Air-conditioner hot-water composite machine

A technology of air-conditioning hot water and composite machines, which is applied in the direction of heating and cooling combination, refrigerators, compressors, etc., and can solve the problem that the cooling effect of heat pump hot water units can no longer be fully recovered, and the condensation heat can only be partially recycled, affecting refrigeration or Heating efficiency and other issues, to achieve the effect of simple structure, convenient manufacture and maintenance, and improved energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

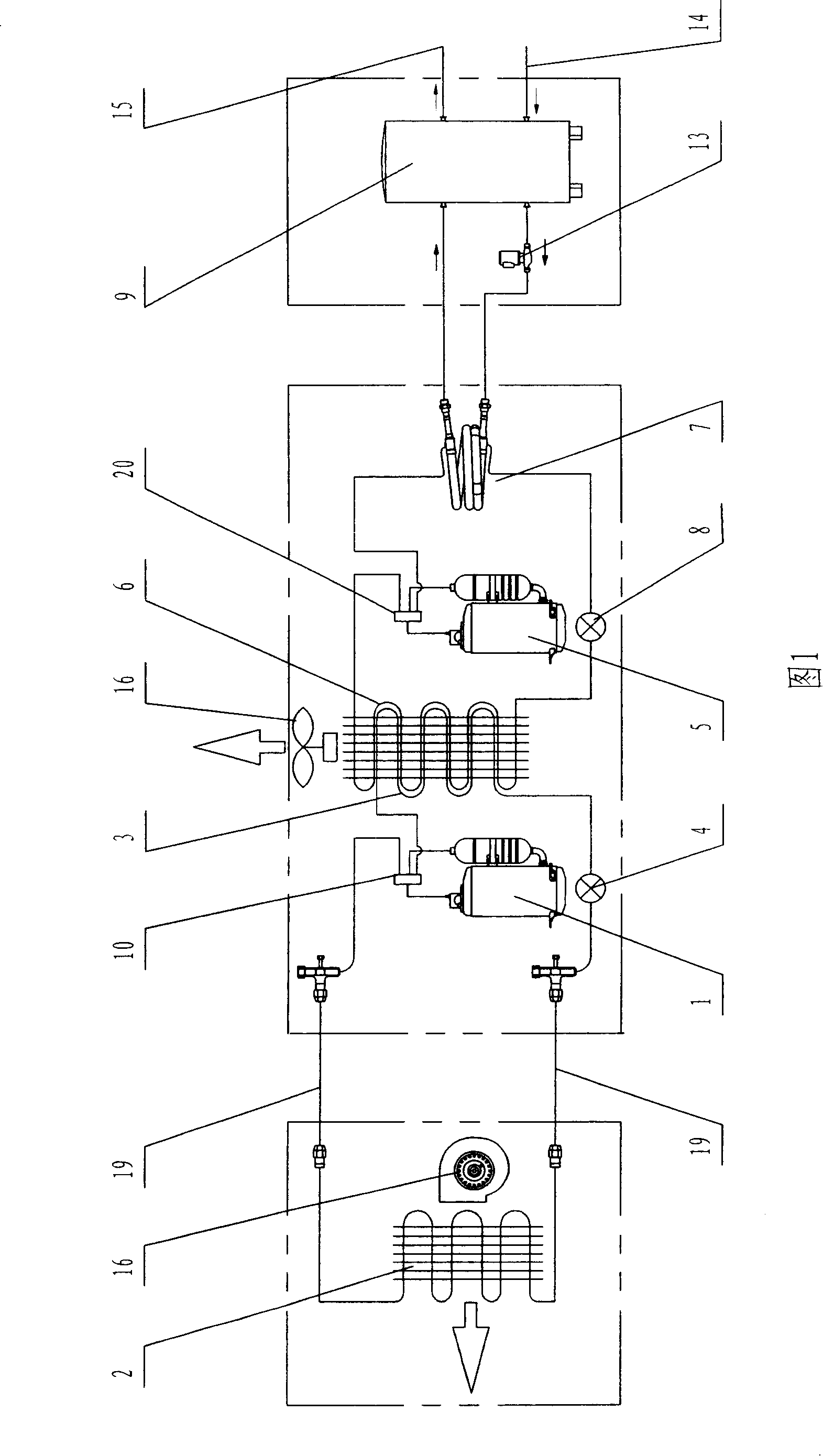

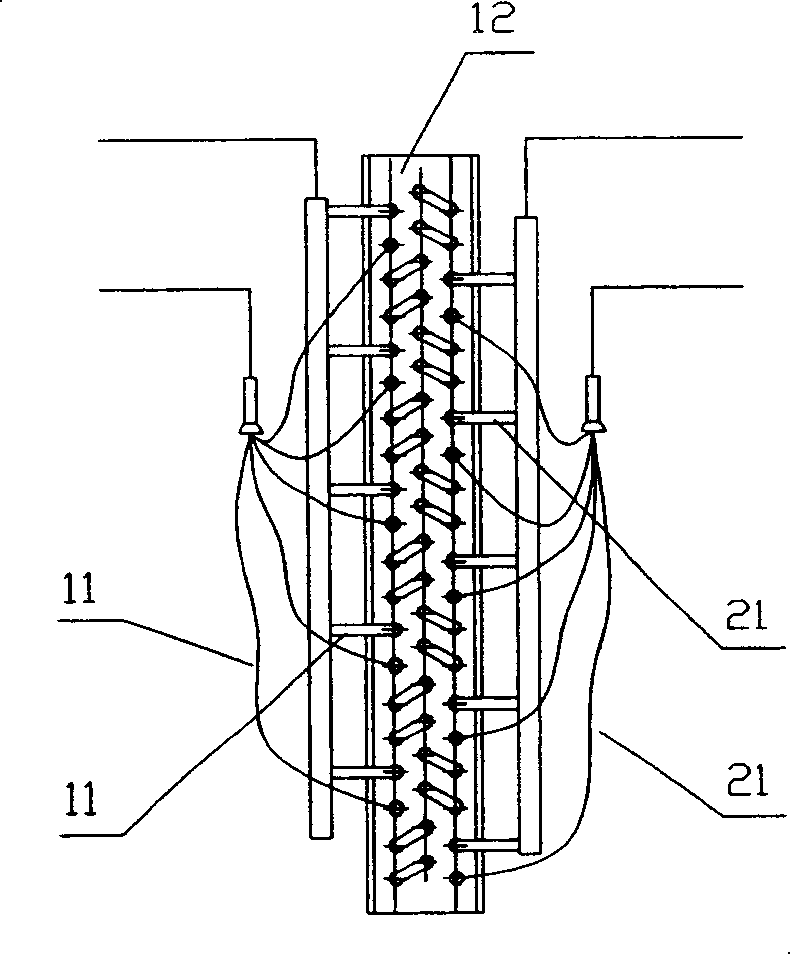

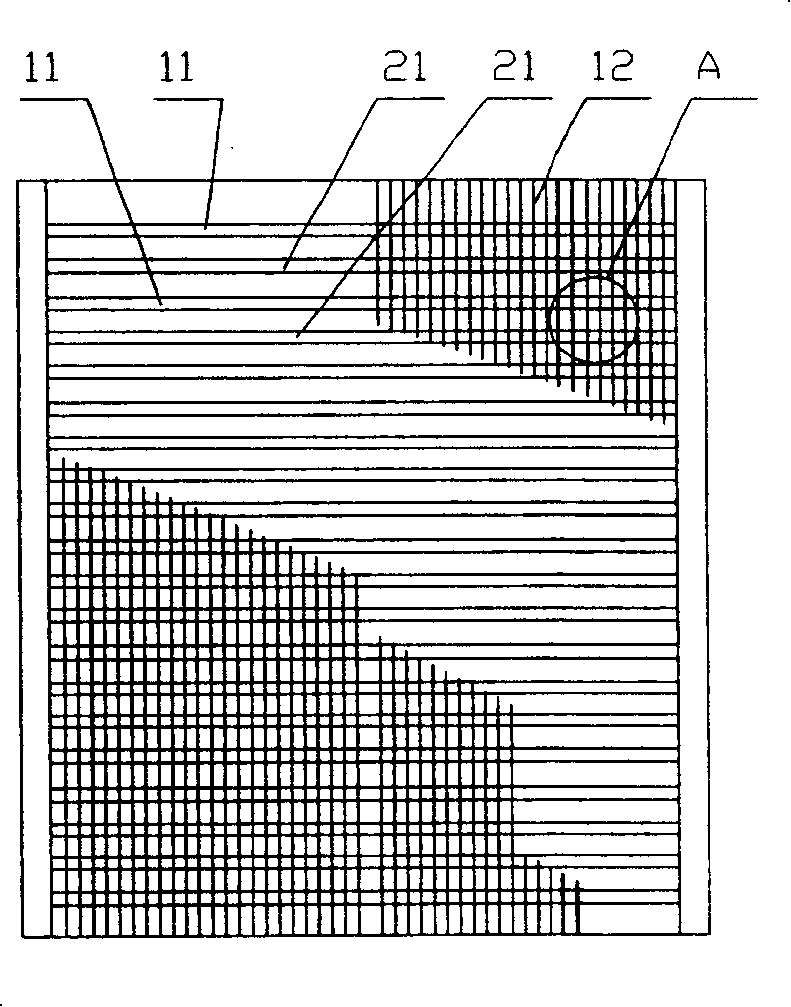

[0046] See Figure 1 to Figure 4 , an air-conditioning and hot-water composite machine, the air-conditioning and hot-water composite machine includes a circulation circuit for an air-conditioning system composed of a first compressor 1, a first heat exchanger 2, a second heat exchanger 3, and a first throttling mechanism 4 , and a hot water heating circulation loop composed of the second compressor 5, the third heat exchanger 6, the fourth heat exchanger 7, and the second throttling mechanism 8; the second heat exchanger 3 and the third heat exchanger The heat exchanger 6 forms a heat exchange connection; the fourth heat exchanger 7 forms a waterway connection with the hot water pipeline, and the hot water pipeline is provided with a water inlet and a water outlet; the water inlet and the water outlet are connected to the heat storage tank 9 at the same time, and A hot water pump 13 is arranged on the hot water pipeline, and a water inlet pipe 14 and a water outlet pipe 15 are...

Embodiment 2

[0066] Please refer to Fig. 5, the difference between this embodiment and the first embodiment is that the fourth heat exchanger 7 is a coil type immersed in the heat storage tank 9, and the high-temperature and high-pressure gaseous refrigerant discharged by the second compressor 5 Enter the fourth heat exchanger 7 through the second four-way valve 20 to condense and release heat, and heat the water in the hot water storage tank 10 through the released condensation heat, so that the temperature of the water stored in the hot water storage tank 9 gradually increases , to achieve the effect of producing hot water. After the refrigerant is condensed in the fourth heat exchanger 7, it is throttled by the second throttling mechanism 8 and then enters the third heat exchanger 6 to evaporate and absorb heat. The second four-way valve 20 re-enters the second compressor 5 .

Embodiment 3

[0068] Please refer to FIG. 6 , the difference between this embodiment and the first embodiment is that the first heat exchanger 2 is a water-refrigerant type, which cools or heats the circulating water of the air conditioner.

[0069] During refrigeration, the high-temperature and high-pressure gaseous refrigerant discharged from the first compressor 1 enters the second heat exchanger 3 through the first four-way valve 10 to exchange heat with the outdoor air to release heat. At this time, the second heat exchanger 3 is used as a condenser. The condensed refrigerant liquid enters the first heat exchanger 2 after throttling through the first throttling mechanism 4, exchanges heat with the air-conditioning circulating water in the first heat exchanger 2, reduces the temperature of the circulating water, and passes through the air-conditioning circulating water pump 18 The refrigerant circulates into the indoor coil 17 for cooling the room, and the refrigerant re-enters the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com