Porous metal medium burner capable of burning low heat value gas

A low calorific value gas, porous metal technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., to achieve the effects of reducing pollution, saving energy, and reducing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

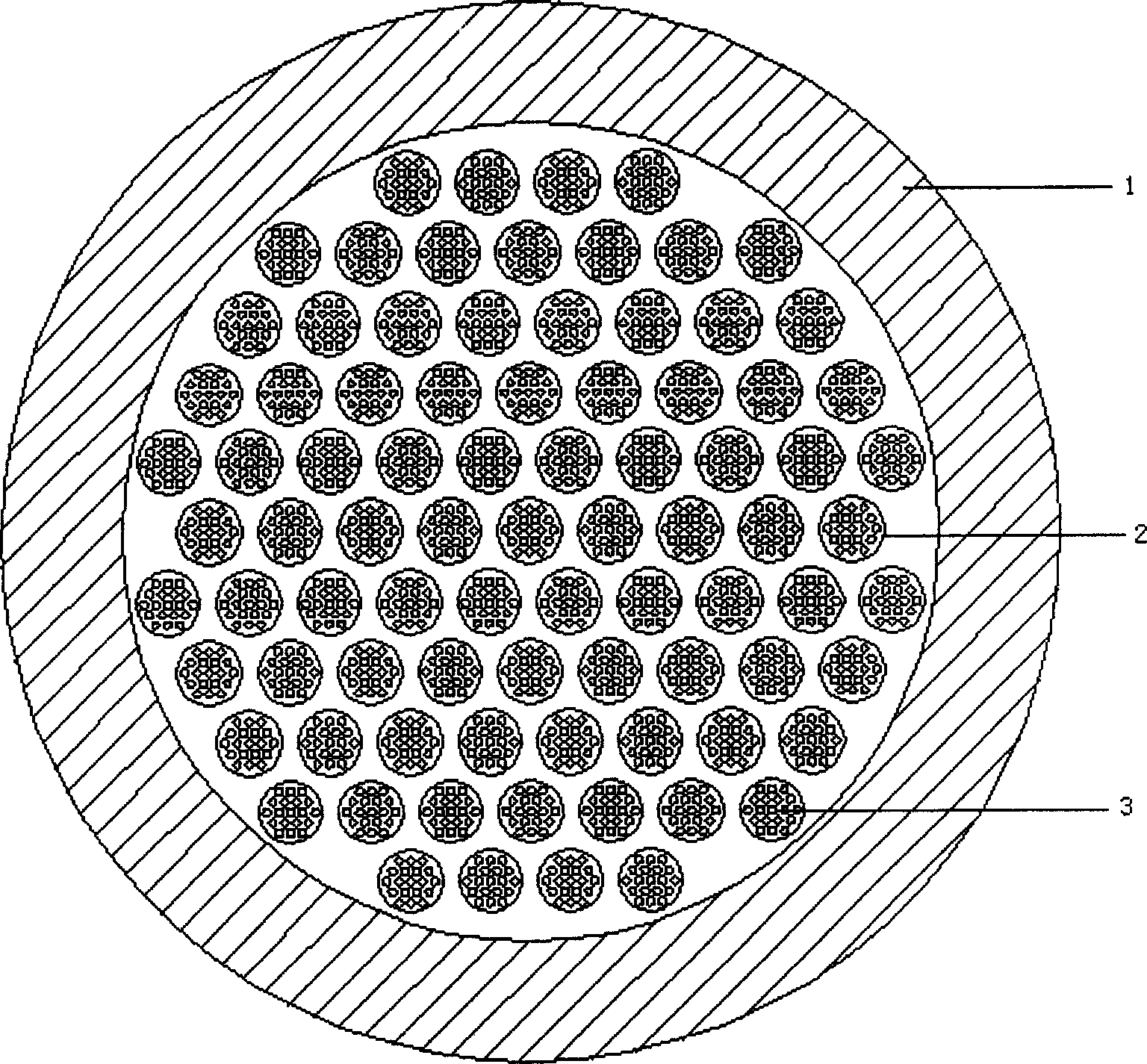

[0025] like figure 1 , figure 2 As shown, the main body of the burner is composed of 1 refractory casing, 2 large-pore medium in the combustion zone, 3 small-pore medium in the preheating zone, 4 burner shell, 5 dust removal metal mesh or metal brush, 6 gas pipeline, 7 premixing chamber and 8 air pipes, in the cavity formed by the burner casing 4 and the refractory sleeve 1, the large-pore medium 2 in the combustion zone, the small-pore medium 3 in the preheating zone, and the combustion zone are arranged in sequence from top to bottom. The materials of the inner large-pore medium 2 and the small-pore medium 3 in the preheating zone can all be made of high-temperature-resistant stainless steel. The top of the small hole medium 3 in the preheating zone is flush with the top of the burner shell 4, the large hole medium 2 in the combustion zone and the small hole medium 3 in the preheating zone can be a whole, it is best to design a number of large holes Small hole. From the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com