Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

92results about How to "Improved anti-pilling properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antibacterial, safe, moisture absorbing and quick-drying fabric and production method thereof

ActiveCN104278421AGood skin affinityBump effect is prominentWeft knittingFibre treatmentYarnPolyester

The invention discloses an antibacterial, safe, moisture absorbing and quick-drying fabric and a production method thereof. The fabric is woven from first yarns, second yarns and third yarns, wherein the first yarns are pure cotton fiber yarns or cotton fiber type blended yarns, and the cotton fiber type blended yarns are yarns formed by blending of cotton fibers and one or several of jute fibers, polyester fibers, polyacrylonitrile fibers and polyarmide fibers; the second yarns are modified polyester fiber yarns with non-circular cross sections where nano silver ions are guided or modified polyester fiber type blended yarns with non-circular cross sections, and the modified polyester fiber type blended yarns are yarns blended by the modified polyester fibers with nano silver ions guided in and regenerated cellulose fibers; the third yarns are polyurethane fiber yarns. The fabric is good in antibacterial, moisture absorbing and quick-drying performance and excellent in safety. Meanwhile, the production method is simple in operation and applicable to large-scale industrial production.

Owner:武汉爱帝针纺实业有限公司

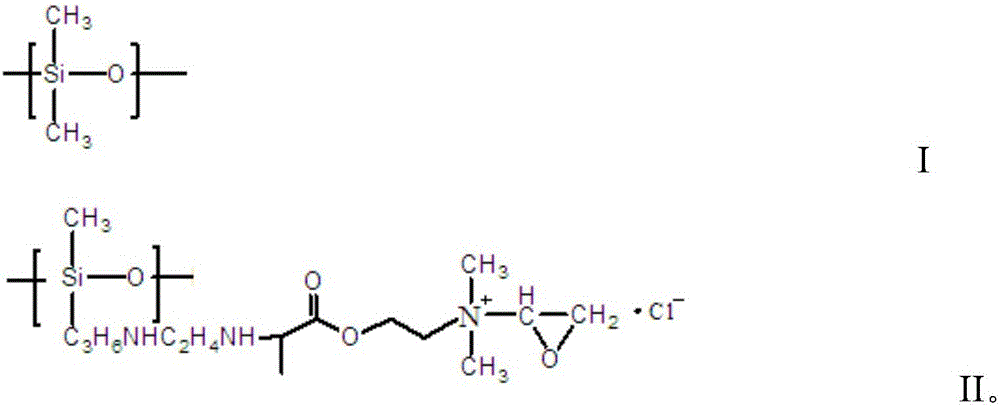

Synthesis of epoxy quaternised modified amino-silicone oil

InactiveCN101367941AImprove hydrophilicityImproved anti-pilling propertiesFibre treatmentEpoxyPotassium hydroxide

The invention relates to a method for synthesizing epoxy quaternization modified amino-silicone oil, pertaining to the technical field organic silicide amino-silicone oil preparation. The method includes the following main procedures: (1) synthesis of amino-silicone oil: the raw material of octamethylcy-clotetrasiloxane (D4 linear body), N-Beta-aminoethylGemma- aminopropylmethyldimethyoxysilane (KH-602), hexamethyl dimethyl siloxane (MM), catalyst potassium hydroxide and deionized water are placed in a reactor for reaction for 5-6 hours under 100-110 DEG C, and the desired amino-silicone oil is achieved after being cooled; (2) proper amount of epichlorohydrin is added for reaction under 80 DEG C, the amino-silicone oil is processed by epoxy quaternization to achieve epoxy quaternary ammonium salt amino-silicone oil; (3) the quaternary ammonium salt amino-silicone oil is emulsified by deionized water, water is slowly added under 85 DEG C and stirred, and the water miscible liquid of epoxy quaternization modified amino-silicone oil is finally achieved. The product achieved by the method is applicable to textile fabric neatening and has pilling resistant and fluffing resistant properties.

Owner:SHANGHAI UNIV

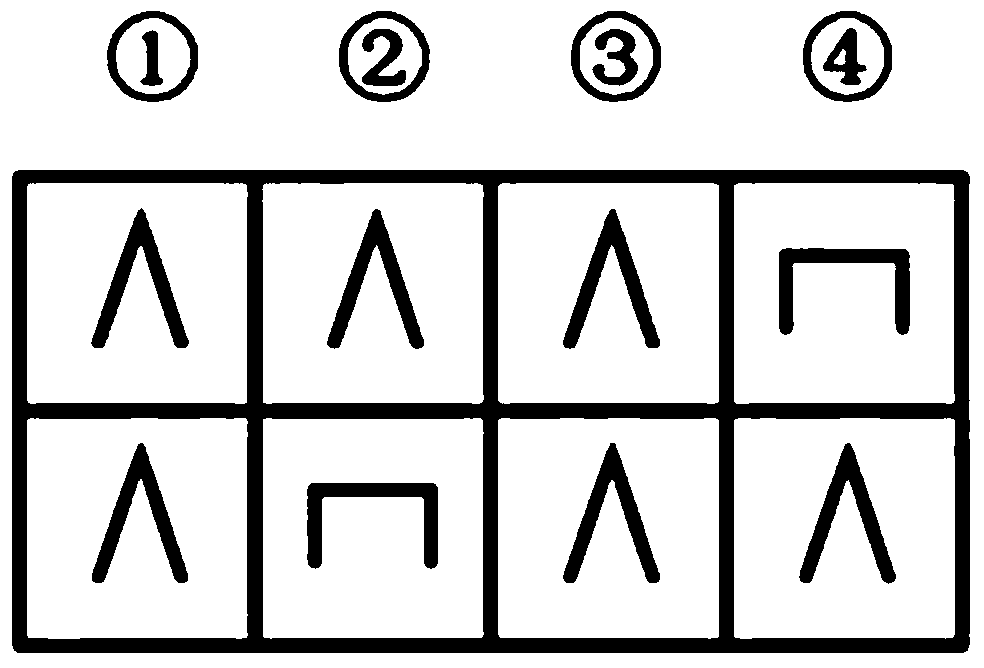

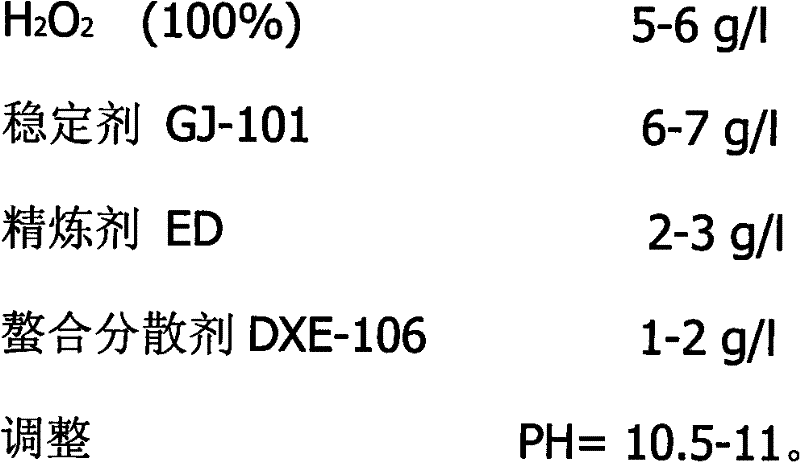

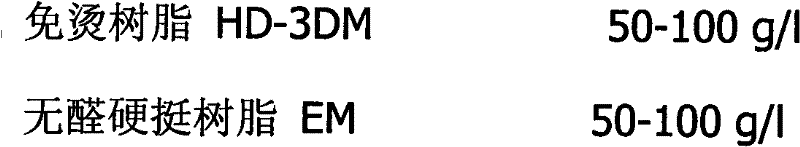

New anti-fluffing and anti-pilling technology for polyester-cotton fabric under special standards

ActiveCN102561040AImprove refining effectReduce slipMercerising of indefinite length fabricsFibre treatmentPolyesterEngineering

The invention relates to the technical field of dyeing and finishing production of polyester-cotton anti-fluffing and anti-pilling fabrics. A new anti-fluffing and anti-pilling technology for a polyester-cotton fabric under special standards comprises the following steps of: (1) grey cloth seam turning, (2) primary singeing, (3) flat bleaching, (4) secondary singeing, (5) sizing, (6) mercerizing, (7) dyeing (dispersion / reduction), (8) finishing with a compound solution of ironing-free resin and an anti-fluffing and anti-pilling agent, (9) baking, (10) tentering, (11) pre-shrinking, (12) inspection, and (13) formation of a finished product. The product prepared by the technology meets the special quality requirement of customers for washing for 5 times, 30 minutes in each time, in hot water at 92 DEG C, the anti-fluffing and anti-pilling quality index of the fabric is detected, and the anti-fluffing and anti-pilling quality index of the product for clothes reaches the export standard, namely level 3-4.

Owner:辽宁宏润源印染有限公司

Bulk blended yarn and production method thereof

The invention discloses a bulk blended yarn and a production method thereof. The bulk blended yarn is a staple fiber yarn having a skin core structure, wherein the staple fiber yarn is obtained by removing water-soluble polyvinyl alcohol fibers through dissolving, and the staple fiber yarn is formed by at least high shrinkage staple fibers and common staple fibers; meanwhile, the filling power of the bulk blended yarn is up to 90 % and more. The obtained bulk blended yarn is characterized in light weight and warm-keeping; the filling power is stable and durable; the bulk blended yarn is suitable for making sweaters, underwear, blankets, and the like.

Owner:东丽国际贸易(中国)有限公司

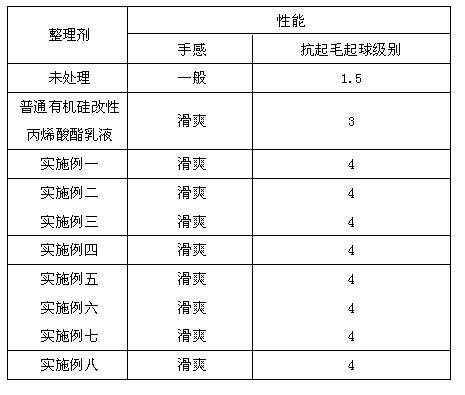

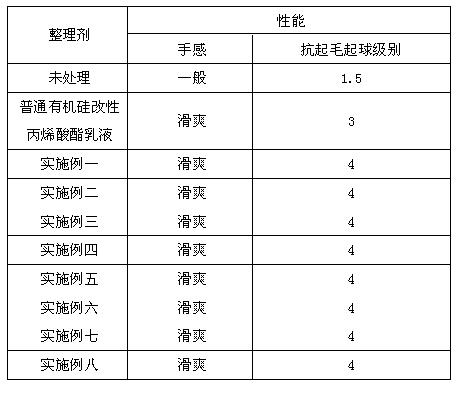

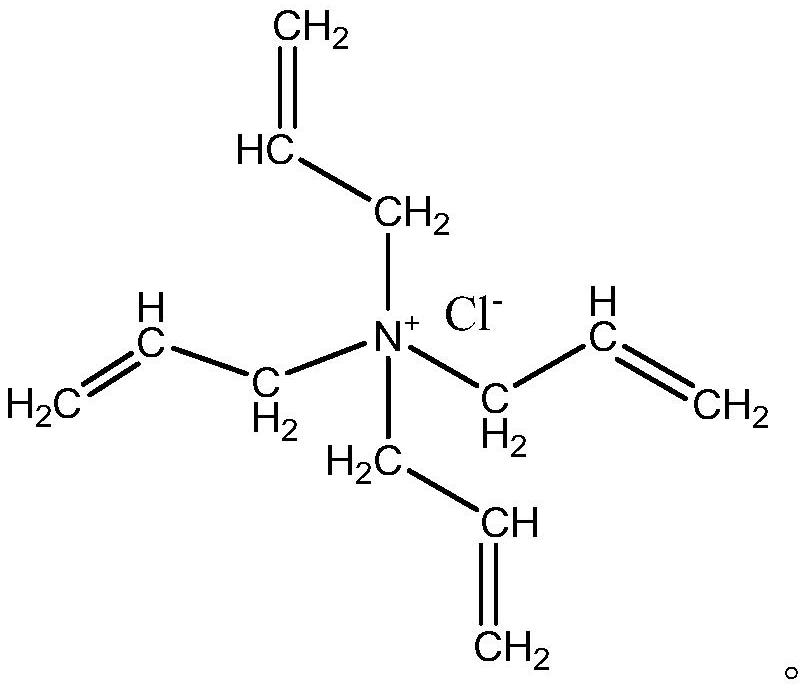

Synthesis method of quaternized organosilicon modified acrylate emulsion

The invention relates to a preparation method of a quaternized organosilicon modified acrylate emulsion. The method mainly comprises the processes of: (1) synthesizing amino silicone oil by putting otcamethylcyclotetrasiloxane, a double bond-containing silane coupling agent, N-beta-(aminoethyl)-gamma-aminopropylmethyldimethoxysilane, hexamethyldisiloxane, potassium hydroxide and deionized water in a reaction container for reaction at a temperature of 100-110DEG C; (2) adding an alkyl halide or epoxy alkyl halide for quaternization treatment at a temperature of 50-90DEG C, thus obtaining quaternized modified amino silicone oil; (3) adding an emulsifier, acrylate monomers and deionized water into the quaternized modified amino silicone oil obtained on step (2), and employing an oxidation-reduction initiating system for copolymerization reaction, thus obtaining a quaternized organosilicon modified acrylate emulsion. The product of the invention can be used for textile finishing, especially for acrylic fabric, and has good pilling resistance.

Owner:YANCHENG CHANGHUA OUTDOOR PROD CO LTD

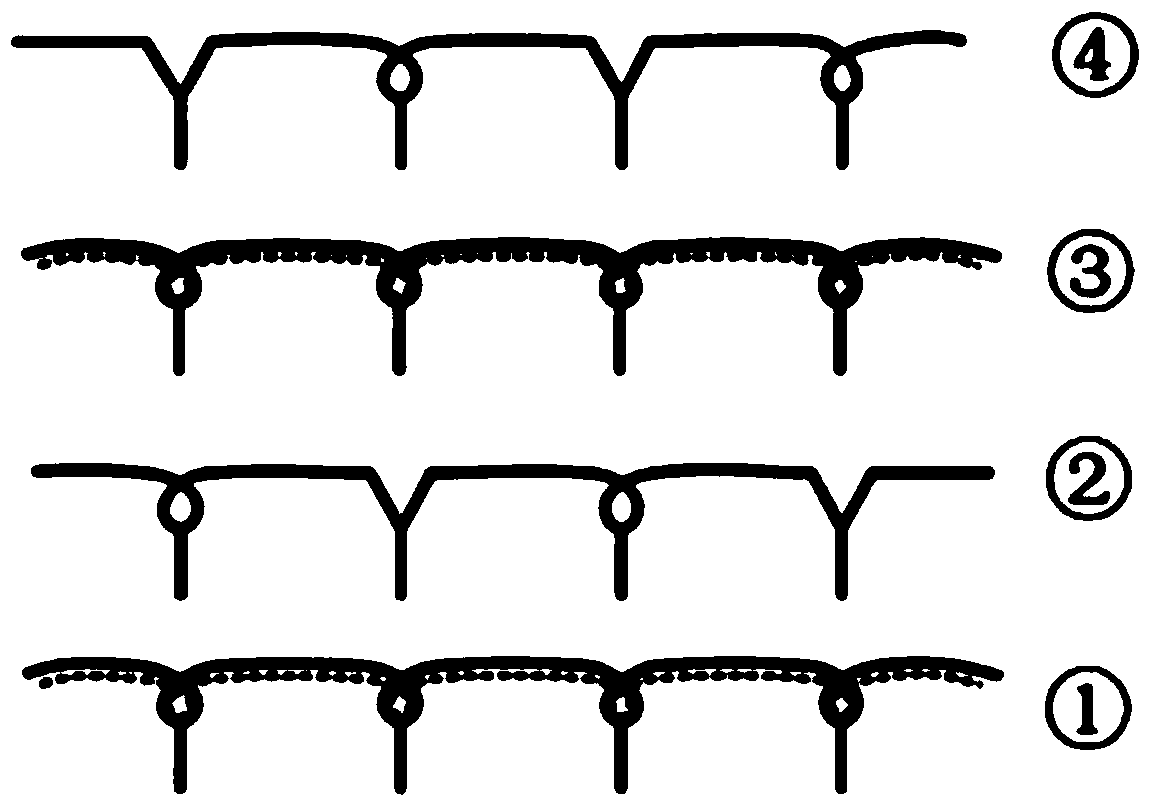

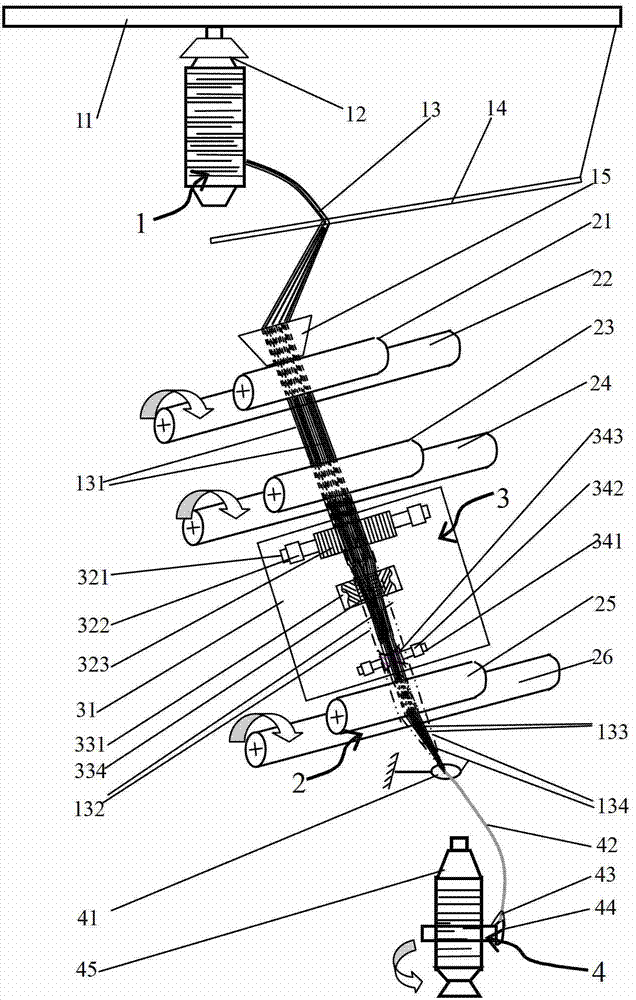

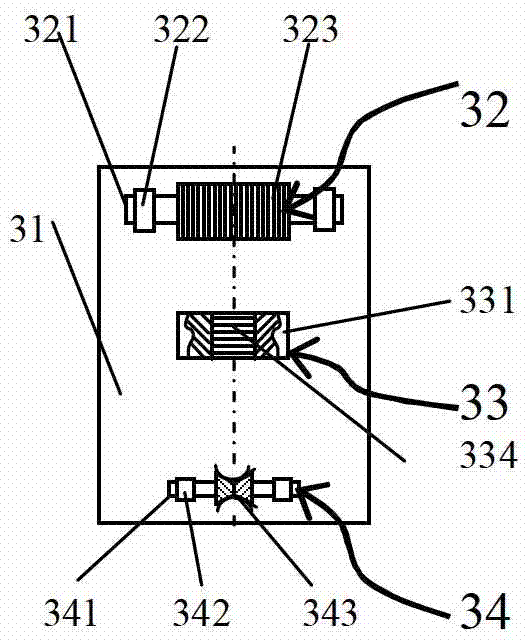

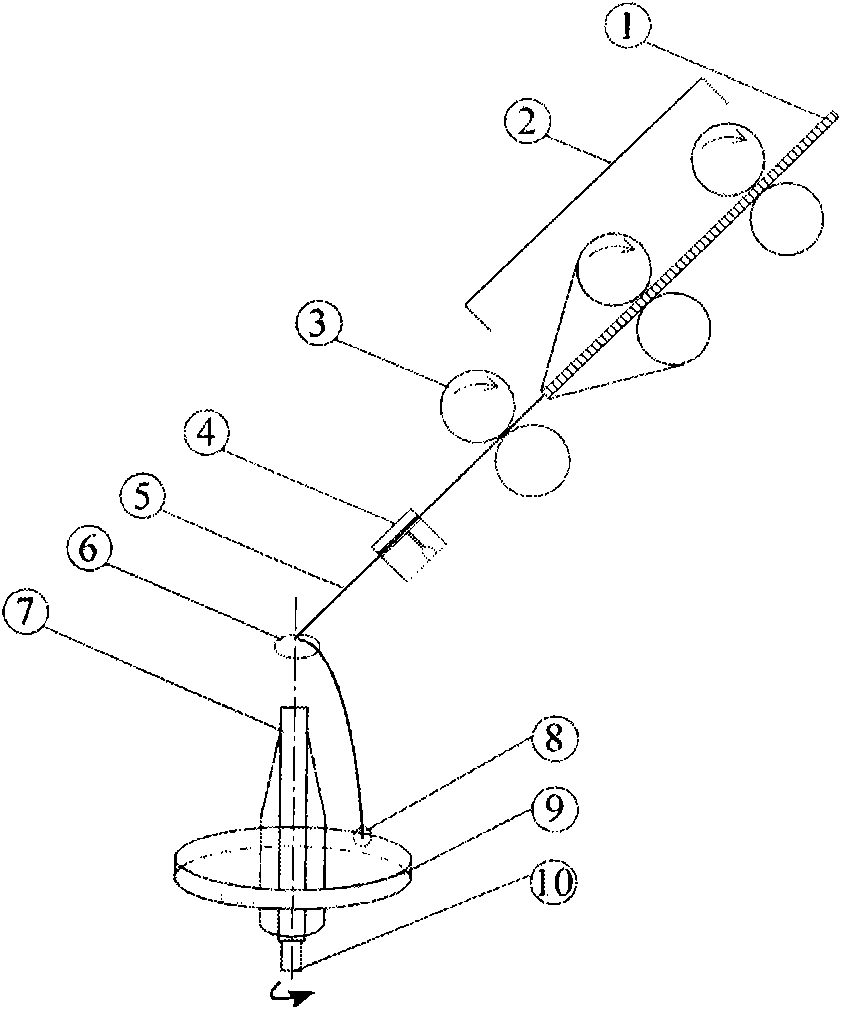

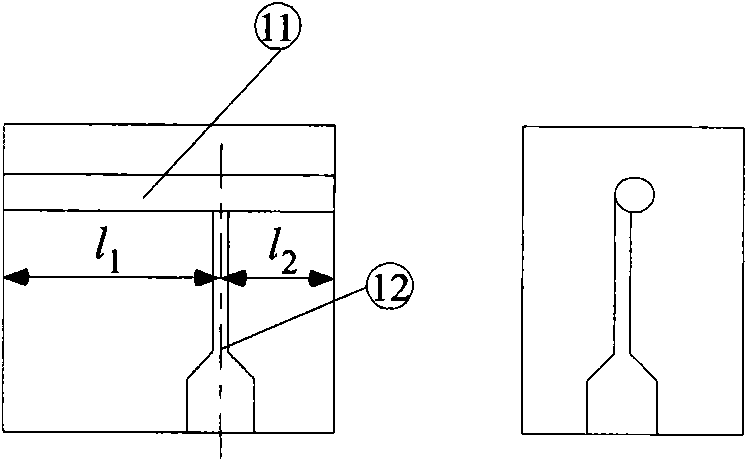

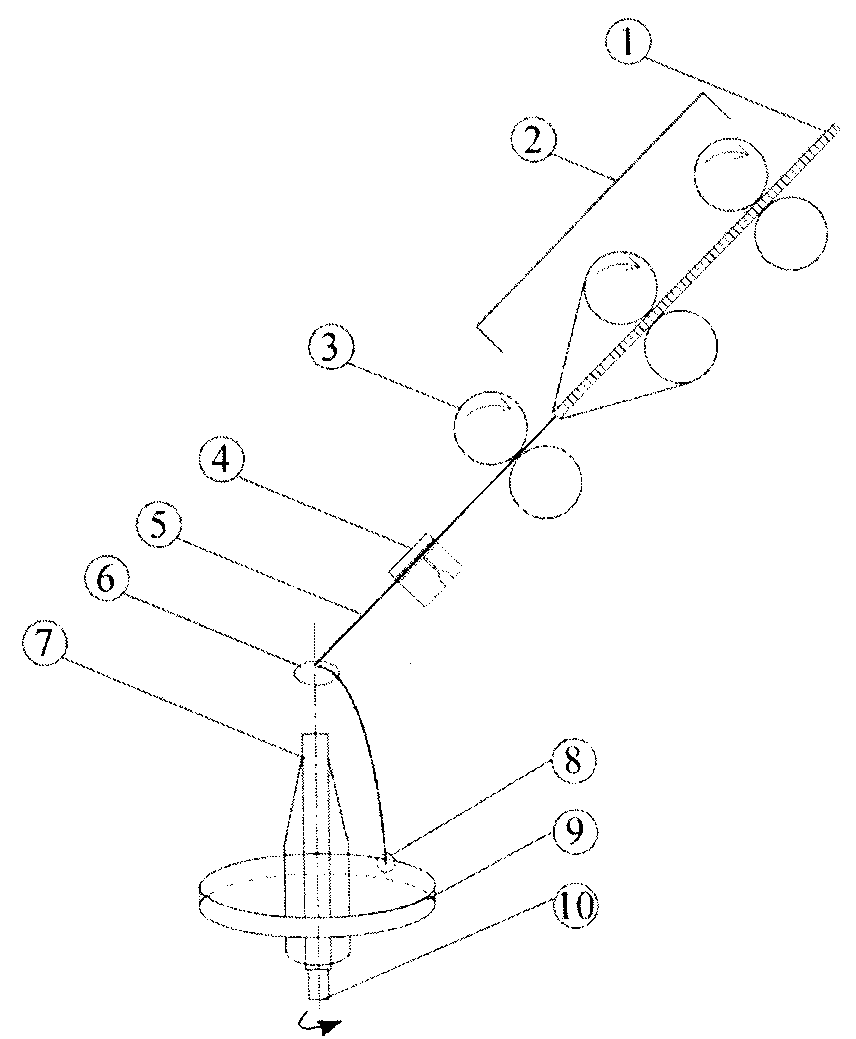

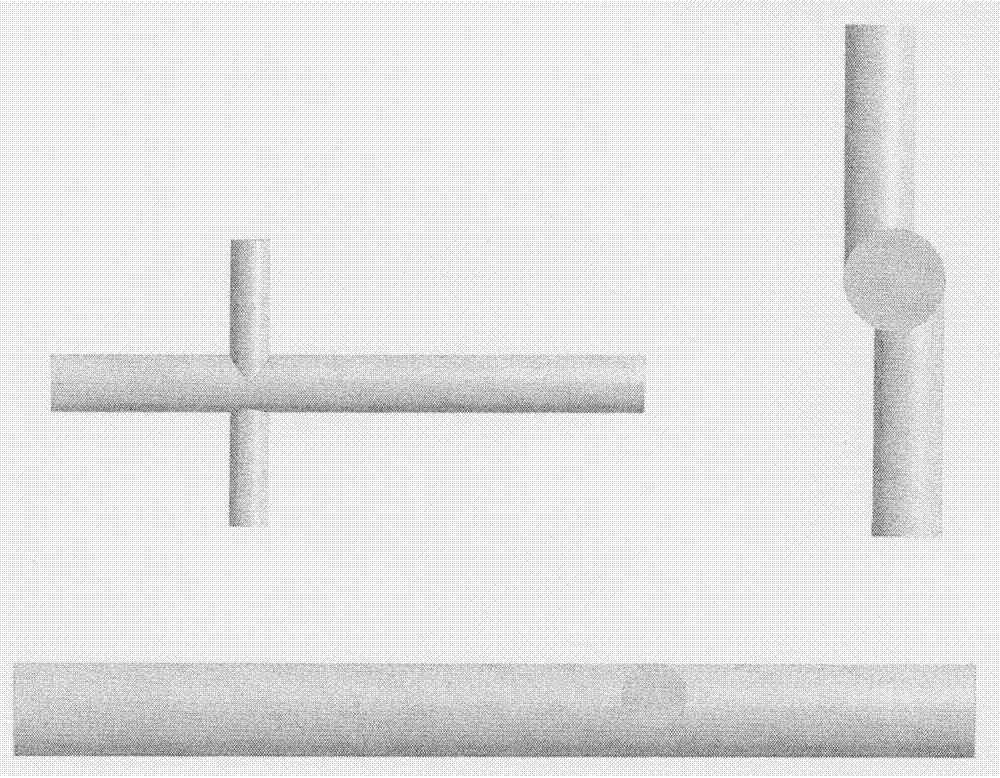

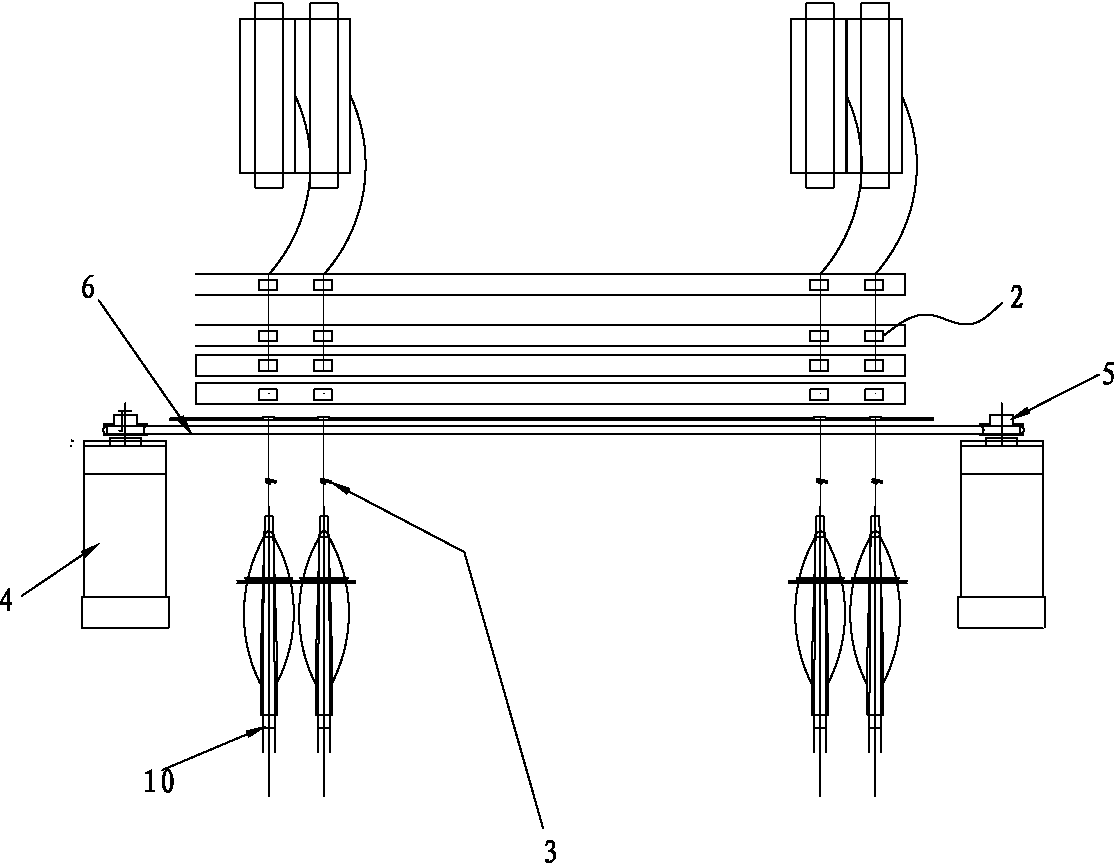

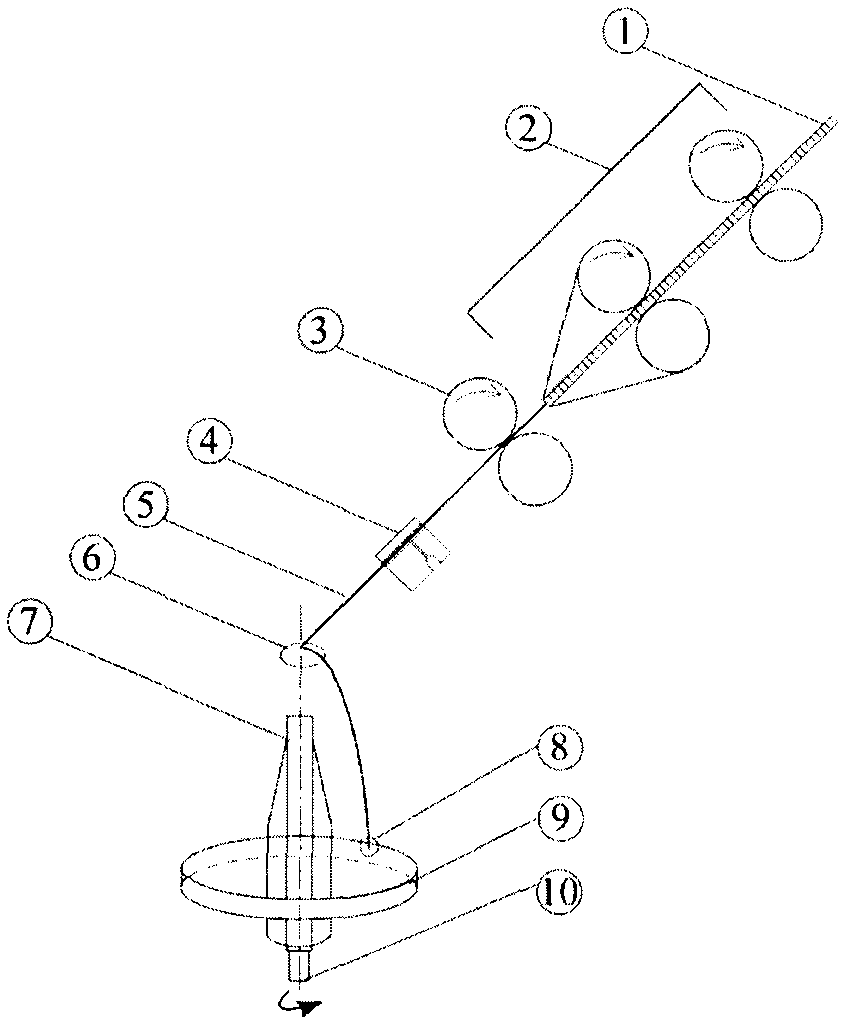

Composite nozzle device capable of reducing resultant yarn hairiness

InactiveCN102926056ASimple structureImproved anti-pilling propertiesFilament handlingDrafting machinesWinding machineYarn

The invention relates to a device for reducing resultant yarn hairiness by utilizing a composite nozzle, which belongs to the technical field of textile engineering, wherein the composite nozzle substantially comprises a raw head cavity, an intensive cavity and a vortex cavity, the raw head cavity is convenient for yarn joints, the intensive cavity is used to pretreat hairiness which is arranged on the surfaces of resultant yarns, and prevents fibers on the surfaces of the resultant yarns from losing, compressed airflow in the vortex cavity can involve the hairiness on the surfaces of the resultant yarns into a yarn body, and the composite nozzle can conveniently arranged on a spinning frame or a cone winding machine. The device utilizing the composite nozzle to reduce resultant yarn hairiness is simple in structure, convenient to install and low in energy consumption, and is convenient for large-scale promotion and use.

Owner:JIANGNAN UNIV

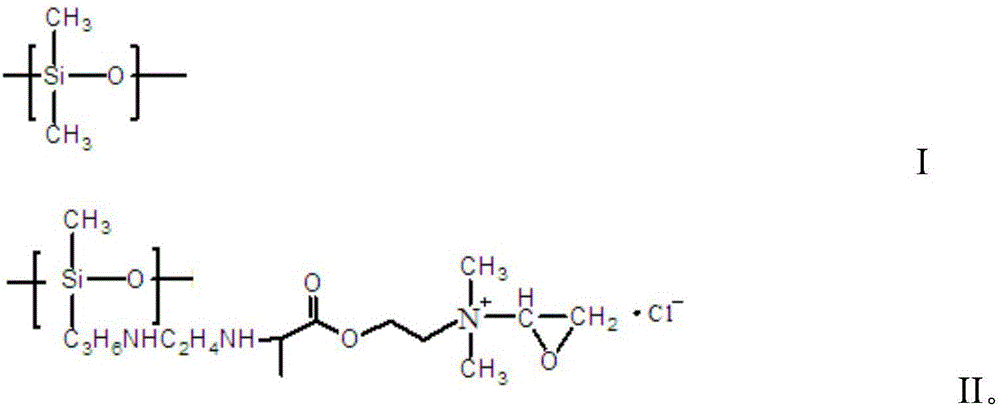

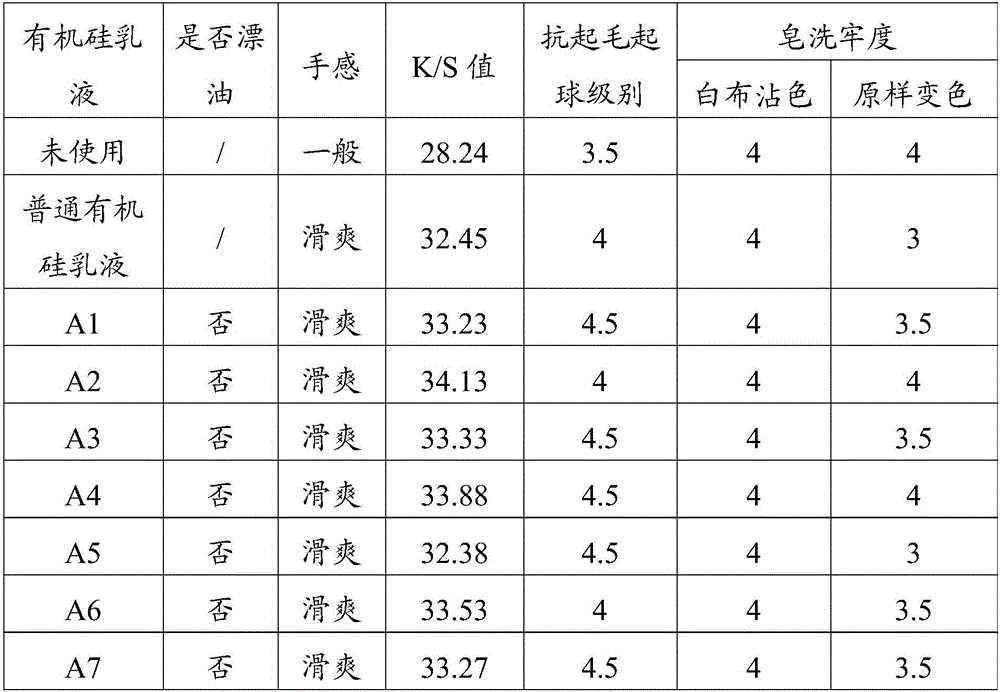

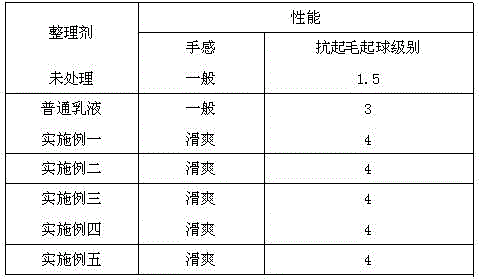

Organosilicon emulsion and preparation method thereof, and fabric finishing agent

ActiveCN105837823AImprove performanceSmall particle sizeGrip property fibresAbrasion resistant fibresSelf emulsifyingAlkaline catalyst

The invention relates to the field of textiles, specifically to a preparation method for an organosilicon emulsion. The preparation method comprises the following steps: subjecting an aqueous solution of a highly basic catalyst, a linear compound of octamethylcyclotetrasiloxane, an ammonia type coupling agent and an end-capping reagent to mixing and reaction so as to obtain amino silicon oil; then reacting the amino silicon oil with dimethylaminoethyl methacrylate so as to obtain modified amino silicon oil; and adding the modified amino silicon oil into chloropropylene oxide and carrying out quaternization. Compared with the prior art, the preparation method for the organosilicon emulsion in the invention has the advantages that Michael addition is employed, and a novel preparation method for the organosilicon emulsion is provided; and the prepared organosilicon emulsion does not need emulsification by an emulsifier and can realize self-emulsifying. The invention also discloses the organosilicon emulsion and a fabric finishing agent.

Owner:科凯精细化工(上海)有限公司

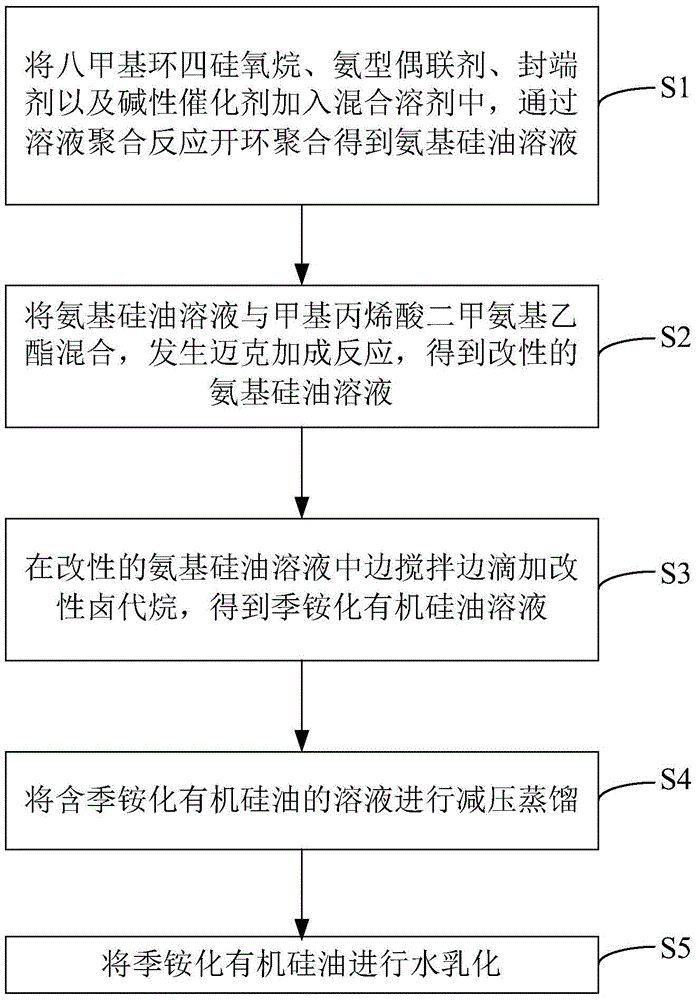

Quaternized organic silicone oil and preparation method thereof

The invention relates to quaternized organic silicone oil and a preparation method thereof. The preparation method comprises the following steps: (1) adding octamethylcyclotetrasiloxane, an ammonia type coupling agent and an alkali catalyst into a mixed solvent, using hexamethyldisiloxane as an end-capping agent, and conducting ring opening polymerization through solution polymerization reaction so as to obtain an amino silicon oil solution; (2) adding dimethylaminoethyl methacrylate, and enabling Michael addition reaction so as to obtain the modified amino silicon oil solution; (3) adding alkyl halide, conducting quaternization reaction, and conducting reduced pressure distillation to remove the mixed solvent so as to obtain the quaternized organic silicone oil; (4) conducting water emulsification on the quaternized organic silicone oil. According to the quaternized organic silicone oil and the preparation method thereof, not only can the obtained quaternized organic silicone oil be self-emulsified, but also no emulsifying agent needs to be added when in water emulsification, influence exerted on performance of adhesive force, water resistance, scrubbing resistance and the like can be avoided, and the quaternized organic silicone oil has antibacterial performance and an obvious color-deepening effect on dark-color polyester fabric when being used as a color-deepening finishing agent.

Owner:科凯精细化工(上海)有限公司

Soybean fiber fabric lousiness-pilling-resistance finishing method

InactiveCN1776085AImproved anti-pilling propertiesIncreased durabilityFibre treatmentFiberMethacrylate

This invention discloses a fuzzing-pilling resisting finishing method for soybean fiber fabric. It makes grafting modification to soybean fiber fabric, finishes by resin finishing agent. The monomer for grafting modification is diacritic acid or methacrylate of diatomic alcohol or with other active group, the finishing agent is organic silicon modified polyacrylate dispersion or modified polyurethane like finishing agent. Said invention has fine washing resistance and no formaldehyde in process agent.

Owner:SUZHOU UNIV

Finishing method high-hygroscopic and perspire fibre with cotton-dispersion

ActiveCN1818199AImprove the finishGuaranteed strongBiochemical fibre treatmentVegetal fibresFiberEnzyme

A treatment to make cotton fiber more hygroscopic .The process includes enzyme treatment on cotton fiber to enhance its smoothness and strength, dyeing on fiber, softening agent treatment to make it more hygroscopic and to lower its specific resistance. Cotton made by this process shows high quality such as softy, smoothy and hygroscopic. It is also time saving and energy saving.

Owner:ZHEJIANG HUAFU COLOR TEXTILE

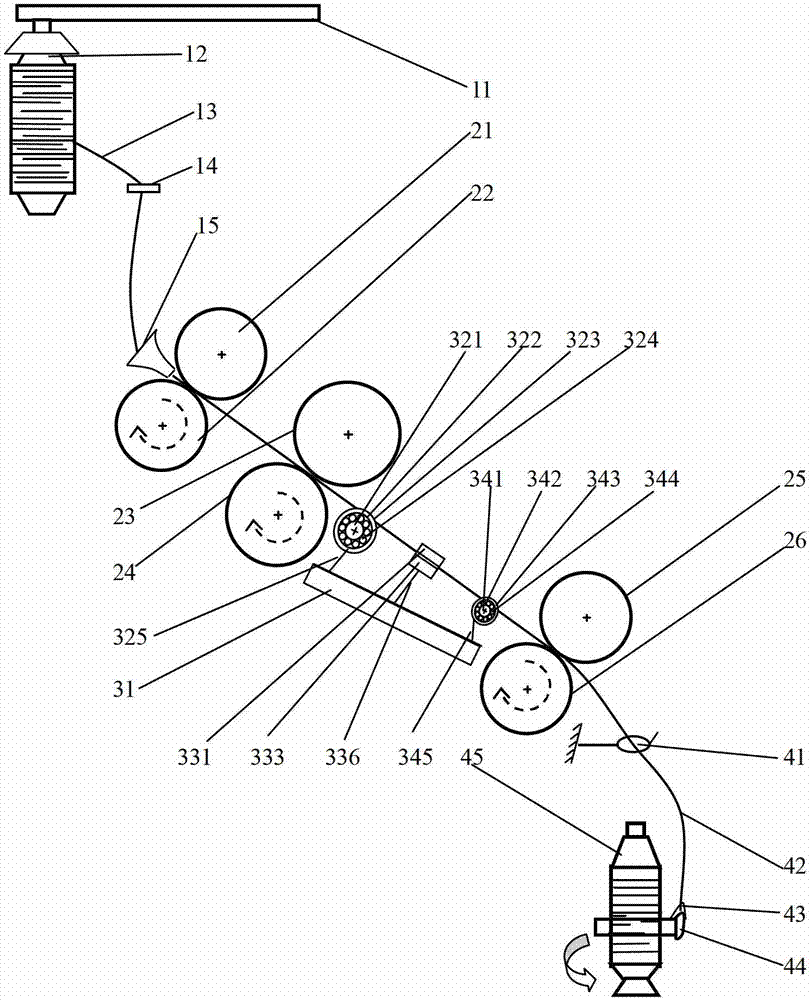

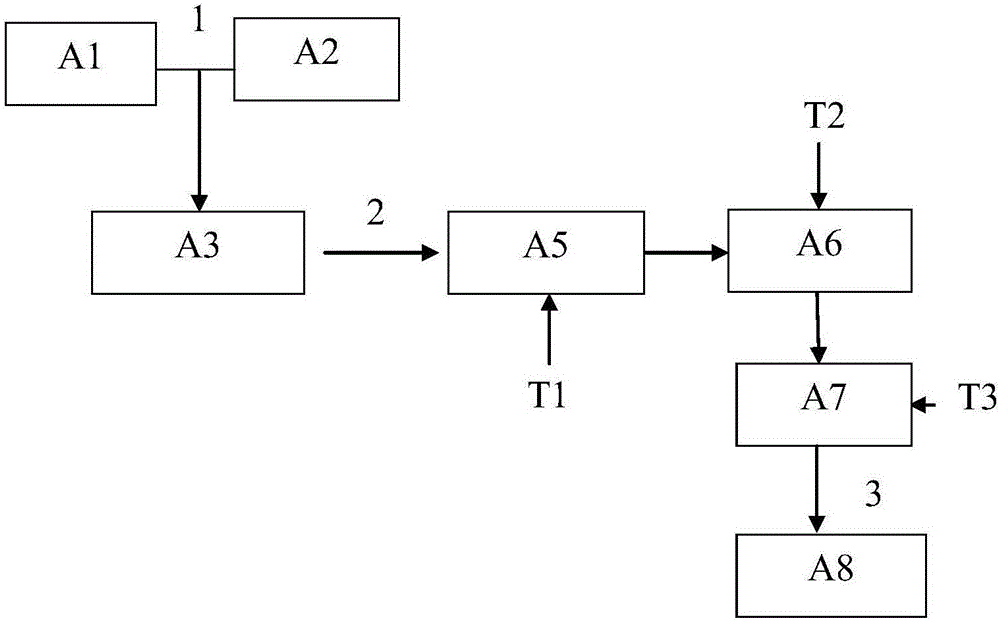

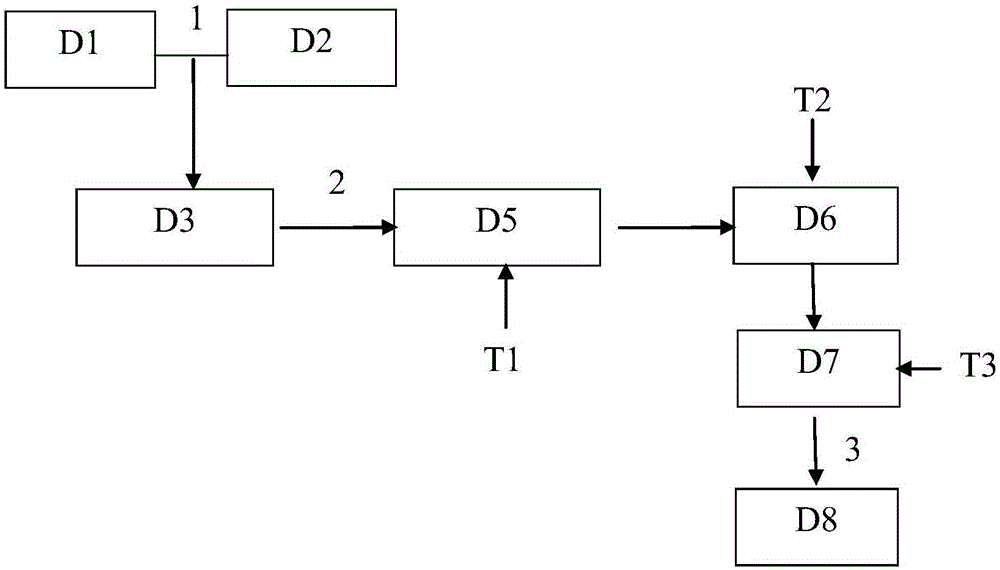

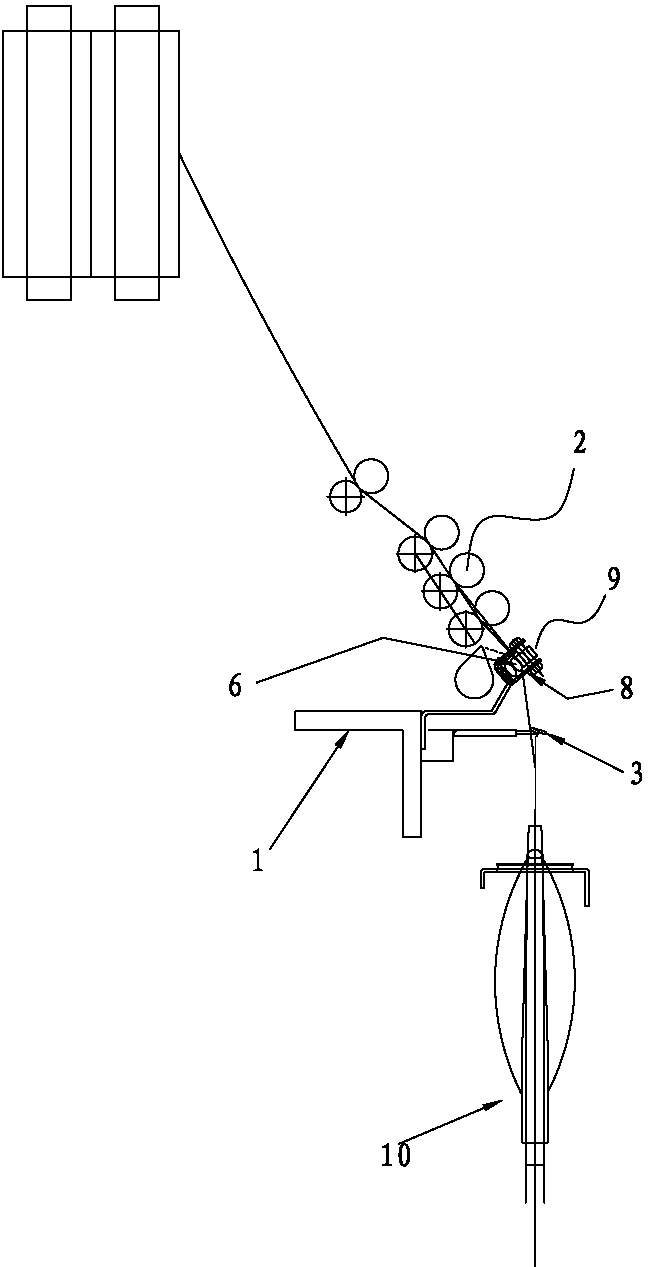

Bright yarn spinning device and application thereof

InactiveCN102965773AReduce spinning end break rateImprove spinning efficiencyDrafting machinesContinuous wound-up machinesCombingYarn

The invention discloses a bright yarn spinning device and an application thereof. The spinning device comprises a rough yarn feeding mechanism, a draft mechanism and a twisting and winding mechanism, and is characterized by further comprising a finishing mechanism which is composed of a fixed plate fixedly mounted on the draft mechanism, as well as a combing mechanism, a straight mechanism and a cluster mechanism all fixedly connected with the fixed plate; both the combing mechanism and the straight mechanism are provided with hairiness combing textures which are respectively used for combing and straightening cluttered hairiness and back curved hairiness projected from the bottom and periphery of the rough yarn; and the cluster mechanism is provided with a side horse-shaped surface and a symmetric V-shaped texture so as to complete rough yarn condensation and hairiness combing. The application of the spinning device is that the rough yarn fed by the rough yarn feeding mechanism is processed into the bright fine yarn after the procedures of drawing of the draft mechanism, combing and condensation of the finishing mechanism, and twisting and winding of the twisting and winding mechanism. The spinning device can also be used for bright spinning of cotton, mucilage and polyster fibre. According to the invention, the fine yarn is less in hairiness, and high in uniformity and strength; the preparation technology spinning septa is small; the end breakage rate and energy consumption are low; and the efficiency is high.

Owner:FUJIAN JINTAI TEXTILE

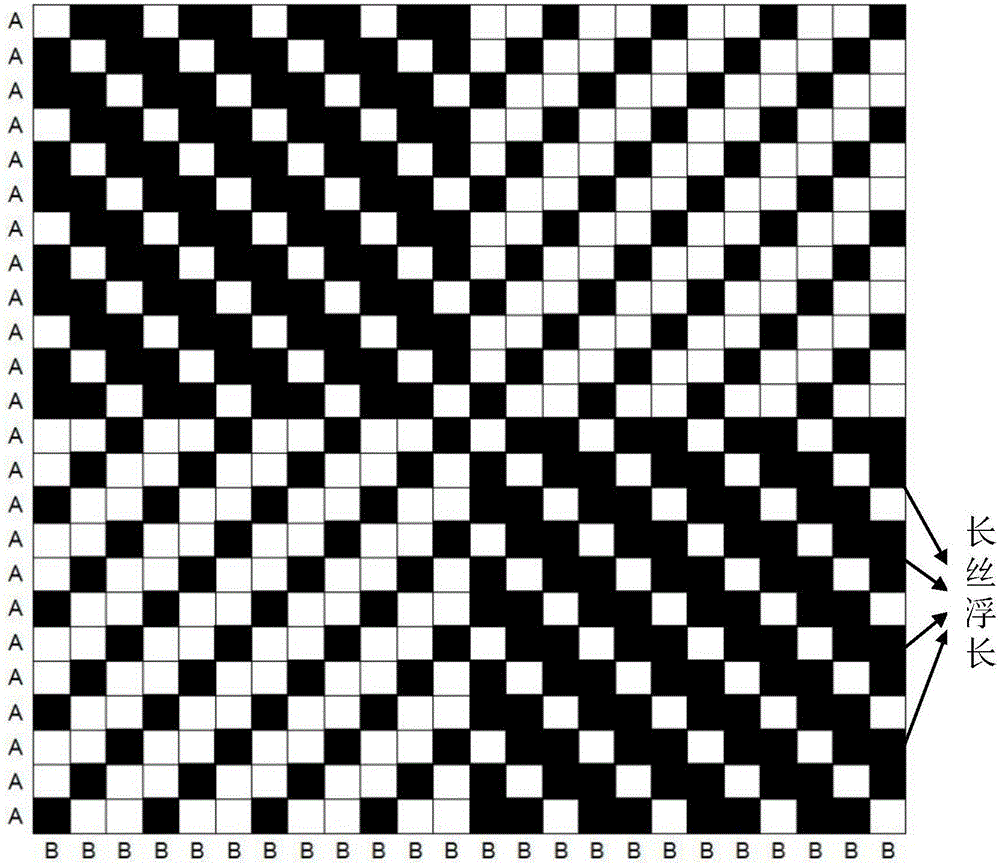

Comfortable anti-flaming fabric and manufacturing method thereof

InactiveCN106592064AFlame retardant permanentComfortable foreverHeat resistant fibresHeating/cooling textile fabricsEngineeringFire resistance

The invention discloses a comfortable anti-flaming fabric. The comfortable anti-flaming fabric is characterized by being formed by vertically interweaving first yarns and second yarns, wherein the first yarns are made from staple fibers with anti-flaming property; the second yarns are made from anti-flaming filament yarns; after the fabric is padded, a firm fibroin sericin film is formed on the surface. The comfortable anti-flaming fabric has the advantage that the fire resistance and the comfort property are effectively combined so that the fabric has permanent flame retardance, wet-absorbing and breathable properties, skin-friendly and smooth properties, anti-pilling property, shrink-proof and anti-wrinkle properties, and the like.

Owner:北京邦维普泰防护纺织有限公司

Cationic organosilicon-modified polyurethane emulsion and preparation method thereof

InactiveCN104130376AStrong cation chargeEasy to manufactureFibre treatmentSilanesPotassium hydroxide

The invention relates to a cationic organosilicon-modified polyurethane emulsion and a preparation method. The method comprises the following steps: 1)synthesizing amino silicone oil, placing octamethylcyclotetrasiloxane, N-beta-(aminoethyl)-gamma- aminopropyl methyl dimethoxyl silane, hexamethyldisiloxane, potassium hydroxide and deionized water in a reaction container under the temperature of 100-110 DEG C to prepare the amino silicone oil; 2)adding haloalkane or epoxy alkyl halide, performing quaternization under 50-90 DEG C, removing micromolecule matter to obtained quaternized modified amino silicone oil; and 3)adding the quaternized modified amino silicone oil in the step 2) drop by drop in high molecular weight polyether polyalcohol, cationic glycol chain extender and isophorone diisocyanate prepolymer and reacting under 60-90 DEG C to obtain cationic organosilicon-modified, then adding deionized water to obtain the cationic organosilicon-modified polyurethane emulsion. The product can be used for textile arrangement, and is especially suitable for acrylic fibers fabric, and has good pilling resistance and hand feel.

Owner:SHANGHAI UNIV

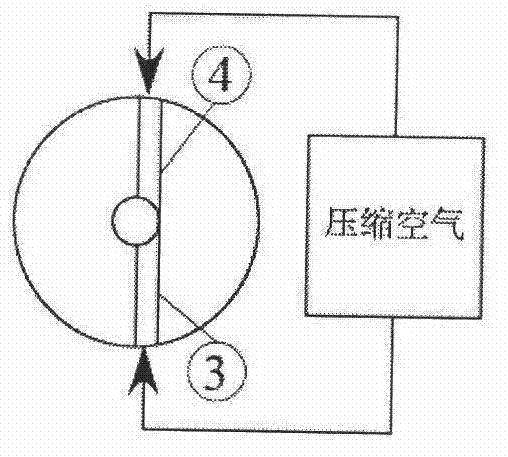

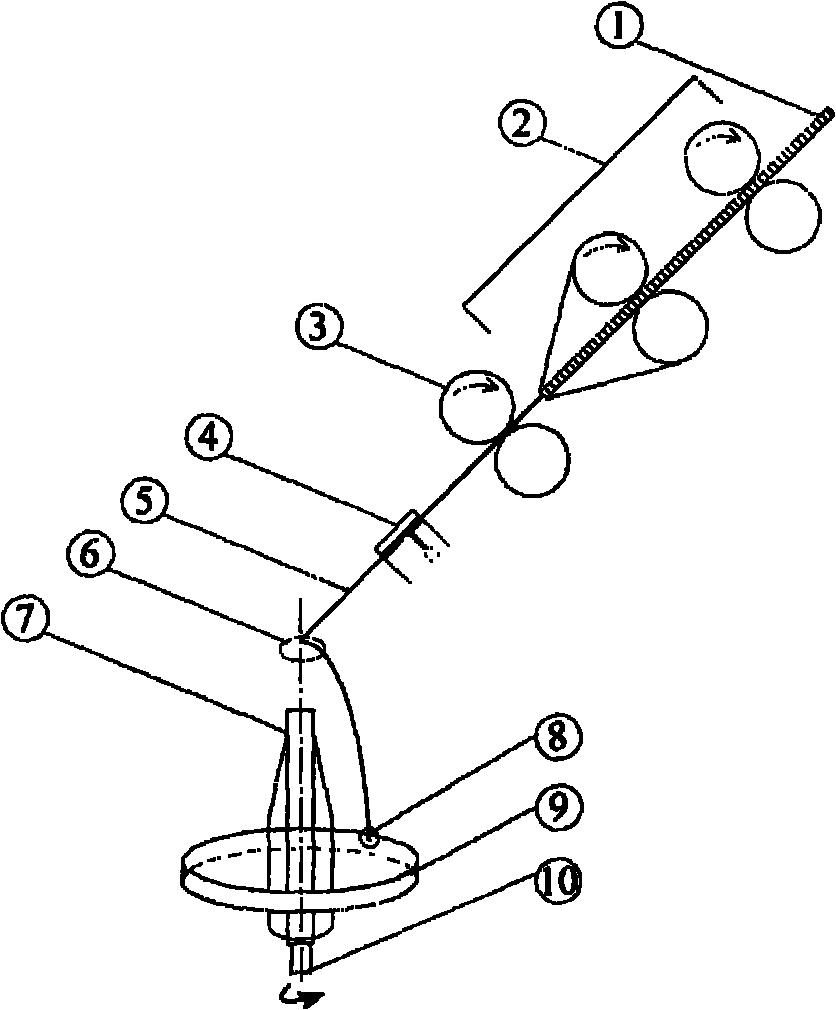

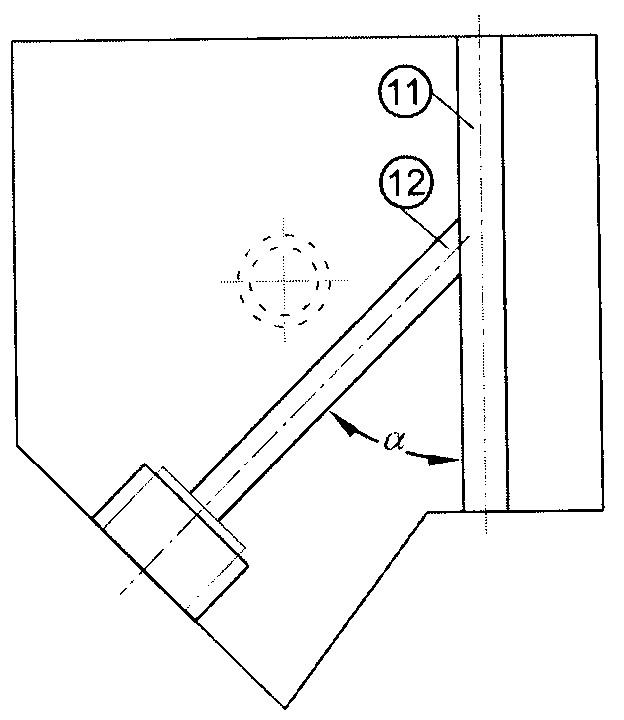

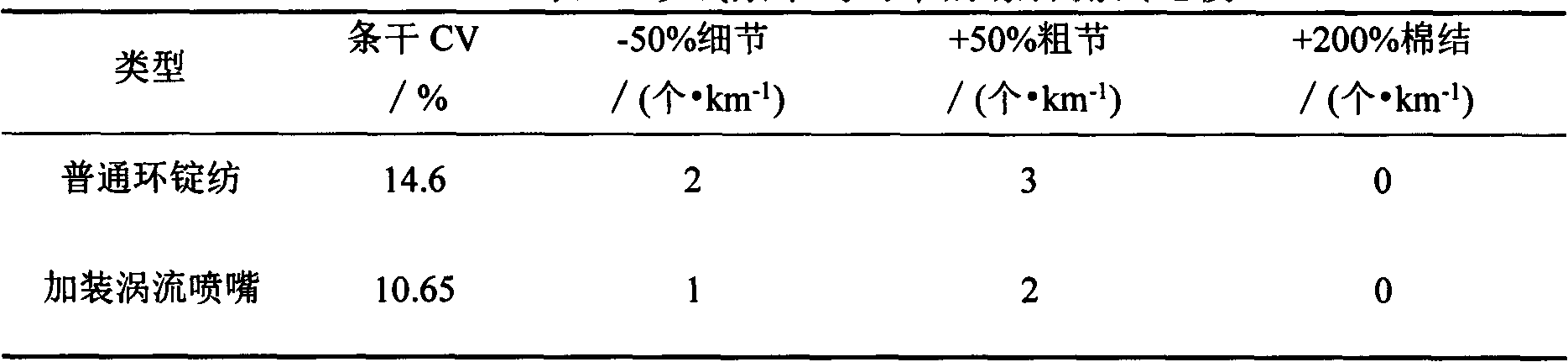

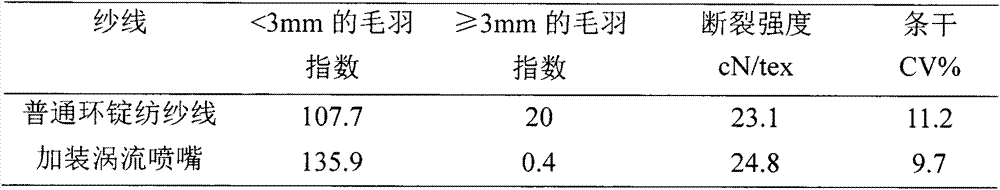

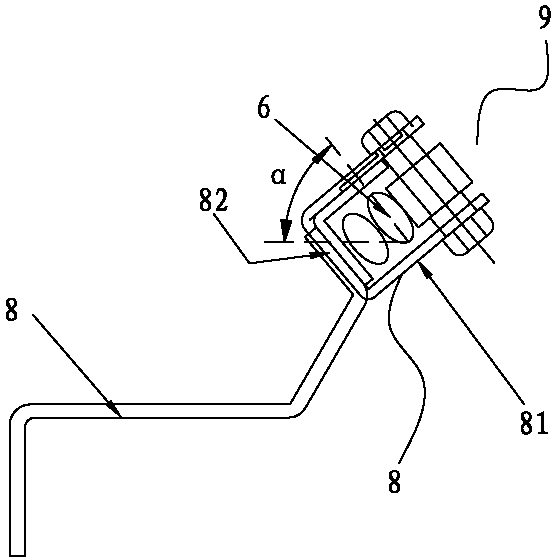

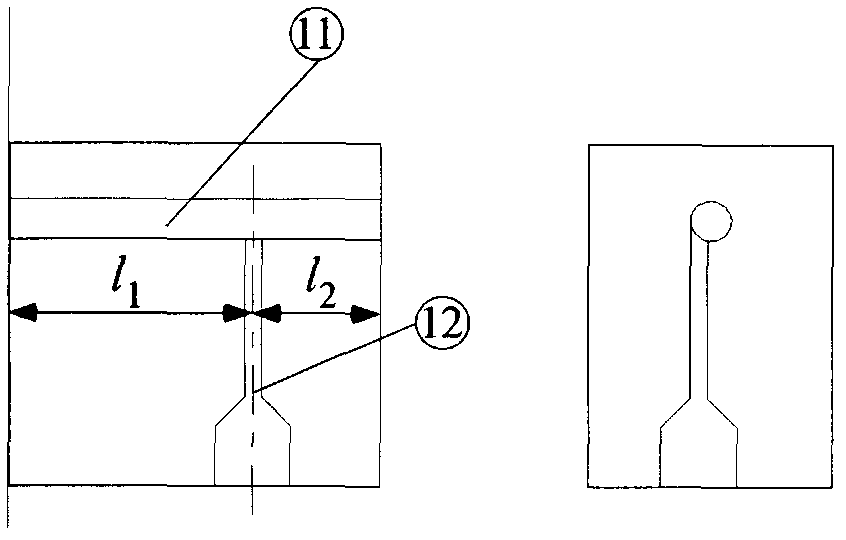

Device for reducing yarn hairiness by utilizing vortex nozzle and application

The invention discloses a device for reducing yarn hairiness by utilizing a vortex nozzle, and belongs to the technical field of textile engineering. The device is called the vortex nozzle for short. The vortex nozzle mainly comprises a yarn channel and an air channel, is arranged on a stander of a spinning frame and is positioned between a front roller and a guide wire. When the vortex nozzle is used, a yarn which passes through the center of the yarn channel is subjected to the action of air flow in the air channel which is vertically tangential to the yarn channel. Vortex is formed by the air flow injected into the yarn channel from the air channel, so that the yarn with much hairiness is subjected to the action of untwisting and re-twisting; therefore, the hairiness is effectively reduced; meanwhile, the evenness and strength of the yarn are improved. The device has a simple structure, low cost for equipment transformation, and high development and application value, and is convenient to install.

Owner:WUJIANG JINGYI SPECIAL FIBER

Device for improving spun yarn quality by utilizing eddy nozzle and applications

A device for improving the spun yarn quality by utilizing an eddy nozzle belongs to the technical field of textile engineering. The nozzle consists of a yarn channel, an air channel and a yarn guider, is installed on a rack of a spinning machine and positioned between a front roller and a yarn guide hook. When the device is used, yarns passing through the center of the yarn channel are subjected to the action of compressed gas in the air channel which forms a certain angle with the yarn channel and is tangent with the yarn channel. Eddy is formed by air flow sprayed into the yarn channel from the air channel, the yarns with more yarn hairness are untwisted and are rewrapped, so that the yarn hairness is effectively reduced, and meanwhile, the yarn evenness and strength of the spun yarns can be improved. The device has the advantages that the installation is convenient, the equipment transformation cost is low, and the industrialization prospect is good.

Owner:JIANGNAN UNIV

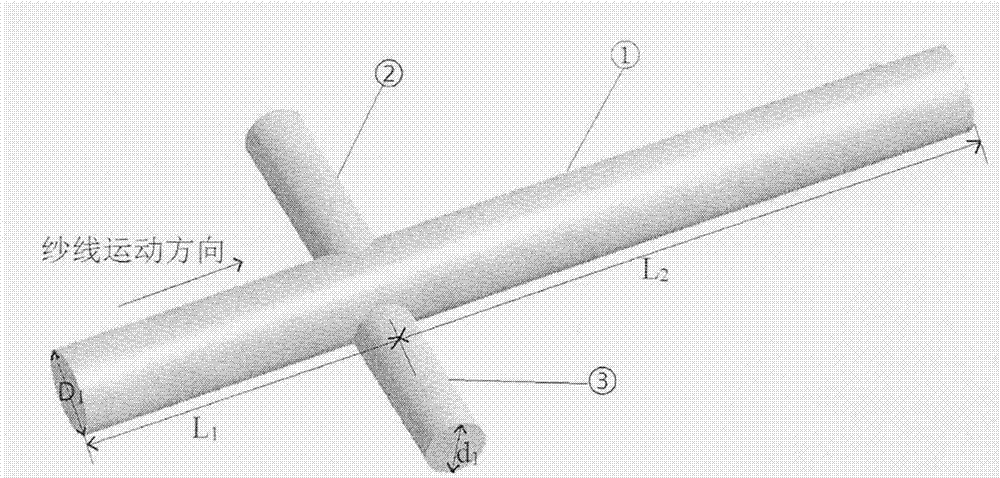

Device for improving quality of spun yarn by means of vortex dual-spraying pipe and application thereof

InactiveCN103572418ASimple structureHigh breaking strengthContinuous wound-up machinesOpen-end spinning machinesFiberYarn

The invention relates to a device for improving the quality of ring-spun yarn by means of vortexes introduced into the device. The device is composed of a round yarn channel and two round air channels tangent to the round yarn channel and therefore is called a vortex dual-spraying pipe. The vortex dual-spraying pipe has the advantages of being simple in structure, convenient to operate and low in machining cost. The vortex dual-spraying pipe can be directly installed between a front roller and a guide wire of a traditional ring spinning machine. When the vortex dual-spraying pipe is used, air flow is introduced through the air channels and makes spiral motions in the yarn channel. Furthermore, the design of the dual-spraying pipe enables the air flow field in the yarn channel to be more stable and evener, and therefore fibers on the yarn can be well folded, bent and wrapped in the body of the yarn. Therefore, the number of long fibers on the surface of the yarn is effectively reduced, and other performance of the yarn is improved to a certain degree at the same time.

Owner:JIANGNAN UNIV

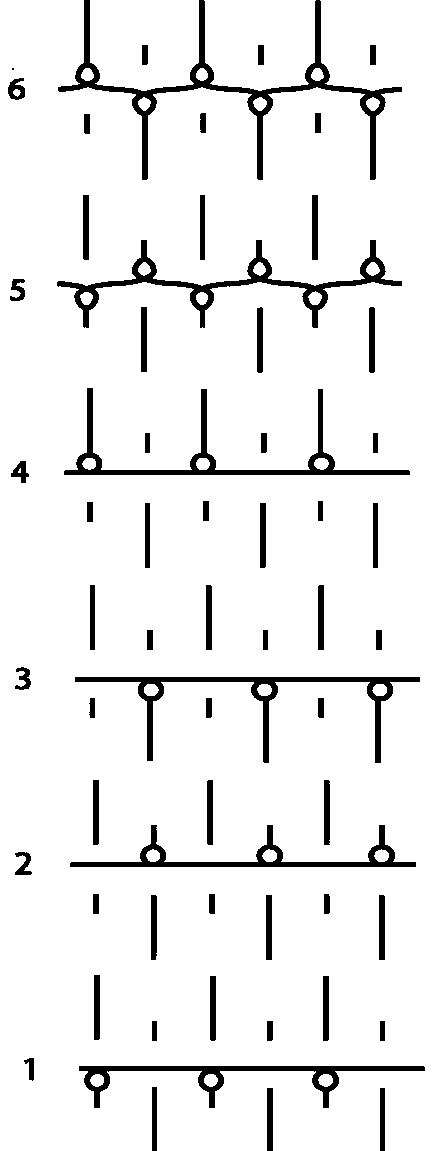

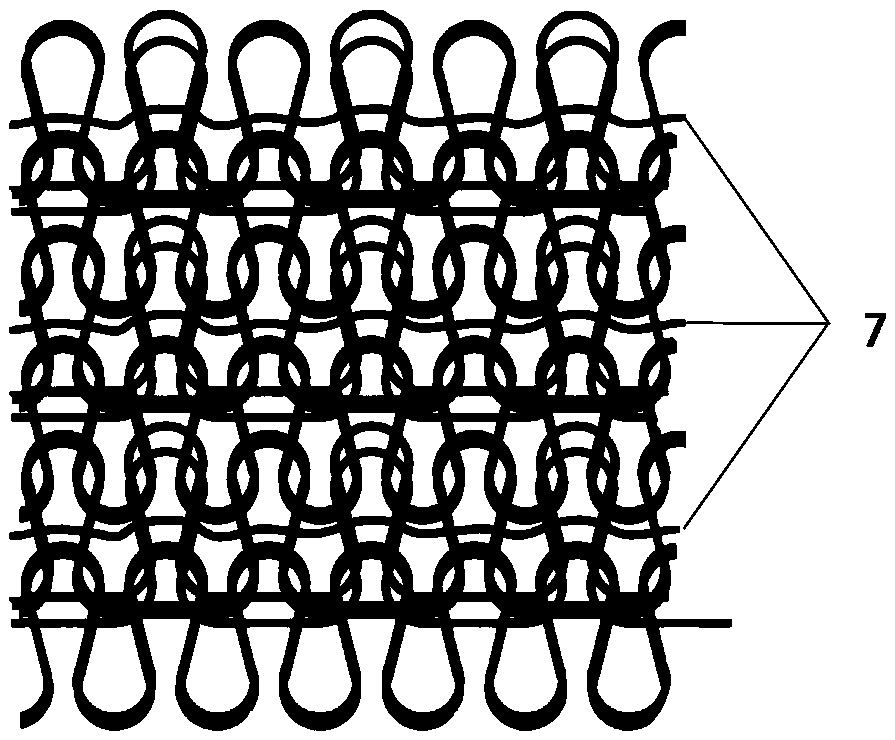

High-heat preservation air-layer wool fabric and process thereof

The invention relates to the field of textile and apparel, in particular to a high-heat preservation air-layer wool fabric. The wool fabric is selected for knitting, six-way knitting in a double-needle disc coiling mode with upper and lower needle discs is adopted, the air layer is formed in the middle of the fabric, hollow polyester yarn is introduced at the same time in the air layer, while theair storage capacity is greatly improved, the air is made to be still in the fabric, air convection is weakened, the heat preservation of the fabric is enhanced obviously, and the heat preservation iscomparable to that of a down product. The invention also provides a preparation method for the above fabric. A loom-state fabric is firstly subjected to polar fleece processing before a fulling process, a mode of primary fulling, singeing and secondary fulling is adopted, the wool feel is more uniform, plump and compact, shearing is carried out after further heat setting, the wool feel on the front is short and dense, the wool feel on the back is relatively thick, and while the heat preservation is ensured, the fabric style and the hand feel are both excellent.

Owner:LILANG CHINA

Bamboo charcoal fiber yarn and production method thereof

The invention discloses a type of bamboo charcoal fiber yarn and a production method of the bamboo charcoal fiber yarn. The bamboo charcoal fiber yarn is characterized in that the bamboo charcoal fiber yarn is formed by bamboo charcoal fibers with the monofilament fineness ranging from 0.8 dtex to 1.5 dtex, and siwear fibers with the monofilament fineness ranging from 0.9 dtex to 1.4 dtex in a spinning mode, the bamboo charcoal fibers account for 65% to 80% of the main-body yarn in weight, and the siwear fibers account for 20% to 35% of the main-body yarn in weight; the yarn is formed in the spinning mode through working procedures of blowing, cotton carding, drawing, roving and spinning, a semi-compact spinning technology is adopted for the spinning working procedure, resultant yarn is the same as ring spun yarn in structure, and is still a twist yarn body, but the resultant yarn is more advanced in structure, hairness in the circumferential direction is substantially reduced in the yarn body, the yarn is soft, smooth and clean, the yarn has a positive effect of pilling resistance, and the spun fabric is pure in color, has good breathability, hygroscopicity, wrinkle resistance and serviceability and has the gloss of silk.

Owner:NANTONG FANGKE TEXTILE TECH

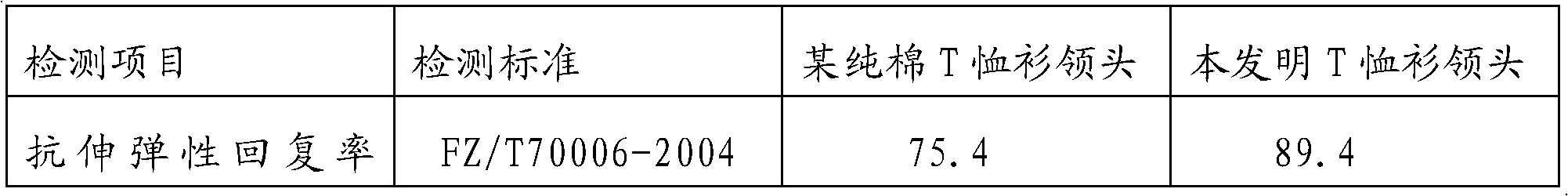

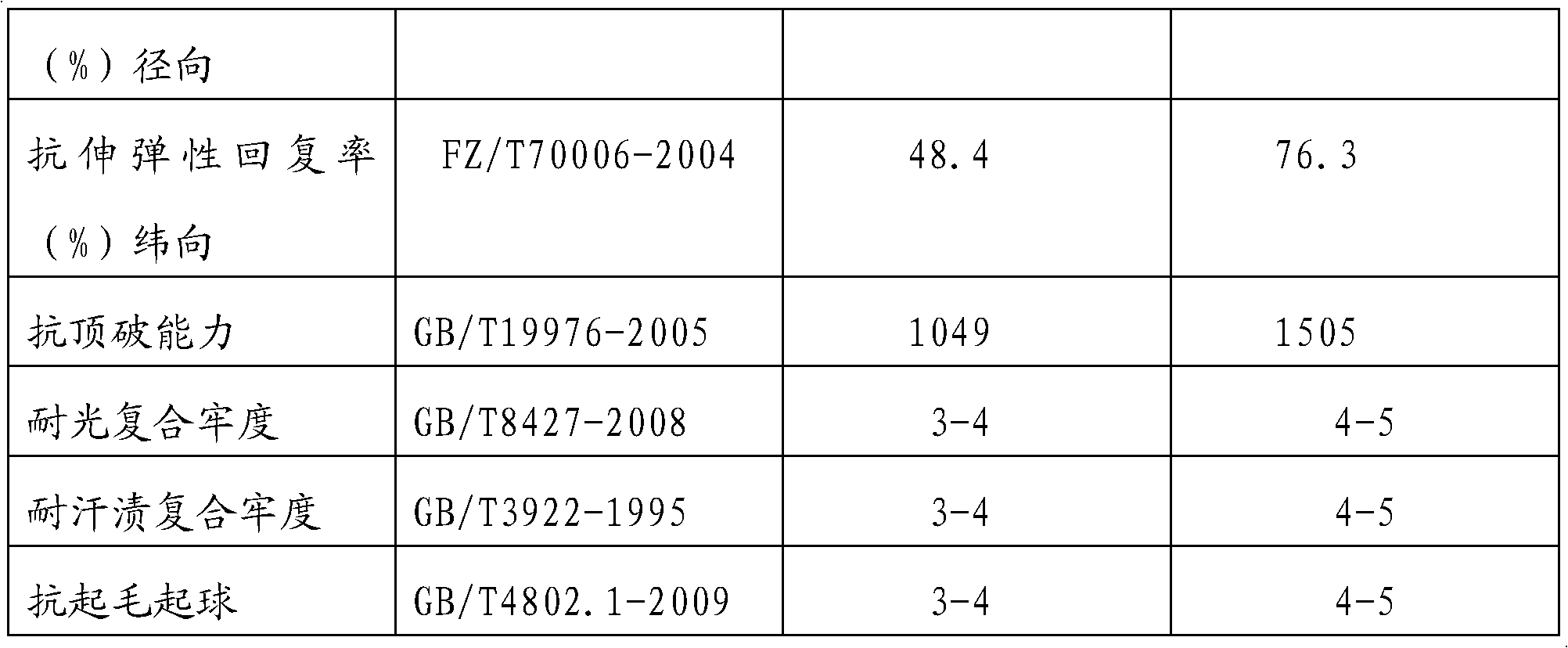

Cotton coated yarn collar and production method thereof

The invention relates to a collar, in particular to a cotton coated yarn collar and a production method thereof. The collar is woven by adopting the following components in percentage by weight: 52 to 56 percent of cotton yarns, 27 to 31 percent of polyester yarns and 15 to 19 percent of polyurethane coated yarns. Compared with the prior art, the invention has the advantages that: the polyester yarns and the polyurethane coated yarns with low cost are adopted for greatly substituting cotton yarns to weave the collar, and the performance of the produced cotton coated yarn collar is even superior to that of a pure cotton collar, so that the production cost of the collar is greatly reduced, the collar is hardwearing and durable, and the market competitiveness of the collar is improved; and proved by detection, the produced collar keeps the original appearance of the pure cotton collar, is close to the skin and comfortable, has thermal insulation property and air permeability, is light, elastic, stiff and smooth, and is not easily deformed or pilled.

Owner:泉州市劲超针织实业有限公司

Cotton/wood fiber/cashmere wool/spun silk soft and clean color-spun knitted yarn and production method thereof

The invention provides a multifunctional soft and clean color yarn developed by using dyed cotton, wood fiber, cashmere wool and spun silk soft as raw materials and using ring-spun cotton spinning equipment through a transformed soft and clean spinning technology. Firstly, the cotton, the wood fiber, the cashmere wool and the spun silk are dyed, then, a spun silk and wood fiber cotton bag blending method is used for making wood fiber / spun silk raw slivers, next, the wood fiber / spun silk raw slivers, color cotton raw slivers and cashmere wool raw slivers are blended in a sliver blending mode for making drawing slivers, and the drawing silvers are made into rough yarns through a roving frame; finally, the unique spinning features after the transformation of the soft and clean spinning technology are combined for spinning the rough yarns into spun yarns. The cotton, the wood fiber, the cashmere wool and the spun silk in the soft and clean color yarn are respectively dyed, the cotton spinning equipment is used for carrying out technical study of the spinning technology, the soft and clean spun composite color spun yarn realizing the color blending of the cotton, the wood fiber, the cashmere wool and the spun silk in different proportions is developed, the problems of dyeing color fastness, wear-resistance fastness and thermal migration fastness of four kinds of fiber are solved, the spinnability of the dyed fiber is improved, and the clean production of project product color spun yarns is realized.

Owner:YANCHENG INST OF IND TECH

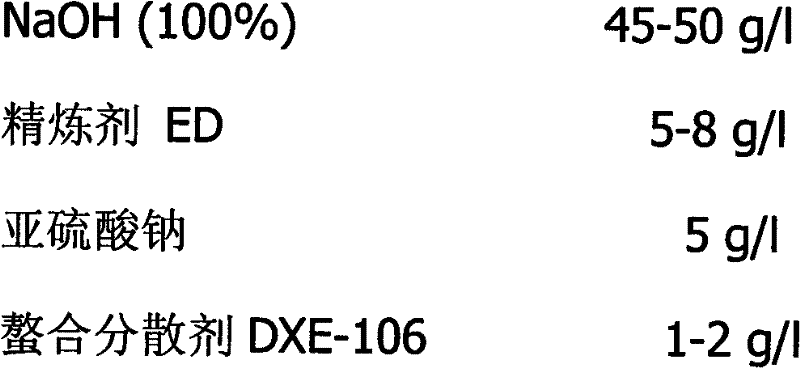

Technology for dyeing and finishing improved terylene polyamide lycra fabrics

InactiveCN105625052AGood moisture absorption and air permeabilityImprove antistatic performanceDyeing processPolyamideEngineering

The invention discloses a technology for dyeing and finishing improved terylene polyamide lycra fabrics. The technology comprises steps of oil-removing refining, pre-formalization, dyeing and finished product formalization. The technology for dyeing and finishing improved terylene polyamide lycra fabrics has the advantages of high-efficiency energy saving, emission reduction, cost reduction, and convenient operation. The technology for dyeing and finishing improved terylene polyamide lycra fabrics also increases breathable moisture absorption, antistatic property and anti-pilling performances of the fabrics.

Owner:江阴市长泾花园毛纺织有限公司

Anti-pilling finishing agent for polyester cotton garment fabric and preparing method thereof

InactiveCN105506996AImproved anti-pilling propertiesInhibit migrationAbrasion resistant fibresVegetal fibresPolyesterTherapeutic effect

The invention discloses an anti-pilling finishing agent for polyester cotton garment fabric and a preparing method thereof. The anti-pilling finishing agent is prepared from, by weight, 30-35 parts of polyester polyhydric alcohol, 20-25 parts of isophorone diisocyanate, 10-15 parts of organic tin, 16-19 parts of dihydroxy methyl propionate, 5-8 parts of N-methyl pyrrolidone, 12-15 parts of sodium hydrogen sulfite, 11-14 parts of carboxylic acid, 13-17 parts of triethylamine and 30-35 parts of deionized water. The preparing method includes the steps that polyester polyhydric alcohol is heated, dehydrated in vacuum and naturally cooled to 20 DEG C-25 DEG C, isophorone diisocyanate and organic tin are added and react with the polyester polyhydric alcohol for 1.5-2.5 h at the temperature of 60 DEG C-70 DEG C, then a solution prepared by mixing dihydroxy methyl propionate and N-methyl pyrrolidone for 5-10 min is added, and a polyurethane prepolymer containing carboxyl hydrophilic groups are prepared after reaction is conducted for 20-40 min. The anti-pilling finishing agent has an excellent anti-pilling function, the preparing process is simple, easy to operate and low in cost, a chemical method is used in the finishing process, the garment fabric is stable in performance after being treated, the treatment effect is good, the operation of finishing the garment fabric is simple, and finishing time is short.

Owner:福建省品诚环保科技有限公司

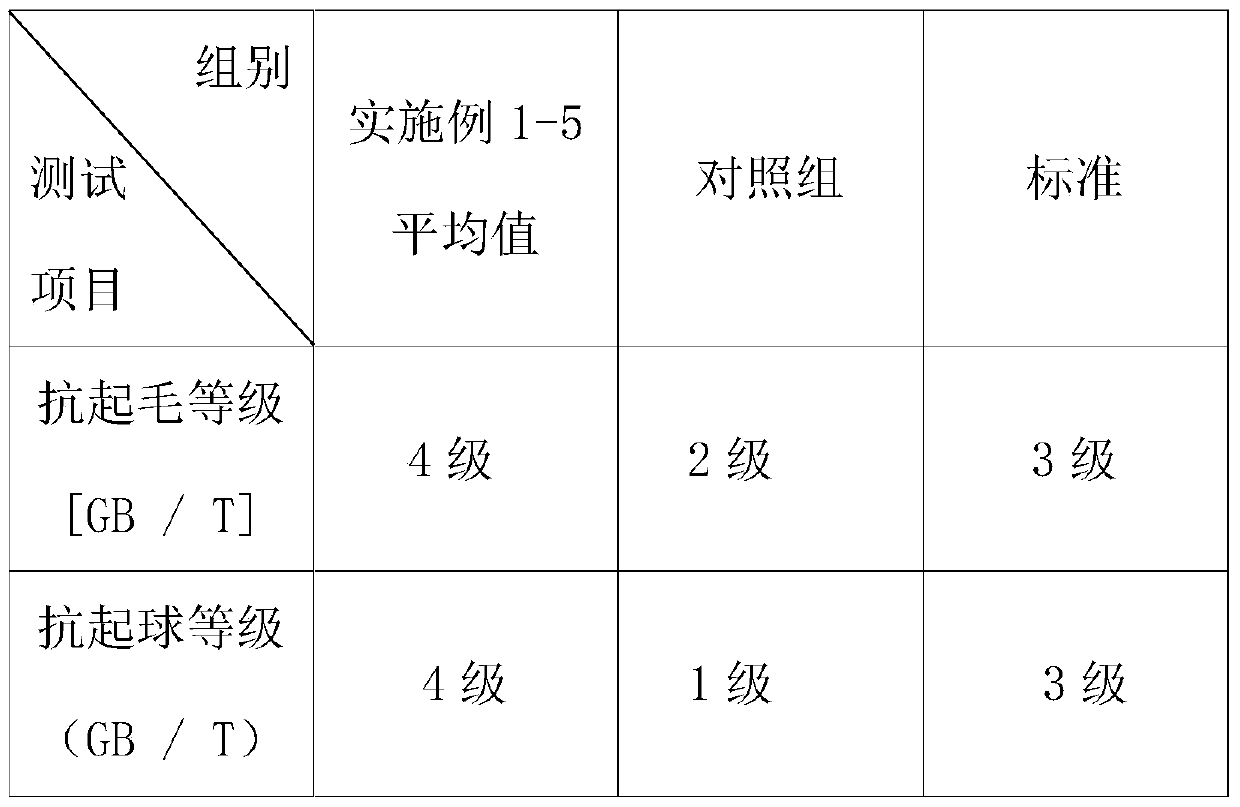

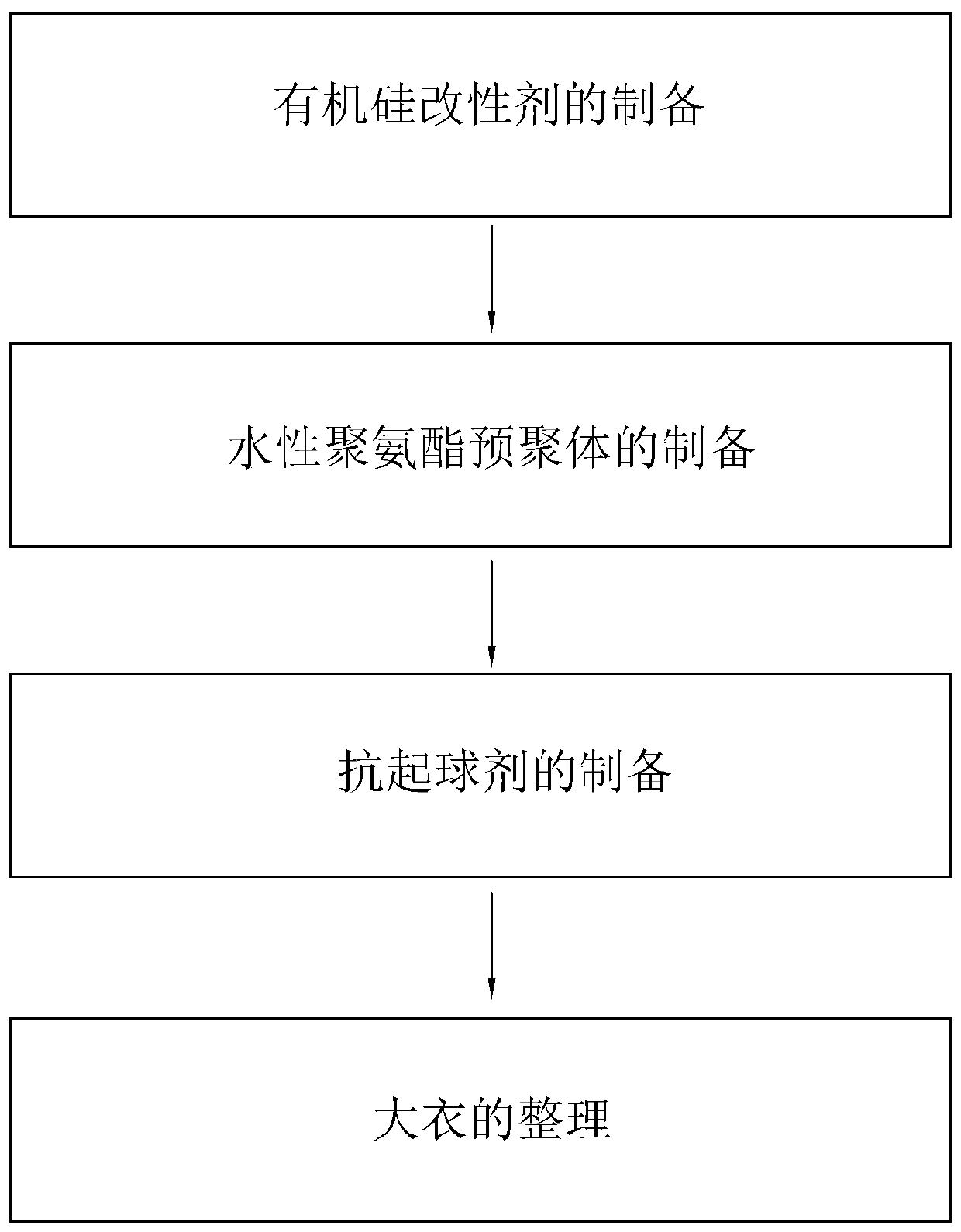

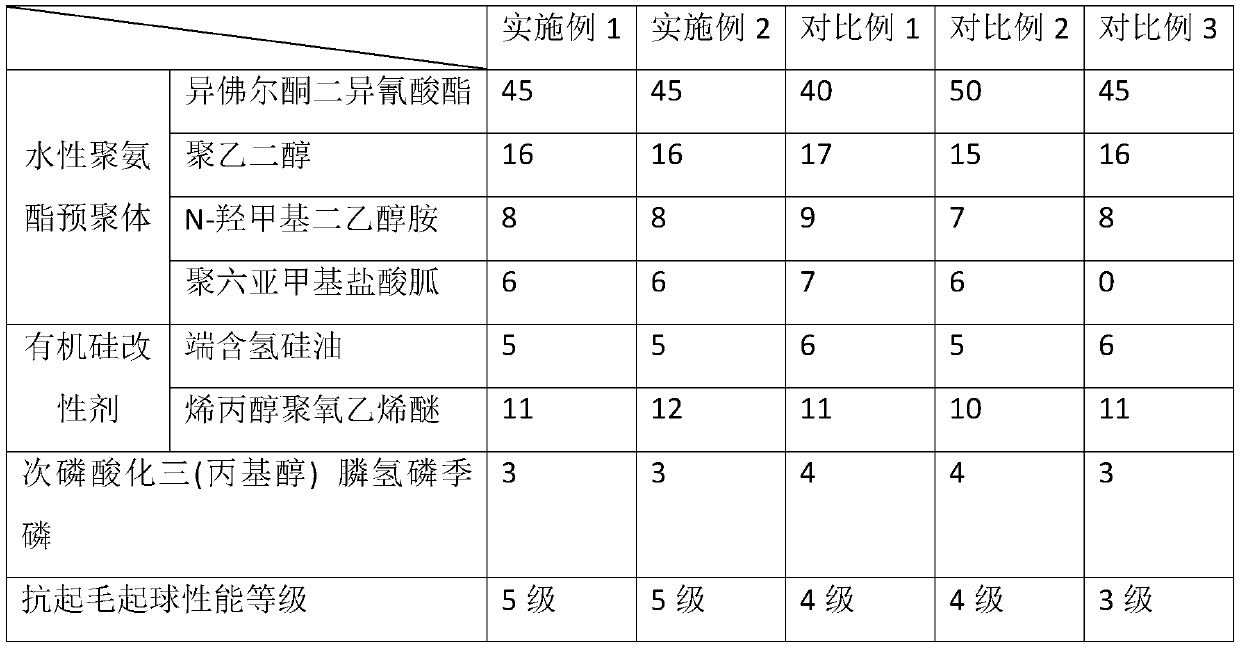

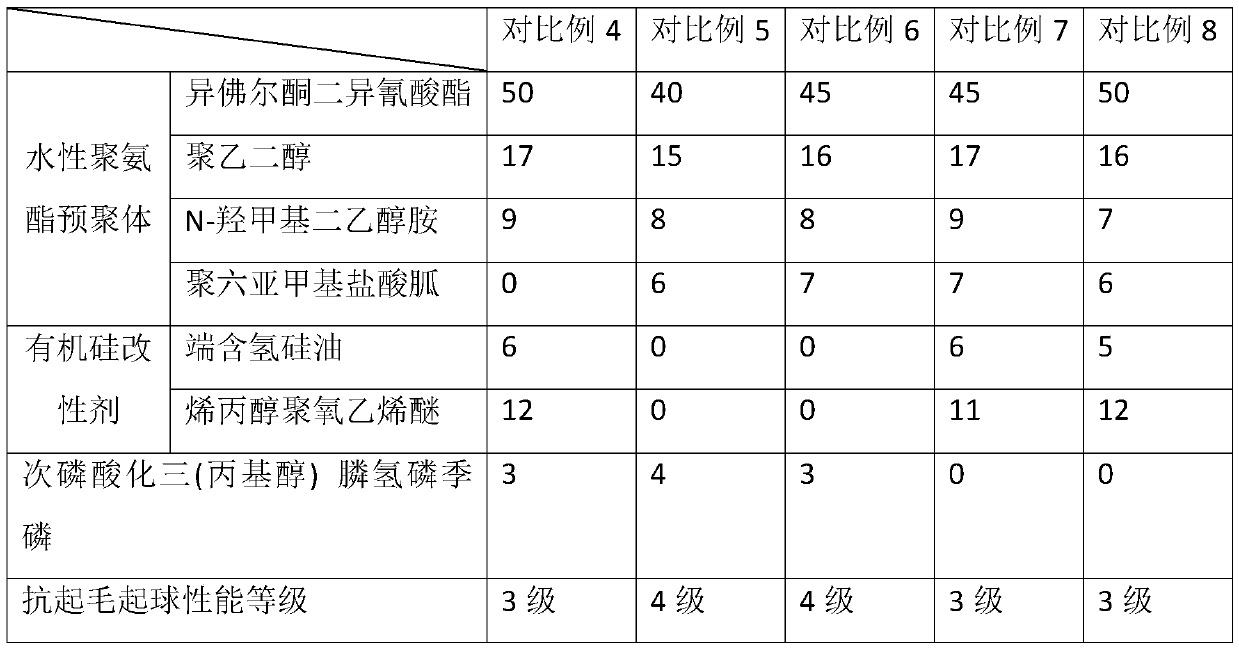

Anti-pilling overcoat and treatment process thereof

InactiveCN109736091AImprove anti-pilling performanceImprove temperature resistanceAnimal fibresFiberCarbamate

The invention discloses an anti-pilling overcoat comprising an overcoat body; raw materials of the overcoat body are treated by using an anti-pilling agent; raw materials of the anti-pilling agent include waterborne polyurethane prepolymer and an organic silicon modifier; and the waterborne polyurethane prepolymer comprises the following components: isophorone diisocyanate, polyethylene glycol anda chain extender. The anti-pilling overcoat has the following advantages that waterborne polyurethane is synthesized by isocyanate, polyether polyol, a small-molecular chain extender and an end capping agent. A polyurethane molecule contains a great deal of carbamate and carbamido and is good in film forming property and wear resistance, high in adhesive force and excellent in mechanical properties. A waterborne polyurethane polymer can form a net structure with a certain crosslinking degree together with a fiber structure, so that the phenomena such as winding and pilling of the fiber are effectively avoided and relieved, and furthermore, the anti-pilling and anti-fuzzing performances of a fabric are greatly improved. Compared with polyacrylate, polyurethane is more excellent in performance, however, the neatened fabric is relatively hard in handfeel to affect the wearing comfort level of a textile.

Owner:乐清市雅格狮丹服饰有限公司

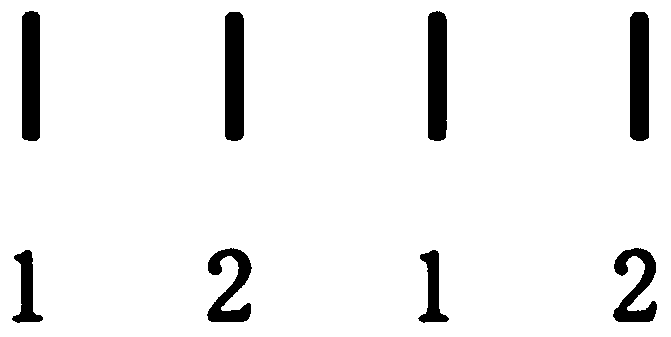

Device conducting false twisting on cotton yarns

InactiveCN103343412AReduce residual torqueImproved anti-pilling propertiesTextiles and paperYarnEngineering

A device conducting false twisting on cotton yarns comprises an installation base, a plurality of pairs of rollers, yarn guide ceramic parts, false twisting motors, belt wheels and a long false twisting tangential belt. The device further comprises a support and rotary compressing devices, wherein the support is installed between the roller and the yarn guide ceramic parts, the rotary compressing devices are evenly distributed on the support which is fixed on the installation base, and the long false twisting tangential belt is matched with the rotary compressing devices. By the adoption of the structure, the device has the advantages that residual torque of the single yarns is small, woven and knit fabrics have the flat and smooth surfaces and soft hand feel, and are firm and durable, and pilling resistance of the fabrics is enhanced; compared with a long false twisting tangential belt in a square layout in the prior art, the long false twisting tangential belt is in a strip-shaped layout, and therefore the structure is simple and occupied space is small.

Owner:王成铸

Fabric with cotton handfeel, woolen appearance and linen coolness and production process of fabric

InactiveCN106037100AComfortable texture and touchIncrease elasticityDry-cleaning apparatus for textilesWrinkle resistant fibresPolyesterWool fiber

The invention discloses a fabric with cotton handfeel, woolen appearance and linen coolness and a production process of the fabric. The fabric is prepared from microporous polyester fibers, wool fibers and polyester based conductive fibers, wherein the microporous polyester fibers is (1.5-1.8)dtex*(30-45)mm in specification and 80-85% in weight percentage; the wool fibers are (1.7-1.9)dtex*(35-50)mm in specification and 13-18% in weight percentage; the polyester based conductive fibers are (2-2.3)dtex*(30-45)mm in specification and 1-2% in weight percentage. The fabric has comprehensive functions and styles of cotton handfeel, woolen appearance and linen coolness.

Owner:HAIXI NEW TEXTILE MATERIAL OF JINJIANG IND TECH ACAD +1

Finishing method high-hygroscopic and perspire fibre with cotton-dispersion

ActiveCN100487189CImprove the finishGuaranteed strongBiochemical fibre treatmentVegetal fibresFiberEnzyme

A treatment to make cotton fiber more hygroscopic .The process includes enzyme treatment on cotton fiber to enhance its smoothness and strength, dyeing on fiber, softening agent treatment to make it more hygroscopic and to lower its specific resistance. Cotton made by this process shows high quality such as softy, smoothy and hygroscopic. It is also time saving and energy saving.

Owner:ZHEJIANG HUAFU COLOR TEXTILE

Negative oxygen ion-release health cashmere composite fiber and manufacturing method thereof

InactiveCN104911734AIncrease added valueEffective release of active negative oxygen ionsConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsOxygen ionsGinkgo

The invention discloses a negative oxygen ion-release health cashmere composite fiber. The fiber is prepared from 30-40 parts by weight of cashmere fibers, 13-16 parts by weight of polyacrylonitrile fibers, 15-18 parts by weight of soybean fibers, 16-20 parts by weight of bombax ceiba fibers, 0.3-0.6 parts by weight of sodium laurate, 2-3 parts by weight of tourmalinite powder, 1-2 parts by weight of diisocyanate, 5-8 parts by weight of isopropyl palmitate, 10-20 parts by weight of agricultural emulsifier No.600, 3-5 parts by weight of ginkgo leaf, 2-4 parts by weight of lotus leaf, 1-2 parts by weight of radix bupleuri, 100-110 parts by weight of 1-ethyl-3-methylimidazolium acetate, 95-105 parts by weight of 1-allyl-3-methylimidazolium chloride, 20-30 parts by weight of an auxiliary agent and a proper amount of water. The polyacrylonitrile fibers, soybean fibers, bombax ceiba fibers and cashmere fibers are immersed in the Chinese herbal medicine-modified anti-pilling auxiliary agent and modified tourmalinite powder is added into the mixture so that the cashmere composite fibers are prepared. The cashmere composite fiber can effectively release active negative oxygen ions, has the advantages of antibiosis, mildew resistance and wear resistance, reduces cashmere surface friction, improves cashmere fabric anti-pilling performances, is soft, slip and fluffy, has warming effects and further improves a cashmere added value.

Owner:TONGLING HONGZHENG NETWORK SCI & TECH CO LTD

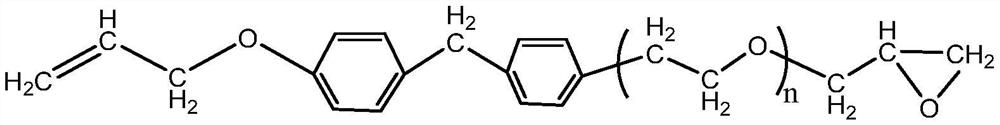

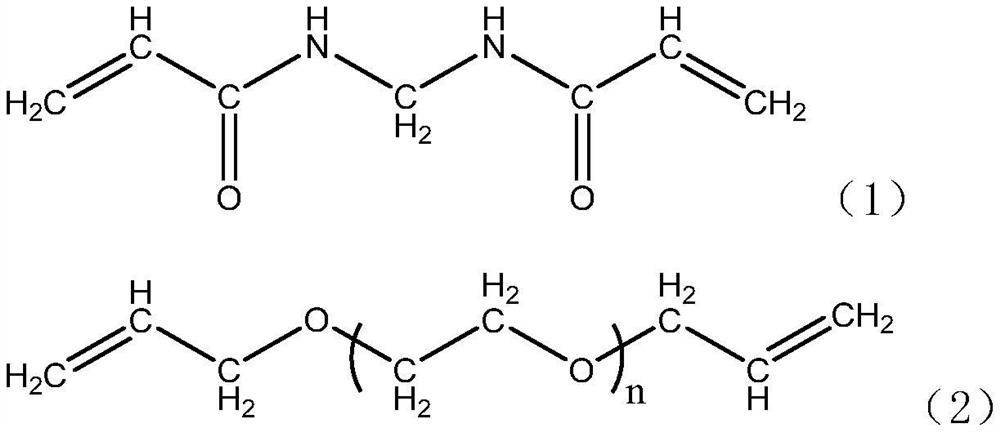

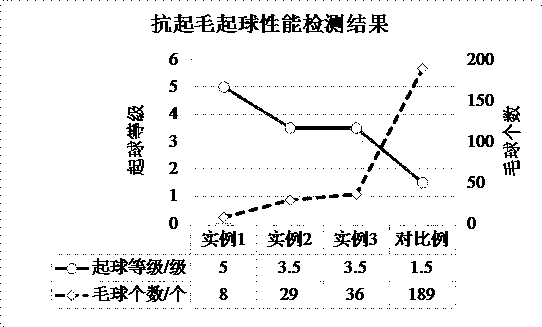

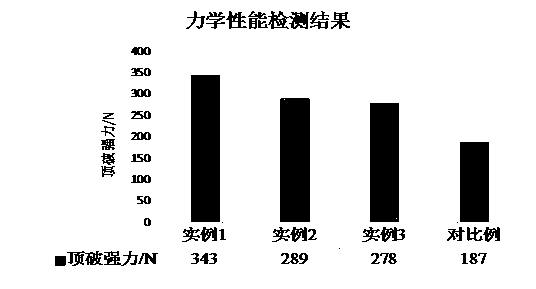

Bubble fastness improver for dyeing polyester and preparation method of bubble fastness improver

ActiveCN114657800AImproved blister fastnessPrevent water from fadingDyeing processDisperse dyePolymer science

The invention discloses a blister fastness improver for dyeing polyester and a preparation method of the blister fastness improver. The blister fastness improver comprises the following components in parts by weight: 10-20 parts of a three-terminal allyl cationic monomer, 20-60 parts of an allyl polyether epoxy end cap, 2-6 parts of a cross-linking agent, 0.2-1.0 part of an initiator and 20-50 parts of deionized water. According to the blister fastness improver for dyeing the polyester and the preparation method of the blister fastness improver, the prepared blister fastness improver for dyeing the polyester is a three-dimensional high-molecular cationic polymer with an epoxy active group, is applied to padding and sizing of a dyed polyester fabric, and can improve the blister fastness of the dyed polyester fabric, so that the blister fastness of the dyed polyester fabric is improved, and the service life of the dyed polyester fabric is prolonged. Meanwhile, the polyester fabric is endowed with antistatic property and pilling resistance, and the quality of the polyester fabric is improved.

Owner:浙江联胜新材股份有限公司

Finishing method capable of preventing Modal fibers from pilling

InactiveCN107794768AAvoid direct contactImproved anti-pilling propertiesAbrasion resistant fibresVegetal fibresPolymer scienceEmulsion

The invention discloses a finishing method capable of preventing Modal fibers from pilling and belongs to the technical field of textile materials. The finishing method includes: mixing man-made spider fibers and silk fibers, adding protease and water, stirring and mixing, and performing rotary evaporation and concentration to obtain mixed fiber concentrate; mixing a eucommia ulmoides gum emulsionwith an oxidizing agent, and performing stirring reaction to obtain an oxidized eucommia ulmoides gum emulsion; mixing the Modal fibers with liquid ammonia, performing reaction under normal temperature and high pressure to obtain activated Modal fibers; mixing the mixed fiber concentrate and the oxidized eucommia ulmoides gum emulsion, adding a dewatering agent, performing stirring reaction, standing, and filtering to obtain a modified eucommia ulmoides gum emulsion; mixing the activated Modal fibers with the modified eucommia ulmoides gum emulsion, adding a catalyst, performing stirring reaction, and filtering, pre-baking, baking and discharging to obtain the Modal fibers resistant to pilling. The finishing method has the advantages that the Modal fibers finished by the method can keep original strength, the pilling resistance of the Modal fibers is increased, and the dry modulus of the Modal fibers is also increased.

Owner:刘滨

Method for improving yarn evenness of spun yarns based on circular yarn path

The invention relates to a device for improving the yarn evenness of spun yarns by using a vortex spray pipe with a circular yarn path, and belongs to the technical field of textile engineering. The device is named the vortex spray pipe for short. The vortex spray pipe is mainly composed of the yarn path and an air path, mounted on a rack of a spinning machine, and placed between a front roller and a snail wire. During usage, yarns which pass through the center of the yarn path are under the action of airflow which is vertically tangent to the yarn path inside the air path, the airflow which is sprayed into the yarn path from the air path forms a vortex, untwisting and twisting are conducted to the yarns with a great deal of hairiness, and thereby the hairiness is effectively reduced. Meanwhile, the yarn evenness and the strength of the spun yarns are improved. The device is simple in structure, low in equipment transformation cost, and convenient to mount, thereby having good development and application value.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com