Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

101 results about "Wet preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wet preparation is the most common way of preparing lowland fields. In this method, the soil is tilled in a saturated or flooded condition. It helps improve weed control and facilitates incorporation of nutrients in the soil. With its nature, wet preparation has a high water requirement.

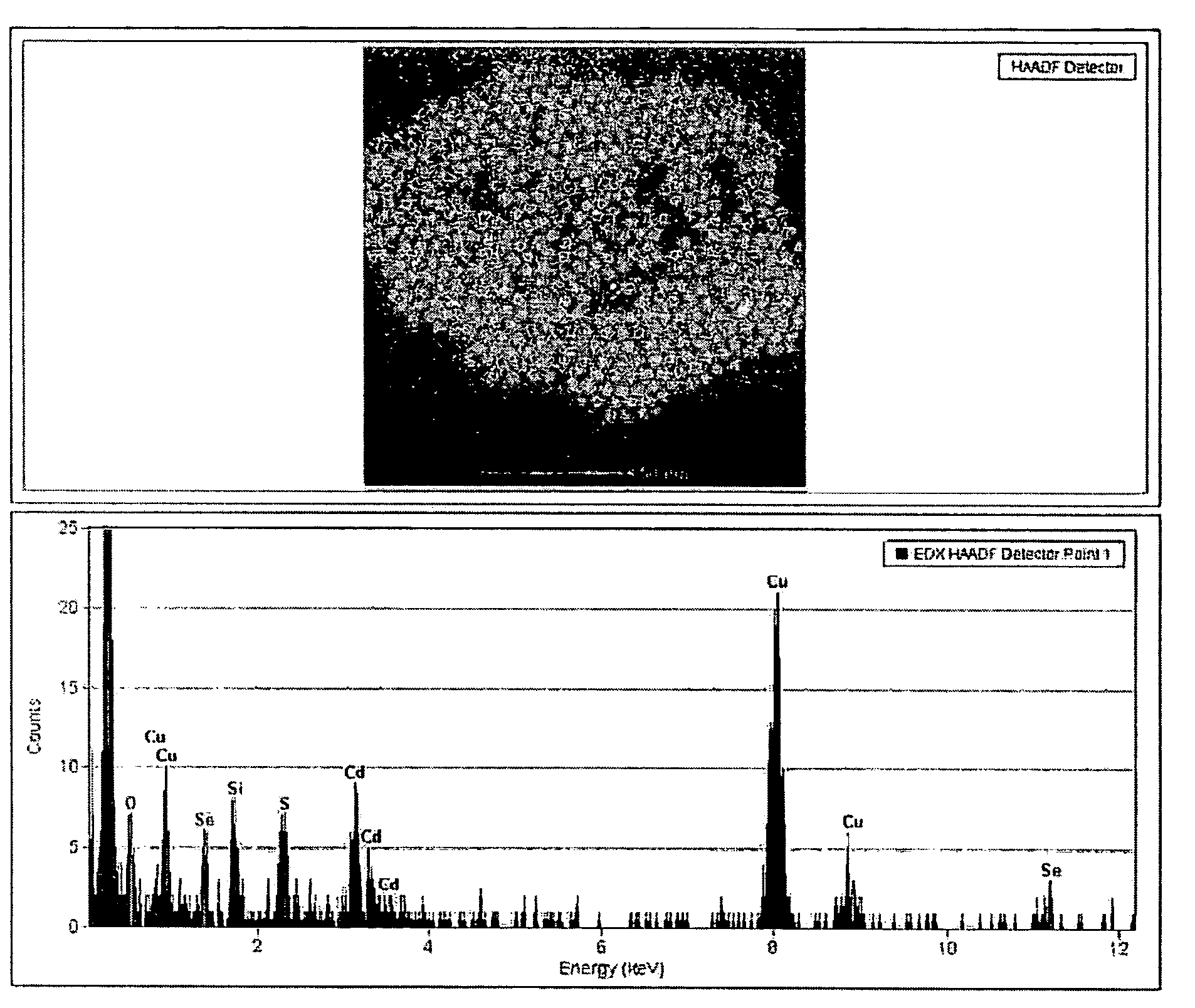

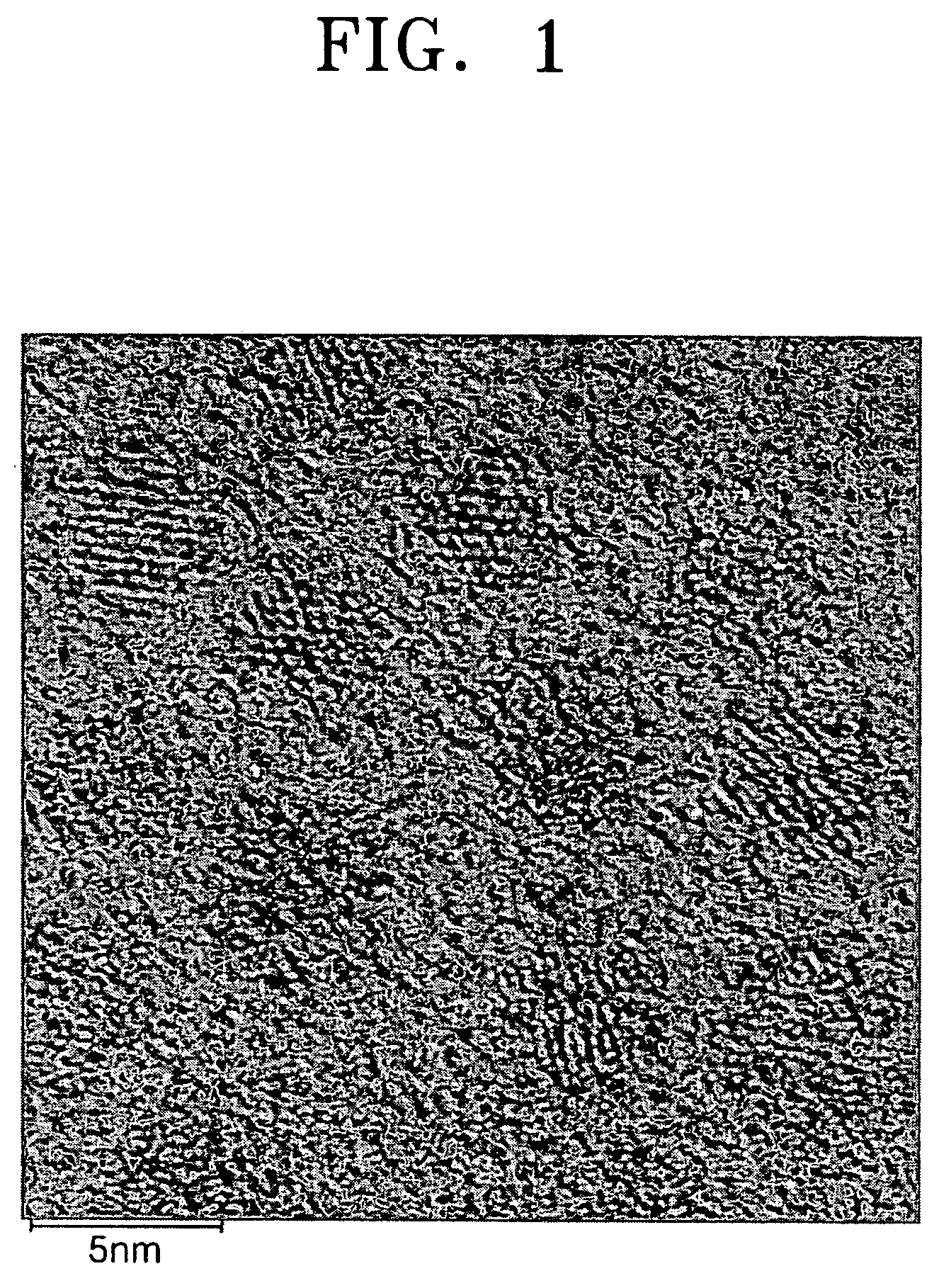

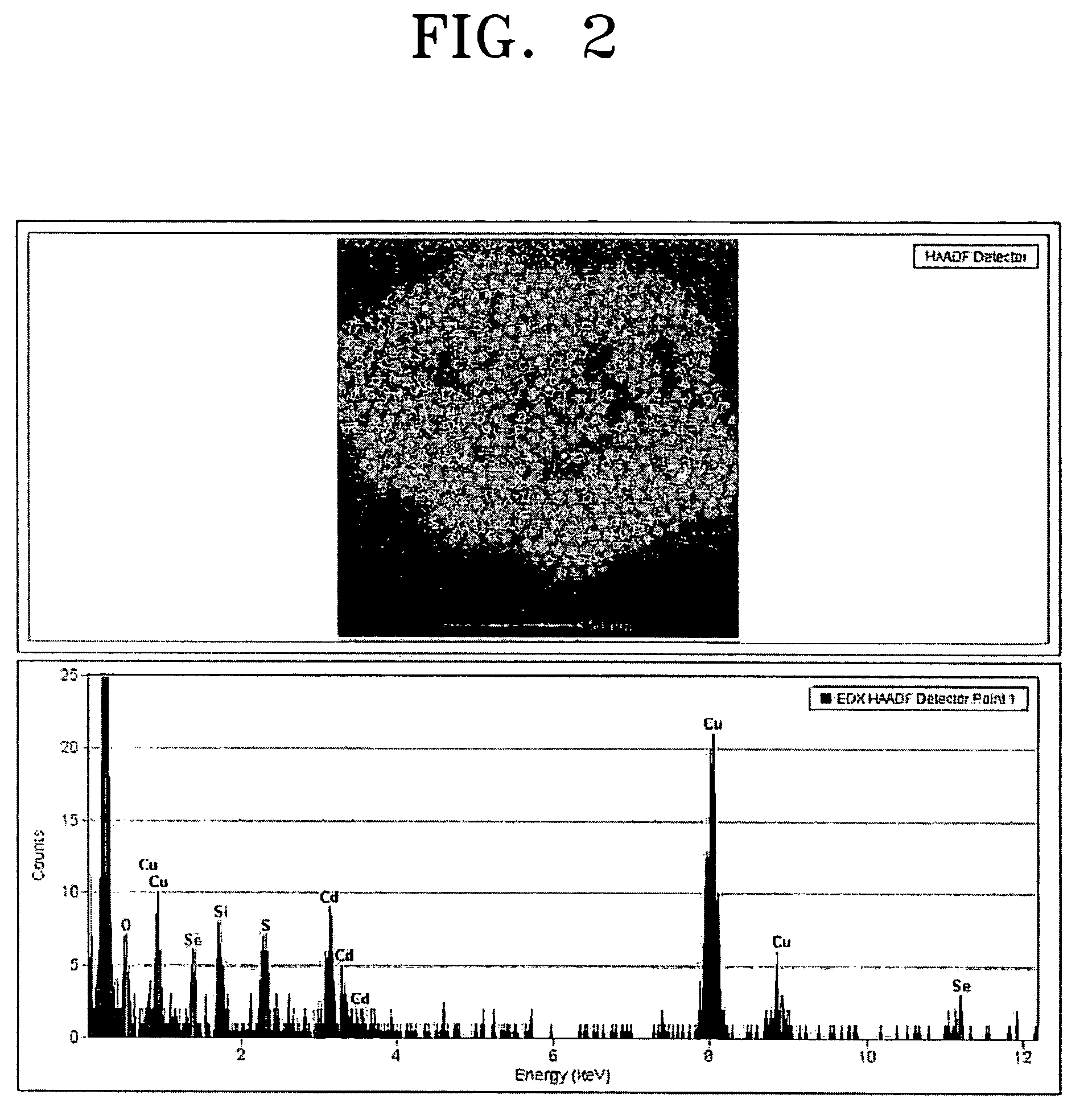

Alloy type semiconductor nanocrystals and method for preparing the same

ActiveUS7250082B2Improve quantum efficiencyUniform shapeMaterial nanotechnologyFrom normal temperature solutionsQuantum efficiencyAlloy

Owner:SAMSUNG ELECTRONICS CO LTD

Dry preparation of battery grade spherical cobaltosic oxide particle

InactiveCN101434417AHigh densityUniform particle size distributionCell electrodesCobalt oxides/hydroxidesCobalt(II,III) oxideCobalt salt

The invention relates to a wet preparation method of battery-level spherical cobaltosic oxide, which comprises the specific steps of: preparing cobalt salt into a first mixed solution with the concentration of 1-3mol / L; preparing a hydrate solution with the concentration of 2-10mol / L into a second mixed solution; preparing a complexing agent A with the concentration of 0.001-200g / L into a third mixed solution; introducing the three mixed solutions into a reaction vessel by adopting a parallel flow method; stirring the mixed solution intensively to cause the three solutions to react; adding a certain amount of oxidizer continually into a reaction system during the reaction process; aging the mixed solution for 2-48 hours under normal temperature; centrifugalizing, washing and drying the material; and calcining the mixture of a pretreated precursor and lithium salt under 750-1000 DEG C to obtain the lithium battery cathode material. The method has the advantage that the cobaltosic oxide powder can be directly obtained from the oxidation of a cobalt compound in the solution owing to the fact that the cobalt compound can be oxidized in the solution under alkaline condition. The material is a relatively ideal battery cathode material for mobile telephones, video cameras, laptops and portable electric appliances.

Owner:NINGBO JINHE NEW MATERIALS

Synthetic fiber paper containing polyphenyl sulfide and aromid fiber and producing method thereof

InactiveCN1974925AHigher than strongHigher than the moldNon-fibrous pulp additionCalendersPolymer scienceThermal expansion

The present invention belongs to the field of synthetic fibre paper. In particular, it relates to a kind of synthetic fibre paper made up by using aramid fiber as structural fiber and utilizing polyphenylene sulfide fiber or granules through the processes of adhesive bonding and finalization. Said synthetic fiber paper possesses the excellent properties of light weight, high strength, resisting high temperature, resisting fatigue, resisting chemical corrosion, resisting radiation, high specific modulus, low thermal-expansion coefficient and good biological compatibility, and can be extensively used in the fields of electromechanical technology and aerospace industry. Besides, said invention also provides a wet preparation method for producing said synthetic fiber paper.

Owner:陶世毅 +3

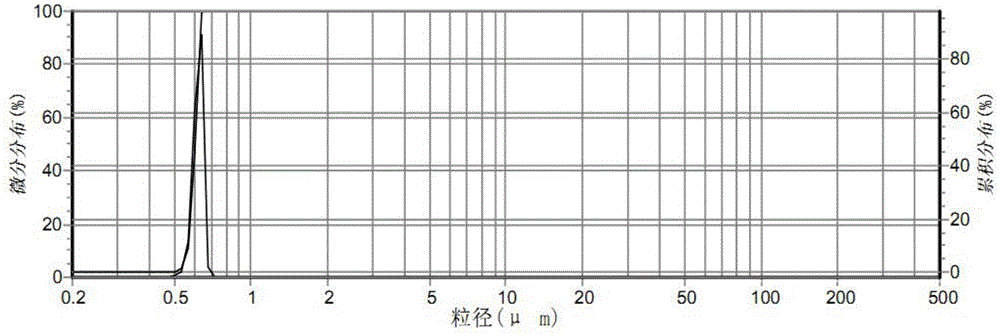

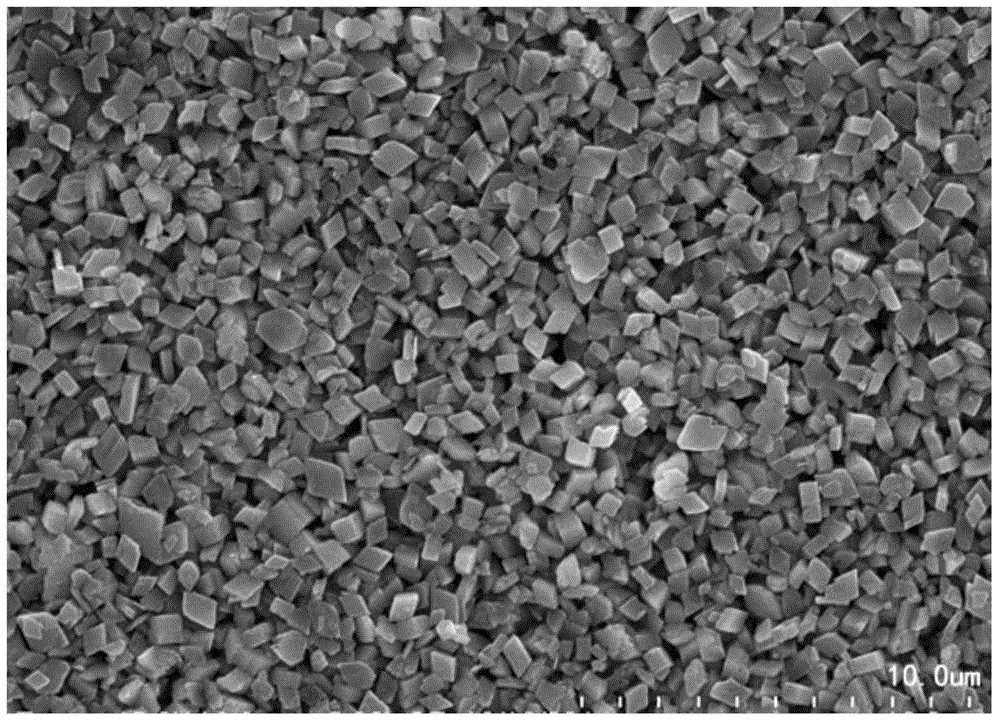

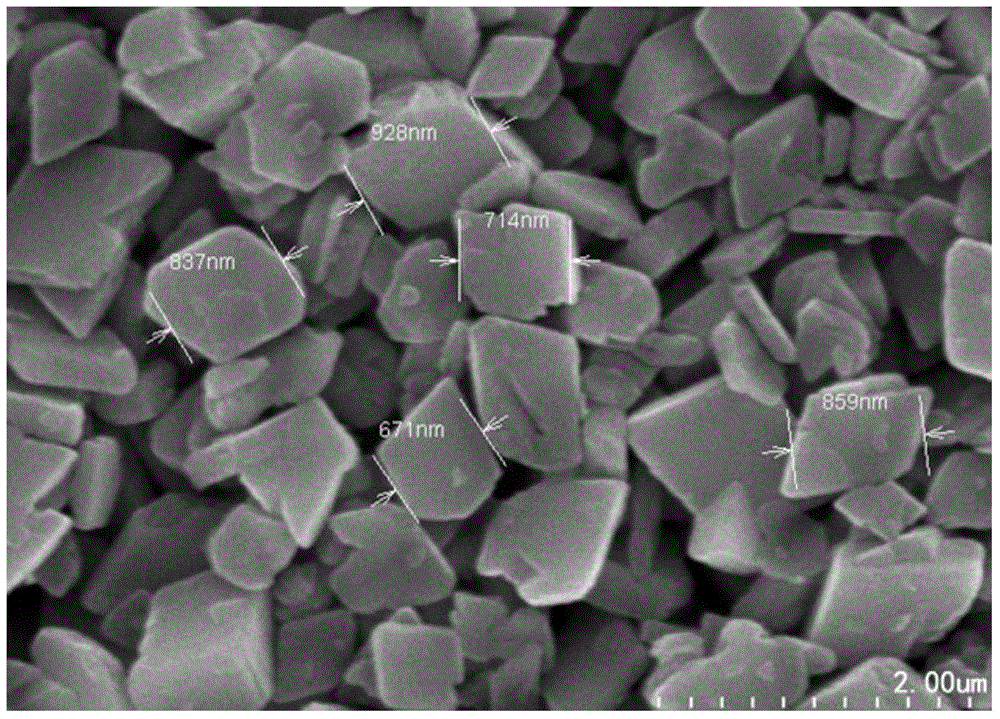

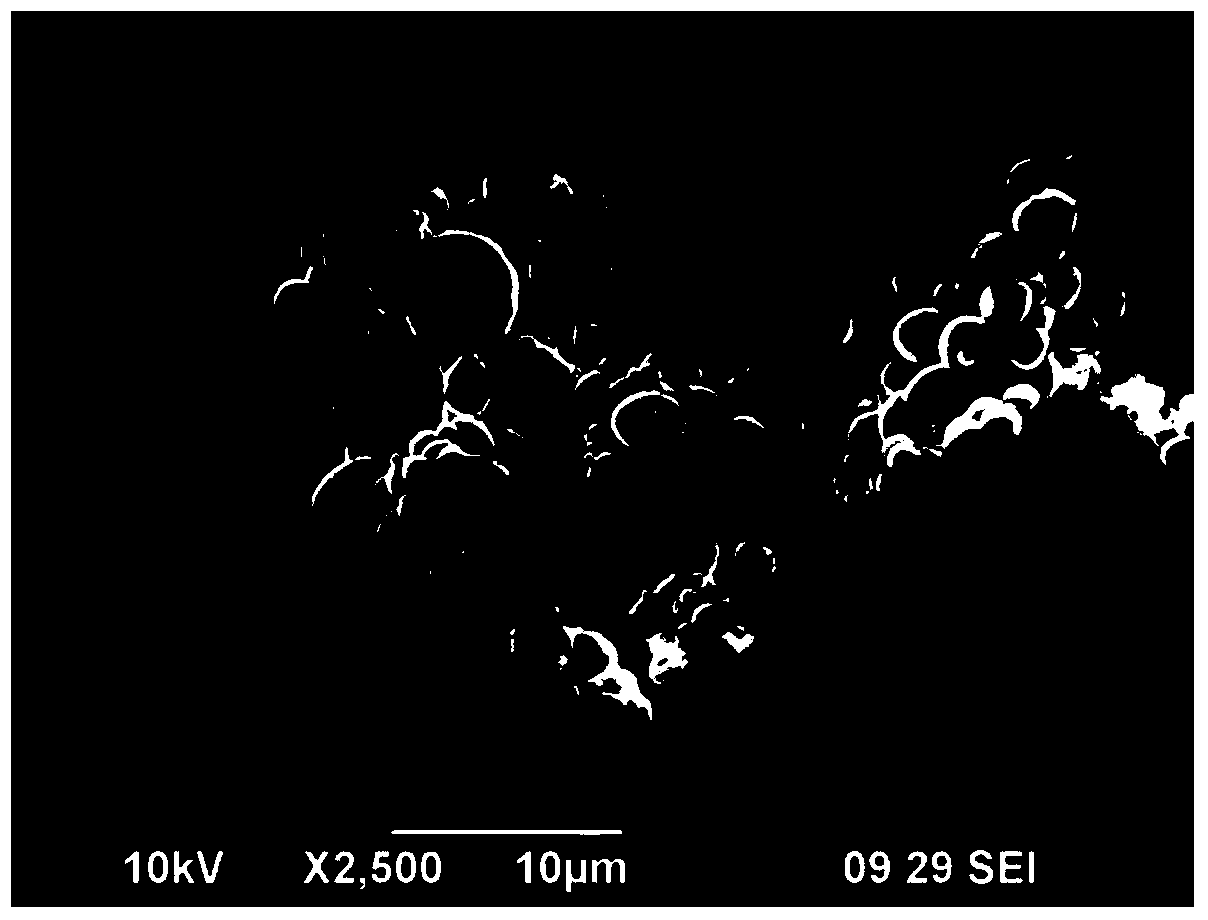

Granularity-controllable boehmite preparation method

InactiveCN104944454AGranularity controllableNarrow particle size distributionMaterial nanotechnologyAluminium oxides/hydroxidesDispersityMicrometer

The invention provides a granularity-controllable boehmite preparation method and relates to the field of new materials. The granularity-controllable boehmite preparation method comprises the following steps: mixing Al(OH)3 and water to form a suspension with the concentration of 20-60% (by weight percent); adjusting the pH of the suspension to be 2-9; treating the suspension for 24-40 h at the temperature of 170-240 DEG C and the pressure of 1.0-1.7 MPa; filtering, drying and dispersing the treated suspension to obtain monodispersed boehmite with the granularity of 0.1-10 micrometers. The granularity-controllable boehmite preparation method is a wet preparation method of boehmite, and the prepared high-purity boehmite is narrow in grain distribution, uniform in appearance, controllable in granularity and favorable in dispersity. The granularity of boehmite can be adjusted through adjusting the pH value and the time of reaction and the granularities of the raw materials.

Owner:ANHUI ESTONE MATERIAL TECH CO LTD

Wet strength agent for paper making and preparation thereof

ActiveCN101328696AHigh reactivityImprove bindingReinforcing agents additionFlocculationPaper production

The invention discloses a wet strengthening agent for making paper. The wet strengthening agent is PAE modified by an aliphatic twain-aldehyde compound crosslinking agent. A molecular chain has a three-dimensional net structure. The wet strengthening agent can be preserved for a long time and does not generate bubble or flocculation, etc. The application of the wet strengthening agent in paper production ensures that the paper has good flexibility resistance and wet strengthen. The invention also discloses a method for preparing the wet strengthening agent for making paper.

Owner:CHINA BANKNOTE PRINTING & MINTING

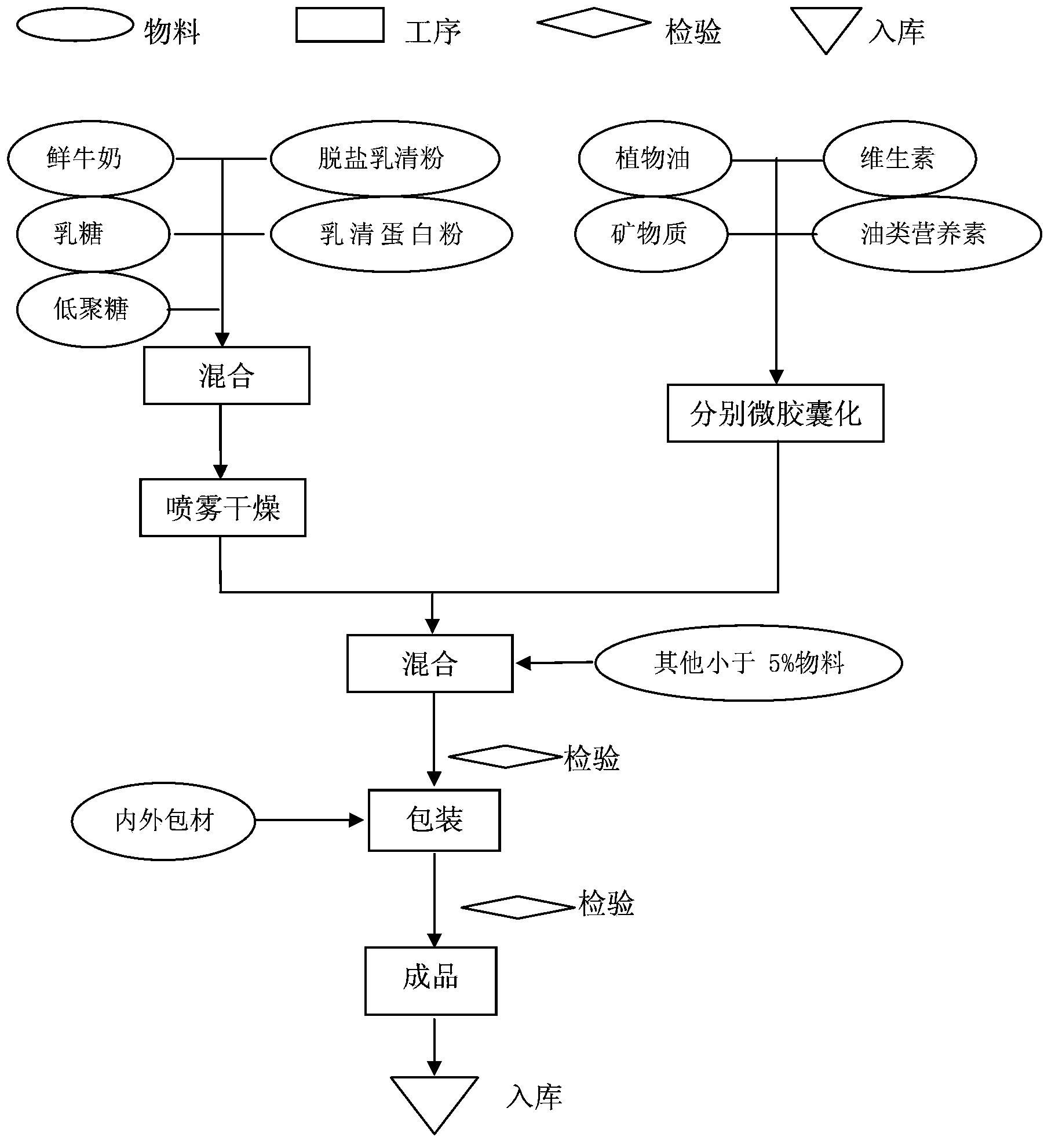

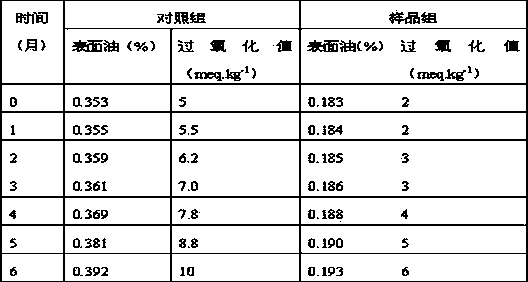

Wet preparation process of infant formula milk powder

The present invention relates to a wet preparation process of infant formula milk powder, wherein raw materials comprise vegetable oil, fresh milk, desalted whey powder, lactose, whey protein powder, oligosaccharide, compound vitamins, compound minerals, other nutrients, a microcapsule wall material and the like. The preparation method comprises: embedding vitamins, minerals, vegetable oil, oils in other nutrients by using a microcapsule technology; uniformly mixing the embedded vitamin powder, the embedded mineral powder, the embedded oil nutrient powder and other nutrients with the amount of less than 5% to obtain a mixture; mixing fresh milk, whey powder, lactose, whey protein and oligosaccharide, carrying out homogenization by using a high pressure homogenization machine, carrying out concentration and spray drying to obtain powdery base powder, and uniformly mixing the mixture and the base powder; and carrying out nitrogen filling quantitative package. According to the present invention, the part of the substances with characteristics of easy reaction generation and instability is embedded through the microcapsule technology, and the mixing and packaging preparation process is performed under a certain condition so as to reduce or prevent adverse reactions among the substances; and the prepared infant formula milk powder has advantages of good stability, good uniformity, good taste and assurance of nutritional activities of various components.

Owner:ZHEJIANG CONBA HEALTH PROD

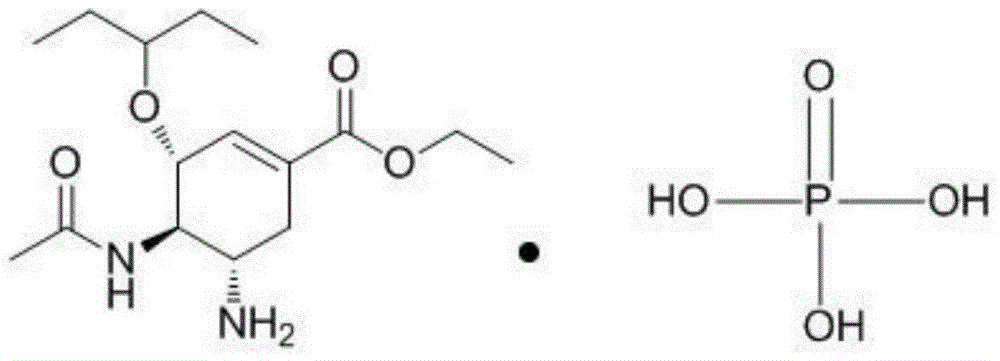

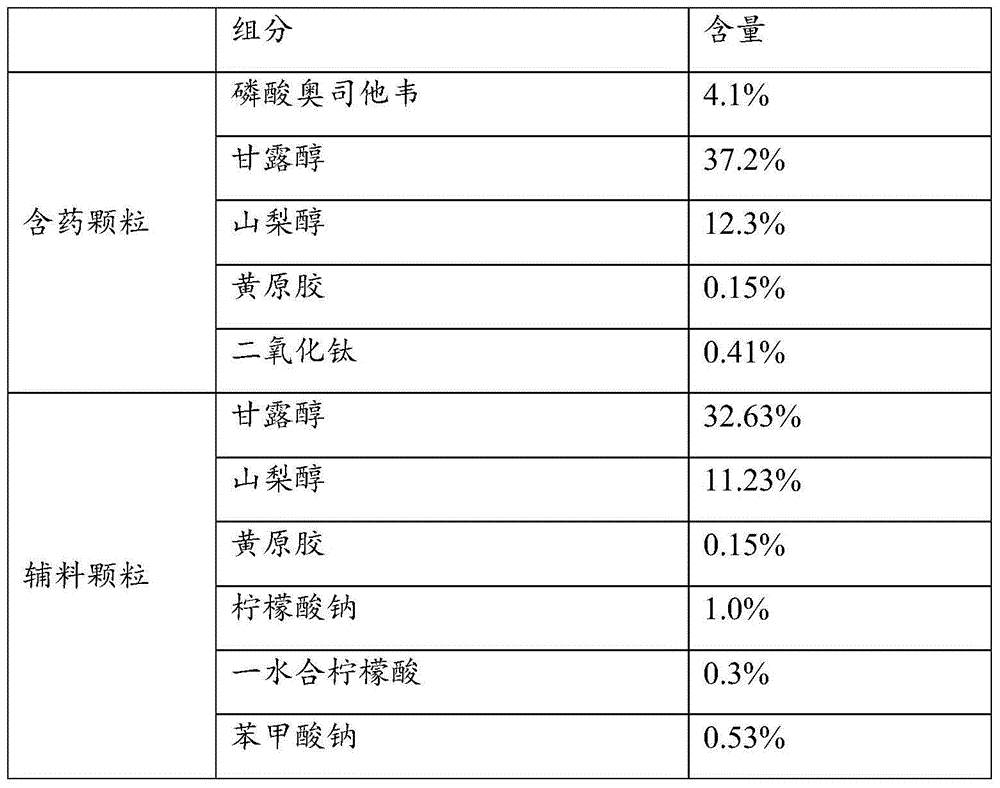

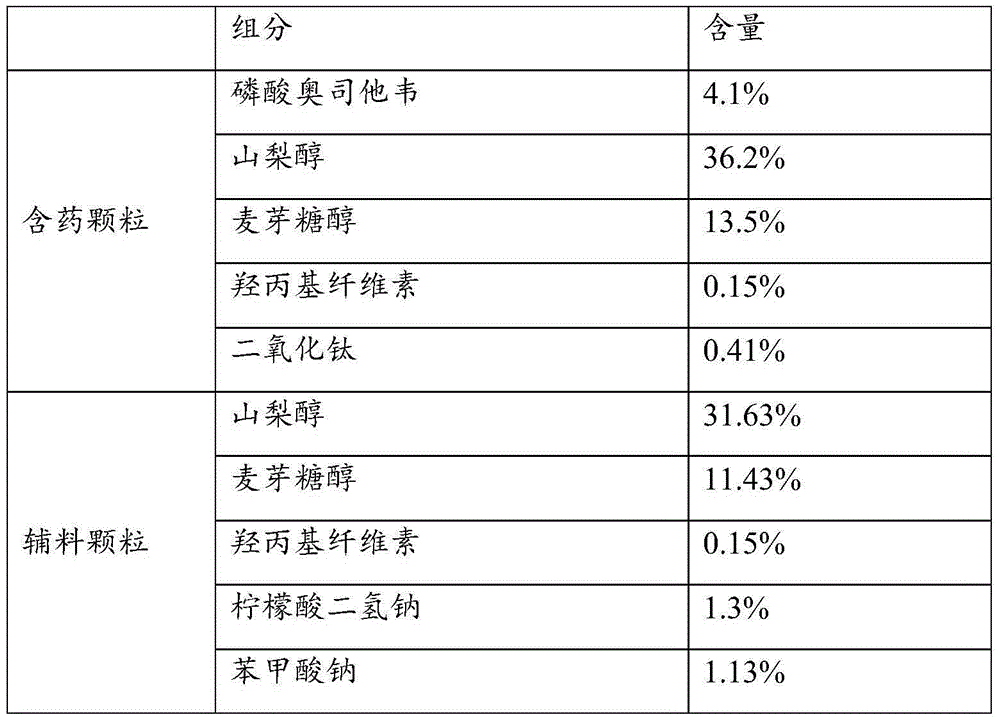

Oseltamivir phosphate dry suspension and preparation method thereof

InactiveCN104138355AFine grainFix stability issuesOrganic active ingredientsDispersion deliveryFiller ExcipientMaltitol

The invention provides an oseltamivir phosphate dry suspension. The oseltamivir phosphate dry suspension comprises oseltamivir phosphate, filler not prone to reacting with the oseltamivir phosphate and other pharmaceutically acceptable accessories, wherein the filler is one or more of maltitol, xylitol and mannitol or is the composition of one or more of the maltitol, the xylitol and the mannitol and sorbitol, the content of the sorbitol in the whole composition is X, and X large than or equal to 0% and less than or equal to 75%. Meanwhile, the invention provides a preparation method of the oseltamivir phosphate dry suspension. Preferably, the preparation method is a step-by-step wet preparation method. The oseltamivir phosphate dry suspension is good in stability, low in cost, simple in preparation technology and capable of being produced in an industrial mode easily.

Owner:SUNSHINE LAKE PHARM CO LTD

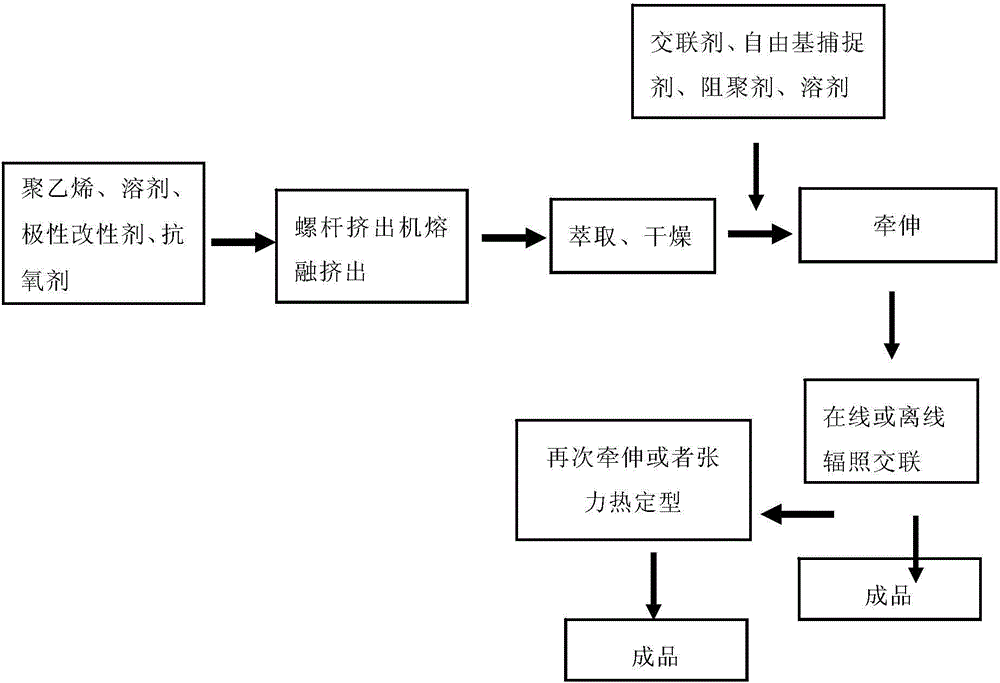

Crosslinked ultrahigh molecular weight polyethylene fiber and wet preparation method thereof

PendingCN104818541AArtificial filament recoveryTextile/flexible product manufactureFiberPolymer science

The invention relates to a crosslinked ultrahigh molecular weight polyethylene fiber and a wet preparation method thereof. The decreasing rate of the weight-average molecular weight of ultrahigh molecular weight polyethylene caused by radiation or irradiation splitting is less than 10%. The ultrahigh molecular weight polyethylene fiber disclosed by the invention has excellent heat resistance and creep resistance and high mechanical strength, and therefore, the ultrahigh molecular weight polyethylene fiber is especially suitable for preparing bulletproof vests, helmets, lightweight armors, sails, mooring ropes, fishing nets, optical cable reinforcement bodies, parachutes, filter materials, radomes, wind turbine blades and the like which are ultrahigh in mechanical strength and heat resistance.

Owner:JIANGSU SHENTAI SCI & TECH DEV

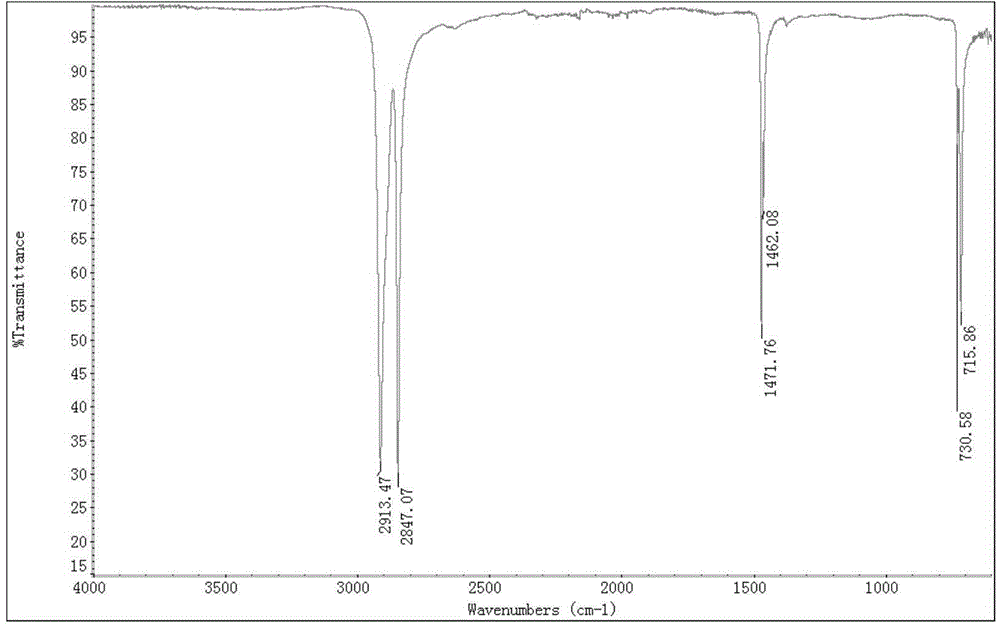

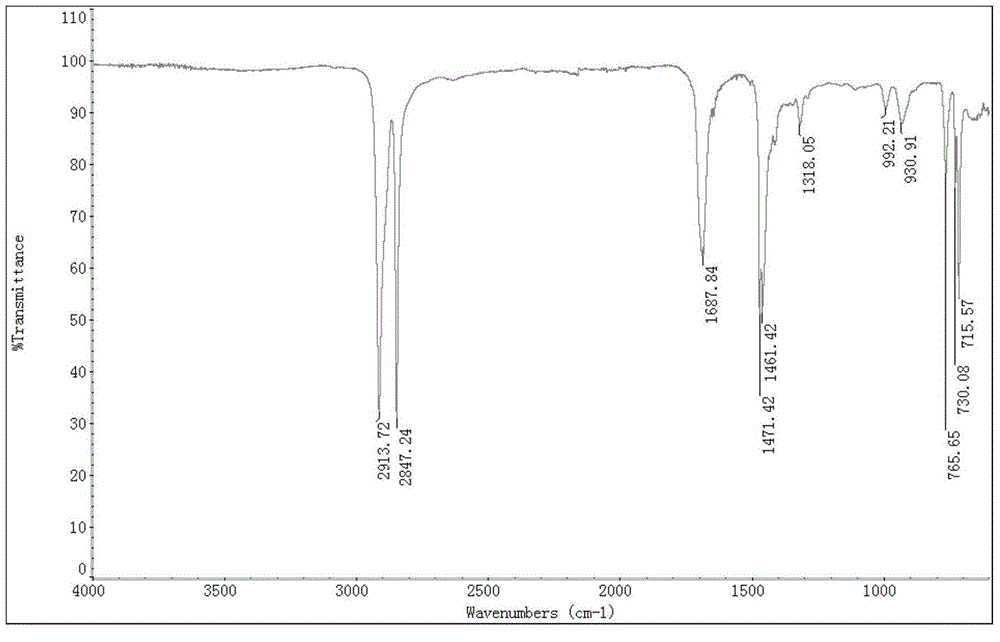

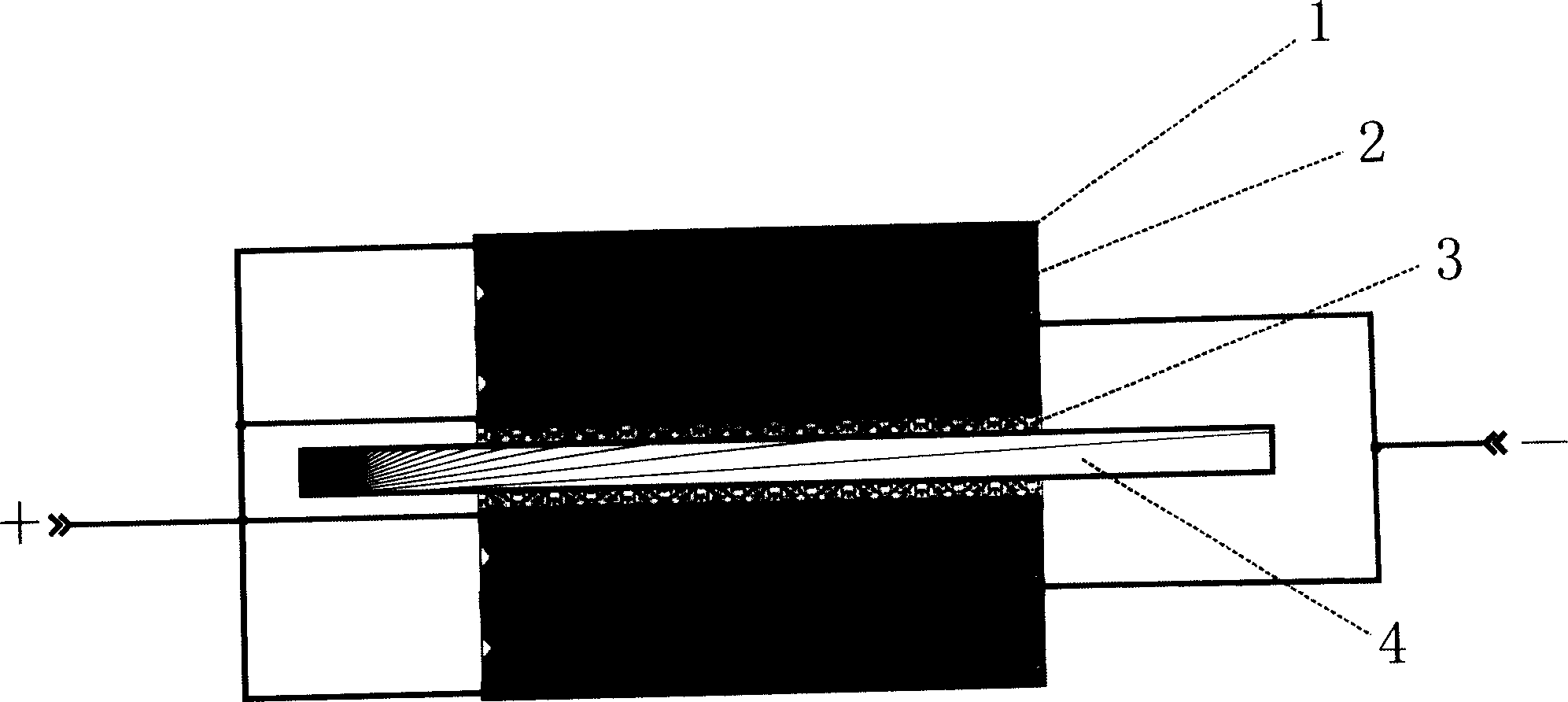

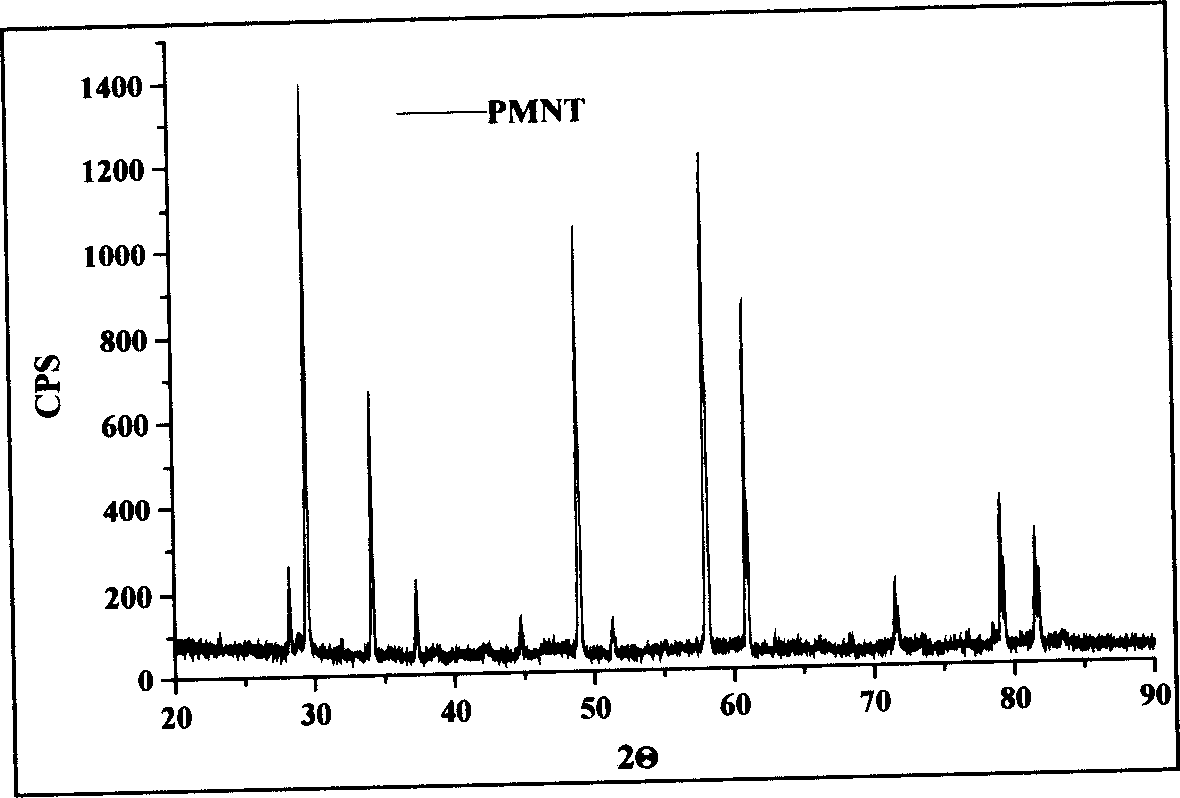

Ferroelectric ceramic micro refrigerator and producing method thereof

InactiveCN1710355AReduce weightReduce volumeMachines using electric/magnetic effectsSustainable buildingsSolid solutionDouble stage

A micro refrigerator of ferroelectric ceramics applies ' double stage - overlap' refrigerating structure and it is prepared adapting relaxation and solid solution of PMNT with high electro biological heat effect under wet preparation method of sol - gel . In said method, new mode of physical-chemical thickness reduction and new detecting means of electro biological heat property are applied.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

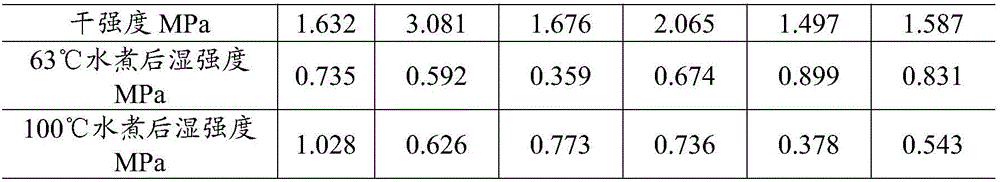

Lignin-based aldehyde-free adhesive and preparation and application method thereof

InactiveCN106753231AHigh strengthImprove dry strengthProtein adhesivesGlue/gelatin preparationAdhesiveWet strength

The invention provides a preparation method of a lignin-based aldehyde-free adhesive, comprising the steps: (1) mixing lignin and / or derivatives thereof, a catalyst and water to obtain a reduction system; (2) regulating the pH value of the reduction system to 10-11, then performing activating treatment to obtain an activating treatment product comprising the upper mixed solution and the lower precipitate; and (3) performing heating treatment on the lower precipitate, a protein-rich substance and water to obtain the lignin-based aldehyde-free adhesive. No aldehyde containing materials are introduced in the process of preparing the lignin-based aldehyde-free adhesive, the obtained lignin-based aldehyde-free adhesive can thoroughly solve the problem of formaldehyde release. In addition, the adhesive provided by the invention has excellent dry strength and wet strength, the highest dry strength is 3.081MPa, the highest wet strength after boiling in water of 63DEG C is 0.899MPa, and the highest wet strength after boiling in water of 100DEG C is 1.028MPa.

Owner:BEIHUA UNIV

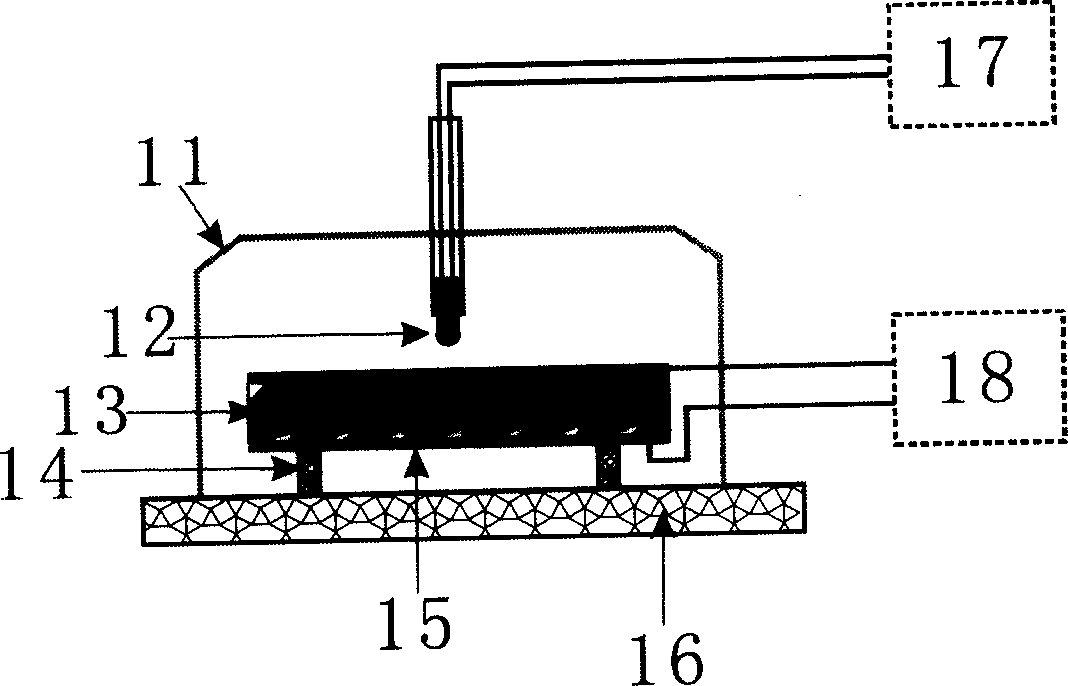

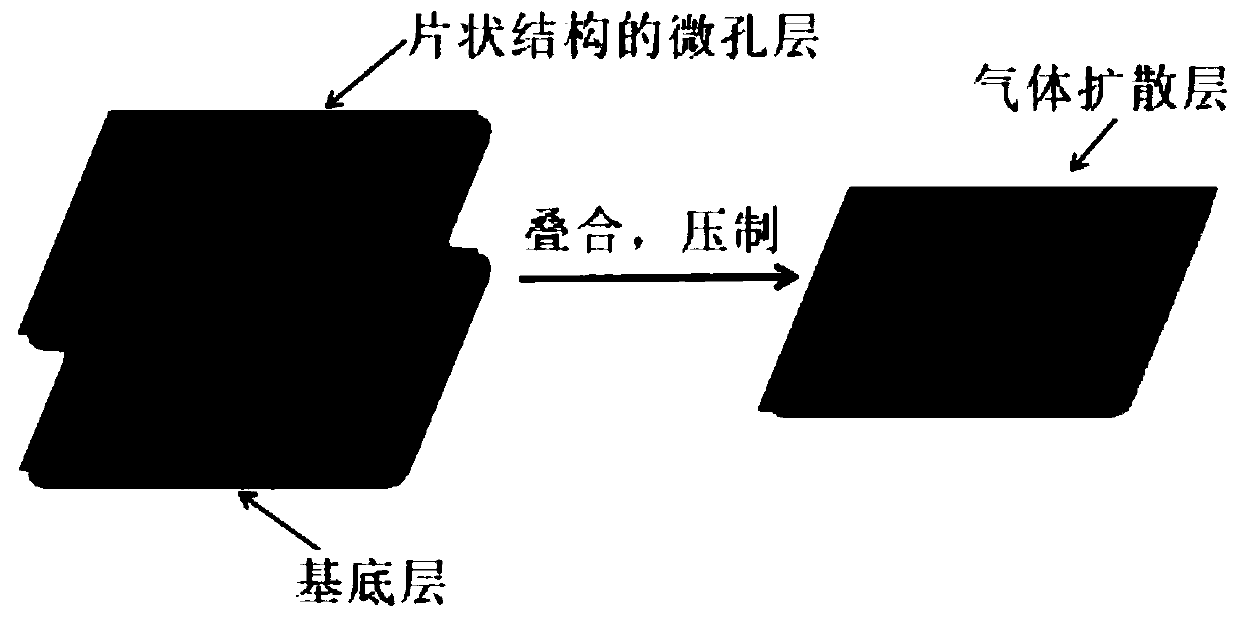

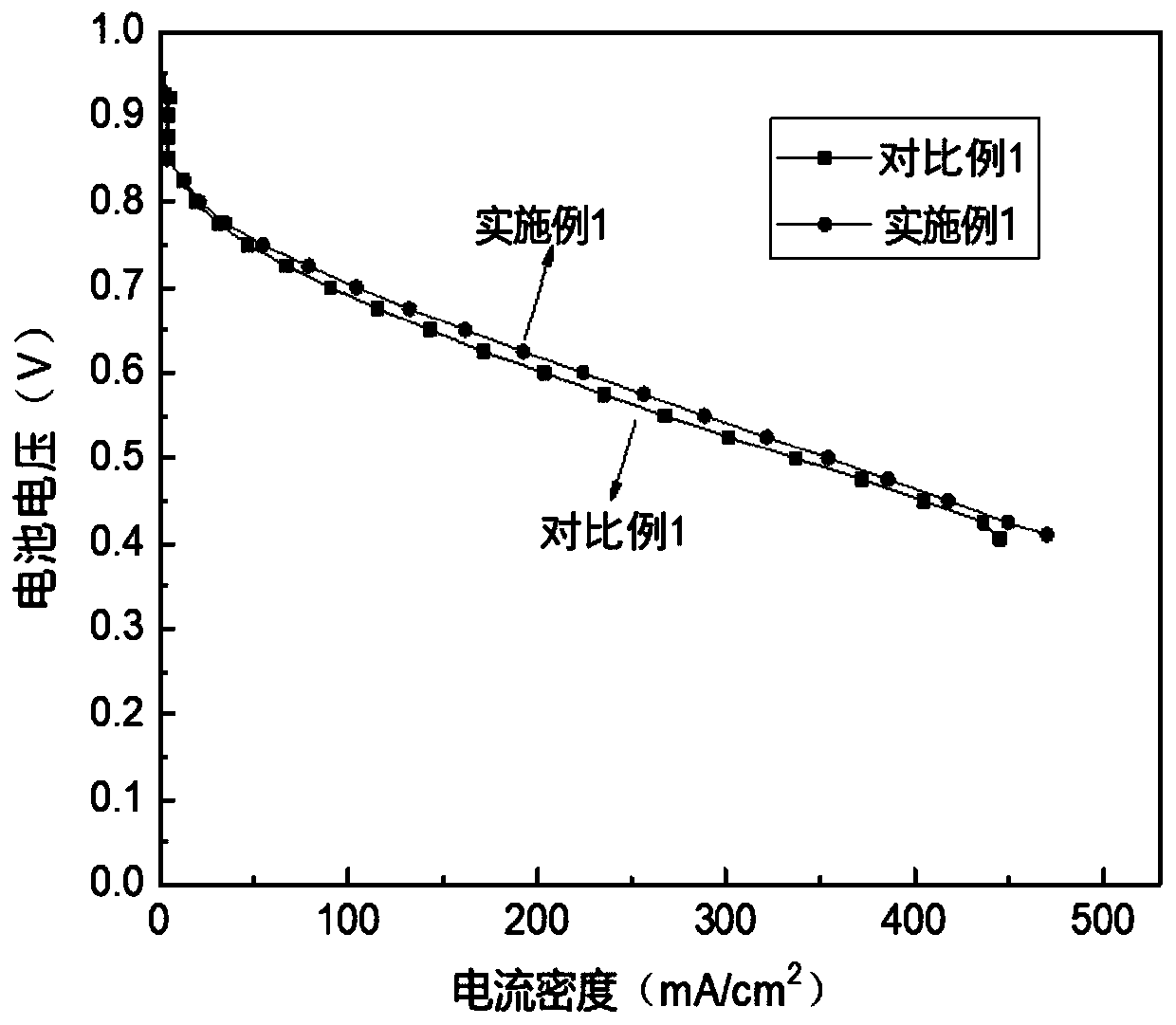

Gas diffusion layer for proton exchange film fuel cell and preparation method thereof, and proton exchange film fuel cell

ActiveCN110380063AEasy to prepareGood flexibilityCell electrodesFuel cellsProtonMicroporous material

The invention belongs to the technical field of a proton exchange film fuel cell and particularly relates to a gas diffusion layer for the proton exchange film fuel cell and a preparation method thereof, and the proton exchange film fuel cell. The gas diffusion layer includes a base layer and a microporous layer, wherein the microporous layer is a sheet-like structure, and the base layer is laminated and connected with the microporous layer. The gas diffusion layer is advantaged in that the microporous layer is the sheet-like structure, the base layer is laminated and connected with the microporous layer, a problem that the preparation slurry leaks into the interior of the base layer to easily block the base layer and block a gas transmission passage during wet preparation of the microporous layer is solved, the gas diffusion layer is made to have better gas transmission capacity, moreover, the microporous layer is the sheet-like structure and can provide a flat surface, and contact ofthe gas diffusion layer with a catalytic layer is improved.

Owner:GUANGDONG UNIV OF TECH

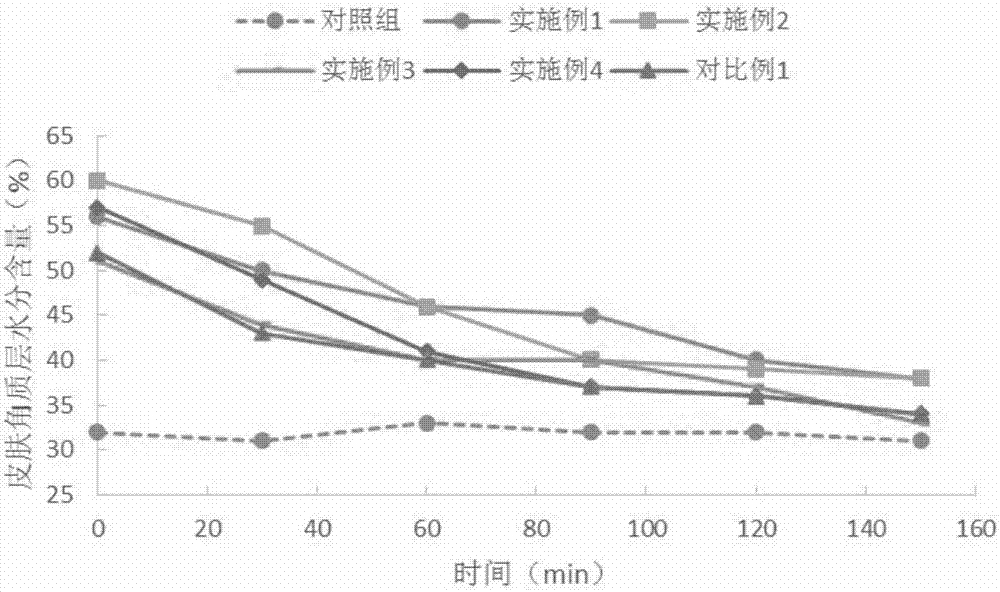

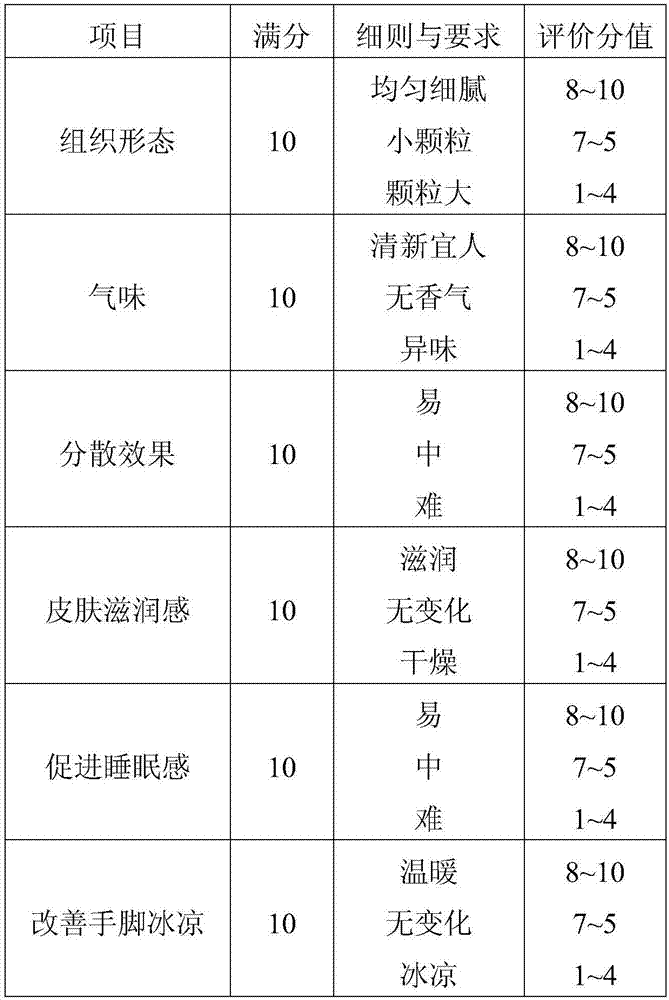

Bubble foot bath ball containing folium artemisiae argyi and preparation method of bubble foot bath ball

InactiveCN107115373AQuality improvementEliminate swellingCosmetic preparationsAntimycoticsVegetable oilRelative humidity

The invention relates to a bubble foot bath ball containing folium artemisiae argyi and a preparation method of the bubble foot bath ball. The bubble foot bath ball is prepared from the following raw materials: 1.0-4.5 parts of folium artemisiae argyi, 0.05-1.0 part of one of ginger, salt, carthamus tinctorius and pepper, 2.0-8.5 parts of carbon source, 1.0-6.5 parts of organic acid, 0.5-6.5 parts of starch, 0.5-0.8 parts of vegetable oil, 0.1-0.3 parts of essential oil and 2.0-6.5 parts of water. The preparation method of the ball comprises the following steps of: (1) grinding and sieving traditional Chinese medicinal materials, (2) weighing, mixing and intensively stirring the carbon source, the organic acid, the starch and the traditional Chinese medicinal materials in proportion to form a dry material, (3) uniformly mixing and stirring the vegetable oil, the essential oil and the water to form a wet preparation, (4) uniformly mixing the wet preparation and the dry material to form a soft material, and (5) pouring the soft material into a mold, placing in air at 20-30 DEG C and relative humidity of 60-75% for drying for 1-3 days, performing demolding, and then putting the material in a plastic bag to be fastened. The bubble foot bath ball is all natural, simple in preparation technology, low in cost and convenient to carry and has multiple health-care effects.

Owner:BEIJING UNION UNIVERSITY

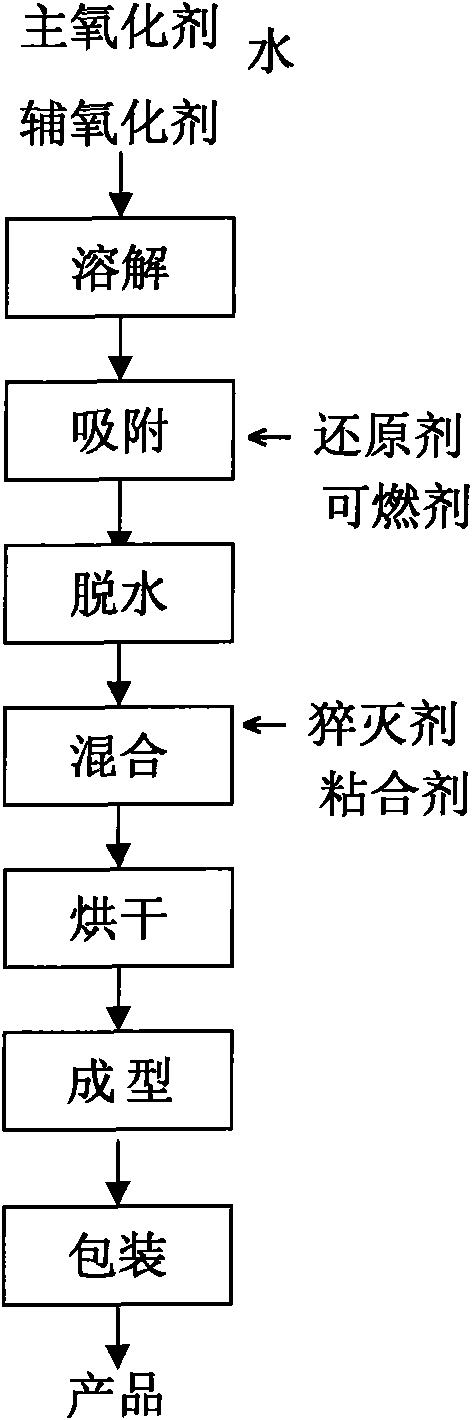

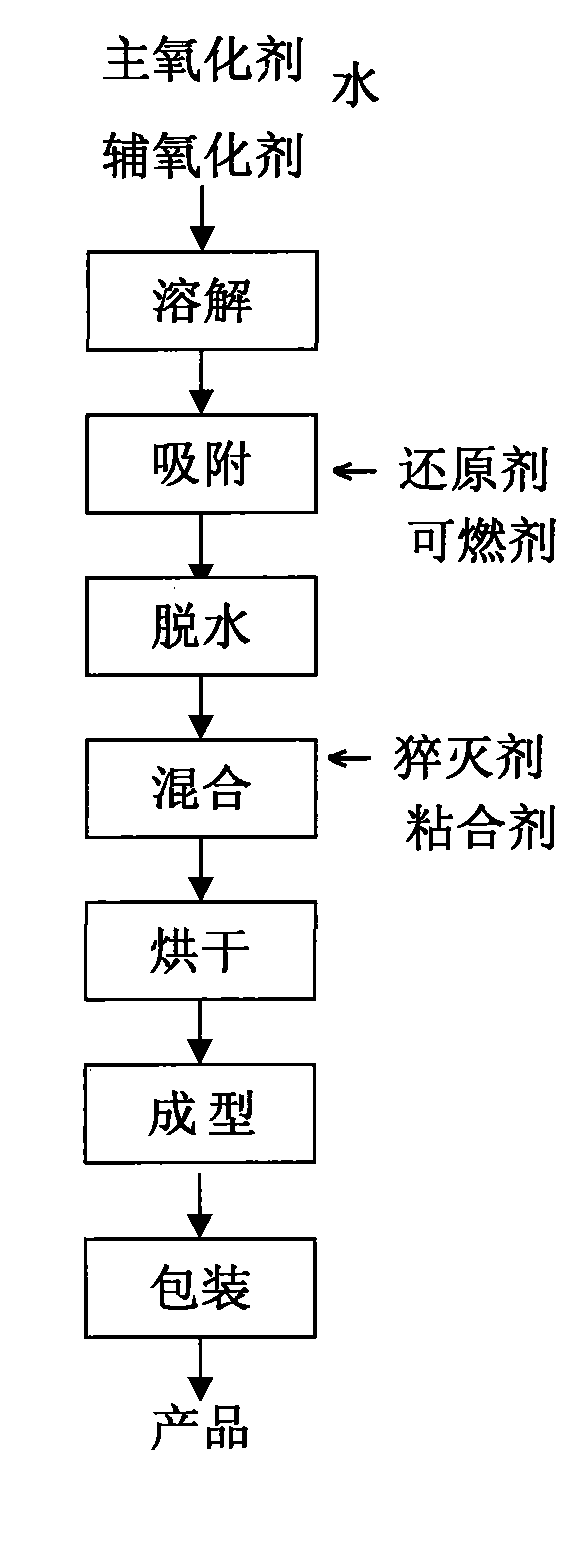

Aerosol fire extinguishing agent and wet preparation method thereof

The invention discloses an aerosol fire extinguishing agent and a wet preparation method thereof. Water is adopted as a solvent and a reducing substance with the porous adsorption capacity is adopted as an incendiary agent, so that an oxidant achieves molecular-scale uniform dispersion. A powerful free radical quenching agent is added, so that the fire extinguishing effect is obviously improved. The wet preparation method for the aerosol fire extinguishing agent has no special requirement on granularity and water content of raw materials, reduces the process of crushing materials, improves the logistics speed of the production process, realizes high yield, and can remarkably reduce the production energy consumption and production cost. The dust pollution is avoided, and the safety and environmental protection in the production process are realized.

Owner:广西国杰斯消防科技有限公司

Flame-retardant benzoxazine resin and preparation method thereof

Owner:XIAMEN UNIV +1

Novel chromium-tin purple dye and its preparing method

InactiveCN1900176ANarrow distributionImprove stabilityInorganic pigment treatmentHigh resistanceRare earth metal compounds

The present invention discloses one new kind of chromium-tin purple dye and its wet preparation process. The chromium-tin purple dye is prepared with tin salt, chromium oxide or salt, RE metal compound, precipitant and dispersant, and through liquid phase reaction and high temperature sintering. The prepared chromium-tin purple dye is RE blended crystal in nanometer level, and has the advantages of high grinding resistance, high heat resistance, high stability, pure color and excellent colorating property. It may be used in glaze and ceramic to result in excellent effect.

Owner:胡秋帆

Method for removing cobalt in cobalt-containing wastewater

ActiveCN103848490AReduce contentEmission complianceWater/sewage treatment by irradiationEnergy based wastewater treatmentSocial benefitsCobalt(II,III) oxide

The invention provides a method for removing cobalt in cobalt-containing wastewater. The method comprises the following steps: reacting the cobalt-containing wastewater and a sodium hypochlorite solution in sunshine under the condition that the pH value is 10-12 so as to obtain a precipitate, and filtering to remove the precipitate. By utilizing the properties of sodium hypochlorite and catalytic action of sunshine, the ion cobalt in the cobalt-containing wastewater is oxidized and precipitated, the cobalt precipitate is filtered and removed, and the content of metal ion cobalt in the cobalt-containing wastewater can be effectively reduced, so that the wastewater can reach the standard to emit, and the metal cobalt can be recycled. The method provided in the invention can be used for treating the wastewater generated in the production process of various cobalt salts such as cobaltosic oxide by virtue of wet preparation, the sedimentation effect is good, novel pollutants are not introduced, and the method is low in cost, simple in operation and suitable for industrialization and has high economic benefits and social benefits.

Owner:NINGBO RONBAY LITHIUM BATTERY MATERIAL CO LTD

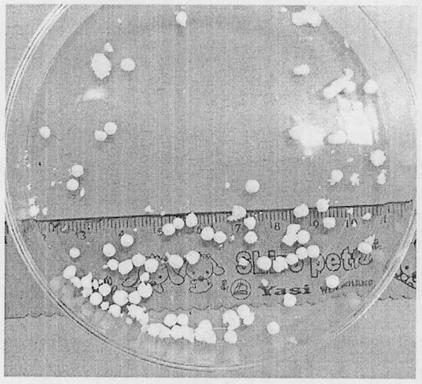

Preparation of chitosan/cellulose aerogel balls with high formaldehyde adsorption characteristics

InactiveCN110330682AMild conditionsSimple processOther chemical processesDispersed particle separationPorosityFreeze-drying

The invention specifically discloses a preparation method of a chitosan modified cellulose composite aerogel. The raw materials are cellulose and chitosan. The preparation method comprises the following steps: acidolyzing the cellulose to prepare a cellulose solution, then dropwise adding the cellulose solution to a regeneration solution to obtain cellulose wet gel balls, dipping the gel balls into the chitosan solution to obtain cellulose-chitosan composite wet gel balls, and freeze-drying to obtain the cellulose-chitosan composite aerogel balls with high-efficiency formaldehyde adsorption characteristics. The cellulose / chitosan composite aerogel balls have large specific surface area and porosity, strong adsorption performance on formaldehyde and good application prospect.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Chitosan oral scented pieces and preparation thereof

InactiveCN101297669AKeep the scentIncrease the fragranceOrganic active ingredientsMetabolism disorderMentholMagnesium stearate

The invention relates to a preparation method of a chitosan cachou. The chitosan cachou is prepared by chitosan, corn starch, xylitol, maltodextrin, acesulfame potassium, sodium cyclamate, menthol, and magnesium stearate, and the preparation method includes the following steps: embedding processing of essence, mixing, damp mass making, wet granule making, drying, granule finishing, final mixing, sheeting, sterilization, and packaging, thus obtaining the chitosan cachou.

Owner:WUHAN POLYTECHNIC UNIVERSITY

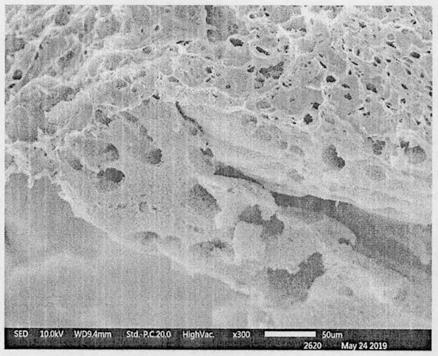

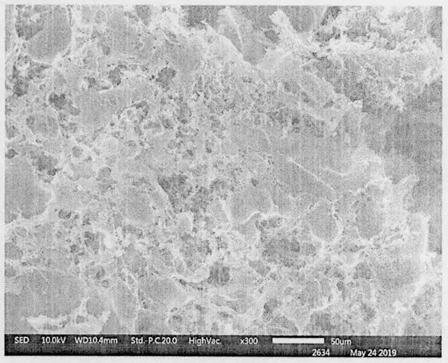

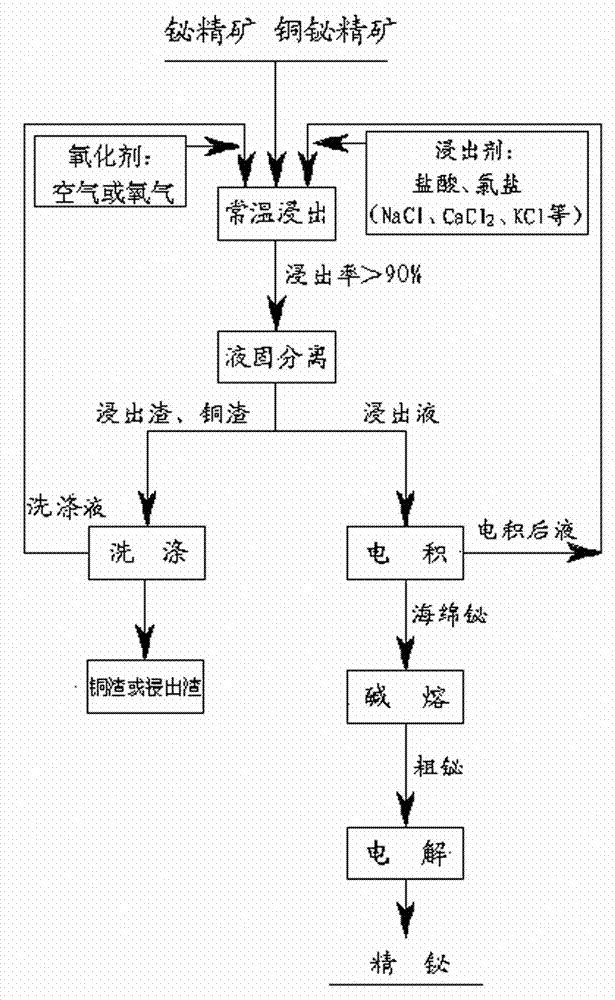

Environment-friendly energy-saving normal pressure and temperature wet preparation process for refined bismuth

ActiveCN103498171AImprove leaching rateSimple and fast operationPhotography auxillary processesProcess efficiency improvementElectrolysisOxygen

The invention discloses an environment-friendly energy-saving normal pressure and temperature wet preparation process for refined bismuth. The process comprises the procedures of normal temperature leaching, liquid-solid separation, electrodeposition, alkali fusion and electrolysis. The process comprises the following concrete steps: placing bismuth oxide, a bismuth concentrate or a copper-bismuth concentrate in an acidic chlorine salt system at normal temperature and normal pressure, using air or oxygen as an oxidizing agent and carrying out normal temperature leaching; carrying out solid-liquid separation, i.e., directly delivering a leachate to a cyclone electrolyzer at normal temperature and normal pressure, carrying out electrolysis for 1 to 7 h under the conditions that direct voltage and current density are controlled to be 1 to 3.5 V and 150 to 800 A / m<2>, respectively, so as to obtain clear post-electrodeposition liquid and sponge bismuth and returning the post-electrodeposition liquid to the procedure of leaching for cyclic usage; subjecting sponge bismuth obtained in electrodeposition to alkali covering and melting so as to obtain crude bismuth; and allowing the crude bismuth to undergo electrolysis so as to obtain refined bismuth. According to the invention, air or oxygen is used for oxidizing leaching of a bismuth ore in the acidic chlorine salt system at normal temperature and normal pressure, cyclone electrodeposition is adopted to directly extract bismuth from the leachate, so the process can be implemented at normal temperature and normal pressure and has the advantages of simple and convenient operation, high leaching rate of the bismuth ore, low cost and environmental protection.

Owner:云南业胜环境资源科技有限公司

Polyacrylonitrile/cellulose acetate fiber composite hemodialysis membrane and preparation method thereof

InactiveCN104368246ASemi-hydrophilicImprove pressure resistanceSemi-permeable membranesSuction devicesHollow fibre membraneCellulose acetate

The invention discloses a polyacrylonitrile / cellulose acetate fiber composite hemodialysis membrane and a preparation method thereof, and relates to the field of biological materials. The hemodialysis membrane refers to a hollow fiber membrane, the average inner diameter of hollow fibers is 122-245 microns, and the wall thickness is 22-50 microns. The hemodialysis membrane comprises the following components in parts by mass: 35-60 parts of polyacrylonitrile fibers, 25-40 parts of cellulose acetate fibers, 3-7 parts of a coupling agent and 30-60 parts of solvents, wherein the solvents refer to acetone and DMAC or acetone and DMSO. In the method for preparing the polyacrylonitrile / cellulose acetate fiber composite hemodialysis membrane, a dry-wet preparation process is adopted. The polyacrylonitrile / cellulose acetate fiber composite hemodialysis membrane provided by the invention is relatively high in retention rate of bovine serum albumin, relatively high in biocompatibility, relatively high in permeability on vitamin B12 and relatively low in cost and is a relatively ideal hemodialysis membrane material.

Owner:SUZHOU COSMETIC MATERIALS

Method for preparing hydrophobic starch

The invention provides a hydrophobic starch preparation method, relates to a preparation method for the hydrophobic starch, in particular to a wet preparation method for the hydrophobic starch. The invention aims to provide the preparation method for the hydrophobic starch. The preparation method comprises the following steps: brewing overcooked starch into starch milk with the mass concentration of between 25 and 40 percent by water or 80-95 mass percent ethanol aqueous solution, placing and stirring the starch milk in a reaction kettle; adding anhydrous sodium sulfate accounting for 3 to 15 mass percent of the overcooked starch, and keeping a constant temperature for 5 to 15 minutes; regulating the pH value of the emulsion to 8.5 to 11.0 by a 3 to 6 percent sodium hydroxide aqueous solution, starting to add hexamethyldisilazane accounting for 5 to 15 mass percent of the overcooked starch, keeping the constant pH value of the emulsion by 5 to 10 mass percent hydrochloric acid or the 3 to 6 mass percent sodium hydroxide aqueous solution, and carrying out the reaction for 2 to 15 hours; and after the reaction is finished, regulating the pH value of the emulsion to 6.0 to 7.0 by 5 to 10 mass percent hydrochloric acid, and obtaining the product after filtrating, washing, drying and crushing the starch milk.

Owner:SHENYANG POLYTECHNIC UNIV

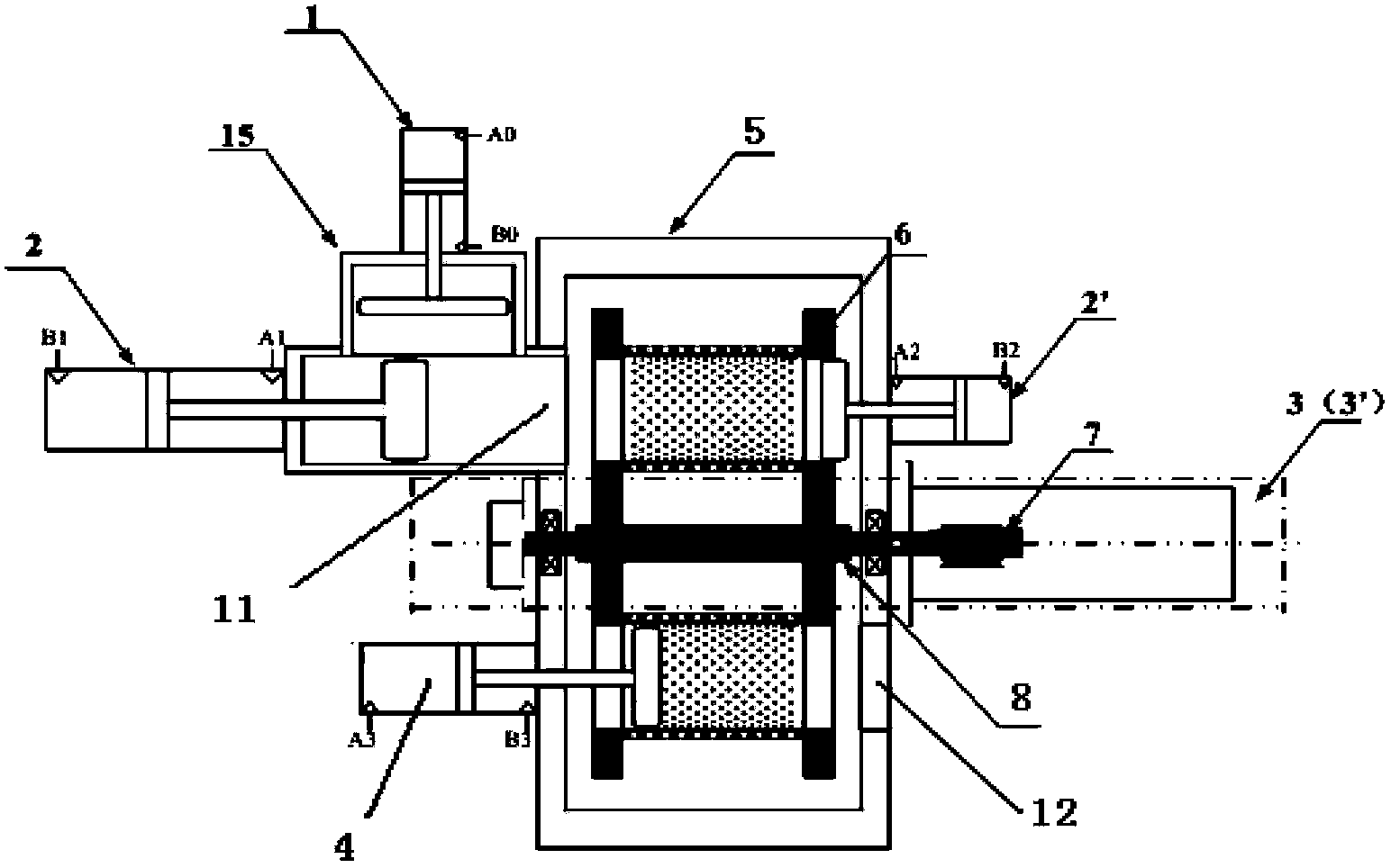

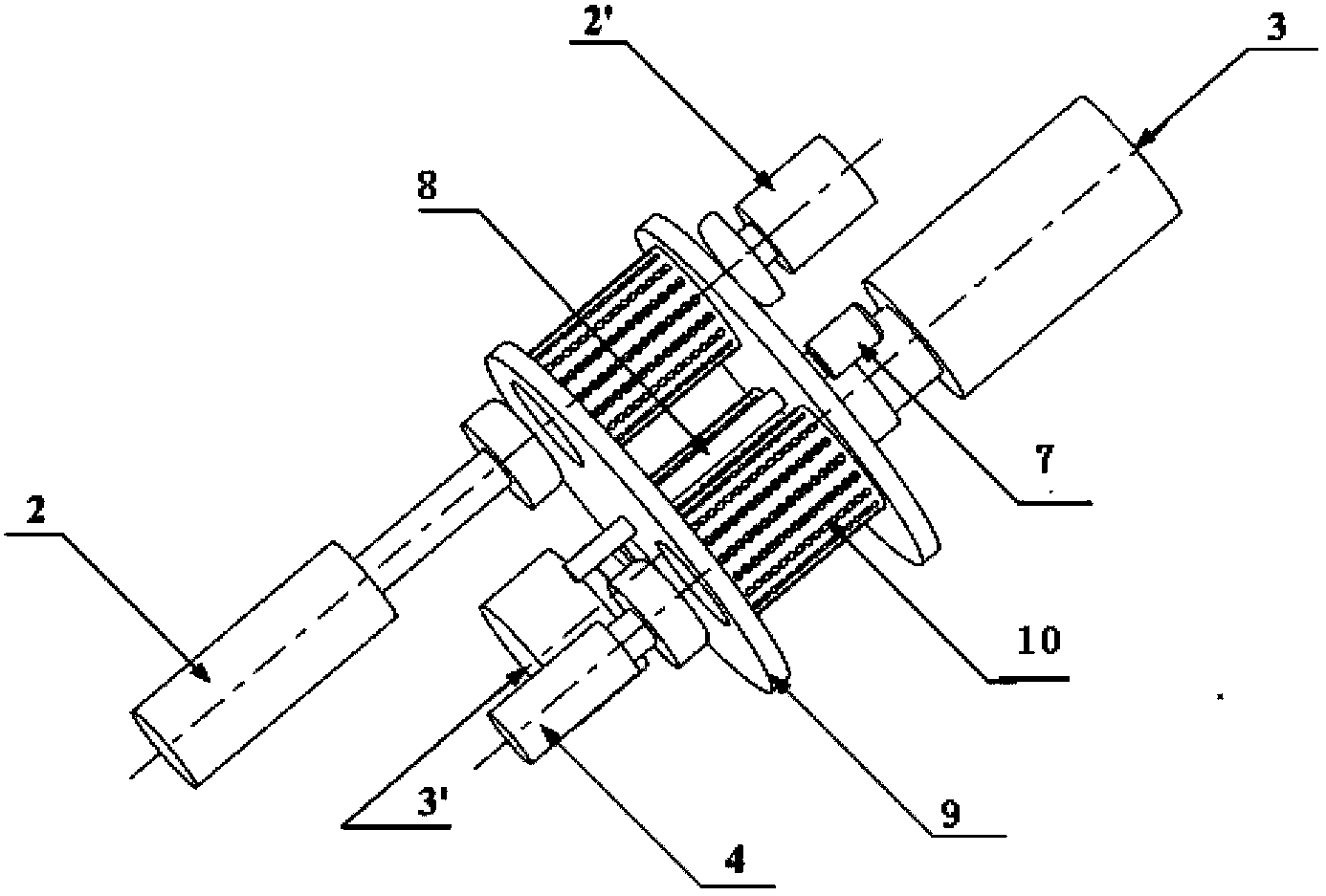

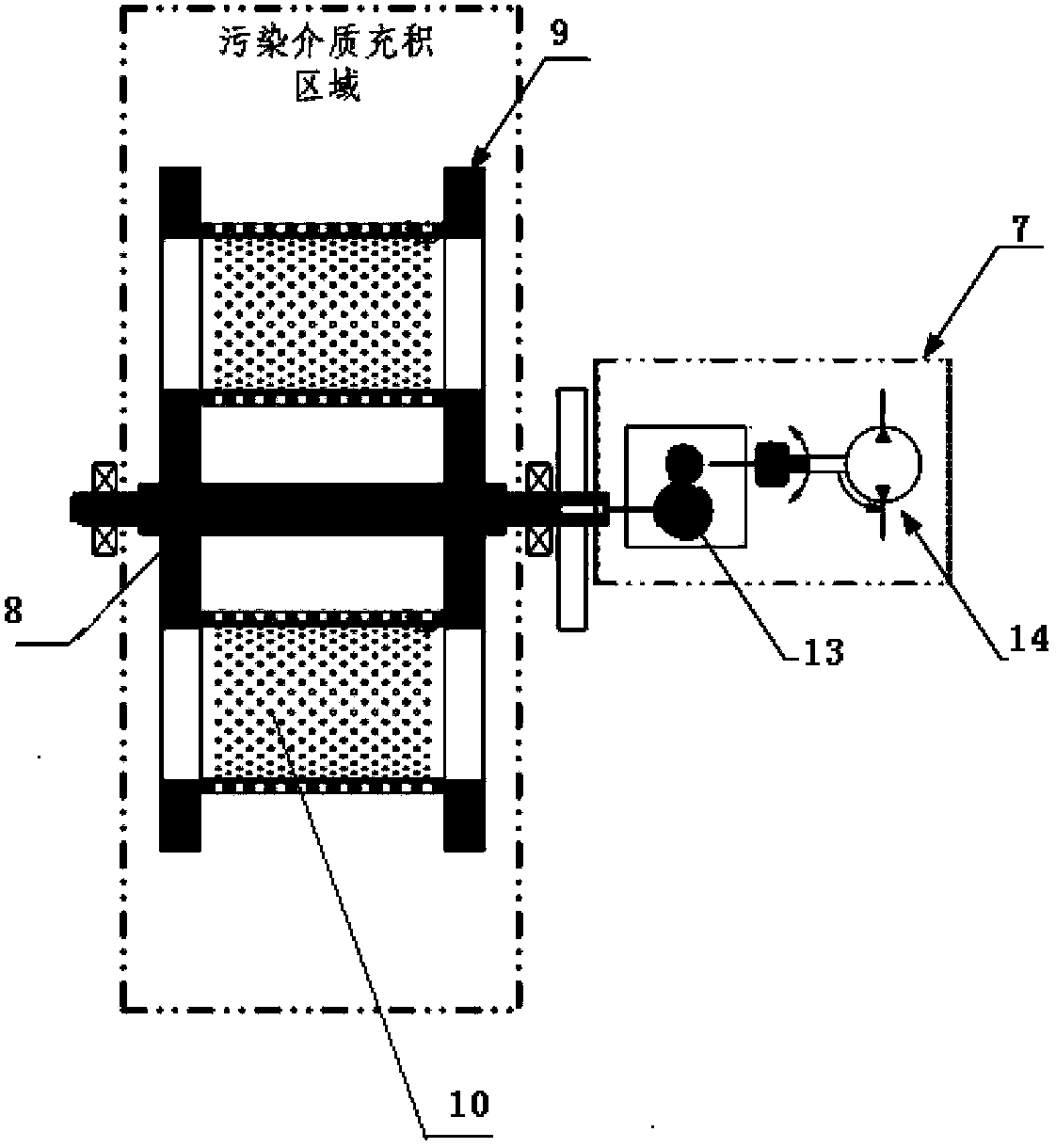

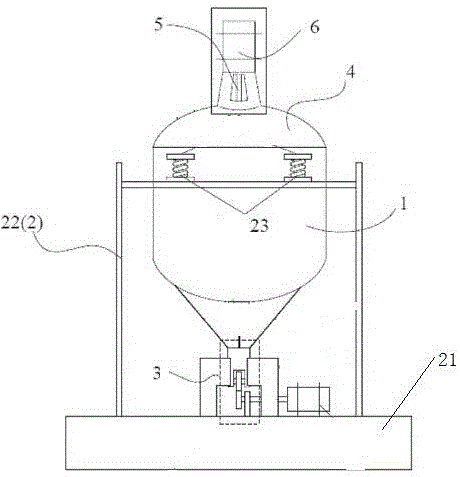

Extruding-separating device for dry and wet separation of municipal solid waste

The invention relates to waste disposal equipment, in particular to an extruding-separating device for dry and wet separation of municipal solid waste. The extruding-separating device solves the problem that dry and wet separation of municipal solid waste in China cannot meet the requirement for recycling resources. A feeding mechanism, a pre-pressing mechanism, an extruding mechanism and a discharging mechanism are arranged on the outer side of a machine body, the feeding mechanism and the pre-pressing mechanism are arranged perpendicular to each other, the pre-pressing mechanism, the extruding mechanism and the discharging mechanism are arranged in parallel, the axis of the pre-pressing mechanism, the axis of the extruding mechanism and the axis of the discharging mechanism are located in the same circumferential line and are arranged at 120-degree intervals, a rotating mechanism is arranged on the central axis in the machine body, the rotating mechanism and a driving mechanism are arranged coaxially or in parallel, and the driving mechanism is arranged on the outer side of the machine body. The extruding-separating device can ensure dry and wet separation of municipal solid waste in China, the water content of the dry municipal solid waste is lower than 30%, and outstanding improvements are made in the respects of waste adaptability, equipment maintainability, equipment reliability, cost reduction and the like.

Owner:BEIJING XINCHANGZHENG TIANGAO INTELLIGENT MACHINE TECH CO LTD

Condensed milk powder and wet preparation technology

ActiveCN105053216AHigh sweetnessLow calorific valueMilk preparationDipotassium hydrogen phosphateSodium Caseinate

The condensed milk powder comprises the following components in parts by weight: grape syrup 40-60%, coconut oil 20-50%, fructose 10%-20%, milk powder 10%-20%, sodium caseinate 2-7%, silicon dioxide 0.3-0.6%, dipotassium hydrogen phosphate 1-2%, sodium tripolyphosphate 0.3-0.6%, mono- and di-glycerin fatty acid ester 0.3-0.6%, sodium stearyl lactate 0.3-0.5% and edible essence 0.2-0.5%. The above-mentioned formula and technology produced condensed milk powder not only has a pure and delicate fragrance of fresh milk, but also has an original flavor of condensed milk, and the condensed milk powder is convenient for eating and storing, long in shelf life and higher in milk protein and fat contents and nutritional value than the condensed milk.

Owner:江苏志威乳业有限公司

Oil body extraction and uses

InactiveCN103534343AEasy to transportImprove storage characteristicsCosmetic preparationsOrganic active ingredientsOil bodyPetroleum engineering

The present invention provides a method of extracting naturally occurring oil bodies comprising obtaining material containing naturally occurring oil bodies,recovering the oil bodies in a wet preparation and drying the oil bodies; and dried oil bodies obtained by the method and uses thereof.

Owner:UNIVERSITY OF NOTTINGHAM

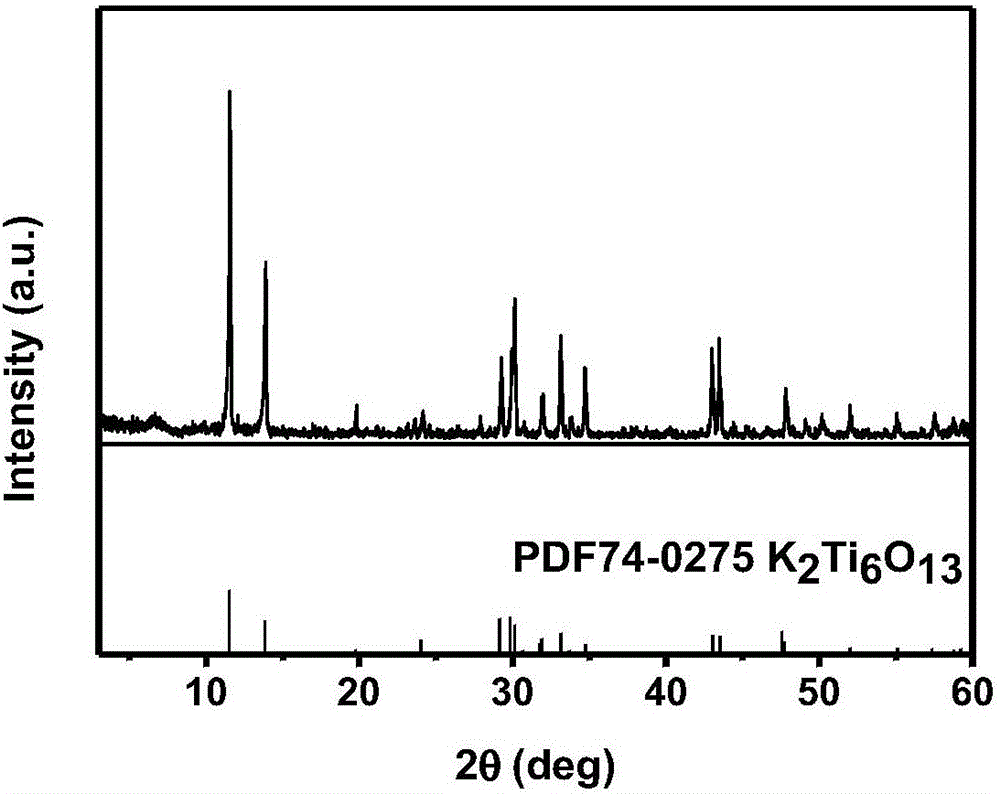

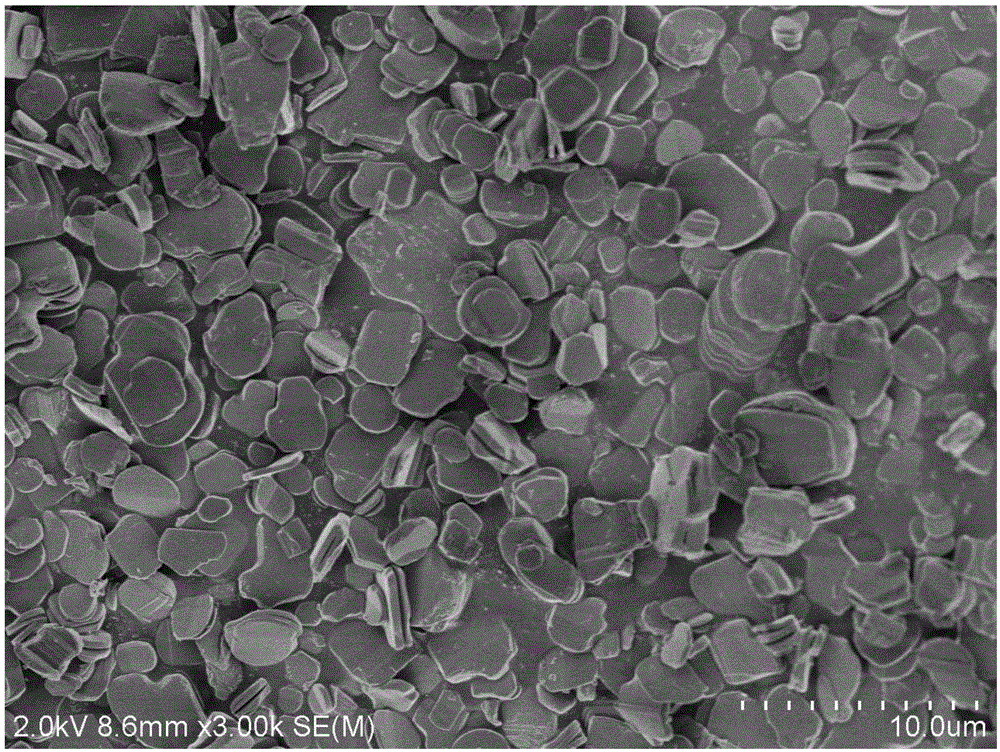

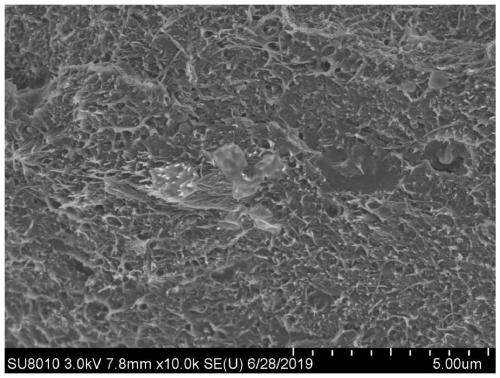

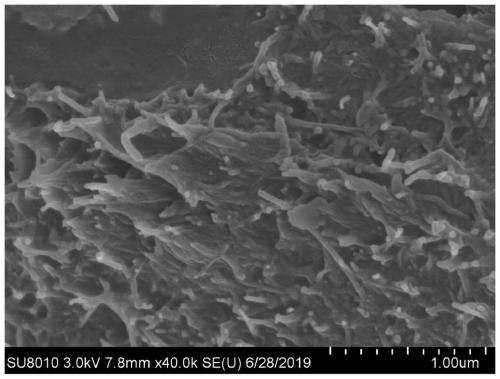

Method for preparing potassium hexatitanate lamellar crystal by using solid phase method

InactiveCN106801256AAvoid it happening againEasy to producePolycrystalline material growthFrom solid stateLamellar crystalsPotassium

The invention discloses a method for preparing potassium hexatitanate lamellar crystal by using a solid phase method, belonging to the technical field of preparing an inorganic material. The method is mainly characterized by comprising the following steps: by taking potassium source and tiantium source as raw materials, adding less crystal form inducer, evenly mixing, then calcinating the mixture at high temperature to obtain potassium tetratitanate lamellar crystal, and performing secondary calination through taking the potassium tetratitanate lamellar crystal as a precursor, thus preparing the potassium hexatitanate lamellar crystal with the average diameter of being 1.0-5.7mum and the average thickness of being 0.1-0.5mum. The potassium hexatitanate lamellar crystal is prepared by using the solid phase method rather than the traditional wet technology, not only can the production proceudres be simplified and the energy consumption of enterprises be reduced and potassium tetratitanate lamellar crystal can be prepared at one step by utilizing the crystal form inducer, but also the treatment problem of waste water generated by using the wet preparation technology can be avoided, therefore, the method is suitable for industrial production.

Owner:JIANGNAN UNIV

Water-based wet preparation method of genuine leather case leather

ActiveCN108977595ASolve the adhesionSolve the problem of mildew in the leatherSpecial leather manufactureLeather surface finishingWater basedSurface layer

The invention provides a water-based wet preparation method of genuine leather case leather, which comprises the following steps: Genuine leather base material processing, coating, coagulating, washing with water, drying and dry veneering; and the method intelligently solves the problems of difficult adhesion of water-based polyurethane foaming material on genuine leather and easy molding on the genuine leather, and also solves the problems of easy cracking and bubbling in case of agglomeration by the traditional water-based wet process; and the water-based genuine leather case leather is obtained through the method of coagulating with intermittent spraying coagulating liquid, washing with water, drying and transferring with dry veneering. A wear-resistant auxiliary agent and a water-basedhydrophobic agent are added to a water-based surface layer slurry system to improve the wear resistance and waterproof performance of the case leather. The water-based genuine leather case leather obtained by the method provided by the invention has the advantages of safety and environmental protection, soft hand feeling, excellent waterproof performance, and molding and wear resistance.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD +1

Carbon nano-tube plastic electric-conduction composite material and wet preparation process thereof

The invention relates to the technical field of electric-conduction composite materials, particularly to a carbon nano-tube plastic electric-conduction composite material and a wet preparation processthereof, wherein the raw materials comprise plastic emulsion, amino acids, carbon nano-tubes and an electric-conduction filler, and the amino acids can produce pi-pi action with the carbon nano-tubes. The process comprises: preparing an amino acid aqueous solution; adding carbon nano-tubes and an electric-conduction filler to the amino acid aqueous solution; adding the carbon nano-tube amino aciddispersion liquid to a plastic emulsion, and carrying out uniformly demulsification mixing; filtering, and drying; mixing with an auxiliary material; and mixing, extruding, and granulating. Accordingto the present invention, carbon nano-tubes are subjected to surface modification by using the biological amino acid capable of producing pi-pi action with the carbon nano-tubes to improve the dispersion performance of the carbon nano-tubes, and the carbon nano-tubes and the plastic emulsion are subjected to wet mixing so as to obtain the uniformly dispersed carbon nano-tube plastic electric-conduction composite material.

Owner:SHANDONG DAZHAN NANO MATERIALS +1

Wet preparation method for polypropylene-attapulgite filling master batch

InactiveCN106009293AIncreased impact strength at room temperatureIncreased flexural modulusElastomerBenzoyl peroxide

The invention discloses a wet preparation method for polypropylene-attapulgite filling master batch. The wet preparation method for the polypropylene-attapulgite filling master batch includes steps of carrying out modification and mechanical activation on dolomite type attapulgite clay to obtain serous fluid for standby application; adding the dolomite type attapulgite clay serous fluid into a reaction kettle and adding polypropylene powder, St, MAH (maleic anhydride) and BPO (benzoyl peroxide) into the reaction kettle to obtain polypropylene-attapulgite copolymers; adding coupling agents and stearic acid into calcium carbonate in a high-speed mixing machine and activating the surfaces of the calcium carbonate; arranging the polypropylene-attapulgite copolymers and the calcium carbonate with the activated surfaces into a stirring machine, stirring the polypropylene-attapulgite copolymers and the calcium carbonate to obtain mixed and stirred materials, arranging the mixed and stirred materials in a disc machine, manufacturing granules from the mixed and stirred materials, conveying the processed and formed small granules into a rotary dryer and drying the small granules to obtain the polypropylene-attapulgite filling master batch. The wet preparation method has the advantages that the wet preparation method is simple and is favorable for operation, the polypropylene-attapulgite filling master batch is free of expensive elastomer materials, and accordingly the production cost can be reduced.

Owner:盱眙恒泰矿业科技有限公司

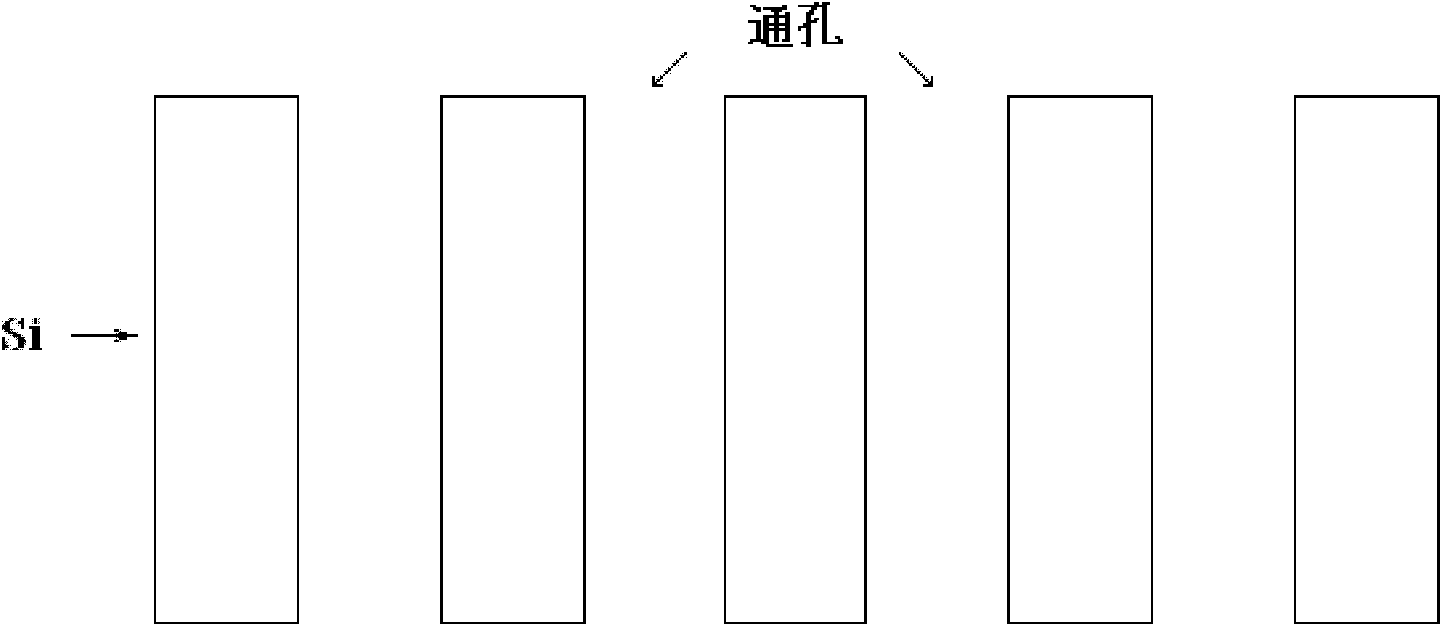

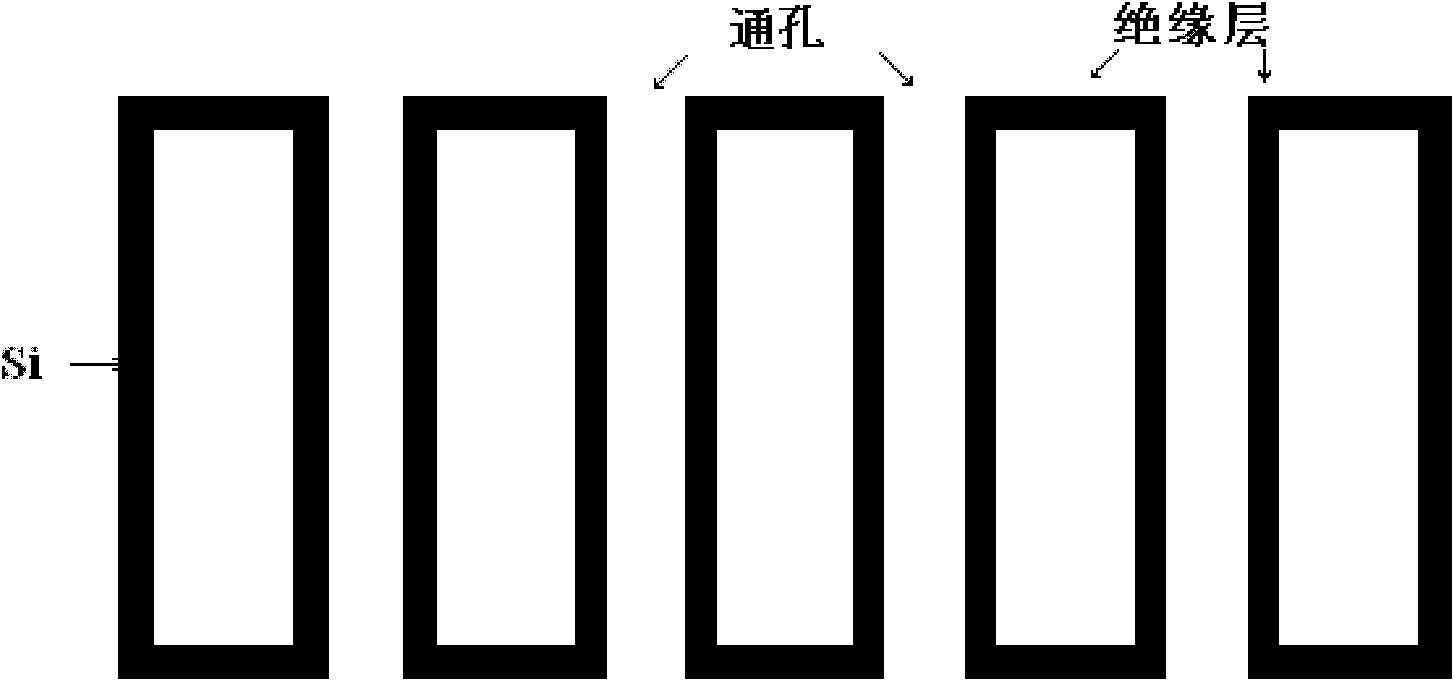

Ultrathin film wet preparation method for TSV insulating layer

InactiveCN101886286AAppropriate thicknessMeet needsElectrophoretic coatingsElectrophoresisSilicon chip

The invention relates to an ultrathin film wet preparation method for a TSV insulating layer in the technical field of microelectronic materials, which comprises the following steps of: (1) connecting a silicon chip subjected to DRIE etching with a conductive device into an anode or cathode system serving as an anode or a cathode of the conductive device to connect an electrophoresis apparatus so as to form a circuit; (2) putting the silicon chip connected with the conductive device into electrophoretic coating solution; (3) switching on a power supply and starting to carry out electrophoretic coating; (4) after growth is completed, switching off the power supply, taking the silicon chip out of the electrophoretic coating solution and carrying out ultrasonic cleaning on a silicon through hole by using deionized water to wash off a suspended coating; and (5) carrying out primary drying and secondary drying treatment on the clean electrophoretic coated silicon chip. The ultrathin insulating film is prepared by the ultrafthin film wet preparation method of the invention. The thickness of the ultrathin insulating film is between 1 and 3mu m. The ultrathin insulating film has excellent bonding force. A test result shows that the breakdown voltage of the insulating film can reach over 2mV / cm. The process flow can be operated at a low temperature. The growth speed of the coating is high. The process cost is low.

Owner:SHANGHAI JIAO TONG UNIV

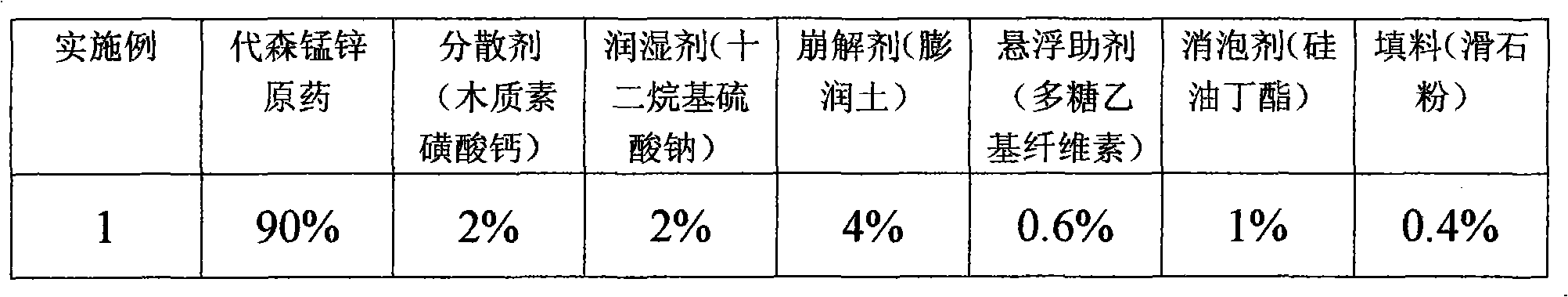

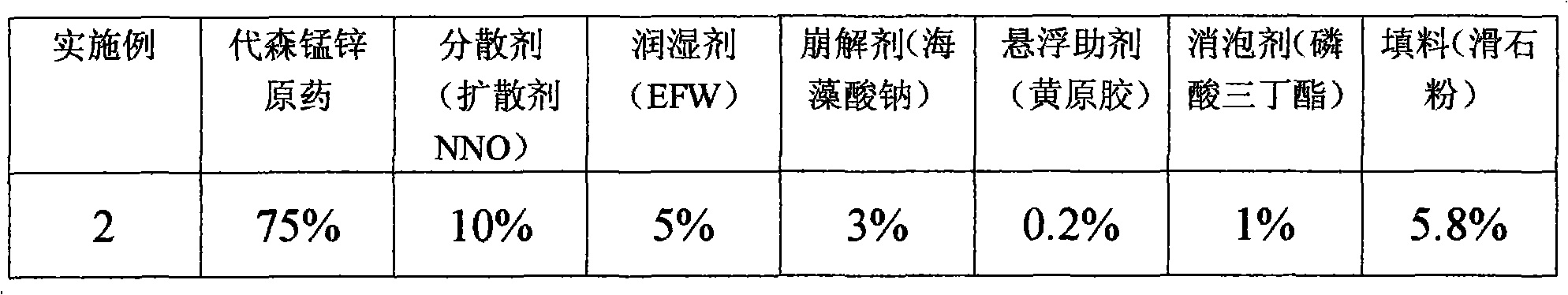

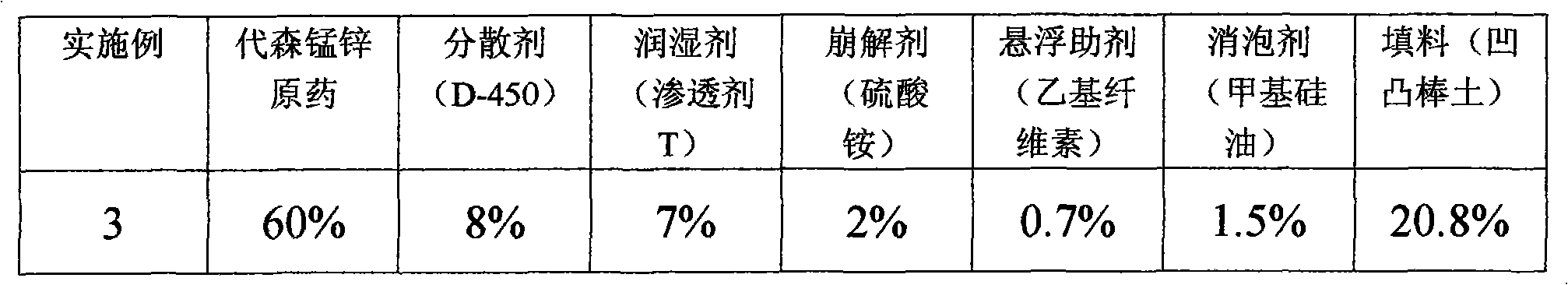

Wet-preparation process for mancozeb water dispersible granules

InactiveCN101961006ASolve pollutionSolve the costBiocideFungicidesWater dispersibleAdditive ingredient

The invention discloses a wet-preparation process for mancozeb water dispersible granules, which aims to solve the technical problems of heavy pollutions and difficult storage, transport and dissolution of agricultural carmazine. The adopted technical scheme is that: the preparation process is realized by a dispersion machine, a grinding machine and a spray granulation and drying tower, and specifically comprises the following steps of: adding crude mancozeb and a filler into a dispersion tank of the dispersion machine, and fully mixing the ingredients to form uniformly-dispersed slurry by using the dispersion machine; feeding the uniformly-dispersed slurry into a grinding hopper of the grinding machine by using a feeding pipeline, and performing grinding by using the grinding machine; and feeding the ground slurry to the spray granulation and drying tower, and performing spray granulation by using granulation spray orifices to form the mancozeb granules. The key of the wet-preparation process is that: the crude mancozeb and the filler are crushed by a wet method, so dust pollutions to the atmosphere are reduced and economic cost is saved.

Owner:河北双吉化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com