High-temperature biomass micron fuel

A biomass and fuel technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of litter and weed rot, pollution, accidents, etc., and achieve the advantages of easy industrial control, broad application prospects, and high combustion temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0023] The biomass is cotton stalk. After the cotton stalk is pre-processed (less than 50mm in length) and dried (with moisture less than 12%), the biomass crusher invented by the inventor is used to prepare it into a biomass micron fuel, which is composed of 100% plants. In the mass fraction of the fiber powder, the particles smaller than 50 microns account for 30.5%, those smaller than 100 microns account for 71%, those smaller than 250 microns account for 96.5%, and those smaller than 400 microns account for 100%.

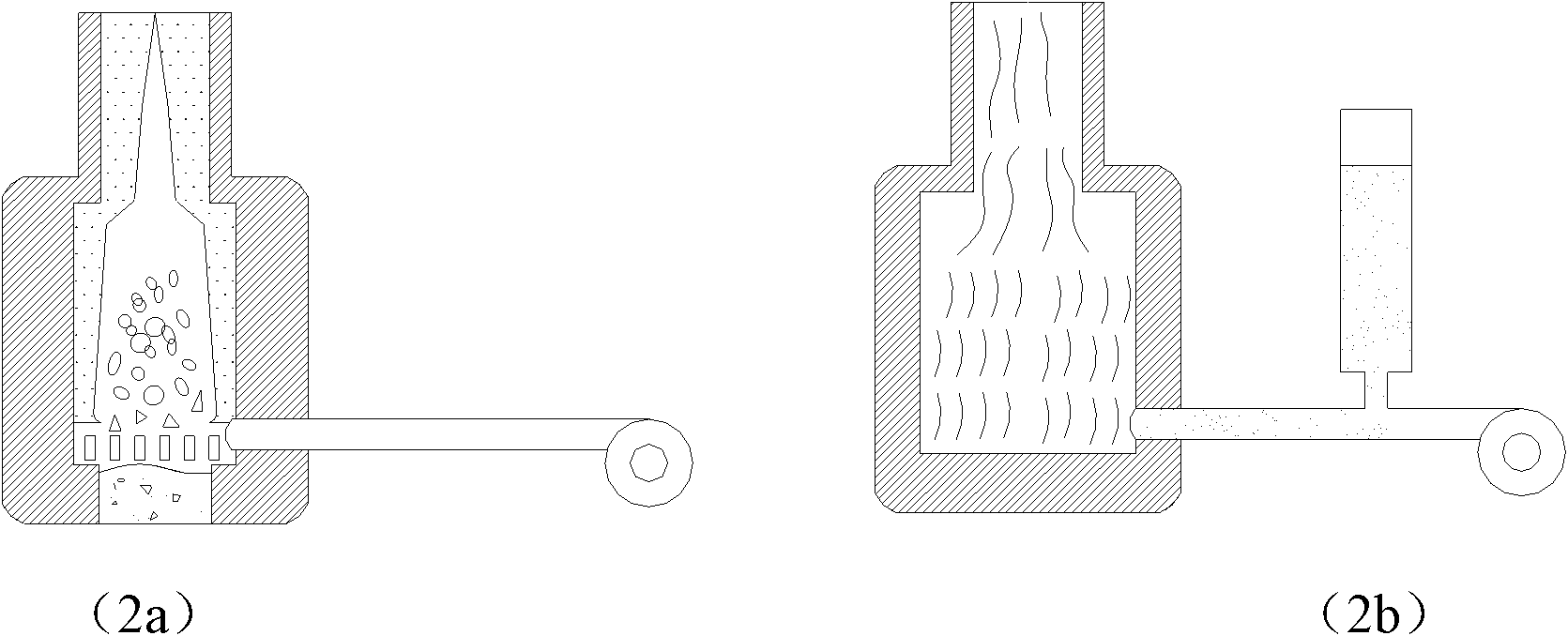

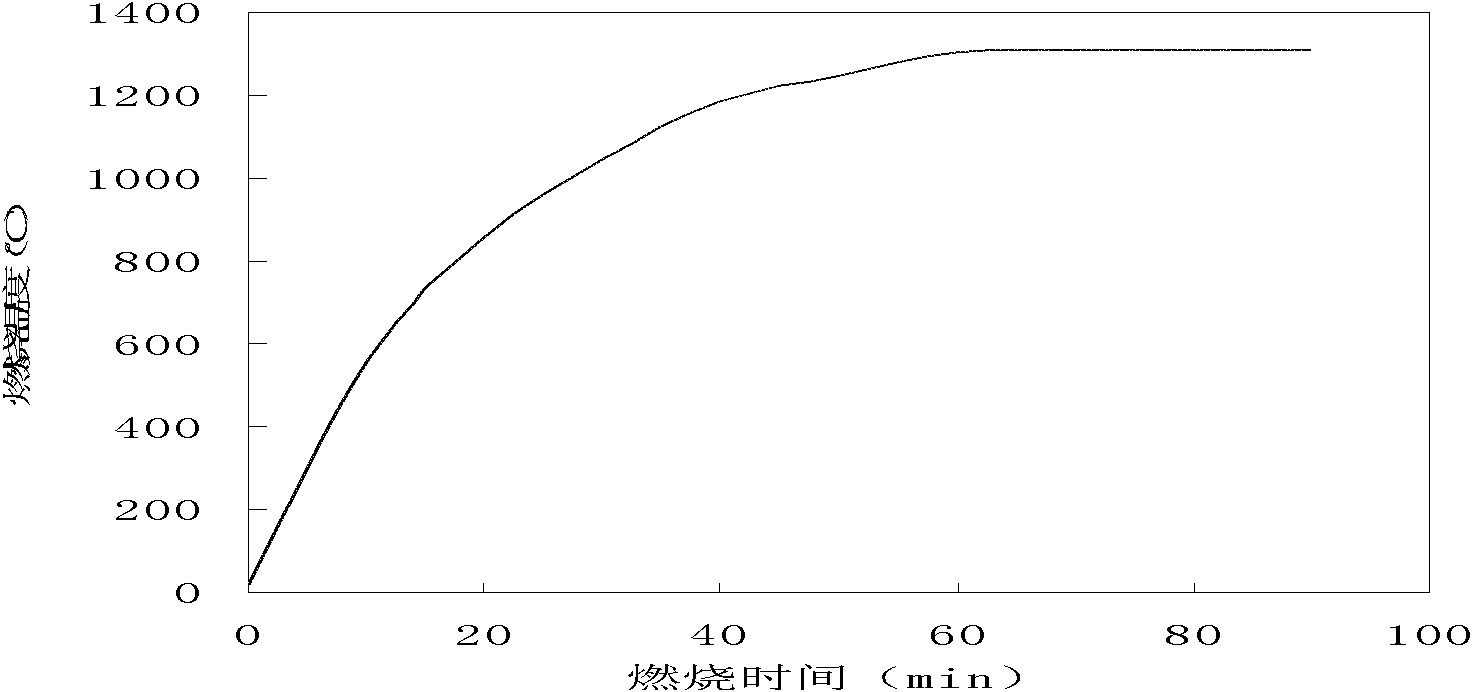

[0024] The biomass micron fuel is placed in the fuel hopper, and the biomass micron fuel is given by the quantitative feeding device, and is mixed with an appropriate amount of air to form a dust cloud. (300mm in diameter) under the ignition conditions of pre-ignited firewood and waste paper flames, the micron fuel is heated and gasified into combustible gases such as carbon monoxide, hydrogen and methane, and burns with air, and the furnace temperature continues...

example 2

[0028] The biomass is cotton stalks, after the cotton stalks are preprocessed (less than 50mm in length) and dried (moisture is less than 12%), the biomass crusher invented by the inventor is used to prepare biomass micron fuel, which is composed of plant fiber powder 75%, coal powder 20%, lime powder 5% (<150 microns). The particle size of the plant fiber powder is less than 50 microns, 30.5%, less than 100 microns, 71%, less than 250 microns, 96.5%, and less than 400 microns, 100%.

example 3

[0030] The biomass is cotton stalks, after the cotton stalks are preprocessed (less than 50mm in length) and dried (moisture is less than 12%), the biomass crusher invented by the inventor is used to prepare biomass micron fuel, which is composed of plant fiber powder 75%, coal powder 20%, red mud powder 5% (<150 microns). The particle size of the plant fiber powder is less than 50 microns, 30.5%, less than 100 microns, 71%, less than 250 microns, 96.5%, and less than 400 microns, 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com