Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

503 results about "Hexamethyldisiloxane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hexamethyldisiloxane (HMDSO) is an organosilicon compound with the formula O[Si(CH₃)₃]₂. This volatile colourless liquid is used as a solvent and as a reagent in organic synthesis. It is prepared by the hydrolysis of trimethylsilyl chloride. The molecule is the protypical disiloxane and resembles a subunit of polydimethylsiloxane.

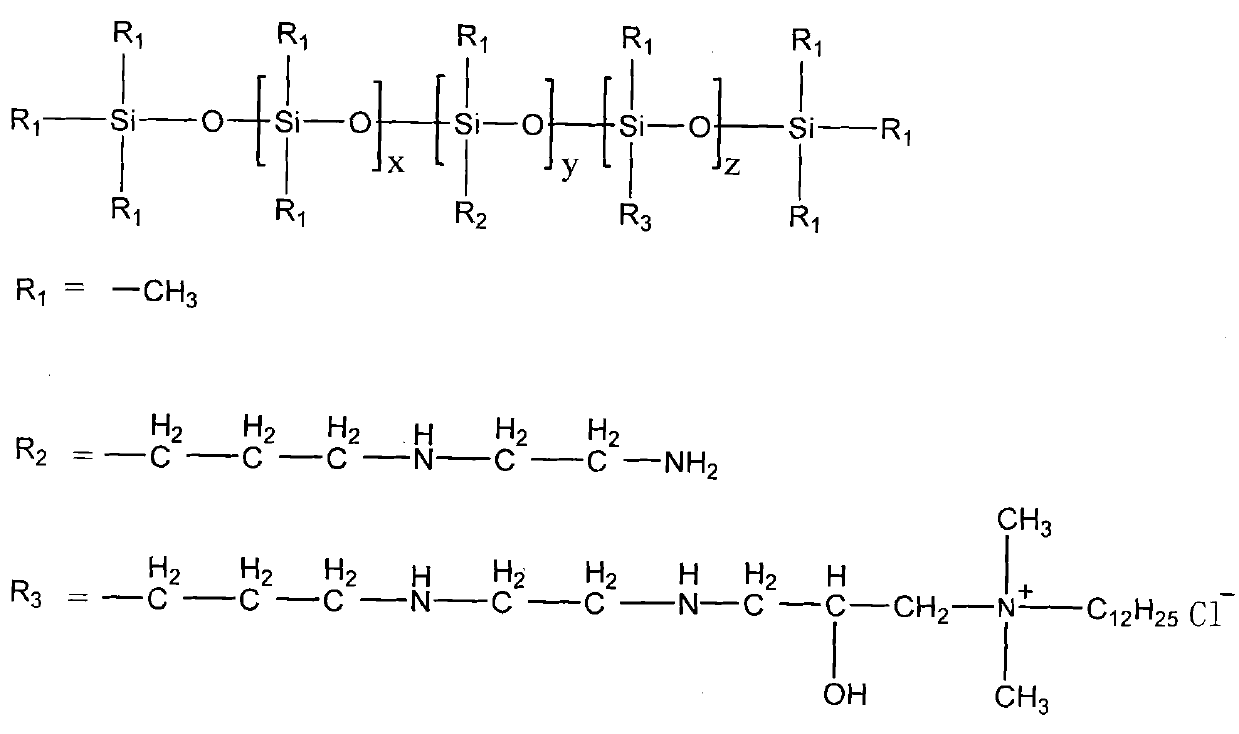

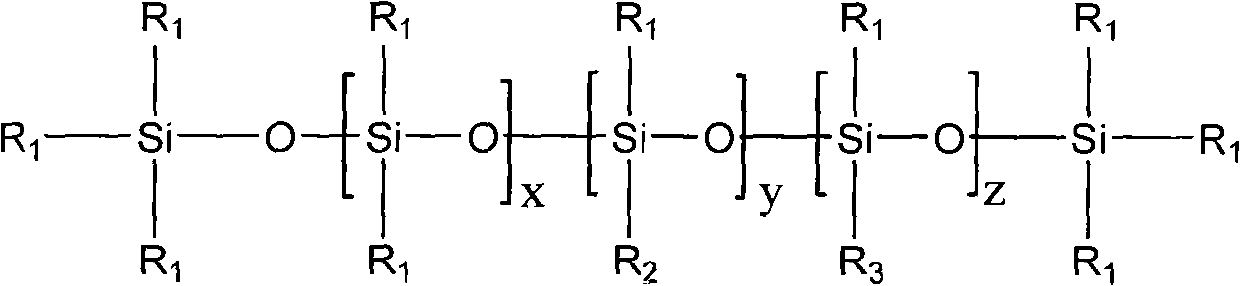

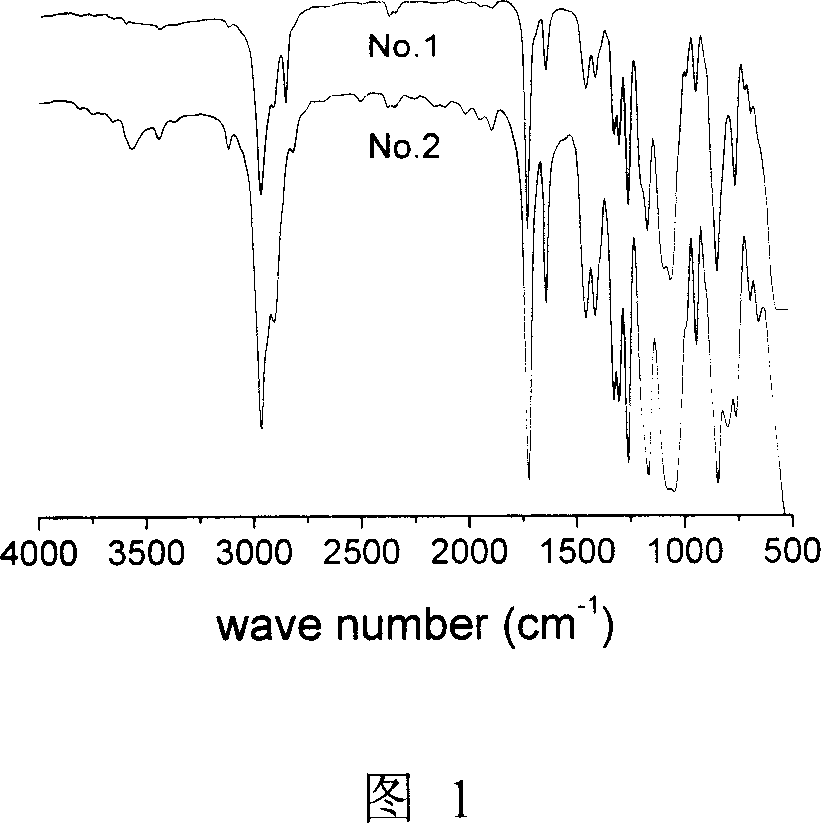

Quaternized modified amino silicone oil softener and preparation and application thereof

InactiveCN101914206AAvoid yellowingImprove hydrophilicityVegetal fibresTetramethylammonium hydroxideDisiloxane

The invention relates to a quaternized modified amino silicone oil softener and preparation and application thereof. The softener comprises the following general formula in the specification. The preparation comprises the following steps of: (1) adding octamethylcy-clotetrasiloxane into a container, adding a coupling agent N-beta-(aminoethyl)-gamma-aminopropyl methyl dimethoxysilane into the container dropwise, adding a tetramethyl ammonium hydroxide catalyst and subsequently a capping agent hexamethyl disiloxane into the container, and then performing reduced pressure distillation to obtain amino silicon oil; (2) dissolving the amino silicon oil into a solvent, adding the mixture into epichlorohydrin, stirring and heating to react under the protection of nitrogen, and removing the solvent by steaming to obtain an intermediate product; and (3) uniformly mixing N,N-dimethyl-decanamide and the solvent to obtain a mixture, stirring with heating, adding the intermediate product dropwise into the mixture under the protection of nitrogen, performing a thermostatic reaction, and removing the solvent by steaming to obtain the product. The softener of the invention has high hydrophilicity and high stability; fabric processed by the softener has excellent soft handfeel, high hydrophilicity, low yellowing, antibacterial property and the like; and the softener is simple to prepare and is suitable for industrial production.

Owner:DONGHUA UNIV

Synthesis of epoxy quaternised modified amino-silicone oil

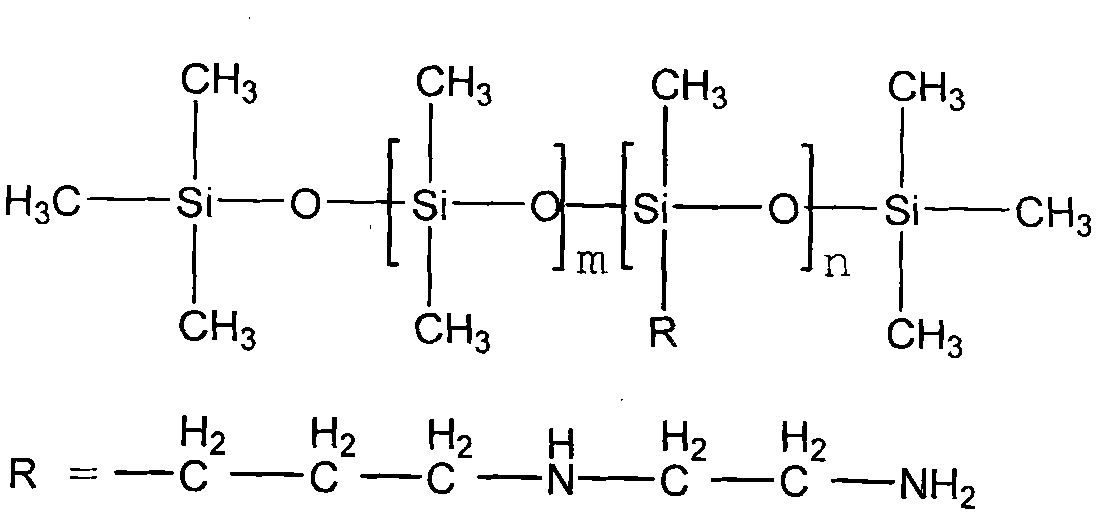

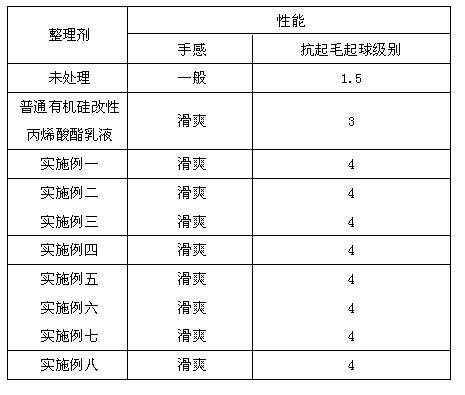

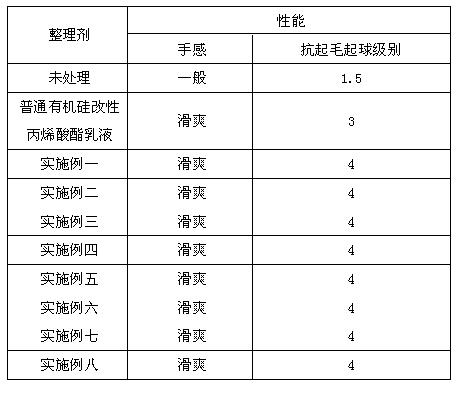

InactiveCN101367941AImprove hydrophilicityImproved anti-pilling propertiesFibre treatmentEpoxyPotassium hydroxide

The invention relates to a method for synthesizing epoxy quaternization modified amino-silicone oil, pertaining to the technical field organic silicide amino-silicone oil preparation. The method includes the following main procedures: (1) synthesis of amino-silicone oil: the raw material of octamethylcy-clotetrasiloxane (D4 linear body), N-Beta-aminoethylGemma- aminopropylmethyldimethyoxysilane (KH-602), hexamethyl dimethyl siloxane (MM), catalyst potassium hydroxide and deionized water are placed in a reactor for reaction for 5-6 hours under 100-110 DEG C, and the desired amino-silicone oil is achieved after being cooled; (2) proper amount of epichlorohydrin is added for reaction under 80 DEG C, the amino-silicone oil is processed by epoxy quaternization to achieve epoxy quaternary ammonium salt amino-silicone oil; (3) the quaternary ammonium salt amino-silicone oil is emulsified by deionized water, water is slowly added under 85 DEG C and stirred, and the water miscible liquid of epoxy quaternization modified amino-silicone oil is finally achieved. The product achieved by the method is applicable to textile fabric neatening and has pilling resistant and fluffing resistant properties.

Owner:SHANGHAI UNIV

Vinyl silicon resin for reinforcing organic silicon pouring sealant and preparation method thereof

The invention discloses a vinyl silicon resin for reinforcing an organic silicon pouring sealant and a preparation method thereof. The preparation method comprises the following steps of: adding an appropriate amount of hexamethyl disiloxane and tetramethyl divinylsiloxane into a mixture of hydrochloric acid, an organic solvent and water to perform reaction for some time and then adding tetraethoxysilane and bis-functional or trifunctional siloxane to perform reaction; adding a certain amount of hexamethyl disiloxane and tetramethyl divinylsiloxane according to circumstances, standing and demixing after the reaction is finished, washing lower mixed liquor with deionized water until the liquor is neutral, and drying the liquor to obtain the vinyl silicon resin. The spherical core of the silicon resin prepared by the method, namely SiO2 has high content, and the spherical shell is tightly encircled by an R3SiO0.5 layer, so the silicon resin has good reinforcing effect; and the resin hashigh solubility or dispersibility in silicon rubber, can be separately used as a reinforcing filler for the organic silicon pouring sealant, and can also be matched with other fillers, so that the organic silicon pouring sealant with required performance can be obtained.

Owner:GUANGZHOU GLORYSTAR CHEM +1

Silicon-containing (methyl) acrylate monomer and its copolymer and their prepn process

InactiveCN1974581AGood adhesionImprove water resistanceGroup 4/14 element organic compoundsSilanesDisilane

The present invention discloses silicon-containing (methyl) acrylate monomer and its copolymer and their preparation process. The silicon-containing (methyl) acrylate monomer as silane or silane oligomer with methyl propenyl acyloxy radical or propenyl acyloxy radical is prepared through the catalytic reaction of silane coupler with (methyl) propenyl acyloxy radical, and hexamethyl disilane or hexamethyl disilane and active organosilicon under the action of catalyst. The present invention also discloses one kind of silicon-containing (methyl) acrylate copolymer and its solution copolymerization, water emulsion copolymerization and ultraviolet curing process. The copolymer has excellent adhering performance, waterproof and antifouling performance and weather resistance.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Preparation method of methylsilicone oil

The invention discloses a preparation method of methylsilicone oil, and specifically relates to methyl silicone oil with different viscosity (molecular weight) prepared by using supported solid superacid SO4<2-> / ZrO2-ZSM-5 as a catalyst and by adopting inexpensive and commercially available methylsilicone oil (Dn), octamethylcyclotetrasiloxane (D4) and hexamethyldisiloxane (MM), so as to fit various needs. Compared with a conventional catalyst for producing methylsilicone oil, the supported solid superacid catalyst provided by the invention has higher catalytic activity, higher stability, lower cost and the like. More importantly, the supported solid superacid catalyst is in a solid state and can be separated via simple filtration and reused, thereby enabling the production to have the advantages of simple process, convenient operation, no pollutions, no corrosion toward equipment, and the like.

Owner:JIANGNAN UNIV

Emulsion type organic silica pressure-sensitive gel and preparation method thereof

The invention belongs to the technical field of silicone pressure-sensitive adhesive preparation, and in particular relates to an emulsion-type silicone pressure-sensitive adhesive and a preparation method thereof. It is composed of silicone rubber emulsion, MQ silicone resin emulsion, crosslinking agent and organic tin catalyst. The weight ratio of MQ silicone resin to silicone rubber is (40-70): (60-30), and the amount of crosslinking agent added is MQ silicone resin and 1% to 10% of the total weight of silicone rubber, the amount of organotin catalyst added is 0.1% to 1% of the total weight of MQ silicone resin and silicone rubber, wherein, MQ silicone resin is combined with hexamethyldisiloxane as M group and As the Q group, tetraethyl orthosilicate or water glass is hydrolyzed and condensed, the molar ratio of M group to Q group is (0.6~1.0):1, and the number average molecular weight Mn of MQ silicone resin is 2000~6000 ; The crosslinking agent is an organosiloxane crosslinking agent with three active functional groups. The organosiloxane emulsion synthesized by the invention solidifies after water evaporation to form a pressure-sensitive adhesive elastomer film with good initial tack and cohesive strength.

Owner:TONGJI UNIV

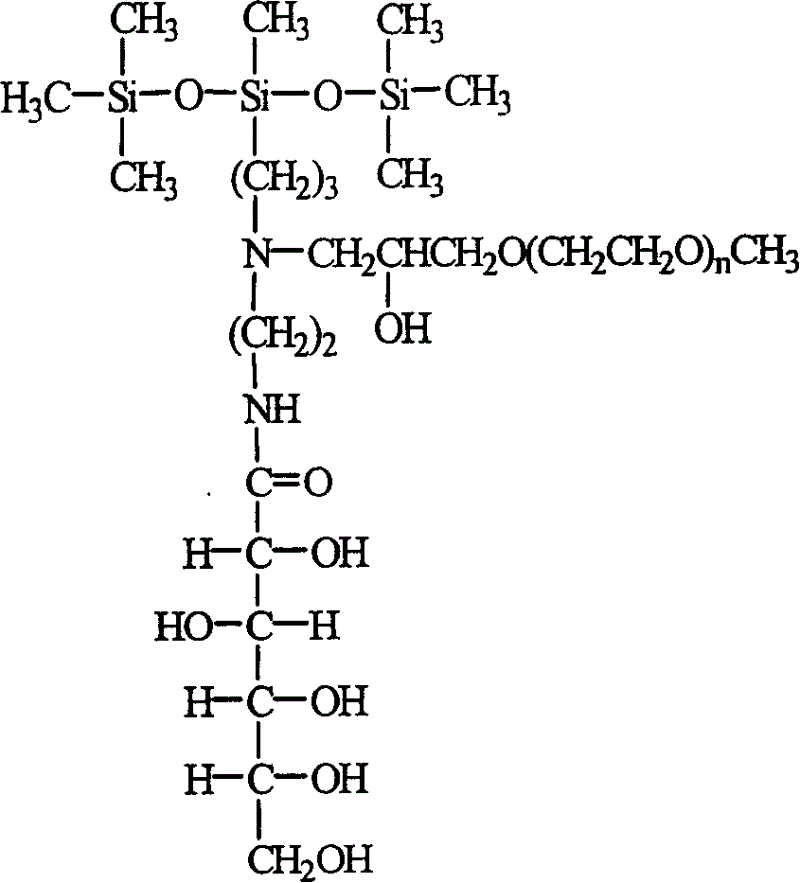

Method for preparing oxane trisilicate of containing glucosyacylamino

InactiveCN1660882AAvoid toxicityAvoid the hydrosilylation reaction stepSugar derivativesDisiloxaneSolvent

A process for preparing trisiloxane containing glucosylamido used as the assistant of agricultural chemical to decrease the surface tension of water includes catalytic reaction between hexamethyl disiloxane and aminosilane to obtain aminotrisiloxane, and reacting on lacton gluconate in methanol.

Owner:CHINA RES INST OF DAILY CHEM IND

T-chain unit phenyl-containing MTQ silicon resin and preparation method thereof

ActiveCN102898650AHigh refractive indexHigh phenyl contentOther chemical processesRefractive indexMechanical property

The invention relates to the field of organic polymer chemistry and discloses a T-chain unit phenyl-containing MTQ silicon resin and a preparation method thereof. The T-chain unit phenyl-containing MTQ silicon resin solves the problem that a MTQ silicon resin as a silicon rubber reinforcement filler leads to a large difference between refractive indexes of a packaging material and a LED chip because of a small refractive index of the MTQ silicon resin and thus optical efficiency of a semiconductor lighting device is reduced. The preparation method comprises that tetraethoxysilane as a Q chain unit source, phenyltrimethoxysilane as a T chain unit source, hexamethyldisiloxane as an M chain unit source and 1,3-divinyltetramethyldisiloxane as an M chain unit source undergo a co-hydrolytic condensation reaction in the presence of hydrochloric acid as a catalyst to produce the T-chain unit phenyl-containing MTQ silicon resin. The T-chain unit phenyl-containing MTQ silicon resin can improve luminous efficacy of a semiconductor lighting device and improve mechanical properties of a packaging material. The preparation method allows mild reaction conditions, has simple processes and is suitable for large-scale industrial production.

Owner:HANGZHOU NORMAL UNIVERSITY +1

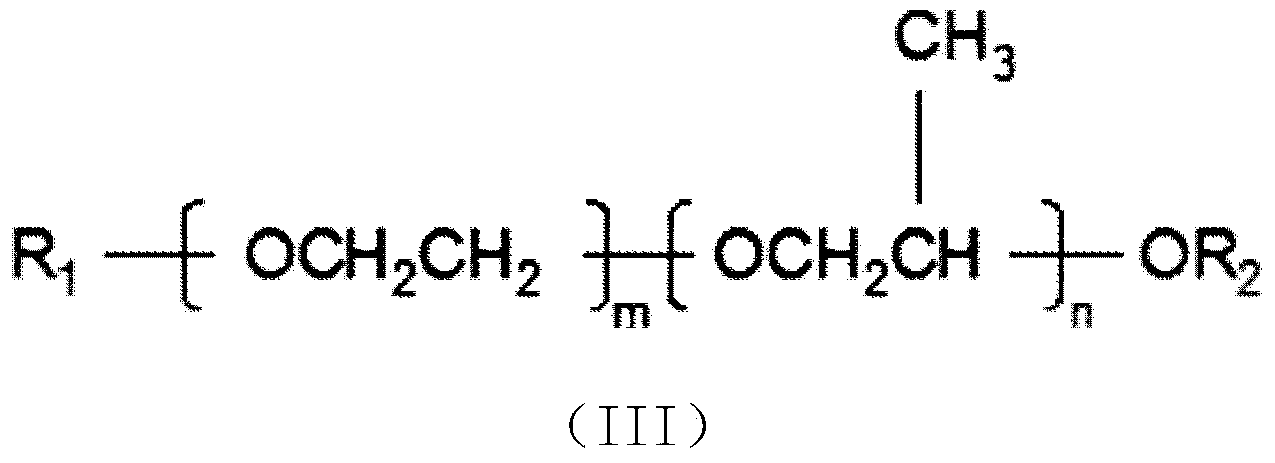

Preparation method of organosilicon foam stabilizer applied to single-component polyurethane foam sealing agent

The invention discloses a preparation method of an organosilicon foam stabilizer applied to a single-component polyurethane foam sealing agent. The preparation method comprises the steps of (1) adding allyl alcohol, ethylene oxide and propylene oxide to a reaction kettle, and reacting under the action of a base catalyst at the temperature of 90-130 DEG C and pressure not more than 0.5MPa for 4-6h to obtain allyl-terminated copolymer ether; (2) reacting the polyether prepared in the step 1 with sodium at 85-120 DEG C, introducing excess haloalkane, and reacting for 4-6h to obtain methyl-terminated copolymer ether; (3) reacting octamethyl cyclotetrasiloxane, hexamethyl disiloxane and high-hydrogen-content silicone oil with hydrogen content of 1-2% in the presence of an acid ion exchanger to obtain low-hydrogen-content silicone oil with hydrogen content of 0.05-1.0%; (4) mixing the products obtained in the steps 1,2, and 3, adding a catalyst, and reacting under the condition of pressure being 0.5-2atm for 3-8h to obtain the organosilicon foam stabilizer. During foaming, the foam stabilizer has excellent dimensional stability and high foaming ratio and fluidity.

Owner:苏州思德新材料科技有限公司

Refractive index-adjustable MDT silicone resin and preparation method thereof

ActiveCN102898649AAdjustable refractive indexReduce the refractive index differenceOther chemical processesRefractive indexSolvent

The invention relates to the field of organic polymer chemistry and provides a refractive index-adjustable MDT silicone resin and a preparation method thereof. The refractive index-adjustable MDT silicone resin solves the problem that the existing MDT silicone resin has a small refractive index thereby leading to a large difference between refractive indexes of the silicone resin and a polymer and thus an organic silicon polymer packaging material reinforced by the existing MDT silicone resin has poor optical properties and a semiconductor lighting device adopting the organic silicon polymer packaging material has low optical efficiency. The preparation method comprises that hexamethyldisiloxane as a blocking agent, bifunctional organic dichlorosilane as a D chain unit source, and trifunctional organic trichlorosilane as a T chain unit source undergo a co-hydrolytic condensation reaction in the presence of a water-acetone-toluene mixed solution as a solvent under the self-catalysis effect of hydrochloric acid produced by chlorosilane hydrolysis to produce the refractive index-adjustable MDT silicone resin. The refractive index-adjustable MDT silicone resin improves optical properties of a MDT silicone resin-reinforced high-refractive index organic silicon polymer packaging material and also improves mechanical properties of the packaging material.

Owner:HANGZHOU NORMAL UNIVERSITY +1

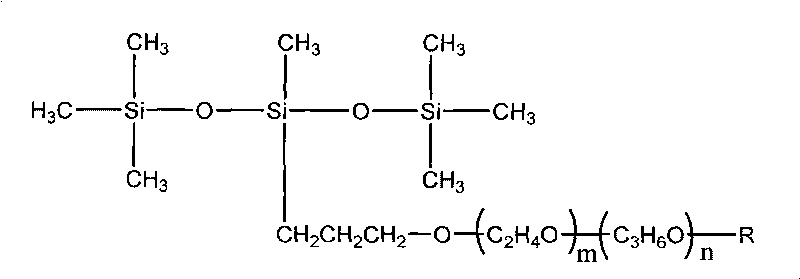

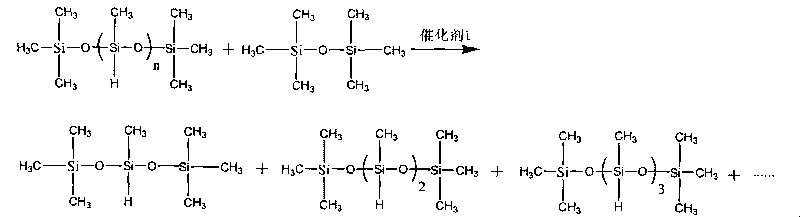

Method for manufacturing organosilicon surfactant with T-shaped structure for pesticide

InactiveCN101690878ANothing producedUseless amountBiocideSilicon organic compoundsCross-linkDisiloxane

The invention relates to a method for preparing an organosilicon surfactant with a T-shaped structure for a pesticide. The method comprises the following steps: (1) preparation of hydrogen containing trisiloxane, in which, full containing hydrogen silicone oil, hexamethyl disiloxane and catalyst are added into a reactor, the temperature of the mixture is controlled to be between 10 and 100 DEG C with stirring, after reacting for 0.5 to 12 hours, the mixture is cooled, and then distilled and purified to prepare the hydrogen containing trisiloxane; and (2) synthesis of the organosilicon surfactant, in which, the hydrogen containing trisiloxane and allyl polyether are added into the reactor, are heated to a temperature of between 60 and 120 DEG C under stirring in nitrogen, catalyst platinum-allyl polyether is added into the reactor to react for 2 to 12 hours, and the mixture is devolatilized in vacuum for 30 minutes and is cooled to a room temperature to prepare the organosilicon surfactant. The method has a simple process, easy industrial production and high product purity without cross linked polymer impurities.

Owner:GUANGZHOU TINCI SILICONE TECHNOLOGY CO LTD

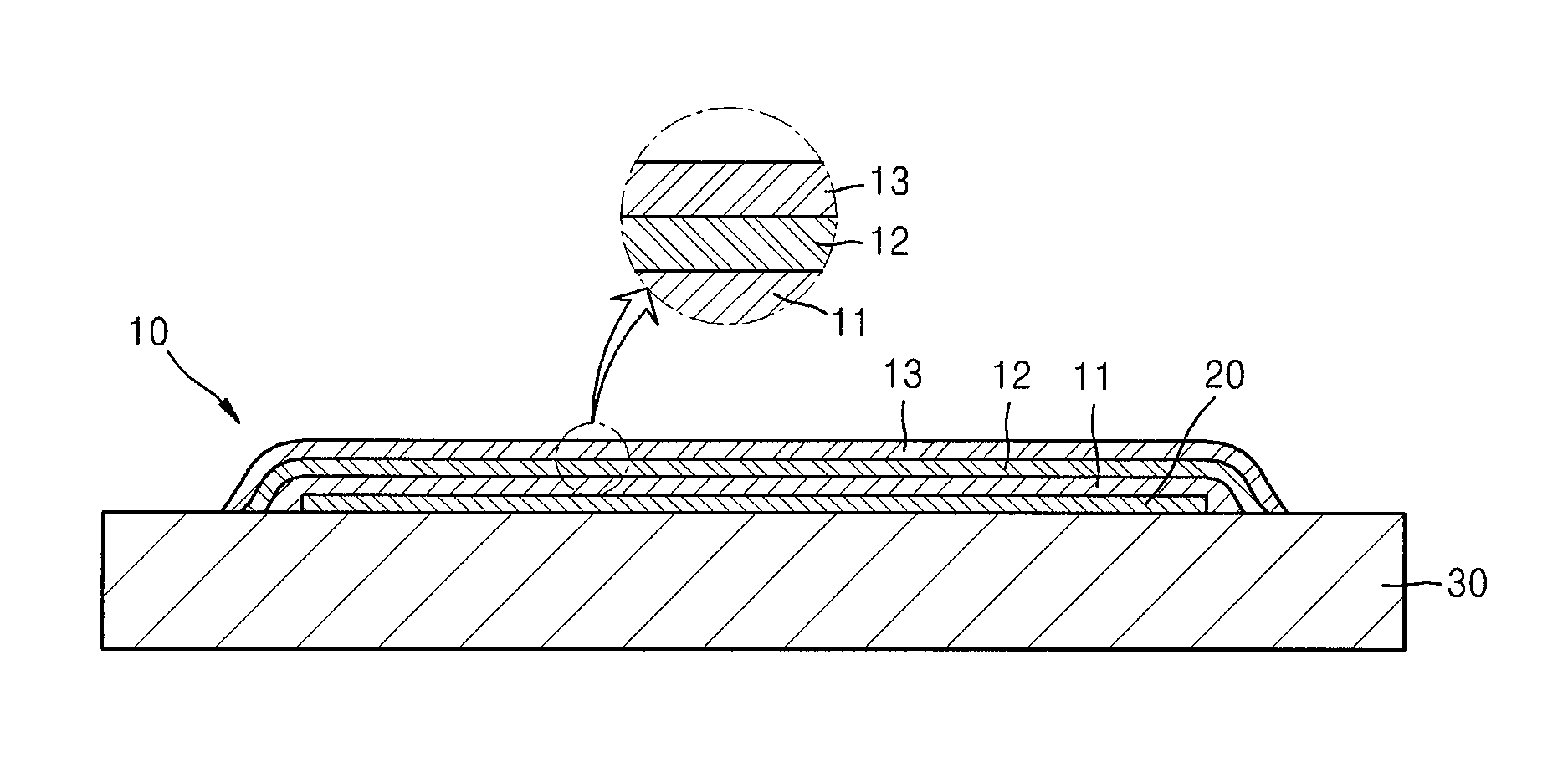

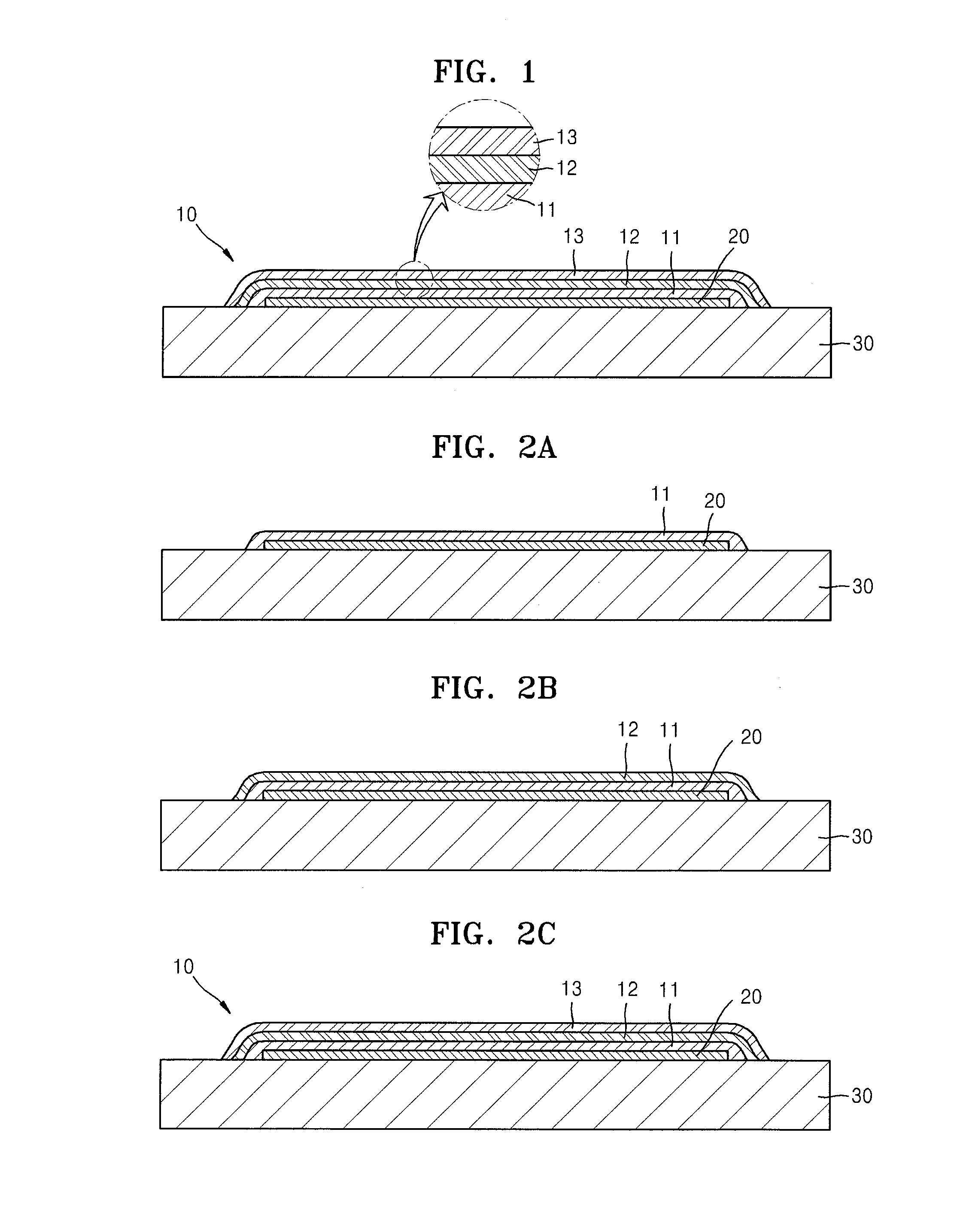

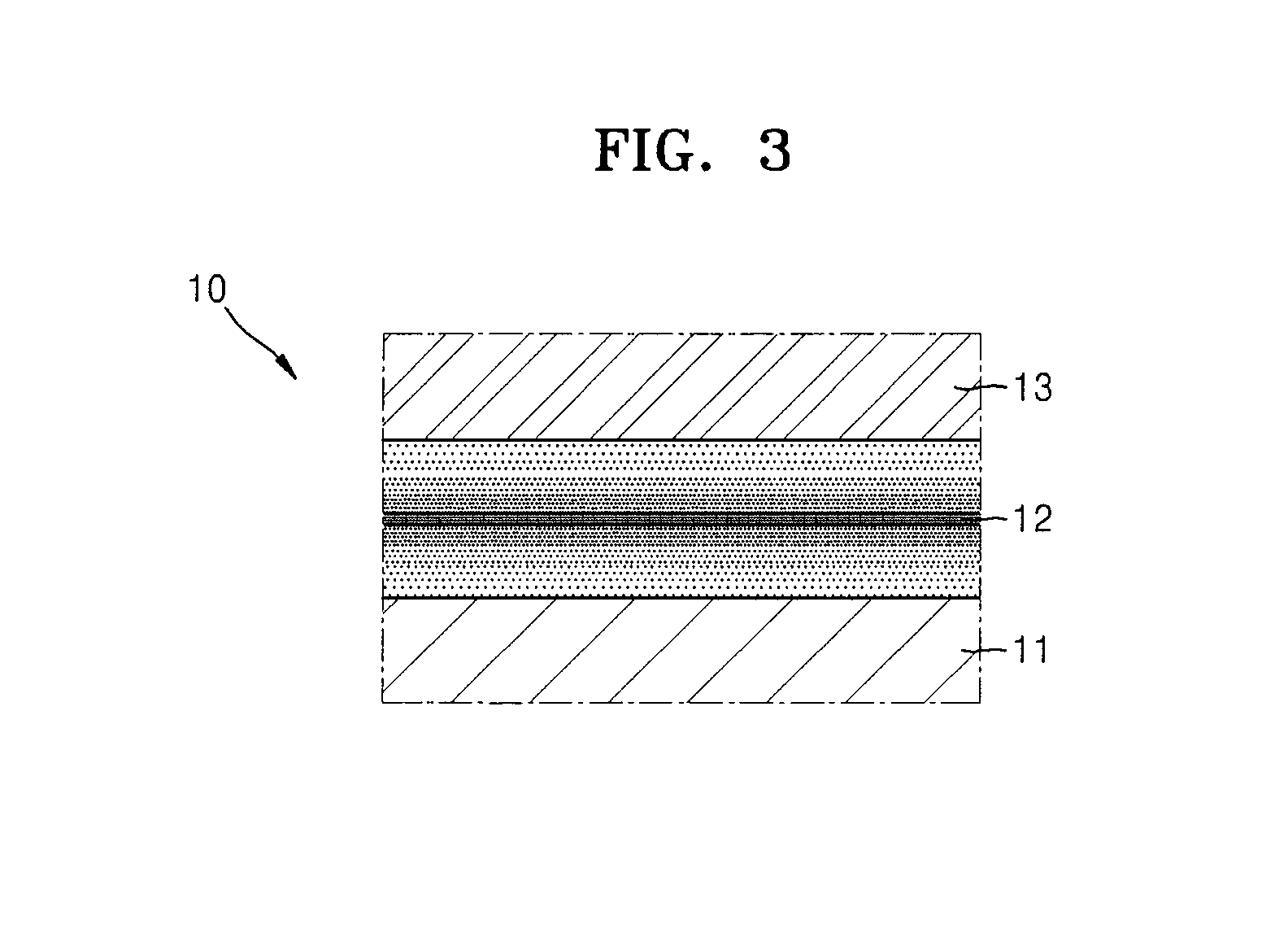

Thin film encapsulation for flat panel display device and method of manufacturing thin film encapsulation structure

ActiveUS8461760B1Reduced risk of crackingSimple manufacturing processDischarge tube luminescnet screensLayered productsEngineeringSingle chamber

Thin film encapsulation for a flat panel display device and a method of manufacturing the thin film encapsulation structure. The thin film encapsulation structure of the flat panel display device includes thin film layers covering a display unit formed on a substrate, wherein the thin film layers comprise a plurality of inorganic layers and a hexamethyldisiloxane (HMDSO) layer interposed between the inorganic layers. Accordingly, as multiple layers of the thin film encapsulation structure may be formed in a single chamber, the manufacturing process may be simplified, and also, as the HMDSO layer, which is flexible, absorbs stresses, a risk of cracks occurring may also be reduced.

Owner:SAMSUNG DISPLAY CO LTD

Long-chain alkyl phenyl modified hydrogen containing silicone oil releasing agent preparation method

InactiveCN104497312AImprove utilization efficiencyImprove conversion rateSilicon organic compoundsNitrogen gasAlpha-olefin

The invention discloses a long-chain alkyl phenyl modified hydrogen containing silicone oil releasing agent preparation method. The method includes the steps of subjecting tetramethyl tetra-hydrogen cyclotetrasiloxane and a catalyst of chloroplatinic acid to reaction, dropping styrene for reaction for some time, dropping long-chain alpha-olefin and a chloroplatinic acid isopropyl propanol solution to obtain an intermediate product of tetramethyl alkyl phenyl cyclotetrasiloxane, subjecting the obtained intermediate product of tetramethyl alkyl phenyl cyclotetrasiloxane, octamethylcyclotetrasiloxane, hexamethyldisiloxane and an acid catalyst to full reaction, fully cooling the obtained liquid, slowly adding calcium hydroxide to adjusting the PH value to 6-7, filtering out solids produced in neutralization with a vacuum pump, adding anhydrous magnesium sulfate to adsorb water produced in neutralization, and filtering to obtain a long-chain alkyl phenyl modified hydrogen containing silicone oil releasing agent. The long-chain alkyl phenyl modified hydrogen containing silicone oil releasing agent prepared through the preparation method has the advantages of being simple in process, high in efficiency, low in cost, short in cycle and the like.

Owner:仪征市新源新材料科技有限公司

Polyglycol modified trisilicate containing glucose amide group and preparation method

A polyethanediol modified trisiloxane containing glucosylamido used as the assistant of agricultural chemical to decrease the surface tension of water is prepared through catalytic reaction between hexamethyldisiloxane and aminosilane to obtain aminotrisiloxane, reacting on lactone gluconate in methanol to obtain trisiloxane containing glucosylamido, and modifying it by polyethanediol method glicideether.

Owner:CHINA RES INST OF DAILY CHEM IND

Synthesis method of quaternized organosilicon modified acrylate emulsion

The invention relates to a preparation method of a quaternized organosilicon modified acrylate emulsion. The method mainly comprises the processes of: (1) synthesizing amino silicone oil by putting otcamethylcyclotetrasiloxane, a double bond-containing silane coupling agent, N-beta-(aminoethyl)-gamma-aminopropylmethyldimethoxysilane, hexamethyldisiloxane, potassium hydroxide and deionized water in a reaction container for reaction at a temperature of 100-110DEG C; (2) adding an alkyl halide or epoxy alkyl halide for quaternization treatment at a temperature of 50-90DEG C, thus obtaining quaternized modified amino silicone oil; (3) adding an emulsifier, acrylate monomers and deionized water into the quaternized modified amino silicone oil obtained on step (2), and employing an oxidation-reduction initiating system for copolymerization reaction, thus obtaining a quaternized organosilicon modified acrylate emulsion. The product of the invention can be used for textile finishing, especially for acrylic fabric, and has good pilling resistance.

Owner:YANCHENG CHANGHUA OUTDOOR PROD CO LTD

Long chain alkyl modified silicon oil and synthetic process thereof

The invention relates to long-chain alkyl modified silicone oil which is obtained by the reaction of methyl hydric silicone material containing dense hydrogen and hexamethyl disiloxane and being modified by Alpha-alkene. The long-chain alkyl modified silicone oil can be applied as an excellent metal release agent. The invention also relates to a synthetic process of the long-chain alkyl modified silicone oil; wherein, under the protection of nitrogen, 65g to 222g of methyl hydric silicone oil intermediate product is added in a dripping manner to 123g to 308g of Alpha-alkene which is prepared by weight ratio and with a carbon length of 8 to 20 and the mixture reacts for 1 hour to 4 hours at the temperature of 100 DEG C to 120 DEG C; at the temperature of 110 DEG C to 150 DEG C and under a pressure lower than 0.01 MPa, the low-volatile substance is removed until the content of the low-volatile substance is less than 2 percent; and the long-chain methyl modified silicone oil is obtained.The invention adopts a platinum catalysts-isopropanol-acetylacetone-acetoacetate acetoacetic ester system which is conducive to rendering the reaction condition of the invention milder and the reaction time shorter. The method is easier and quicker to be operated.

Owner:JIANGXI BLUESTAR XINGHUO SILICONE CO LTD

Chemical crosslinking-curable phenyl MDQ-type silicone resin and preparation method thereof

ActiveCN102898648AImprove mechanical propertiesGood optical performancePolymer scienceMethyl palmoxirate

The invention relates to the field of organic polymer chemistry and provides a chemical crosslinking-curable phenyl MDQ-type silicone resin and a preparation method thereof. The chemical crosslinking-curable phenyl MDQ-type silicone resin solves the problem that the existing MDQ-type silicone resin has a low refractive index and is not cured by a chemical crosslinking method, and improves optical and mechanical properties of a silicone resin-reinforced rubber-type packaging material. Hexamethyldisiloxane and 1,3-divinyltetramethyldisiloxane as blocking agents, methylphenyldiethoxysilane as a D chain unit source and tetraethoxysilane as a Q chain unit source undergo a co-hydrolytic condensation reaction in the presence of an ethanol aqueous solution as a reaction solvent, toluene as an extractant and hydrochloric acid as a catalyst to produce the chemical crosslinking-curable phenyl MDQ-type silicone resin. The chemical crosslinking-curable phenyl MDQ-type silicone resin improves mechanical properties of a MDQ-type silicone resin-reinforced rubber-type packaging material and improves optical properties of the rubber-type packaging material. The preparation method has mild reaction conditions, has simple processes and is suitable for large-scale industrial production.

Owner:XINYAQIANG SILICON CHEM JIANGSU

Preparation method of reactive MQ silicon resin

The invention discloses a preparation method of reactive MQ silicon resin. The method comprises the following steps of: (1) hydrolyzing and condensing siloxane, alkoxy silane and a homopolymer thereof; (2) leaching a product prepared in the step (1) with a weak-polar or non-polar solvent; (3) washing the product with an aqueous solution to a neutral state; and (4) distilling and concentrating at reduced pressure to obtain the reactive MQ silicon resin, wherein an M unit of the reactive MQ silicon resin in the step (1) contains hexamethyldisiloxane, divinyl tetramethyl disiloxane, tetramethyldisiloxane, 1,1,3,3-tetramethyl-1,3 diphenyldisiloxane, 1,3-diethyl-1,1,3,3-tetramethyldisiloxane or a mixture thereof; a Q unit of the reactive MQ silicon resin contains tetramethyl silicate, tetraethoxysilane, tetraisopropoxidesilane, tetrabutoxysilane, tetrakis(butoxyethoxy)silane and a mixture of homopolymers thereof; the solution in the step (3) consists of a methanol aqueous solution, an ethanol aqueous solution, an isopropanol aqueous solution, a normal butanol aqueous solution, an isobutyl alcohol aqueous solution or a mixed aqueous solution thereof; and the mass fraction of the solution is 30-80.

Owner:ZHONGKAI UNIV OF AGRI & ENG

Method for preparing fiber-reinforced silicon dioxide aerogel

ActiveCN107337424AExpand production channelsSimple manufacturing processSilicon compoundsGlass fiberFiber

The invention discloses a method for preparing fiber-reinforced silicon dioxide aerogel. The method comprises the following steps: mixing metasilicic acid butyl ester, tertiary butanol and water according to a ratio, adjusting the pH value through hydrochloric acid and ammonium hydroxide, and compounding with a glass fiber felt so as to obtain wet fiber-reinforced silicon dioxide gel; performing soaking modification with trimethylchlorosilane and hexamethyldisiloxane, and further performing CO2 supercritical drying, so as to obtain hydrophobic fiber-reinforced silicon dioxide aerogel. Novel gel raw materials are used, the channel for preparation of aerogel is further widened, the preparation cost is lowered, moreover, excellent product quality is achieved.

Owner:HUNAN TIANXIN TECH CO LTD

Method for synthesizing hexamethyldisilazane

ActiveCN102766155AReduce manufacturing costAvoid hydrolysis side reactionsGroup 4/14 element organic compoundsBis(trimethylsilyl)amineSolvent

The invention relates to a method for synthesizing hexamethyldisilazane. The hexamethyldisilazane is synthesized by a mixed solvent method through one-step ammoniation reaction, the hydrolysis side reaction of the hexamethyldisilazane can be inhibited by adding hexamethyldisiloxane into a reaction system, and reaction yield is improved. By the method, the yield is high, reaction time is short, energy consumption during rectification is low, the production cost of the hexamethyldisilazane is reduced, and the large advantage of industrialization is achieved.

Owner:鲁南新时代生物技术有限公司

High-flame-retardancy paint

InactiveCN106366740AHigh tensile strengthImprove adsorption capacityFireproof paintsPolyurea/polyurethane coatingsWater basedDimethyl methylphosphonate

The invention discloses a high-flame-retardancy paint which is prepared from a water-based acrylate emulsion, a water-based polyurethane resin, aluminasol, an epoxy resin, polydimethylsiloxane, zinc oxide, hollow glass microspheres, nano zirconium oxide, montmorillonite, nano silicon dioxide, a film forming aid, a defoaming agent, a leveling agent, a wetting agent, a flame retardant and water. The flame retardant is formed by mixing boron oxide, dimethyl methyl phosphonate, phosphorus pentoxide, tri(2-chloropropyl) phosphate, guanylurea phosphate, ammonium polyphosphate, pentaerythritol, melamine and hexamethyl disiloxane. The high-flame-retardancy paint has the advantages of favorable water resistance, favorable wear resistance, excellent flame retardancy and long service life.

Owner:ANHUI JINDUN PAINT

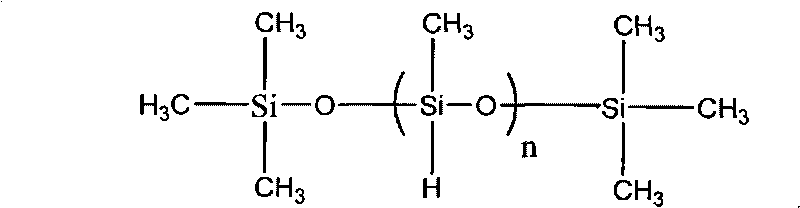

Preparation method for low hydrogen-containing silicon oil

The invention relates to the technical field of chemical engineering, in particular to a preparation method for low hydrogen-containing silicon oil. The preparation method adopts high hydrogen-containing silicon oil (202) and dimethylcyclosiloxane (DMC) as raw materials and hexamethyldisiloxane (MM) as an end-capping agent, under the catalysis of a solid superacid, the temperature is increased to 50-140 DEG C for a telomerization, and the low hydrogen-containing silicon oil is prepared. Compared with the prior art for preparing the low hydrogen-containing silicon oil under the catalysis of vitriol, the preparation method adopts the solid superacid as a catalyst, the catalyst has a good catalysis effect and can be reused, neutralization and washing are not required during the preparation method, and short time is taken by the whole preparation process, continuous method industrial production is likely to be achieved, and the production efficiency is high.

Owner:蓝星安迪苏股份有限公司

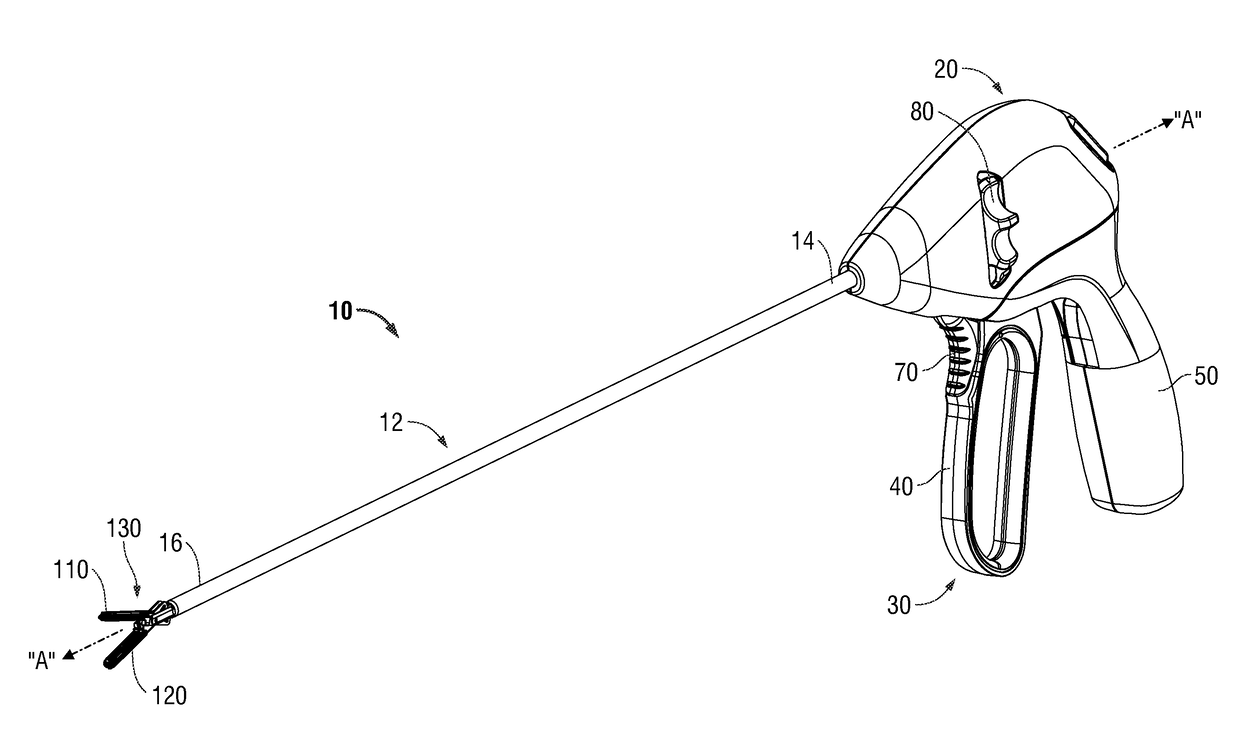

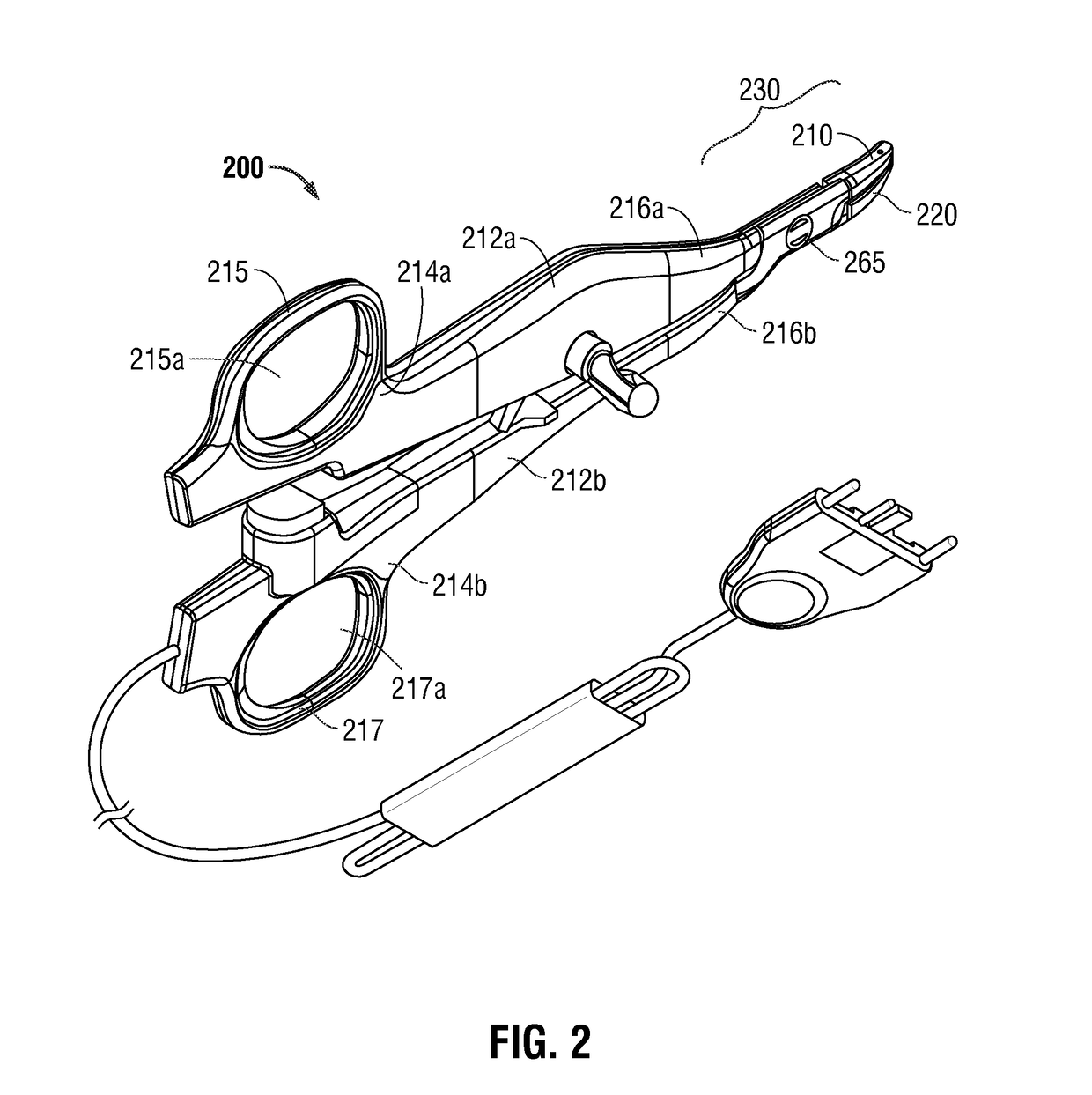

Non-stick coated electrosurgical instruments and method for manufacturing the same

An end effector assembly for use with an electrosurgical instrument is provided. The electrosurgical instrument includes a handle having a shaft that extends therefrom, an end effector disposed at a distal end of the shaft, at least one electrode operably coupled to the end effector and adapted to couple to a source of electrosurgical energy, a chromium nitride coating covering at least a portion of the electrode, and a hexamethyldisiloxane plasma coating covering at least a portion of the chromium nitride coating.

Owner:TYCO HEALTHCARE GRP LP

Organosilicon fire retardant for ABS and preparation method thereof

The invention relates to an organosilicon fire retardant for ABS and a preparation method thereof. The invention provides an organosilicon fire retardant for ABS with good consistency with ABS, small mechanical properties influence on ABS, less addition, excellent flame retardation performance and other characteristics and provides a preparation method of the organosilicon fire retardant for ABS.The organosilicon fire retardant of ABS is a polymer. Under a condition of nitrogen protection, dimethyl siloxane cycle, aminosilane, trialkoxy silane and catalyst undergo a reaction with hexamethyldisiloxane as an end-capping reagent at a temperature of 80 to 140 DEG C. After the reaction, a low-boiling-point substance is extracted by pressure reduction and the organosilicon fire retardant product for ABS can be obtained.

Owner:XIAMEN UNIV

Quaternized organic silicone oil and preparation method thereof

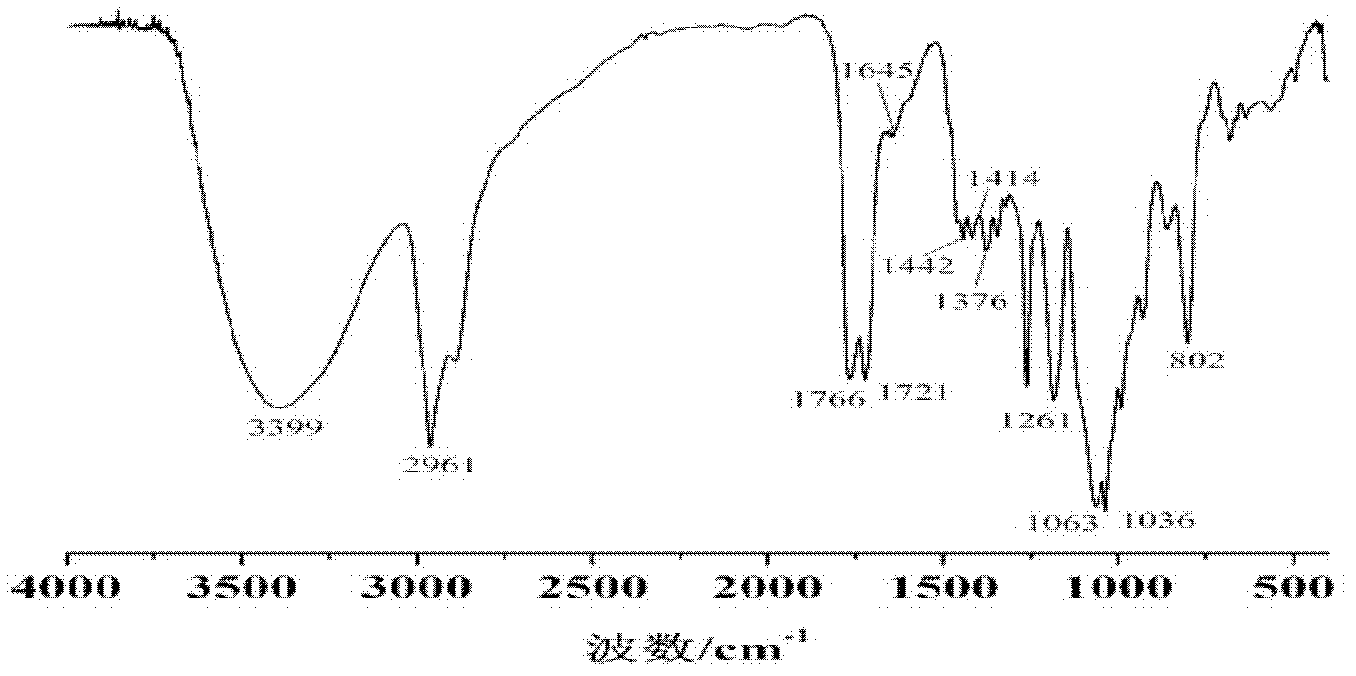

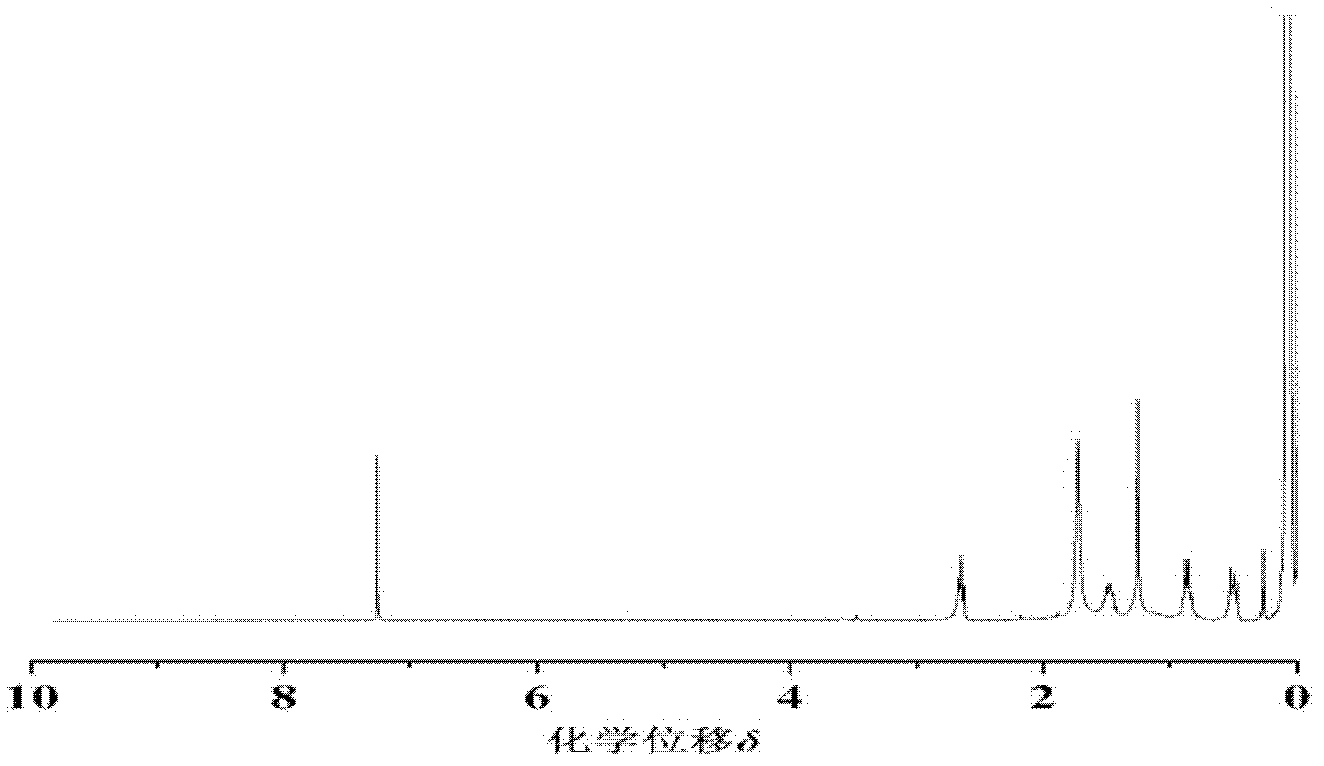

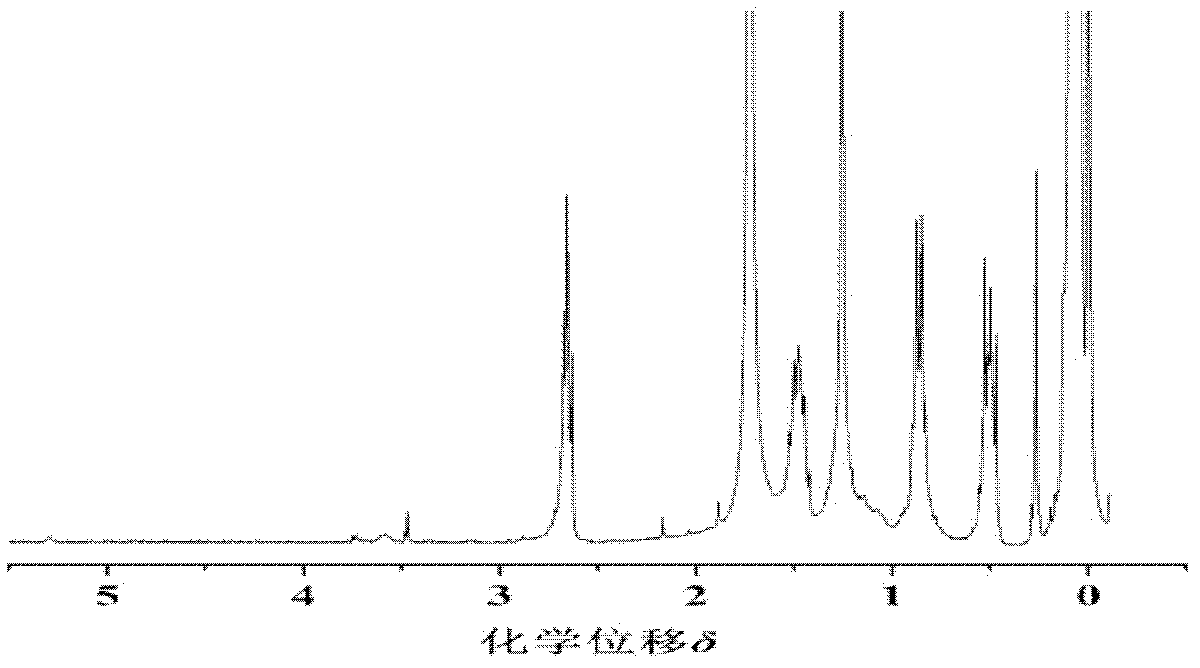

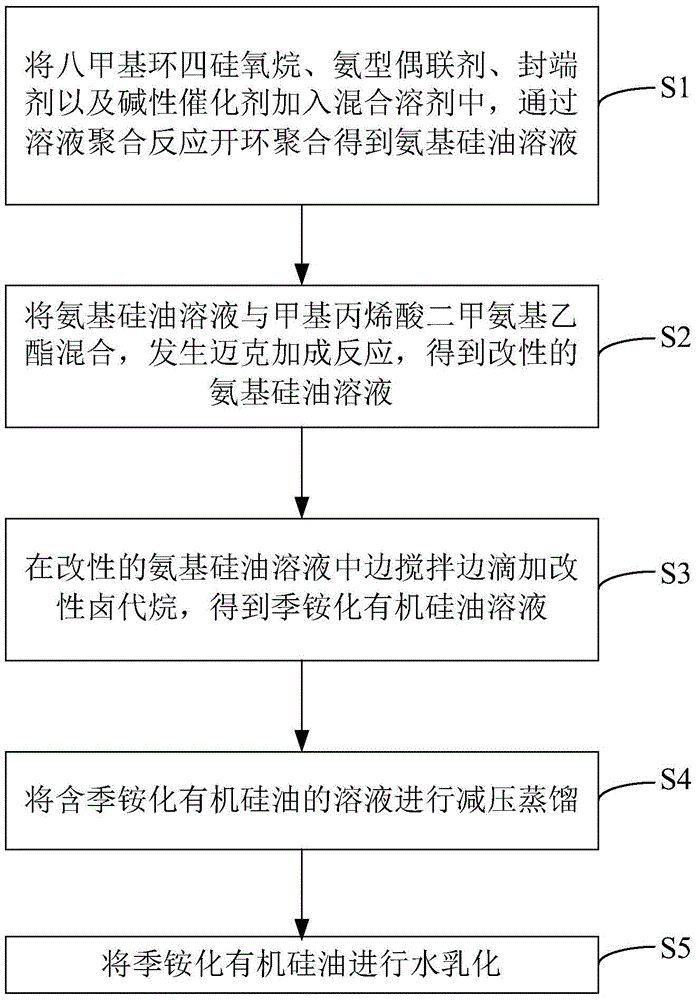

The invention relates to quaternized organic silicone oil and a preparation method thereof. The preparation method comprises the following steps: (1) adding octamethylcyclotetrasiloxane, an ammonia type coupling agent and an alkali catalyst into a mixed solvent, using hexamethyldisiloxane as an end-capping agent, and conducting ring opening polymerization through solution polymerization reaction so as to obtain an amino silicon oil solution; (2) adding dimethylaminoethyl methacrylate, and enabling Michael addition reaction so as to obtain the modified amino silicon oil solution; (3) adding alkyl halide, conducting quaternization reaction, and conducting reduced pressure distillation to remove the mixed solvent so as to obtain the quaternized organic silicone oil; (4) conducting water emulsification on the quaternized organic silicone oil. According to the quaternized organic silicone oil and the preparation method thereof, not only can the obtained quaternized organic silicone oil be self-emulsified, but also no emulsifying agent needs to be added when in water emulsification, influence exerted on performance of adhesive force, water resistance, scrubbing resistance and the like can be avoided, and the quaternized organic silicone oil has antibacterial performance and an obvious color-deepening effect on dark-color polyester fabric when being used as a color-deepening finishing agent.

Owner:科凯精细化工(上海)有限公司

Process for synthesizing iodotrimethylsilane

ActiveCN1962668AEliminate side effectsConvenient post-processingGroup 4/14 element organic compoundsSilanesCopper

The invention discloses a synthesizing method of trimethyl iodine silane, which comprises the following steps: adding aluminium, hexamethyldisilazane and iodine in the autoclave; distilling; obtaining the rough product of trimethyl iodine silane; placing rough product in the distilling autoclave; adding copper powder; heating; collecting fraction; obtaining the refined product.

Owner:扬州三友合成化工有限公司

Mercaptopropyl polysiloxane with photoreaction activity and preparation method thereof

The invention discloses mercaptopropyl polysiloxane with photoreaction activity and a preparation method thereof. Mercaptopropyl polysiloxane is polysiloxane molecules containing mercaptopropyl chain segments, phenyl chain segments and dialkyl chain segments. The preparation method of mercaptopropyl polysiloxane comprises the steps that hexamethyldisiloxane and silane with different substituent groups are subjected to a cohydrolysis-polycondensation reaction under the acidic condition to generate mercaptopropyl polysiloxane. Silane with different substituent groups is a mixture of mercaptopropyl silane, phenyl silane and dialkyl silane or tetramethoxysilane, prepared mercaptopropyl polysiloxane, silicone rubber, epoxy resin, acrylate resin and other materials can have good compatibility by controlling and adjusting the relative content of the mercaptopropyl chain segments, the phenyl chain segments and the dialkyl chain segments, mercaptopropyl polysiloxane can be used for cross-linking and curing of the materials, an optically transparent composite is prepared, the mechanical performance of the material can be improved, the photocuring reaction speed is high, and mercaptopropyl polysiloxane can be used for the fields of electronic packaging materials, optical materials, 3D printing consumables and the like.

Owner:GUANGDONG UNIV OF TECH

SiO2 composite aerogel material loaded with photocatalyst and preparation method of SiO2 composite aerogel material

ActiveCN104689784AIncrease depositionAvoid adverse reactionsOther chemical processesAlkali metal oxides/hydroxidesAlkaneAlcohol

The invention relates to a SiO2 composite aerogel material loaded with a photocatalyst and a preparation method of the SiO2 composite aerogel material, and belongs to the technical field of adsorption / photocatalytic materials. The preparation method of the SiO2 composite aerogel material loaded with the photocatalyst comprises the step of preparing composite gel: dipping SiO2 gel into photocatalyst sol or solution to obtain photocatalyst / SiO2 composite gel; carrying out deposition aging treatment on the obtained photocatalyst / SiO2 composite gel by utilizing alkyl organic solvents, wherein the alkyl organic solvents are hexamethyldisiloxane, alcohol and alkane solvents, and the alkyl organic solvents are respectively hexamethyldisiloxane, alcohol (such as ethanol or isopropanol) and alkane (such as n-hexane or heptane) solvents; then carrying out surface modification and ambient pressure drying to obtain a photocatalyst / SiO2 composite aerogel material; and the prepared photocatalyst / SiO2 composite aerogel is of a mesoporous structure, with a pore diameter of 8-20 nm, a specific surface area of 200-700 m<2> / g, and a pore volume of 0.5-2.0 cm<3> / g.

Owner:DALIAN POLYTECHNIC UNIVERSITY

High performance polyurethane paint

InactiveCN106318181AImprove water resistanceHigh mechanical strengthFireproof paintsAntifouling/underwater paintsWater basedPolymer science

The invention discloses a high performance polyurethane paint. The high performance polyurethane paint is prepared from water-based polyurethane resin, water-based acrylic emulsion, bisphenol F epoxy resin, toluene diisocyanate, zinc oxide, silicon carbide, zinc stannate, expanded graphite, calcined kaolin, nano titanium dioxide, calcium chloride, coalescing agents, (2, 3-dibromo) boron n-propoxide, hexahydro-1, 3, 5-tris(hydroxyethyl)-s-triazine, modified silica sol, tetrahydro perfluorinated trichlorodecyl-silan, silver stearate, hexamethyldisiloxane, Gamma-isocyanate propyl triethoxy silane, hydroxyl-terminated polybutadiene liquid rubber, defoaming agent, wetting agent, and water. The high performance polyurethane paint has good water resistance and wear resistance, and excellent flame retardant performance.

Owner:ANHUI JINDUN PAINT

Hydrogen-containing MQ silicon resin and preparation method thereof

The invention provides a hydrogen-containing MQ silicon resin with a general formula of [(CH3)2HSiO1 / 2]a[(CH3)3SiO1 / 2]b[SiO2]c, wherein M / Q is 0.6-0.9. The invention also provides a preparation method of the hydrogen-containing MQ silicon resin, comprising the following steps: uniformly mixing and stirring a monofunctional monomer, a catalyst, water and a cosolvent, wherein the monofunctional monomer comprises tetramethyldisiloxane and hexamethyldisiloxane, and the catalyst is acid; adding tetraethoxysilane at room temperature in five minutes with vigorous stirring, and reacting for 1-3 hours; and then neutralizing with an alkali, extracting with an extracting agent for layering, and performing reduced pressure dehydration on an extract to obtain the hydrogen-containing MQ silicon resin. By adopting the preparation method disclosed by the invention, the hydrogen-containing MQ resin is prepared by using a tetraethoxysilane method, various powdery and fluidic MQ resins and an MQ resin with different H contents can be prepared by adjusting M / Q, and the hydrogen-containing MQ silicon resin is mainly used for crosslinking agents and reinforcing agents containing molding rubber, can achieve a satisfactory effect, and has the advantages of convenience in operation, readily available raw materials, easy control, short time and the like.

Owner:深圳市红叶杰科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com