Method of controlling internal combustion engine

一种控制方法、内燃机的技术,应用在发动机控制、燃料喷射控制、内燃活塞发动机等方向,能够解决可靠性降低、出来白烟等问题,达到防止白烟、抑制波动和白烟增大、降低噪音的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Next, embodiments of the invention will be described.

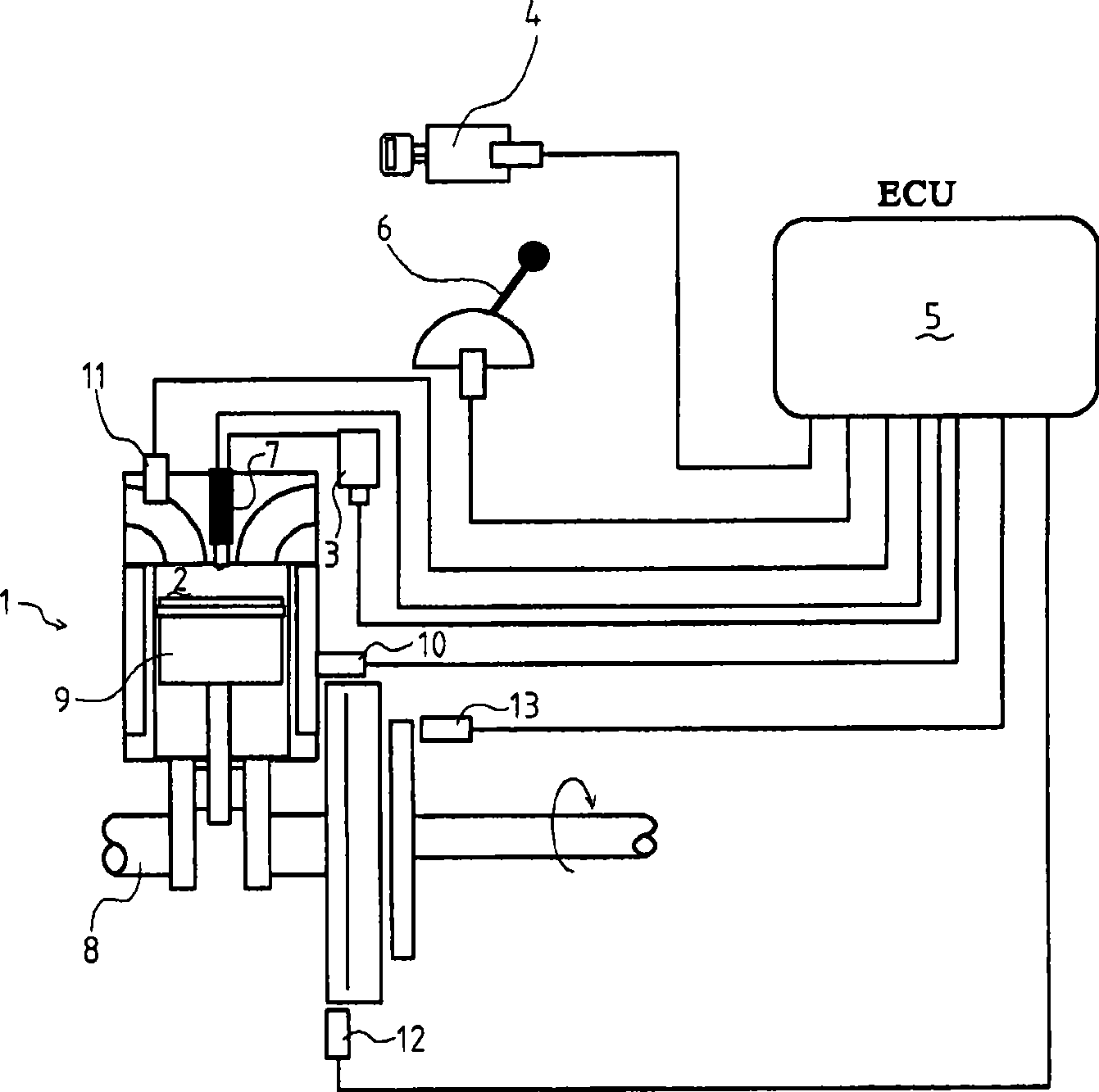

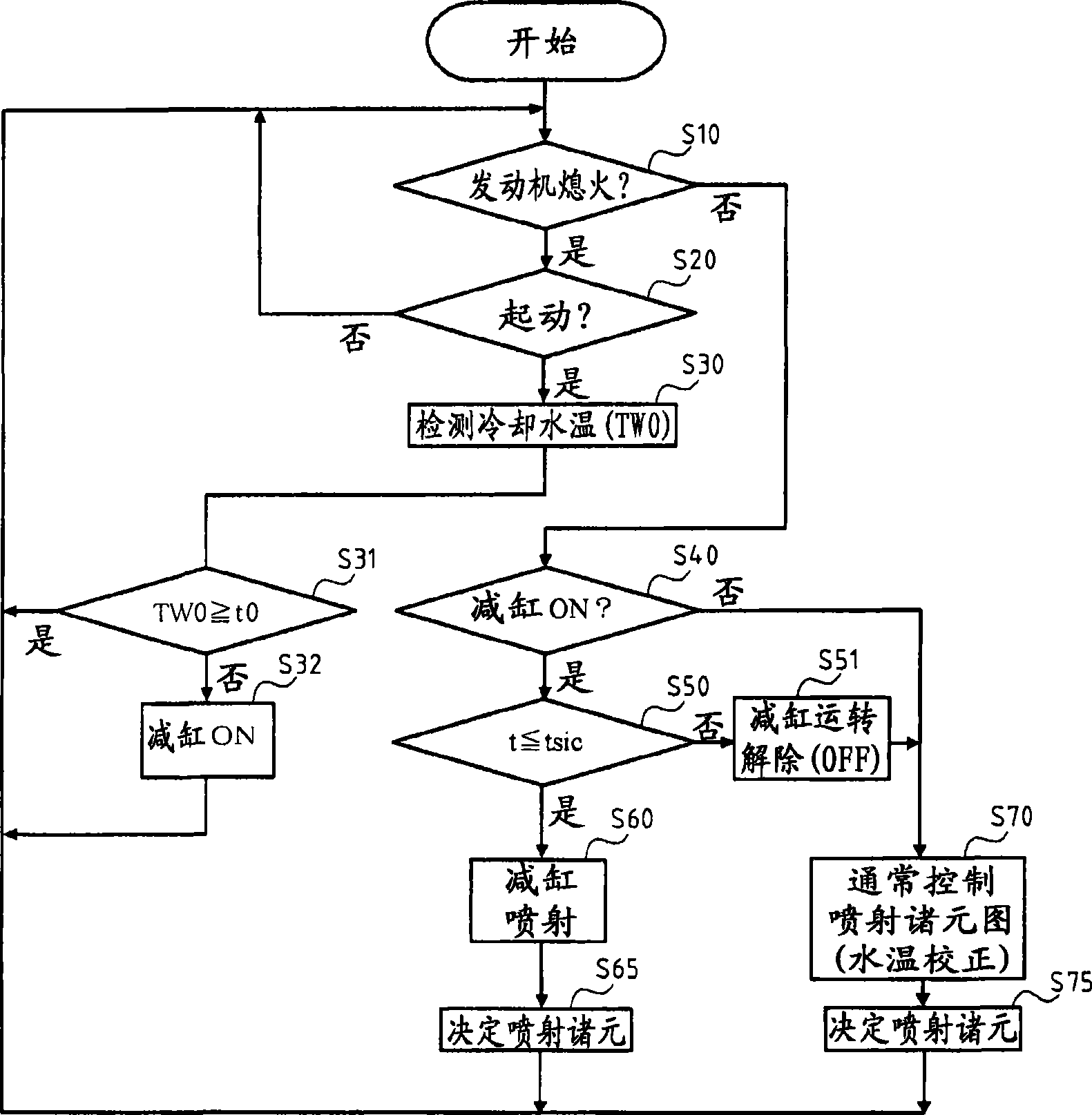

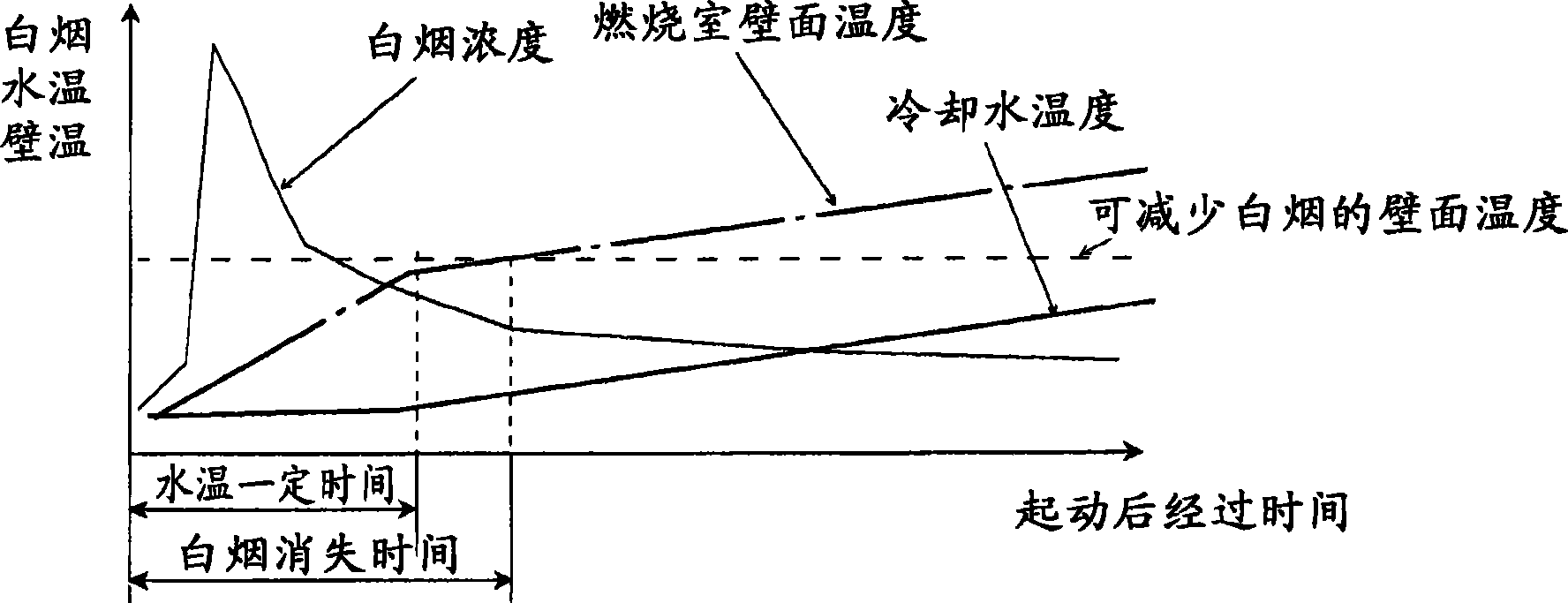

figure 1 It is a schematic configuration diagram of the control system of the direct injection diesel engine related to the present invention, figure 2 is a diagram representing the engine control flow, image 3 It is a graph showing the generation characteristics of white smoke during normal operation, Figure 4 is a diagram showing an example of the operation control with reduced cylinders, Figure 5 It is a graph showing the relationship between the cooling water temperature before starting and the white smoke density, Image 6 It is a graph showing the generation characteristics of white smoke during operation with reduced cylinders, Figure 7 It is a graph showing the time change of the temperature in the combustion chamber, Figure 8 It is a graph showing the relationship between the arrival distance of fuel and time when fuel is injected by single-stage injection, Figure 9 It is a diagram showing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com