Heat-shrinkage-resistant lithium ion battery diaphragm and pore-forming agent composition adopted by same

A technology for lithium-ion batteries and battery diaphragms, which is applied to battery components, separators/films/diaphragms/spacers, circuits, etc., and can solve the problem of incomplete sealing of porogens, easy outflow, and difficulty in controlling consistency And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0187] The polyethylene composition used to prepare heat-shrinkable lithium-ion battery separators includes the following components by weight:

[0188]

[0189]

[0190] in,

[0191] The number average molecular weight of high molecular polyethylene is 500,000,

[0192] The number average molecular weight of UHMWPE is 1.4 million,

[0193] The average molecular weight of white oil is 200,

[0194] The particle size of the nano-magnesium chloride is 50-70nm.

[0195] Above-mentioned composition is made lithium-ion battery diaphragm according to the following method:

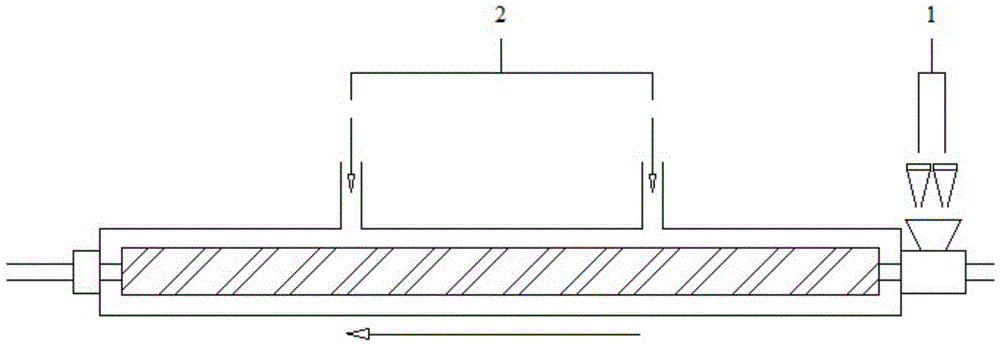

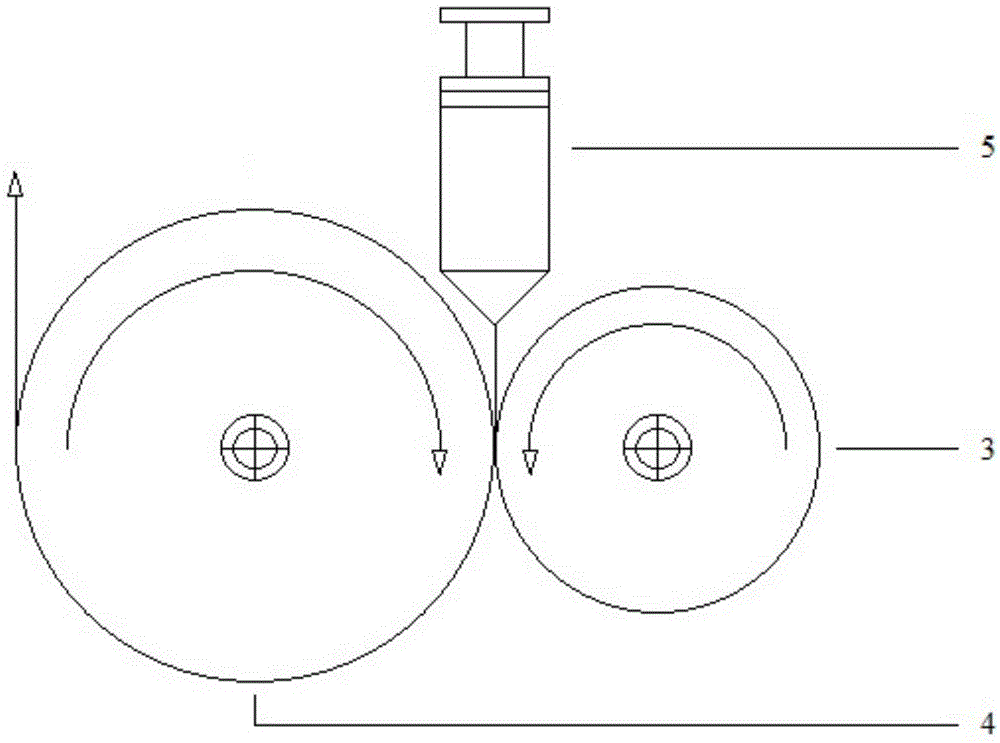

[0196] Step 1), extrusion: melt and mix high molecular polyethylene and nano-magnesium chloride, add ultra high molecular polyethylene, 4,4-thiobis(6-tert-butyl meta cresol), 2,4-dihydroxybenzophenone, sodium octadecyl quaternary ammonium and Tween 80 are added to the extruder by the second feed port, white oil is fed by the first pore-forming agent feed port and The second pore-forming agent feed port...

Embodiment 2

[0203] The composition for preparing lithium-ion battery diaphragm comprises the following components by weight:

[0204]

[0205] in,

[0206] The number average molecular weight of high molecular weight polyethylene is 300,000.

[0207] The number average molecular weight of UHMWPE is 1.3 million.

[0208] The average molecular weight of white oil is 180;

[0209] The particle size of the nano-magnesium chloride is 60-90nm.

[0210] The above-mentioned composition is prepared lithium-ion battery diaphragm according to the following method:

[0211] Step 1), extrusion: melt and mix high molecular polyethylene and nano-magnesium chloride, add ultra high molecular polyethylene, 3,5-di-tert-butyl-4-hydroxytoluene, 4-benzoyloxy-2,2,6,6-tetramethylpiperidine, sodium octadecyl quaternary ammonium and lauric acid are fed into the extruder from the second feed port, white oil is fed from the first The feed port of the pore agent and the feed port of the second pore forming ag...

Embodiment 3

[0218] The method used in this embodiment is similar to the method used in Example 2, except that the polyethylene composition comprises the following components by weight:

[0219]

[0220] in,

[0221] The number average molecular weight of high molecular weight polyethylene is 400,000.

[0222] The number average molecular weight of UHMWPE is 1.4 million.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com