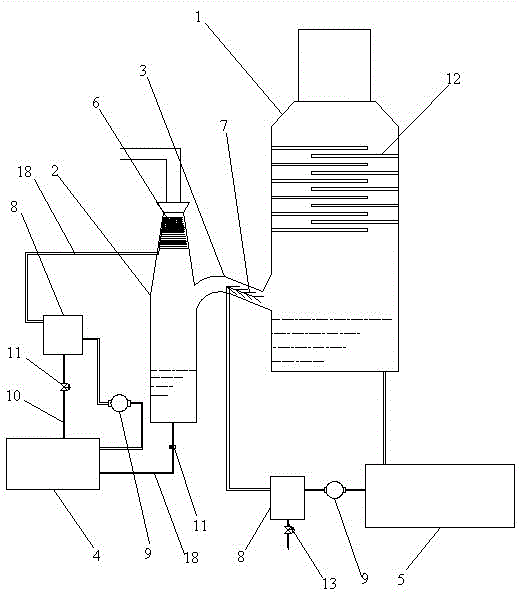

Dedusting method and device

A technology for dust removal equipment and alkaline solution is applied in the field of dust removal methods and equipment for boilers, which can solve the problems of difficult to use, poor dust removal effect and low efficiency, and achieve the effects of convenient production, improved dust removal efficiency and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A dust removal method is to desulfurize the flue gas through an alkaline solution containing calcium carbonate and magnesium oxide (mass percentage of calcium carbonate, magnesium oxide and water: 1:1:50), the flue gas is fully contacted and mixed, and the flue gas SO2 in the air chemically reacts with calcium carbonate and magnesium oxide to achieve the purpose of dedusting. The lye is refluxed and recycled under the action of the pump through the filter; the flue gas that has been desulfurized and dedusted in the previous stage reaches the clear water dedusting spray area for further desulfurization, Dust is removed, and the flue gas is discharged through the flue through the chimney.

Embodiment 2

[0026] A dust removal method is to desulfurize the flue gas through an alkaline solution containing calcium carbonate and magnesium oxide (mass percentage of calcium carbonate, magnesium oxide and water: 10:10:300), the flue gas is fully contacted and mixed, and the flue gas SO2 in the air chemically reacts with calcium carbonate and magnesium oxide to achieve the purpose of dedusting. The lye is refluxed and recycled under the action of the pump through the filter; the flue gas that has been desulfurized and dedusted in the previous stage reaches the clear water dedusting spray area for further desulfurization, Dust is removed, and the flue gas is discharged through the flue through the chimney.

Embodiment 3

[0028] A dust removal method is to desulfurize the flue gas through an alkaline solution containing calcium carbonate and magnesium oxide (mass percentage of calcium carbonate, magnesium oxide and water: 5:5:150), the flue gas is fully contacted and mixed, and the flue gas SO2 in the air chemically reacts with calcium carbonate and magnesium oxide to achieve the purpose of dedusting. The lye is refluxed and recycled under the action of the pump through the filter; the flue gas that has been desulfurized and dedusted in the previous stage reaches the clear water dedusting spray area for further desulfurization, Dust is removed, and the flue gas is discharged through the flue through the chimney.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com