A paste for self-propagating high-heat automatic welding stainless steel and its preparation method and use method

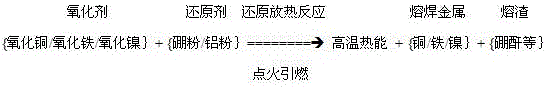

An automatic welding, stainless steel technology, applied in the direction of welding equipment, welding medium, welding/cutting medium/material, etc., to achieve the effect of easy control, stable combustion speed and good performance of welding slag discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

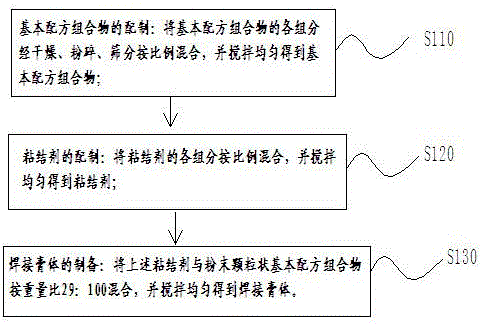

[0034] see figure 1 , the preparation method of the above-mentioned paste free from breeding high-heat automatic welding stainless steel, which comprises the following steps:

[0035] S110, 1) Preparation of the basic formula composition: the components of the basic formula composition are dried, pulverized, sieved and mixed in proportion, and stirred evenly to obtain the basic formula composition; preferably, the specific operation of the drying process is as follows: Dry each component of the basic formula composition at a temperature of 100-110° C. for not less than 1 hour.

[0036] S120, 2) Preparation of the binder: mix the components of the binder in proportion, and stir evenly to obtain the binder;

[0037] S130, 3) Preparation of soldering paste: mix the above-mentioned binder with the basic formula composition in powder and granular form at a weight ratio of 29:100, and stir evenly to obtain a soldering paste.

[0038] The prepared welding paste is packaged into a t...

Embodiment 1

[0043] A paste for self-breeding high-heat automatic welding stainless steel, which includes a basic formula composition and a binder, and the weight ratio of the binder to the basic formula composition is 29:100; the basic formula composition The components include boron powder, copper oxide, nickel oxide, ferric oxide, and potassium nitrate. The weight percentages of the above components are: boron powder 9.9%, copper oxide 61.7%, nickel oxide 23.4%, and ferric oxide 2.1% %, potassium nitrate 2.9%; the components of the binder include ethylene glycol, sodium perchlorate, and ethyl cellulose hydroxide: the above components are respectively in terms of mass fraction: ethylene glycol 54.0%, high Sodium chlorate 45.1%, ethyl cellulose hydroxide 0.9%.

[0044] see figure 1 , the preparation method of the above-mentioned paste free from breeding high-heat automatic welding stainless steel, which comprises the following steps:

[0045] 1) Preparation of the basic formula composit...

Embodiment 2

[0049] A paste for self-breeding high-heat automatic welding stainless steel, which includes a basic formula composition and a binder, and the weight ratio of the binder to the basic formula composition is 29:100; the basic formula composition The components include boron powder, copper oxide, nickel oxide, ferric oxide, and potassium nitrate. The weight percentages of the above components are: boron powder 8.4%, copper oxide 63.6%, nickel oxide 23.1%, and ferric oxide 2.2% %, potassium nitrate 2.7%; the components of the binder include ethylene glycol, sodium perchlorate, and ethyl cellulose hydroxide: the above components are respectively in terms of mass fraction: ethylene glycol 53.8%, high Sodium chlorate 45.2%, ethyl cellulose hydroxide 1.0%.

[0050] see figure 1 , the preparation method of the above-mentioned paste free from breeding high-heat automatic welding stainless steel, which comprises the following steps:

[0051] 1) Preparation of the basic formula composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com