Method for preparing composite lithium-ion battery separator through electrostatic spinning/electrostatic spraying

A technology of electrospinning and electrostatic spraying, which is applied to battery components, circuits, electrical components, etc., can solve the problems of low surface energy, poor compatibility and adhesion, and high processing cost of polytetrafluoroethylene materials, and achieve High electrochemical stability window, excellent thermal shrinkage resistance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

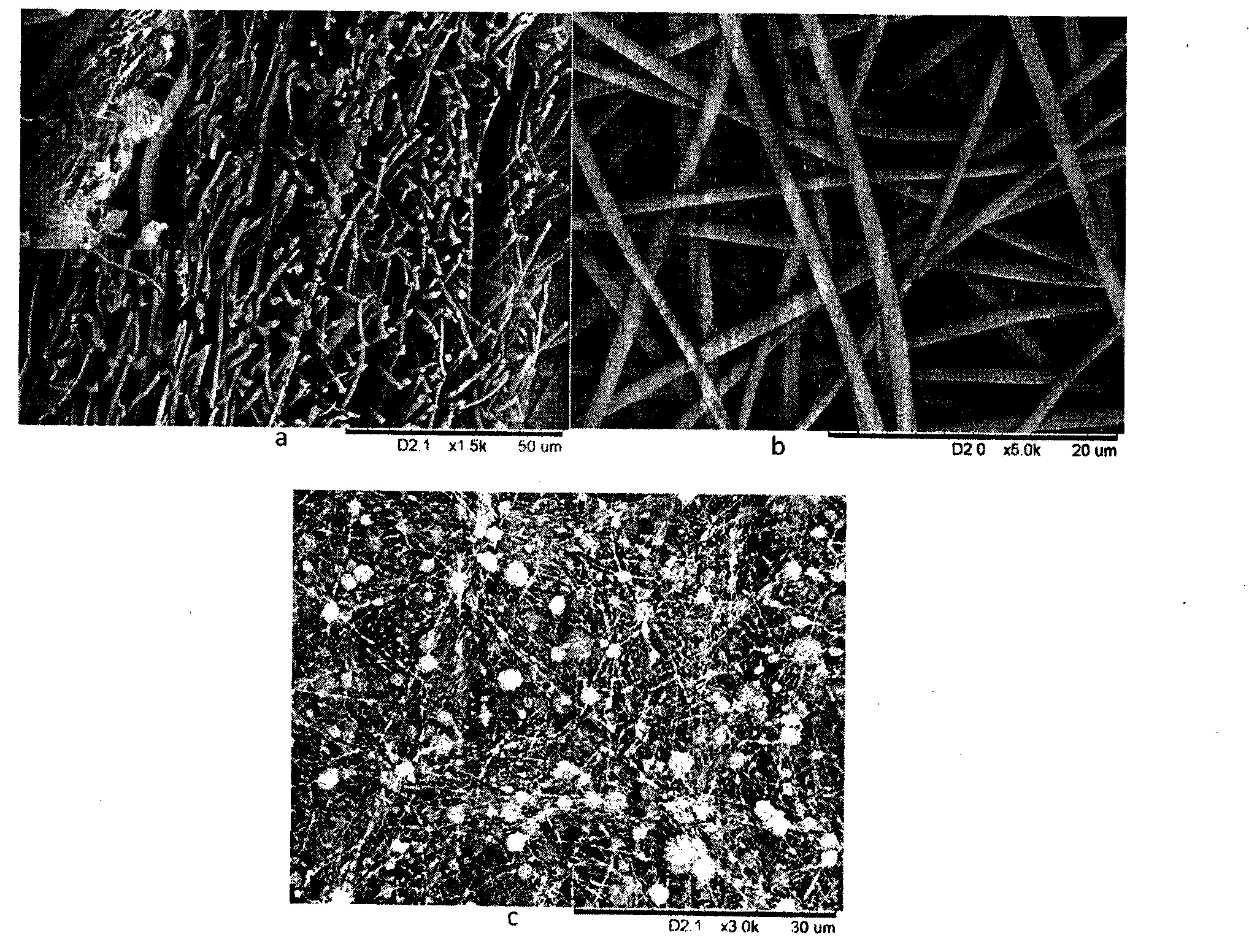

[0030] At room temperature, the dried PVDF was weighed and added to a certain amount of DMF / acetone mixed solvent, stirred and dissolved to prepare a polymer spinning solution. Then weigh the nano-Al 2 o 3 and PVDF (mass ratio 0.8:0.2) were added to DMF solvent to prepare nanoparticle suspension.

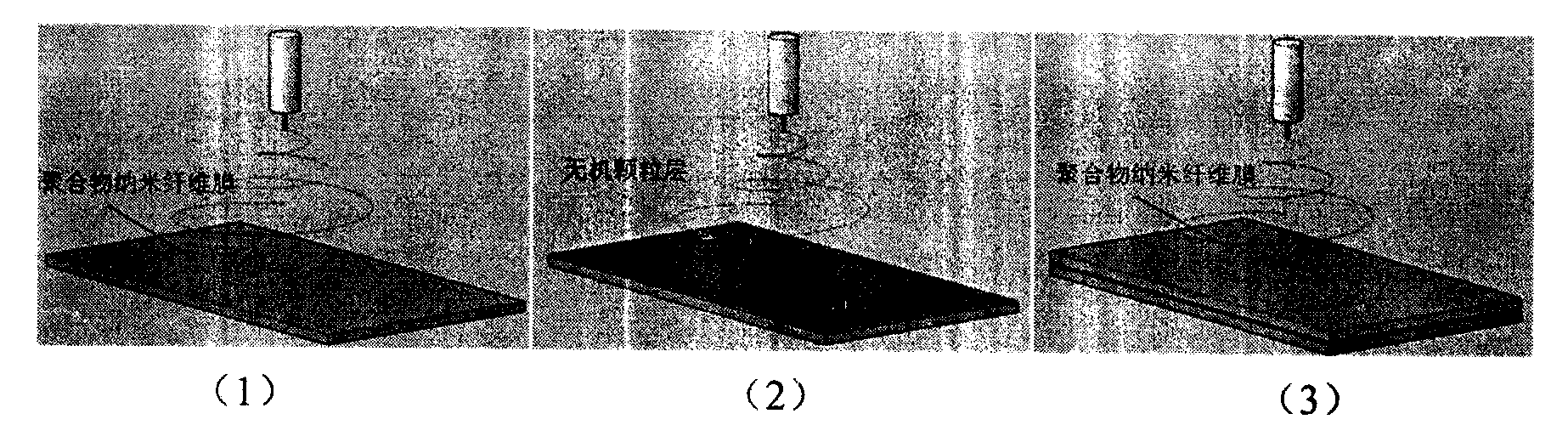

[0031] The polymer spinning solution is electrospun to prepare PVDF nanofiber membrane and deposited on the receiving device, then the nanoparticle suspension is deposited on the nanofiber membrane by electrostatic spraying, and then a layer of electrospun PVDF nanofiber is received on the inorganic particle layer. The fiber membrane, that is, the electrospinning / electrostatic spraying composite lithium-ion battery separator was obtained.

[0032] The prepared electrospinning / electrostatic spraying composite lithium-ion battery separator was placed in a hot box at 150°C for 1 hour, and the shrinkage rate was 1.25%. The fiber membrane was immersed in ethylene carbonate / dimethyl car...

Embodiment 2

[0034] At room temperature, the dried P(VDF-HFP) was weighed and added to a certain amount of DMF solvent, stirred and dissolved to prepare a polymer spinning solution. Then weigh the nano-SiO 2 and P(VDF-HFP) (mass ratio 0.9:0.1) were added to DMF solvent to prepare nanoparticle suspension.

[0035] The P(VDF-HFP) nanofiber film prepared by electrospinning of the polymer spinning solution is deposited on the receiving device, and then the nanoparticle suspension is deposited on the nanofiber film by electrostatic spraying, and then a layer of inorganic particles is received on the inorganic particle layer. A layer of electrospun P (VDF-HFP) nanofiber membrane is obtained to obtain an electrospinning / electrostatic spraying composite lithium-ion battery separator.

[0025] 5. The preparation process of the inorganic nanoparticle suspension in the electrospinning / electrostatic spraying composite lithium-ion battery diaphragm preparation method provided by the present invention ...

Embodiment 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com