Furnace for macromolecule waste heat energy conversion

A thermal energy conversion and polymer technology, applied in incinerators, gasification processes, energy input, etc., can solve the problem of inability to accurately predict gas production and calorific value, and analyze molecular structure, polymer waste ground state, and species one by one. Complex and other problems, to achieve the effect of small size, small amount of inorganic dust, complete combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

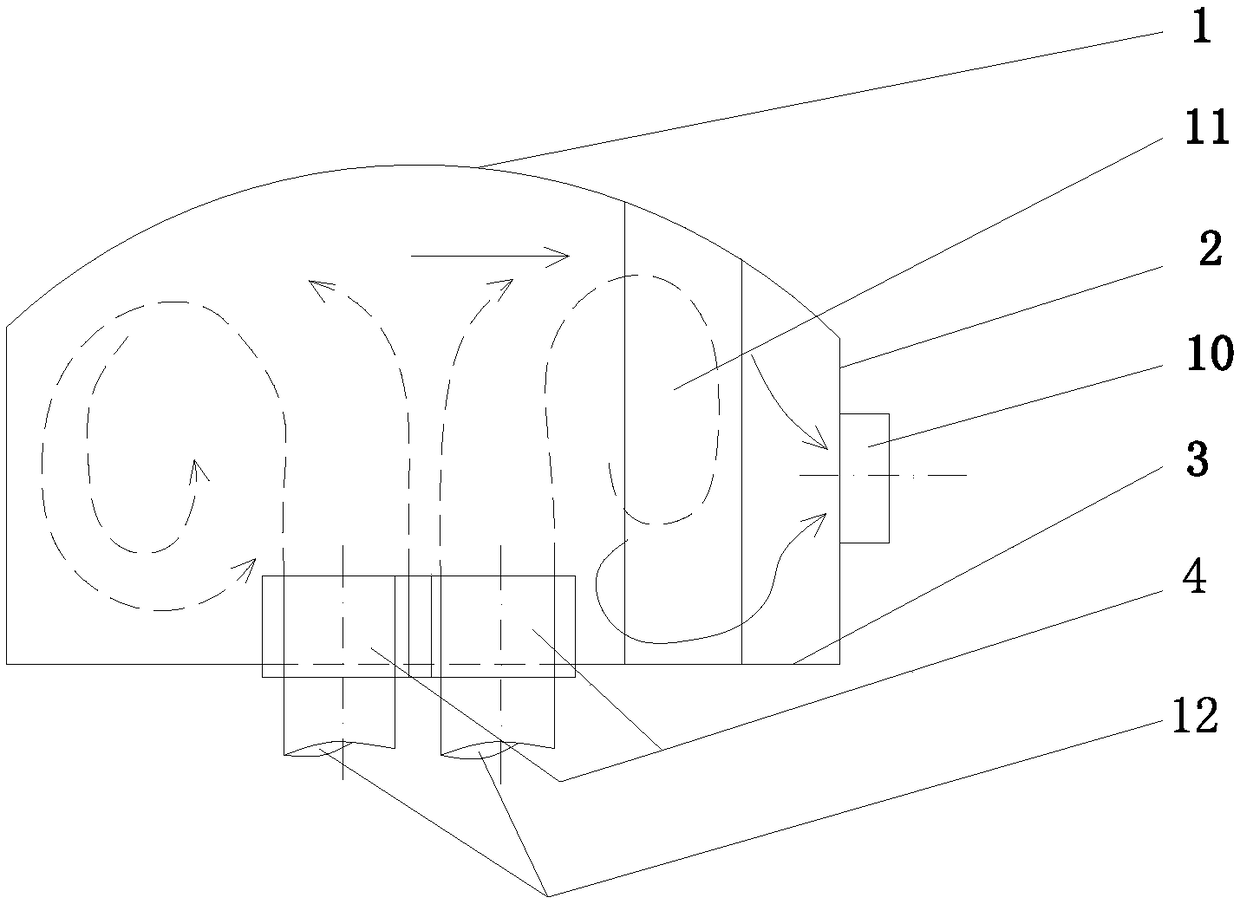

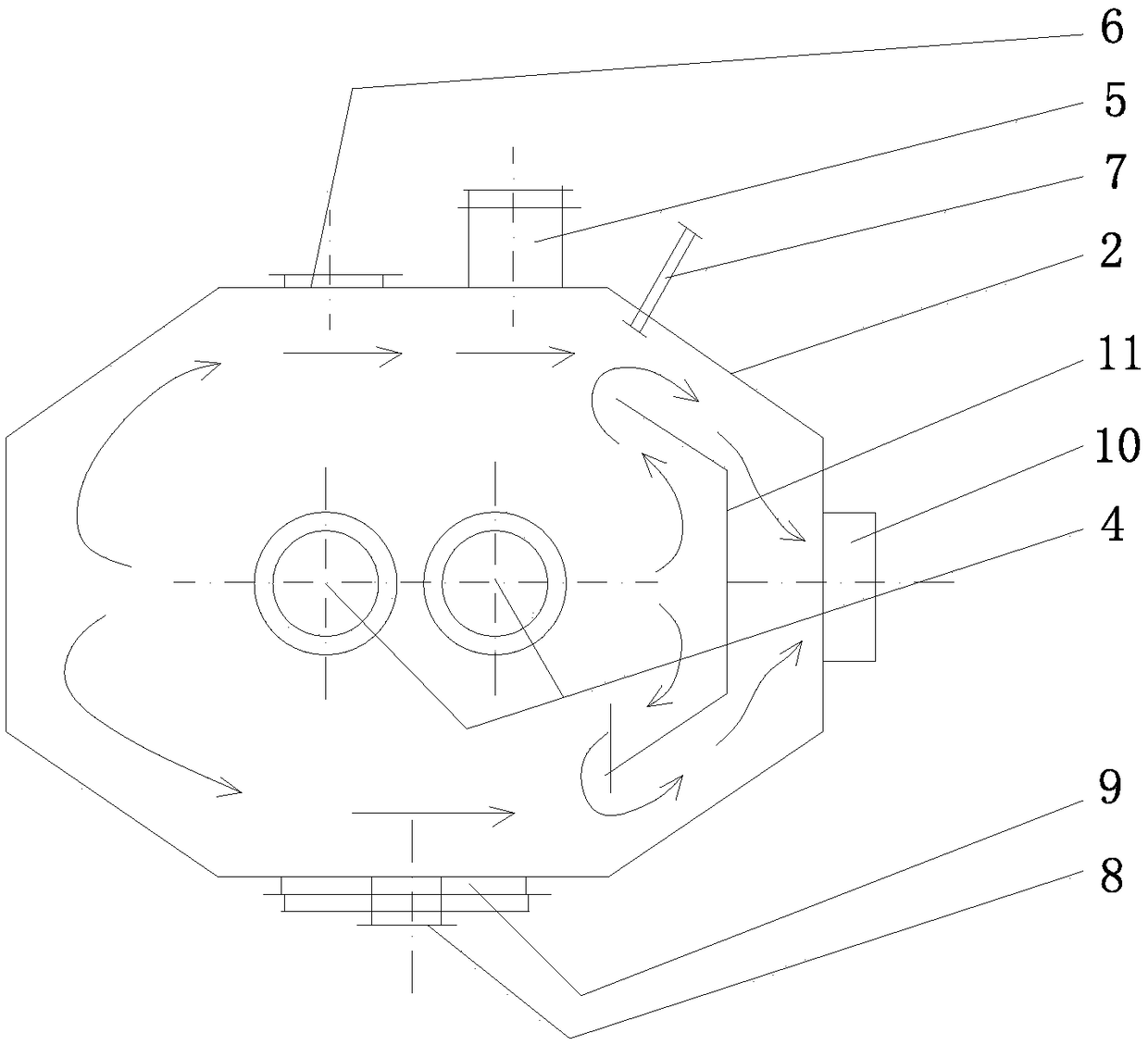

[0038] Such as figure 1 and 2 As shown, the high-temperature combustion chamber is a furnace type with a single outer volute wall and a horizontal torch nozzle. The furnace body of the high-temperature combustion chamber includes an outer volute top cover 1, an outer volute side wall 2, an outer volute bottom plate 3, and The mixer 4 and the flare outlet 10, the air pre-mixer 4 is vertically arranged in the middle of the bottom plate of the outer volute 3, and the side wall 2 of the outer volute is provided with a fuel gas machine 5 and a fuel gas machine matched with the fuel gas machine Flame nozzle cooling device, observation hole 6, detection port 7, hand hole 8 and manhole 9, said torch spout 10 is arranged laterally on the outer volute side wall 2, and the furnace body of the high temperature combustion chamber also includes a single fire retaining wall 11 , the single fire wall 11 is arranged between the air premixer 4 and the torch outlet 10, the upper end of the sing...

Embodiment 2

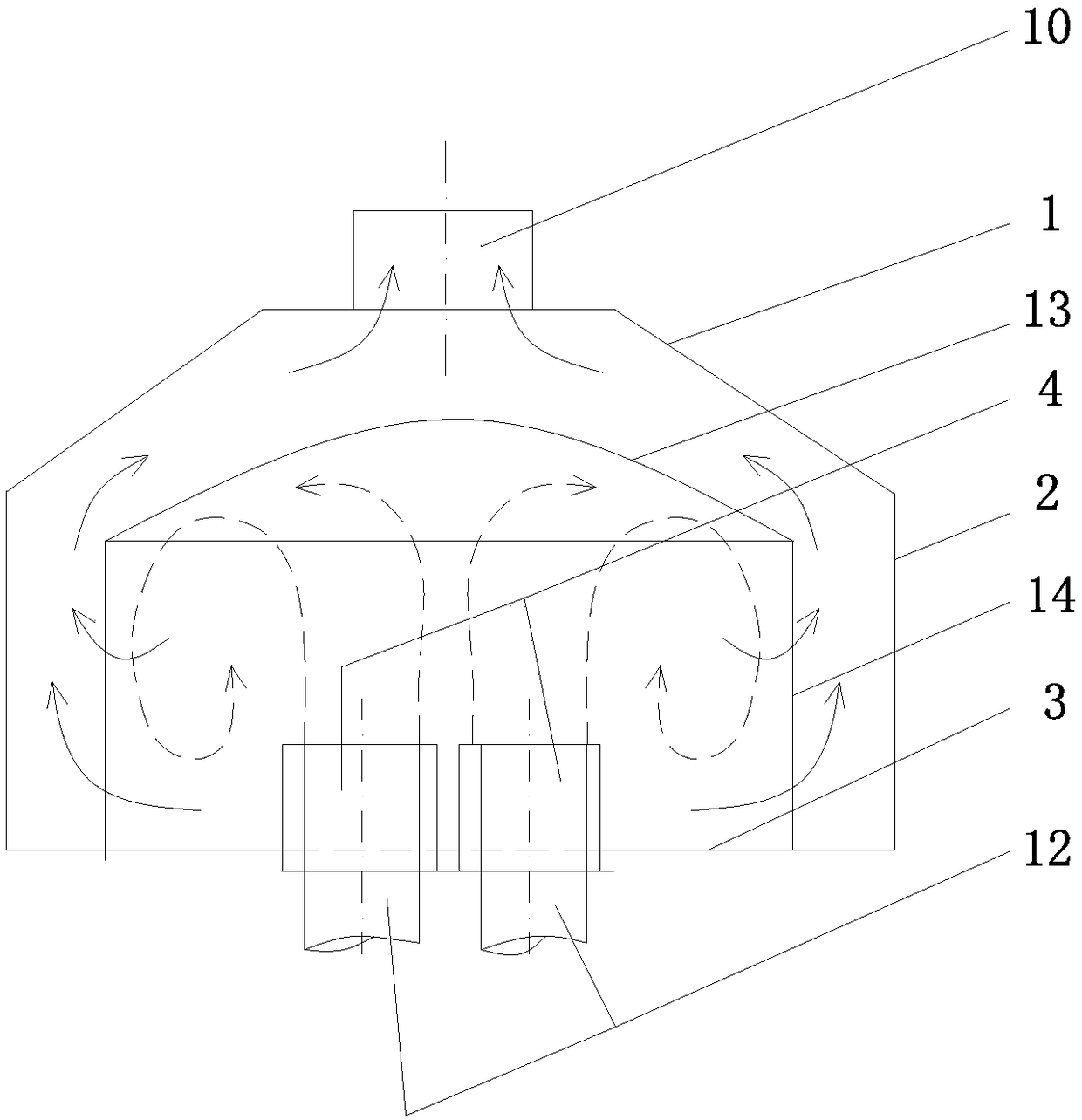

[0065] Such as image 3 and 4 As shown, the high-temperature combustion chamber is a furnace type with double outer volute walls and vertical torch outlet. The furnace body of the high-temperature combustion chamber includes the outer volute top cover 1, the outer volute side wall 2, the outer volute bottom plate 3, the The mixer 4 and the flare outlet 10, the air pre-mixer 4 is vertically arranged in the middle of the bottom plate 3 of the outer volute, and the side wall 2 of the outer volute is provided with a fuel gas engine 5 and a fuel gas engine installed with the fuel gas engine to spray fire Nozzle cooling device, observation hole 6, detection port 7, hand hole 8 and manhole 9, the torch spout 10 is erected on the outer volute top cover 1, and the furnace body of the high-temperature combustion chamber also includes an inner volute cover 13 and The inner volute side wall 14, the inner volute cover 13 is located on the upper part of the inner volute side wall 14, the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com