Organosilicon fire retardant for ABS and preparation method thereof

A flame retardant and organosilicon technology, which is applied in the field of flame retardants, achieves the effects of simple preparation process, small change in mechanical properties, and small addition amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

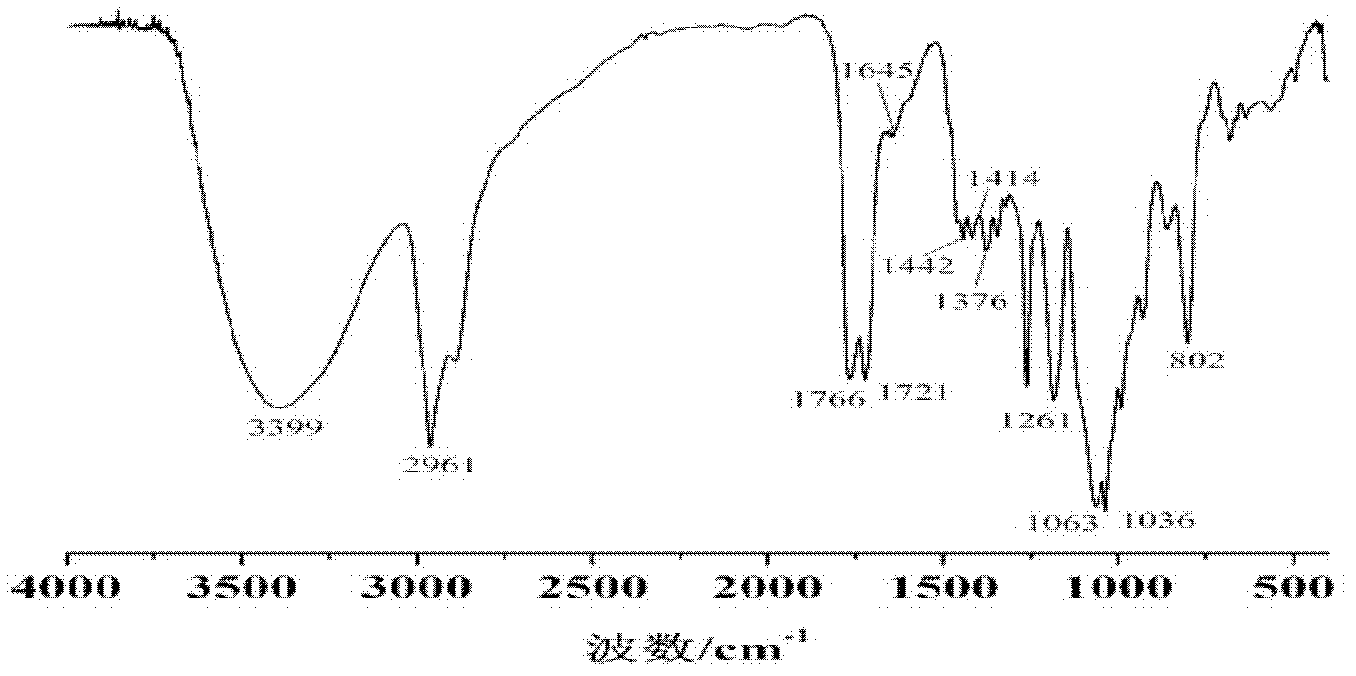

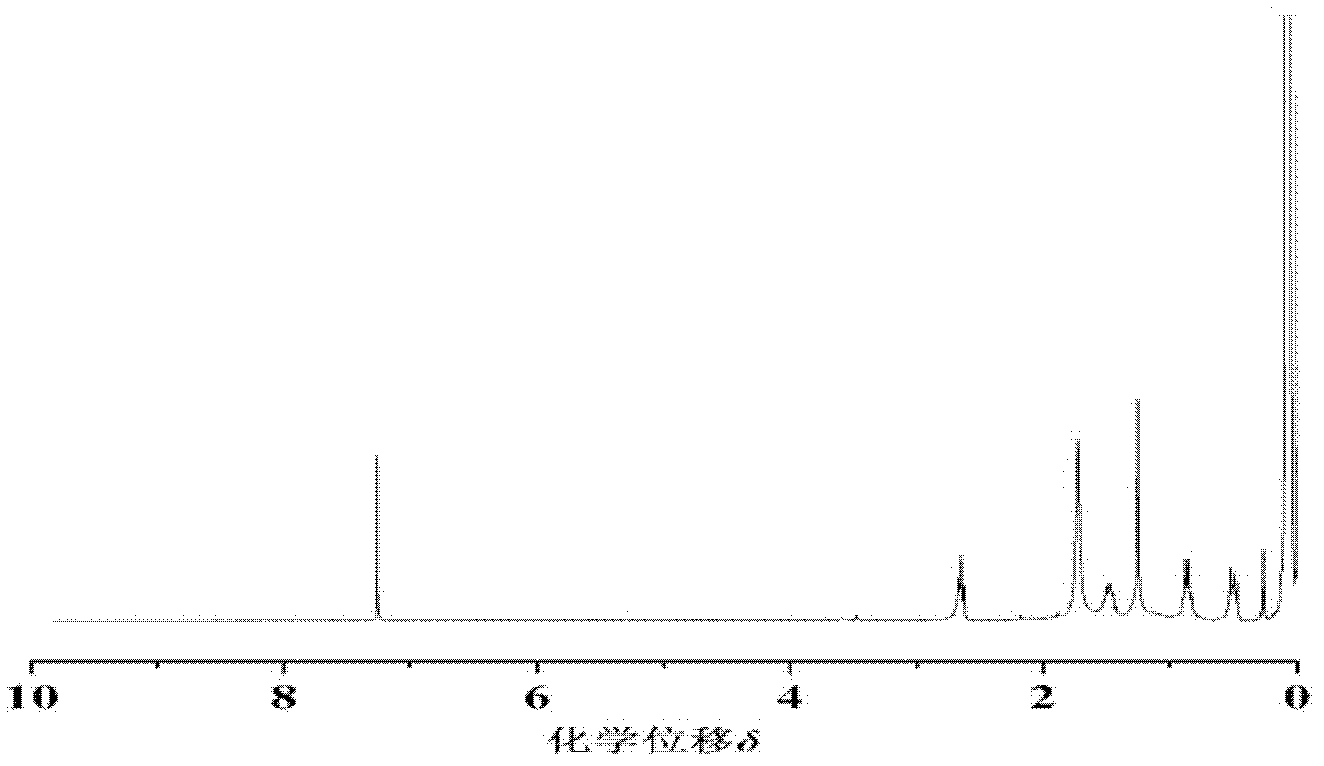

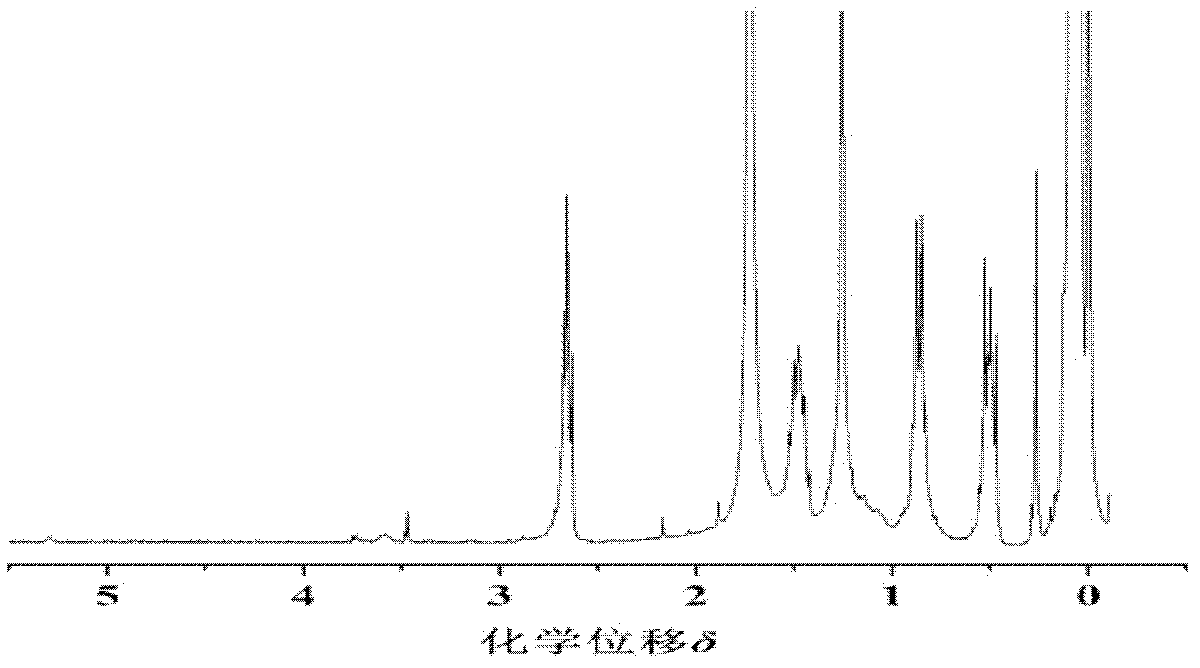

[0027] 500ml dry four-necked flask equipped with mechanical stirring, thermometer, reflux condenser and N 2 Conduit, add 96g dimethylsiloxane mixed ring (DMC), 13.75g γ-aminopropylmethyldiethoxysilane (KH-902), 0.60g γ-methacryloxypropyl trimethoxy Silane (KH-570) and 0.50g of hexamethyldisiloxane and 0.055g of potassium hydroxide were equilibrated at 110°C for 3h, then heated to 135°C for 1h, and the remaining monomers were extracted under reduced pressure to obtain silicone flame retardant.

Embodiment 2

[0029] 500ml dry four-necked flask equipped with mechanical stirring, thermometer, reflux condenser and N 2 Catheter, add 96g dimethylsiloxane mixed ring (DMC), 12.5g N-β-aminoethyl-γ-aminopropylmethyldimethoxysilane (KH-602), 0.60g γ-methylpropene Acyloxypropyltrimethoxysilane (KH-570) and 0.50g hexamethyldisiloxane and 0.055g potassium hydroxide were equilibrated at 110°C for 3h, then heated to 135°C and kept for 1h, then extracted under reduced pressure The remaining monomers are used to obtain silicone flame retardants for ABS.

Embodiment 3

[0031] 500ml dry four-necked flask equipped with mechanical stirring, thermometer, reflux condenser and N 2 Conduit, add 96g dimethylsiloxane mixed ring (DMC), 13.75g gamma-aminopropylmethyldiethoxysilane (KH-902), 0.42g vinyltrimethoxysilane and 0.50g hexamethyl Disiloxane and 0.06g sodium hydroxide, react at 110°C for 3 hours, then raise the temperature to 135°C and keep it for 1 hour. After the reaction, the remaining monomer is extracted under reduced pressure to obtain a slightly milky white liquid silicone for ABS flame retardant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com