Zero-release coupling humidifying dust-removing synergizing system and method for desulfurization wastewater

A technology for desulfurization wastewater and zero discharge, applied in chemical instruments and methods, gaseous effluent wastewater treatment, electrostatic effect separation, etc., can solve problems such as high operating costs, incomplete evaporation, dust accumulation and corrosion, and achieve investment and operation Low cost, lower fly ash specific resistance, water and energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

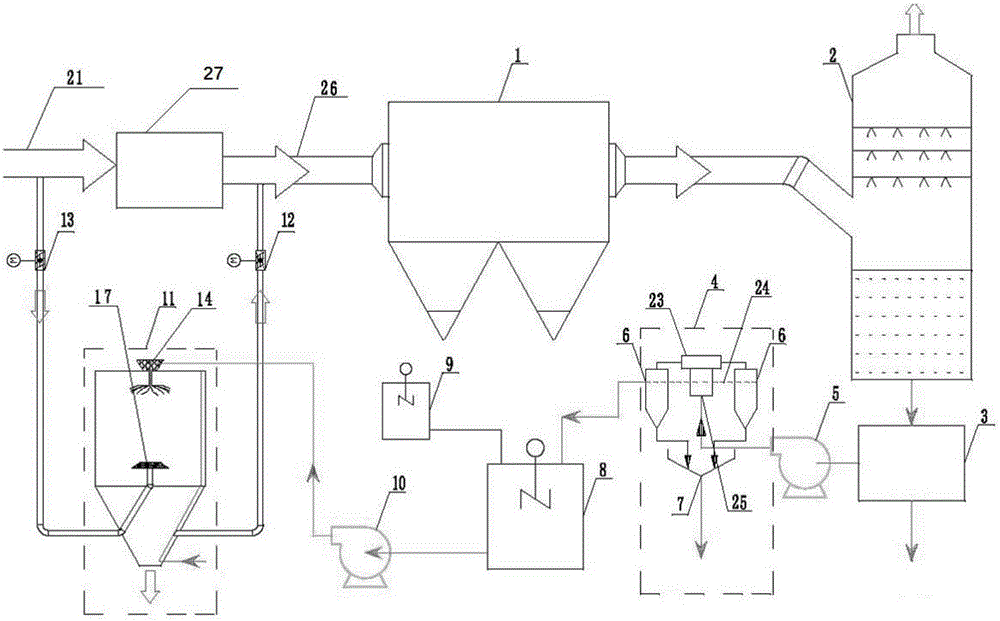

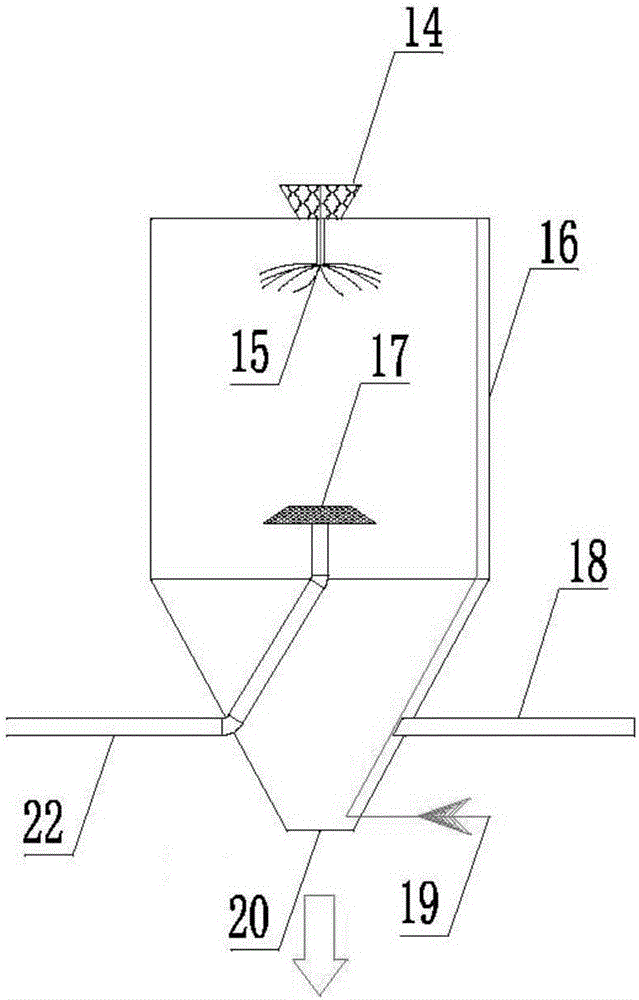

[0037] refer to figure 1 , figure 2, a zero-discharge desulfurization wastewater coupling humidity control and dust removal efficiency enhancement system, including a desulfurization tower 2 connected in sequence, a gypsum dehydration system 3, a waste water cyclone 4, a waste water tank 8, a rotary spray evaporation tower 11 and a dust collector 1. The waste water cyclone includes a swirl sub-body 23 and an overflow pipe 24. The swirl sub-body is provided with a cyclone inlet 25 and a bottom flow port 7, and the bottom flow port 7 is located at the bottom of the swirl sub-body. The inlet 25 of the cyclone is connected to the gypsum dehydration system 3, the bottom outlet 7 of the cyclone is connected to the desulfurization tower 2, the overflow pipe 24 is arranged on the cyclone body, and the overflow pipe has an overflow port 6 , the overflow port 6 is connected to the waste water tank 8, the overflow port 6 is arranged on the upper part of the cyclone sub-body, and the cy...

Embodiment 2

[0041] refer to figure 1 , figure 2 , a desulfurization wastewater zero discharge coupled humidity control and dust removal method, using the system described in Example 1, comprising the following steps:

[0042] (1) After the gypsum slurry in the desulfurization tower 2 is treated by the gypsum dehydration system 3, it is transported to the waste water cyclone 4 through the first waste water delivery pump 5;

[0043] (2) After the waste water is treated by the waste water cyclone 4, it is discharged to the desulfurization tower 2 through the bottom flow port 7 of the waste water cyclone for recycling. The overflow of the cyclone is transported to the waste water tank 8 through the waste water overflow port 6 for collection. The high-level lye tank 9 self-flows to the waste water tank 8, adjusts the pH of the waste water, realizes that the pH of the waste water is greater than 7 and at the same time realizes the softening of the waste water, and the waste water after soften...

Embodiment 3

[0050] refer to figure 1 , figure 2 , for a combined heat and power unit with a boiler capacity of 260t / h, the flue gas volume is about 300,000 Nm 3 / h, the smoke temperature of the flue gas in front of the air preheater 27 is about 350°C, and the flue gas temperature behind the air preheater 27 is about 130°C under the rated load of the boiler. Process + limestone-gypsum wet flue gas desulfurization and dust removal process), the temperature of the wastewater after the gypsum slurry in the desulfurization tower 2 is treated by the gypsum dehydration system 3 is 40°C, and it is transported to the wastewater cyclone 4 through the first wastewater delivery pump 5; The overflow port 6 is transported to the waste water tank 8 for collection, adding a calcium hydroxide solution with a mass fraction of 10% to adjust the pH of the waste water to 9, and the waste water after the pH adjustment is transported to the rotating mist in the rotary spray evaporation tower system through th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com