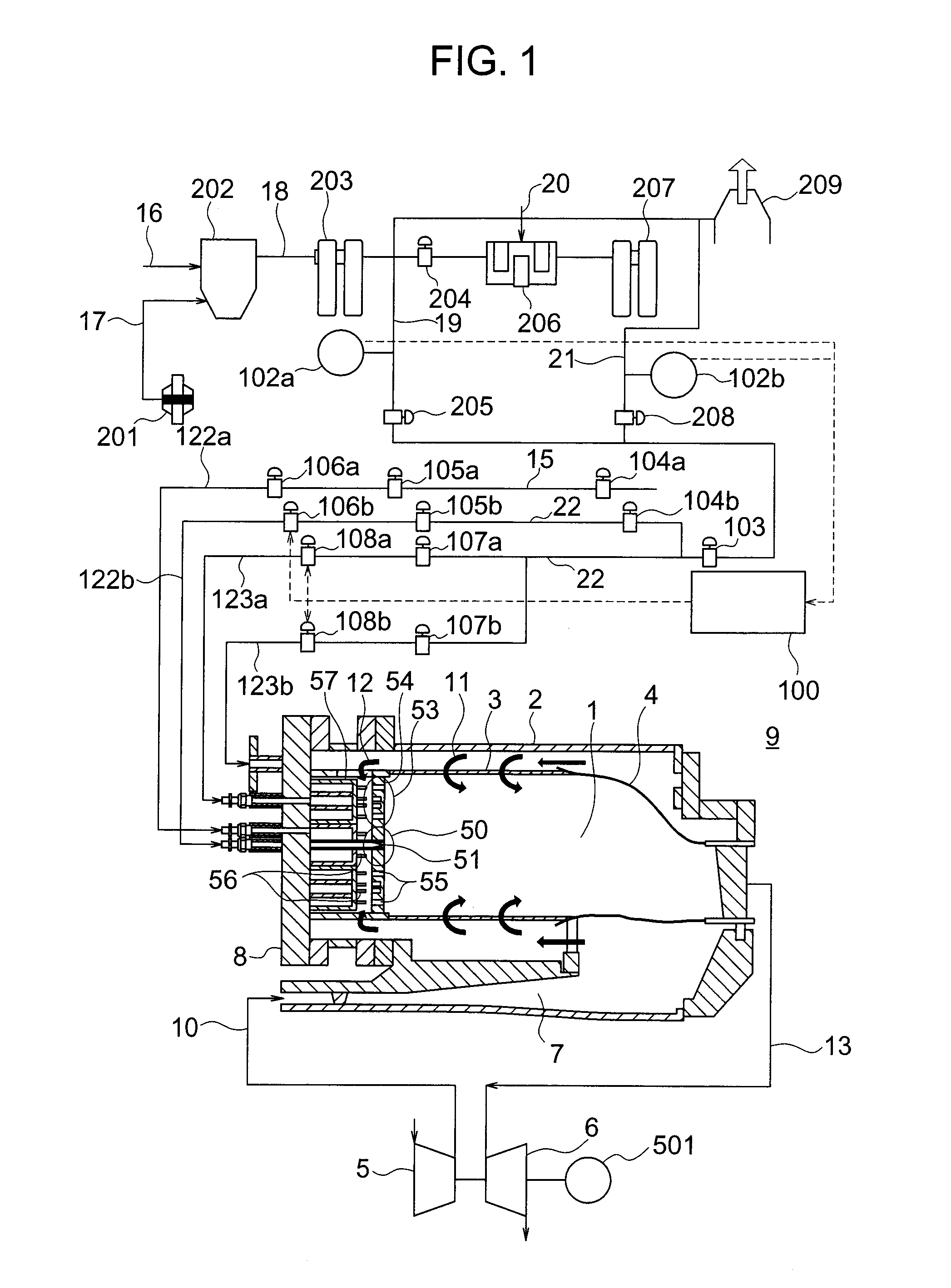

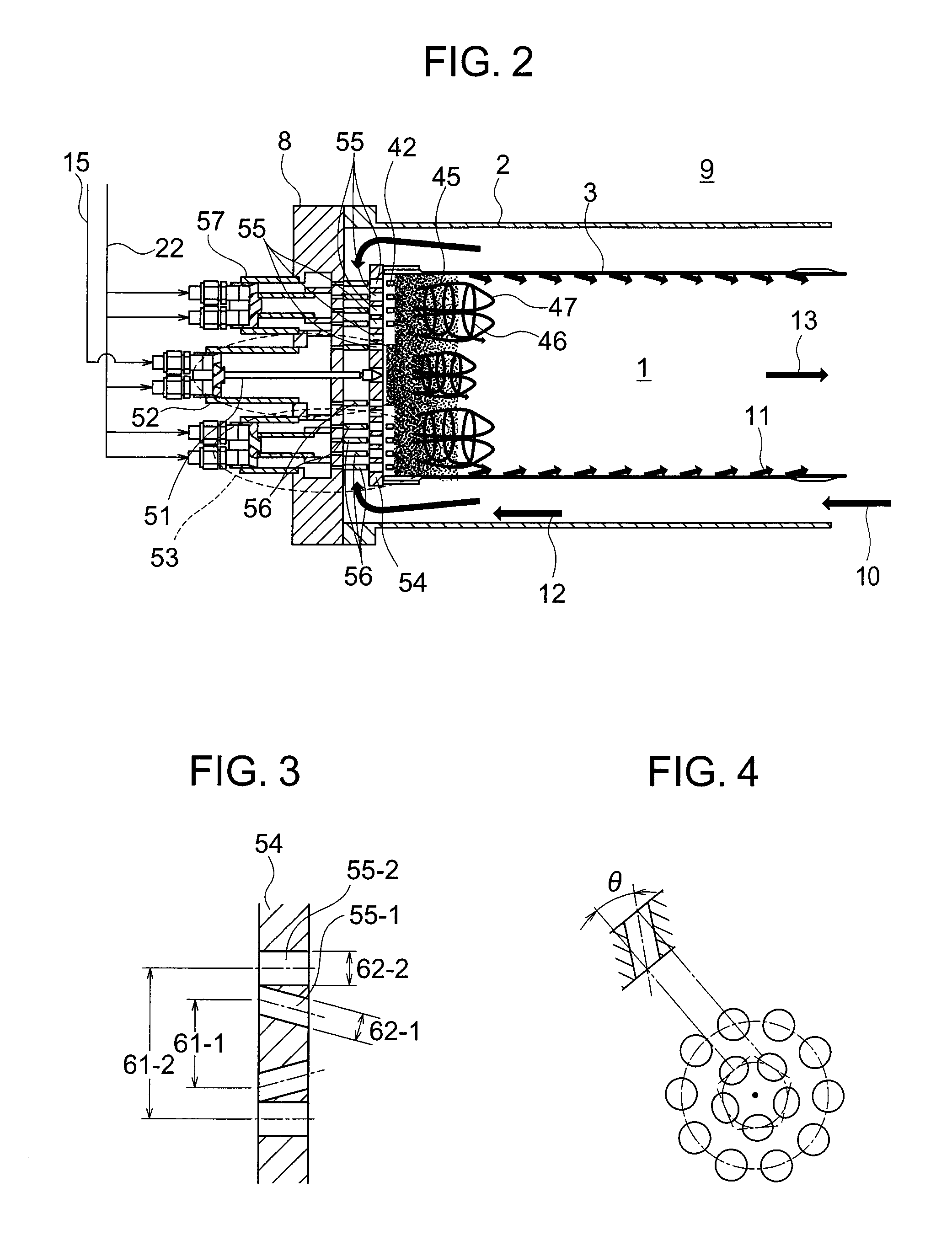

Gas Turbine Combustor

InactiveUS20110185703A1Low NOx combustionImprove power generation efficiencyContinuous combustion chamberGas turbine plantsCombustion chamberCombustor

A gas turbine combustor includes plural multi-coaxial-injection-hole burners in which plural fuel nozzles and plural air holes provided in an air plate to correspond to the respective fuel nozzles are coaxially arranged. Each of the multi-coaxial-injection-hole burners includes a first coaxial injection burner disposed on an inner circumferential side, and a second coaxial injection burner disposed on an outer circumferential side, and a diameter of the air holes of the first coaxial injection burner is smaller than a diameter of the air holes of the second coaxial injection burner. Combustion for carrying out flame holding of a gas turbine combustor is performed by the first coaxial injection burner, and low NOx combustion of the gas turbine combustor is performed by the second coaxial injection burner.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

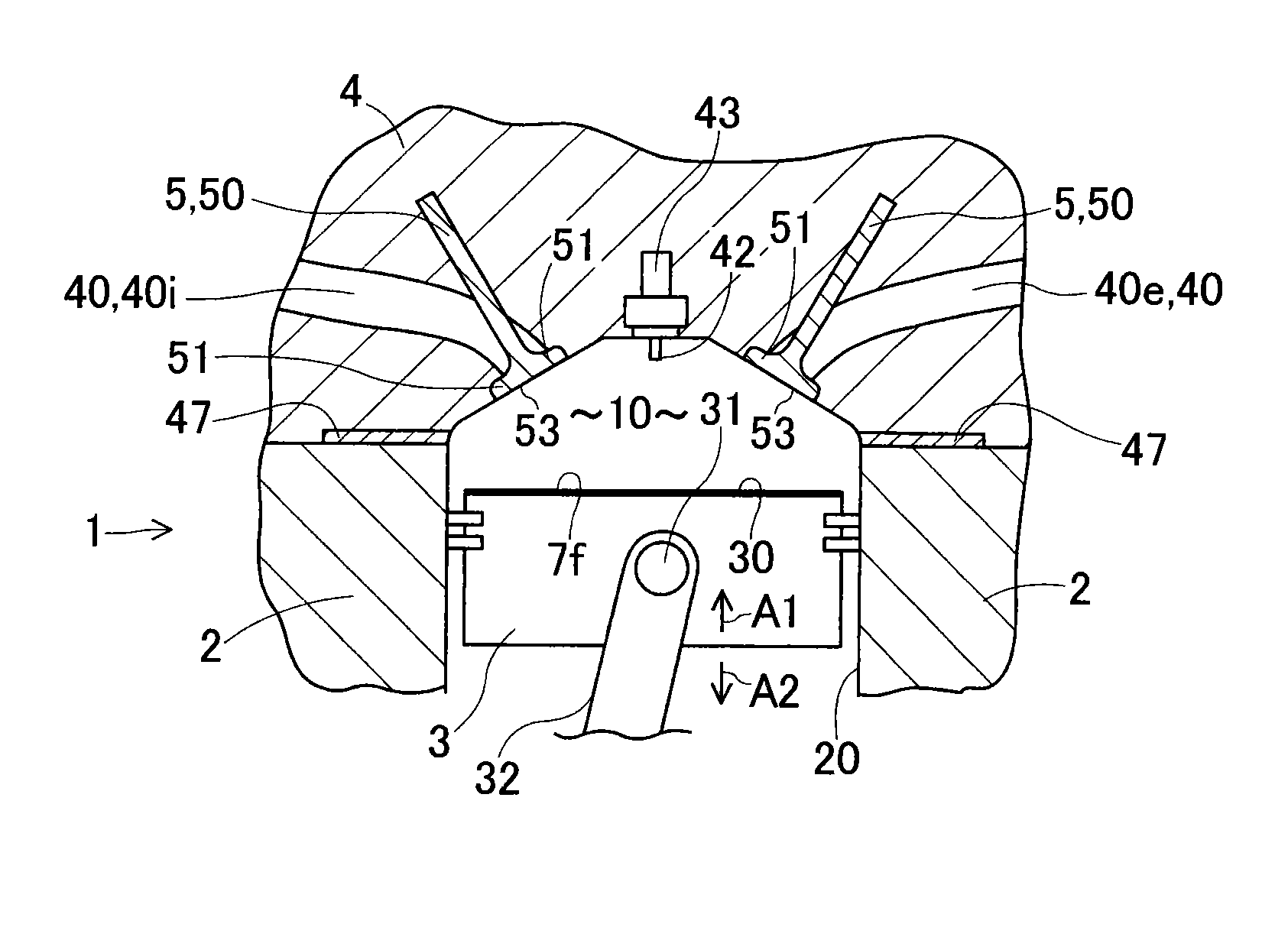

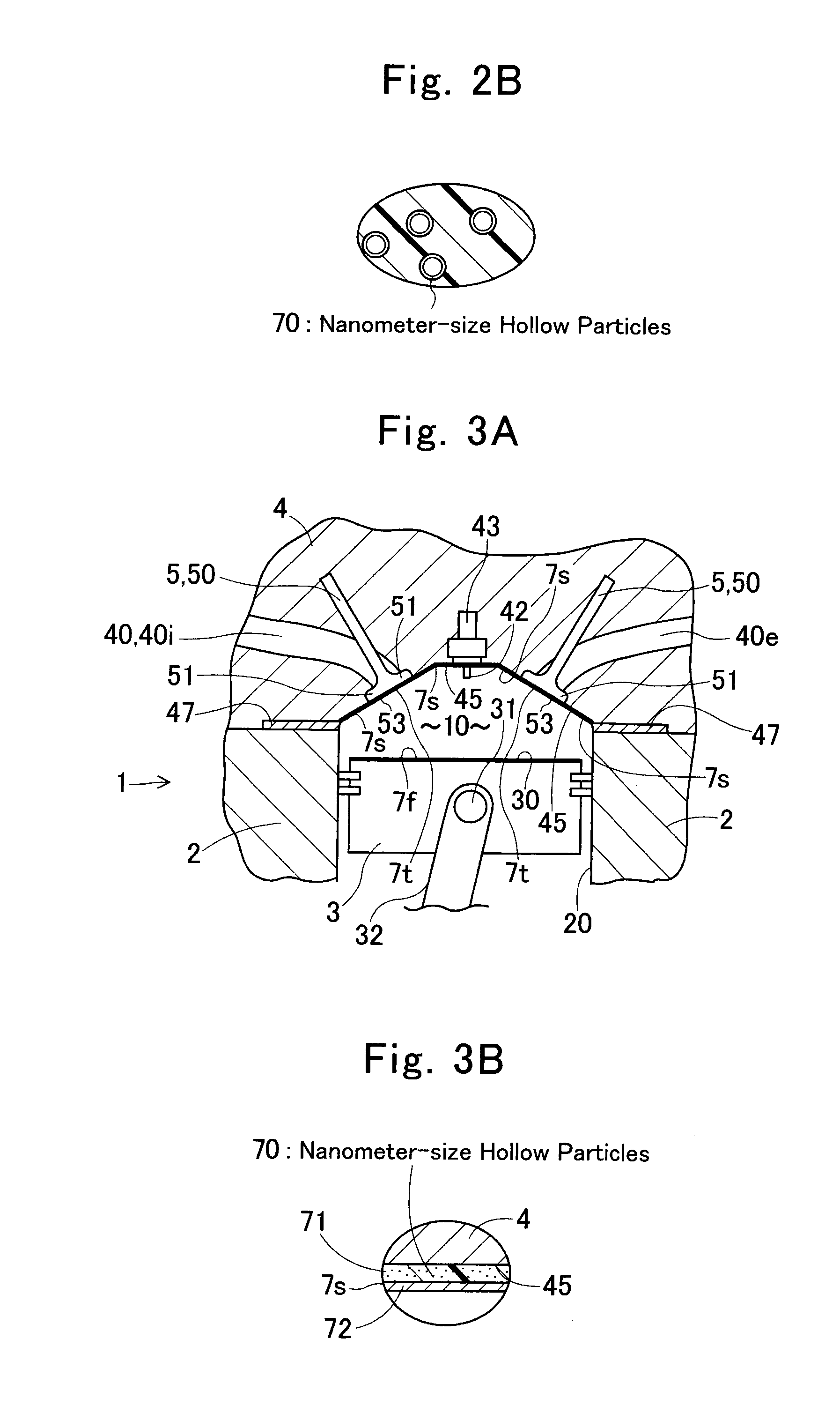

Engine and piston

ActiveUS20150204269A1Improve insulation performanceUpgrading mileagePlungersCylinder headsCombustion chamberCylinder head

Any one or more members of an engine, that is, a piston, a cylinder head and a valve, has a wall face disposed face-to-face to a combustion chamber, and the wall face is coated by a heat-insulation coating film. The heat-insulation coating film includes a heat-insulative layer formed on a surface of the wall face, and an inorganic-system coated-film layer formed on a surface of the heat-insulative layer. The heat-insulative layer includes a resin, and first hollow particles buried inside the resin and exhibiting an average particle diameter being smaller than a thickness of the heat-insulative layer. The inorganic-system coated-film layer includes an inorganic compound.

Owner:AISIN SEIKI KK +1

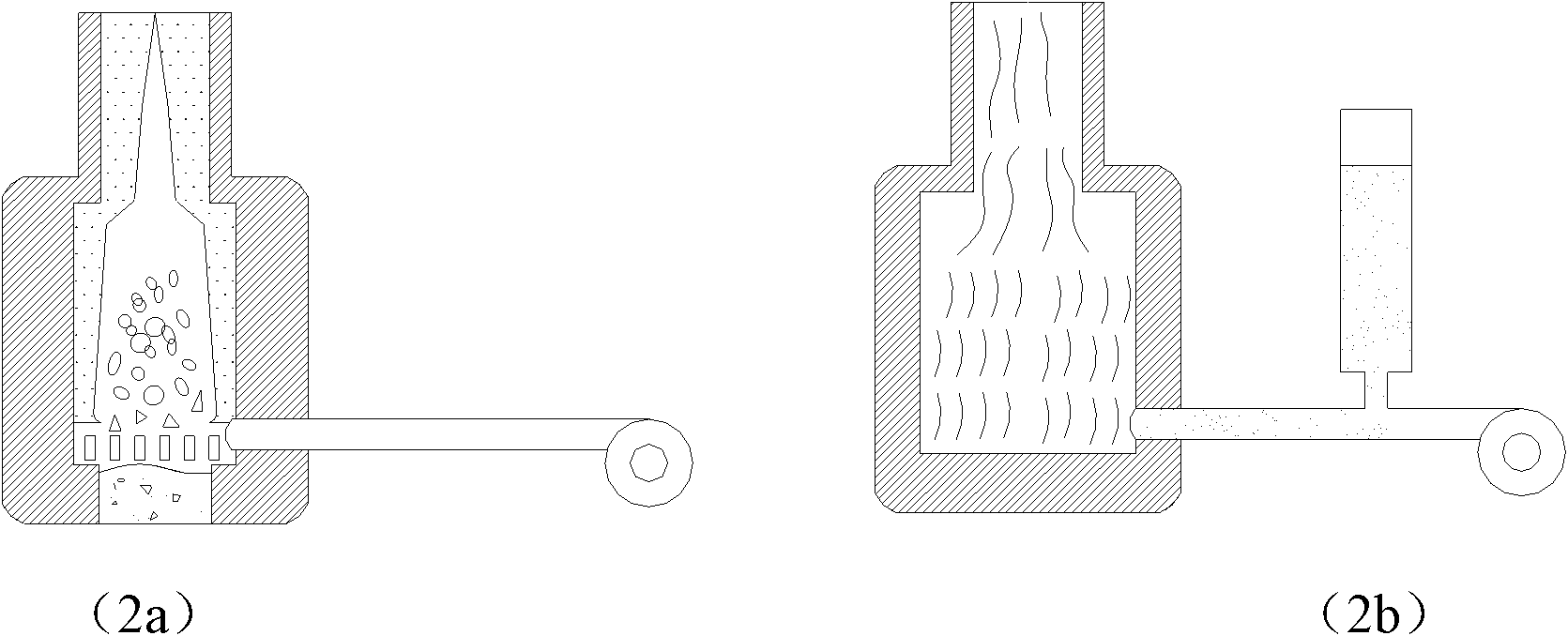

Efficient and energy-saving environment-friendly high-pressure burner

InactiveCN101706103AEnsure safetyStable high pressure combustionGaseous fuel burnerCombustion chamberCombustor

The invention relates to an efficient and energy-saving environment-friendly high-pressure burner, wherein smoke which has high temperature and high pressure as well as low pollution and is generated by the burner can be used in industries of petroleum, chemical engineering and the like. The burner comprises a combustion chamber, the front end of the combustion chamber is provided with a tapered spray nozzle which is provided with a fuel gas spray inlet and a primary air spray inlet, and a fuel air tube and a primary air distribution tube are respectively communicated with the fuel gas spray inlet and the primary air spray inlet. A combustion chamber protective casing is arranged outside the outer wall of the combustion chamber, an annular channel is formed by the surrounding of the outer wall of the combustion chamber and the combustion chamber protective casing, a secondary air inlet is communicated with the annular channel, the tail end of the outer wall of the combustion chamber is provided with a secondary air auxiliary inlet, and secondary air enters the combustion chamber through the secondary air auxiliary inlet. The burner realizes secondary air distribution to the combustion chamber by the secondary air, and secondary air distribution not only plays the role of cooling and heat preservation to the combustion chamber, but also can conduct secondary air distribution combustion supporting by being preheated to certain temperature, thus improving combustion efficiency and saving energy.

Owner:BEIJING UNIV OF TECH

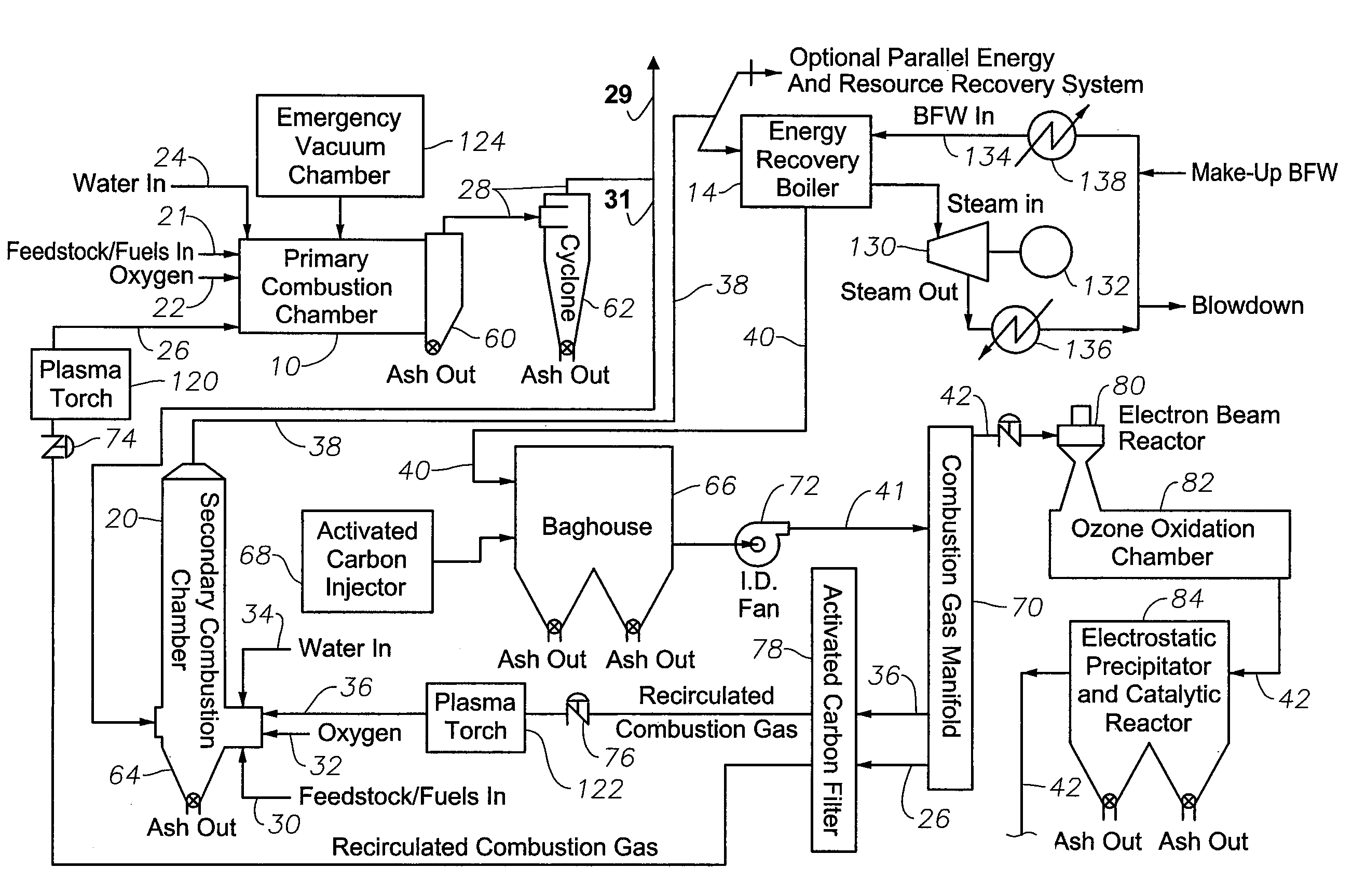

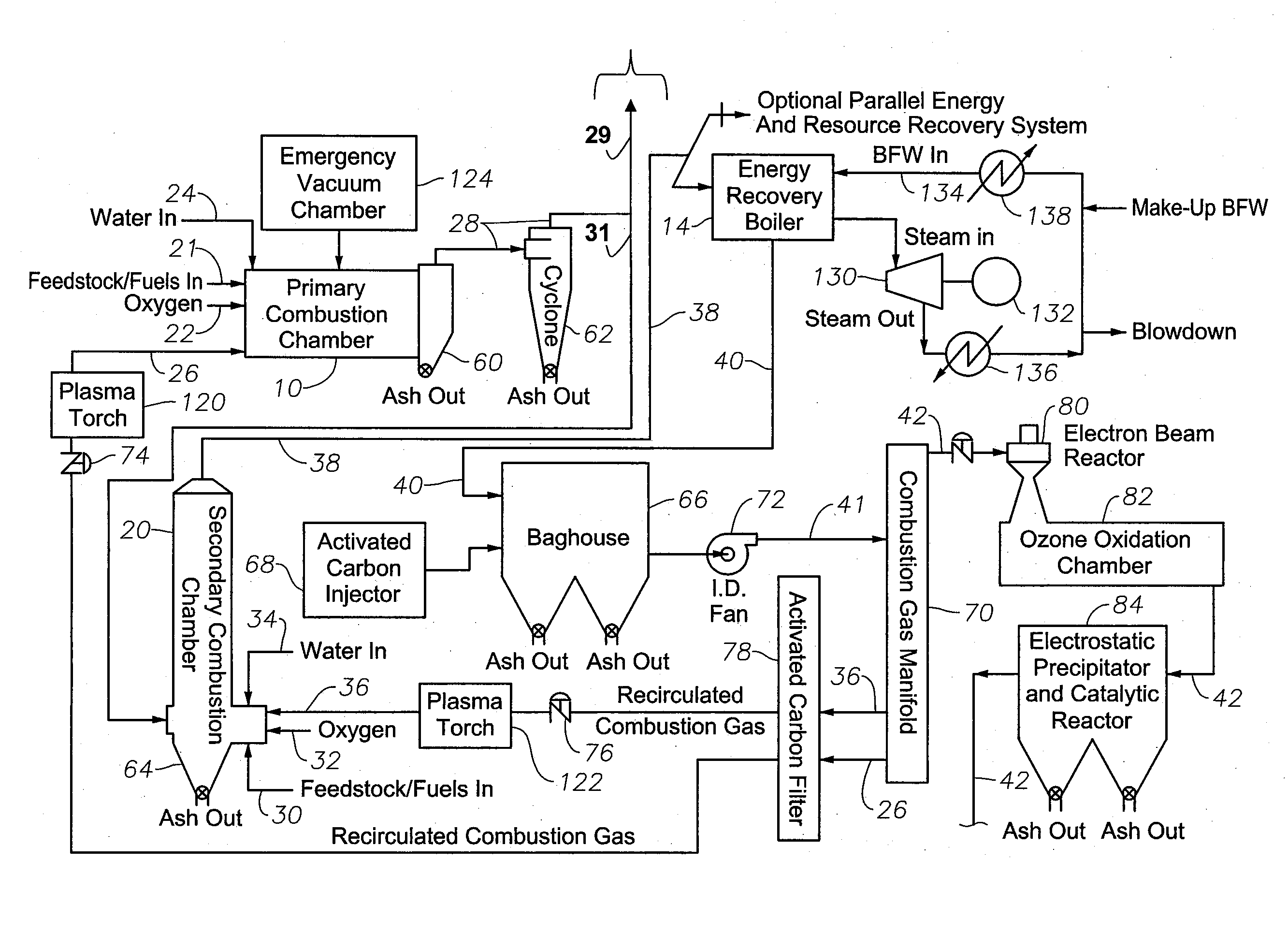

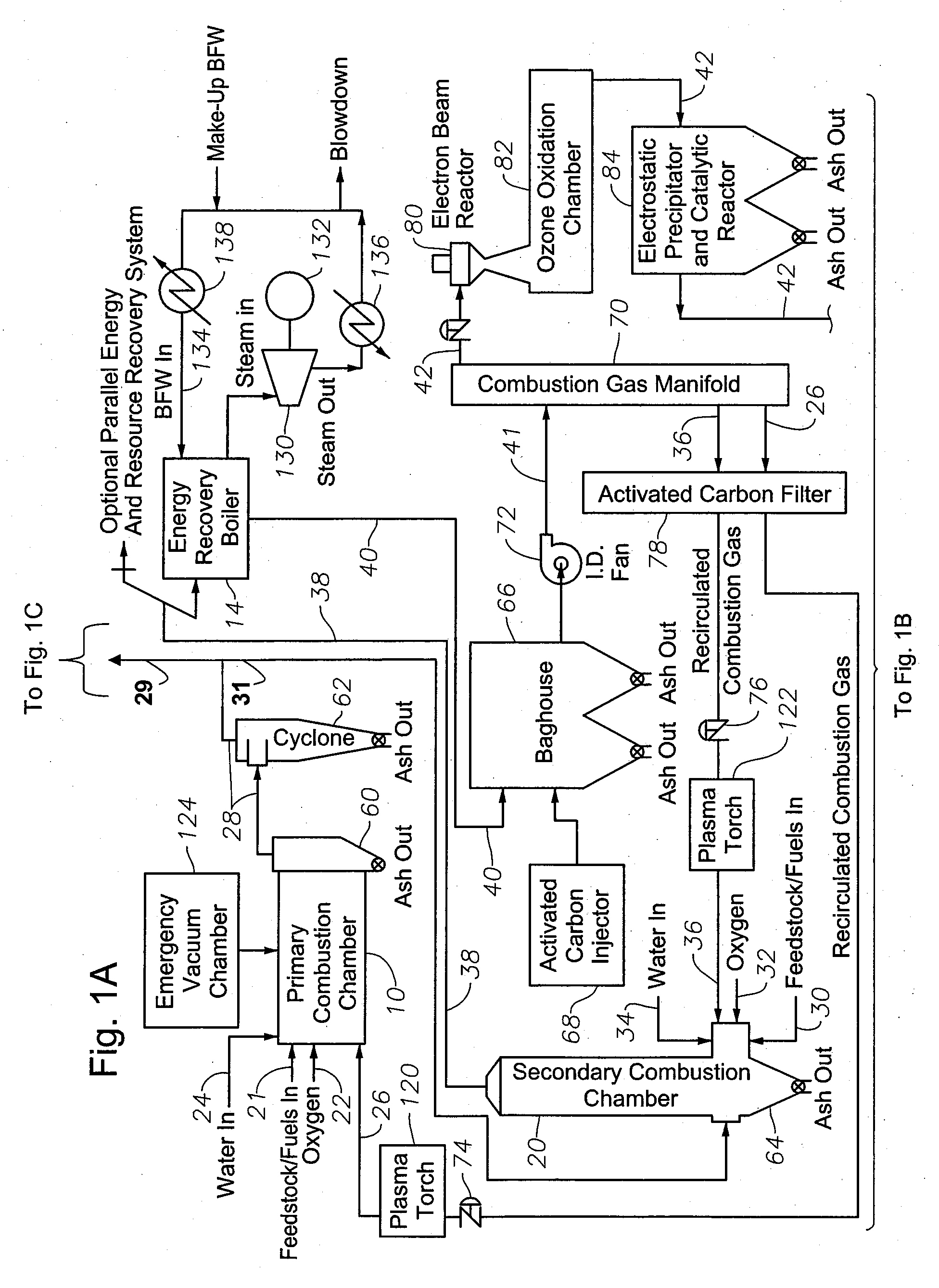

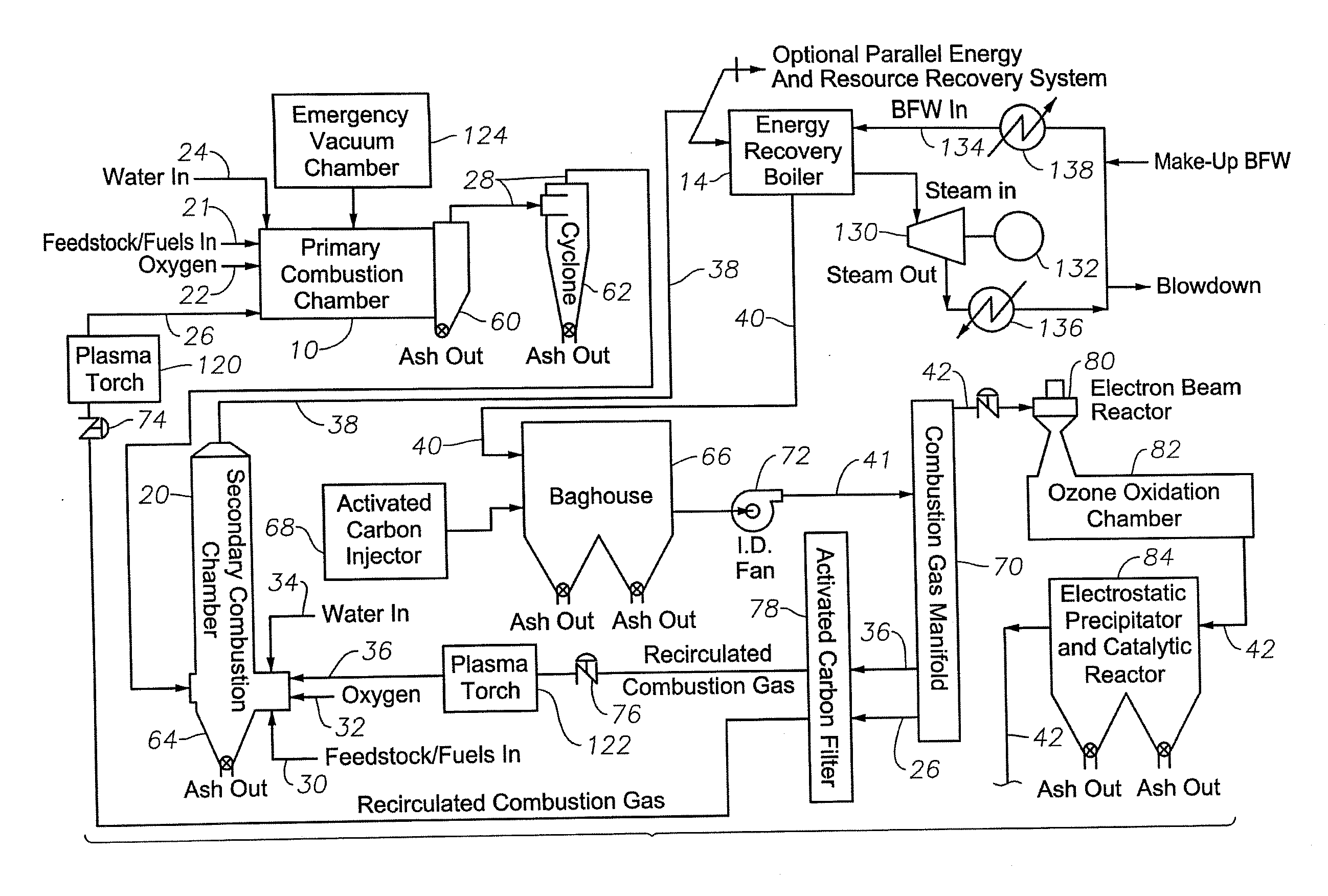

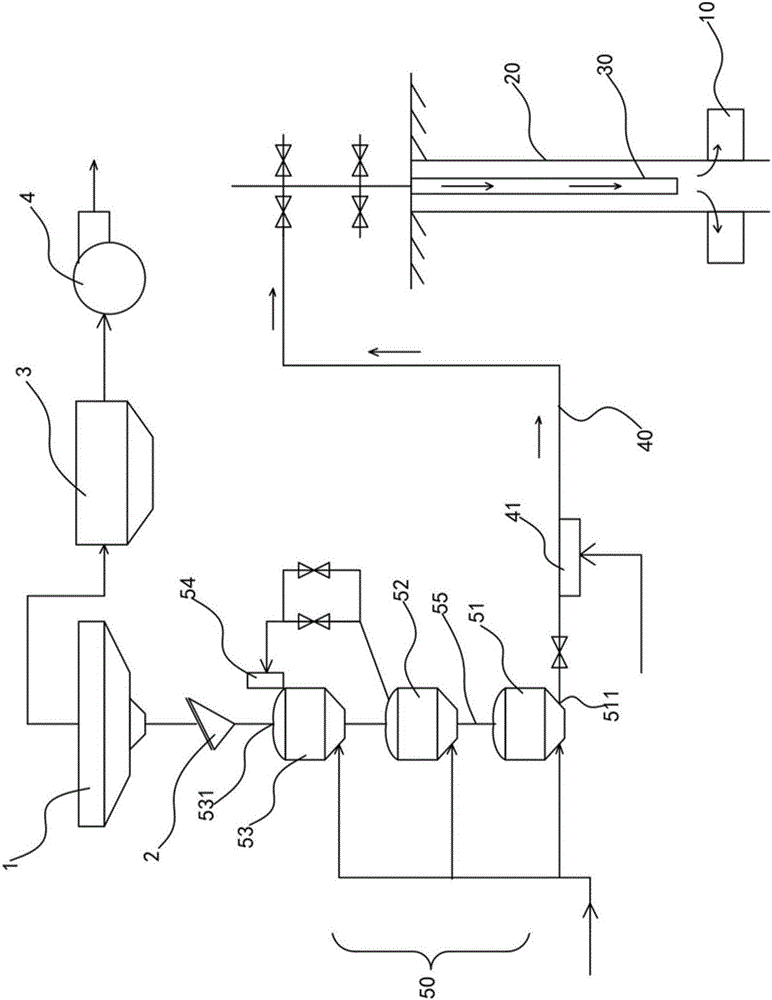

Reduced-emission gasification and oxidation of hydrocarbon materials for power generation

ActiveUS20080184621A1High heat transfer rateRaise the combustion temperatureGas modification by gas mixingSolid fuel combustionThermal energyEngineering

A system and process for maximizing the generation of electrical power from a variety of hydrocarbon feedstocks. The hydrocarbon feedstocks are first gasified and then oxidized in a two-chamber system and process using oxygen gas rather than ambient air. Intermediate gases generated in the system and process are recirculated and recycled to the gasification and oxidation chambers in order to maximize energy production. The energy produced through the system and process is used to generate steam and produce power through conventional steam turbine technology. In addition to the release of heat energy, the hydrocarbon feedstocks are oxidized to the pure product compounds of water and carbon dioxide, which are subsequently purified and marketed. The system and process minimizes environmental emissions.

Owner:CLARK STEVE L

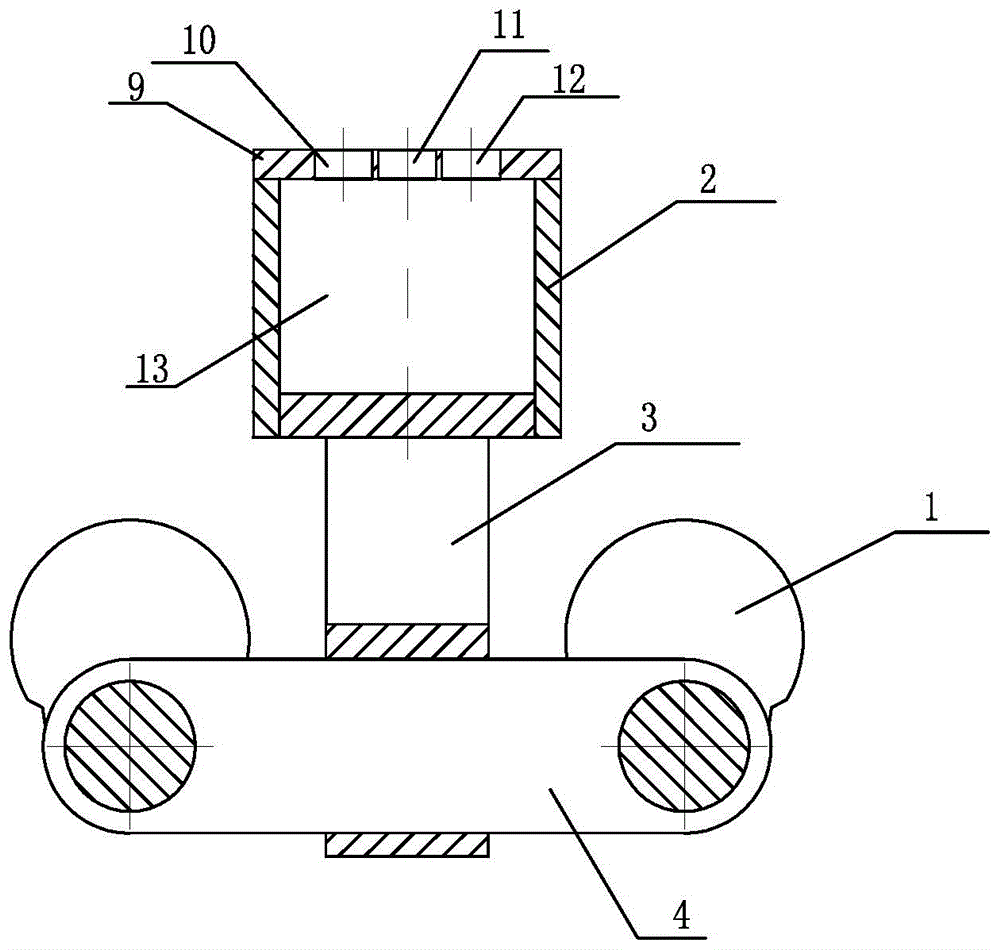

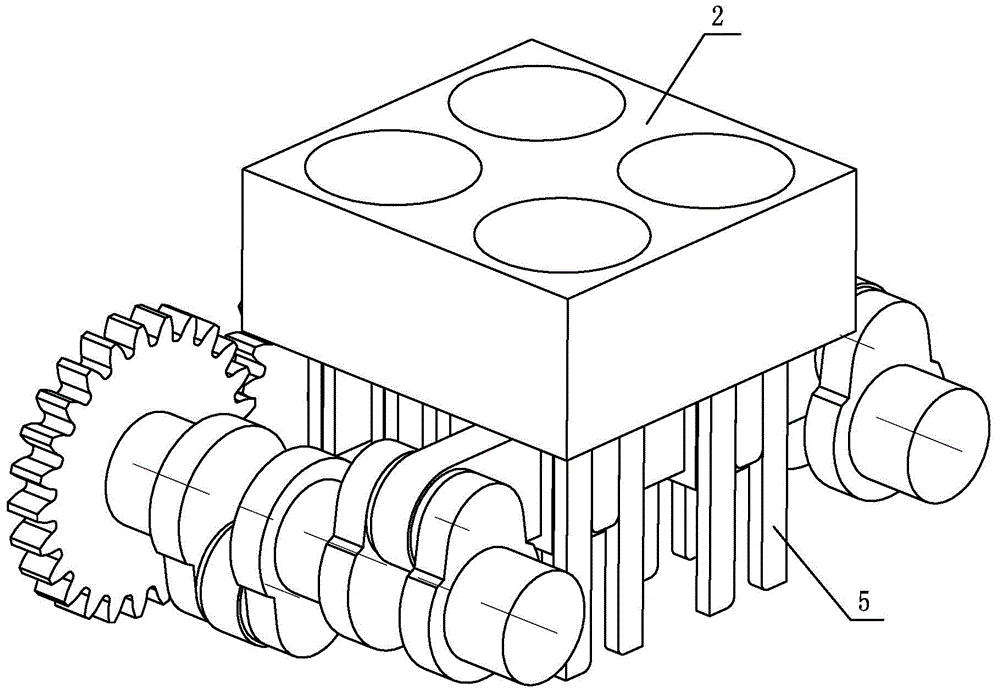

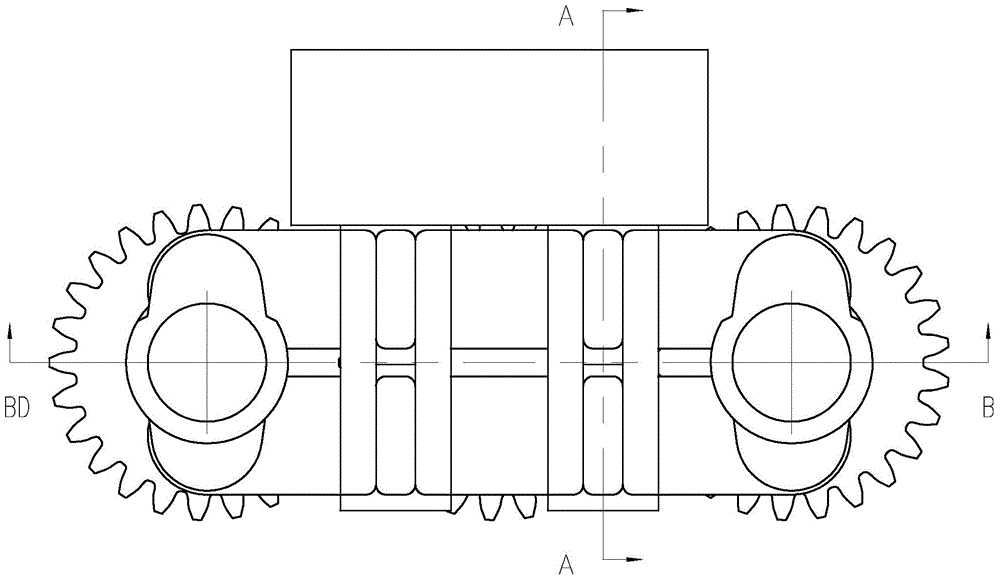

Double-crank mechanism engine

ActiveCN104481689AReduce toughnessReduce manufacturing costCylinder headsCylindersGas cylinderReciprocating motion

The invention discloses a double-crank mechanism engine, belonging to the technical field of engines. The double-crank mechanism engine comprises a gas cylinder and a piston capable of performing straight reciprocating motion in the gas cylinder, wherein two parallel crankshafts are arranged at the two sides of the gas cylinder; a connecting rod is hinged between corresponding crankshaft pins of the two crankshafts to form a double-crank mechanism; a connecting rod insertion slot and a slide block are arranged on a piston rod on the rear end of the piston, the connecting rod is inserted to the connecting rod insertion slot in a sliding manner, a guide block is fixed in the engine; a guide rail for sliding the slide block is formed on the guide block; the slide block is inserted to the guide rail; transmission gears are arranged on the end parts of the crankshafts; an output gear is engaged between the two transmission gears; and an output shaft is arranged on the output gear. The double-crank mechanism engine can be used for effectively lowering the abrasion and the impact of the piston and a cylinder sleeve, improving the reliability of the ceramic material applied to the engine and improving the practical heating efficiency.

Owner:王蓬波

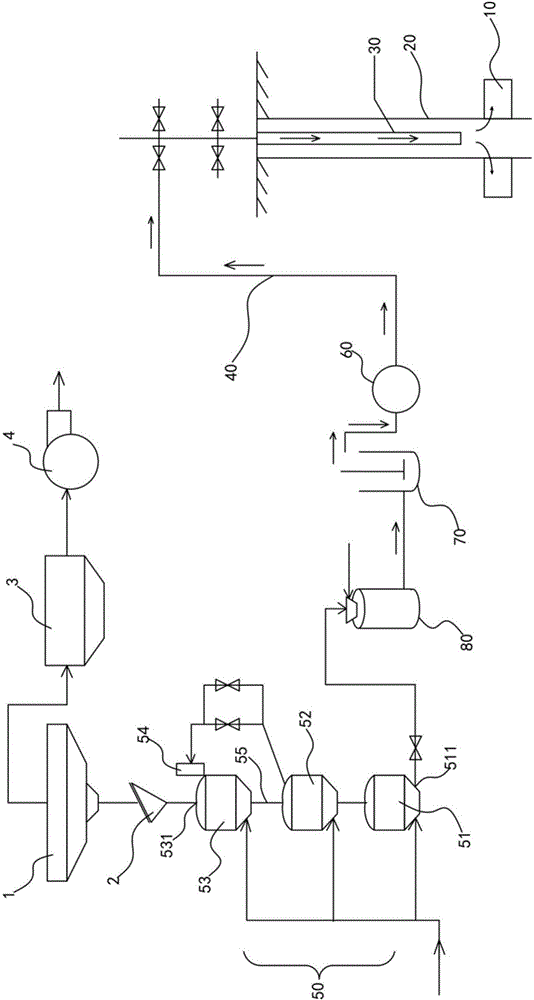

Device for injecting pulverized coal into oil layer and ignition method for in-situ oil combustion

ActiveCN106050207AReduce moisture contentImprove ignition performanceFluid removalCombustionInjection well

The invention provides a device for injecting pulverized coal into an oil layer and an ignition method for in-situ oil combustion and belongs to the field of exploitation through in-situ oil combustion. The device for injecting the pulverized coal into the oil layer comprises an oil pipe arranged in an injection well or a production well, a pulverized coal spray-blowing system arranged on the ground and an injection pipeline, wherein the pulverized coal spray-blowing system is provided with a pulverized coal input port and a spray-blowing port, the spray-blowing port sprays out the pulverized coal, the injection pipeline is connected between the oil pipe and the spray-blowing port of the pulverized coal spray-blowing system, and the pulverized coal sprayed out of the spray-blowing port is delivered to the oil pipe. The device can improve the ignition effect for in-situ oil combustion and can also improve the development effect of the in-situ oil combustion.

Owner:PETROCHINA CO LTD

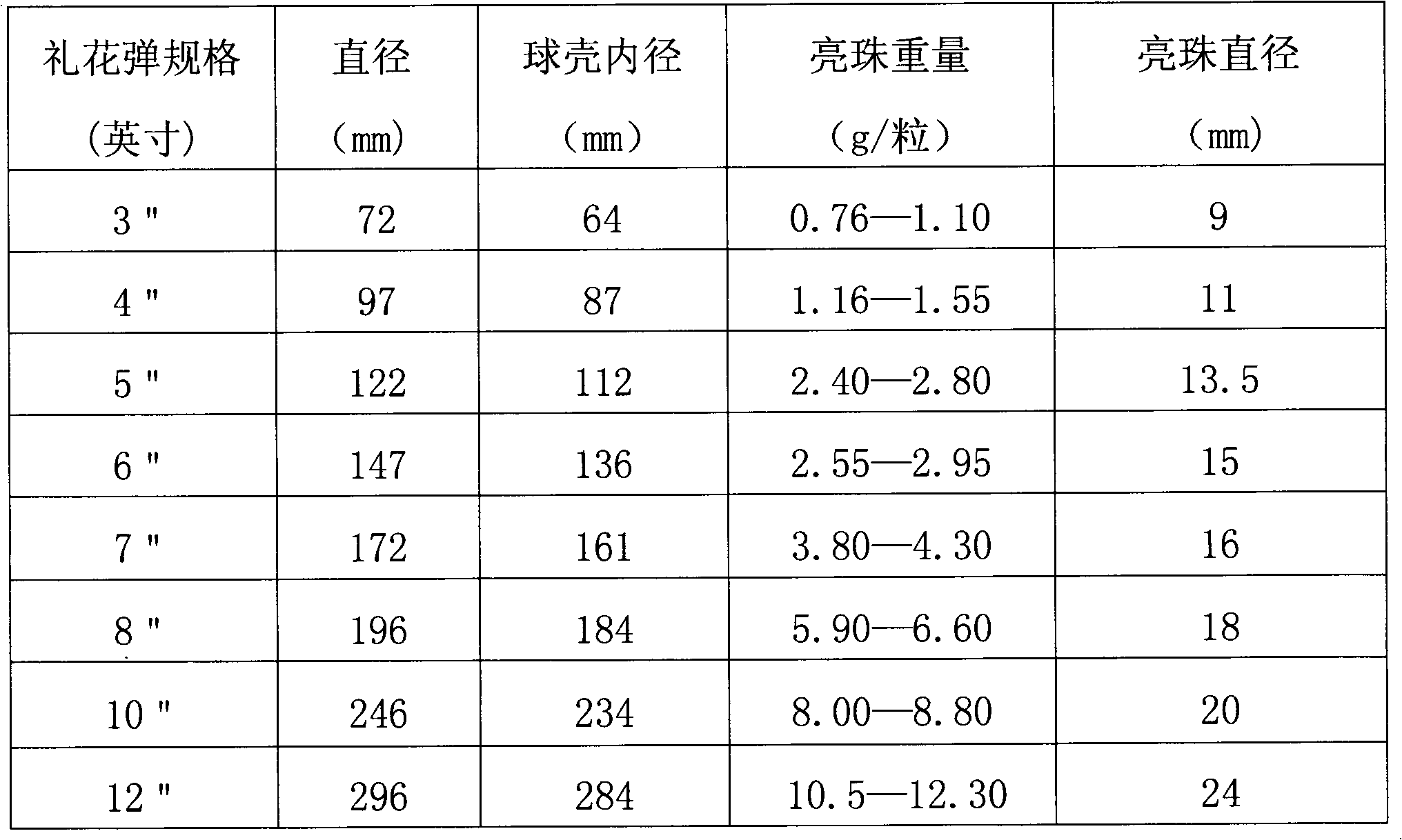

Sparkle beads producing cardamon green firework effect, and manufacturing method thereof

The invention relates to firework effect sparkle beads and a manufacturing method thereof, and specifically relates to sparkle beads producing a cardamon green firework effect, and a manufacturing method thereof. The sparkle beads comprises main components of, by weight: 50-60 parts of barium nitrate, 6-8 parts of phenolic resin, 18-22 parts of aluminum-magnesium alloy, 6-8 parts of polrvinyl chloride, 13-17 parts of potassium perchlorate, and 1-3 parts of cryolite. The manufacturing method of the sparkle beads comprises the steps of: agent weighing; raw material crushing; mixing and stirring; molding; drying; and packaging. With the sparkle beads provided by the invention, a novel firework color variety is provided. A light duration is 3.5 seconds, and a sparkle bead combustion residue rate is lower than 0.3%.

Owner:浏阳市五环烟花厂

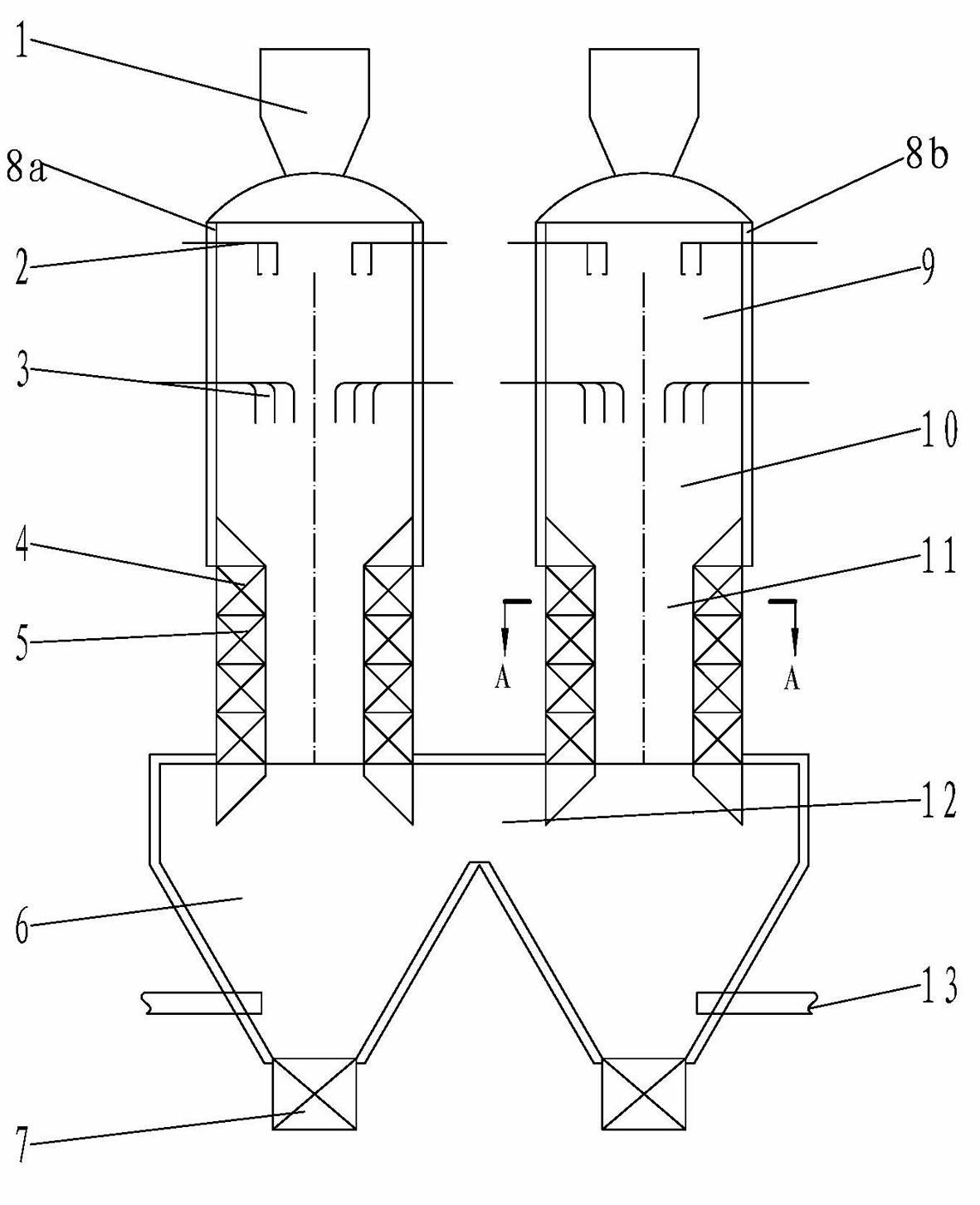

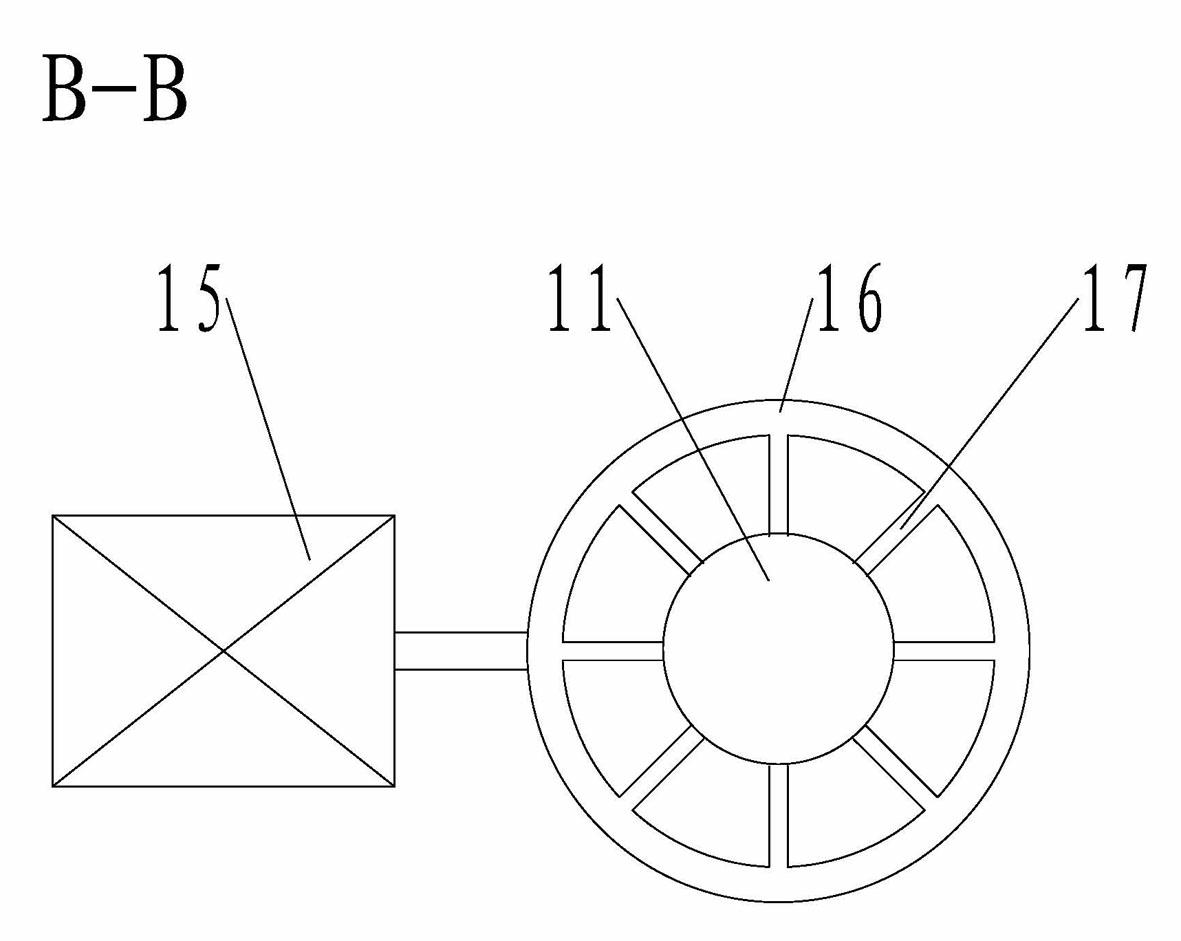

Heat accumulating type double-hearth lime kiln

InactiveCN102557492AShort stayCalcination temperature is highLime productionProcess engineeringSulfur content

The invention relates to a heat accumulating type double-hearth lime kiln. The heat accumulating type double-hearth lime kiln comprises a feeding system, a discharging system, a combustion system, an air supply system, an exhaust emission system and two kiln bodies arranged in parallel, wherein each kiln body is respectively provided with a feeding port, a preheating zone, a calcining zone, a cooling zone and a discharging port; the two kiln bodies are communicated with each other through an annular channel on the upper parts of the cooling zones; a gas collecting device is arranged on the upper part of the preheating zone; an inserting type burner is arranged on the calcining zone; a cooled air inlet is formed in the cooling zone; a high-temperature calcining zone is arranged between the calcining zone and the cooling zone; the high-temperature calcining zone is provided with a fuel gas heat accumulator or 1 to 5 rows of fuel gas heat accumulating burners and 1 to 5 rows of combustion-supporting gas heat accumulating burners; and the fuel gas heat accumulating burners and the combustion-supporting gas heat accumulating burners are arranged at intervals and annularly arranged at the periphery of the kiln wall. The high-temperature calcining zone performs calcination in a secondary combustion manner, so that sulfur content of the calcined product is reduced and the quality of the calcined product is improved. The high-temperature calcining zone adopts the heat accumulating burners and utilizes oxygen for supporting combustion, thereby facilitating the improvement on intensity of combustion and reducing the energy consumption.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

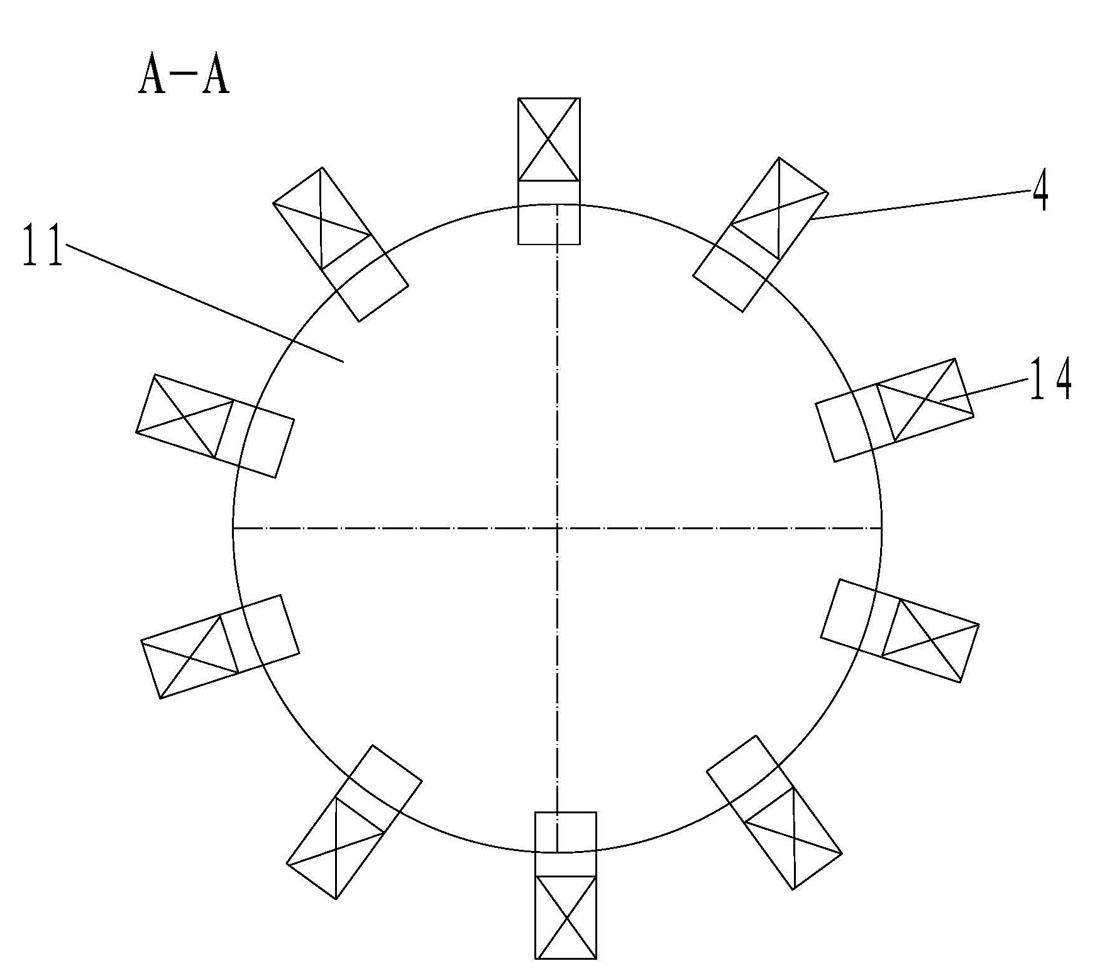

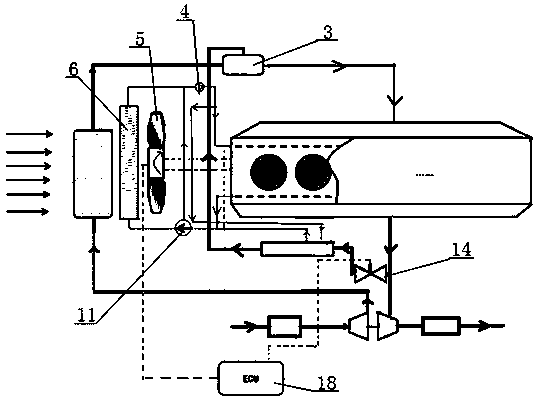

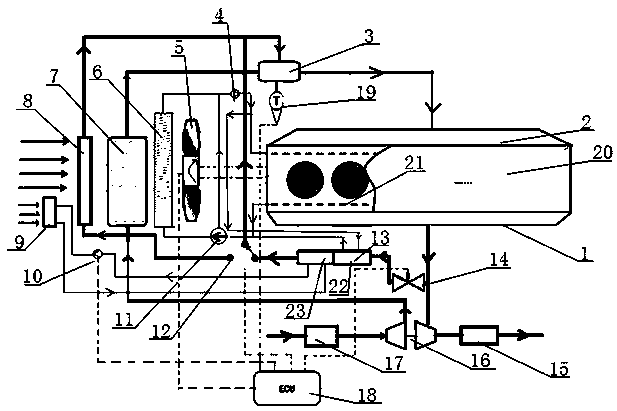

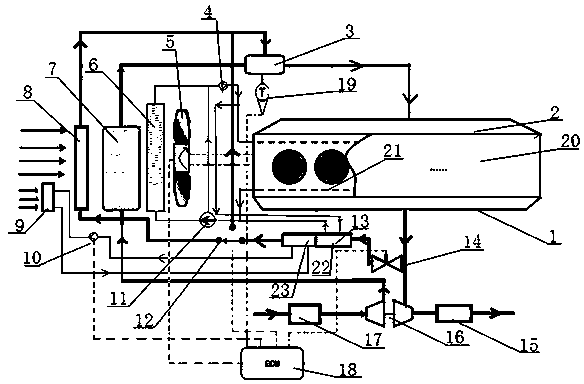

Supercharged diesel engine EGR (Exhaust Gas Recirculation) system intelligent cooling device

ActiveCN103775252AImprove dynamic response performanceSpeed up the warm-up processInternal combustion piston enginesNon-fuel substance addition to fuelExhaust fumesIntercooler

The invention discloses a supercharged diesel engine EGR (Exhaust Gas Recirculation) system intelligent cooling device, comprising an EGR mixer (3), a mechanical water pump (4), an electric control fan (5), a radiator (6), a thermolator (11), an EGR cooler (13), an electric control EGR valve (14), an engine ECU (Electronic Control Unit) (18), a temperature sensor (19), an exhaust gas intercooler (8) and an electric control two-position three-way valve (12), wherein an inlet of the electric control two-position three-way valve (12) is communicated with a gas outlet of the EGR cooler (13); outlets in two ends of the electric control two-position three-way valve (12) are respectively communicated with an exhaust gas inlet of the EGR mixer (3) and a gas inlet of the exhaust gas intercooler (8); a gas outlet of the exhaust gas intercooler (8) is communicated with the exhaust gas inlet of the EGR mixer (3); the electric control EGR valve (14), the electric control fan (5), the temperature sensor (19) and the electric control two-position three-way valve (12) are respectively connected with the engine ECU (18) electrically.

Owner:DONGFENG COMML VEHICLE CO LTD

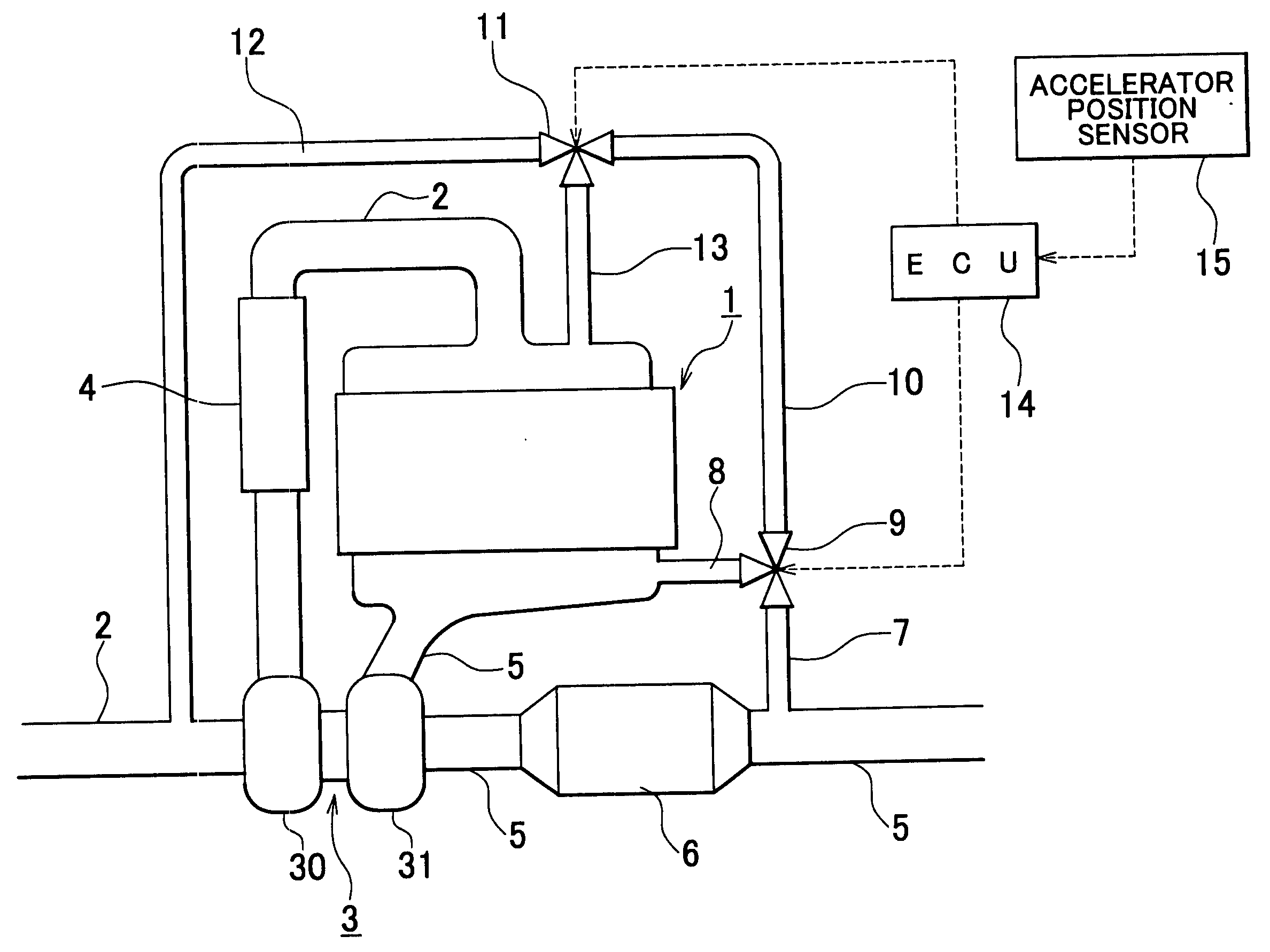

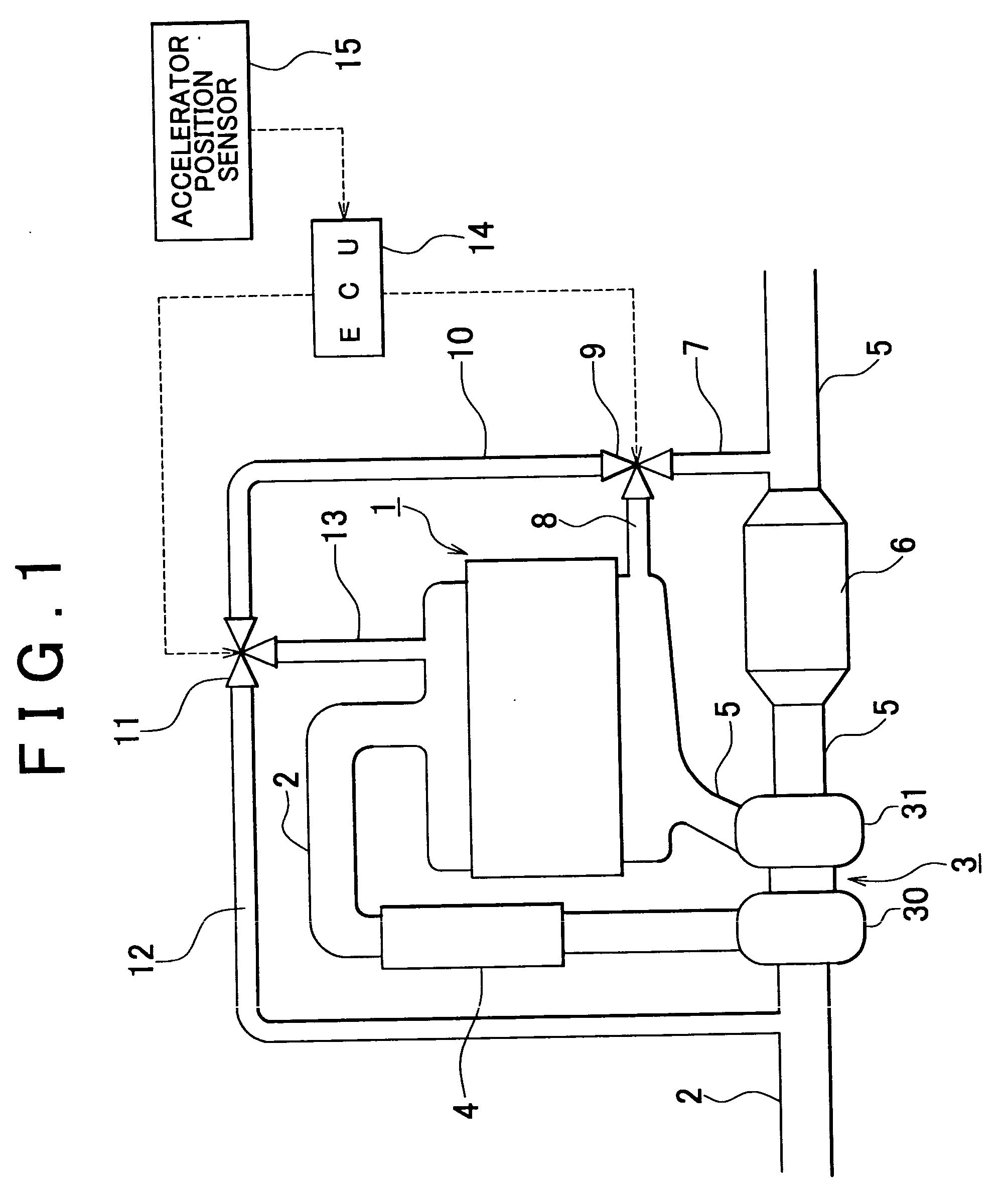

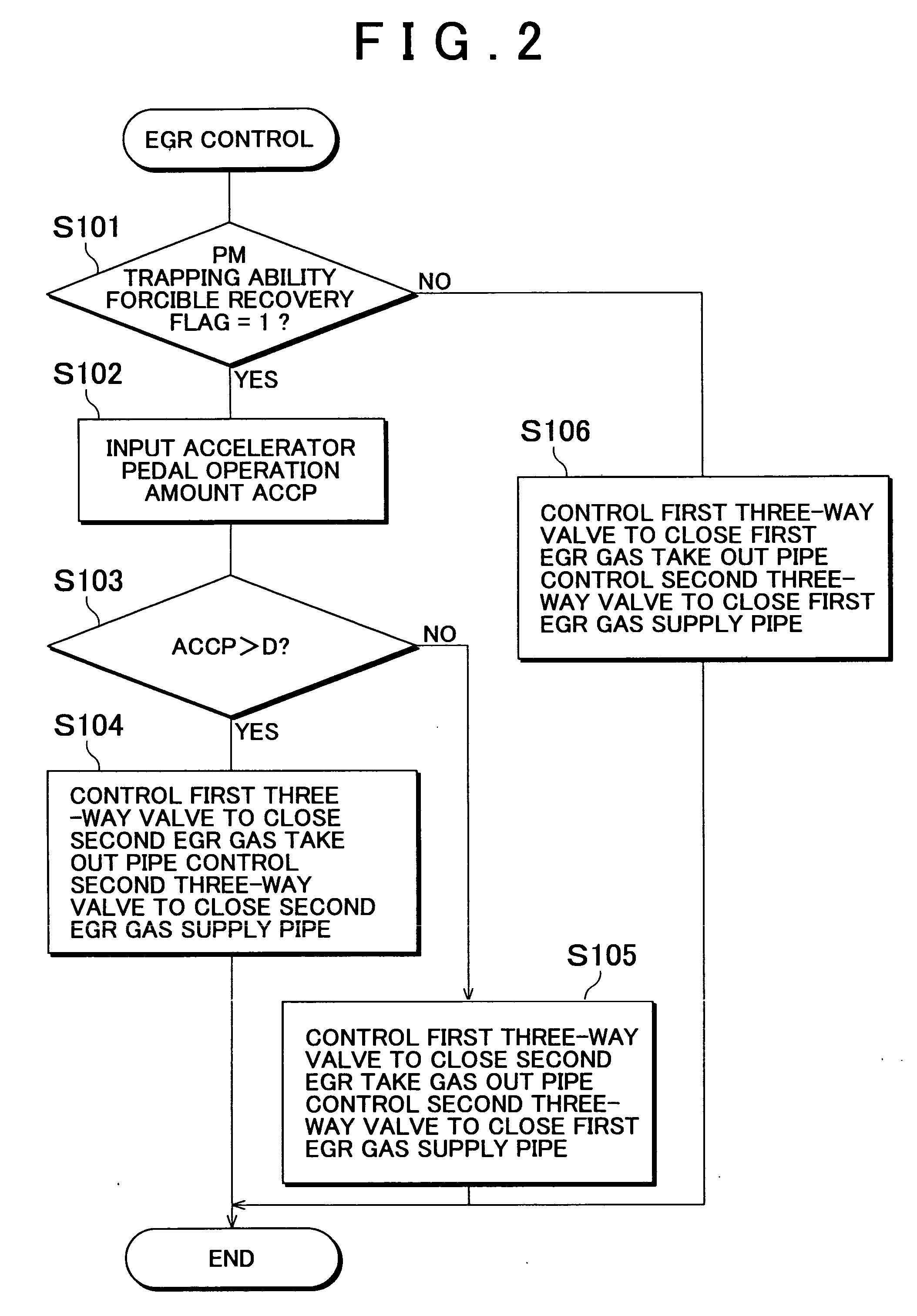

Exhaust gas control apparatus for internal combustion engine

InactiveUS20070186536A1Increase temperatureRaise the combustion temperatureElectrical controlInternal combustion piston enginesParticulatesLow load

In an exhaust gas control apparatus for an internal combustion engine, in a case where an internal combustion engine is in a high load operating state while a PM trapping ability forcible recovery process for a particulate filter is being performed, EGR gas is caused to flow back from a portion downstream of the particulate filter in an exhaust passage to a portion upstream of a compressor housing in an intake passage, whereby the EGR gas is cooled by an intercooler. In a case where the internal combustion engine is in a low load operating state while the PM trapping ability forcible recovery process is being performed, the EGR gas is caused to flow back from the portion downstream of the particulate filter in the exhaust passage to a portion downstream of the intercooler in the intake passage, whereby the EGR gas is prevented from being unnecessarily cooled.

Owner:TOYOTA JIDOSHA KK

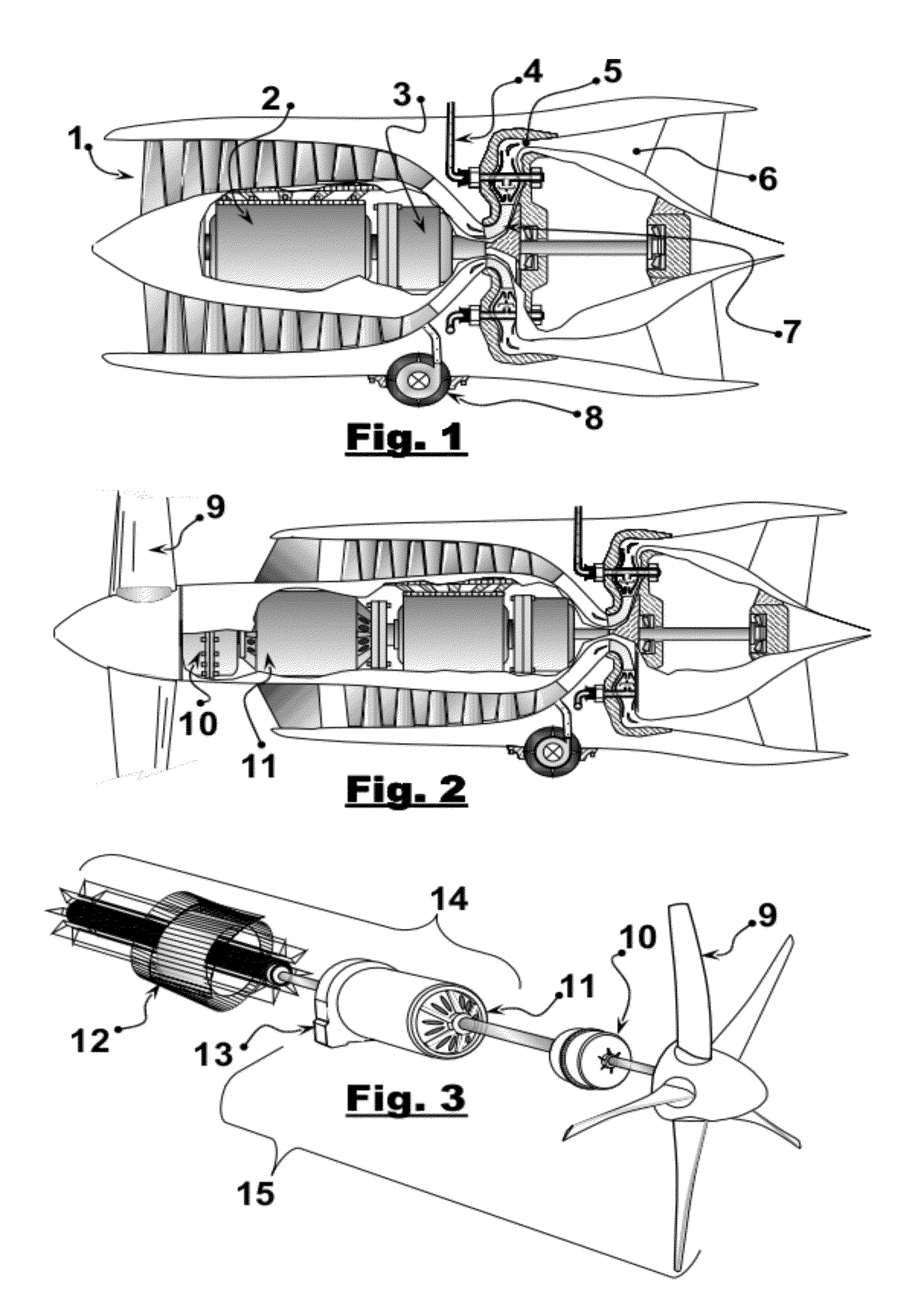

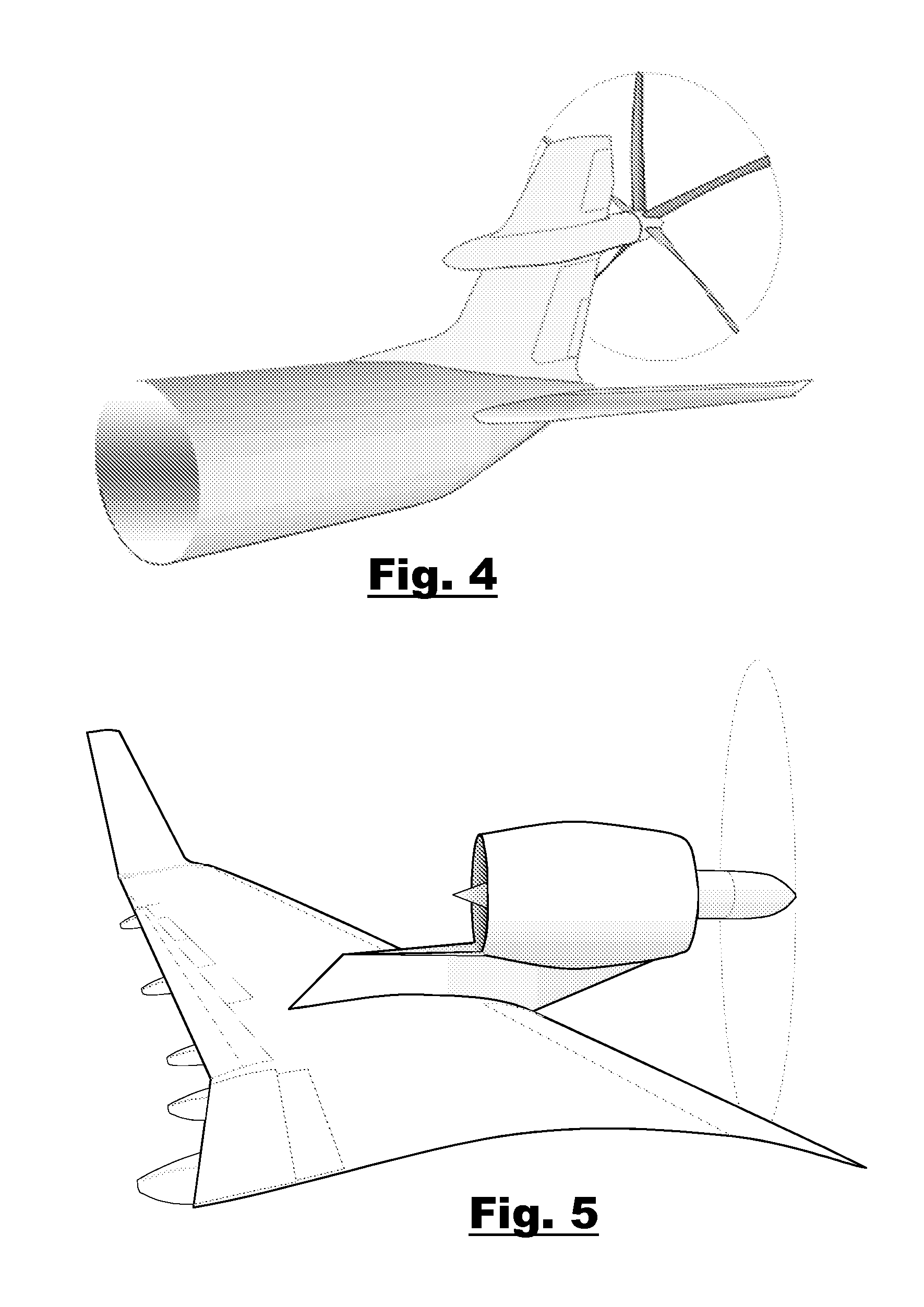

Hybrid free-air gas turbine engine

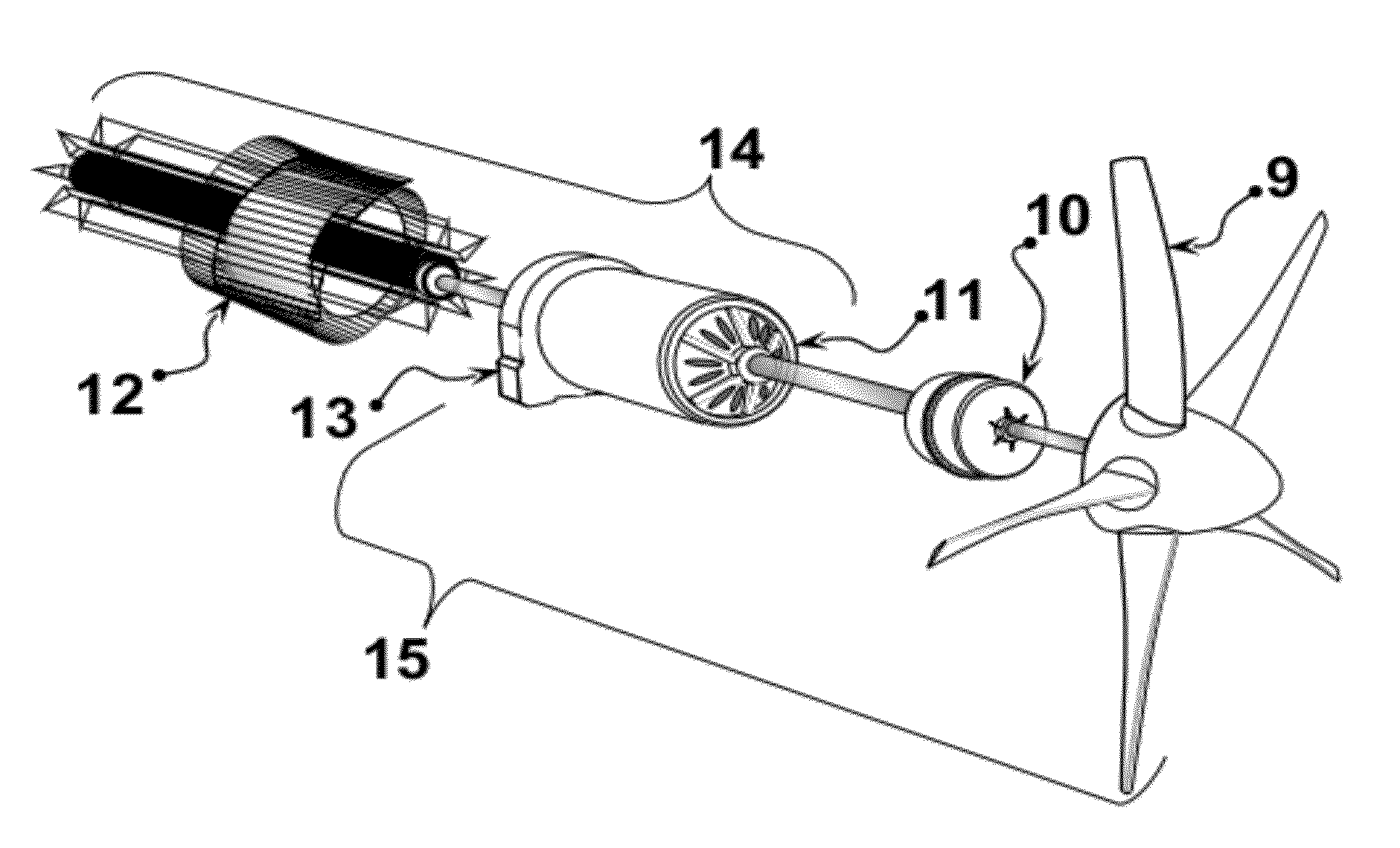

InactiveUS20120128493A1Raise the combustion temperatureIncrease valuePropellersPump componentsTurbineGas turbines

An alternate means of generating the power to drive the compressor section of gas turbine engines is described. Electric motors embedded within gas turbines would rotate the compressor, and receive the requisite power to perform the compression work from: 1) either a high-capacity APU generator, or 2) from a relative-wind driven turbine in a hybrid power-sharing arrangement. The electric motor provides enhanced control of N1 rpm, assuring greater responsiveness to control inputs.

Owner:SHELLEY RUDOLPH ALLEN

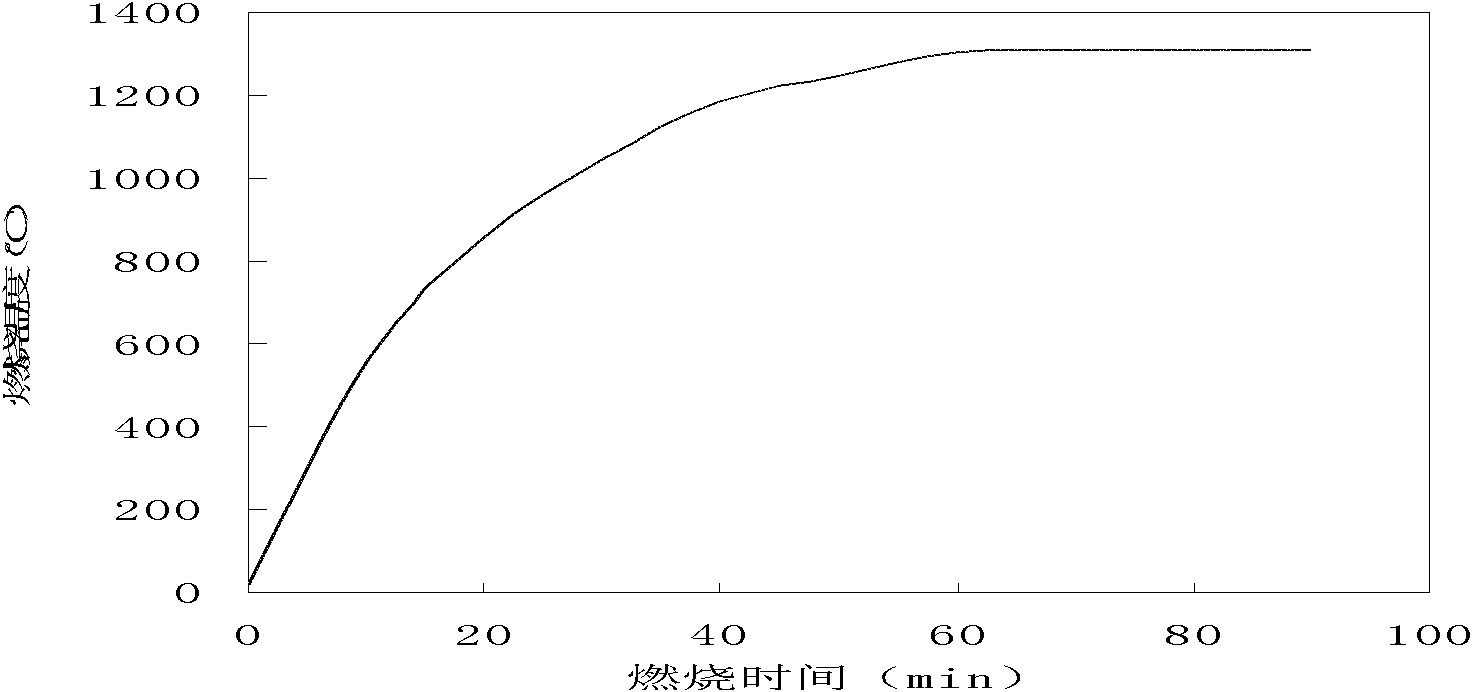

High-temperature biomass micron fuel

ActiveCN101935568ARaise the combustion temperatureEasy to control industriallyBiofuelsSolid fuelsVegetable fibersBiomass

The invention discloses a high-temperature biomass micron fuel. The high-temperature biomass micron fuel comprises 75 to 100 mass percent of vegetable fiber powder and the balance of additive, wherein the additive is at least one of coal powder, lime powder and red mud; and more than 70 percent of the vegetable fiber powder has the grain diameter of less than 250 mu m. Because the specific surface area of the biomass micron fuel is large, the biomass micron fuel can finish solid-gas conversion instantly under the action of the high temperature of a hearth and is decomposed to be combustible gases such as hydrogen (H2), carbon monoxide, methane and the like; the combustible gases combust with oxygen rapidly and vigorously; the energy is released in an explosive model; a high-temperature effect is formed; and the combustion temperature can reach over 1,300 DEG C and the fuel efficiency is over 96 percent. Compared with the traditional method, the method using the high-temperature biomass micron fuel has the advantages that the combustion temperature is increased by about one time and the combustion efficiency is increased by more than one time. The common biomass fiber material can perform fluidization transportation by a micron technique so as to form a high-grade fluid fuel near the grade of fuel oil and fuel gas. The high-temperature biomass micron fuel can be widely applied to thermal power generation, metal melting, the desalination of sea water, urban heating, lime burning, heating air conditioners, industrial heating and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

High efficiency biomass fuel and preparation method thereof

InactiveCN105238480ARaise the combustion temperatureImprove combustion efficiencyBiofuelsSolid fuelsDry weightAdhesive

The invention discloses a high efficiency biomass fuel and a preparation method thereof. The high efficiency biomass fuel comprises the following components by dry weight: 60-80 parts of agricultural and forestry waste, 5-15 parts of sludge, 25-35 parts of organosilicon waste, 1-15 parts of an adhesive, and 5-15 parts of a combustion supporting agent. The combustion supporting agent comprises the following components by weight: 80-100 parts of attapulgite clay, 10-20 parts of dolomite powder, 5-10 parts of heavy calcium carbonate powder, 1-8 parts of carbonyl diamine, 5-15 parts of potassium perchlorate, 2-8 parts of manganese oxide, 6-12 parts of potassium permanganate, and 1-8 parts of carboxymethyl cellulose. The biomass fuel has a high combustion temperature up to 1350-1400DEG C and combustion efficiency enhanced by about 32% compared to ordinary biomass fuels; the calorific value can reach 5100-5300kcal / kg, and per ton of biomass fuel is equivalent to 0.75 ton of standard coal; the combustion tail gas is accord with relevant provisions of the state, also the sulfur removal rate can reach 97.4%, and the nitrate removal rate is up to 93.2%.

Owner:DONGZHI COUNTY XINGNONG MUSHROOM PROCESSING

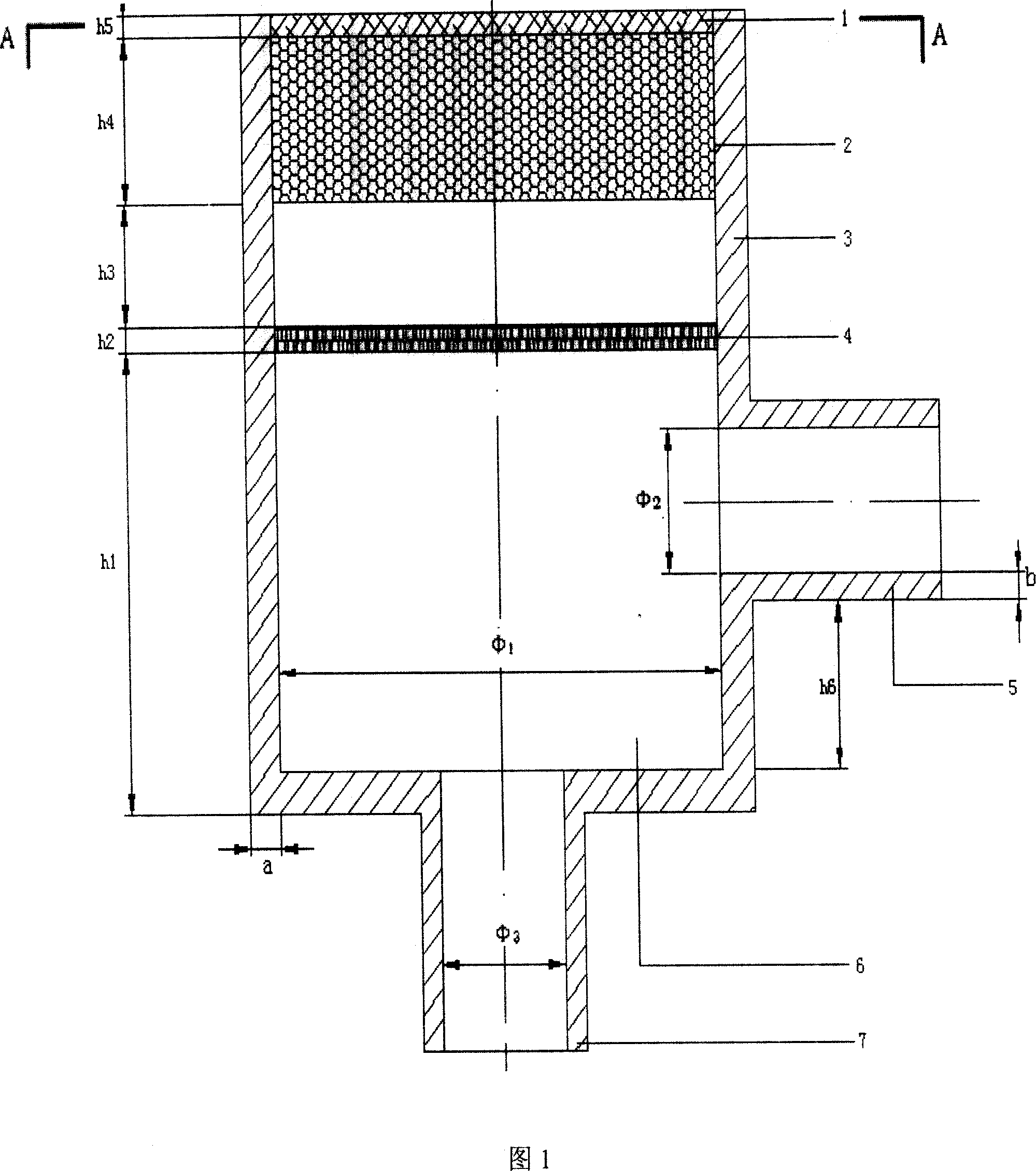

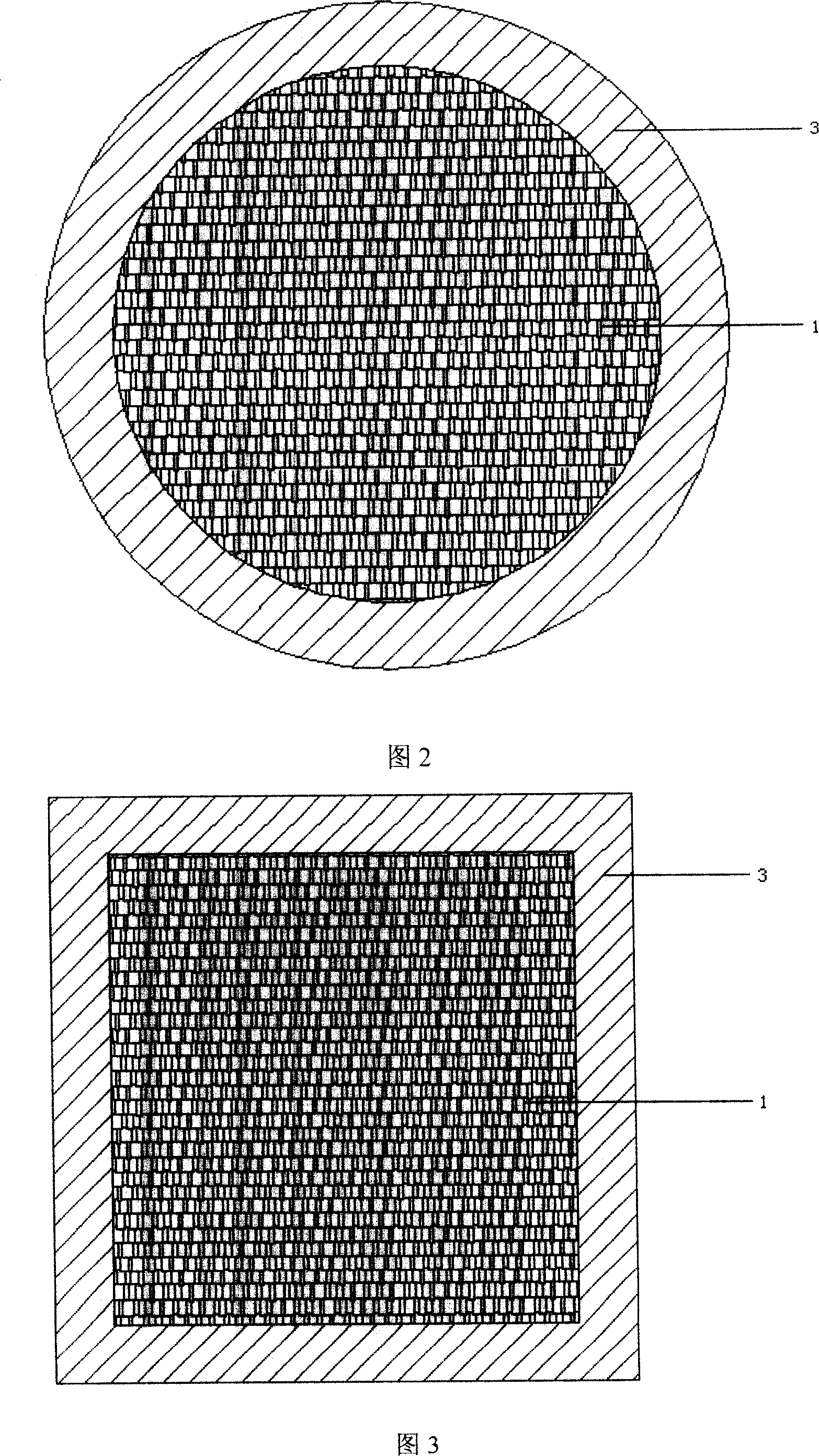

Metal fiber and porous ceramic media surface burner

InactiveCN1995814AExpand the adjustment rangeReduce sulfide contentGaseous fuel burnerMetal fiberAlloy

The invention relates to a metallic fiber and multi-hole ceramic dielectricsurface burner, belonging to heat energy engineering technology area. The burner comprises burner shell, gas pipeline and air pipeline. In the empty cavity constituted by the burner shell, metallic fiber medium in combustion zone and ceramic medium in preheat zone are set from upper to lower in turn and two medium are tightened together. The material of metallic fiber medium in combustion zone is made of Fe-Cr-Al alloy and the material of ceramic medium in preheat zone is made of zirconia or silicon carbide. Compared with ordinary surface burner, the invention can prevent tempering effectively, improve the adjustable range of fuel and air and improve burning temperature in certain range so as to improve thermal efficiency. The burner in invention can burn natural gas, liquefied petroleum gas and mixed gas so on, also burn air fuel with low thermal value which is approached to 1000kcal / m3.

Owner:NORTHEASTERN UNIV

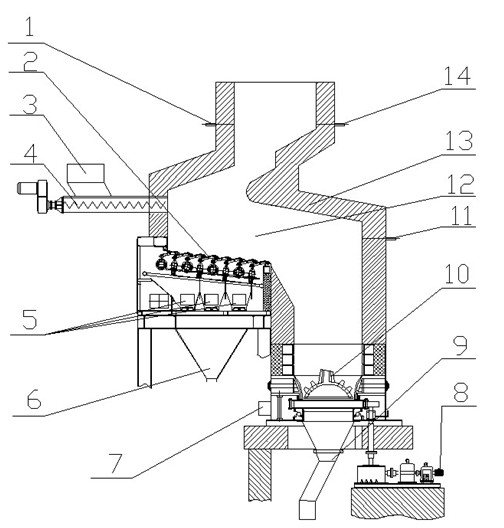

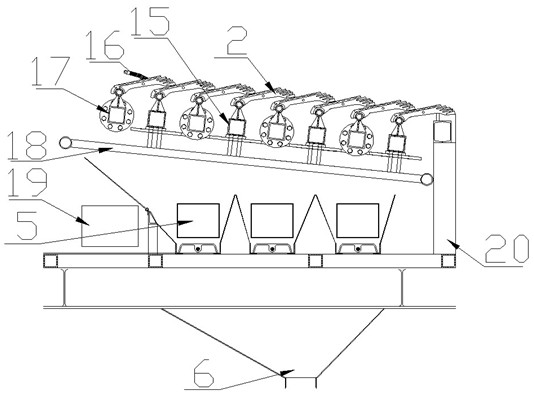

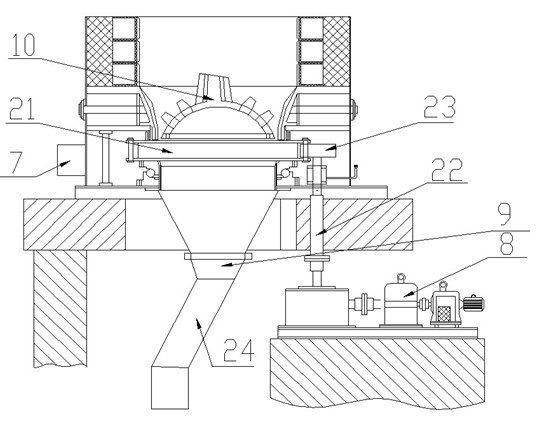

Novel high-efficiency vaporizing combustion compound furnace grate device with slag disintegrating function

ActiveCN102588950APromote precipitationAchieve emissionsChemical industryRevolving grateSlagEngineering

The invention discloses a novel high-efficiency vaporizing combustion compound furnace grate device with a slag disintegrating function. The traditional incinerator has the disadvantages of lower heat efficiency and high repairing and maintenance cost of a furnace grate due to poor fuel mixture and insufficient combustion. The novel high-efficiency vaporizing combustion compound furnace grate device with the slag disintegrating function adopts a two-section compound structure, wherein on the front section of a reciprocating type furnace grate, wastes are dried, vaporized and partially burned; and the unburned parts fall on a back-end rotary furnace grate device to be extruded, crushed and fully mixed to be burned completely. The reciprocating type furnace grate adopts a multi-air-port segmental air distribution way for reasonable air distribution; the heat radiation on the furnace grate is increased due to a long back arch, thereby facilitating the firing of wastes with low heat values. The novel high-efficiency vaporizing combustion compound furnace grate device with the slag disintegrating function is adopted to effectively improve the disadvantages of poor mixing effect and low burn-off rate of the traditional furnace grate incineration device, and meanwhile, the area of a furnace grate bar with high temperature resistance can be reduced, and the investment is reduced.

Owner:ZHEJIANG UNIV

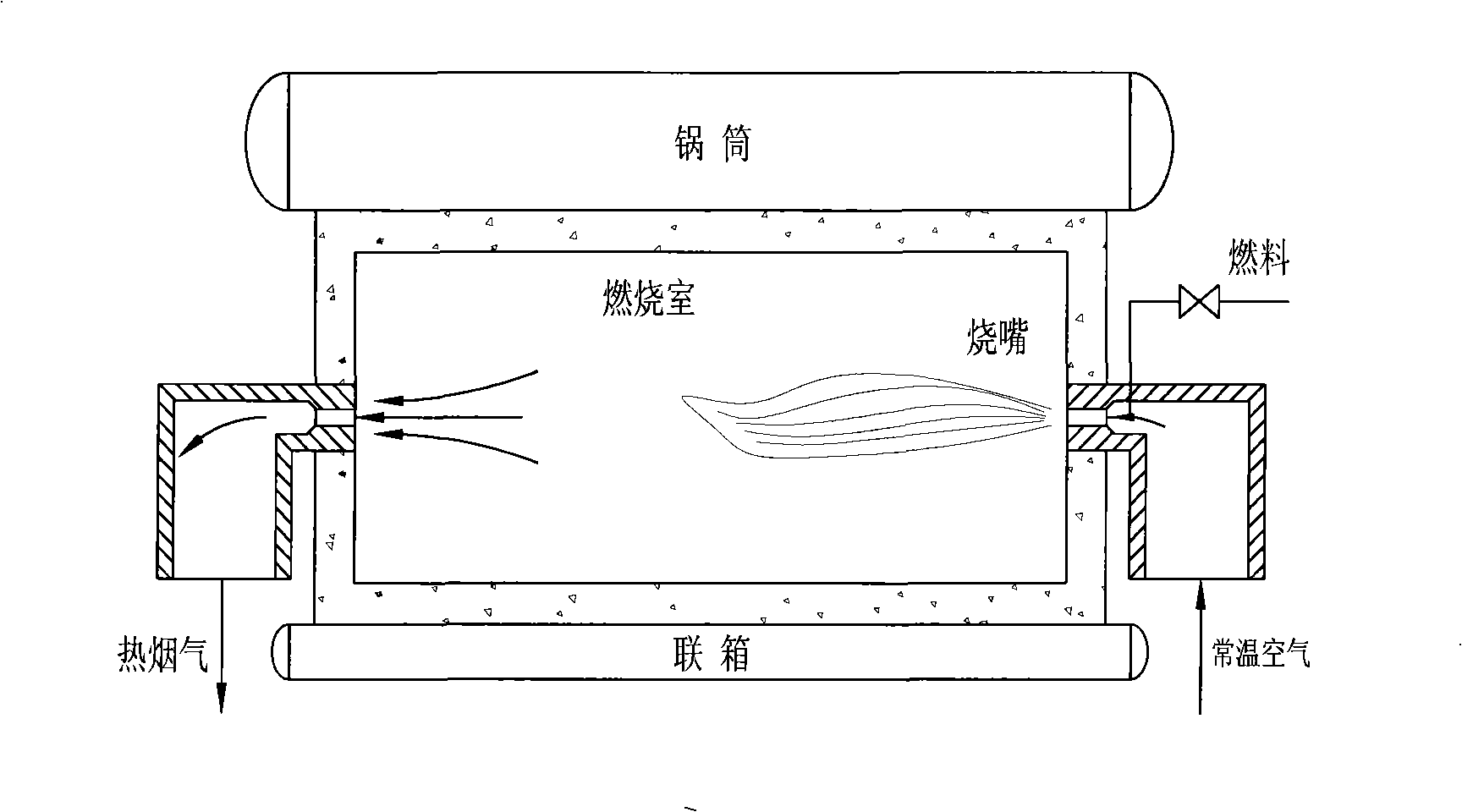

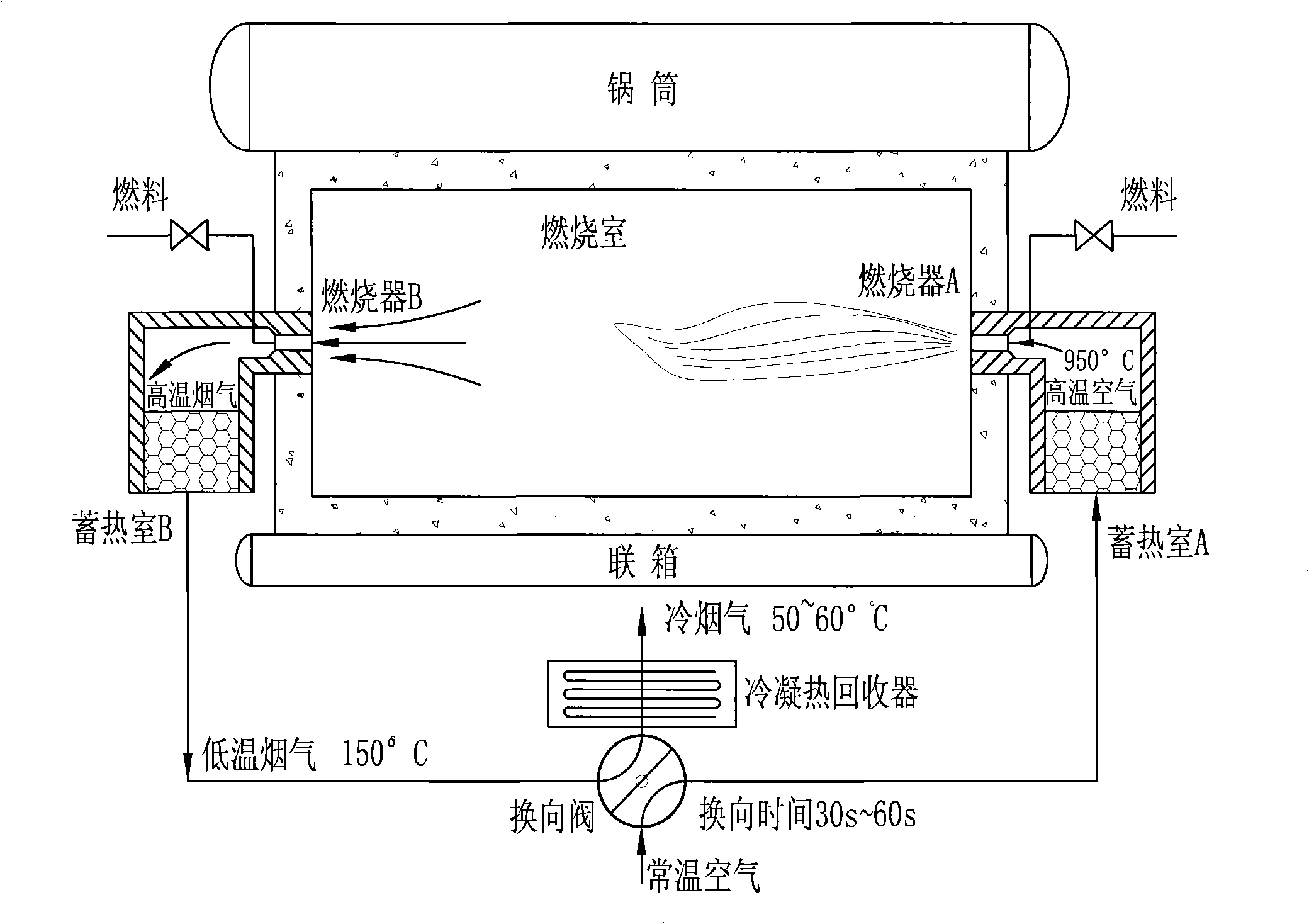

High performance fuel heat accumulation type condensation energy-saving boiler

InactiveCN101319788AReduce lossesEliminate local hot spotsCombustion processDrum steam boilersCombustorHigh energy

The invention discloses a heat accumulating type condensing and energy saving boiler for high energy fuel, which comprises a boiler body. Two or more combustors are arranged in the boiler body, a high-temperature combustion-supporting air inlet opening and a fuel spraying opening are arranged on the combustor, a checker chamber is connected with the high-temperature combustion-supporting air inlet opening, a normal temperature combustion-supporting air inlet and a low-temperature flue gas outlet are connected with the checker chamber, a direction change device is arranged between the normal temperature combustion-supporting air inlet and the low-temperature flue gas outlet, and a condensing heat recoverer is connected with the low-temperature flue gas outlet. On one hand, when the fuel gas is discharged, the waste heat of the fuel gas is recovered through the checker chamber and the condensing heat recoverer, thereby the heat energy loss is reduced, and the combustion efficiency is enhanced; on the other hand, after passing through the checker chamber, the normal temperature combustion-supporting air assists in combustion supporting, and thereby the combustion temperature can be increased; thirdly, a plurality of combustors adopts periodic reversing combustion, thereby the partial high temperature zones in the combustors are avoided, and the internal temperature distribution of the combustors is more uniform. The boiler is applied to various gas fired boilers.

Owner:SHENWU TECH GRP CO LTD

Combustion chamber for charcoal stove

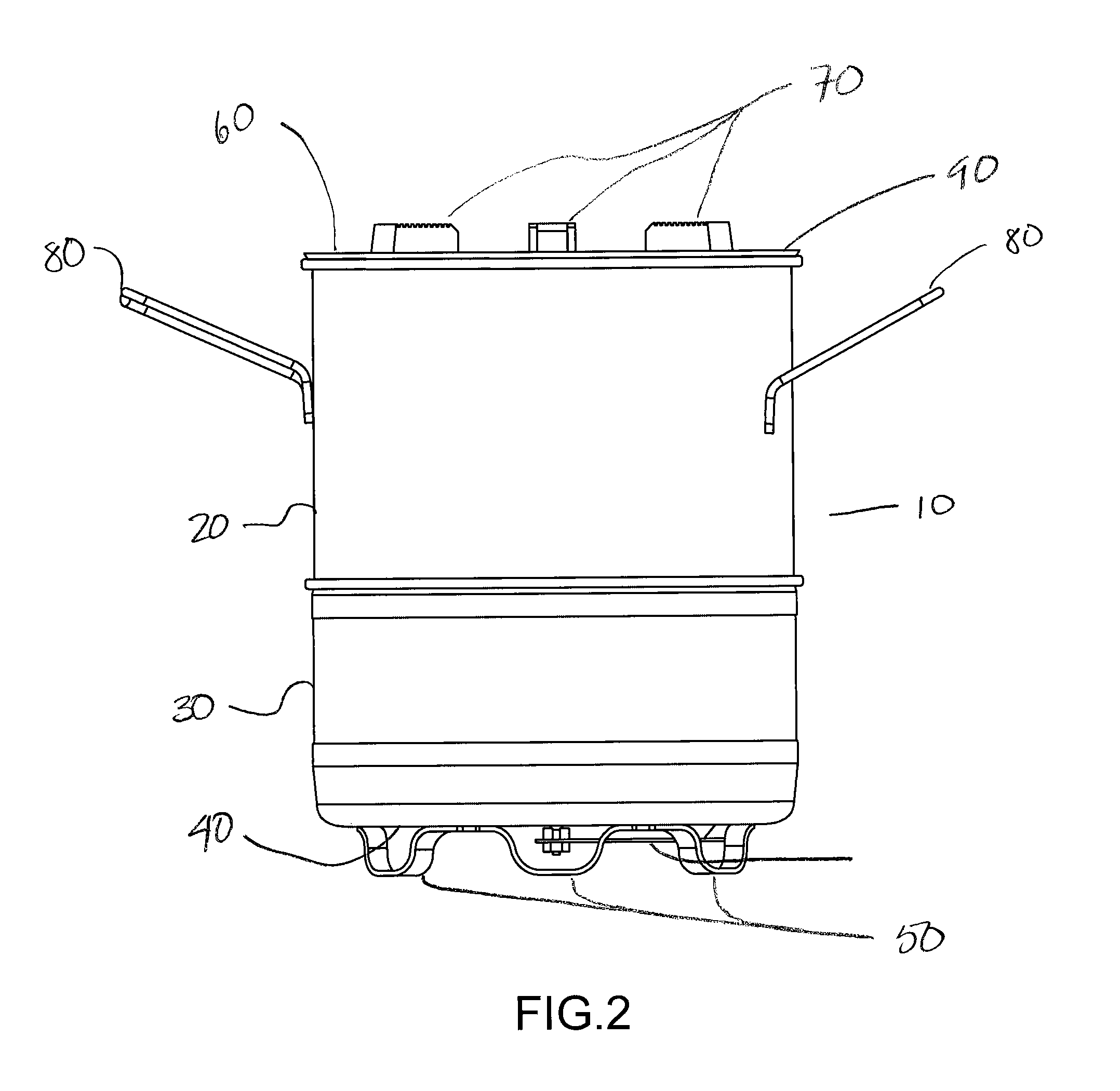

InactiveUS8893703B2Decrease the amount of at least carbon monoxideIncreased durabilityCombustion-air/flue-gas circulation for stovesDamper arrangementCombustion chamberClosed chamber

A combustion chamber may include an upper and a lower chamber. The chambers may be separable to aid in loading fuel and removing spent fuel. The cross-section of the upper combustion chamber may be less than the cross-section of the lower section. Charcoal or other biomass fuel may be added into the lower combustion chamber and may be supported by a grate. Oxygen may be fed into the combustion chamber through a plurality of apertures that may be substantially shielded from direct line of site of the fuel bed. The upper combustion chamber may further include an annular constriction, to aid in constricting the view factor between the cooking vessel and the fuel bed. The constriction may also aid in radiating energy back to the fuel bed.

Owner:COLORADO STATE UNIVERSITY

Biomass fuel and production method thereof

The invention discloses a biomass fuel and a production method thereof. The production method comprises the following steps of: harvesting eupatorium adenophorum, airing, crushing and rubbing for later use; and crushing and rubbing straw, mixing 100 to 120 parts of eupatorium adenophorum, 80 to 160 parts of straw and 5 to 25 parts of combustion improver, pressing, and densifying to form eupatorium adenophorum blocks, wherein the straw is one or more of corn straw, rice straw, wheat straw, peanut straw, rape straw, cured tobacco straw, sawdust, leaves, barks, edible fungus residue and traditional Chinese medicine decoction dreg. The biomass fuel saves energy, protects environment, and has low cost and high heat value.

Owner:贵州安顺惠烽科技发展有限公司

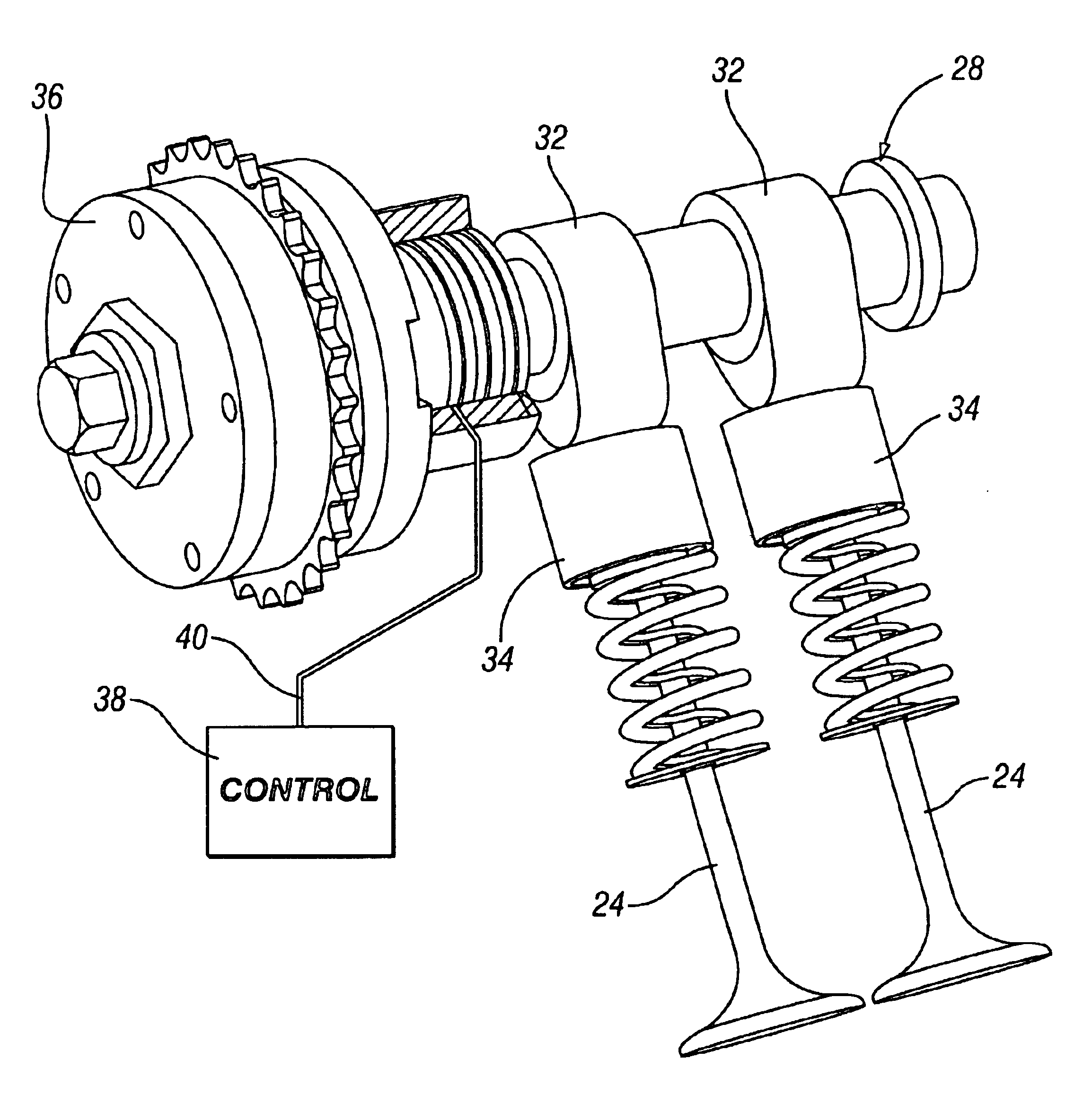

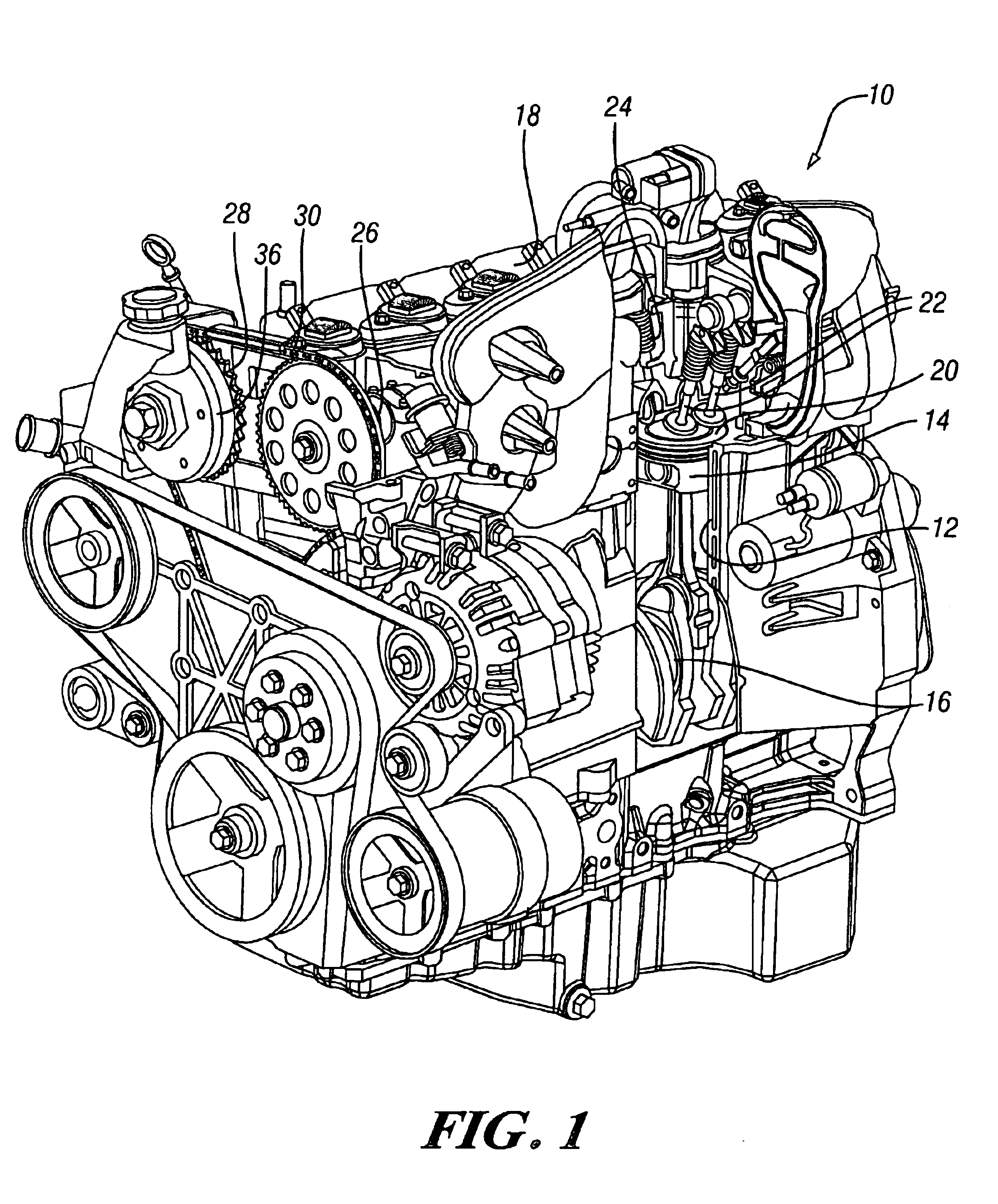

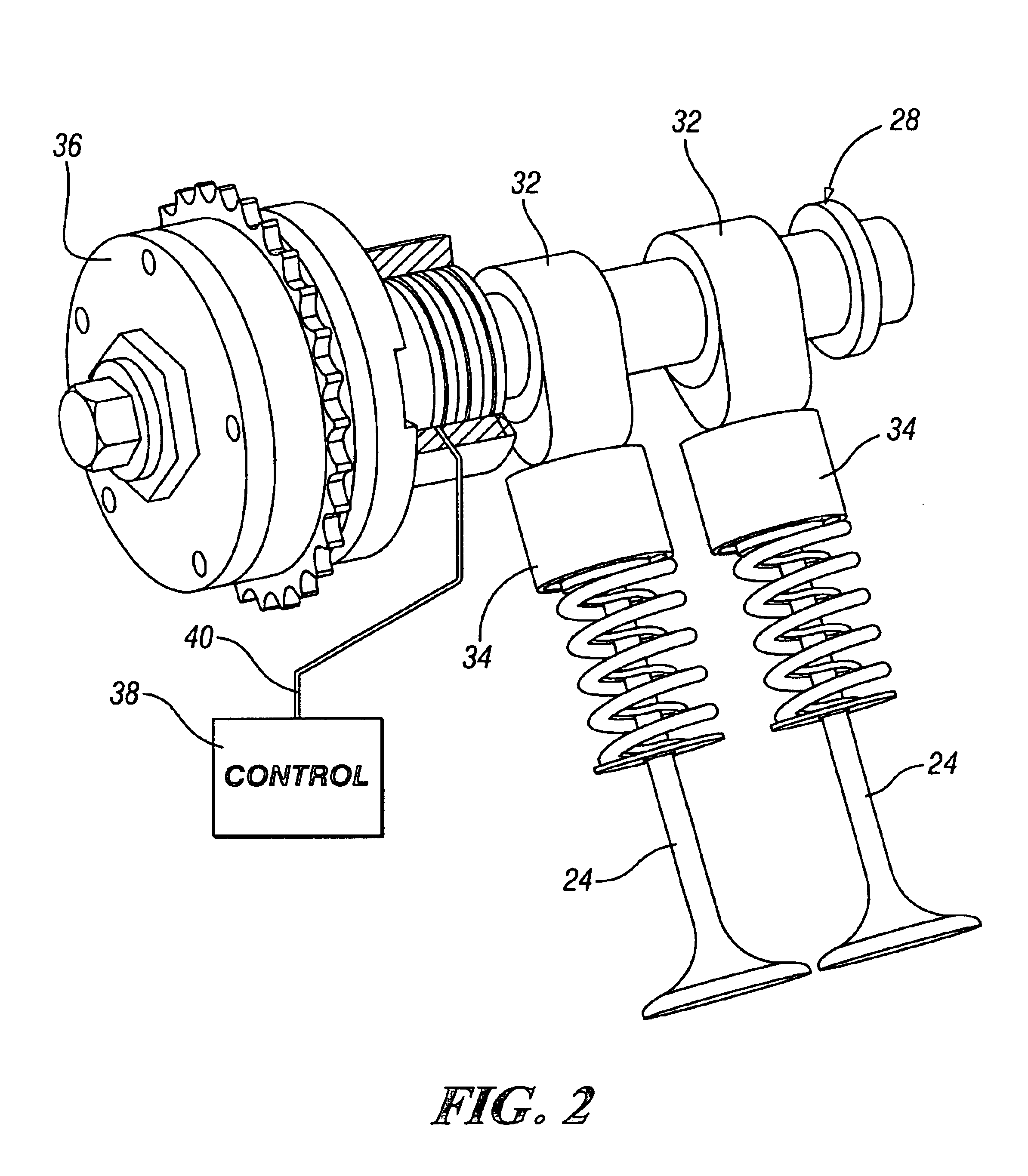

Diesel engine with cam phasers for in-cylinder temperature control

InactiveUS6918384B2Increase temperatureIncrease trapped hot residualValve arrangementsElectrical controlTemperature controlExhaust valve

Owner:GM GLOBAL TECH OPERATIONS LLC

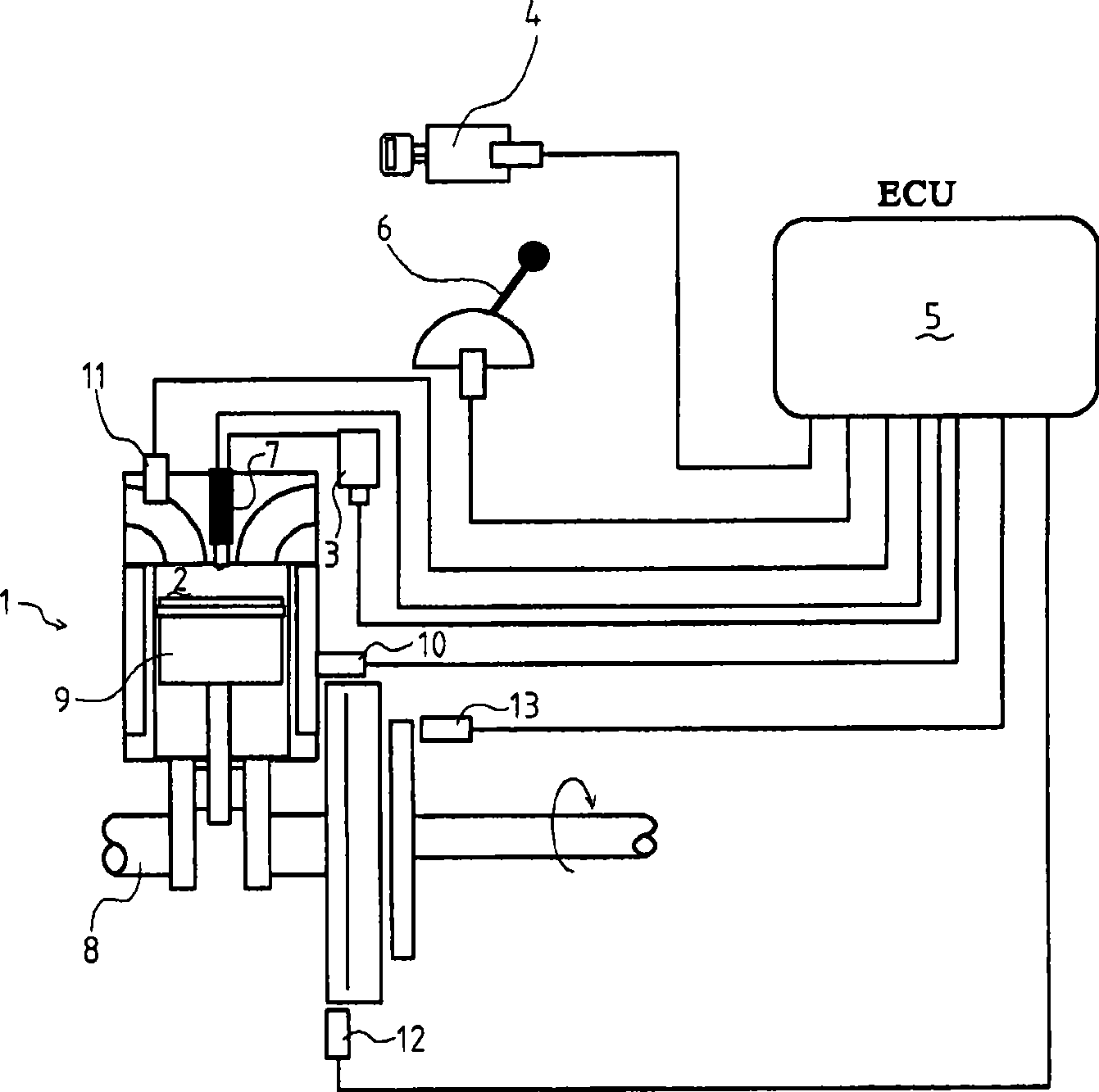

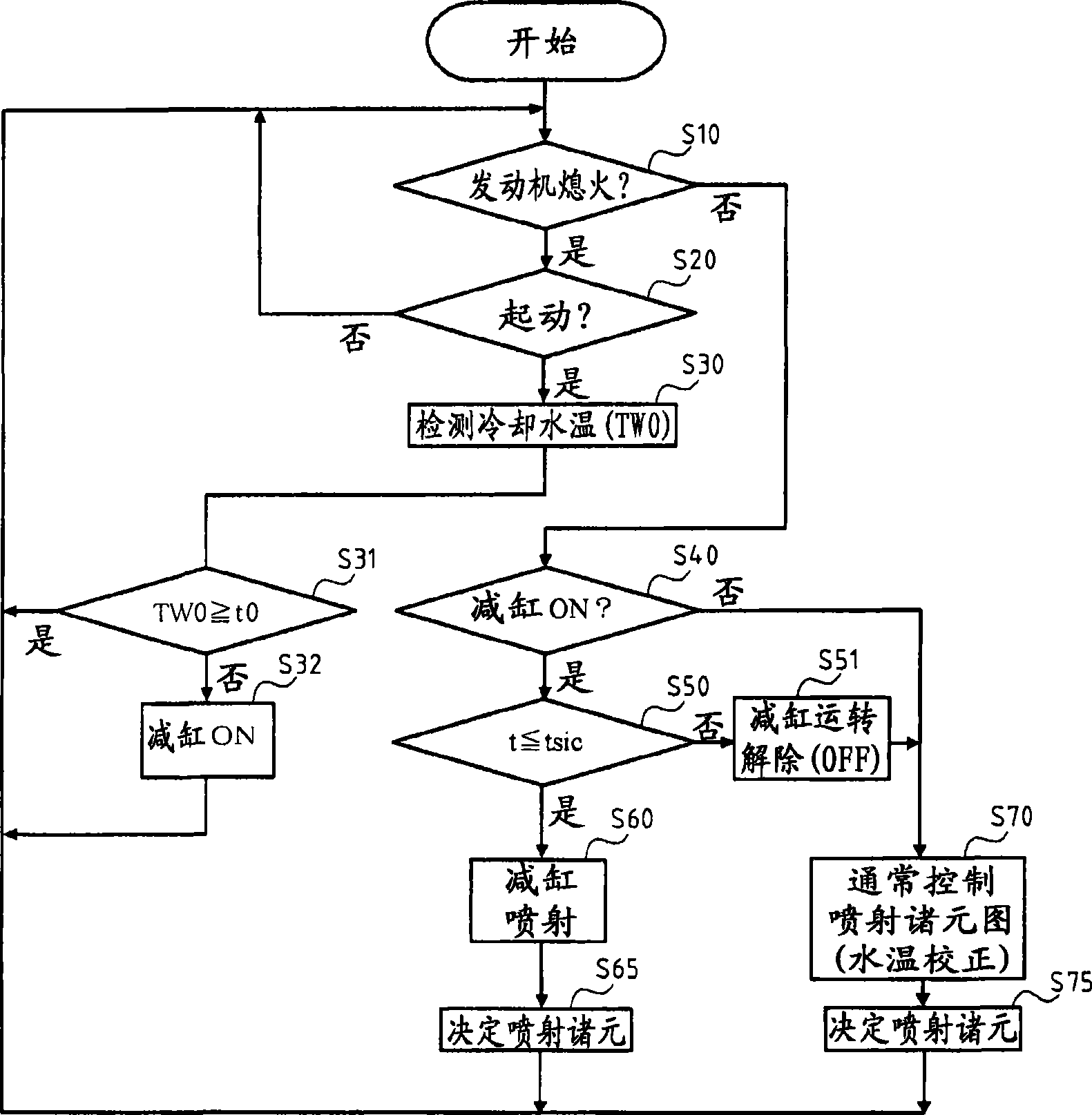

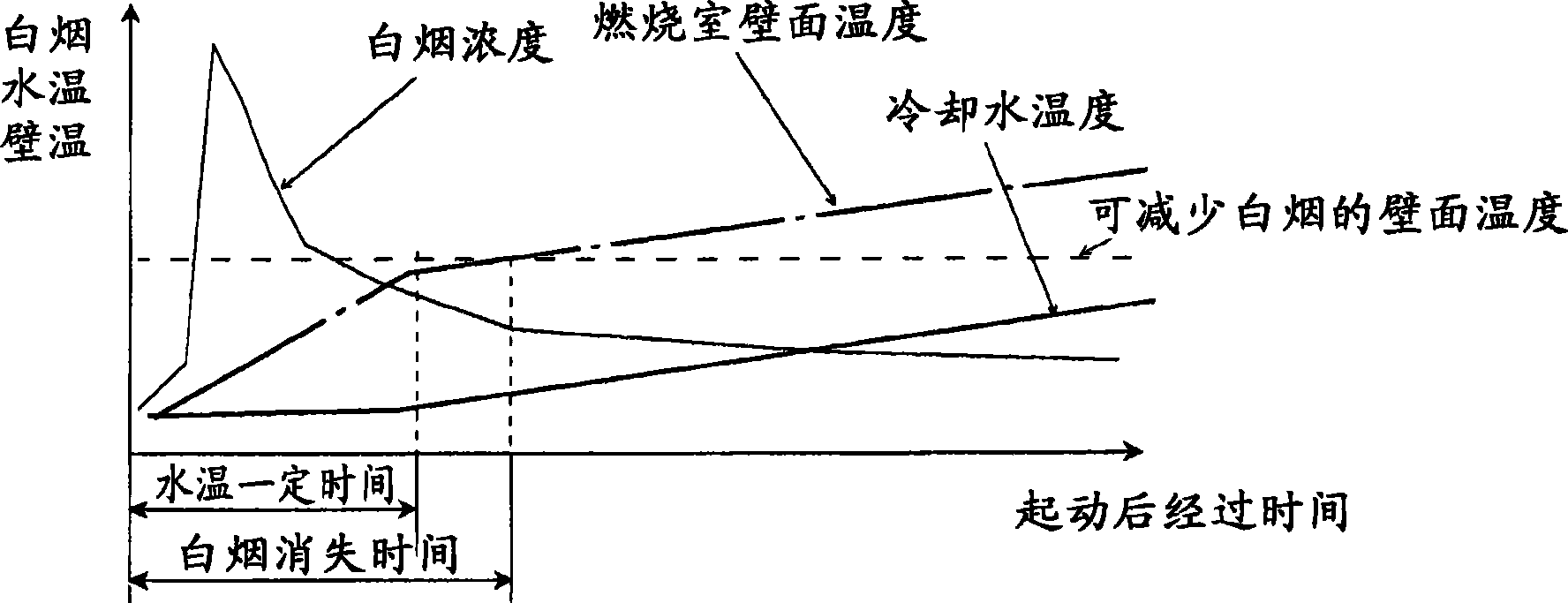

Method of controlling internal combustion engine

InactiveCN101535614ALarge injection volumeRaise the combustion temperatureElectrical controlInternal combustion piston enginesTime lagExternal combustion engine

A method of controlling an internal combustion engine, in which engine operation with a reduced number of cylinders is controlled according to an idling speed after starting the engine to thereby minimize discharge of white smoke during a time lag for temperature equilibrium immediately after a cold start. The method uses a coolant temperature detection means (10) for detecting the temperature of the coolant of the internal combustion engine (1), an engine speed detection means (12) for detecting the speed of the engine, and control means (5) for controlling operation of the engine according to the temperature of the coolant and the engine speed. When the engine is determined to be in a cold start, engine operation with a reduced number of cylinders is started, and in this engine operation, fuel is injected into the cylinders for a predetermined time period after the speed of the engine reaches a predetermined level after the start of the engine.

Owner:YANMAR POWER TECHNOLOGY CO LTD

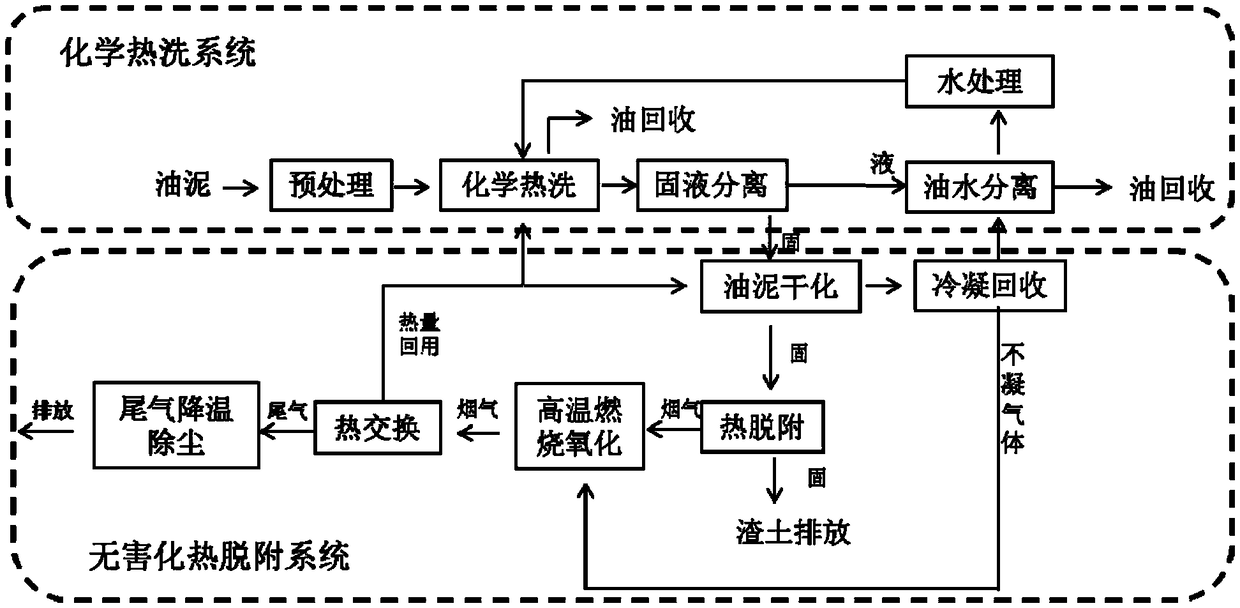

Green cleaning-thermal desorption integrated technology treatment method and treatment system for high-concentration petroleum sludge

ActiveCN108996859ALayering efficiency is fastHigh recovery rateSludge treatment by de-watering/drying/thickeningFatty/oily/floating substances removal devicesHigh concentrationWater storage tank

The invention discloses a green cleaning-thermal desorption integrated technology treatment method and treatment system for high-concentration petroleum sludge. The treatment method includes the treatment steps of homogeneous impurity removal pretreatment, chemical thermal washing treatment, solid-liquid separation and oil-water separation, oil sludge thermal desorption and high temperature combustion oxidation, heat exchange and tail gas cooling and dust removal. The treatment system includes an oil sludge chemical thermal washing system and an oil sludge harmless thermal desorption system. The oil sludge chemical thermal washing system is formed by connecting an oil sludge homogenization slot, an oil sludge chemical thermal washing tank, a high efficiency solid-liquid separator, an oil-water separator, a sewage integrated treatment system and a water storage tank successively. The oil sludge harmless thermal desorption system mainly consists of a sludge dryer, a condensation recoverysystem, a thermal desorption feeding system, a thermal desorption system, a high temperature combustion oxidation system, a waste heat boiler and a discharging system. With adopting of the combined application of the chemical thermal washing technology and the thermal desorption technology, multiple functions such as resource recovery and utilization of petroleum materials and heat, reduction ofoily sludge, harmlessness and the like can be simultaneously realized.

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

Hybrid nozzle guide vane made of ceramic matrix composite materials

ActiveCN103061827AIncrease the allowable temperatureIncrease thrustStatorsMachines/enginesHybrid typeWorking life

A hybrid nozzle guide vane made of ceramic matrix composite materials comprises a vane-shaped part (2) and a core part (5), the core part (5) is mounted inside the vane-shaped part (2) which is made of fiber reinforced ceramic matrix composite materials, an outer surface (3) of the vane-shaped part is a cubic spline curved surface in shape so as to determine aerodynamic shape of the vane, and an inner surface (4) of the vane-shaped part is also a cubic spline curved surface in shape so that an internal area is determined. The core part (5) is made of metal materials totally different from those of the vane-shaped part (2), the exterior shape of the core part (5) is corresponding to the interior shape of the vane-shaped part (2), a plurality of cooling flow channels (6) are arranged on the core part, heat on a vane body (1) is dissipated by feeding cooling air flow (7), and the cooling air flow (7) flows through the cooling flow channels (6) to flow out of a vane trailing edge (11) finally. Compared with a high-temperature alloy vane, the vane has the advantages that available working temperature is increased, structural weight is reduced, working life is prolonged, and the vane has good application prospect.

Owner:BEIHANG UNIV

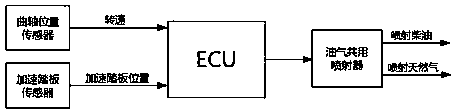

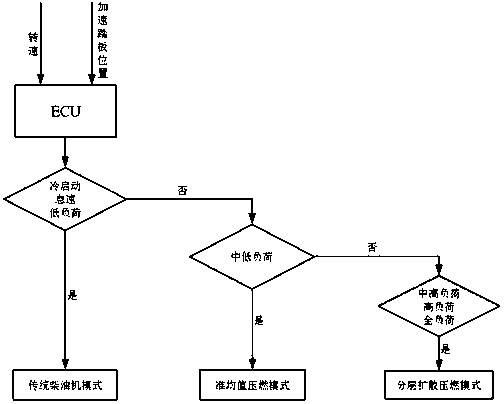

Diesel oil/natural gas dual-fuel engine emission control strategy

InactiveCN108561233AAvoid poor coolingExpand the range of working conditionsElectrical controlFuel injection apparatusOil and natural gasProcess engineering

The invention relates to a diesel oil / natural gas dual-fuel engine emission control strategy which is characterized by comprising the following specific steps: S1, sensing the crankshaft position andjudging load; and S2, controlling an oil gas shared ejector. Ejection of diesel oil and natural gas can be controlled in real time through the oil gas shared ejector and a dual-fuel ECU to adjust concentration distribution and characteristic distribution of fuel in an oil cylinder in real time; and aiming at different working conditions and the combustion characteristics of fuel, and by combiningthe flexible ejection strategy and proper EGR, the mixing characteristic and the ignition characteristic of the interior of the cylinder can be effectively controlled to optimize cylinder interior combustion and reduce emission of NOX, PM, HC and CO at the same time.

Owner:JIANGSU UNIV OF SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com