Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Reduce sulfide content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

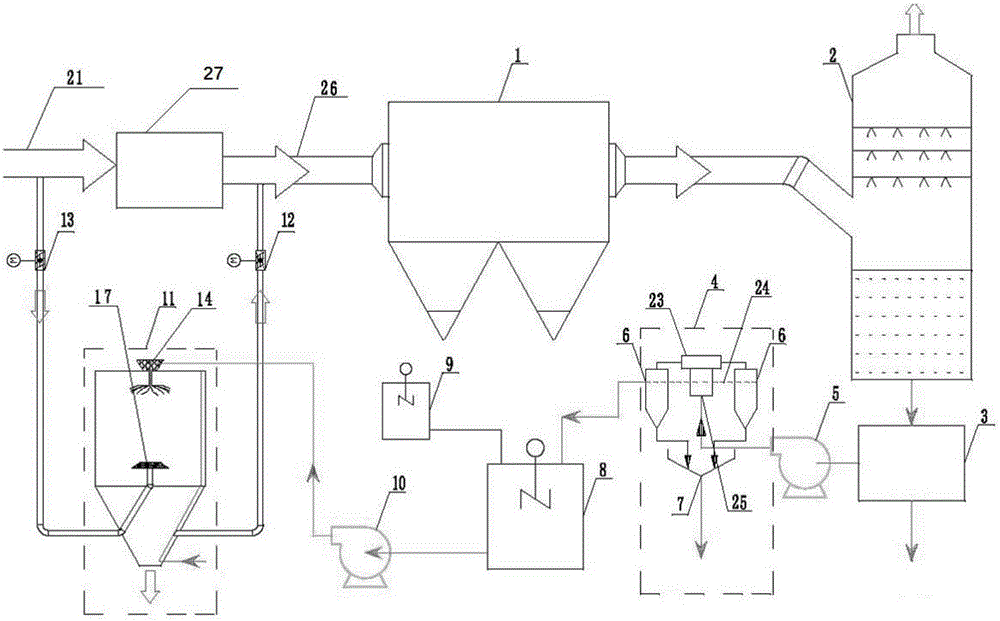

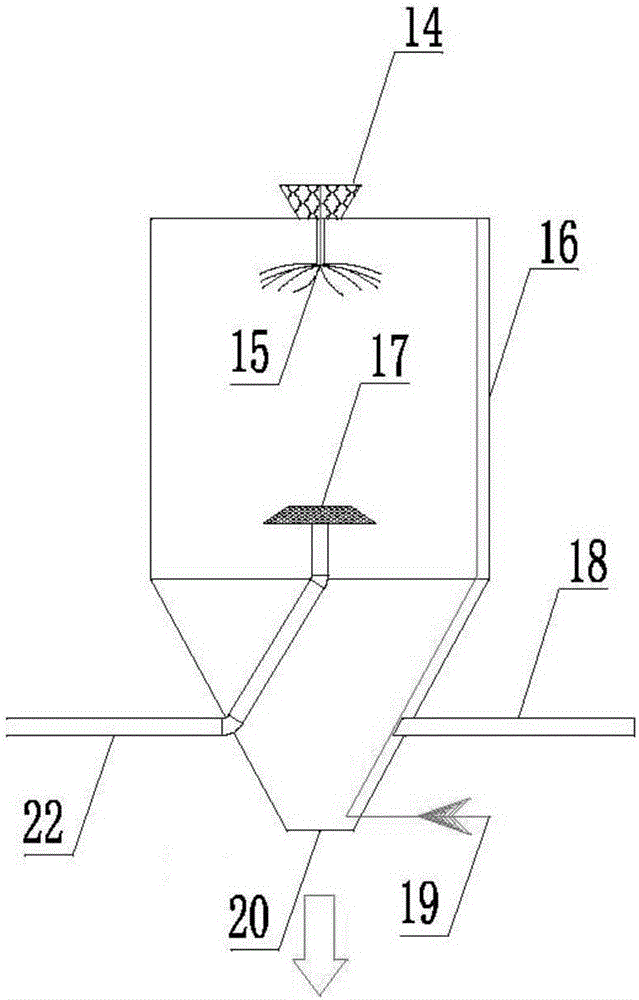

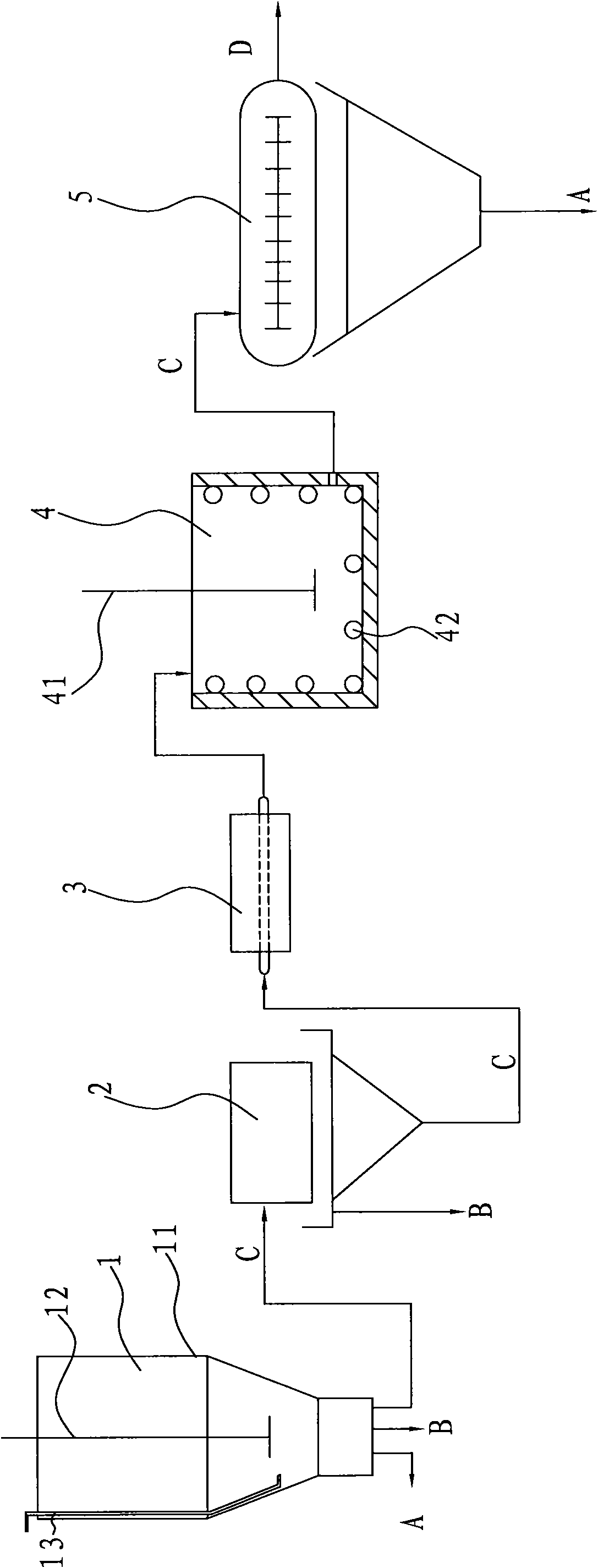

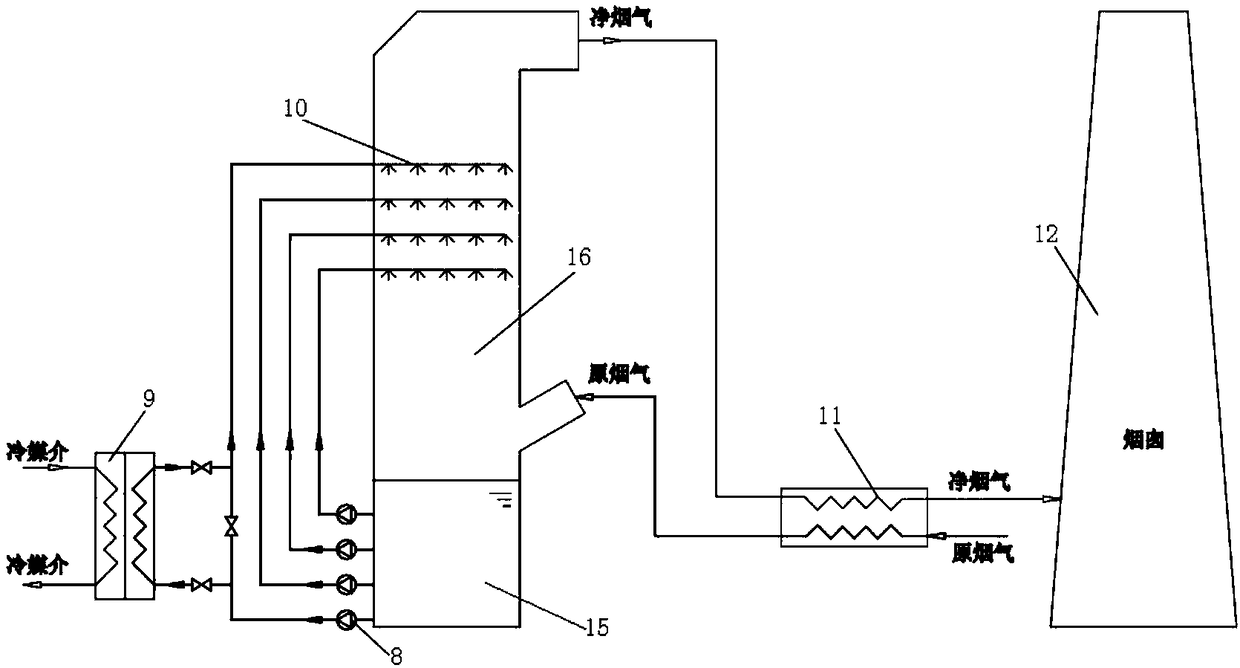

Zero-release coupling humidifying dust-removing synergizing system and method for desulfurization wastewater

PendingCN106630358AAvoid poor evaporationImprove dust removal efficiencyWater/sewage treatment by centrifugal separationElectrostatic separationAir preheaterCyclone

The invention relates to a zero-release coupling humidifying dust-removing synergizing system and a zero-release coupling humidifying dust-removing synergizing method for desulfurization wastewater. The zero-release coupling humidifying dust-removing synergizing system comprises a desulfurizing tower, a gypsum dewatering system, a wastewater cyclone, a wastewater box, a rotary spraying and evaporating tower and a dust remover, wherein wastewater treated through the gypsum dewatering system is treated through the wastewater cyclone; afterwards, one part underflows to the desulfurizing tower to be repeatedly utilized; one part overflows to a wastewater box to be collected; the wastewater is conveyed to a rotary sprayer to be atomized; an atomized fog drop descends, is regressively in contact with a high-temperature fume which is introduced from the front of an air pre-heater; a solid particle in the evaporated wastewater and the fume integrally descend to the lower part of a rotary evaporating tower, and enter a front flue of the dust remover through an outlet flue of the rotary evaporating tower; the wastewater passes through the dust remover in a form of purified water vapor to enter the desulfurizing tower. The zero-release coupling humidifying dust-removing synergizing system and the zero-release coupling humidifying dust-removing synergizing method are high in wastewater treatment stability, and are not influenced by the load of a unit; the investment and running expenses are low; the water consumption and the energy consumption are reduced; the fume humidity is increased while the zero release of the wastewater is realized; the dust removal efficiency of the dust remover is improved.

Owner:ZHEJIANG UNIV

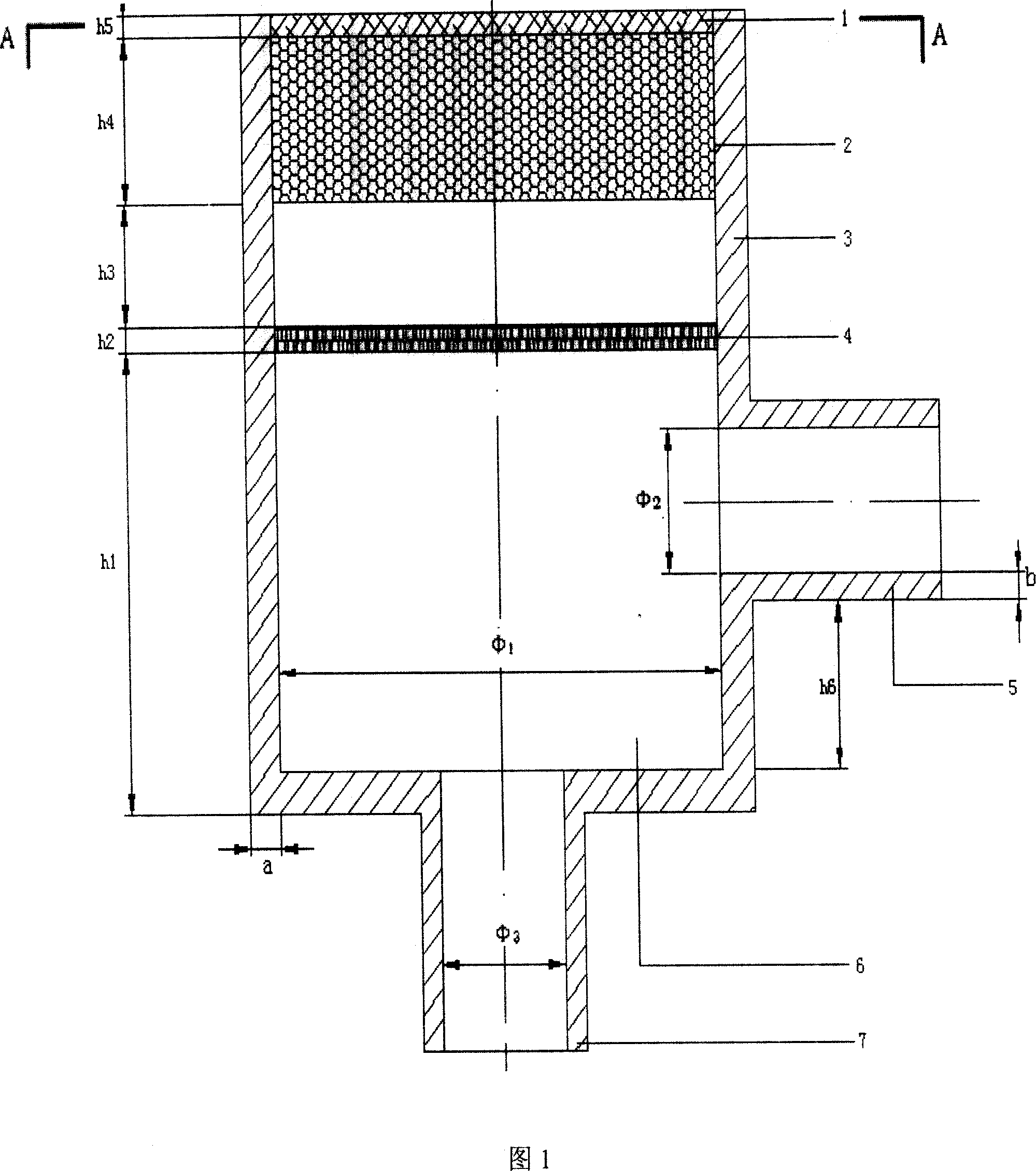

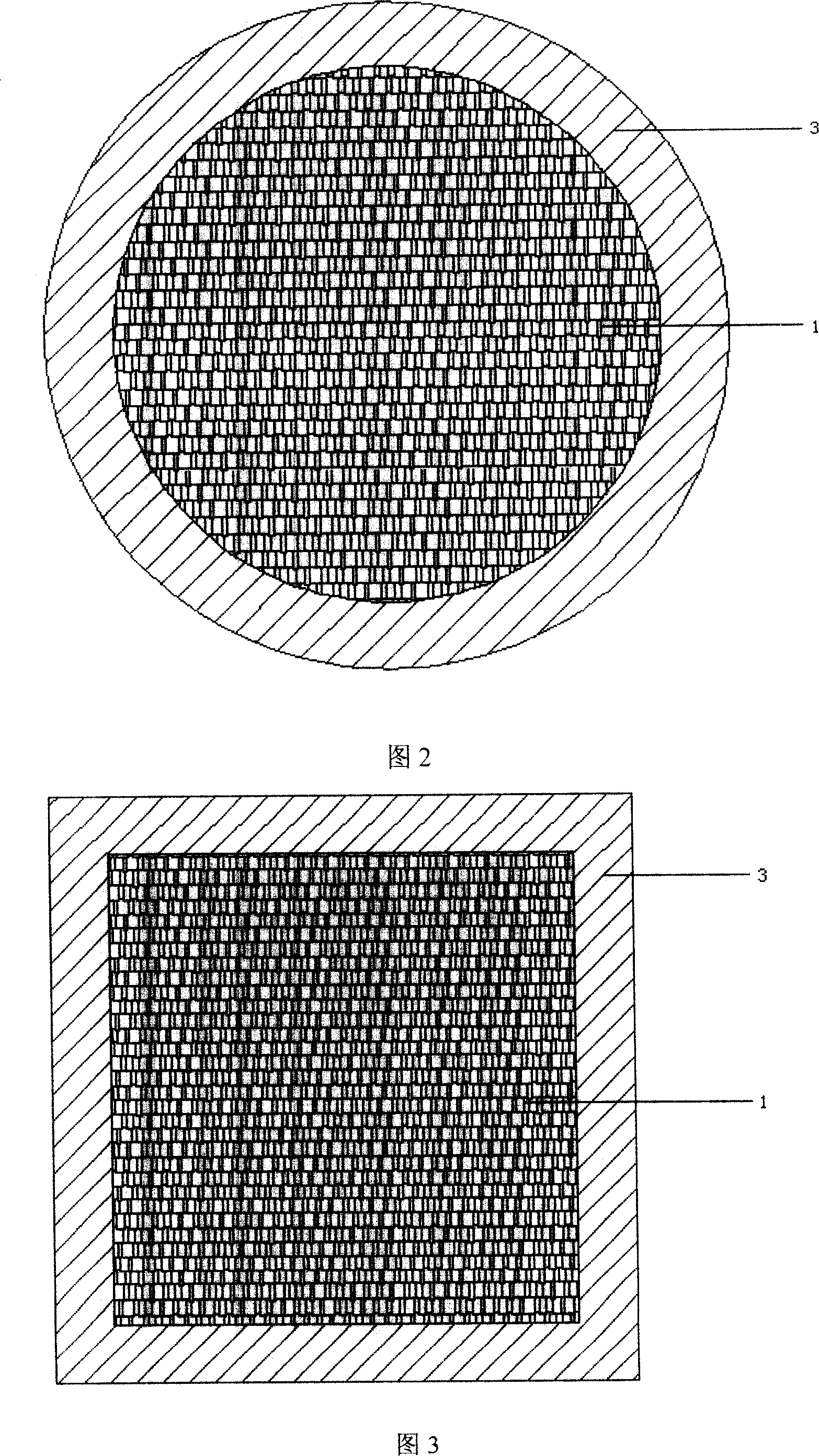

Metal fiber and porous ceramic media surface burner

InactiveCN1995814AExpand the adjustment rangeReduce sulfide contentGaseous fuel burnerMetal fiberAlloy

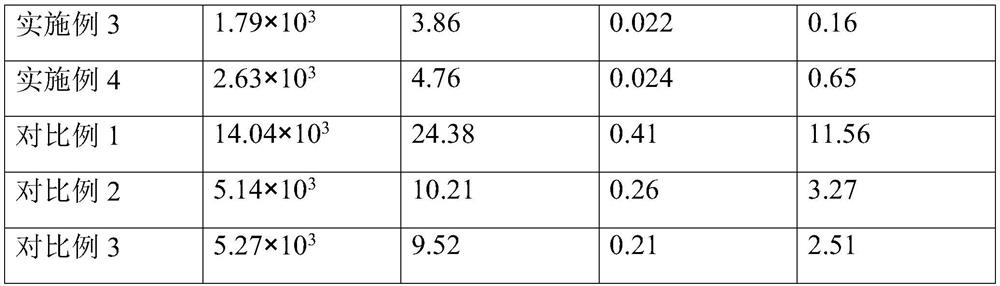

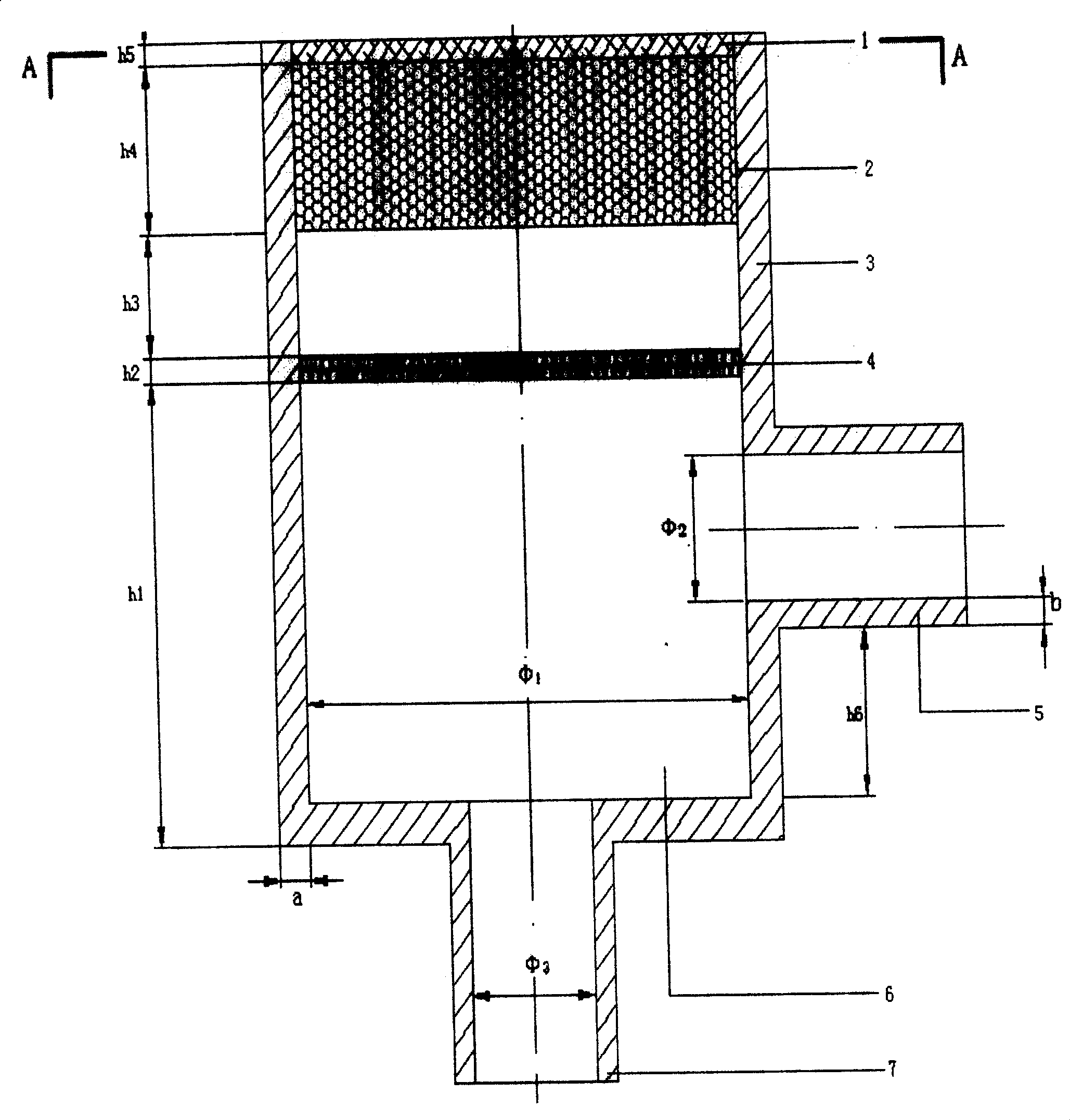

The invention relates to a metallic fiber and multi-hole ceramic dielectricsurface burner, belonging to heat energy engineering technology area. The burner comprises burner shell, gas pipeline and air pipeline. In the empty cavity constituted by the burner shell, metallic fiber medium in combustion zone and ceramic medium in preheat zone are set from upper to lower in turn and two medium are tightened together. The material of metallic fiber medium in combustion zone is made of Fe-Cr-Al alloy and the material of ceramic medium in preheat zone is made of zirconia or silicon carbide. Compared with ordinary surface burner, the invention can prevent tempering effectively, improve the adjustable range of fuel and air and improve burning temperature in certain range so as to improve thermal efficiency. The burner in invention can burn natural gas, liquefied petroleum gas and mixed gas so on, also burn air fuel with low thermal value which is approached to 1000kcal / m3.

Owner:NORTHEASTERN UNIV

Method for desulphurizing gasoline

ActiveCN102093907AImprove stabilityIncrease the degree of exchangeOther chemical processesHydrocarbon oils refiningSorbentCerium

The invention relates to a method for desulphurizing gasoline. In the method, a beta molecular sieve serves as a carrier; a selective adsorbent is adopted to adsorb thiophene sulfides in the gasoline and remove the thiophene sulfides from the gasoline; a hydrogen type beta molecular sieve serves as the carrier of the adsorbent; the molecular sieve carries copper, silver, zinc, nickel or gallium metal ions and metal cerium ions; and the exchange amount of the metal ions is 0.001 to 15 percent based on the mass of the hydrogen type beta molecular sieve. The adsorbent is used to selectively adsorb the thiophene sulfides in the gasoline and deeply remove the thiophene sulfides from the gasoline. A result shows that: the bimetallic ions have a synergistic effect, improve the selectivity of adsorptive desulphurization and can reduce the content of the sulfides in the fluid catalytically cracked (FCC) gasoline to below 1mu g / g or zero from 200mu g / g. The reaction condition is mild; the equipment is simple; the activity of the adsorbent is high; and the adsorbent is easy to regenerate. At normal temperature and normal pressure, hydrogen is not consumed and the gasoline is finely desulphurized.

Owner:PETROCHINA CO LTD +1

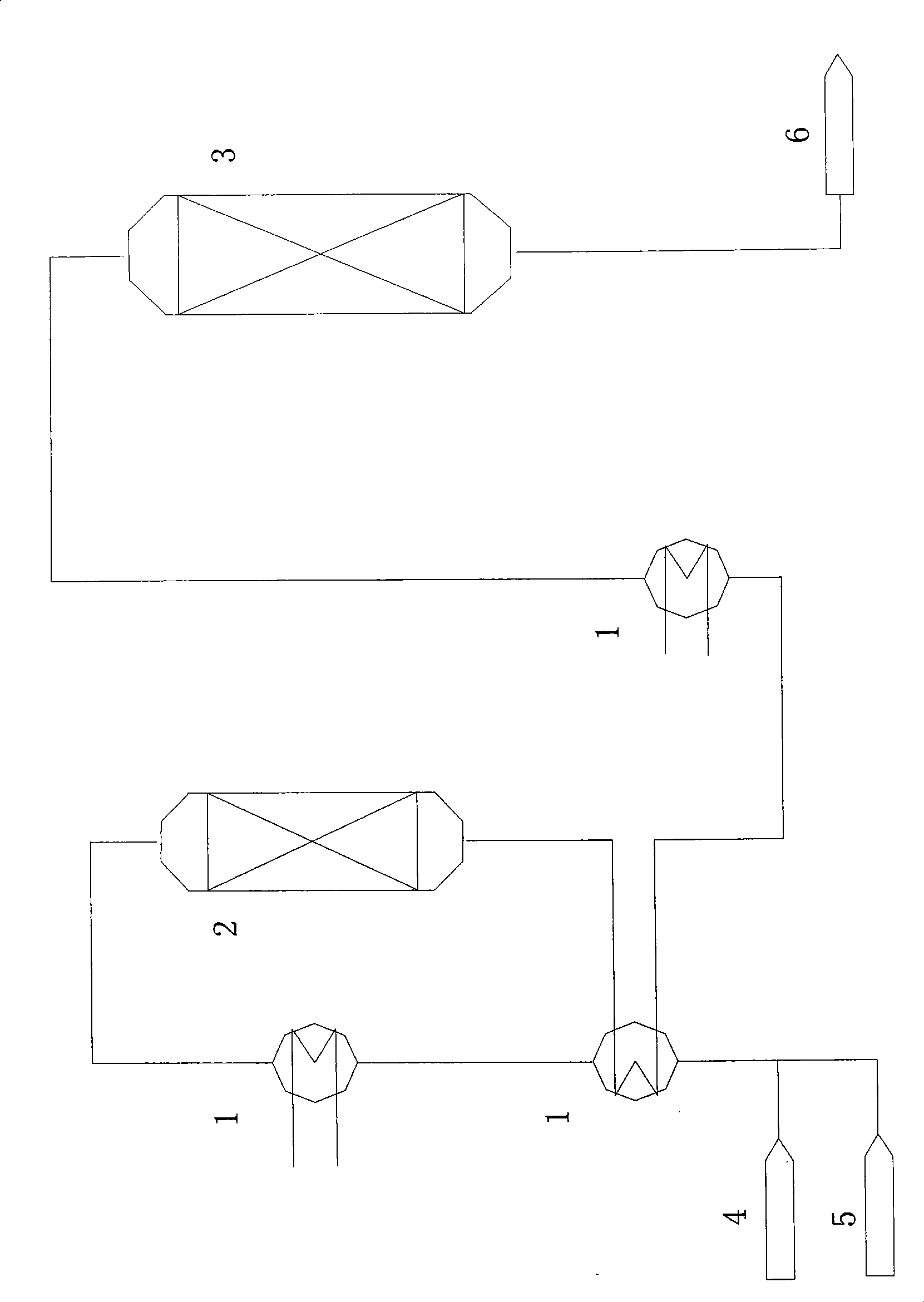

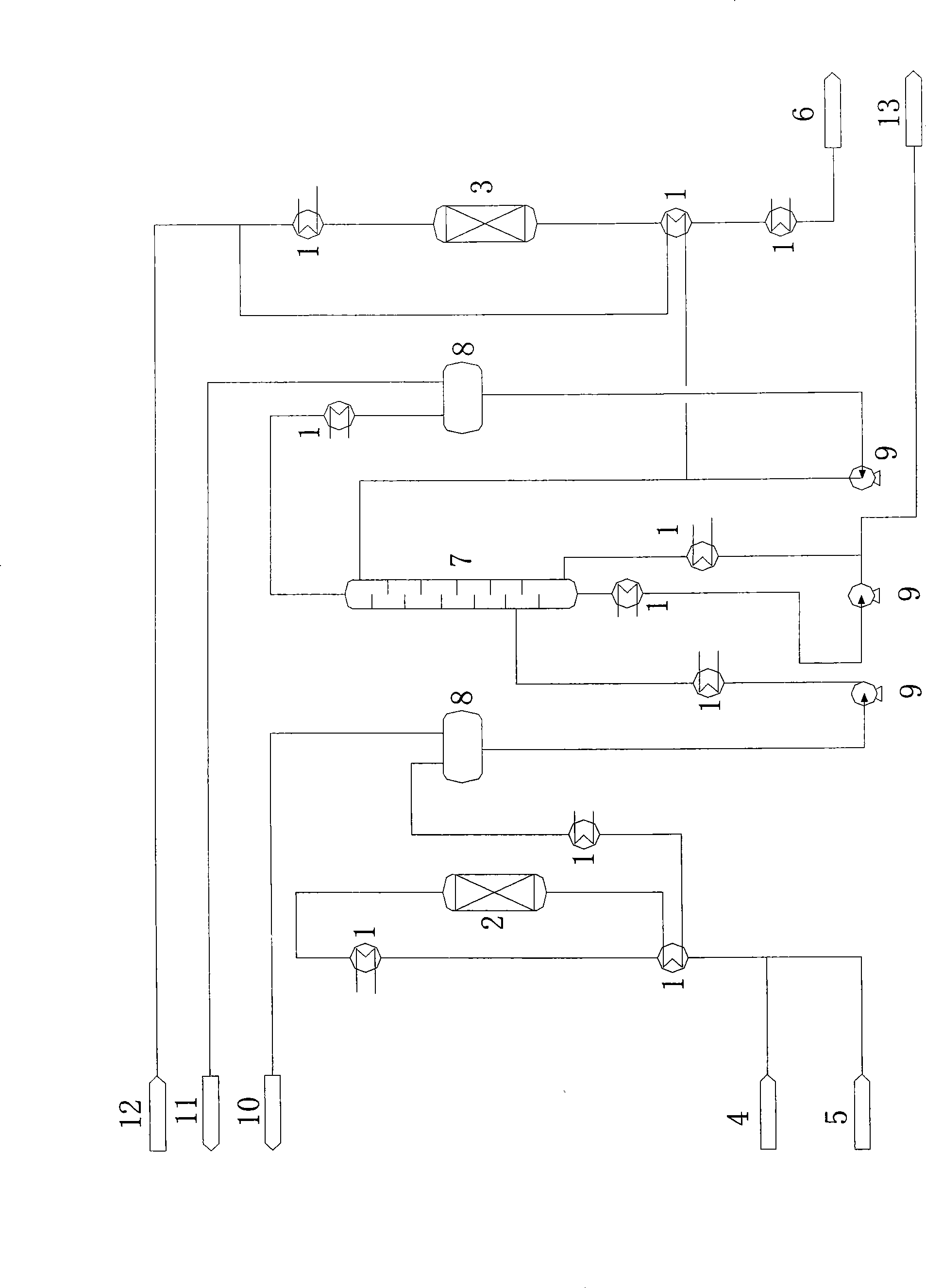

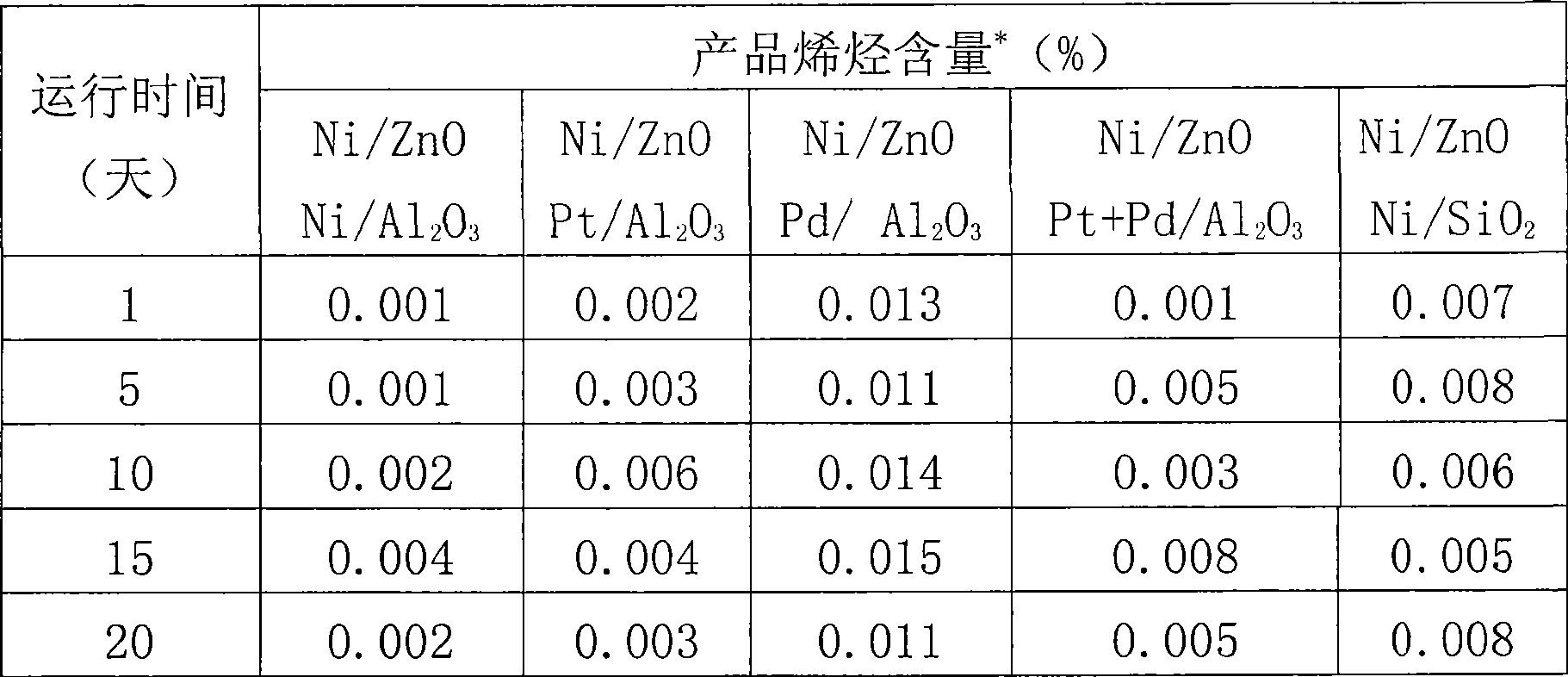

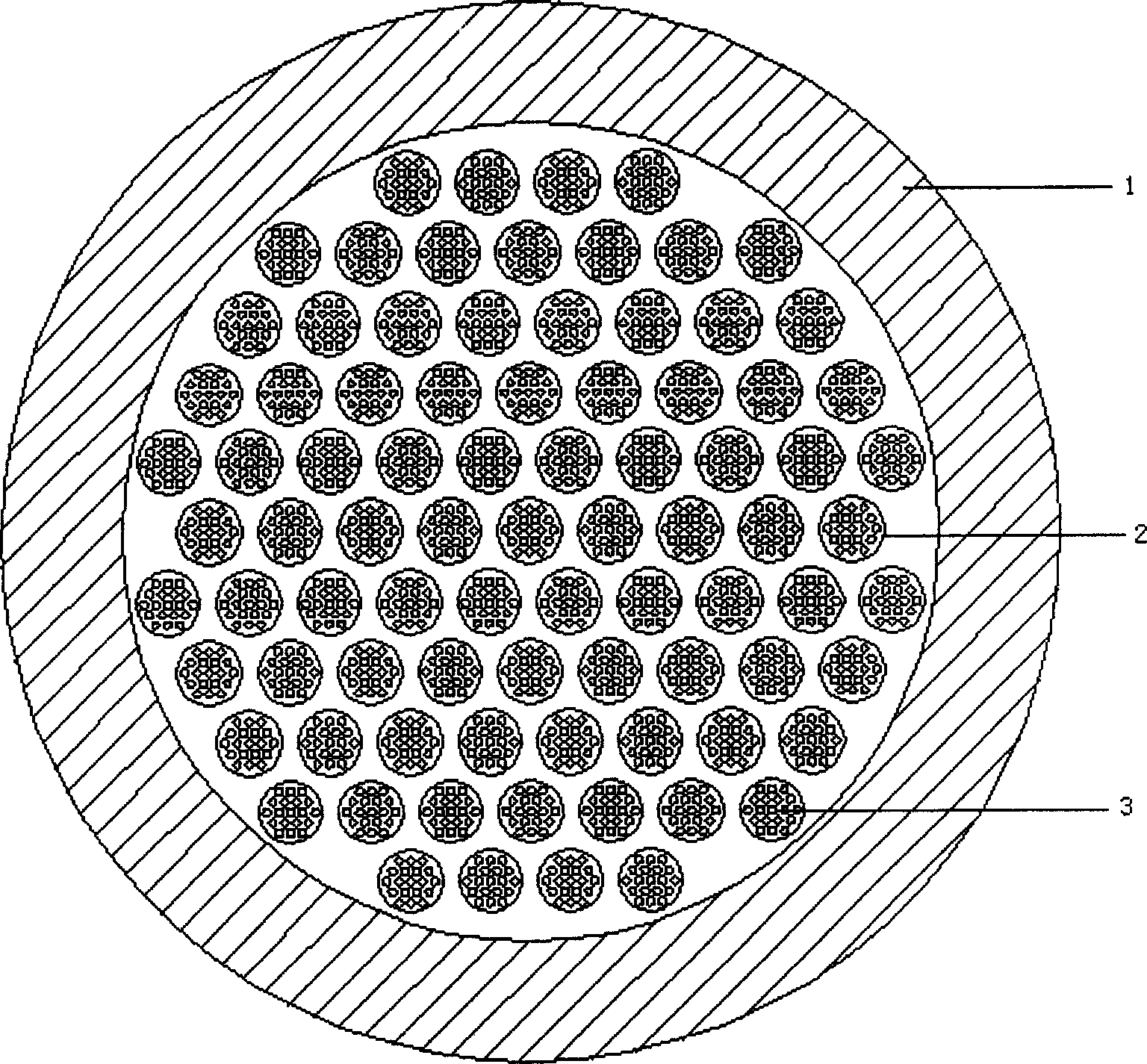

Hydrogenation adsorption desulphurization and catalytic hydro-dearomatization cascade reaction process

ActiveCN101475836AReduce sulfide contentExtend the life cycleTreatment with hydrotreatment processesSulfideAromatic hydrocarbon

The invention discloses a cascade reaction process for hydrogenation adsorption desulfurization and hydro-dearomatization. A hydrogenation adsorption catalyst and a hydro-dearomatization catalyst are directly and serially filled, and a raw material is removed with sulfide through the hydrogenation adsorption catalyst under the condition of hydrogenation adsorption, and then is removed with aromatic hydrocarbon through the hydro-dearomatization catalyst under the condition of hydro-dearomatization. The process has the advantages that no hydrogen sulfide is generated in a first reactor, and thecontent of the sulfide in a product is lower, thereby prolonging the using period of a second hydro-dearomatization catalyst, reducing operation cost, reducing equipment, and saving the investment.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Porous metal medium burner capable of burning low heat value gas

InactiveCN1804461AEnergy savingReduce contentIndirect carbon-dioxide mitigationGaseous fuel burnerSmall holeEnergy source

The invention relates to a porous metallic medium burner which burns the gas with low caloricity. The invention comprises a fire-proof tube, the big porous medium in the burning area, and the small porous medium in the preheating area, the burner case, the dust-cleaning metallic network or metallic brush, a pre-mixing room, and an air channel. The burning area with big porous medium and the preheating area with small porous are arranged from up to down in the burner while both of them uses high-temperature resistant stainless steel to be integrated into a whole; the fire-proof tube packs the outer wall of the upper part of air channel to the upper part of burning area; the dust-cleaning metallic network or metallic brush is arranged under the small porous medium. The invention can burn the gas fuel with the caloricity less than 1000kcal.m3 as blast furnace coal gas, to save the energy source and reduce the nitride and sulfide in the burned product to reduce the pollution. The invention can apply the industries as metallurgy and chemical plant.

Owner:NORTHEASTERN UNIV

Dedusting method and device

InactiveCN102614766ASimple structural designEasy to manufactureLighting and heating apparatusUsing liquid separation agentFlocculationFlue gas

The invention discloses a dedusting method, comprising the following steps: letting flue gas firstly pass through an alkaline solution containing calcium carbonate and magnesium oxide or containing calcium oxide and sodium hydroxide to carry out desulphurization, then putting the desulphurized flue gas in clear water for dedusting, and finally discharging; wherein the mass percent of calcium carbonate to magnesium oxide to water in the alkaline solution containing calcium carbonate and magnesium oxide is 1-10 to 1-10 to 50-300, and the mass percent of calcium oxide to sodium hydroxide to water in the alkaline solution containing calcium oxide and sodium hydroxide is 1-10 to 1-10 to 50-300. A device used in the dedusting method comprises a desulfurization tower, an alkaline solution pool, a main tower, an inlet gas pipe, a communicating pipe and a dedusting flocculation basin. The device has the advantages of simple structure design, good dedusting effect, and high efficiency.

Owner:URUMQI JIN SUI JIAN TECH DEV

Coal gas sampling method for determining content of hydrogen cyanide in coal gas

InactiveCN102607900AReduce sulfide contentSimple methodChemical analysis using titrationWithdrawing sample devicesPotassium hydroxideCadmium acetate

The invention provides a coal gas sampling method for determining the content of hydrogen cyanide in coal gas. The coal gas sampling method includes steps of leading coal gas to pass through cadmium acetate liquor so as to absorb hydrogen sulfide in the coal gas; then leading the coal gas to pass through potassium hydroxide liquor twice respectively to absorb the hydrogen cyanide in the coal gas so as to obtain sample absorption liquid absorbed with the hydrogen cyanide; leading the coal gas to pass through sulfuric acid liquor to absorb ammonia in the coal gas so as to protect a flow meter; and finally, leading the coal gas to pass through saturated picric acid liquor to absorb naphthalene in the coal gas and leading the coal gas to pass through the flow meter to obtain coal gas sampling quantity. After the sample absorption liquid absorbed with the hydrogen cyanide is inspected, the content of the hydrogen cyanide in the coal gas is obtained by means of conventional calculation. The coal gas sampling method effectively resolves the problem that as the content of sulfion in absorption liquid for determining the content of the hydrogen cyanide in the prior art is high, the content of the hydrogen cyanide in coal gas cannot be determined by a silver nitrate titration method. In addition, the coal gas sampling method is simple and practicable, and is easy in implementation.

Owner:云南昆钢煤焦化有限公司

Hair-saving and hair removing tanning method by adopting micro enzyme-alkaline process

The invention relates to a hair-saving and hair removing tanning method by adopting a micro enzyme-alkaline process, belongs to the technical field of leather treatment, in order to solve the problems of difficulty in operation and extremely high index of contaminants in wastewater of the prior art. The hair-saving and hair removing tanning method comprises the following steps of: transferring cow leather with flesh removed through soaking in water in a drum, adding in water and an enzyme-containing adjuvant 4008-C, adjusting the pH value to be 9.0-10.0, combing rotating and stopping, adding in tare lime, maintaining the temperature to be 20 DEG C-25 DEG C, rotating for 50-80 minutes, adding a hair removal agent, maintaining the temperature to be 20-25 DEG C, rotating for 30 minutes, then stopping for 30 minutes, maintaining for 120-150 minutes, finally adding in lime and a liming auxiliary, combining rotating and stopping, continuing for 10 hours, taking out of the drum, and splitting. The method has the advantages of simple technology, low cost, and low contents of ammonia nitrogen, sulfide, COD cr and solid waste.

Owner:苏州盛泽科技创业园发展有限公司

Deep desulfurization method for high-sulfur-containing wastewater of oil and gas field

InactiveCN106698733ATo achieve the purpose of deep removalMeet the reinjection water standardWaste water treatment from quariesMultistage water/sewage treatmentSulfideSulfur containing

The present invention relates to a deep desulfurization method of high-sulfur-containing wastewater of an oil and gas field, and the method comprises the following steps: according to the characteristic of a hydrogen sulfide presence form of sulfides in the high-sulfur-containing wastewater of the oil and gas field under acidic conditions, first, most of hydrogen sulfide in the wastewater is removed by a negative pressure desulfurization technology for centralized incineration; and secondly, residual hydrogen sulfide in negative pressure desulfurization unit effluent is oxidized by a chemical catalysis oxidation technology so as to finally realize the purpose of deep removal of the sulfides in the high-sulfur-containing wastewater of the oil and gas field, and the sulfur content of the effluent meets the reinjection water standard of the oil and gas field. The deep desulfurization method of the high-sulfur-containing wastewater of the oil and gas field can effectively remove the sulfides in the wastewater, solves the problem of too high sulfur content in the reinjection process of the high-sulfur-containing wastewater, and solves the disadvantages of huge equipment, complex process, low efficiency, poor environmental adaptability, high operation cost, difficulties in maintenance and the like in the prior art.

Owner:CHINA PETROLEUM & CHEM CORP +1

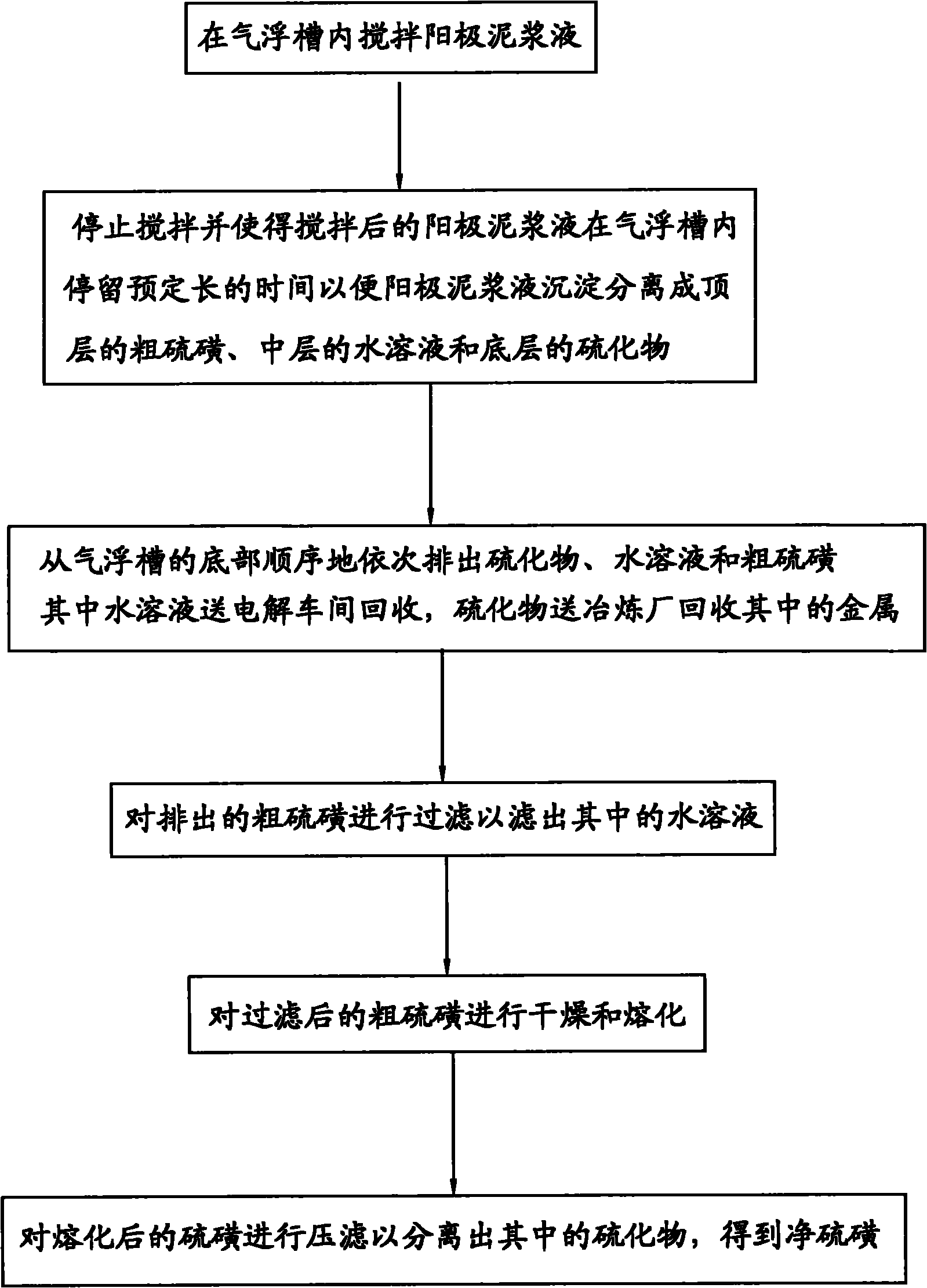

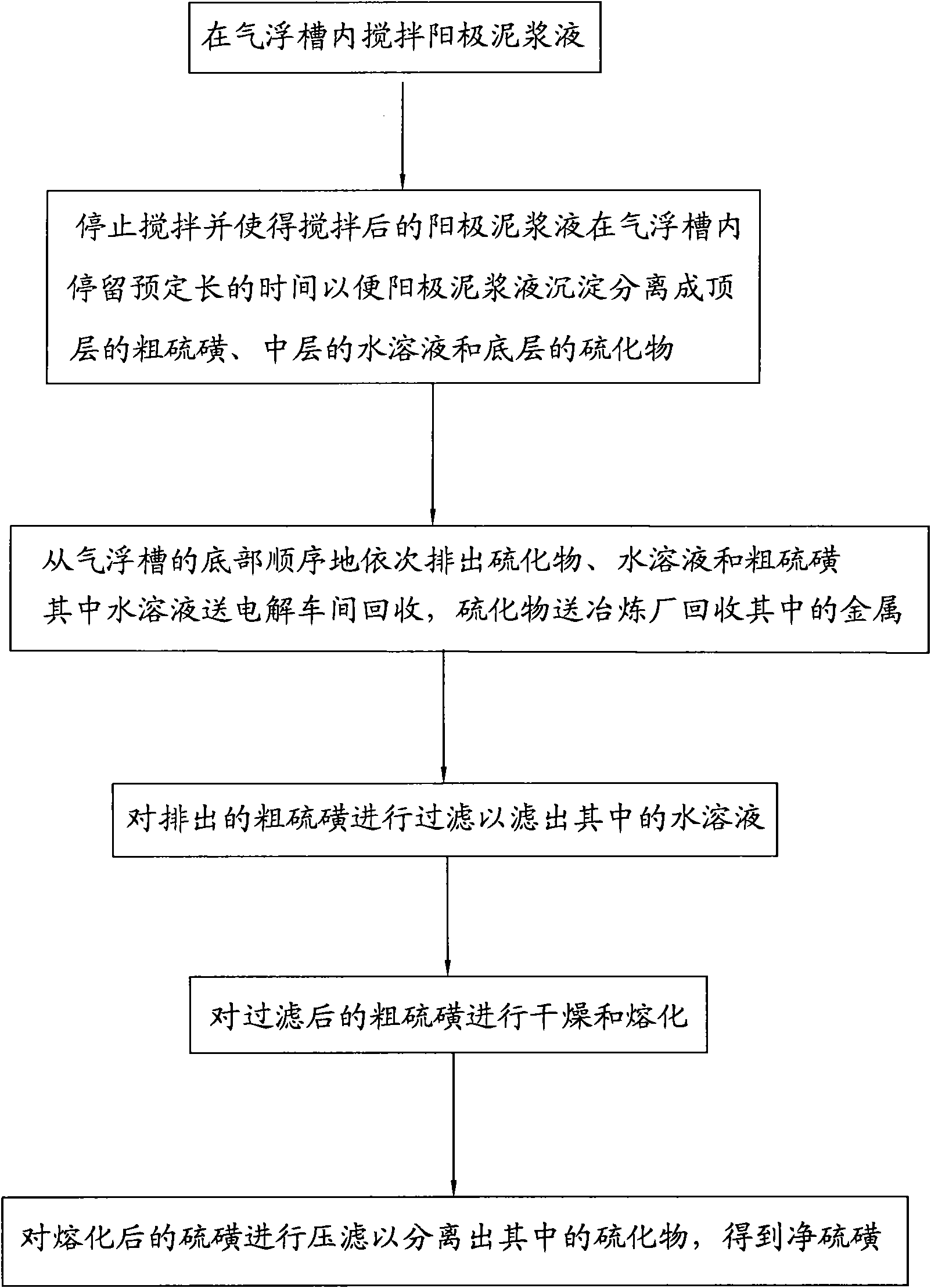

Anode mud treatment method

ActiveCN101838088AEasy to operateGood effectSludge treatmentProcess efficiency improvementFiltrationSulfate

The invention discloses an anode mud treatment method, which comprises the following steps: stirring anode mud slurry in an air flotation slot; enabling the anode mud slurry to stay in the air flotation slot for preset time after stirring is stopped so as to settle and separate the anode mud slurry into three layers, wherein the top layer is crude sulfur, the middle layer is the aqueous solution of sulfate, and the bottom layer is a sulfide containing valuable metals; discharging the sulfide, the aqueous solution and the crude sulfur in sequence from the bottom of the air flotation slot; drying and then melting the crude sulfur; and carrying out pressure filtration on the melted crude sulfur to separate the sulfide containing the valuable metals to obtain pure sulfur. According to the anode mud treatment method, three substances in anode mud are simultaneously separated in the same air flotation slot, less equipment is needed, and the separation effect is good. The sulfur content in the separated crude sulfur is high, and the energy consumption in melting is further reduced because the crude sulfur is dehydrated and dried before being melted. Since the sulfur content in the crude sulfur is high, and the sulfide content is low, the operation and the efficiency performance of a sulfur filter press become convenient.

Owner:CHINA ENFI ENGINEERING CORPORATION

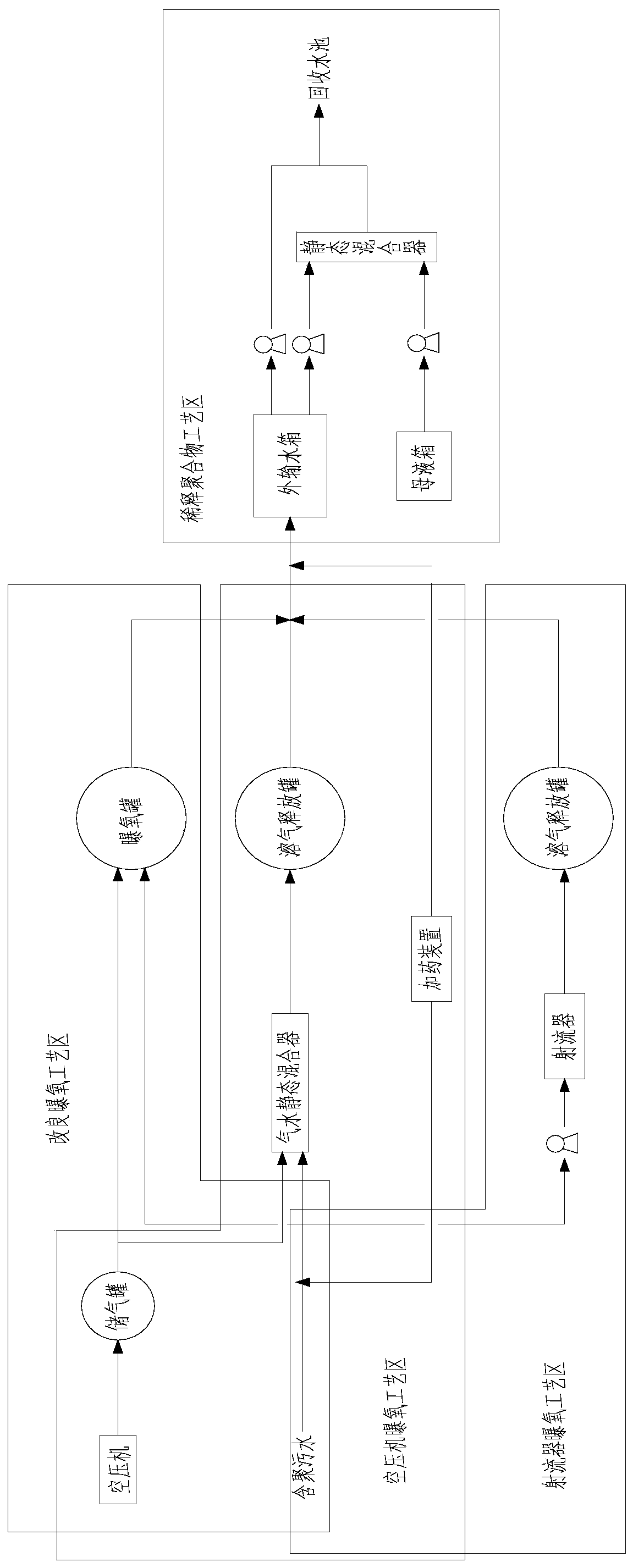

Hydrothermal or pyrohydrolysis tail gas resource utilization system and hydrothermal or pyrohydrolysis tail gas resource utilization method

InactiveCN111001277AFull recoveryLess investmentGas treatmentDispersed particle separationExhaust fumesProcess engineering

The invention discloses a hydrothermal or pyrohydrolysis tail gas resource utilization system, which comprises a slurrying reactor, an anaerobic reactor, a biogas cabinet and a desulfurizing tower, wherein the slurrying reactor is communicated with the anaerobic reactor, the anaerobic reactor is communicated with the biogas cabinet, the biogas cabinet is communicated with the desulfurizing tower,a waste gas condenser and a steam-water separator are arranged between the slurrying reactor and the anaerobic reactor, the waste gas outlet of the slurrying reactor is connected with the gas inlet ofthe waste gas condenser, the gas outlet of the waste gas condenser is connected with the gas inlet of the anaerobic reactor, a check valve is arranged between the gas outlet of the waste gas condenser and the gas inlet of the anaerobic reactor, and the gas inlet of the anaerobic reactor is lower than the working liquid level of the anaerobic reactor. According to the invention, the hydrothermal waste gas of an anaerobic reaction needing heat is directly connected with an anaerobic reactor, and the hydrothermal waste gas of an anaerobic reaction doing not need heat passes through a waste gas condenser and a steam-water separator and then is connected with the anaerobic reactor.

Owner:四川深蓝环保科技有限公司

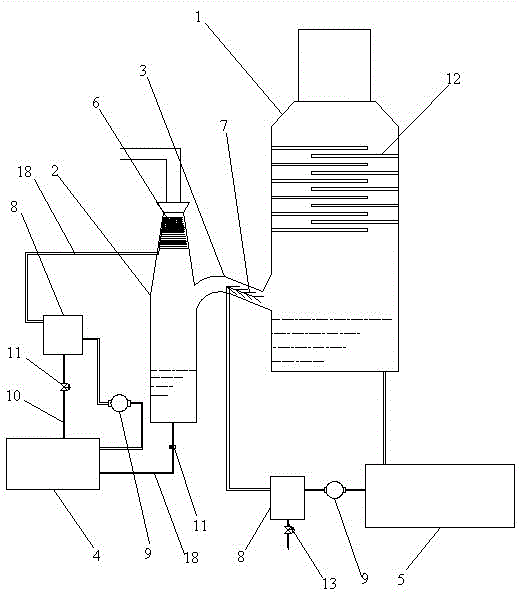

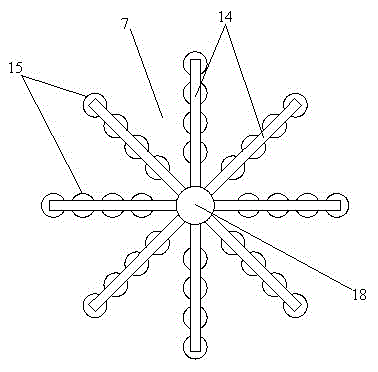

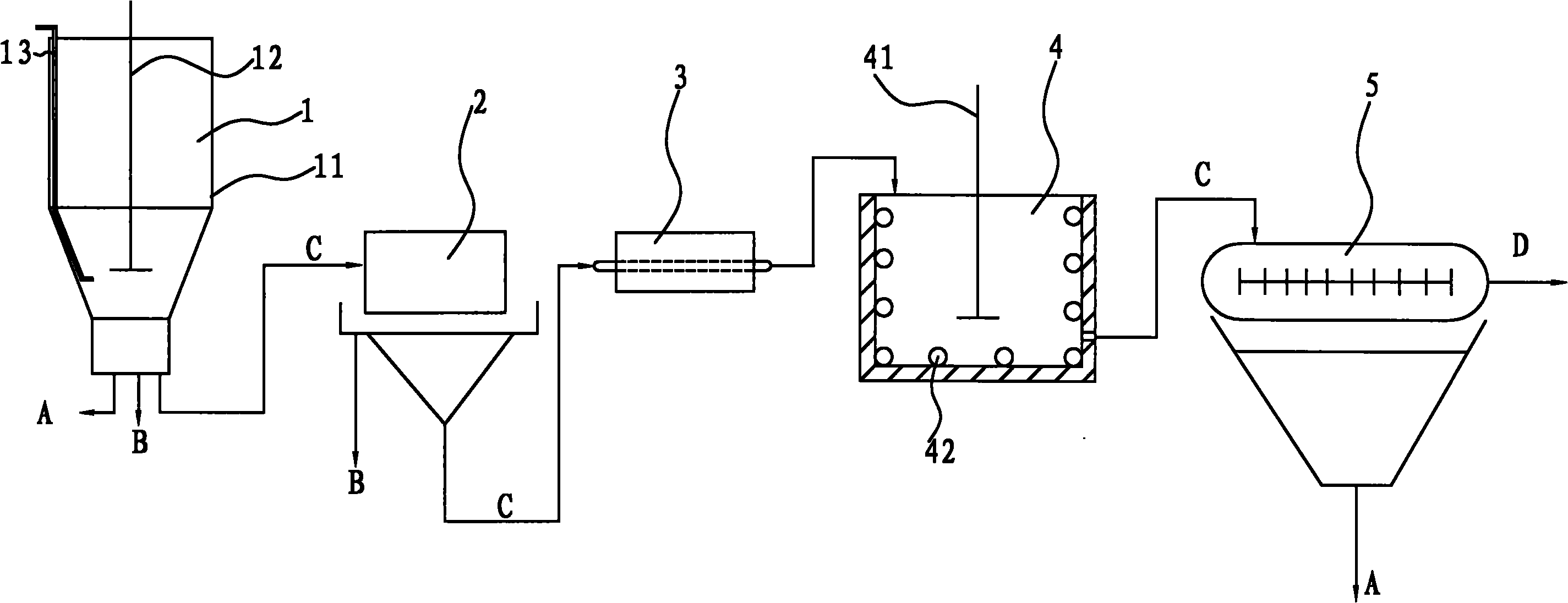

Anode mud treatment equipment and air flotation slot thereof

ActiveCN101838087ASimple structureSimple processSludge treatmentProcess efficiency improvementFiltrationEnergy expenditure

The invention discloses anode mud treatment equipment, which comprises an air flotation slot, a dryer, a melting slot and a sulfur filter press, wherein the dryer is connected with the air flotation slot and is used for receiving and drying crude sulfur discharged from the air flotation slot; the melting slot is connected with the dryer and is used for melting the dried crude sulfur; and the sulfur filter press is connected with the melting slot and is used for carrying out pressure filtration on the melted sulfur. The invention also discloses the air flotation slot used for the anode mud treatment equipment. According to the invention, three substances in anode mud are simultaneously separated in the same air flotation slot, less equipment is needed, and the separation effect is good. The sulfur content in the separated crude sulfur is high, and the energy consumption in melting is further reduced because the crude sulfur is dehydrated and dried before being melted. Since the sulfur content in the crude sulfur is high, and the sulfide content is low, the operation and the efficiency performance of the sulfur filter press become convenient.

Owner:CHINA ENFI ENGINEERING CORPORATION

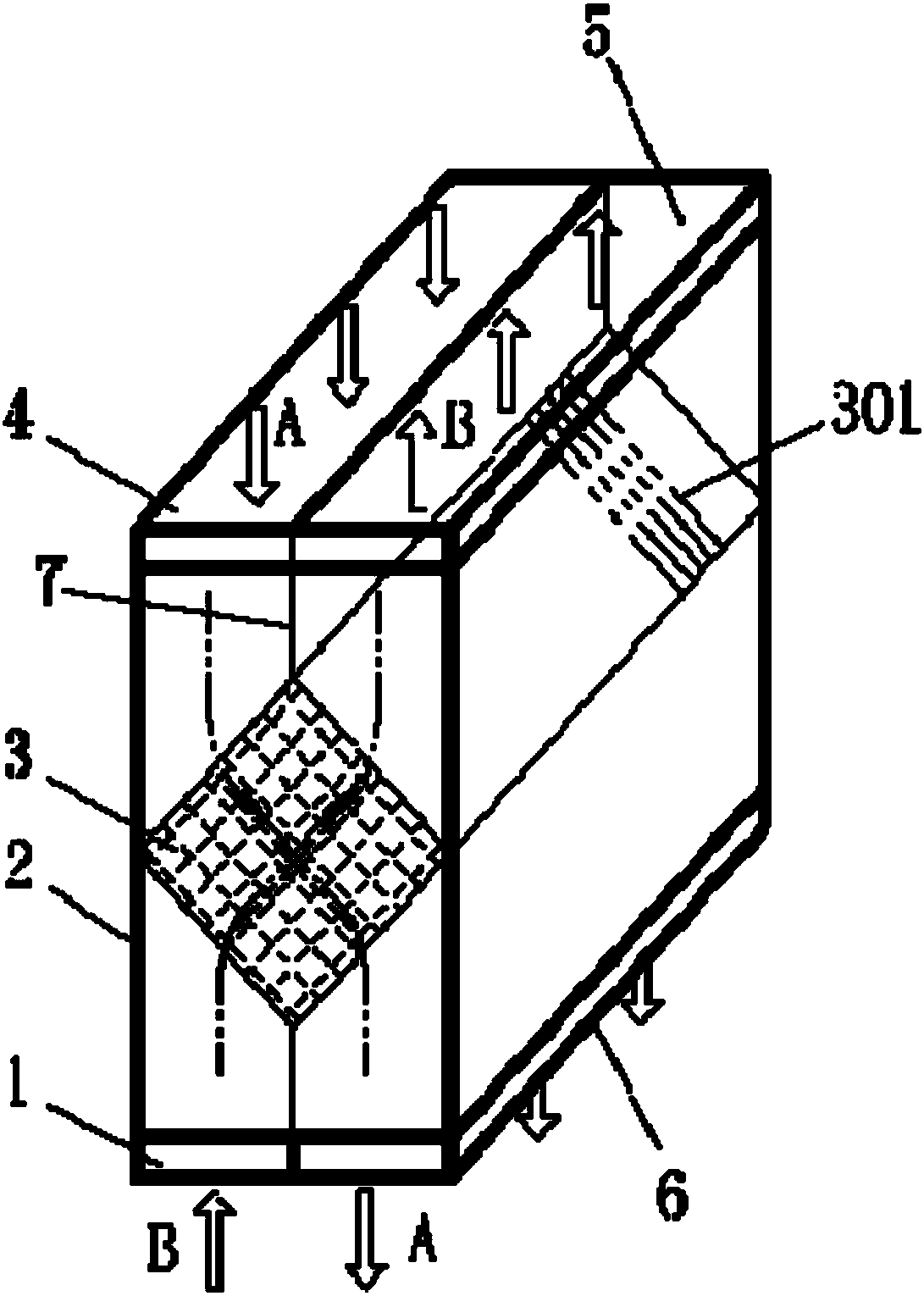

Cyclone de-dusting method for desulfurization wastewater

InactiveCN107176742AReduce sulfide contentRaise the acid dew pointWater/sewage treatment by centrifugal separationWaste water treatment from gaseous effluentsAir preheaterCyclone

The invention provides a cyclone de-dusting method for desulfurization wastewater. The method comprises the following steps: adopting a wastewater hydrocyclone for treating wastewater after being treated by a gypsum dehydration system; causing part of underflow to flow to a desulfurization tower for reusing and causing the other part of underflow to overflow to a wastewater tank for collecting; conveying the wastewater to a rotary atomizer for atomizing; causing the atomized fog drop to descend and to be in reverse contact with high-temperature flue gas entering from the front side of an air pre-heater; causing the solid particle in the evaporated wastewater and the flue gas to downward flow to the lower part of a rotary evaporation tower, pass by an outlet flue of the evaporation tower and enter into a front flue of a dust collector; causing the wastewater to enter into the desulfurization tower through the dust collector in the form of purified steam. According to the invention, the wastewater treatment stability is high, the treatment is not influenced by unit load, the investment and running cost is low, the water consumption and the energy consumption are saved, the wastewater treatment is realized while the humidity of the flue gas is increased and the de-dusting efficiency of the dust collector is increased.

Owner:江阴宇博科技有限公司

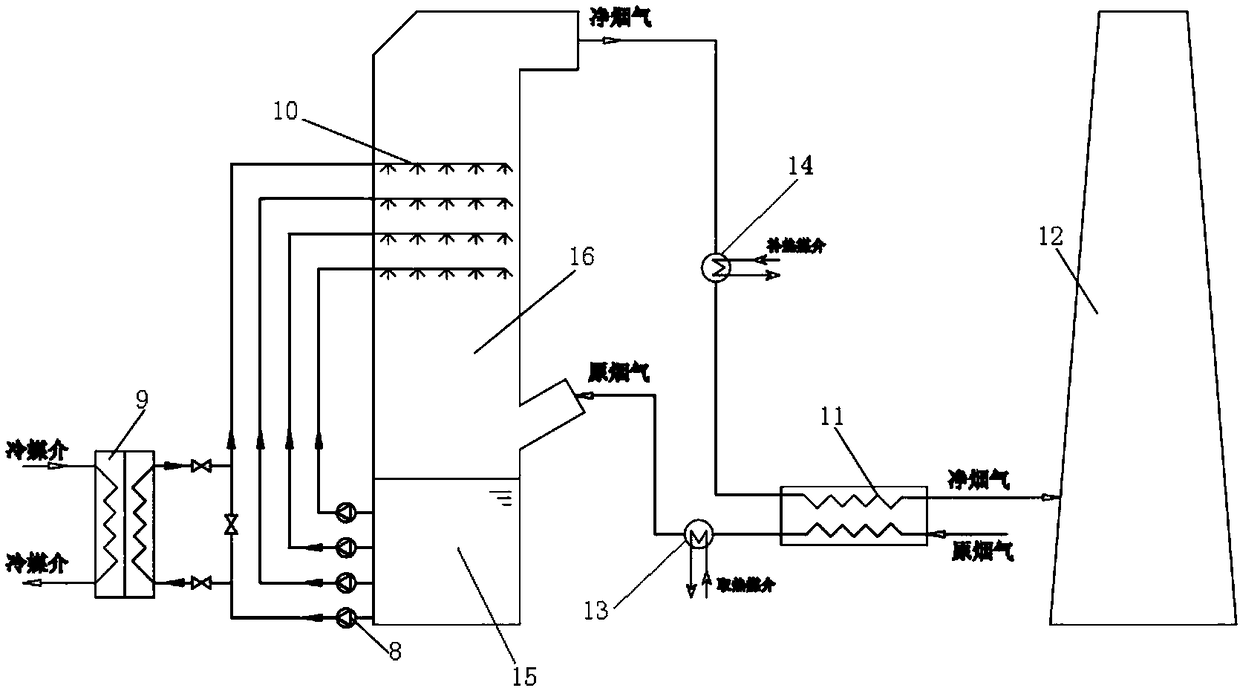

Treatment system and method for flue gas

PendingCN108654353AReduce contentReduce consumptionDispersed particle separationLaminated elementsProcess systemsSlurry

The invention relates to the field of flue gas desulfurization applications, and in particular relates to a treatment system and method for a flue gas. The treatment system comprises a gas-gas heat exchanger, a desulfurization tower equipped with a slurry cooler, a desulfurization slurry cooler and a chimney; in the gas-gas heat exchanger, high-temperature crude smoke before desulfurization treatment is utilized as a heat source to heat low-temperature clean smoke obtained after the desulfurization treatment, and desulfurization slurry is cooled by utilizing the desulfurization slurry heat exchanger. According to the system and method provided by the invention, after temperature of the high-temperature crude smoke is reduced, dust removing efficiency can be effectively improved; after temperature of the desulfurization slurry is reduced, desulfurization efficiency can be effectively improved, loss of the desulfurization slurry can be reduced, and a moisture content of the low-temperature clean smoke can be reduced; and after temperature of the low-temperature clean smoke is improved, white smoke in the flue gas can be effectively eliminated. The system and method provided by the invention effectively eliminate the white smoke in the flue gas while improving the desulfurization efficiency, and reduce investment of a whole desulfurization process system.

Owner:TIANJIN HUASAIER HEAT TRANSFER EQUIP

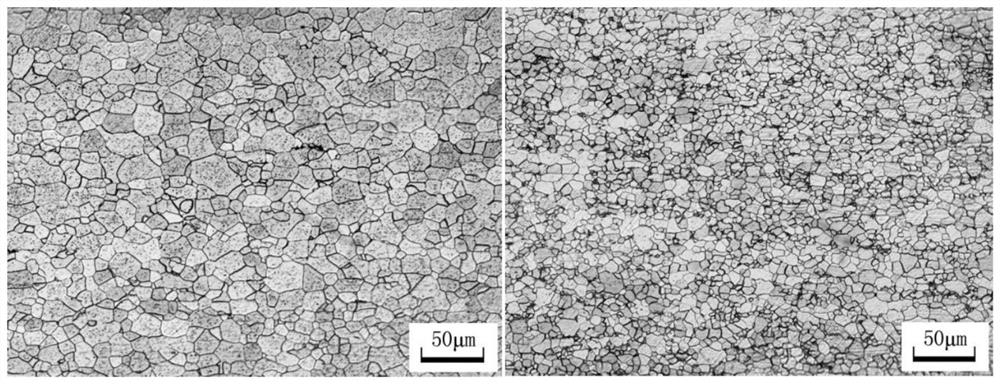

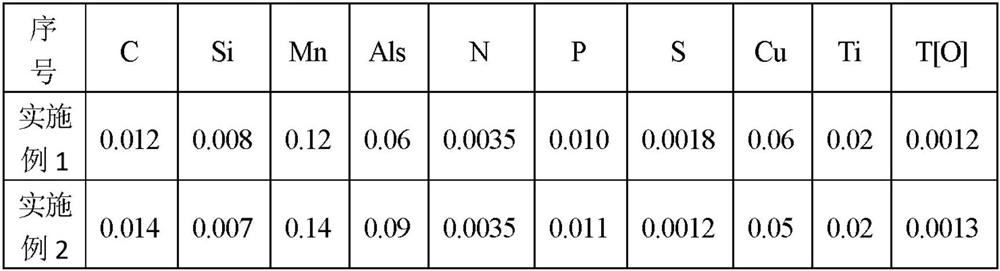

Low-cost well-formed battery shell steel and production method thereof

ActiveCN113774274AImprove toughnessExcellent formabilityCell component detailsSteelmakingUltimate tensile strength

The invention relates to the field of iron and steel smelting, in particular to a low-cost well-formed battery shell steel and a production method thereof. The low-cost well-formed battery shell steel is prepared from components in percentage by mass, 0.008%-0.02% of C, 0.1%-0.3% of Mn, smaller than or equal to 0.01% of Si, 0.050%-0.10% of Als, smaller than or equal to 0.015% of P, smaller than or equal to 0.0020% of S, smaller than or equal to 0.004% of N, smaller than or equal to 0.01% of Cu, smaller than or equal to 0.01% of Ti, smaller than or equal to 0.002% of T [O] and the balance of Fe and inevitable impurities, wherein T [O] is an oxidation inclusion; T [O] in steelmaking is the content of oxidation series inclusions, the deoxidation time can be shortened, the inclusions in steel are reduced, and a steel plate formed through follow-up punch forming has more excellent machining forming performance; the steel toughness is improved, the steel anisotropy is reduced, and the process is matched, so that the steel has good yield strength elongation and good forming performance.

Owner:武汉钢铁有限公司

Reduced-injection standardized discharge method for high-sulfur wastewater in oil and gas fields

ActiveCN107417014ARealize the goal of reducing injection and meeting standardsSolve hugeWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentChemical reactionChemistry

The invention relates to a reduced-injection standardized discharge method for high-sulfur wastewater in oil and gas fields. The method includes the following steps: 1) removing majority of H2S in the high-sulfur wastewater through negative pressure desulfurization; 2) performing chemical reaction to residual H2S in the water generated through the negative pressure desulfurization to form precipitates; 3) performing flocculating settlement to the water generated through the chemical reaction desulfurization; 4) filtering the water generated by the flocculating settlement through a ceramic membrane filtration unit; 5) separating and concentrating the water generated through the ceramic membrane filtration in a high-effective electro-dialysis unit; and 6) performing ozone catalytic oxidization to the fresh water generated through the high-effective electro-dialysis, and discharging the water, which meets the standards, after the ozone catalytic oxidization. By means of the reduced-injection standardized discharge method, sulfides, suspension solids, organic matters, chlorides and oil in the high-sulfur wastewater are deeply removed, and the sulfur content, suspension solid content and oil content of eletro-dialyzed concentrated water satisfy standard of reinjection water of oil and gas fields. The water outputted after the ozone catalytic oxidization meets the standard and is discharged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ammonia distillation treatment process for residual ammonia water

PendingCN113896265ALow costImprove liquidityDispersed particle separationWater/sewage treatment by neutralisationSaline waterProcess engineering

The invention discloses an ammonia distillation treatment process for residual ammonia water. The process aims at an ammonia distillation section, 20% concentrated ammonia water can be produced, and the problem of liquid expansion during desulfurization is solved. An alkali liquor inlet is arranged under a gas phase side sampling port of an ammonia still, so that the content of sulfide in the tower kettle wastewater can be greatly reduced by adding the alkali liquor, and the biochemical treatment cost is reduced. A tar discharge pipe of a bottom seal head of the ammonia still is designed to be inclined, a structure that the tar discharge pipe is vertically downward and then horizontally out of a skirt is not adopted, and steam sleeve heat tracing is added while the tar discharge pipe is inclined. The flowability is increased through inclined discharge, low-temperature solidification is prevented through sleeve heat tracing, and the problem that the tar discharge pipe is blocked is thoroughly solved. The shell side of a dephlegmator adopts a two-section type design, the two sections of shell sides operate in full load, and only one section of shell side operates in low load, so that the overlarge area allowance can be reduced. Cooling water is changed into steam condensate, and the steam condensate is desalted water and is not easy to scale; and through an indirect heat exchange mode, the operation time and the service life of the dephlegmator are obviously prolonged.

Owner:TIANJIN CHUANGJU TECHNOLGOY

Deep desulphurization method of high sulfur-containing waste water from oil and gas field

InactiveCN106256778ARealize deep desulfurizationHigh degree of automationMultistage water/sewage treatmentChemical reactionIndustrial waste water

The invention relates to the field of industrial waste water processing, and concretely relates to a deep desulphurization method of high sulfur-containing waste water from oil and gas field. The deep desulphurization method comprises the following steps: removing most hydrogen sulfide in waste water by employing a negative-pressure desulphurization technology for burning the hydrogen sulfide; forming precipitate on the residual hydrogen sulfide in a negative-pressure desulphurization effluent obtained by employing a chemical catalytic oxidation technology through a chemical reaction, removing the precipitate; and finally deeply removing sulfide in the high sulfur-containing waste water from oil and gas field. The deep desulphurization method can effectively remove the sulfide in the waste water, the problem of overhigh sulfur content during a high sulfur-containing waste water re-injection process of the oil and gas field is solved, and the disadvantages of large equipment, complex process, low efficiency, poor environment adaptability, high operation cost and difficult maintenance in the current processing technology can be solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

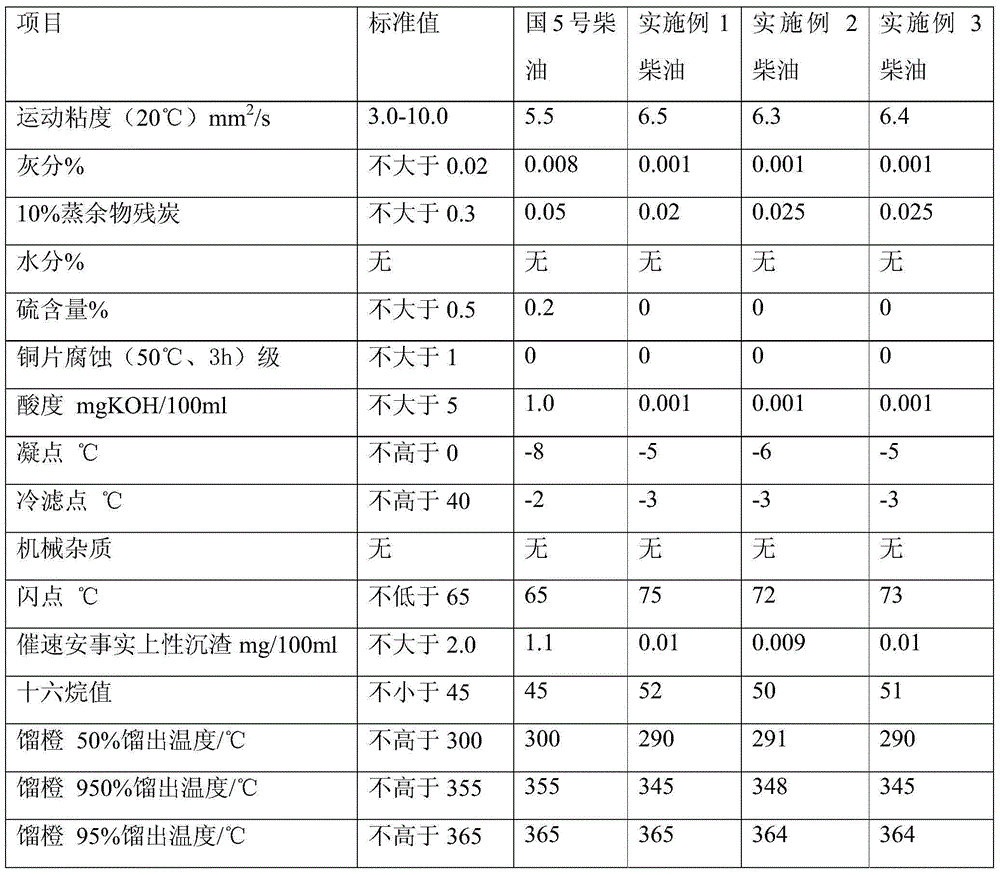

Smokeless vehicle diesel oil and preparation method thereof

The invention discloses a smokeless vehicle diesel oil, which comprises the following components in parts by weight: 180 to 220 parts of aviation kerosene, 90 to 110 parts of plant oil, 245 to 265 parts of finely-processed drainage oil, 290 to 310 parts of self-made smokeless oil, 45 to 55 parts of anti-freezing and pour point reducing agent, 8 to 12 parts of upgrading agent, and 30 to 40 parts of flame retardant. The finely-processed drainage oil is prepared by the following steps: heating drainage oil, removing impurities from drainage oil, carrying out primary filtration by a filter screen, and carrying out secondary filtration through pressurization. The smokeless vehicle diesel oil is prepared by the following steps: mixing smoke oil and edible vinegar according to a weight ratio of 1000:10-15, stirring for 40 to 50 minutes at a temperature of 11 to 12 DEG C in a rotation speed of 60 to 120 r / min, allowing the system to stand still, when the precipitate has a dark-red color and the supernatant oil has a white-green color so as to obtain the self-made smokeless oil (supernatant oil); mixing kerosene, plant oil, and finely-processed drainage oil, stirring until specific gravity reaches 0.85, transferring the mixture to another container, adding self-make smokeless oil, an anti-freezing and pour point reducing agent, an upgrading agent, and a flame retardant, stirring until the specific gravity of the mixture reaches 0.85, stopping stirring, and completely transferring the mixture to an oil storage tank so as to obtain the smokeless vehicle diesel oil. The raw material costs of the smokeless vehicle diesel oil are reduced, moreover, the diesel oil is smokeless and environment-friendly, and the quality of the diesel oil meets the standards of DB11 / 239-2010.

Owner:郭永秋 +2

Non-stink black denim dyeing technology

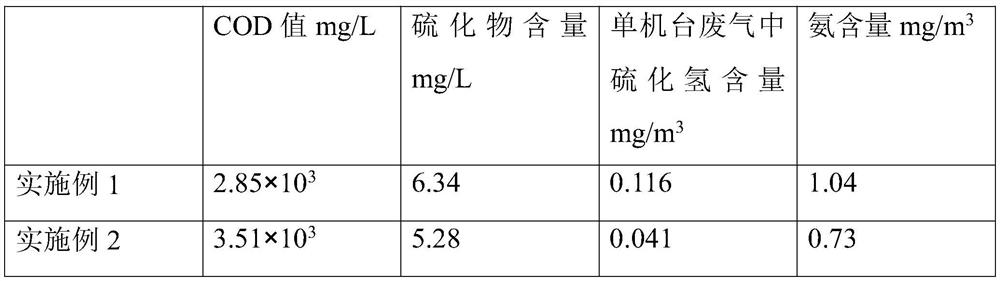

The invention discloses a non-stink black denim dyeing technology. The non-stink black denim dyeing technology includes a basic yarn beam wetting step, a dyeing step, a water washing step, a color fixing step, a brittleness preventing step, a drying sizing step and a lease reeling step which are continuously completed in one step through a sizing and drying combined machine. According to the dyeing step, under the condition that the temperature ranges from 90 DEG C to 98 DEG C, warp yarn is subjected to dip dyeing through a dyeing base solution, and the dyeing base solution includes the following components of 95 g / L-105 g / L of sulfur black, 25 g / L-35 g / L of a novel composite reducing agent, 1 g / L-5 g / L of an alkali-resisting penetrating agent, 1 g / L-5 g / L of Turkey red oil and 25 g / L-35 g / L of caustic soda. In the denim dyeing technology, the novel composite reducing agent is adopted for replacing sodium sulfide, free sulfides of black denim fabric can be greatly reduced, people cannot smell the stink smell on the fabric, the COD index of sewage generated by subsequent production of clothes manufacturing, water washing and the like is reduced by 76% or higher, the content of the sulfides is reduced by 74% or higher, the content of hydrogen sulfide in waste gas of a single machine is reduced by 72% or higher, the ammonia content is reduced by 91% or higher, the free sulfides ofthe fabric are obviously reduced, and people cannot smell the stink smell completely.

Owner:佛山市南海德耀翔胜纺织有限公司

A gas mixing system

ActiveCN111288297BReduce usageMeet calorific value requirementsTransportation and packagingPipeline systemsSulfideProcess engineering

The invention discloses a gas mixing system, comprising: a first-stage gas mixing device and a second-stage gas mixing device cascaded in sequence; the first-stage gas mixing device is used to mix blast furnace gas and converter gas to obtain high-revolution gas ; The second-stage gas mixing device is used to mix high-rev gas with refined coke oven gas to obtain low-sulfur mixed gas; and mix high-rev gas with ordinary coke oven gas to obtain ordinary mixed gas. This application maximizes the use of low-quality blast furnace gas and converter gas through the first-stage gas mixing device, and reduces the amount of coke oven gas used by the second-stage gas mixing device to meet the needs of equipment for high calorific value. At the same time, it can relatively reduce the mixing The sulfide content in the coal gas solves the technical problem in the prior art that the requirements of different equipment and processing techniques on the calorific value and sulfide of the gas cannot be taken into account at the same time.

Owner:SHOUGANG CORPORATION

Metal fiber and porous ceramic media surface burner

InactiveCN100460756CExpand the adjustment rangeReduce sulfide contentGaseous fuel burnerMetal fiberAlloy

The invention relates to a metallic fiber and multi-hole ceramic dielectricsurface burner, belonging to heat energy engineering technology area. The burner comprises burner shell, gas pipeline and air pipeline. In the empty cavity constituted by the burner shell, metallic fiber medium in combustion zone and ceramic medium in preheat zone are set from upper to lower in turn and two medium are tightened together. The material of metallic fiber medium in combustion zone is made of Fe-Cr-Al alloy and the material of ceramic medium in preheat zone is made of zirconia or silicon carbide. Compared with ordinary surface burner, the invention can prevent tempering effectively, improve the adjustable range of fuel and air and improve burning temperature in certain range so as to improve thermal efficiency. The burner in invention can burn natural gas, liquefied petroleum gas and mixed gas so on, also burn air fuel with low thermal value which is approached to 1000kcal / m3.

Owner:NORTHEASTERN UNIV LIAONING

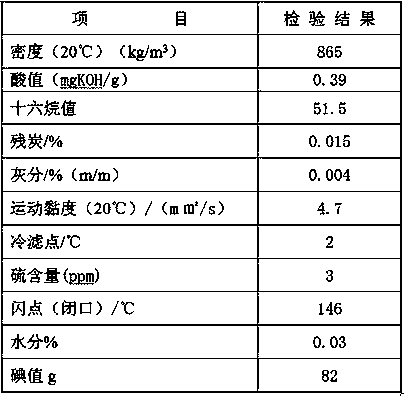

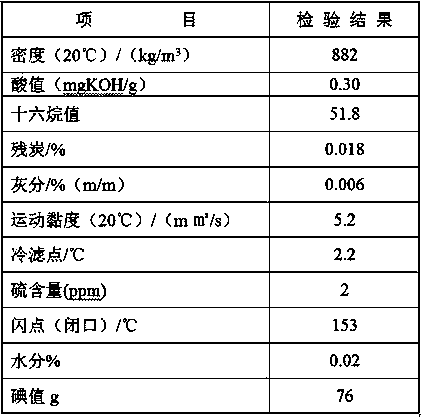

Novel catalyst for synthesizing biodiesel and application method of novel catalyst

InactiveCN110882693AReduce sulfide contentLess side effectsFatty acid esterificationHeterogenous catalyst chemical elementsCelluloseTrans esterification

The invention provides a novel catalyst for synthesizing biodiesel and an application method of the novel catalyst. The novel catalyst comprises an esterification catalyst and an ester exchange catalyst, wherein the esterification catalyst is zinc oxide, the ester exchange catalyst is a supported catalyst, and the ester exchange catalyst comprises the raw materials in parts by weight: 10-15 partsof aluminum oxide, 10-12 parts of zinc nitrate, 5-8 parts of dioctyl tin oxide, 20-25 parts of bentonite, 1-2 parts of polyvinyl alcohol and 5-8 parts of cellulose. The catalyst provided by the invention is used for preparing biodiesel; under a condition that a sulfur-containing catalyst is not used, the reaction yield of the esterification reaction can reach 91-96%, the ester exchange reaction yield can reach 96-98%, the purity of the finally prepared biodiesel product reaches 99.0-99.6%, the density (20 DEG C) is 865-890 / kg / m<3>, the acid value is 0.30-0.45 mg KOH / g, and the product qualityis excellent.

Owner:WEIFANG JIN XIN DA BIO CHEM

A process for recovering all components of desulfurization waste liquid

ActiveCN112125319BRealize resource utilizationReduce sulfide contentAmmonium sulfatesCatalytic transformationHydrogen Sulfate

The invention discloses a process for recovering all components of desulfurization waste liquid. The process is to pretreat the desulfurization waste liquid. The pretreatment process includes preheating or evaporation concentration; then the pretreatment liquid is passed into an oxidation conversion reactor, Carry out catalytic conversion treatment, add concentrated sulfuric acid with a mass percentage of 92%-98% during the conversion process, the conversion temperature is 110-130°C, and the conversion pressure is 0.1-0.5 MPa; the converted acid gas is washed with desulfurization liquid, and the converted The desulfurization solution is decolorized to obtain a sulfuric acid solution containing ammonium bisulfate. The invention converts all auxiliary salts in desulfurization waste liquid, has simple process flow, low investment and operation costs, solves the problems of difficult desulfurization waste liquid treatment and slow sales of desulfurization waste liquid auxiliary salts, and realizes full component recovery of desulfurization waste liquid and use.

Owner:TAIYUAN UNIV OF TECH

Method for desulphurizing gasoline

ActiveCN102093907BImprove stabilityIncrease the degree of exchangeOther chemical processesHydrocarbon oils refiningSorbentCerium

The invention relates to a method for desulphurizing gasoline. In the method, a beta molecular sieve serves as a carrier; a selective adsorbent is adopted to adsorb thiophene sulfides in the gasoline and remove the thiophene sulfides from the gasoline; a hydrogen type beta molecular sieve serves as the carrier of the adsorbent; the molecular sieve carries copper, silver, zinc, nickel or gallium metal ions and metal cerium ions; and the exchange amount of the metal ions is 0.001 to 15 percent based on the mass of the hydrogen type beta molecular sieve. The adsorbent is used to selectively adsorb the thiophene sulfides in the gasoline and deeply remove the thiophene sulfides from the gasoline. A result shows that: the bimetallic ions have a synergistic effect, improve the selectivity of adsorptive desulphurization and can reduce the content of the sulfides in the fluid catalytically cracked (FCC) gasoline to below 1mu g / g or zero from 200mu g / g. The reaction condition is mild; the equipment is simple; the activity of the adsorbent is high; and the adsorbent is easy to regenerate. At normal temperature and normal pressure, hydrogen is not consumed and the gasoline is finely desulphurized.

Owner:PETROCHINA CO LTD +1

High-density pelletizing biomass and pelletizing method thereof

The invention relates to high-density pelletizing biomass and a pelletizing method thereof. The pelletizing method comprises the steps that a mixture of straw powder particles with a certain proportion is fed into a forming machine, and extrusion is carried out under the condition of the temperature being 110-150 DEG C and pressure being 105-120 MPa to obtain the high-density pelletizing biomass with the density being 1.2-1.4g / cm<3> and 10-12% water content; and packaging is carried out after obtained forming fuel is reduced to a room temperature. The fuel is convenient to transport and easy to store, has extremely low sulfide content after combustion, and is a novel energy source with sustainable development.

Owner:江苏东工环保科技股份有限公司

A kind of diesel oil for smokeless vehicles and its preparation method

The invention discloses a smokeless vehicle diesel oil, which comprises the following components in parts by weight: 180 to 220 parts of aviation kerosene, 90 to 110 parts of plant oil, 245 to 265 parts of finely-processed drainage oil, 290 to 310 parts of self-made smokeless oil, 45 to 55 parts of anti-freezing and pour point reducing agent, 8 to 12 parts of upgrading agent, and 30 to 40 parts of flame retardant. The finely-processed drainage oil is prepared by the following steps: heating drainage oil, removing impurities from drainage oil, carrying out primary filtration by a filter screen, and carrying out secondary filtration through pressurization. The smokeless vehicle diesel oil is prepared by the following steps: mixing smoke oil and edible vinegar according to a weight ratio of 1000:10-15, stirring for 40 to 50 minutes at a temperature of 11 to 12 DEG C in a rotation speed of 60 to 120 r / min, allowing the system to stand still, when the precipitate has a dark-red color and the supernatant oil has a white-green color so as to obtain the self-made smokeless oil (supernatant oil); mixing kerosene, plant oil, and finely-processed drainage oil, stirring until specific gravity reaches 0.85, transferring the mixture to another container, adding self-make smokeless oil, an anti-freezing and pour point reducing agent, an upgrading agent, and a flame retardant, stirring until the specific gravity of the mixture reaches 0.85, stopping stirring, and completely transferring the mixture to an oil storage tank so as to obtain the smokeless vehicle diesel oil. The raw material costs of the smokeless vehicle diesel oil are reduced, moreover, the diesel oil is smokeless and environment-friendly, and the quality of the diesel oil meets the standards of DB11 / 239-2010.

Owner:郭永秋 +2

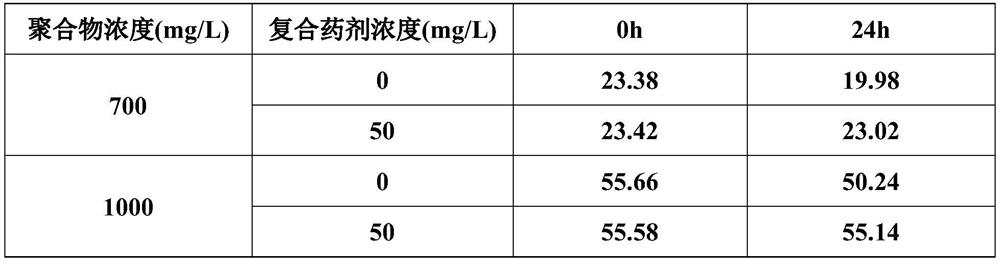

Composite agent for changing metabolic mode of sulfate reducing bacteria and using method thereof

ActiveCN111676006AReduce sulfide contentReduce decompositionFluid removalDrilling compositionNitrate saltsEnvironmental engineering

The invention discloses a composite agent for changing a metabolic mode of sulfate reducing bacteria and a using method thereof. In order to solve the problems of unstable polymer viscosity and a large loss in the process from polymer preparation to underground injection in the prior art, the composite agent is prepared from a nitrate substrate, urea, nutrient elements and water. The composite agent for changing the metabolic mode of the sulfate reducing bacteria is used for preparing a polymer mother liquor and diluting polymers, and then is used for oil exploitation. According to the invention, the sulfide content in the polymer solution is reduced, and the viscosity loss of the polymer in the process from preparation to underground injection is greatly reduced. The composite agent is suitable for an oil field ground system for preparing clear water and sewage or diluting polymers, and an oil field ground system with large polymer viscosity loss in the process from polymer preparation to polymer injection.

Owner:HUACHEN ENVIRONMENTAL PROTECTION ENERGY (GUANGZHOU) CO LTD

Process for evaluating polymer-containing sewage diluted polymer solution by clear water preparation and oxygen exposure treatment

InactiveCN111323337AReduce ferrous ironReduce sulfide contentFlow propertiesPreparing sample for investigationEnvironmental engineeringPolymer solution

The invention relates to the technical field of oilfield produced water treatment, in particular to a process for evaluating a polymer-containing sewage diluted polymer solution by clear water preparation and oxygen exposure treatment. The evaluation process comprises the following steps: a, evaluating three oxygen exposure processes by adopting a series connection mode of an oxygen exposure process (air compressor oxygen exposure, ejector oxygen exposure and improved oxygen exposure) and a polymer dilution process; b, an oxygen aeration process: respectively carrying out air compressor oxygenaeration, ejector oxygen aeration and improved oxygen aeration treatment on the polymer-containing sewage by adjusting the gas-water ratio; and c, a polymer dilution process: fully mixing the polymer-containing sewage in the output water tank with the polymer mother liquor in the polymer mother liquor tank at the static mixer. According to the evaluation process, through the water quality of thetreated polymer-containing sewage and the viscosity of a diluted polymer solution, the application effects of an air compressor oxygen exposure process, an ejector oxygen exposure process and an improved oxygen exposure process are compared and evaluated, and the optimal oxygen exposure mode and optimal oxygen exposure process parameters are optimized.

Owner:DAQING OILFIELD CO LTD +2

Preparation and application methods of triple composite deodorant

InactiveCN111575200AImprove survival rateNo pollutionBacteriaWater contaminantsBiotechnologyFermentation

The invention relates to the technical field of biological environments, in particular to a preparation method of a triple composite deodorant. The triple composite deodorant is composed of thiobacillus thioparus, rhodospirillum sphaeroides and lactobacillus plantarum. The preparation method comprises the following specific steps of performing separation to obtain the thiobacillus thioparus, the rhodospirillum sphaeroides and the lactobacillus plantarum, and storing the strains in an LB solid flat plate; picking the three strains by using an inoculating loop, and inoculating the three strainsinto a liquid culture medium; and sequentially carrying out primary fermentation culture on the three strains, and carrying out composite inoculation on the three strains in a fermentation tank filledwith the liquid culture medium according to a ratio of 4: 3: 3 for secondary fermentation culture, thereby obtaining the liquid triple composite deodorant. The invention also provides an applicationmethod of the triple composite deodorant. According to the invention, the thiobacillus thioparus, the lactobacillus and photosynthetic bacteria are organically combined, so that the generation of odorous gases in black and odorous rivers and landfill leachate can be effectively reduced, and the self-repairing capability of the culture water environment is maintained.

Owner:南京师盛生态环境研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com