Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

486 results about "Bis(trimethylsilyl)amine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bis(trimethylsilyl)amine (also known as hexamethyldisilazane and HMDS) is an organosilicon compound with the molecular formula [(CH₃)₃Si]₂NH. The molecule is a derivative of ammonia with trimethylsilyl groups in place of two hydrogen atoms. An electron diffraction study shows that silicon-nitrogen bond length (173.5 pm) and Si-N-Si bond angle (125.5ᵒ) to be similar to disilazane (in which methyl groups are replaced by hydrogen atoms) suggesting that steric factors are not decision in regulating angles. This colorless liquid is a reagent and a precursor to bases that are popular in organic synthesis and organometallic chemistry. Additionally, HMDS is also increasingly used as molecular precursor in chemical vapor deposition techniques to deposite silicon carbonitride thin films or coatings.

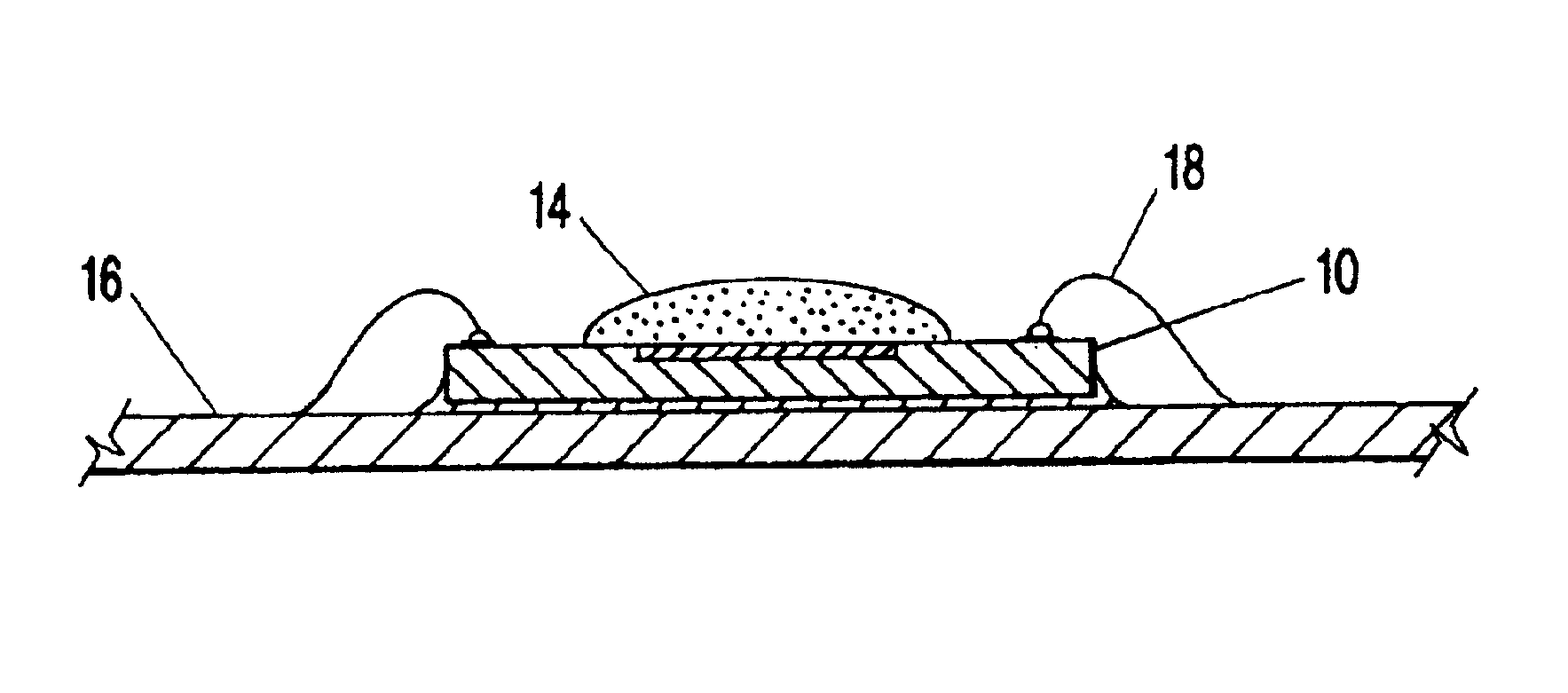

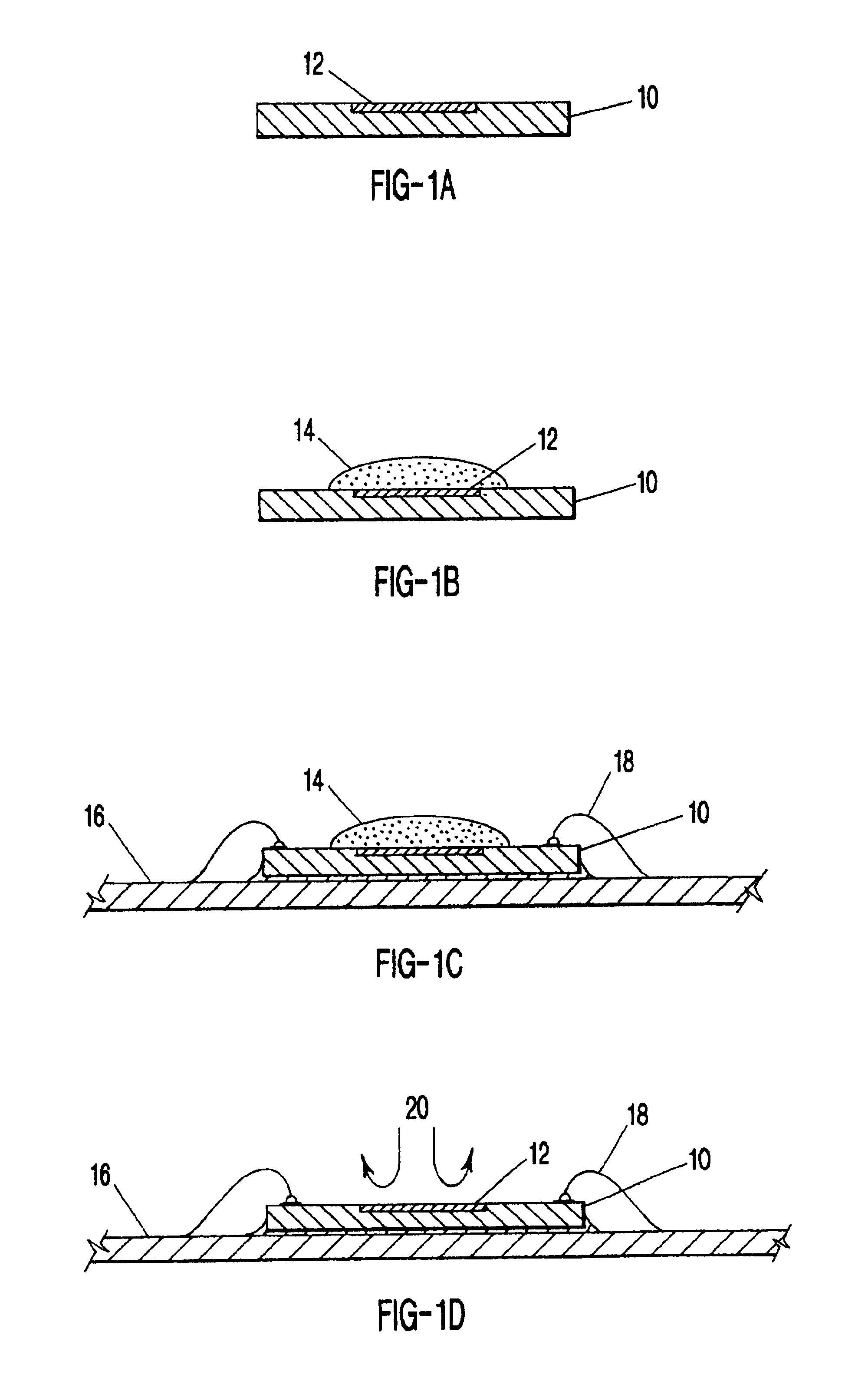

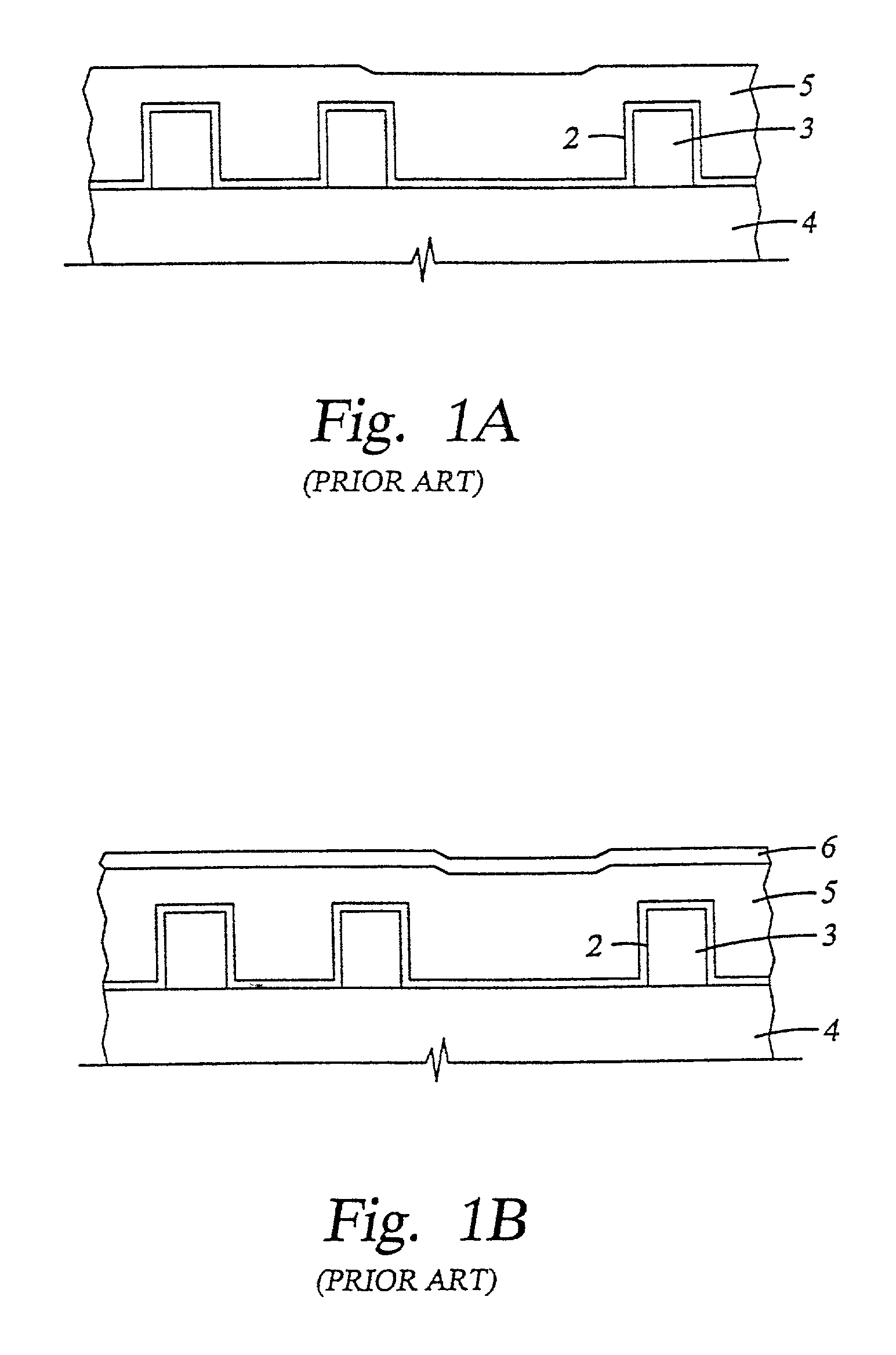

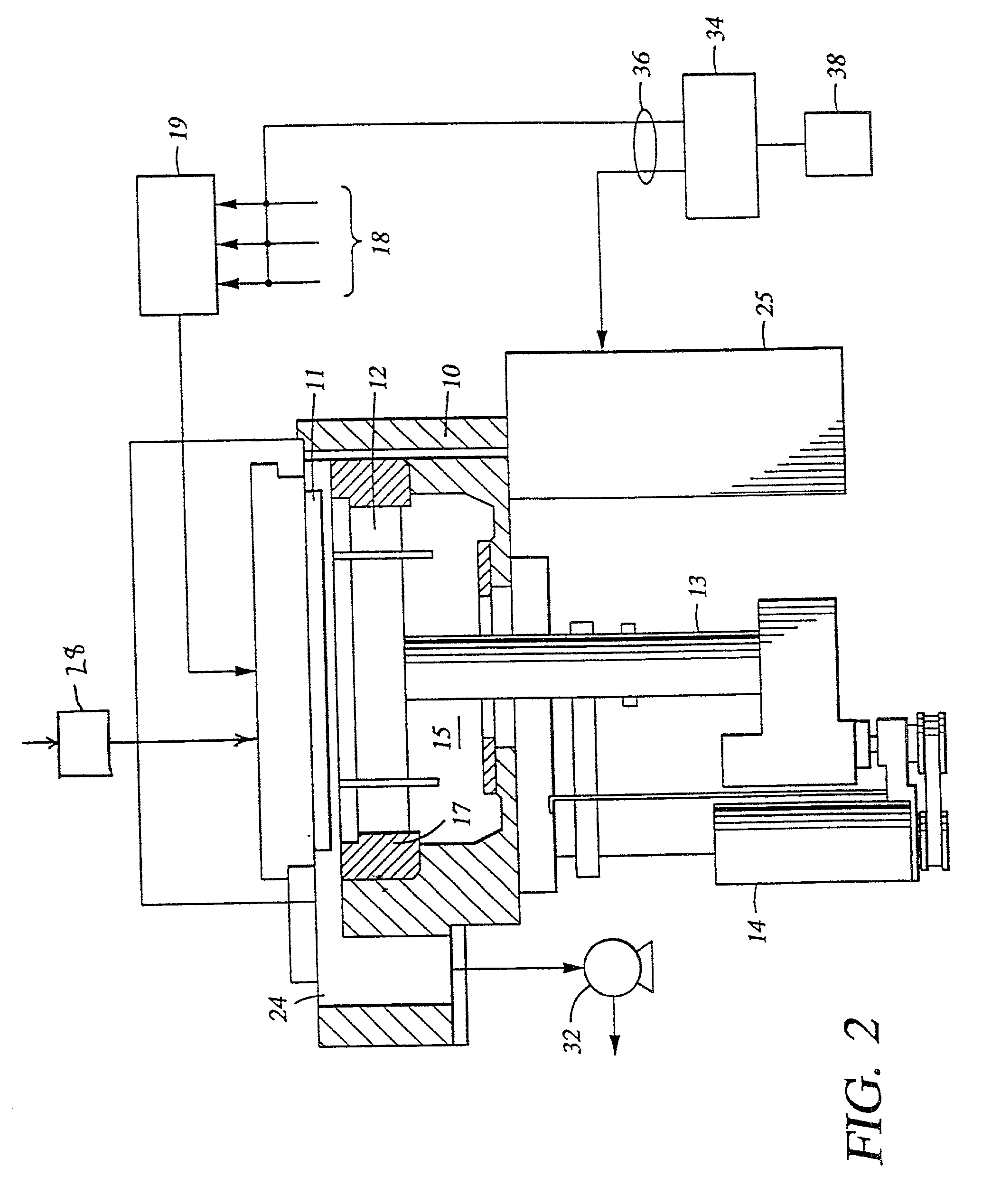

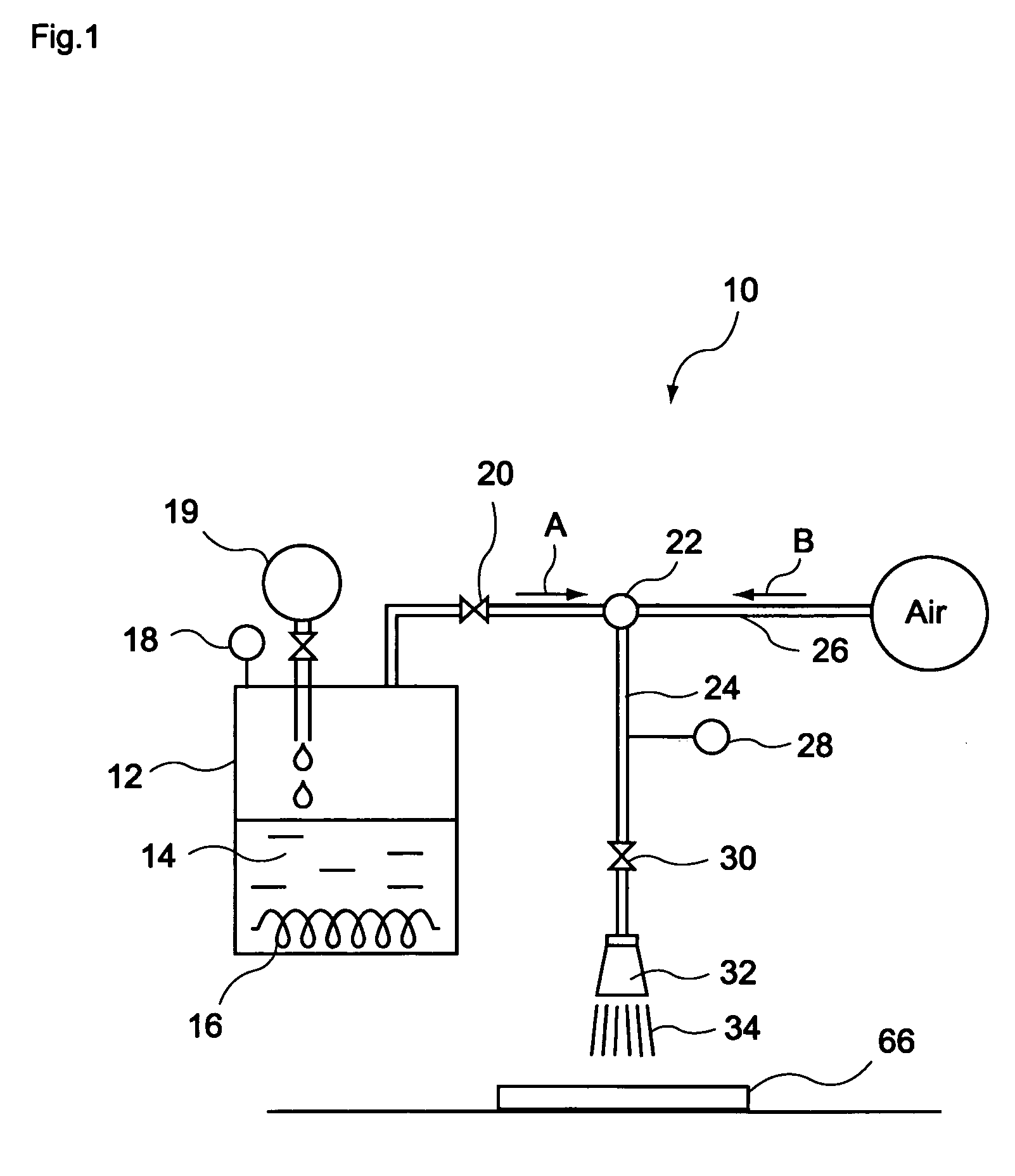

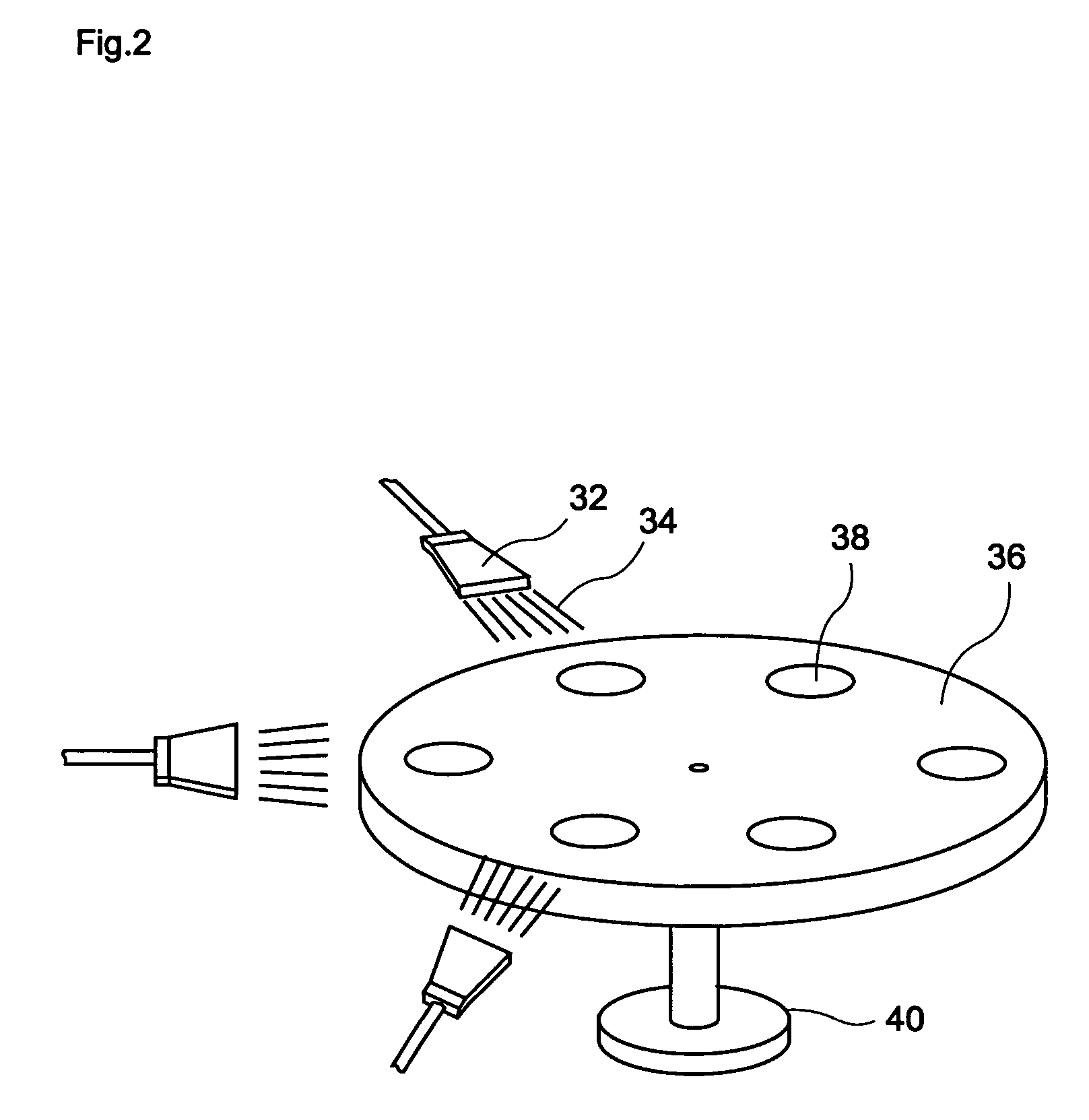

Temporary coatings for protection of microelectronic devices during packaging

InactiveUS6844623B1Decorative surface effectsSemiconductor/solid-state device detailsCarbon filmParylene

The present invention relates to a method of protecting a microelectronic device during device packaging, including the steps of applying a water-insoluble, temporary protective coating to a sensitive area on the device; performing at least one packaging step; and then substantially removing the protective coating, preferably by dry plasma etching. The sensitive area can include a released MEMS element. The microelectronic device can be disposed on a wafer. The protective coating can be a vacuum vapor-deposited parylene polymer, silicon nitride, metal (e.g. aluminum or tungsten), a vapor deposited organic material, cynoacrylate, a carbon film, a self-assembled monolayered material, perfluoropolyether, hexamethyldisilazane, or perfluorodecanoic carboxylic acid, silicon dioxide, silicate glass, or combinations thereof. The present invention also relates to a method of packaging a microelectronic device, including: providing a microelectronic device having a sensitive area; applying a water-insoluble, protective coating to the sensitive area; providing a package; attaching the device to the package; electrically interconnecting the device to the package; and substantially removing the protective coating from the sensitive area.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

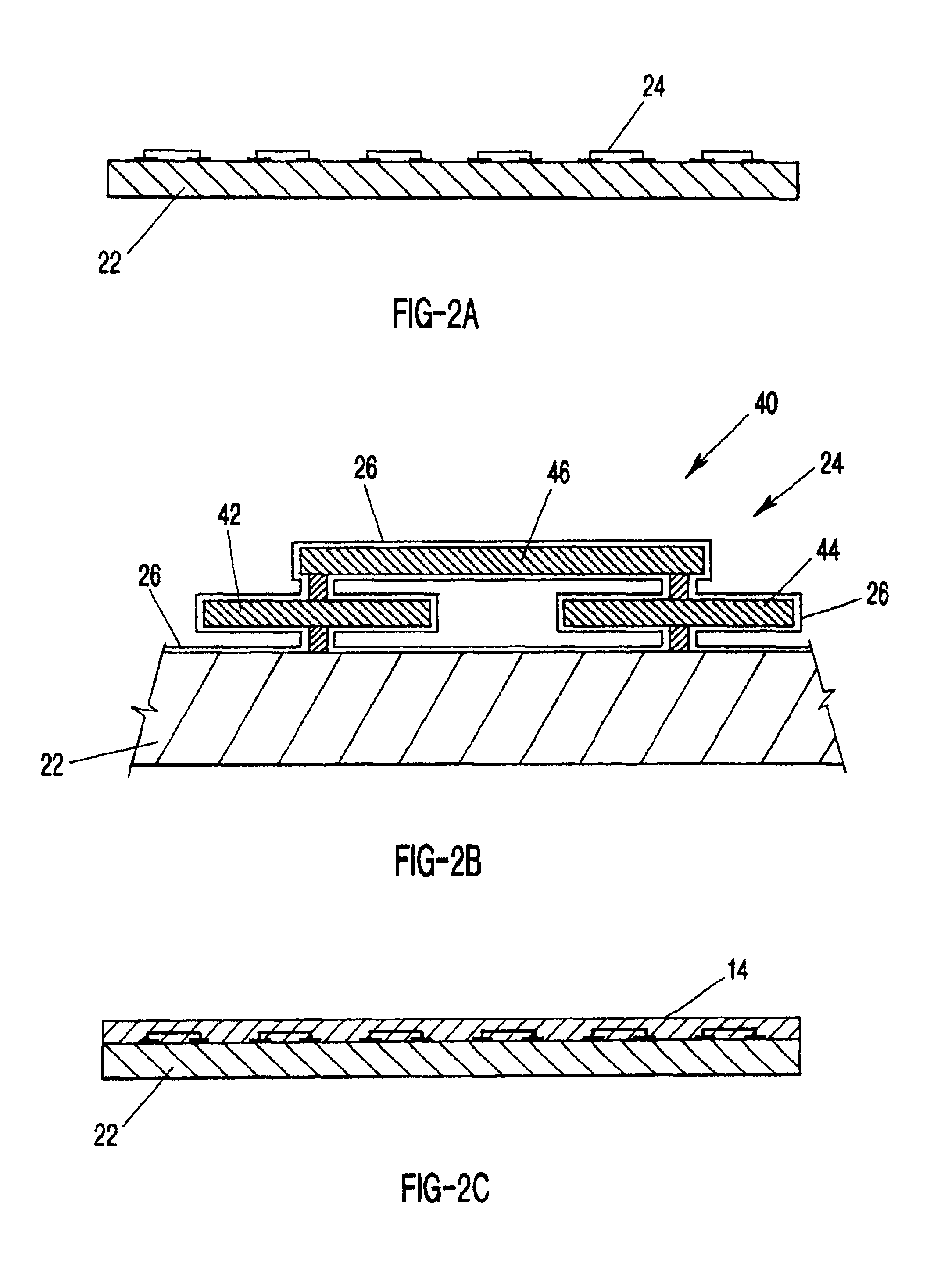

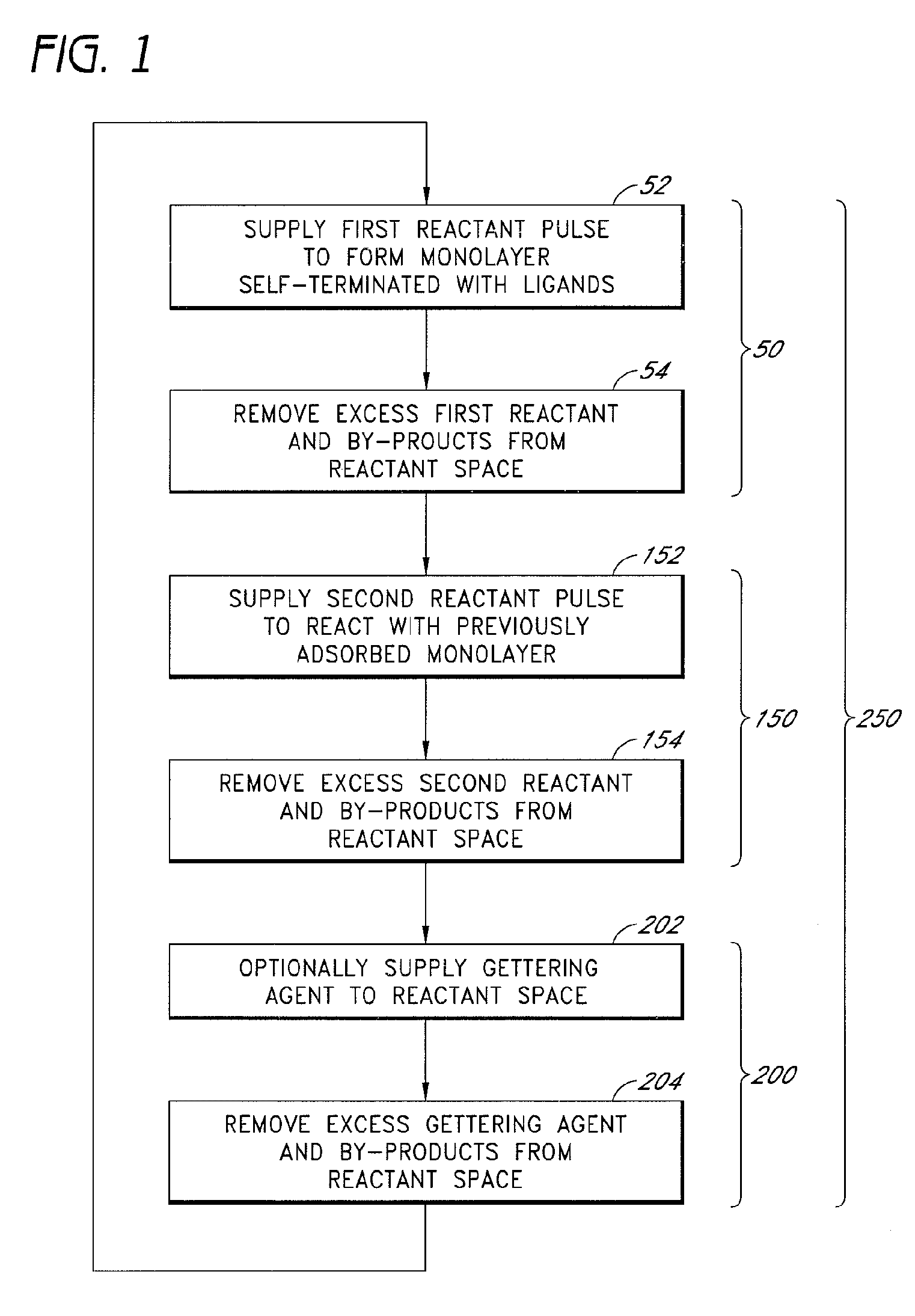

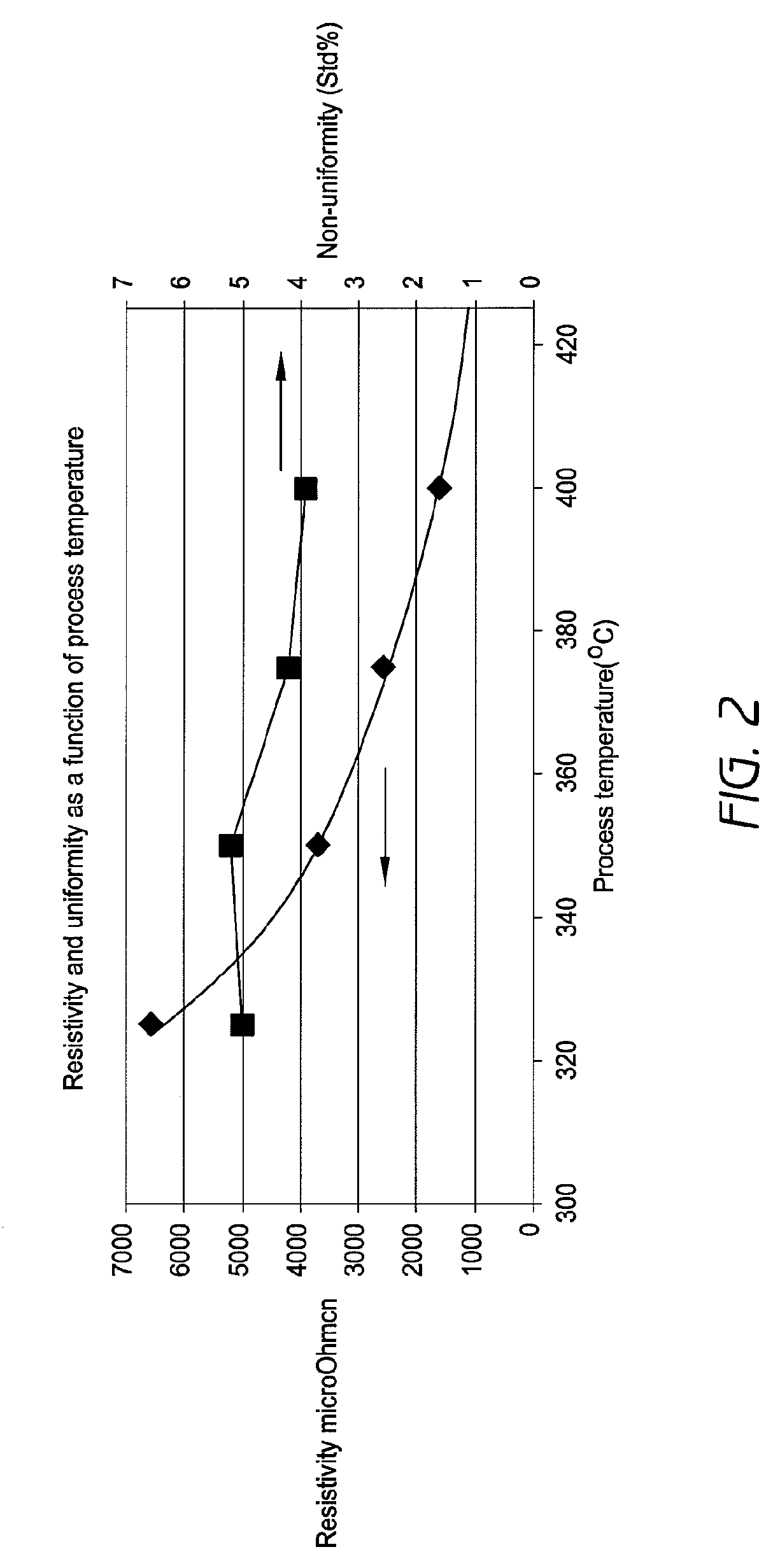

Low resistivity metal carbonitride thin film deposition by atomic layer deposition

ActiveUS7638170B2Polycrystalline material growthFrom chemically reactive gasesBis(trimethylsilyl)amineDisilane

Owner:ASM INTERNATIONAL

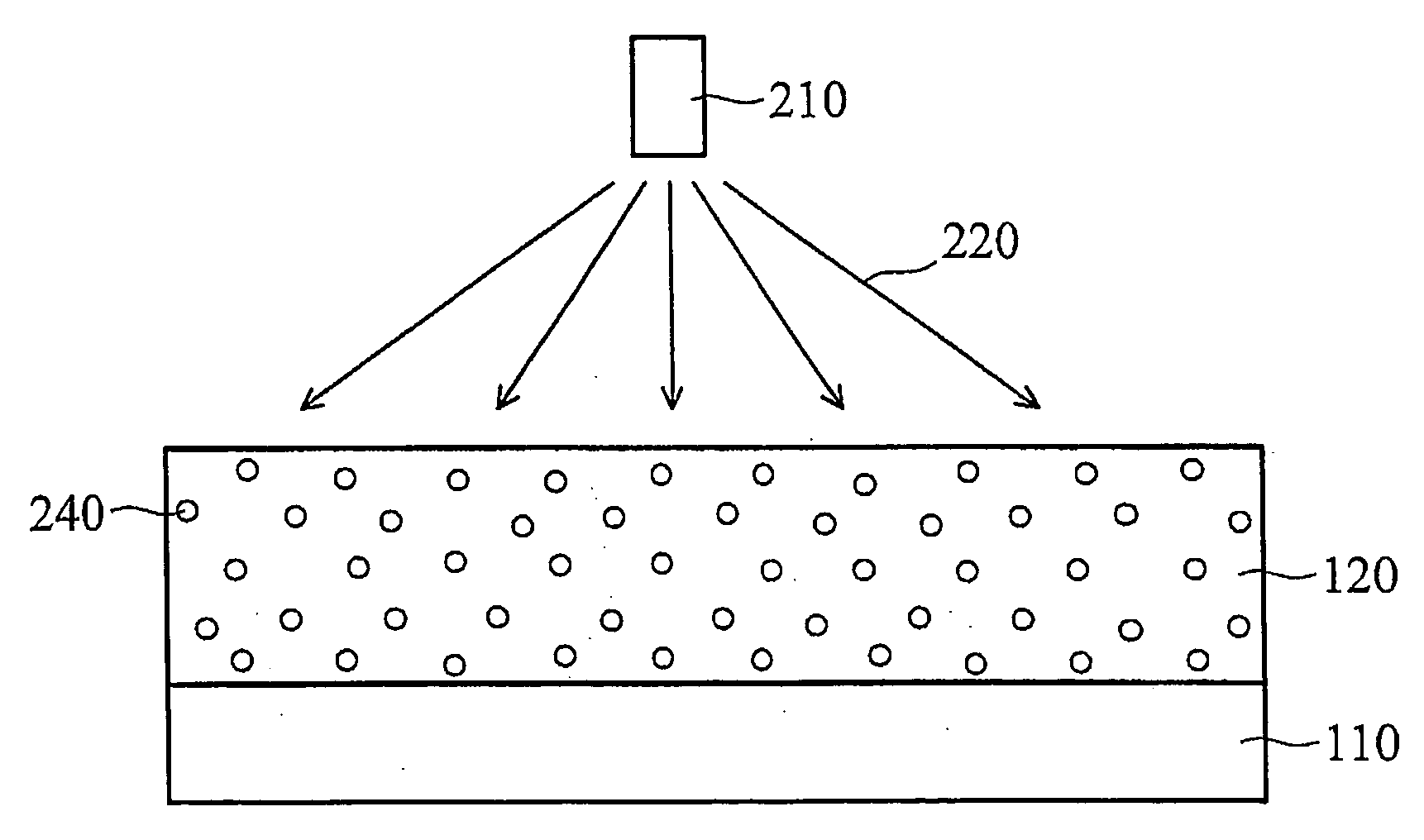

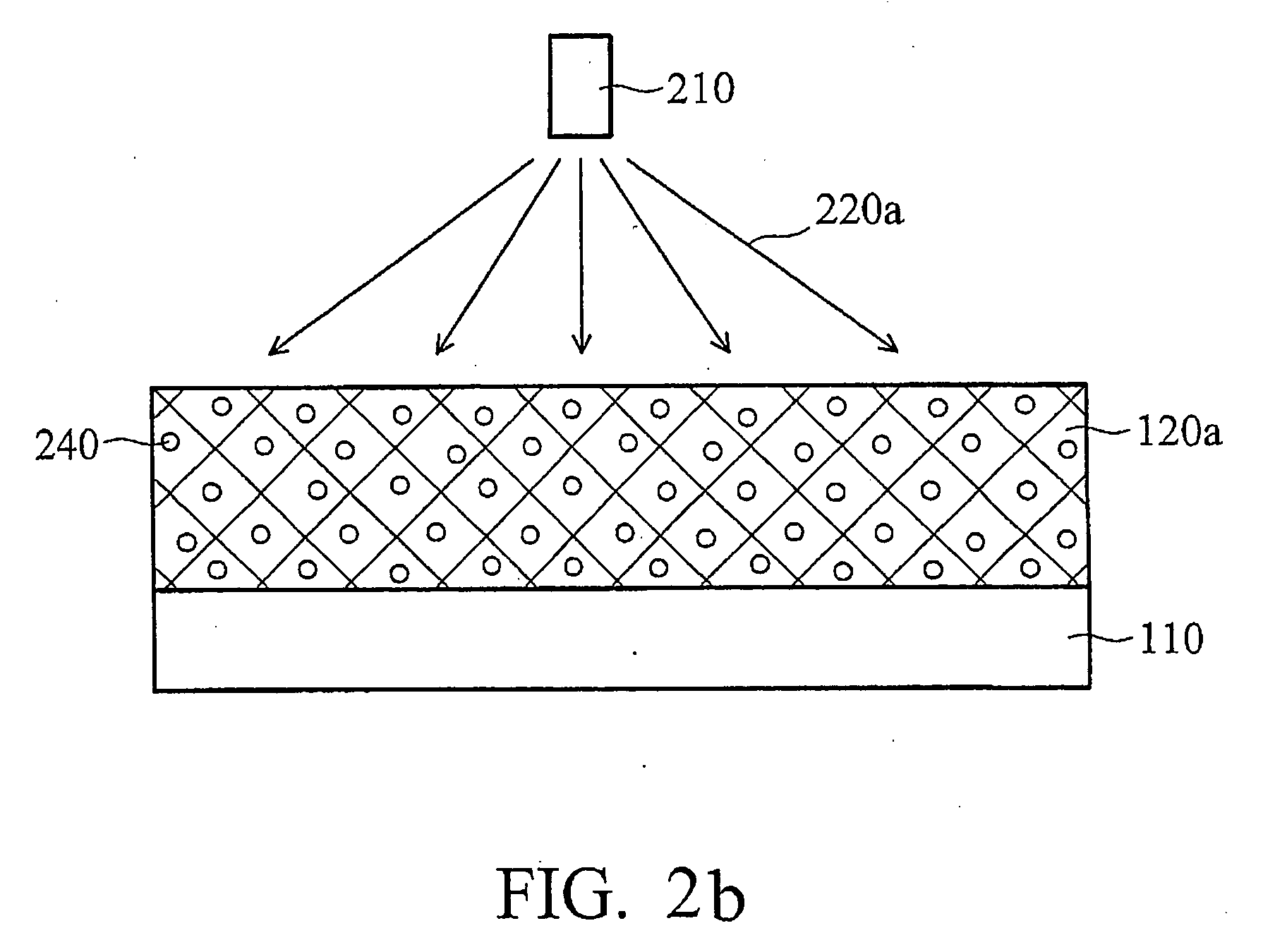

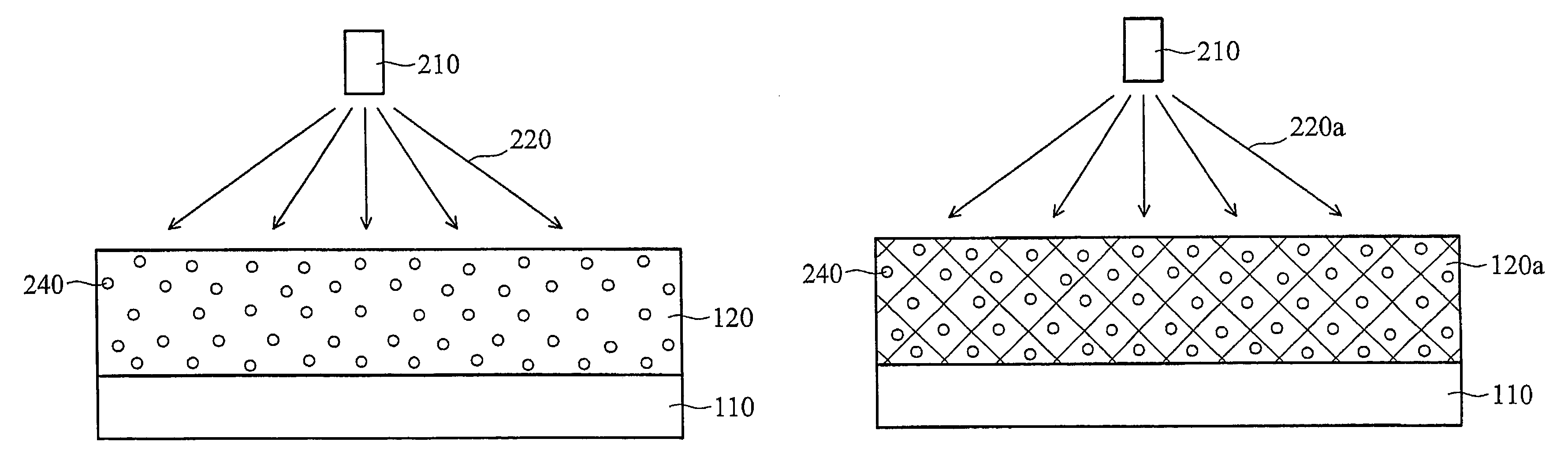

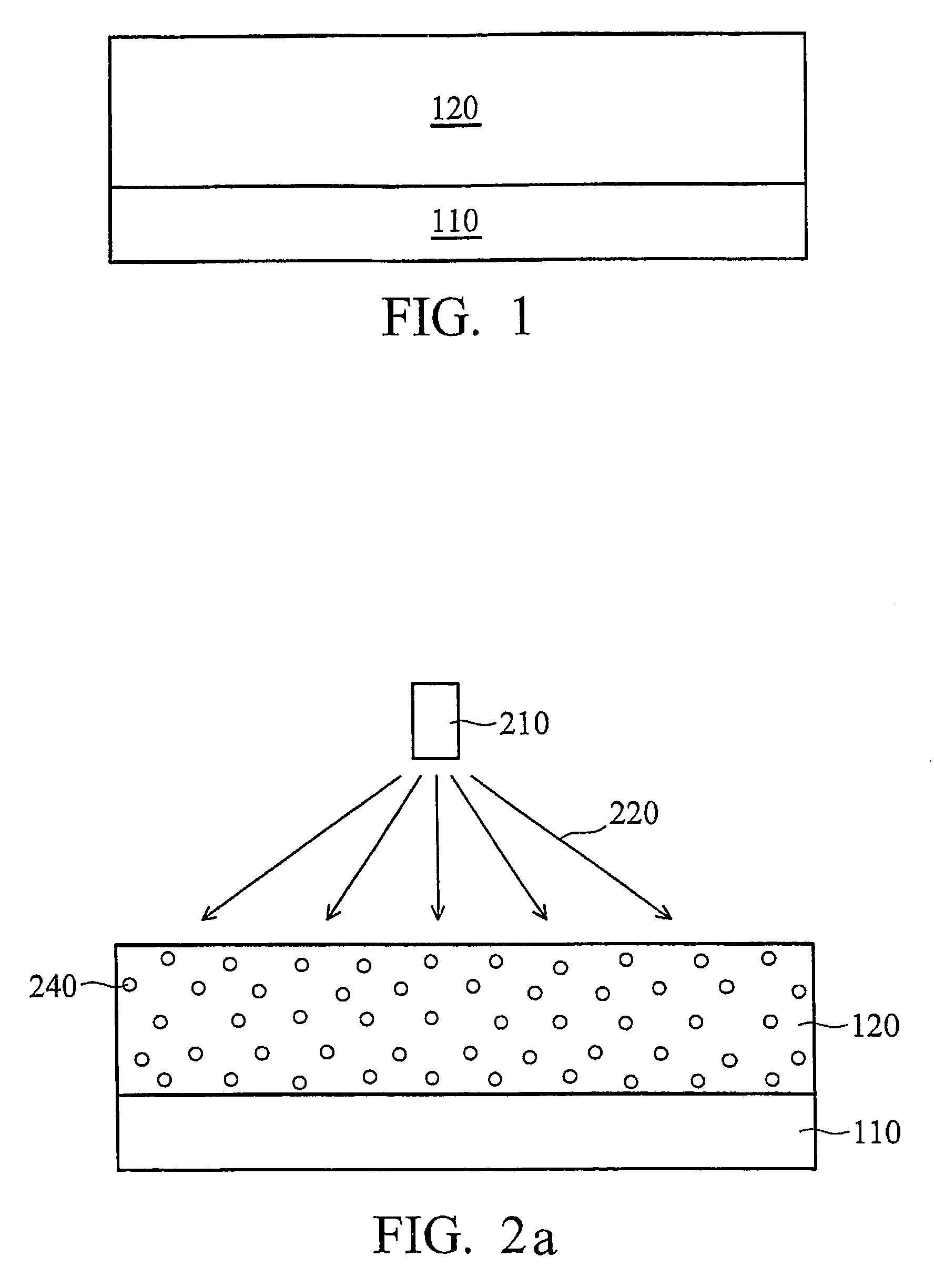

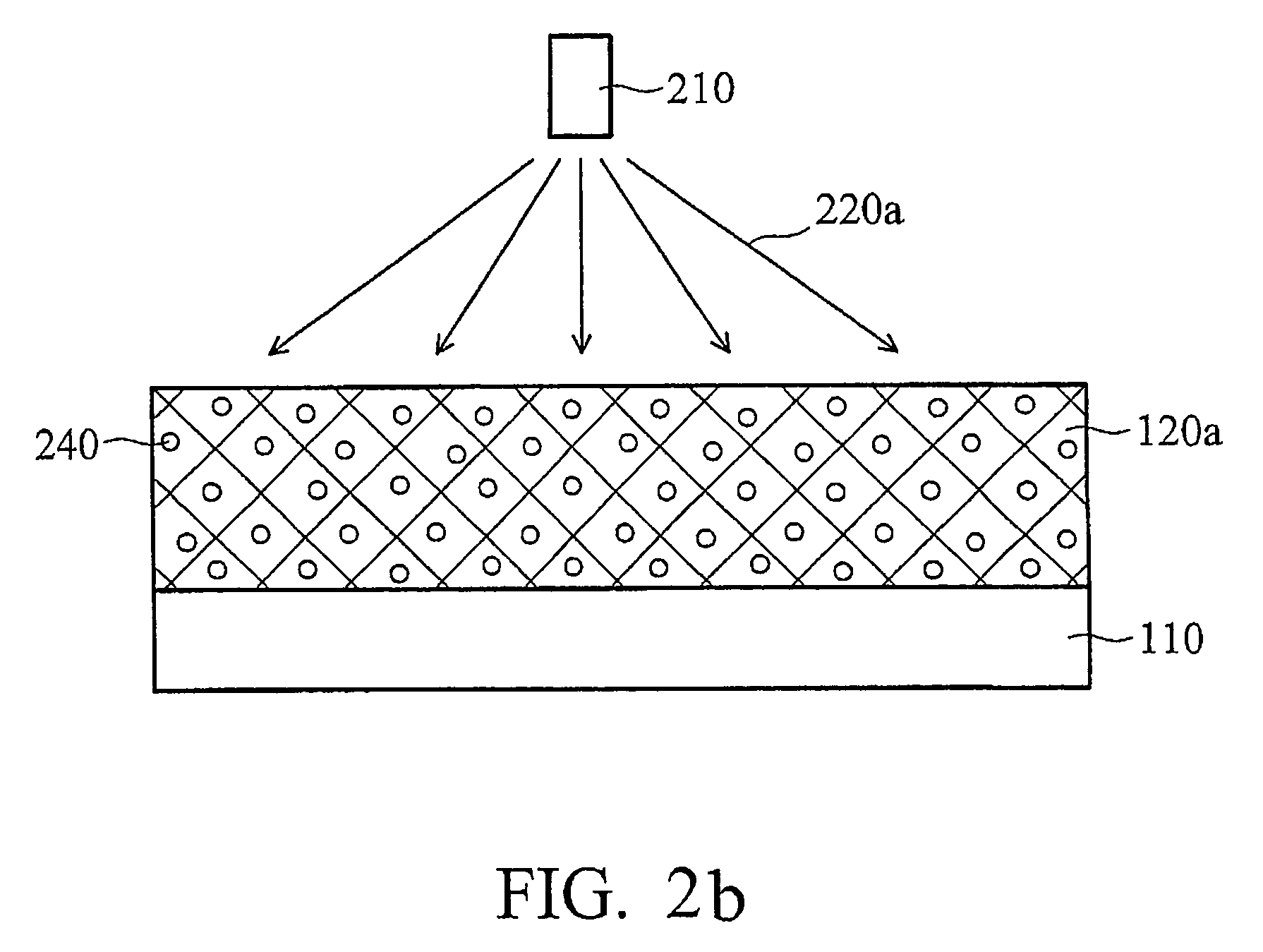

UV curing of low-k porous dielectrics

InactiveUS20070161230A1Solid-state devicesSemiconductor/solid-state device manufacturingCross-linkDevice material

A method of manufacturing a semiconductor device having a low-k dielectric layer is provided. An embodiment comprises forming a dielectric layer on a substrate, wherein the layer comprises a pore generating material dispersed in an uncured matrix. A second step comprises forming pores in the uncured matrix by irradiating the layer with radiation having a first wavelength. After pore forming, a third step comprises cross-linking the dielectric by irradiating it at a second wavelength, the second being less than the first. In an embodiment, the irradiating wavelengths comprise ultra-violet radiation. Embodiments may further include repairing processing damage wherein the damage includes dangling bonds or silanol formation. The repairing includes annealing in a carbon-containing ambient such as C2H4, C3H6, or hexamethyldisilazane (HMDS).

Owner:TAIWAN SEMICON MFG CO LTD

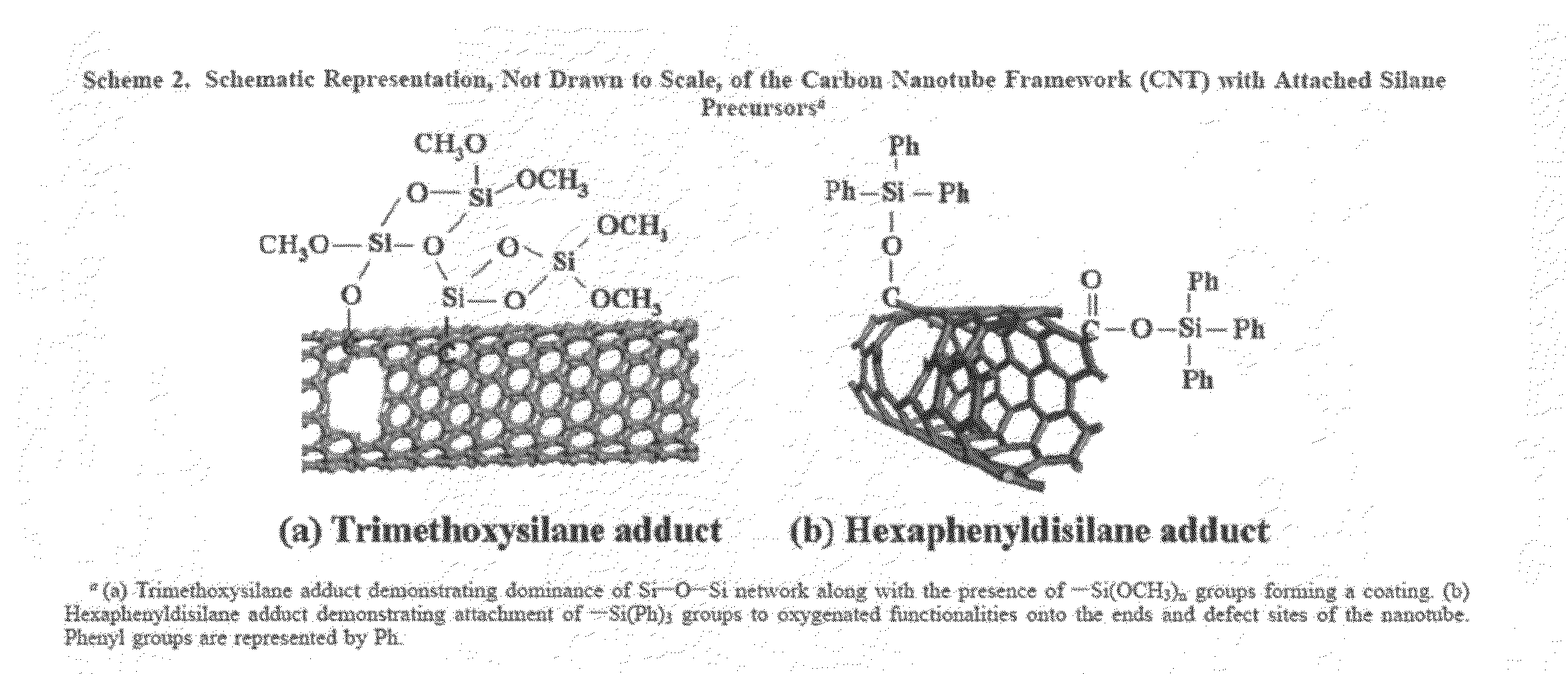

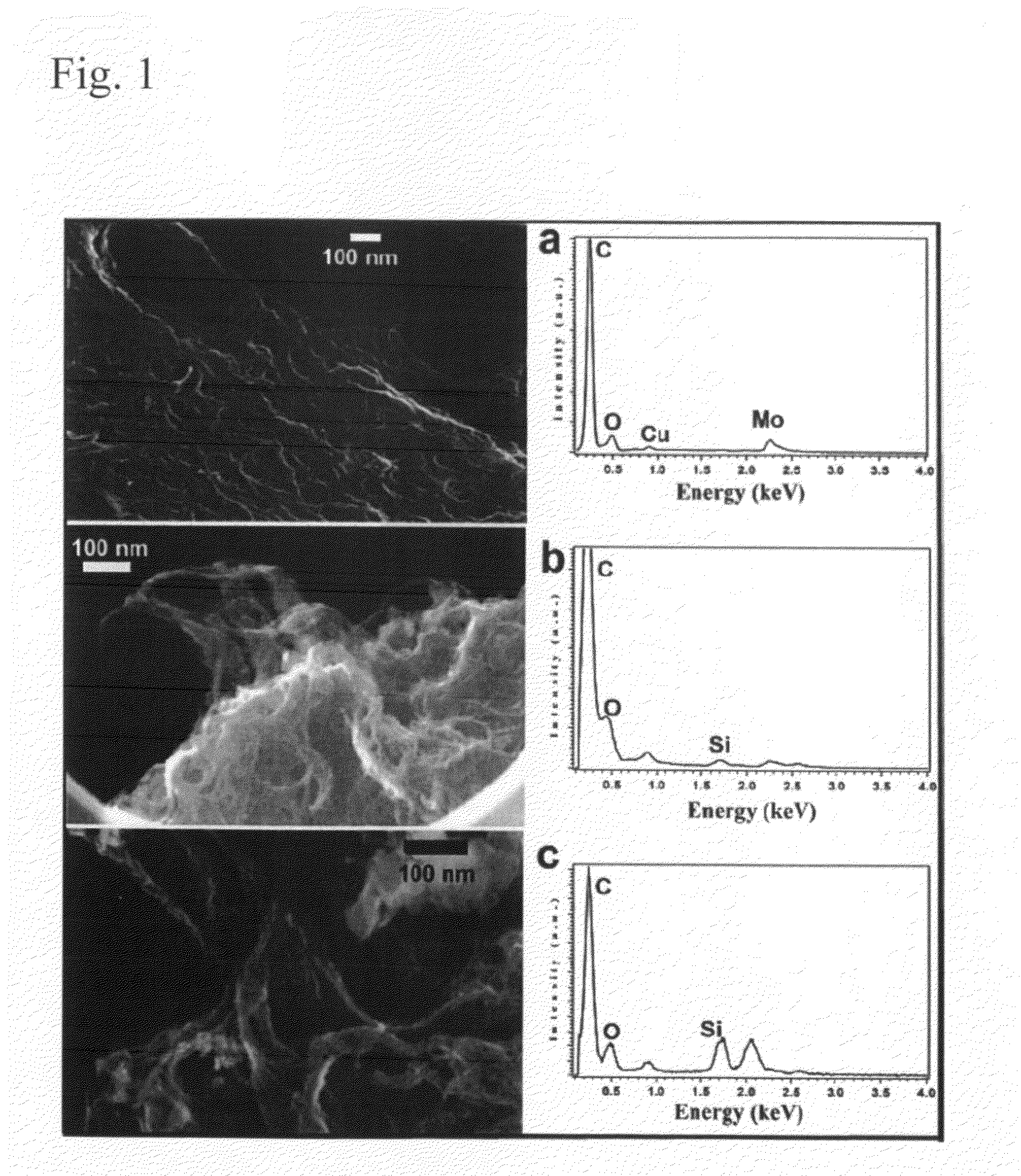

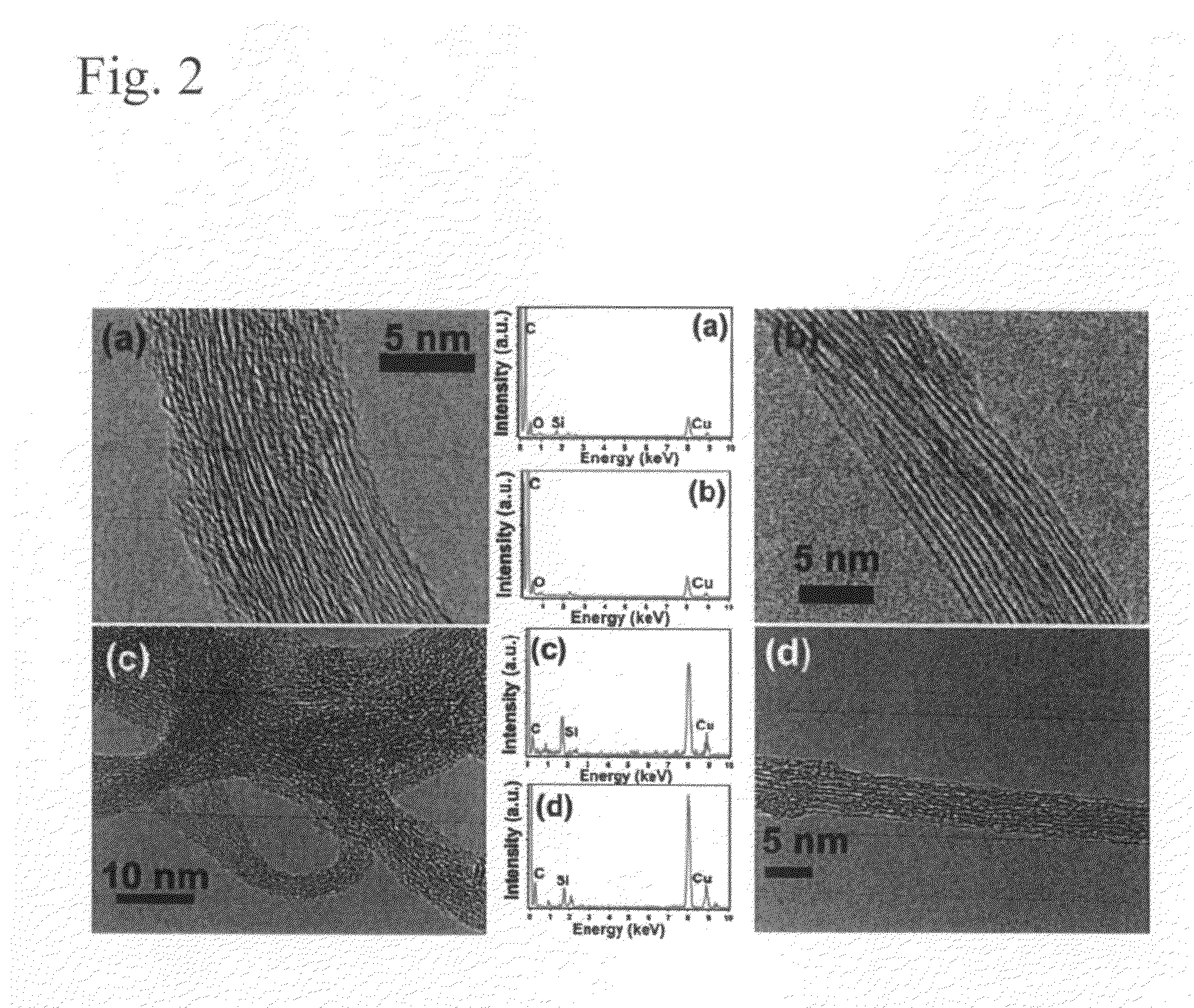

Silylated carbon nanotubes and methods of making same

InactiveUS20090060815A1Silicon organic compoundsMaterial nanotechnologyTert-butyldimethylsilaneBis(trimethylsilyl)amine

The invention provides adducts comprising a carbon nanotube with covalently attached silane moieties, and methods of making such adducts. Examples of silane moieties include trimethoxysilane; hexaphenyldisilane; silylphosphine; 1,1,1,3,5,5,5-heptamethyltrisiloxane; polydimethylsiloxane, poly(N-bromobenzene-1,3-disulfonamide); N,N,N′,N′-tetrabromobenzene-1,3-disulfonamide; hexamethyldisilazane (HMDS); chlorotrimethylsilane (TMCS); trichloromethylsilane (TCMS); an alkyl(alkylamino)silane; a tri(alkoxy)silane; tert-butyldimethylsilane; monochloroaminosilane; dichloroaminosilane; trichloroaminosilane; and dimethylaminosilane.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

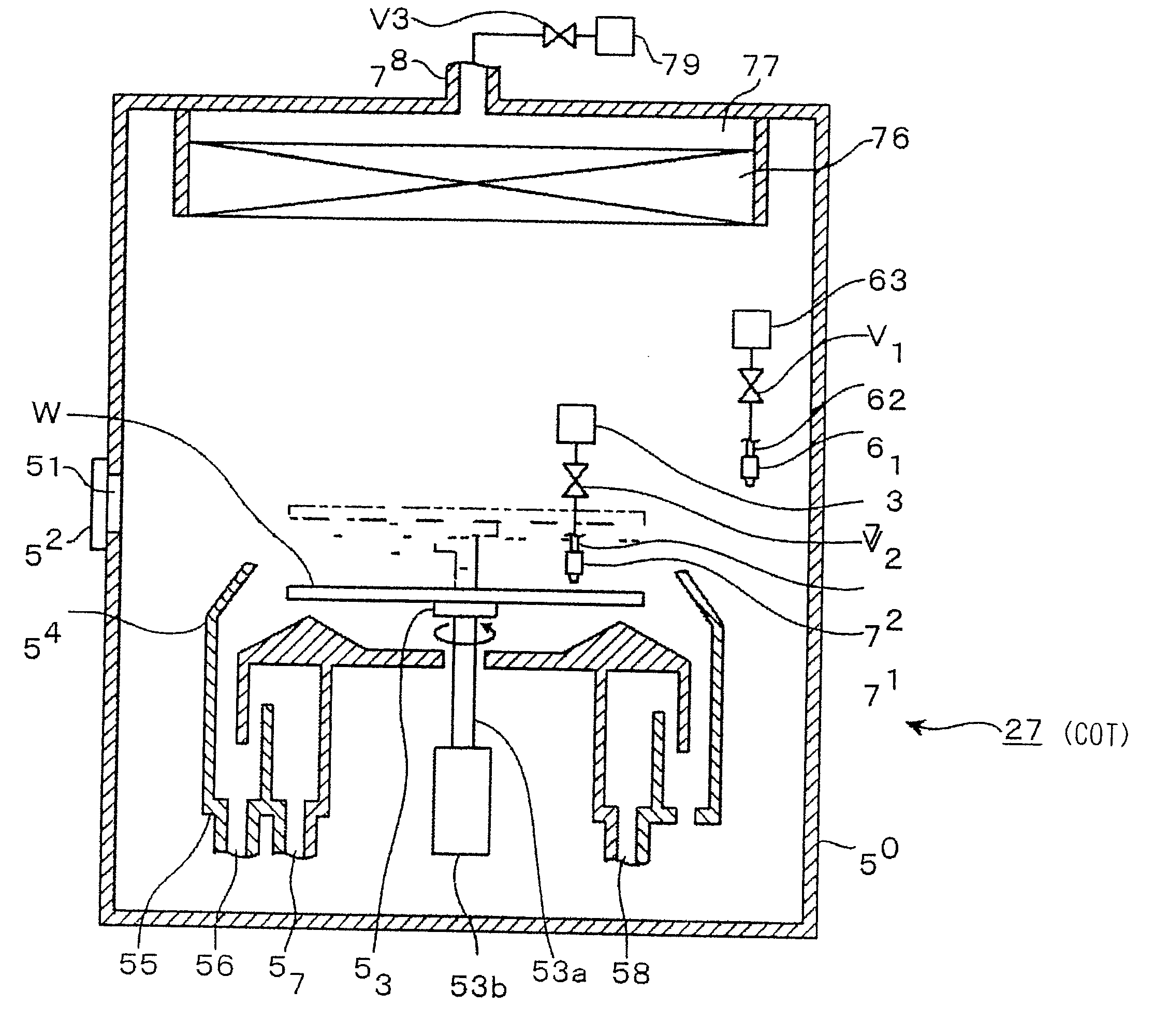

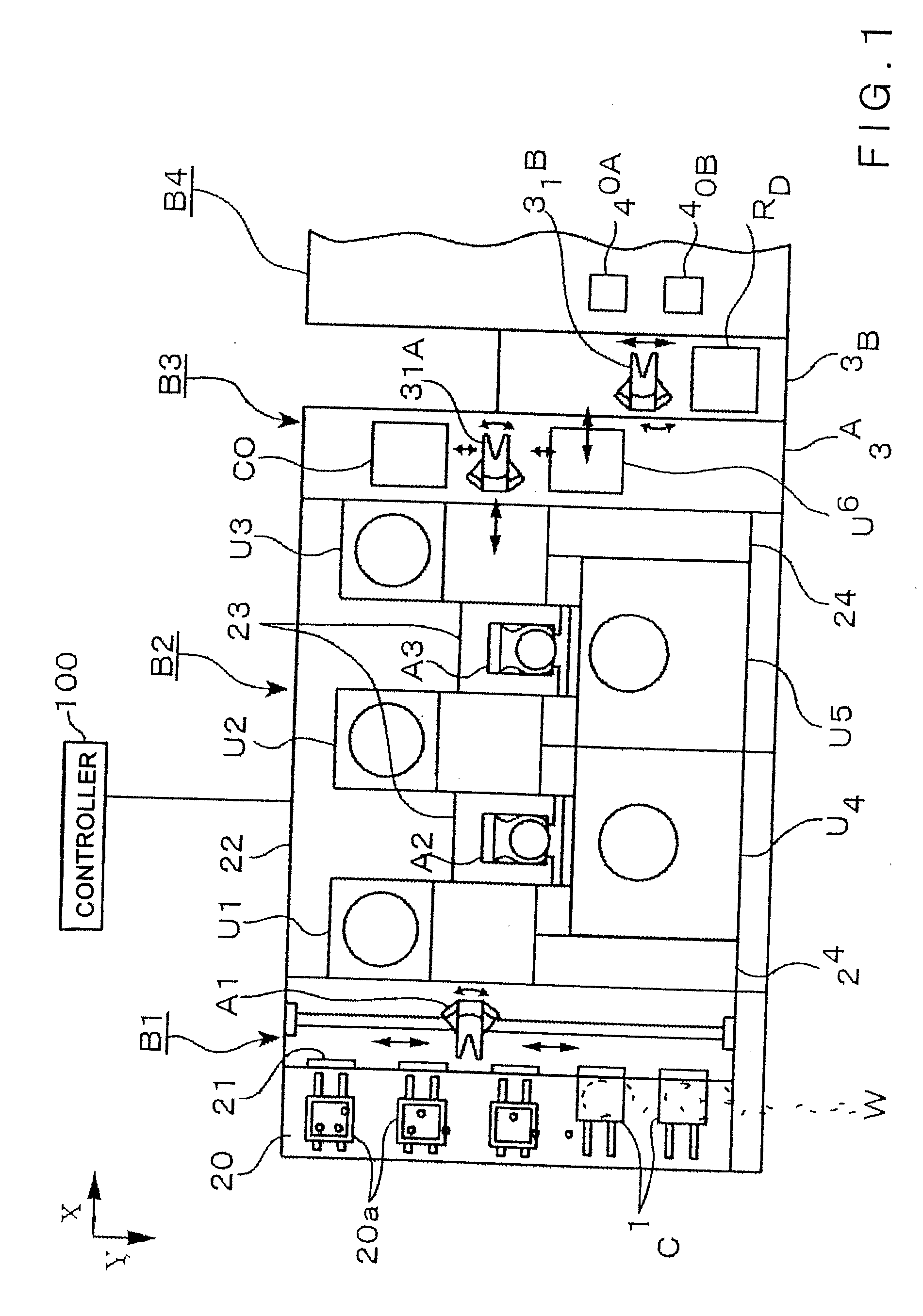

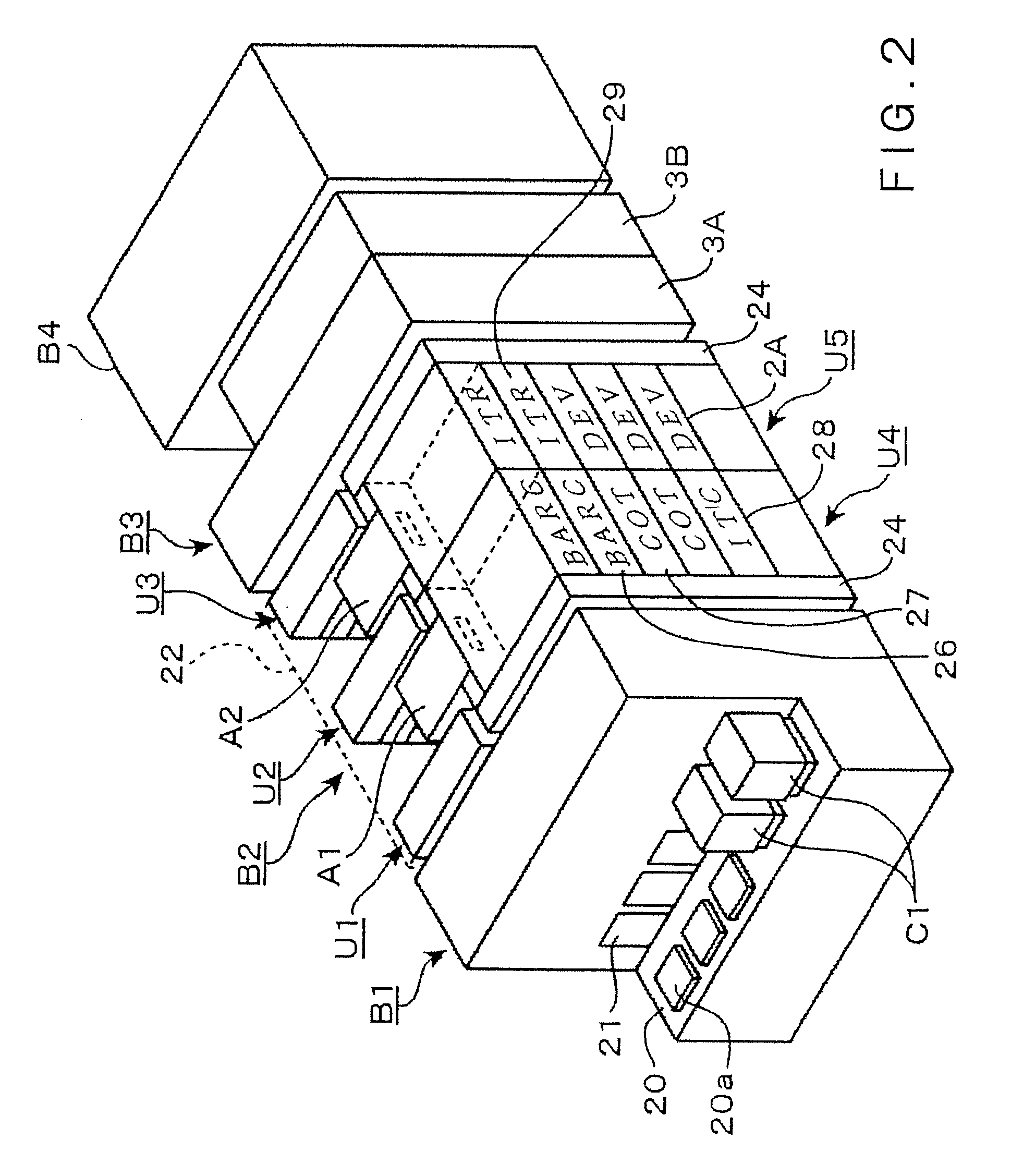

Coating and developing apparatus, coating film forming method, and storage medium storing program for performing the method

ActiveUS20070212884A1Improve adhesionLiquid surface applicatorsSemiconductor/solid-state device manufacturingResistBis(trimethylsilyl)amine

Disclosed is a technique for preventing a water-repellent protective film formed on a resist film from peeling off during immersion exposure. A resist film is formed on the front surface of a substrate and then the peripheral edge portion of the resist film is removed. Before forming a water-repellent protective film onto the resist film, an adhesion-improving fluid, preferably hexamethyldisilazane gas, for improving the adhesion of the water-repellent protective film, is supplied to the region from which the resist film is removed.

Owner:TOKYO ELECTRON LTD

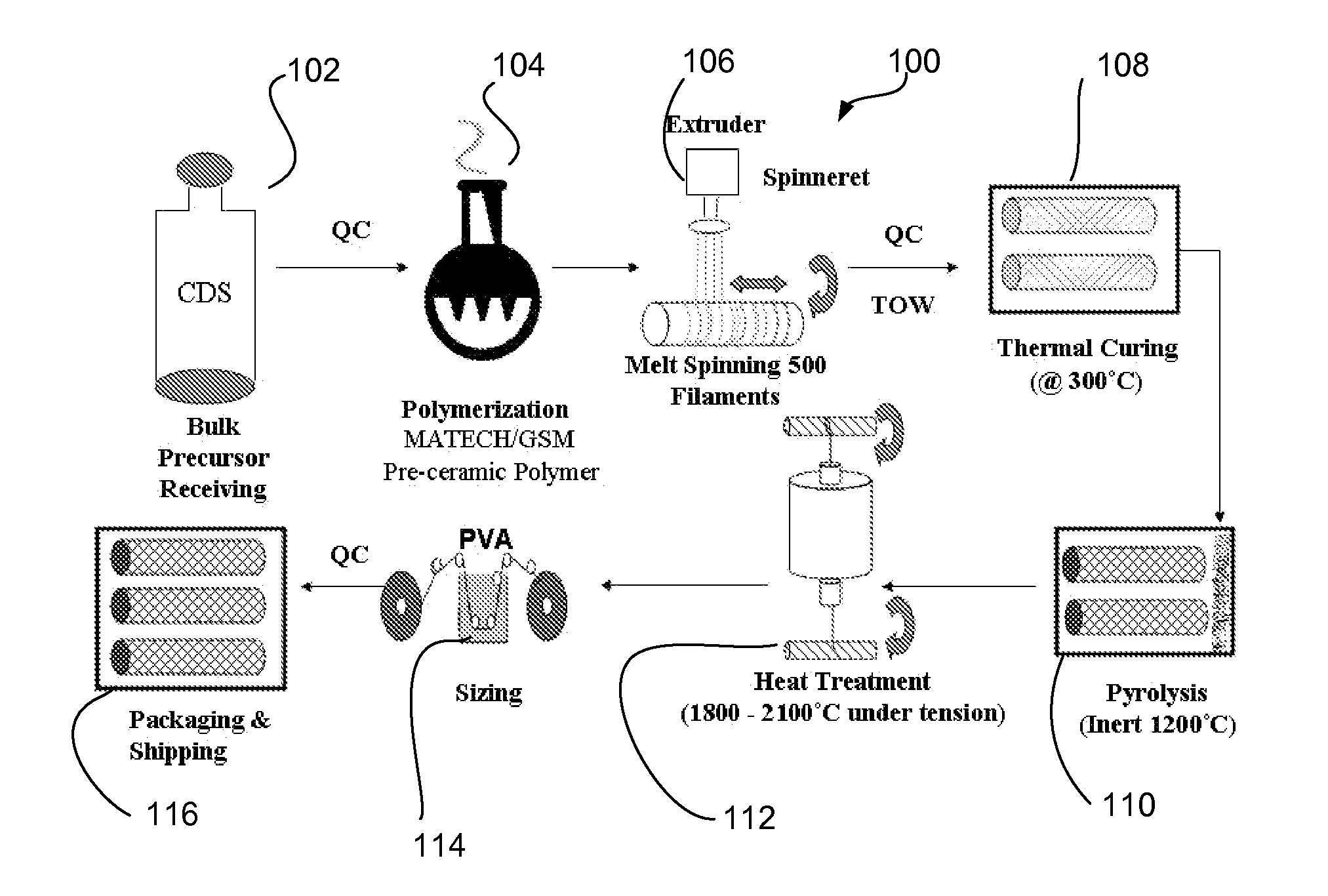

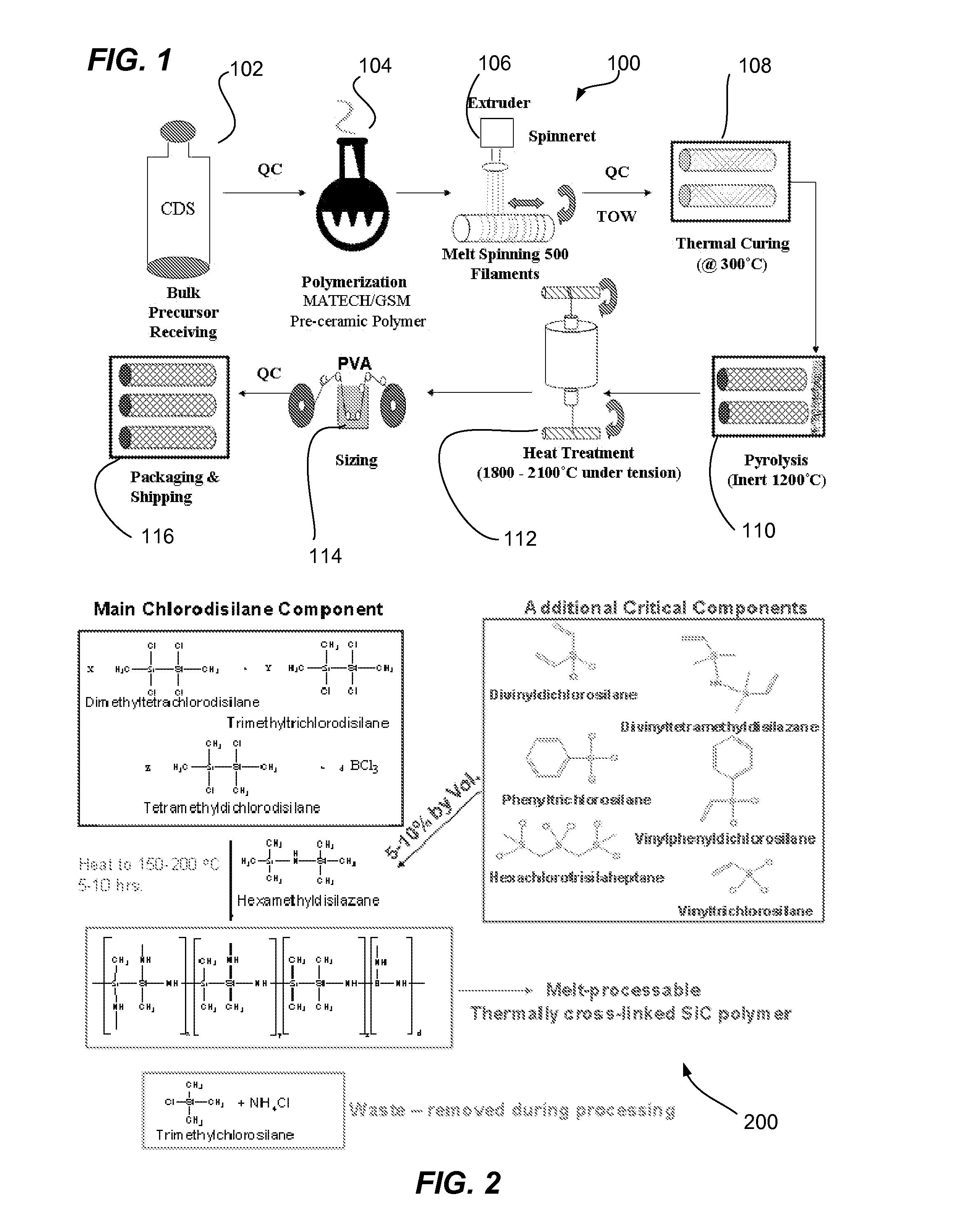

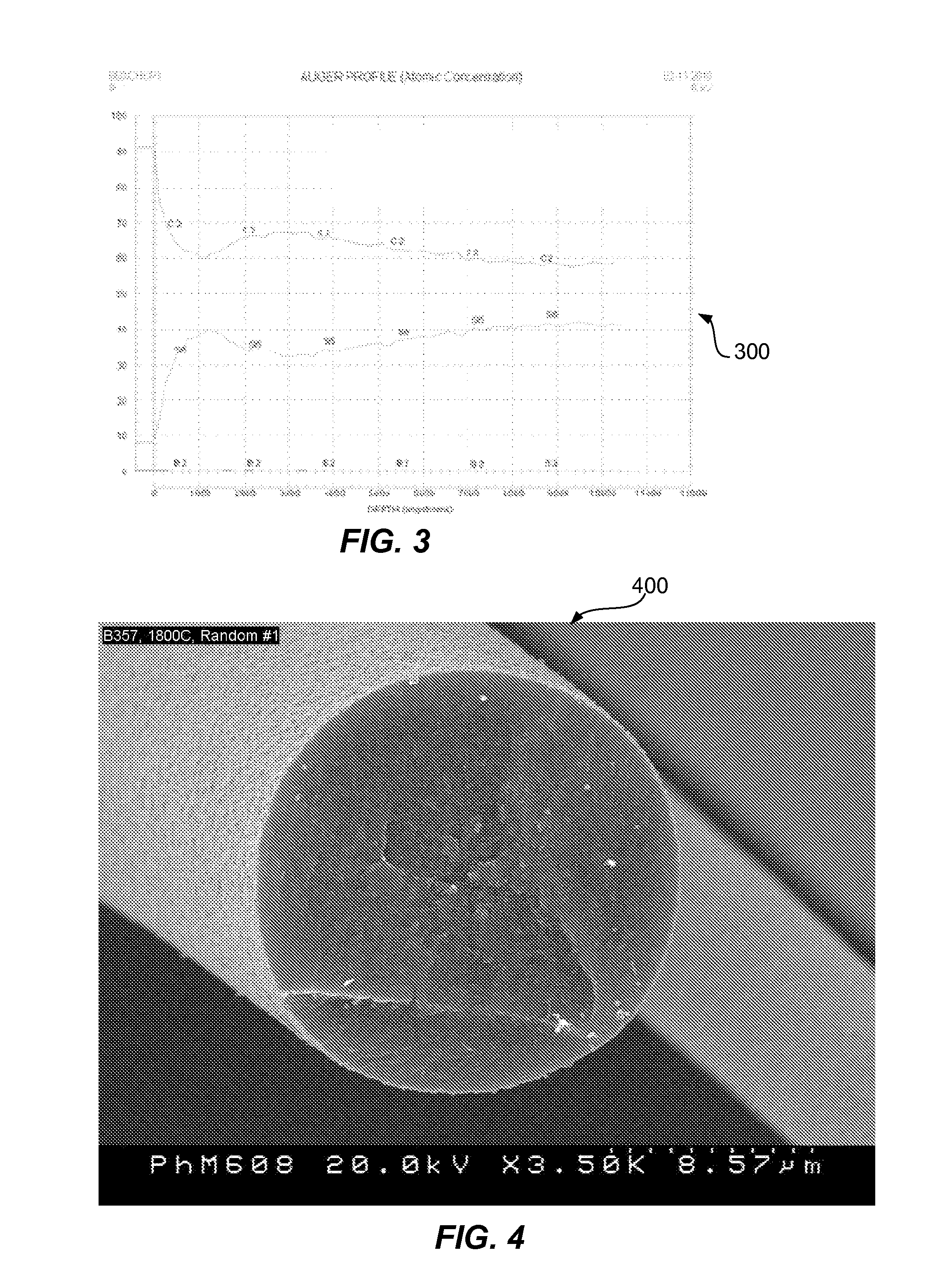

Stiochiometric silicon carbide fibers from thermo-chemically cured polysilazanes

ActiveUS20110212329A1Reduce manufacturing complexityReduce property variabilityNitrogen compoundsLayered productsPolymer sciencePolymer resin

A novel polycrystalline stoichiometric fine SiC fiber substantially free of impurities is produced using a novel pre-ceramic polymer. The pre-ceramic polymer is prepared by reacting a mixture of chlorodisilane, boron trichloride, and a vinyl chlorodisilane with an excess of hexamethyldisilazane to form the pre-ceramic polymer resin, which may then be melt-spun, cured, pyrolyzed and heat-treated to obtain the finished SiC fiber. The manufacturing process for the production of the fine SiC ceramic fiber allows for flexibility with respect to cross-linking, in that low-cost thermal treatments may replace more complex methods, while obtaining fibers with improved materials properties as compared to currently available SiC fibers.

Owner:GENERAL ELECTRIC CO

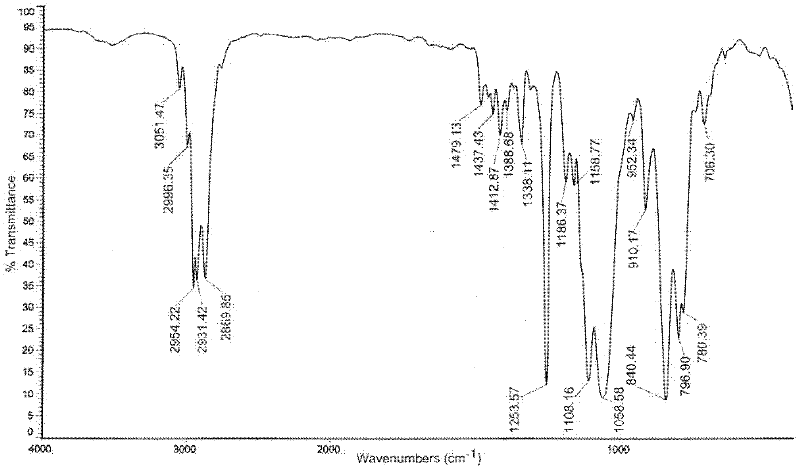

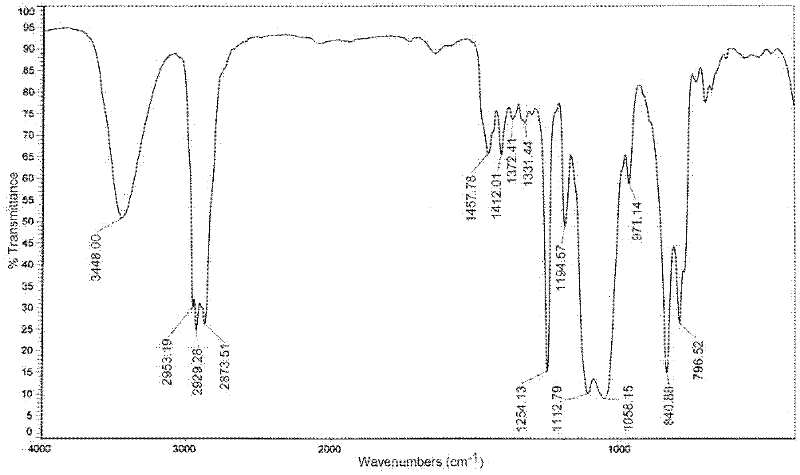

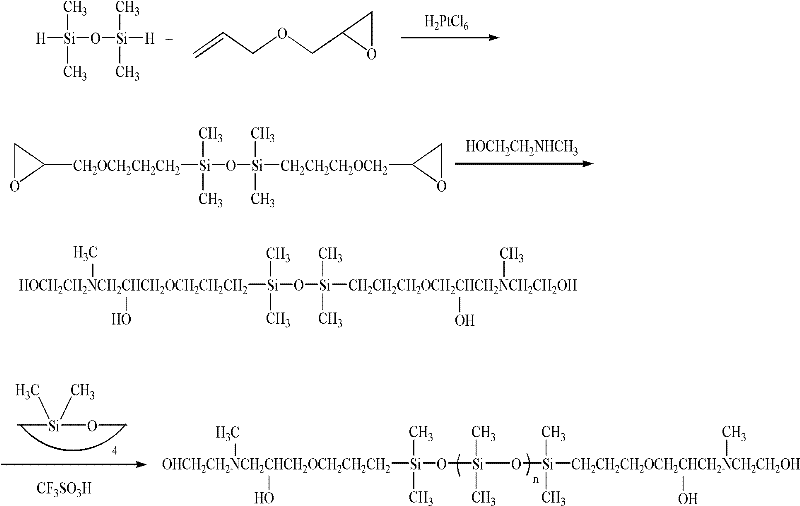

Method for synthesizing dihydroxyl-terminated polysiloxane

InactiveCN102504260AReduce manufacturing costShort overall reaction timeEpoxyTrimethylsilyl chloride

The invention discloses a method for synthesizing dihydroxyl-terminated polysiloxane. The method synthesizes the target dihydroxyl-terminated polysiloxane compound by using unsaturated epoxy compound, tetramethyldisiloxane, methylaminoethanol and octamethylcyclotetrasiloxane as starting materials and by hydrosilylation, epoxy-opening and equilibrium polymerization. The hexamethyldisilazane or trimethylchlorosilane are not needed as a hydroxyl protector, so the production cost is reduced; and hydroxyl protection and deprotection are avoided in a preparation process, so reaction steps are reduced, the total reaction time for synthesizing the final product is short and the production efficiency is increased.

Owner:邬元娟

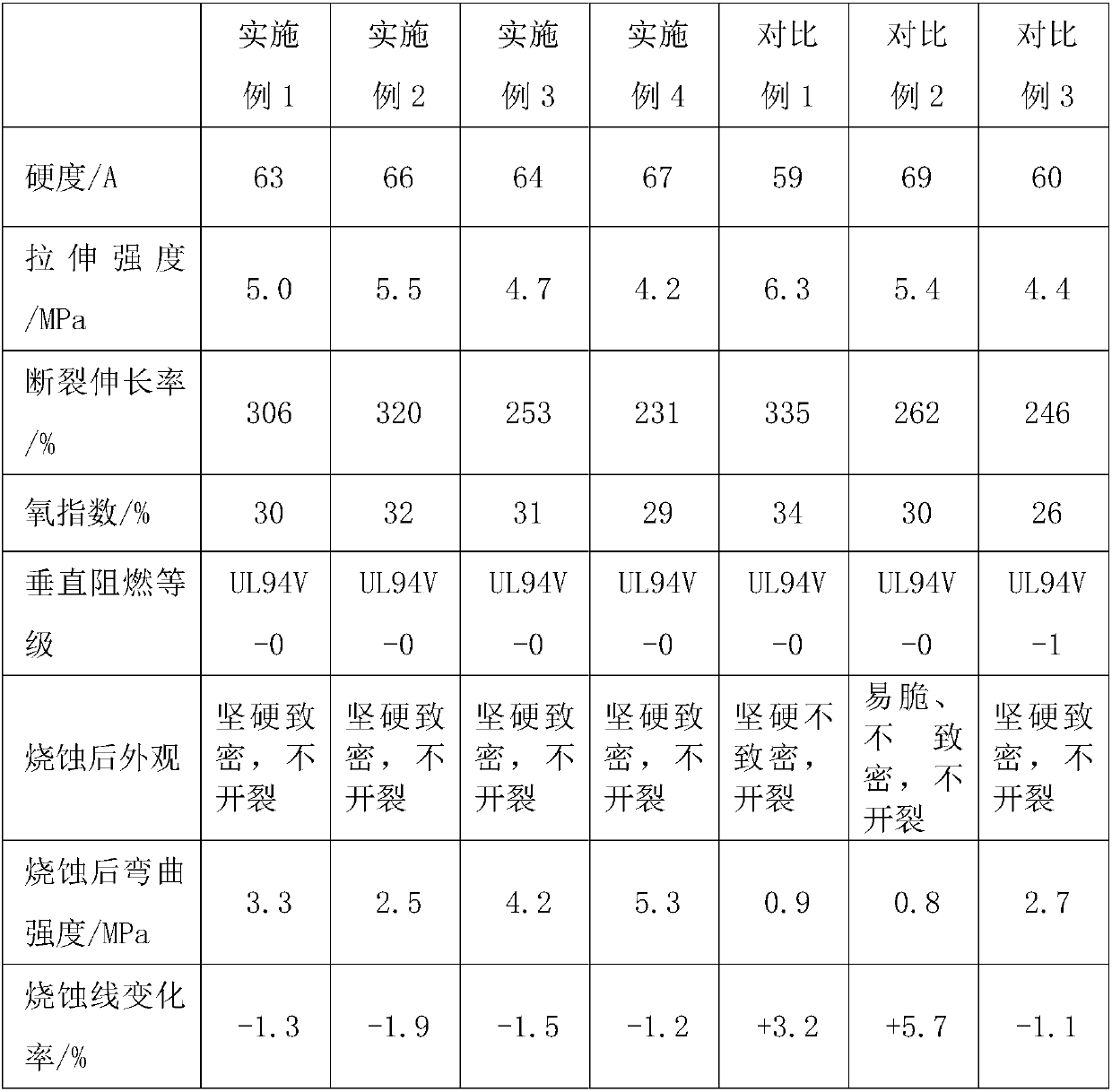

Ceramic flame-retardant and fireproof silicone rubber and preparation method thereof

The invention discloses ceramic flame-retardant and fireproof silicone rubber and a preparation method thereof. The silicone rubber contains the following components in parts by weight: 100 parts of raw silicone rubber, 10-50 parts of white carbon black, 10-100 parts of aluminum hydroxide, 10-50 parts of low-melting-point glass powder, 10-100 parts of sericite powder, 1-20 parts of hydroxyl silicone oil, 1-20 parts of hexamethyl disilazane, 0.1-3 parts of a platinum compound and 0.1-5 parts of a vulcanizing agent. The silicone rubber is good in flame retardance, excellent in mechanical property, safe and environmentally friendly, has good mechanical strength and insulating property after being ablated, is capable of preventing burnt objects from being damaged and keeping a circuit completefor a long time and can play a good fireproof role.

Owner:GUANGDONG POLYSIL TECH CO LTD

Hydrophobic silicon dioxide aerogel and preparation method thereof

The invention relates to a preparation method of hydrophobic silicon dioxide aerogel, and relates to a silicon dioxide aerogel and a preparation method thereof. The method includes steps of taking tetraethoxysilane and methyl triethoxy silane as a common precursor, ethanol as a solvent, water as hydrolysis agent, and hydrolysis as catalyst, ethanol added with carbon fluorinated surfactant as aging fluid; performing supercritical drying process, and obtaining the block-shaped silicon dioxide aerogel with good hydrophobic rate. The preparation method is simple in technique, and able to make samples hydrophobic instead of introducing hexamethyldisilazane and other combustible finishing agent with peculiar smell; the prepared product is low in density, good in hydrophobic property, stable in thermal performance, and excellent in heat insulation performance.

Owner:浙江省普瑞科技有限公司

UV curing of low-k porous dielectrics

InactiveUS7482265B2Solid-state devicesSemiconductor/solid-state device manufacturingCross-linkFluence

A method of manufacturing a semiconductor device having a low-k dielectric layer is provided. An embodiment comprises forming a dielectric layer on a substrate, wherein the layer comprises a pore generating material dispersed in an uncured matrix. A second step comprises forming pores in the uncured matrix by irradiating the layer with radiation having a first wavelength. After pore forming, a third step comprises cross-linking the dielectric by irradiating it at a second wavelength, the second being less than the first. In an embodiment, the irradiating wavelengths comprise ultra-violet radiation. Embodiments may further include repairing processing damage wherein the damage includes dangling bonds or silanol formation. The repairing includes annealing in a carbon-containing ambient such as C2H4, C3H6, or hexamethyldisilazane (HMDS).

Owner:TAIWAN SEMICON MFG CO LTD

Delivery of hydroxy carboxylic acids

The present invention provides greater than 99% pure bis(triorganosilyl)hydroxycarboxylates of the general formulae: R3SiO-CHR1-COO-SiR3 R3SiO-CHR1-R2COO-SiR3wherein each R is independently a monovalent straight or branched chain alkyl or alkenyl group having from 1 to about 6 carbon atoms, or an aryl group, R1 may be hydrogen, a monovalent straight or branched chain alkyl group having from 1 to about 18 carbon atoms, or an aryl group, and R2 is a divalent straight or branched chain alkyl group having from 1 to about 18 carbon atoms, an aryl group, or a straight or branched chain alkaryl group having from 7 to about 18 carbon atoms; a process for producing the bis(trimethylsilyl)hydroxycarboxylates comprising the trimethylsilylation with hexamethyldisilazane of the corresponding hydroxy carboxylic acids; cosmetic formulation comprising the greater than 99% pure bis(trimethylsilyl)hydroxycarboxylates dissolved in aprotic media; and a method of delivering hydroxycarboxylic acids to the epidermis without apparent irritation or inflammation of the epidermis or stratum corneum.

Owner:SIVANCE

Preparation method of submicron silica powder

ActiveCN103627215ASolving Dispersion ProblemsSimple processPigment treatment with organosilicon compoundsPigment physical treatmentSlurrySilicon dioxide

The invention discloses a preparation method of submicron silica powder and relates to the technical field of preparation of submicron materials. The preparation method comprises the following specific steps: placing raw materials in a ball mill and grinding the raw materials; screening the ground materials; adding the materials into a sand mill; adding water or an organic solvent used as a dispersion medium, simultaneously adding one or more of dispersing agents including a silane coupling agent, a titanate coupling agent and hexamethyl-disilazane and performing wet grinding; deironing the ground slurry through a slurry deironing device; carrying out filter pressing on the deironed slurry to obtain a filter cake, wherein clear liquid obtained by filter pressing can be continuously used as a dispersion medium. The preparation method is simple in process and high in efficiency; a product is low in manufacturing cost, high in yield, short in production period, free of agglomeration, controllable in size and suitable for industrial production.

Owner:JIANGSU NOVORAY NEW MATERIAL CO LTD

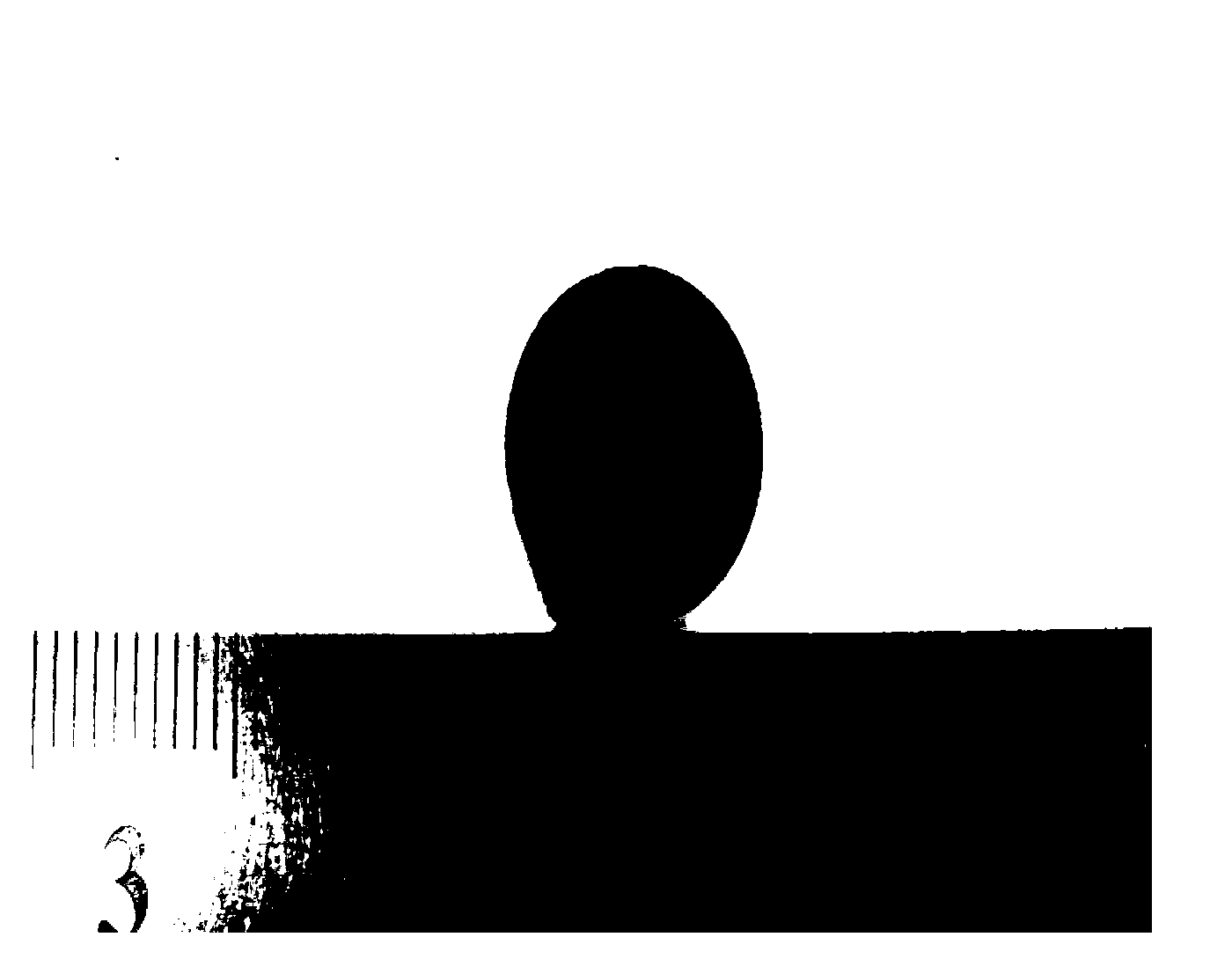

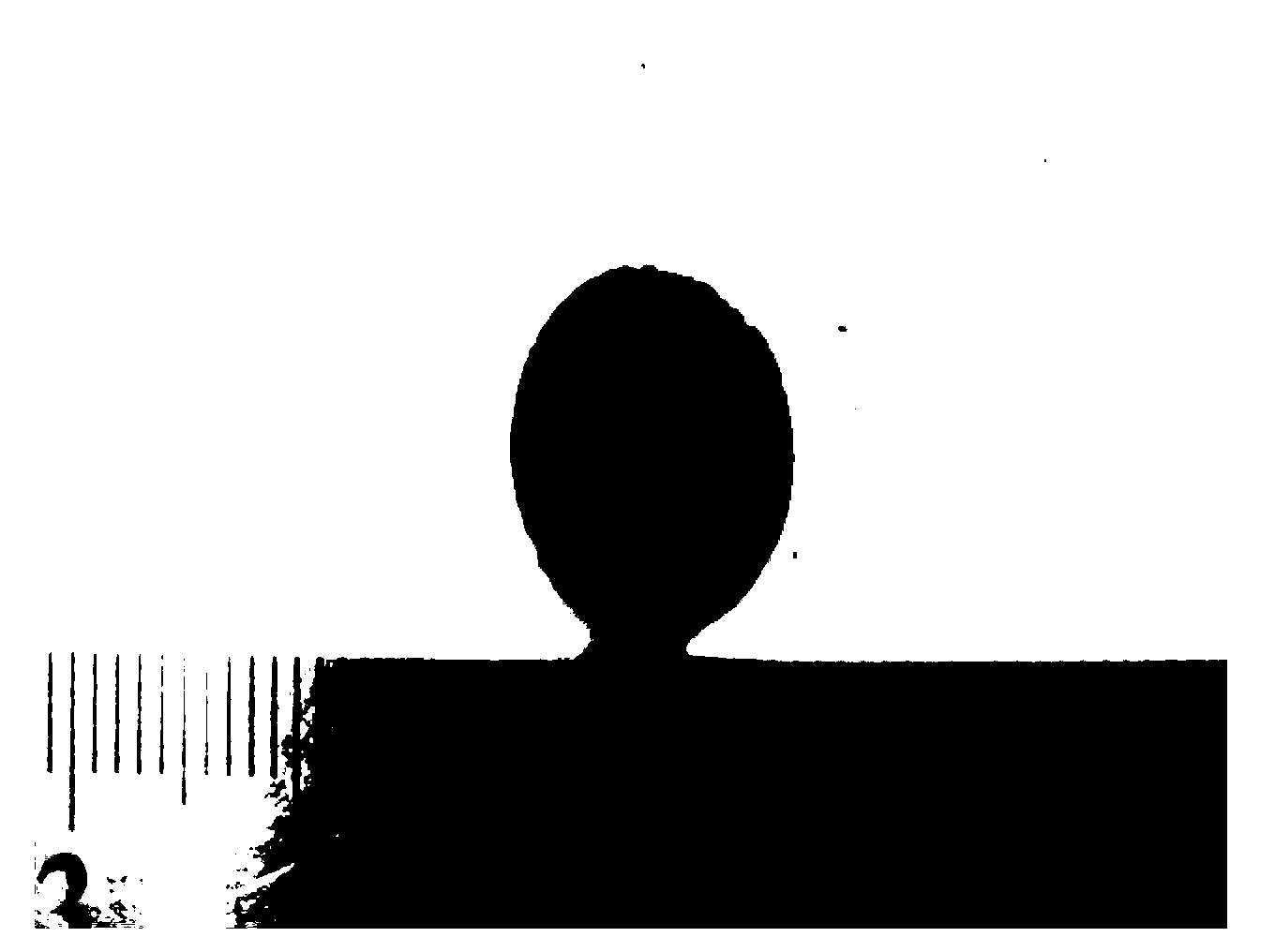

Pressure-sensitive adhesive tape and method of manufacturing the pressure-sensitive adhesive tape

InactiveUS20110151249A1Easy to manufactureSufficient adhesion forceAdhesive articlesSynthetic resin layered productsBis(trimethylsilyl)amineSilicon dioxide

A pressure-sensitive adhesive tape is provided with a pressure-sensitive adhesive layer and a water-repellent layer formed on the pressure-sensitive adhesive surface of the pressure-sensitive adhesive layer. The water-repellent layer is formed by using a water repellent exhibiting the water repellency in which a contact angle with water is greater than or equal to 140°. The water-repellent layer may have hydrophobic fine particles. The hydrophobic fine particle may contain a hydrophobic fine silica compound. The hydrophobic fine silica compound may be modified with hexamethyldisilazane.

Owner:NITTO DENKO CORP

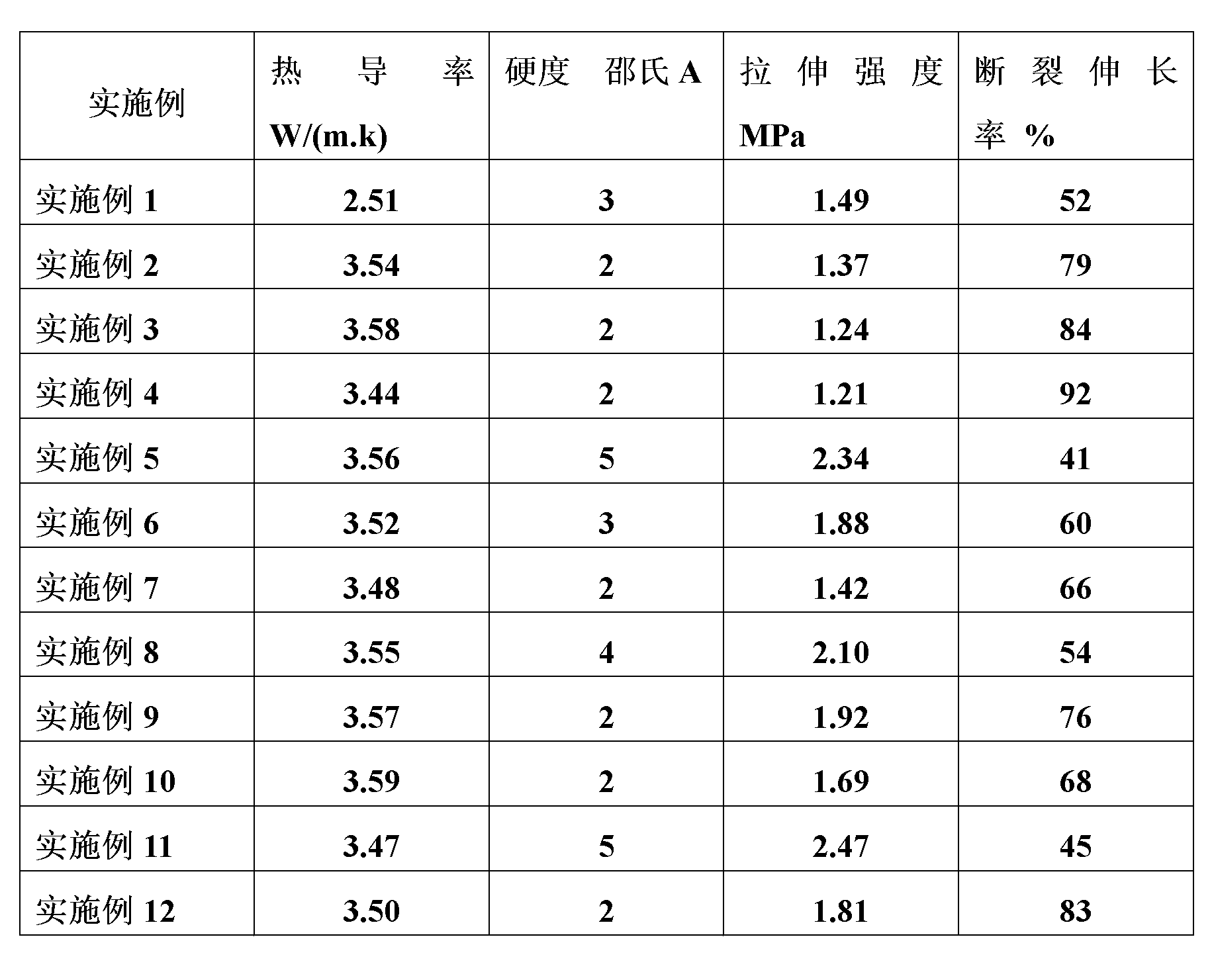

Double-component low-hardness high-heat-conductivity room-temperature-curing organosilicon heat conducting adhesive

InactiveCN102936484AApplicable coolingReduce hardnessNon-macromolecular adhesive additivesAdhesiveHeat conducting

The invention relates to a double-component low-hardness high-heat-conductivity room-temperature-curing organosilicon heat conducting adhesive, belonging to the technical field of electric insulation adhesives for binding and packaging electronic and electric appliance elements. The double-component low-hardness high-heat-conductivity room-temperature-curing organosilicon heat conducting adhesive comprises a component A and a component B, wherein the component A is prepared by mixing the following components in parts by weight: 100 parts of base material and 0.1-0.5 part of platinum catalyst; the component B is prepared by mixing the following components in parts by weight: 100 parts of base material, 0.1-10 parts of terminal-hydrogen-containing silicone oil, 0.1-10 parts of side-hydrogen-containing silicone oil and 0.01-1 part of inhibitor; and the base material is prepared by the following steps: mixing 100 parts by weight of divinyl silicone oil and 800-1500 parts by weight of aluminum oxide, treating with hexamethyldisilazane at 115-125 DEG C, and cooling to room temperature to obtain the base material. The adhesive has the advantages of high heat conductivity (up to 2.5-3.6 W / (m.k)), low hardness and ideal mechanical properties; and the adhesive can be closely combined with the electronic element, and therefore, can be ideally used for heat dissipation of high-power elements.

Owner:西卡(江苏)工业材料有限公司

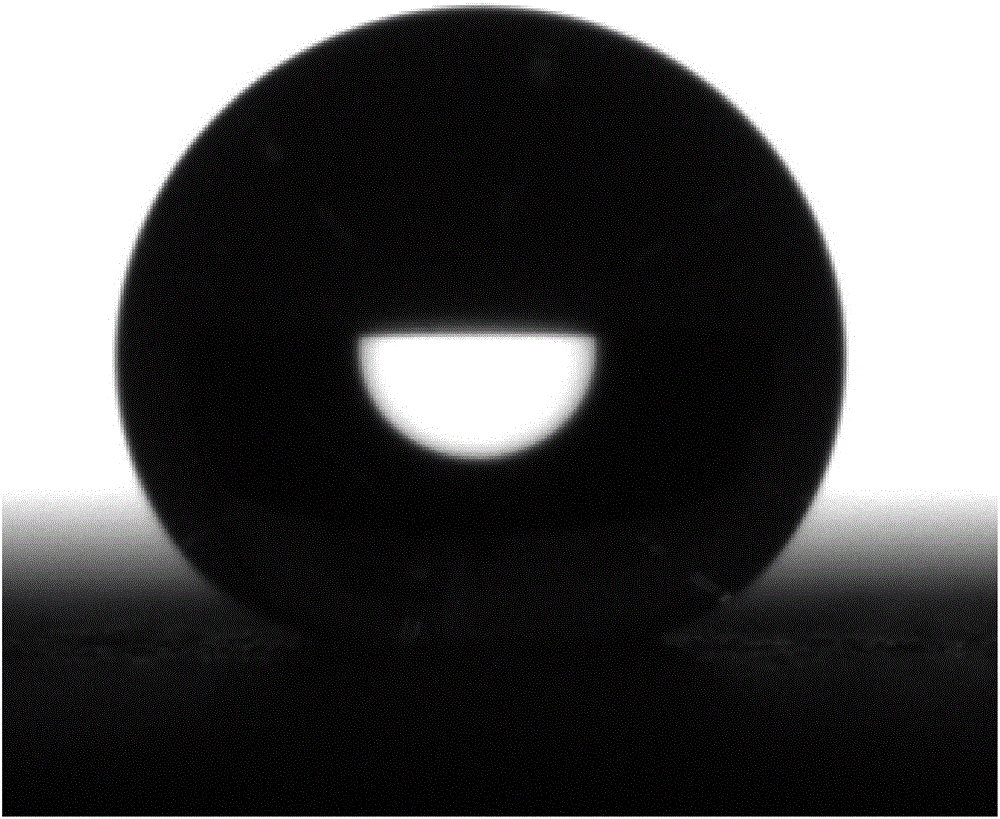

Preparation method of super-hydrophobic polymeric fiber

The invention relates to the technical field of high polymer material and particularly relates to a preparation method of a super-hydrophobic fiber. The preparation method of the super-hydrophobic fiber provided by the invention comprises the following steps: (a) constructing a nano-micro structure, namely coating the surface of polymeric fiber with a coating, thereby obtaining the polymeric fiber with surface subjected to functionalization, wherein the coating is dopamine, gamma-glycidyl ether oxygen propyl trimethoxy silane, tetraethoxy-silicane or aminopropyl triethoxysilane; and (b) performing surface modification, namely modifying the polymeric fiber with surface subjected to functionalization by use of a material with low surface energy, thereby obtaining the super-hydrophobic polymeric fiber, wherein the material with low surface energy is alkyltrichlorosilane or hexamethyl bisilazane. A contact angle between a fiber membrane manufactured by the fiber prepared by the method and water can be 168 degrees, the rolling angles of water drops on the fiber membrane are 4.5 degrees, and the fiber membrane has excellent affinity with ordinary organic solvents such as hexane and gasoline.

Owner:SICHUAN UNIV

Radiation-curing coating systems

Owner:EVONIK OPERATIONS GMBH

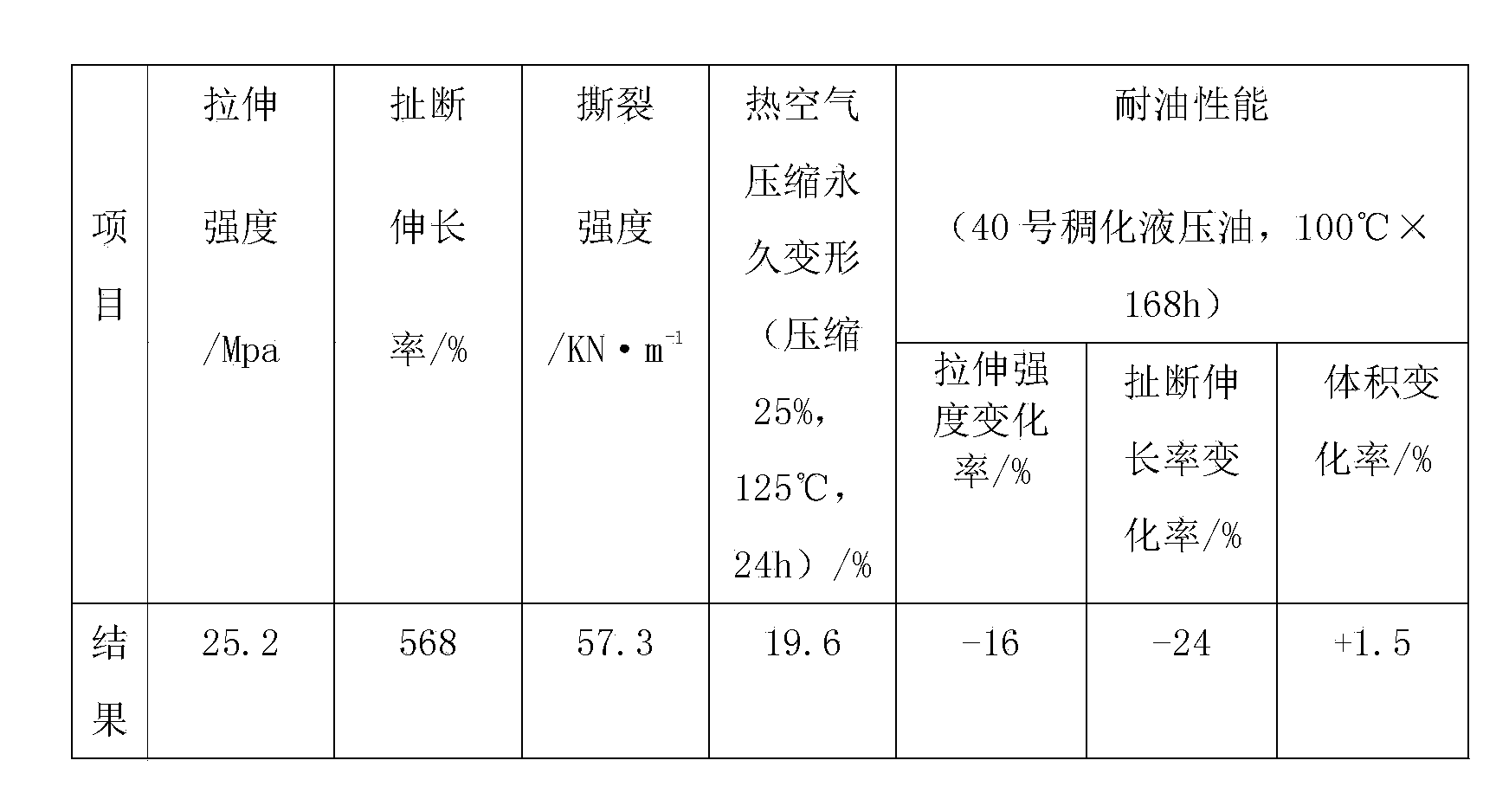

Silicon rubber/polyurethane rubber composite hydraulic sealing gasket and preparation method thereof

The invention relates to a silicon rubber / polyurethane rubber composite hydraulic sealing gasket and a preparation method thereof. The silicon rubber / polyurethane rubber composite hydraulic sealing gasket is prepared from methylvinylsiloxane rubber, polyether based polyurethane rubber, 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, diphenyl silanediol, hexamethyldisilazane, gas-phase white carbon black, modified wollastonite and the like. The methylvinylsiloxane rubber, which has the advantages of excellent heat resistance, excellent freezing resistance, excellent ozone resistance, excellent atmospheric aging resistance and small permanent compression set, and the polyurethane rubber with favorable mechanical properties are compounded and blended, so that the respective advantages are displayed, thereby enhancing the sealing property of the sealing material; and in the blending process, the organically / inorganically modified wollastonite is added to obviously improve the dispersity of the wollastonite in the rubber, thereby enhancing the mechanical strength, oil resistance, wear resistance, high temperature resistance and other properties of the sealing material.

Owner:WUHU YINHONG HYDRAULIC COMPONENTS

Method of improving moisture resistance of low dielectric constant films

InactiveUS20010026849A1Vacuum evaporation coatingPretreated surfacesMicrowaveBis(trimethylsilyl)amine

A method and apparatus for depositing a low dielectric constant film includes depositing a silicon oxide based film, preferably by reaction of an organosilicon compound and an oxidizing gas at a low RF power level from about 10W to about 500W, exposing the silicon oxide based film to water or a hydrophobic-imparting surfactant such as hexamethyldisilazane, and curing the silicon oxide based film at an elevated temperature. Dissociation of the oxidizing gas can be increased in a separate microwave chamber to assist in controlling the carbon content of the deposited film. The moisture resistance of the silicon oxide based films is enhanced.

Owner:APPLIED MATERIALS INC

Preparation method of super-hydrophobic nanoscale white carbon black membrane and super-hydrophobic nanoscale white carbon black powder

InactiveCN102583403AWide variety of sourcesLow costSilicaSolid waste disposalPetrochemicalPrinting ink

The invention provides a preparation method of a super-hydrophobic nanoscale white carbon black membrane and super-hydrophobic nanoscale white carbon black powder. The preparation method provided by the invention is characterized by comprising the following steps of 1, preparing nanoscale rice husk ash by a self-propagating combustion method, 2, adding the nanoscale rice husk ash into a NaOH solution having concentration of 1M in a way that each 1g of the nanoscale rice husk ash is added into 10ml of the NaOH solution, carrying out boiling, cooling, removing precipitated impurities, and adjusting a pH value to 3 by a HCl solution to obtain a sodium-silicon solution, and 3, preparing the super-hydrophobic nanoscale white carbon black membrane and the super-hydrophobic nanoscale white carbon black powder by an improved sol-gel method, wherein a used modifier is hydroxyl silicone oil or hexamethyldisilazane. The super-hydrophobic nanoscale white carbon black powder obtained by the preparation method has SiO2 content of 99.64%. The super-hydrophobic nanoscale white carbon black membrane has a wetting contact angle of 166.32 degrees. The super-hydrophobic nanoscale white carbon black membrane and the super-hydrophobic nanoscale white carbon black powder belong to the field of hydrophobic surfaces and can be utilized as water resistance agents, catalysts, catalyst carriers, raw materials of a petrochemical industry, decolorants, delustering agents, rubber strengthening agents, plastic fillers, printing ink thickening agents, metal soft polishing agents, insulative heat-insulation fillers, high-grade daily cosmetic fillers and spraying materials.

Owner:SHANDONG UNIV OF TECH

Preparation method of polyurethane rubber / silicone gross rubber

The invention discloses a preparation method of polyurethane rubber / silicone gross rubber. The method includes the following steps: 1, fully mixing 100 parts of white carbon black and 20 parts of hexamethyl-disilazane in a mixing mill, baking the mixture an oven at 80 DEG C to a neutral state, and placing for 24 h; 2, adding the mixture with 200 parts of methyl vinyl silicone rubber and 10 parts of diphenyl silanediol in a vacuum kneading machine, and kneading the mixture into gross rubber; and 3, respectively milling the silicone rubber gross rubber and polyurethane rubber in a double roller for 2 min, and then evenly mixing silicon rubber gross rubber and polyurethane rubber in a weight ratio of 3:2, adding a vulcanizing agent, conducting thin-filming and discharging. According to the preparation method of the polyurethane rubber / silicone gross rubber provided by the invention compound, white carbon black is added to methyl vinyl silicone rubber for mixing, and then subjected to co-mixing with polyurethane; without the addition of the compatibilizer, the curing agent can realize the vulcanization; and the prepared gross rubber has good mechanical properties.

Owner:青岛欧美亚橡胶工业有限公司

Preparation method for SiBNC fiber/SiBNC composite material

The invention relates to a preparation method for a SiBNC fiber / SiBNC composite material. The preparation method for the SiBNC fiber / SiBNC composite material comprises the following steps: (1) preparing a precursor polymer by polymerizing a micromolecular monomer boron trichloride, methyl hydrogen dichlorosilane and hexamethyldisilazane; (2) pretreating the surface of the SiBNC fiber and performing pre-crosslinking with the precursor polymer; (3) performing thermoforming to obtain a prefabricated product; (4) performing infusible treatment on the prefabricated product; and (5) performing ceramic treatment at high temperature. The SiBNC fiber / SiBNC composite material prepared by the method has high density, uniform components, low porosity, high-temperature resistance and excellent mechanical performance.

Owner:DONGHUA UNIV

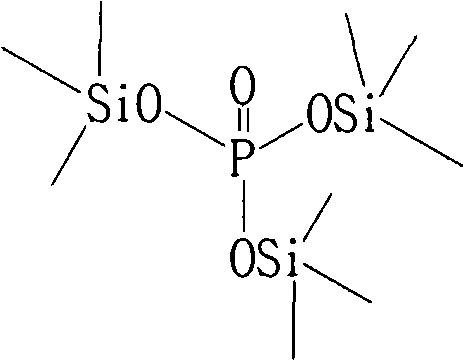

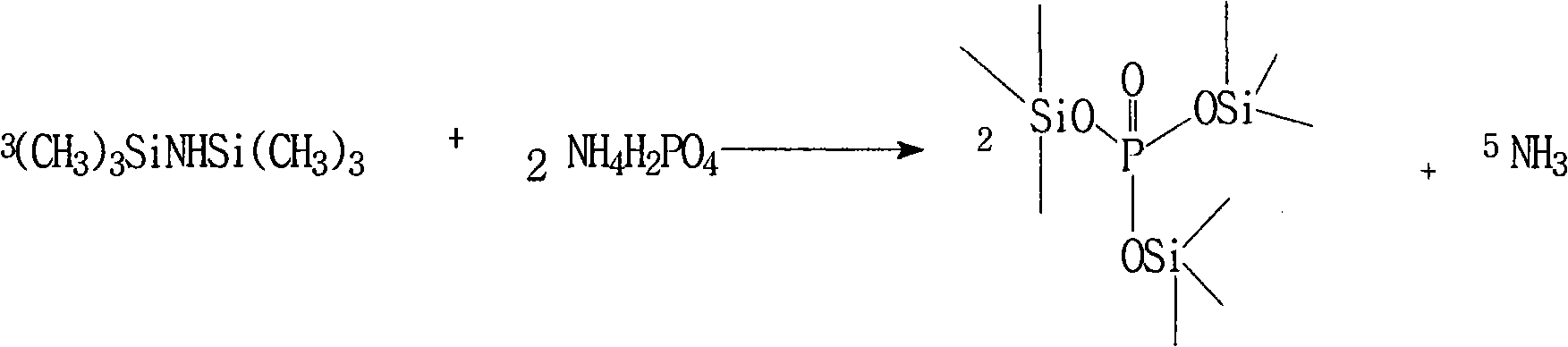

Synthesis method of tris(trimethylsilyl) phosphate

ActiveCN101870711AIncrease weightEasy to useSecondary cellsPhosphorus organic compoundsBis(trimethylsilyl)aminePhosphate

The invention relates to a synthesis method of a tris(trimethylsilyl) phosphate, which comprises the following steps: reacting hexamethyldisilazane with a phosphate for 2 to 5 hours at the temperature of 80 to 160 DEG C so as to form a tris(trimethylsilyl) phosphate and ammonia; then carrying out rectification and purification on the obtained crude product so as to obtain a fine product of the tris(trimethylsilyl) phosphate. The method has the advantages of simple operation, easy-taking raw material and simple post-processing, is suitable for industrial production, and can synthesize high quality product.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Method for synthesizing hexamethyldisilazane

ActiveCN102766155AReduce manufacturing costAvoid hydrolysis side reactionsGroup 4/14 element organic compoundsBis(trimethylsilyl)amineSolvent

The invention relates to a method for synthesizing hexamethyldisilazane. The hexamethyldisilazane is synthesized by a mixed solvent method through one-step ammoniation reaction, the hydrolysis side reaction of the hexamethyldisilazane can be inhibited by adding hexamethyldisiloxane into a reaction system, and reaction yield is improved. By the method, the yield is high, reaction time is short, energy consumption during rectification is low, the production cost of the hexamethyldisilazane is reduced, and the large advantage of industrialization is achieved.

Owner:鲁南新时代生物技术有限公司

Preparation method of electronic-grade lithium difluoro bis-oxalate phosphate

ActiveCN108910919AEasy to operateGuaranteed purityHybrid capacitor electrolytesLithium compoundsLithiumOxalate

The invention discloses a preparation method of electronic-grade lithium difluoro bis-oxalate phosphate. The method comprises the following steps: weighing oxalic acid and lithium hexafluorophosphatein a reaction apparatus, adding a non-aqueous solvent, dropping hexamethyl-disilazane, fully stirring the materials for a reaction to obtain a reaction solution, filtering the reaction solution, performing vacuum concentration after filtering to obtain a solid product, and performing recrystallization to obtain the electronic-grade lithium difluoro bis-oxalate phosphate. The preparation method employs the raw materials with low cost to prepare the lithium difluoro bis-oxalate phosphate, the method has the advantages of easy and convenient operation, avoids the defects of multiple reaction stepand complex operation of the other methods, and excessive impurities of the final product, guarantees the purity and quality of the product, and the product having high quality and high purity can beobtained, and the preparation method is suitable for industrial production.

Owner:JIUJIANG TINCI ADVANCED MATERIALS CO LTD

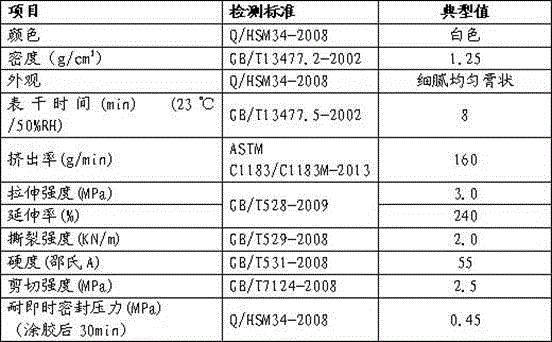

Instant-sealing silicone sealant and preparation method thereof

ActiveCN106147694ALow viscosityHigh strengthNon-macromolecular adhesive additivesPolymer scienceSilanes

The invention belongs to the technical field of a high polymer material and a preparation method thereof, and especially relates to an instant-sealing silicone sealant and a preparation method thereof, and the instant-sealing silicone sealant comprises the following components by weight: 28 to 32% of hydroxyl-terminated polydimethylsiloxane(20000cp), 20 to 24% of hydroxyl-terminated polydimethylsiloxane(3000cp), 35 to 40% of nano calcium carbonate, 4.0 to 6.0% of methyl-tri-(butanone-oxime)silane, 1.0 to 2.0% of vinyl-tri-(butanone-oxime)silane, 3.0 to 5.0% of fumed silica, 0.03 to 0.06% of hexamethyl-disilazane, 0.03 to 0.06% of dibutyltin dilaurate and 0.03 to 0.06% of N-(beta-aminoethyl)-gamma-aminopropyltrimethoxysilane. The instant-sealing silicone sealant has the advantages of being fast to cure, instant to seal, environmental-friendly, conserving and non-solvent, and has the characteristics of excellent thixotropy, aging resistance, ultraviolet resistance and the like. The instant-sealing silicone sealant can be widely applied to instant sealing of railway vehicles and automobile mechanical parts, quick bonding and sealing of lamp materials, and the like.

Owner:山东汉斯曼高分子材料有限公司

Method for surface preparation of solid substances and surface-prepared solid substances

InactiveUS20060222868A1Improve adhesion strengthUniform modificationMolten spray coatingLayered productsAdhesion strengthMaterials science

Owner:MORI YASUHIRO

Preparation method for corrosion-free SiO2 aerogel

The invention relates to a preparation method for corrosion-free SiO2 aerogel. The preparation method for the corrosion-free SiO2 aerogel adopts a sol-gel two-step method and comprises the steps of enabling a mixed solution of industrial water glass and deionized water to be subjected to exchange with weakly acidic cation exchange resin so as to remove Na<+> and obtain sol with the pH of 3.0-4.0, standing the sol, then, adjusting the pH value of the sol with ammonia water so as to obtain wet gel, then, aging the wet gel in an aging solution of ethyl orthosilicate and ethanol, putting the aged wet gel in ethanol for solvent replacement, then, putting the wet gel subjected to solvent replacement in a mixed solution of hexamethyldisilazane and ethanol for surface modification, then, putting the modified wet gel in ethanol for second-time solvent replacement, and finally, putting the wet gel in a carbon-dioxide supercritical drying kettle for supercritical drying, thereby preparing the SiO2 aerogel which has the advantages of no corrosion, excellent product performance and low process cost.

Owner:北京建工新型建材有限责任公司

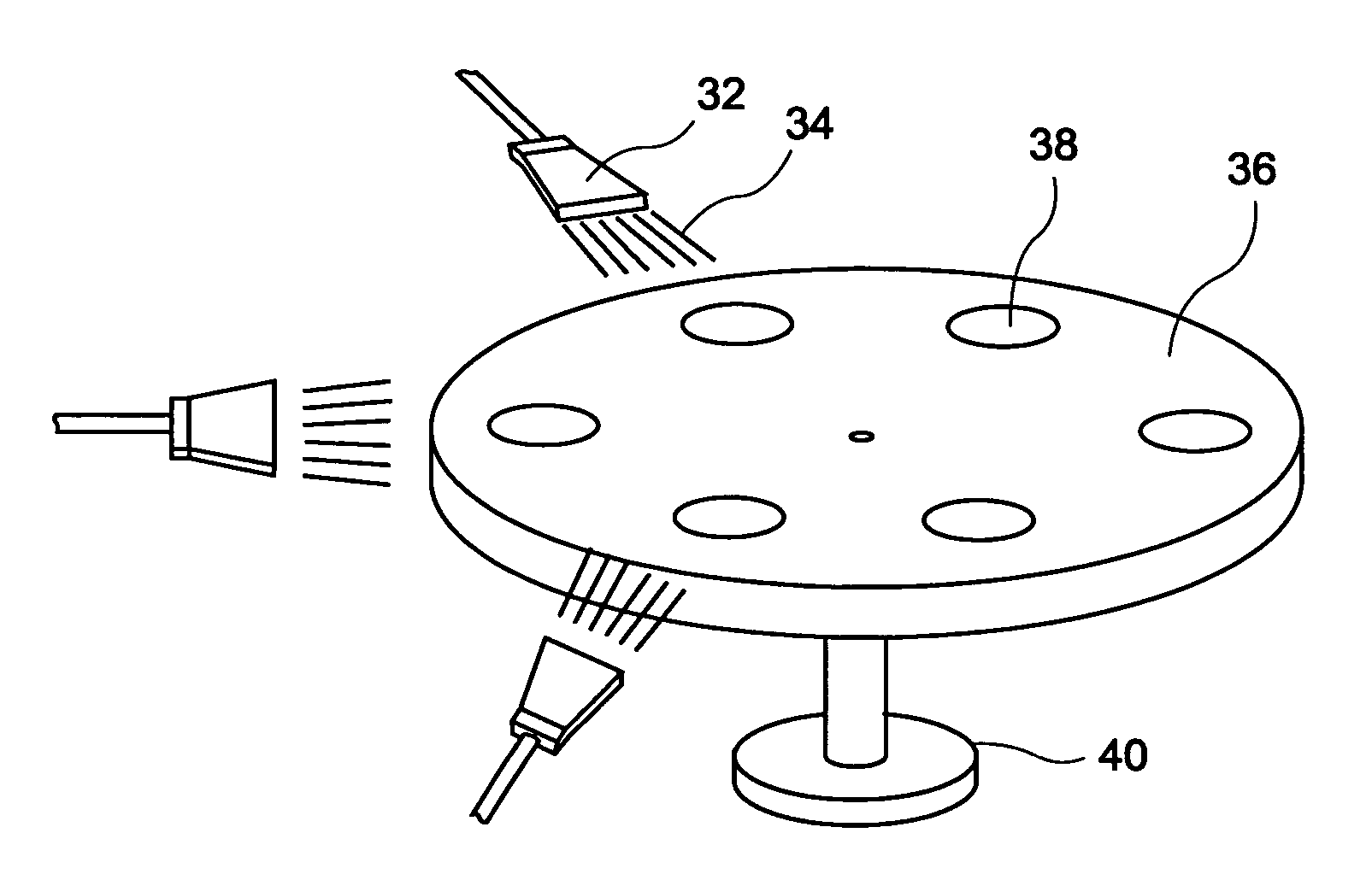

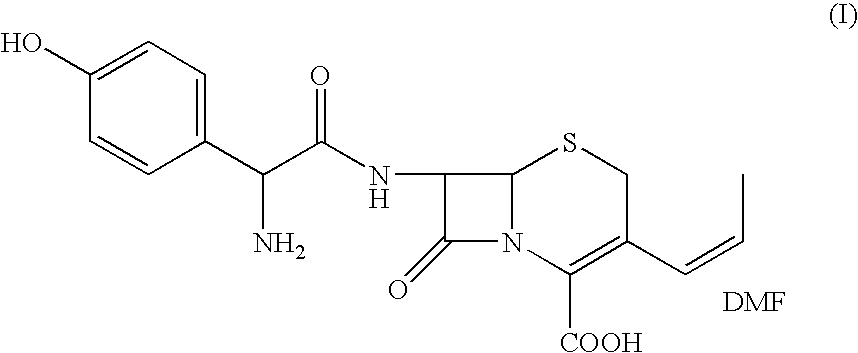

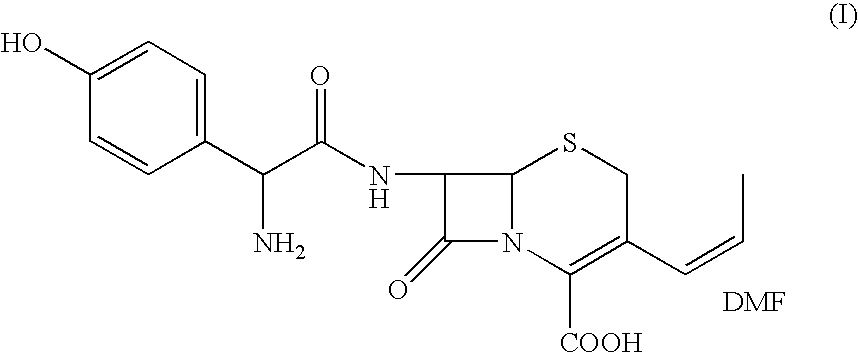

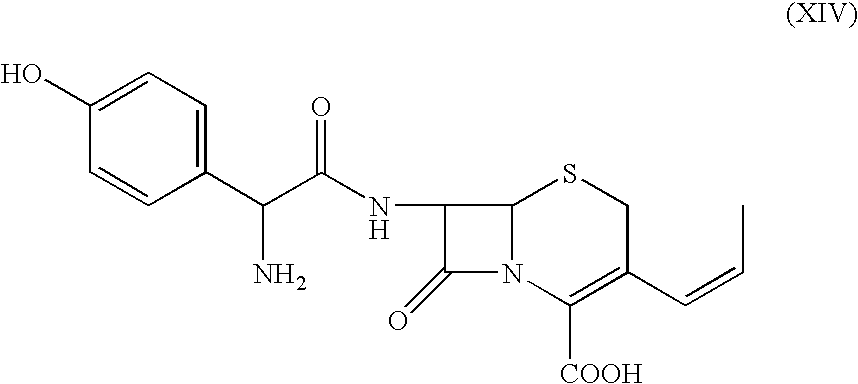

Process for the preparation of 3-propenyl cephalosporin DMF solvate

InactiveUS6903211B2High purityHigh yieldAntibacterial agentsOrganic chemistryEnzymatic hydrolysisBis(trimethylsilyl)amine

The present invention relates to an improved process for the preparation of cefprozil DMF solvate of formula (I), which is useful for the preparation of cefprozil, comprising:i) reacting a compound of formula (VIII) with acetaldehyde to produce a compound of formula (IX),ii) deesterifying the carboxy protecting group of the compound of formula (IX) using an acid to yield a compound of formula (X),iii) converting the compound of formula (X) to a compound of formula (XI),iv) neutralizing the compound of formula (XI) followed by enzymatic hydrolysis to produce an APCA of formula (V),v) silylating the APCA using a mixture of trimethylsilylchloride and hexamethyldisilazane to produce silylated APCA of formula (XII), andvi) condensing the silylated APCA with a mixed anhydride to produce the DMF solvate compound of formula (I).

Owner:ORCHID CHEM & PHARM LTD

Delivery of hydroxy carboxylic acids

Owner:SIVANCE

Method for preparing a silica suspension in a vulcanisable silicon matrix to form elastomers

InactiveUS6391944B2Easy to useInexpensive and able to be applied on an industrial scaleElastomerParticulates

The invention concerns the preparation of a silica suspension in a silicon fluid, said suspension being used to produce silicon vulcanizable by polyaddition (RTV elastomers). The problem which the invention aims to solve is that of finding a technical compromise between the rheological and mechanical properties of the final RTV. The invention solves the problem by providing a method for preparing a silica suspension treated with hexamethyldisilazane (HMDZ) in a silicon fluid with siloxyl Si-Vinyl function, characterised in that it consists essentially in introducing HMDZ in the preparation medium, before and / or substantially while bringing at least part of the silicon fluid prepared with at least part of the particulate filler used, said introduction being carried out once or several times for a HMDZ fraction corresponding to a proportion not more than 8% by dry weight with respect to the total silica charge and after bringing together the POS and the filler.

Owner:BLUESTAR SILICONES FRANCE SAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com