Carbon nano-tube plastic electric-conduction composite material and wet preparation process thereof

A technology of conductive composite materials and carbon nanotubes, applied in the field of conductive composite materials, can solve problems such as difficult dispersion and high pollution, and achieve the effects of improving dispersion, good processing performance, and simple and stable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

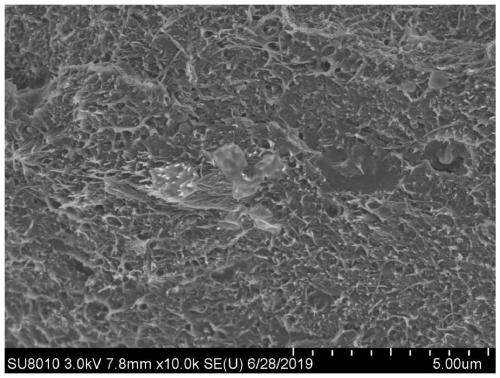

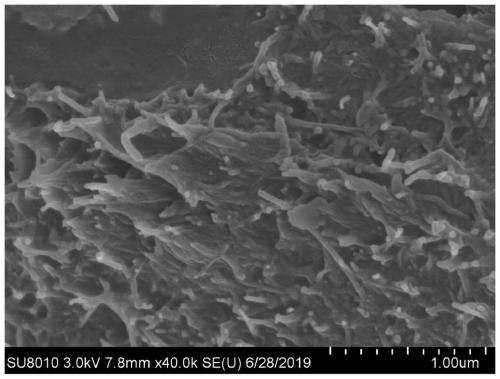

Image

Examples

Embodiment 1

[0041] A PS special material, raw materials include plastic emulsion, amino acid aqueous solution, carbon nanotubes and conductive fillers,

[0042] The mass fraction of amino acids in the amino acid aqueous solution is 0.3%, the types of amino acids are phenylalanine and tryptophan, and the mass ratio of phenylalanine and tryptophan is 2:1,

[0043] Carbon nanotubes are iron-based multi-wall carbon nanotubes, with a diameter of 20-30nm and a specific surface area of 180-220m 2 / g,

[0044] Conductive fillers are carbon black and graphene, and graphene has a specific surface area of 1000-1200m 2 / g of thin-layer graphene prepared by redox method,

[0045] The mass ratio of amino acid: carbon nanotube: carbon black: graphene is 3:10:5:1,

[0046] The plastic emulsion is a PS emulsion with a solute mass fraction of 2.5%,

[0047] The demulsifier is 2% calcium chloride solution,

[0048] The auxiliary materials are 120g white oil, 30g PE wax, and 15g paraffin wax.

[0049...

Embodiment 2

[0057] A special material for ABS, the raw materials include plastic emulsion, amino acid aqueous solution, carbon nanotubes and conductive fillers,

[0058] The mass fraction of amino acids in the amino acid aqueous solution is 0.5%, the types of amino acids are tyrosine and tryptophan, and the mass ratio of tyrosine and tryptophan is 1:3.

[0059] Carbon nanotubes are nickel-based multi-wall carbon nanotubes, with a diameter of 40-60nm and a specific surface area of 80-120m 2 / g,

[0060] Conductive fillers are carbon black and graphene, and graphene has a specific surface area of 500-700m 2 / g of graphene oxide prepared by physical method,

[0061] The mass ratio of amino acid: carbon nanotube: carbon black: graphene is 5:20:4:3,

[0062] The plastic emulsion is an ABS emulsion with a solute mass fraction of 4%,

[0063] The demulsifier is 2.5% calcium chloride solution,

[0064] The auxiliary materials are 250g white oil, 50g PE wax, and 20g paraffin wax.

[0065...

Embodiment 3

[0073] A kind of EVA masterbatch, raw material comprises plastic emulsion, amino acid aqueous solution and carbon nanotube,

[0074] The mass fraction of amino acids in the amino acid aqueous solution is 0.45%, the types of amino acids are phenylalanine and valine, and the mass ratio of phenylalanine and valine is 3:4,

[0075] Carbon nanotubes are carbon nanotubes, which are cobalt-based multi-wall carbon nanotubes, with a diameter of 10-20nm and a specific surface area of 250-300m 2 / g,

[0076] The mass ratio of amino acid: carbon nanotube is 1:4,

[0077] The plastic emulsion is an EVA emulsion with a solute mass fraction of 1.25%.

[0078] The demulsifier is 1% calcium chloride solution,

[0079] The auxiliary materials are 80g white oil, 20g PE wax, and 10g paraffin wax.

[0080] The preparation process of the above-mentioned mixing composite material comprises the following steps:

[0081] S1: Prepare 30L of amino acid aqueous solution with a mass fraction of ami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com