Glass plastic package injection molding die

A technology of injection molding and plastic wrap, applied in coating and other directions, can solve the problems of difficult glass positioning, difficult to improve production efficiency, poor frame size accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

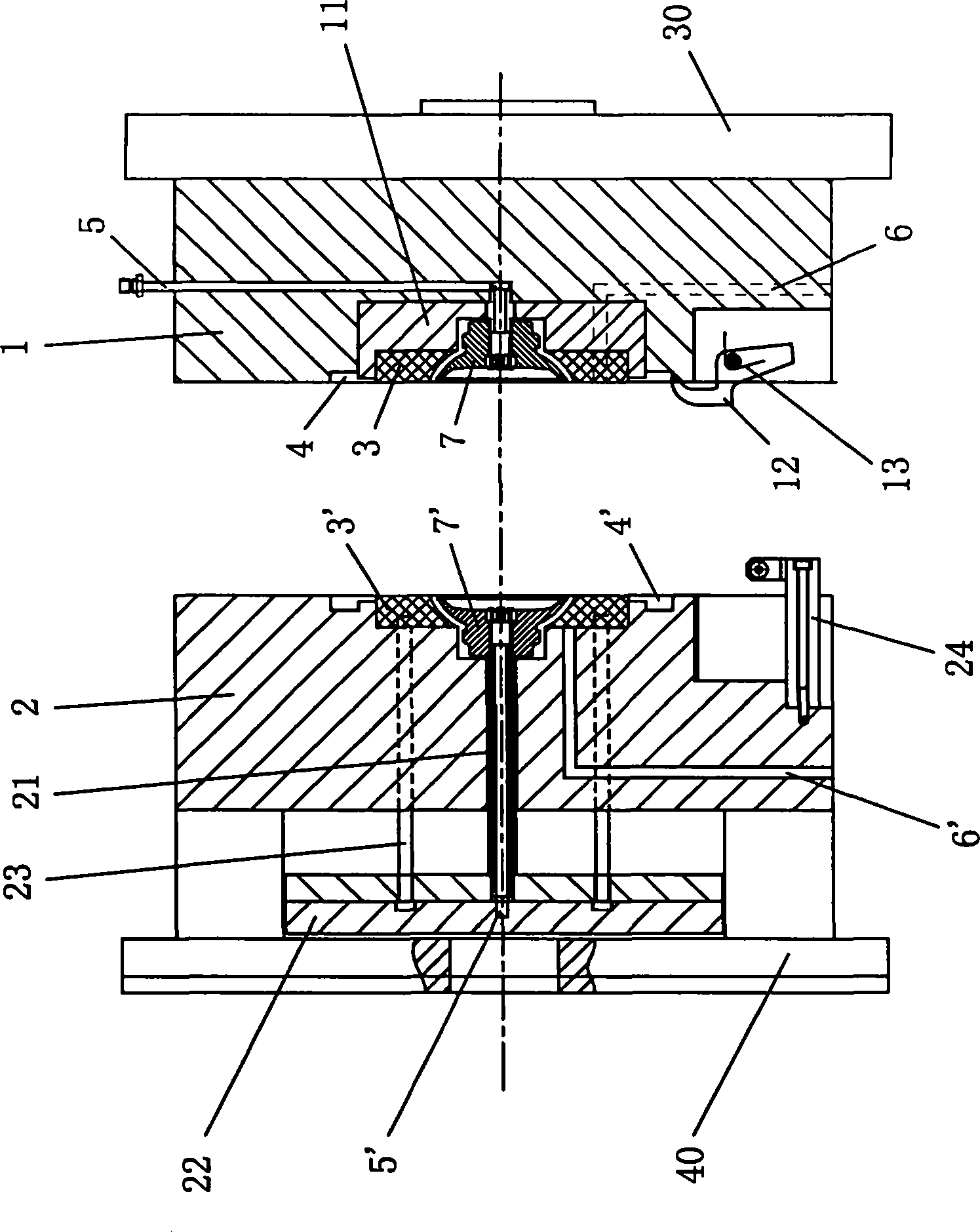

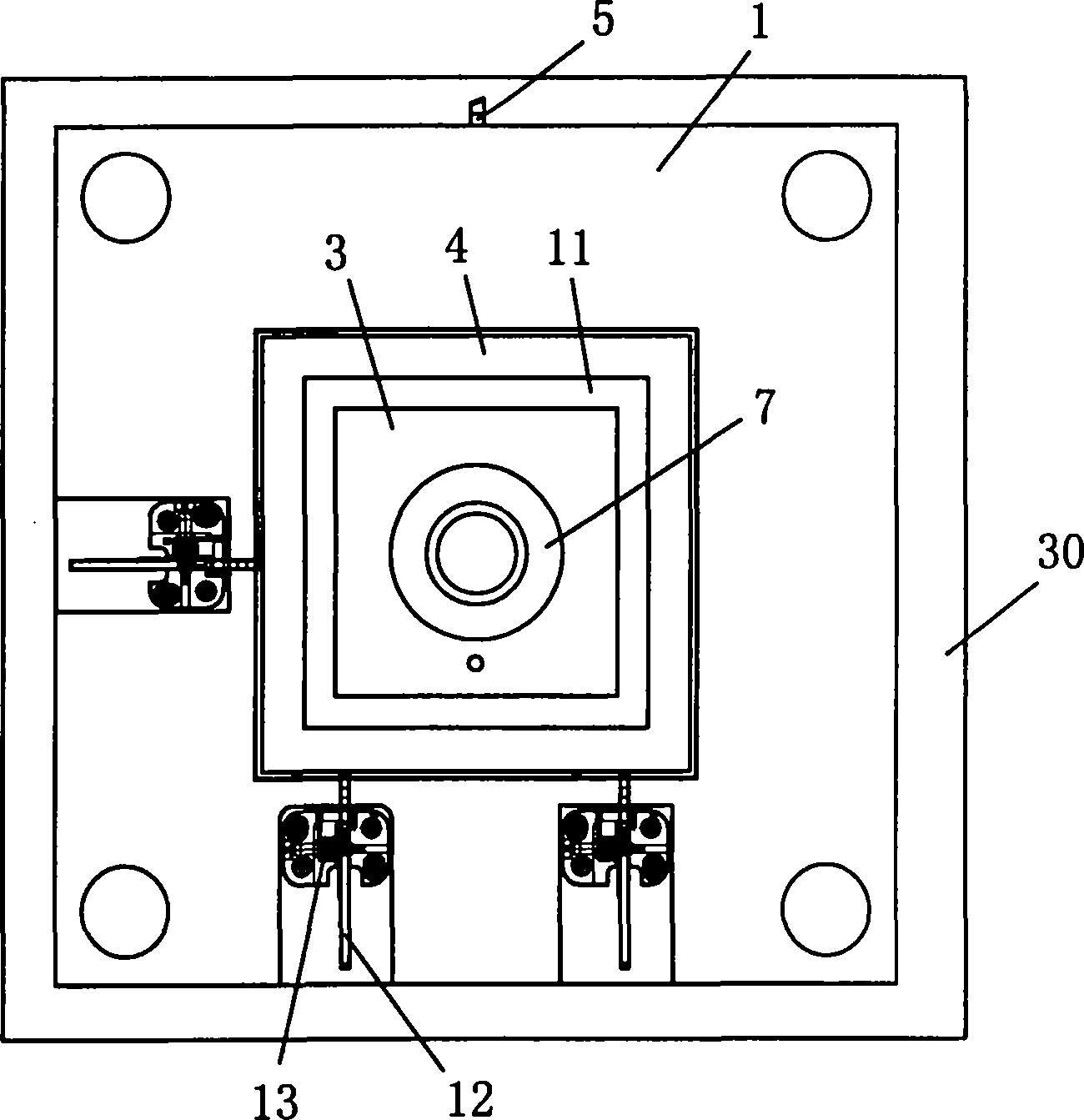

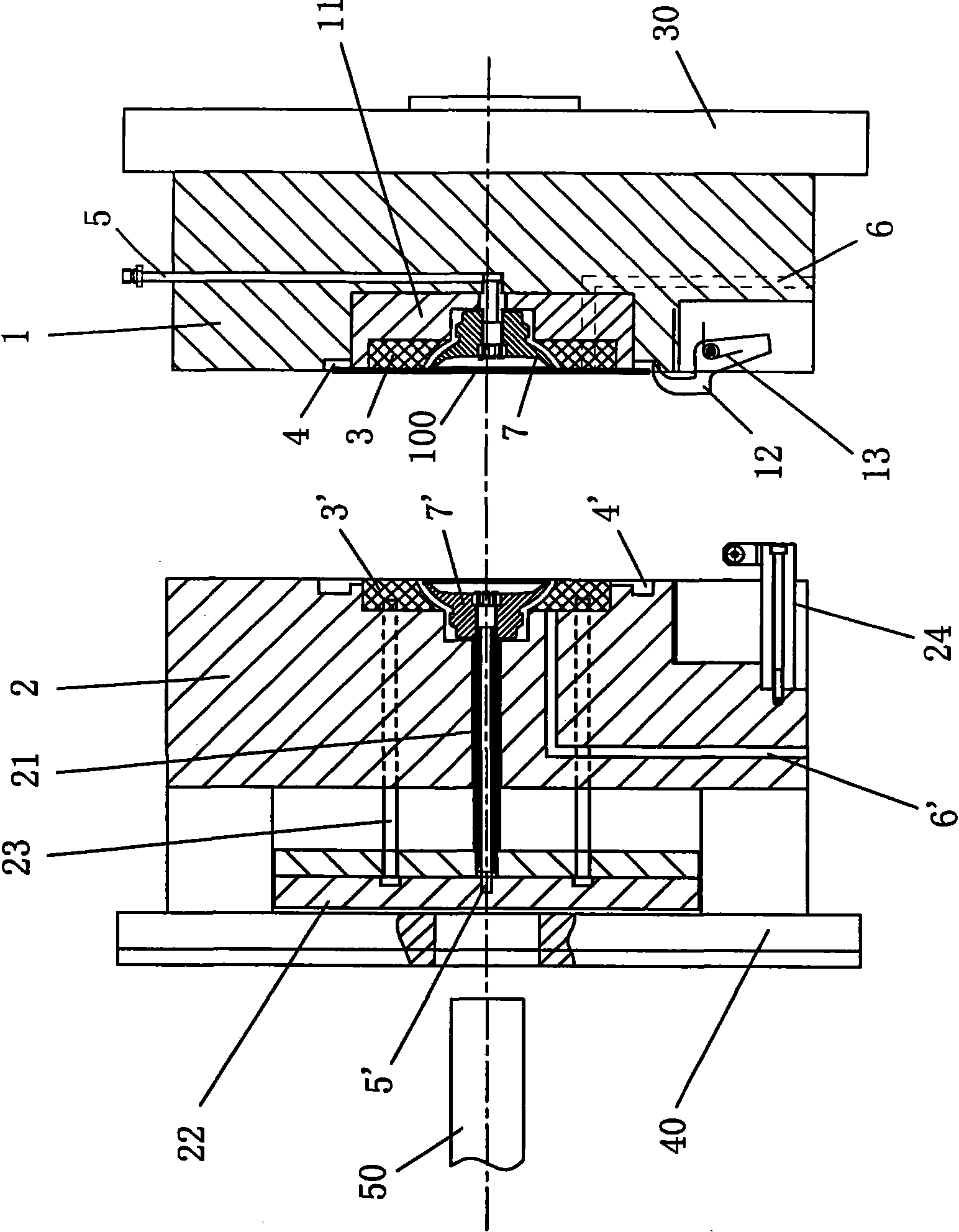

[0024] The present invention will be described in further detail below in conjunction with the embodiments in the accompanying drawings. The embodiments are only for illustrating the principle of the present invention, and should not be understood as constituting any limitation to the present invention.

[0025] The reference numerals in the figure represent the following elements: fixed template 1, insert block 11, rotating positioning block 12, torsion spring 13, movable template 2, moving plate top tube 21, top plate 22, product ejector pin 23, top block 24 , fixed mold rubber pad 3, movable mold rubber pad 3', fixed mold cavity 4, dynamic mold cavity 4', fixed mold vacuum air channel 5, movable mold vacuum air channel 5', fixed mold air channel 6, movable mold air channel 6', fixed mold sucker 7, movable mold sucker 7', original glass 100, plastic edged glass product 102, fixed mold seat plate 30, movable mold seat plate 40, machine tail jack post 50.

[0026] In the foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com