Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

131results about How to "Guaranteed strong" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

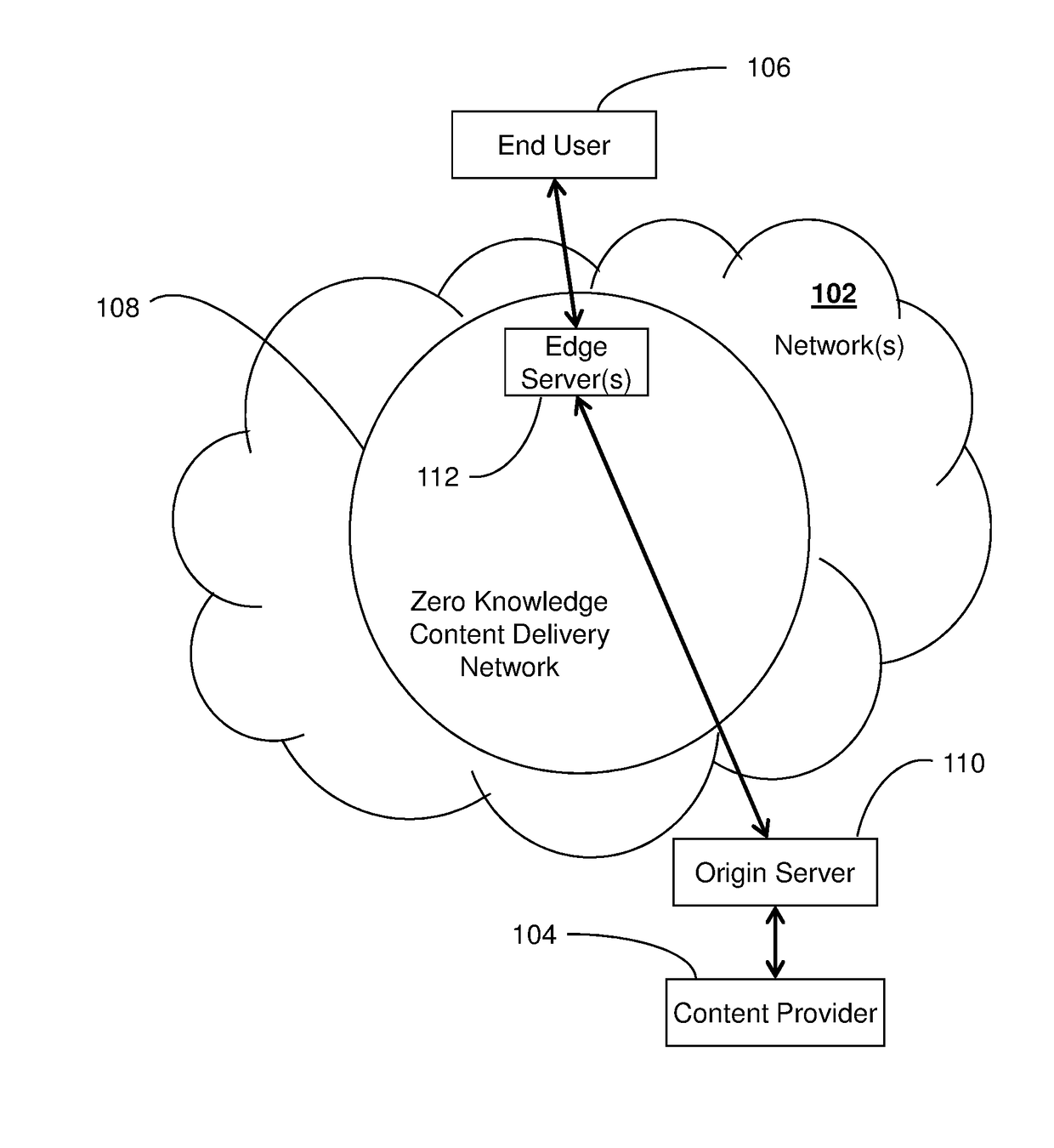

Cryptographically provable zero-knowledge content distribution network

ActiveUS20170277909A1Guaranteed strongAssures both integrity for content owners and privacyCryptography processingDigital data protectionEdge serverComputer network

A system, a computer readable storage medium, and methods for delivering content from a zero-knowledge edge server node in a content delivery network to an end user device, ensuring content control by a content provider (i.e. reduce piracy) while ensuring privacy of an end user device. One method includes publicizing that a particular content is available for download from the server node; initiating with the server node a communication session using a zero-knowledge protocol between the end user device and the server node operating in zero knowledge; downloading, while in the communication session, the particular content from the server node to the end user device; and receiving a response message from the end user device, including an indication of a content media player application, using the particular content, successfully executed at the end user device. The indication can be accompanied by a cryptographically verifiable proof of integrity.

Owner:IBM CORP

Production process of high-count and high-density long stapled cotton shirt fabric

ActiveCN105671727AImprove permeabilityImprove wear resistanceSucessive textile treatmentsDry-cleaning apparatus for textilesYarnHigh density

The invention relates to a production process of a high-count and high-density long stapled cotton shirt fabric. The finished product fabric is prepared from long stapled cotton yarns sequentially by processes of slashing, weaving, singeing, desizing, boiling-off, cold pad batch dyeing, liquid ammonia mercerized finishing, moist-cure anti-crease finishing and preshrinking, and the long stapled cotton yarns adopt 140s / 2 celo compact-spun GIZA45 long stapled cotton yarns and are woven into twill weaves. According to the production process provided by the invention, the long stapled cotton yarns are used as raw materials; technologies of cold pad batch dyeing, liquid ammonia mercerized finishing and moist-cure anti-crease finishing are combined; the energy-saving environmental-friendly high-count and high-density shirt fabric is developed; the high-count and high-density long stapled cotton shirt fabric has soft and comfortable hand feeling, fine and soft gloss and excellent wear comfort, mode-holding nature and anti-crease property and can be free of ironing; the comprehensive technology of the product reaches the domestic advanced level; the high-count and high-density long stapled cotton shirt fabric has wide market prospect and social and economic benefits; meanwhile, the energy-saving environmental-friendly fabric production process reduces pollution to the environment and makes a contribution to development of a cleaning fabric processing technology and social sustainable development.

Owner:FUJIAN SEPTWOLVES IND

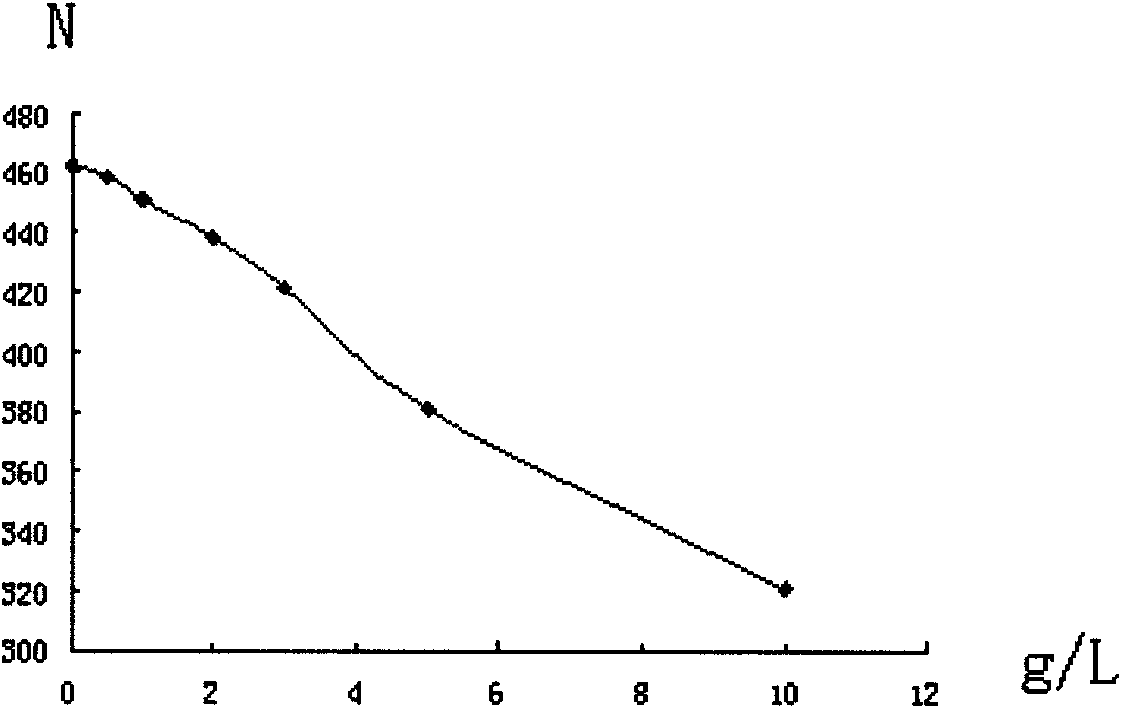

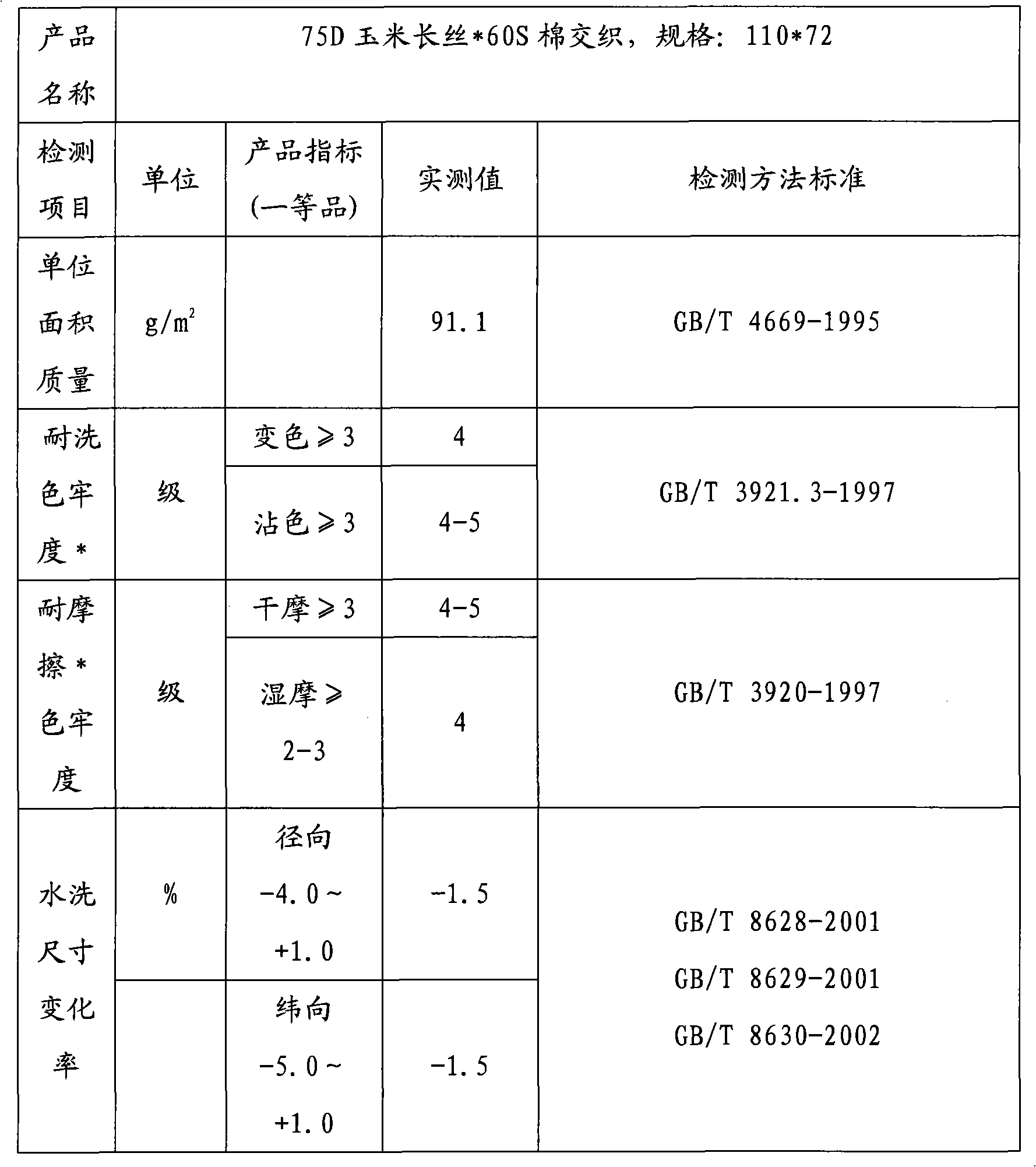

Technology for dyeing and finishing real silk/corn fabric

ActiveCN101736616AGuaranteed high color fastnessGuaranteed strongBiochemical fibre treatmentDyeing processDisperse dyeEngineering

The invention relates to technology for dyeing and finishing real silk / corn fabric. In order to solve the technical problem, the invention provides the provided technology for dyeing and finishing which can effectively improve the dye uptake of the corn fiber and the color fastness of the fabric, and maximize the strength of the corn fiber and the fabric. The technical scheme of invention is that: the technology for dyeing and finishing the real silk / corn fabric comprises the processes of bleaching, dyeing and heat shaping in turn. The technology for dyeing and finishing the real silk / corn fabric is characterized in that: 1) the bleaching (refining) process comprises steps of pretreating, enzyme scouring, and second scouring; 2) the dyeing process comprises steps of dyeing, reduction clearing, and water washing, wherein staining solution comprises a disperse dye and a reactive dye, or the dyeing process comprises steps of disperse dye dyeing, reduction clearing, water washing, reactive dye dyeing, soap boiling and water washing; and 3) the heat shaping process comprises steps of padding soft solution and heat shaping, wherein the enzyme scouring in the bleaching process adopts neutral enzyme scouring or alkaline enzyme scouring; the staining solution of the disperse dye comprises 0 to 2 g / L of darkening agent DL-6; and the fabric dyed by the disperse dye needs to be washed by adopting acid reduction technology.

Owner:HIGH FASHION CHINA CO LTD

Dyeing and finishing process of corn fibers and cotton blending and mixed fabrics

ActiveCN101671947ASufficient sourceNo need for petrochemical resourcesBiochemical fibre treatmentHeating/cooling textile fabricsDisperse dyeDying processes

The invention discloses a dyeing and finishing process of corn fibers and cotton blending and mixed fabrics, comprising the following steps: end stitching of greige cloth, pre-setting, pre-treatment,dyeing, dehydration, post finishing, and warehouse entry inspection. In the pre-setting process, the temperature is 120-130 DEG C and the time is 30-45 minutes; in the pre-setting process, the presetfabrics are placed in an overflow dying machine to conduct desizing and remove the hairiness on the surface of the fabrics; in the dying process, the corn fibers adopt middle temperature type and lowtemperature type dispersing dyes to conduct dying; and in the post finishing process, the dyed fabrics are placed in a 8-12g / L of hydrophilic amino-silicone softener for padding, and then the padded fabrics are dried and stentered and set at 100-120 DEG C. The dyeing and finishing process of corn fibers and cotton blending and mixed fabrics has good coloring rate, ensures the strength and feel ofcorn fibers, and also has significant impact on the industrial development of the textile industry.

Owner:安徽三宝棉纺针织投资有限公司

Banana bast fiber and preparation method thereof

ActiveCN101736407AAntibacterial propertiesMoisture absorption and dehumidification fastMechanical fibre separationBacteriological rettingBreaking strengthFiber bundle

The invention discloses a method for preparing a banana bast fiber by adopting biological degumming, which is characterized by comprising the following steps of: preprocessing, inoculating, fermenting, inactivating, stamping and postprocessing. The prepared banana bast fiber has soft and loose appearance and uniform color and has no taste or obvious flaws; the fiber length is 80mm-200mm, the fiber count is 300Nm-500Nm, the breaking strength of fiber bundles is 3.5g / D-5.0g / D, and the residual gum content is 1.5 percent-3.2 percent. The biologically degummed banana bast fiber effectively removes the non-spinnable components of colloid, lignin, hemicellulose and the like and keeps the bacteria proofing, rapid moisture absorption and release of the self characteristics of the fiber, thereby ensuring the strength of the fiber; meanwhile, the banana fiber is kneaded and rolled by sterilization and machines before degumming, thereby ensuring the degumming effect and the smooth going of degumming and enabling the degummed fiber to be beneficial to the production and production development of the next working procedure.

Owner:湖南华升益鑫泰科技有限公司

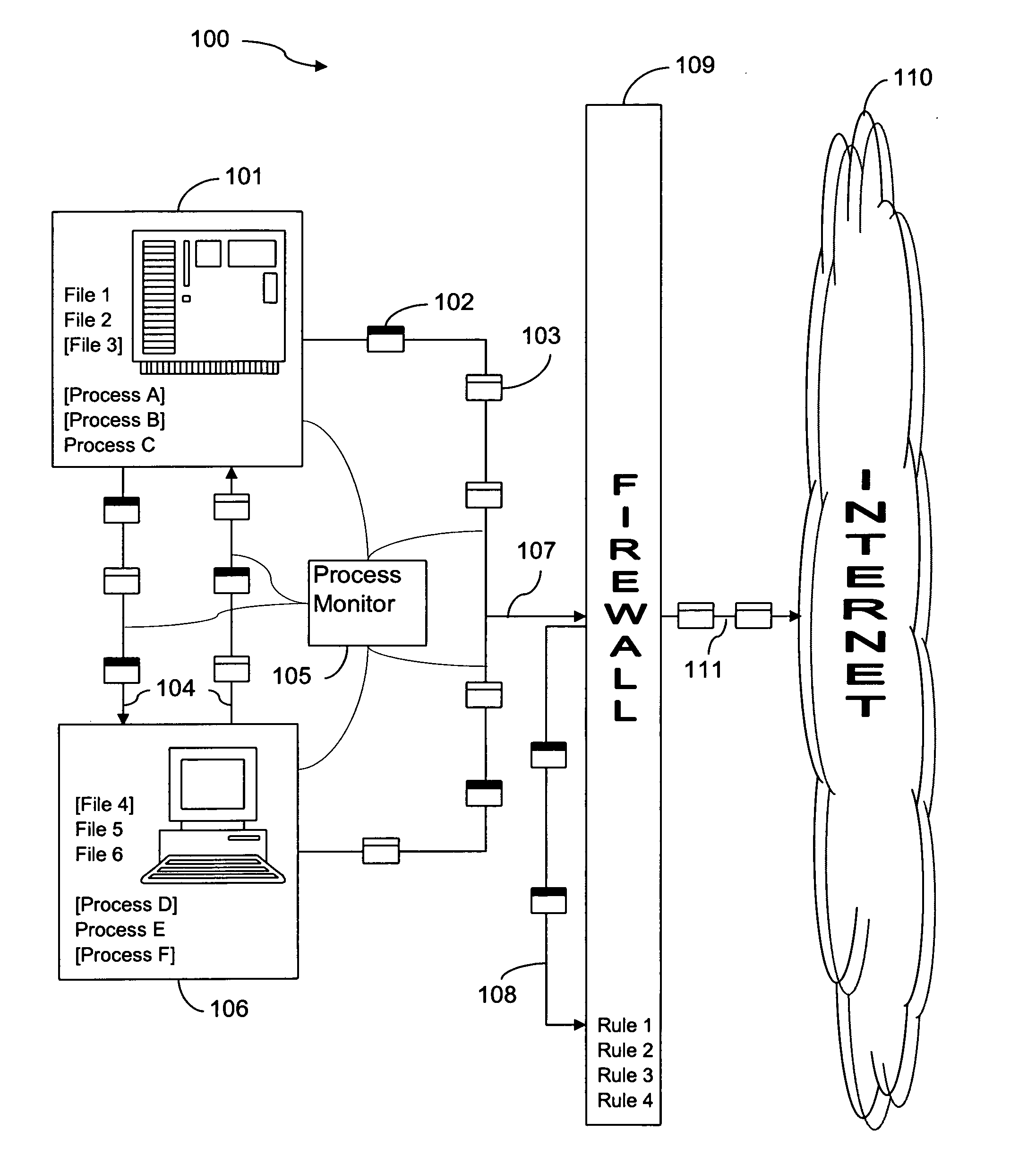

Unique packet identifiers for preventing leakage of sensitive information

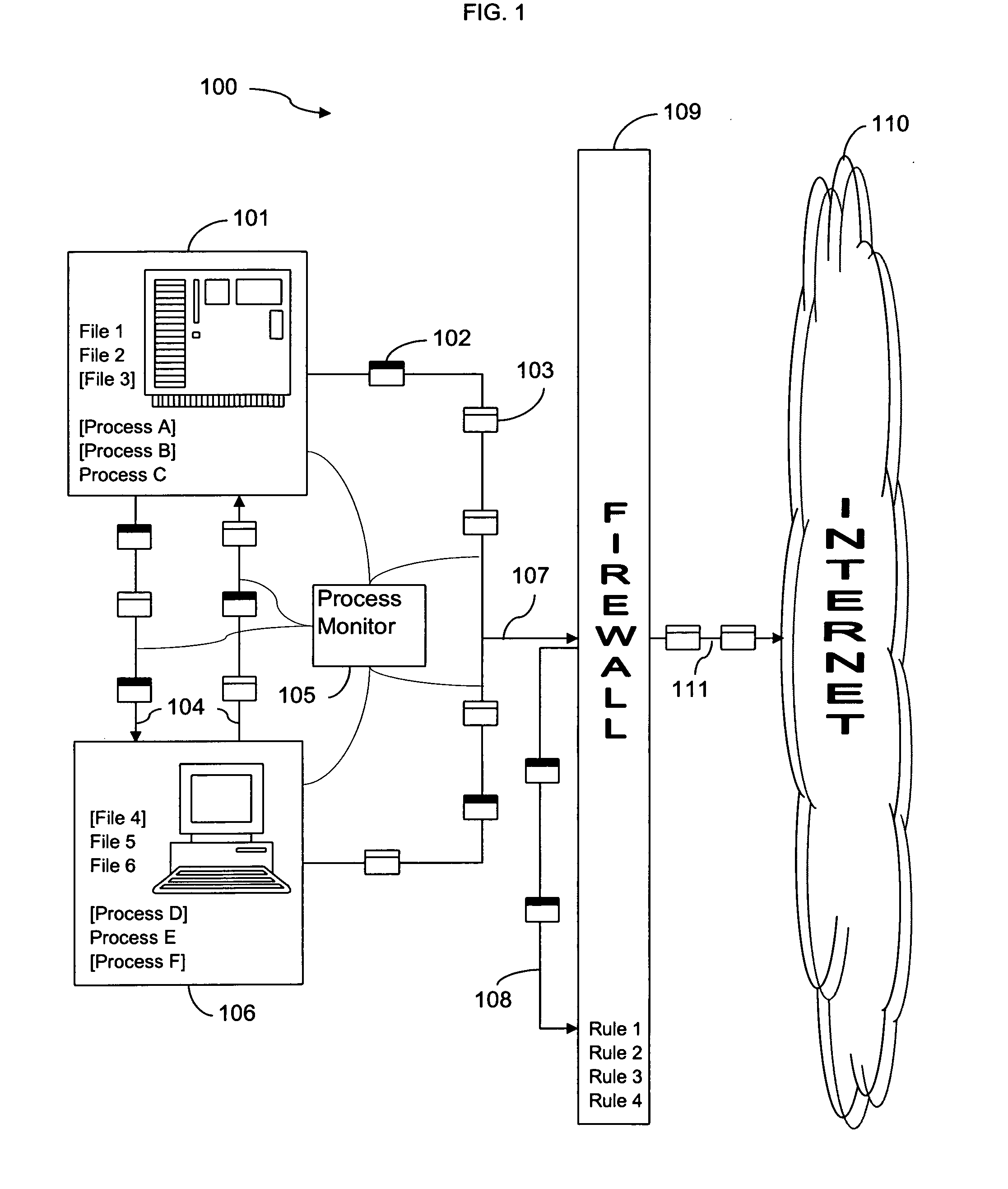

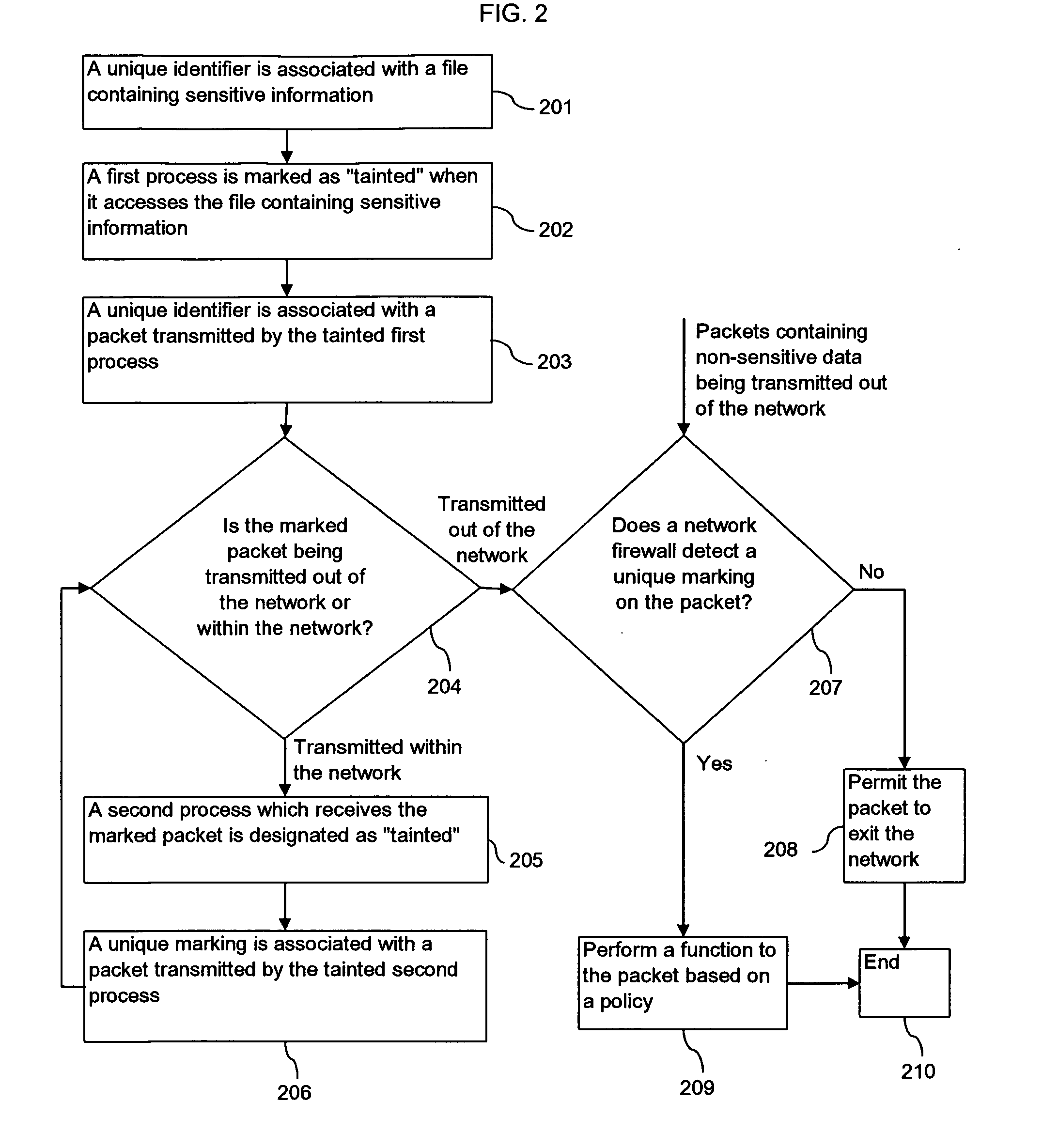

InactiveUS20090300751A1Easy to monitorAvoid restrictionsComputer security arrangementsMultiple digital computer combinationsNetwork packetUnique identifier

In accordance with an aspect of the invention, leakage prevention is implemented by: a) associating—within a network—a unique identifier with a packet transmitted by a process which has previously accessed data containing sensitive information, and b) searching a packet before it exits a network for the unique identifier. This mechanism provides a strong guarantee against leakage of sensitive data out of a network by facilitating the monitoring of packets which potentially contain the sensitive information. The unique identifier may be located in the header of the packet, which is detectable without requiring a heavy investment of network resources. Additionally, a packet's movement within a network may be tracked by analyzing trapped system calls. Furthermore, an exiting packet may be analyzed by a network firewall, the firewall utilizing various policies to determine how to proceed when a packet containing a unique identifier is located.

Owner:AT&T INTPROP I L P +1

Plasma and enzyme combined anti-felting method for tidying wool knitted fabric

InactiveCN101177915AProcess for improving felting resistanceBurst downBiochemical fibre treatmentUltrasonic/sonic fibre treatmentEngineeringEnzyme

The invention relates to an antifelting finish method of wool knits combining plasma and bio-enzyme, comprising the steps that: wool washing, plasma treatment, protease treatment, water washing, Transglutaminase treatment, water washing, and drying. The invention can lead wool knits to reach machine washable standard (with a felting rate less than 2 percent) while the intensity is ensured (intensity damage is less than 10 percent), and has little damage during the finish process, with safety and environmental protection performance, and is an energy-conservation and clean wool post-treatment technique.

Owner:DONGHUA UNIV

Green multifilament blended fabric

InactiveCN101275328AMeet the requirements of the yarn standardGood moisture absorption and air permeabilityWeft knittingWarp knittingFiberWrinkle skin

The inventive green multifilament blended facing material is formed by blended spinning of zein fibre, bamboo fibre and flaxrichce fibre, wherein, the chaine is same with the weft yarn, and the weight proportion of spinning raw material is 35-45 percent of zein fibre, 35-45 percent of bamboo fibre and 15-25 percent of flaxrichce fibre. The invention adopts a plurality of green fibres for blended spinning and interweaving, which sufficiently exerts the moisture absorption ventilating, peculiar silk like brightness, favorable reversion performance, wrinkle resistance, and pilling resistance of the zein fibre, and the favorable hydroscopicity , dyeability, soft comfortable hand feeling, and good drapability of the wood fiber, thereby the performance of various fibres is ascendency complementary, the spinning perfromance of fibre is increased, the brute force and quality of the yarns is improved; meanwhile the facing material is provided with features of favorable moisture absorption ventilating, comfort of wear, sliding feel well hand feeling, pendant dynamic, non electrostatic puzzle, good reversion perfromance and wrinkle resistance, etc.

Owner:SHANDONG QISAI TEXTILE

Preparation technology of far-infrared cotton fiber

ActiveCN104695227AGood antibacterial effectImprove adsorption capacityBiochemical fibre treatmentVegetal fibresCross-linkApocynum venetum

The invention discloses a preparation technology of far-infrared cotton fiber. The preparation technology comprises the steps of preparing raw materials, treating the raw materials, preparing a far-infrared mixed solution, carrying out coating treatment and spinning. The preparation technology is simple in method; the far-infrared coating mixed solution is prepared by mixing far-infrared ceramic powder with a resin bonding agent, a cross-linking agent, a dispersing agent and the like; the treated raw material fiber is coated with the far-infrared coating mixed solution, and the far-infrared coating mixed solution is firmly combined with the raw material fiber, so that the far-infrared fiber is good in effect. An ultraviolet light absorber is also added to the far-infrared coating mixed solution and is dipped into the cotton fiber, so that the finished product fiber has an ultraviolet resistant function. The cotton fiber is refined by alkaline biological enzyme, and alkali treatment is replaced, so that the preparation technology is low in damage to fiber and is beneficial to maintaining fiber strength; apocynum venetum fiber and activated carbon fiber are added into the raw material fiber for use, so that the finished product fiber also has a good antibacterial effect.

Owner:浙江世纪晨星纤维科技有限公司

Stiffening agent and production method thereof

InactiveCN102454106AExcellent yarn cohesionDoes not affect shadeFibre treatmentPolymer sciencePolyvinyl acetate

The invention discloses a stiffening agent and a production method thereof. The stiffening agent is composed of 40% polyvinyl acetate emulsion, soluble starch, gelatin, and deionized water. With the stiffening agent, fabric is provided with a stiff and thick texture, and can be prevented from coiling. Finished fabric is prevented from moisture regaining and mellowing, and is provided with certain washing fastness. With the stiffening agent, the strength of the fabric can be maintained to a maximal extent, and a fabric gliding phenomenon can be prevented. The stiffening agent can be used in a same bath with most of finishing agents.

Owner:南通斯恩特纺织科技有限公司

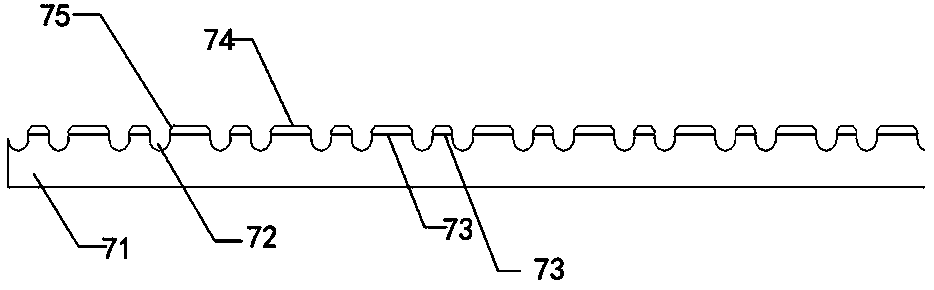

Polytetrafluoroethylene punched felt and manufacturing method thereof

ActiveCN101805958AHigh saturationReduce voidsHeating/cooling textile fabricsNon-woven fabricsMaterial consumptionEngineering

The invention relates to a polytetrafluoroethylene punched felt. From the outside to the inside, the structure of the punched felt comprises a polytetrafluoroethylene crimped staple layer, a polytetrafluoroethylene filament base fabric and a polytetrafluoroethylene crimped staple layer, wherein the thickness of the punched felt ranges from 0.8 to 1.8 millimeters; polytetrafluoroethylene crimped staples mutually hooked and crossed are inserted in the base fabric from upside and downside and tightly connected with the base fabric. The punched felt produced by the invention has the advantages of stable chemical properties, high filtering effect, high strength, low heating shrinkage, low material consumption, low cost, no smoke pollution and the like.

Owner:常州华福环境科技股份有限公司

Cotton blended spinning elastic knitted underwear face fabric and processing technique thereof

InactiveCN101148801AStress reliefImprove the finishWeft knittingBiochemical fibre treatmentYarnPolymer science

The elastic knitted underwear fabric of blended cotton fiber and viscose fiber is woven with the materials including cotton fiber in 72-77 wt%, superfine viscose fiber in 19-25 wt% and elastic polyurethane fiber in 3-7 wt%, and through the technological process including frame spinning with cotton fiber and superfine viscose fiber to obtain 40S combed blended cotton-viscose yarn, yarn steaming, knitting the blended cotton-viscose yarn and elastic polyurethane fiber in a single-sided large circular weaving machine to obtain the underwear fabric, and final polishing to eliminate hairs biologically with enzyme. The elastic knitted underwear fabric has improved fluffing and balling up performance, smooth surface, fully handling and high wearability.

Owner:SHANGHAI PLANDOO TEXTILE TECH DEV

Multifunctional fancy yarn and spinning method thereof

InactiveCN101377033AGood hygroscopicity and wearing comfortAvoid easy pilling and snaggingAdhesivesYarnPolyesterYarn

The invention relates to multi-functional fancy yarn and a spinning method thereof; the fancy yarn comprises core yarn, decorative yarn and fixed yarn; the core yarn is polyester fiber with infrared functional nano powder, the decorative yarn is polyester fiber with nano bamboo charcoal, and the fixed yarn is viscose fiber with pearl nano powder. The spinning steps of the fancy yarn are as follows: (1) the raw material fiber of the core yarn, the decorative yarn and the fixed yarn are respectively processed into roved yarn; (2) the roved yarn of the decorative yarn and the fixed yarn are fed on a special spinning machine at the same time to prepare bobbin yarn after drafting, twisting and packaging by roved yarn blending, and prepare into cone yarn 1 through a winding procedure; (3) the roved yarn of the core yarn is separately spun into spun yarn in the spinning machine, and prepared into cone yarn 2; (4) the cone yarn 1 and the cone yarn 2 are fasciated together to prepare the fancy yarn, and the fasciating method is adjusted according to product purposes to obtain fancy yarn in different types.

Owner:江阴市茂达棉纺厂有限公司

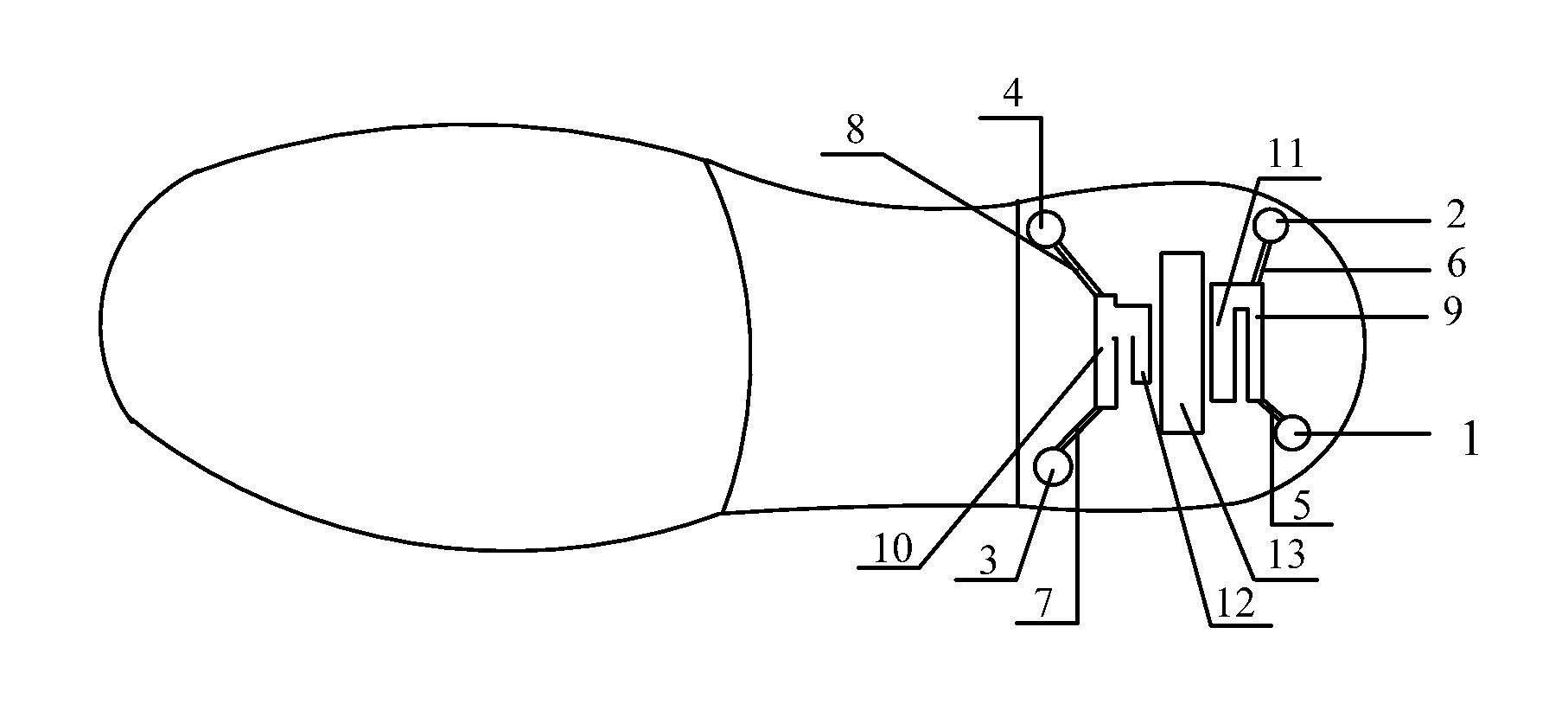

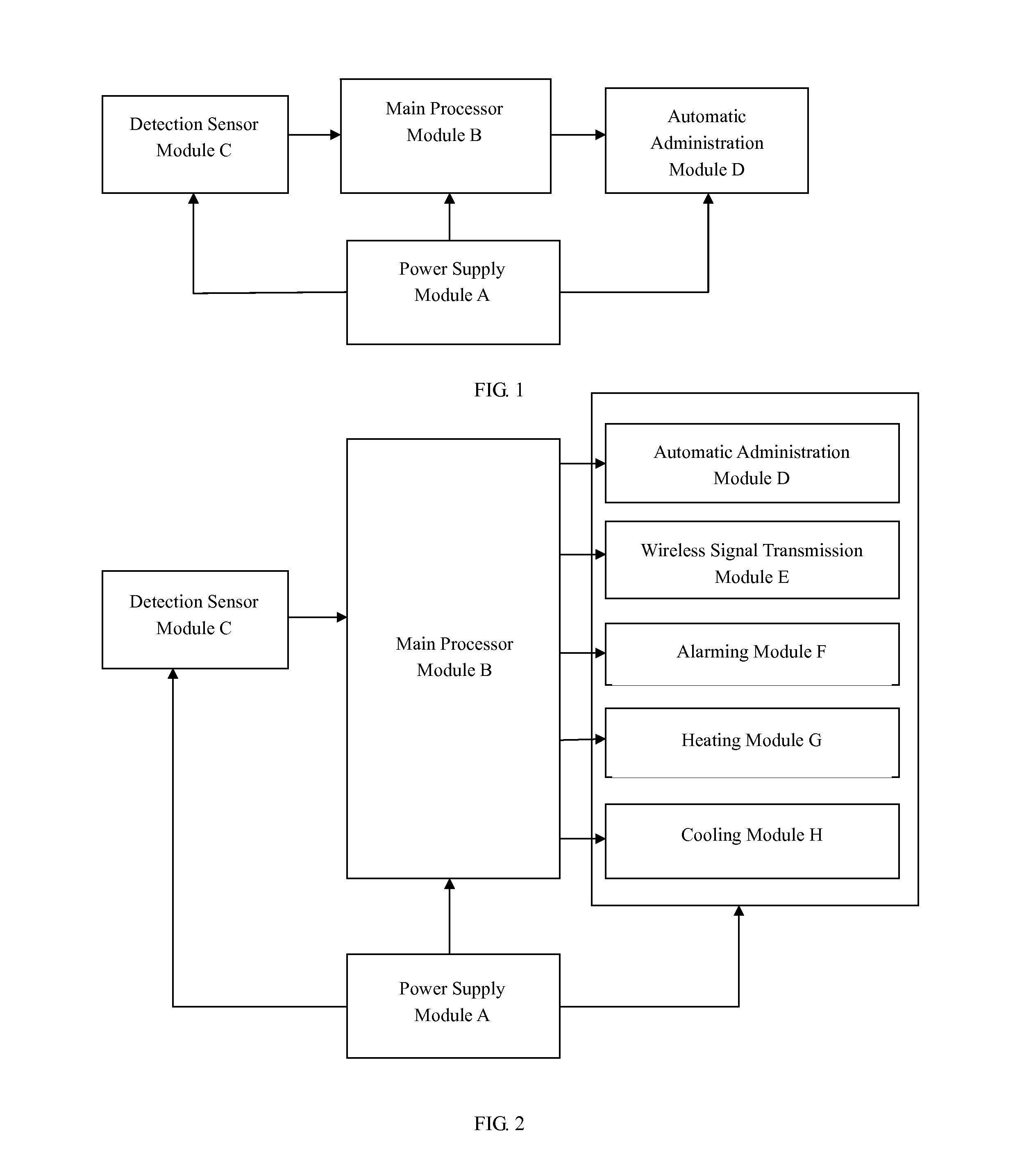

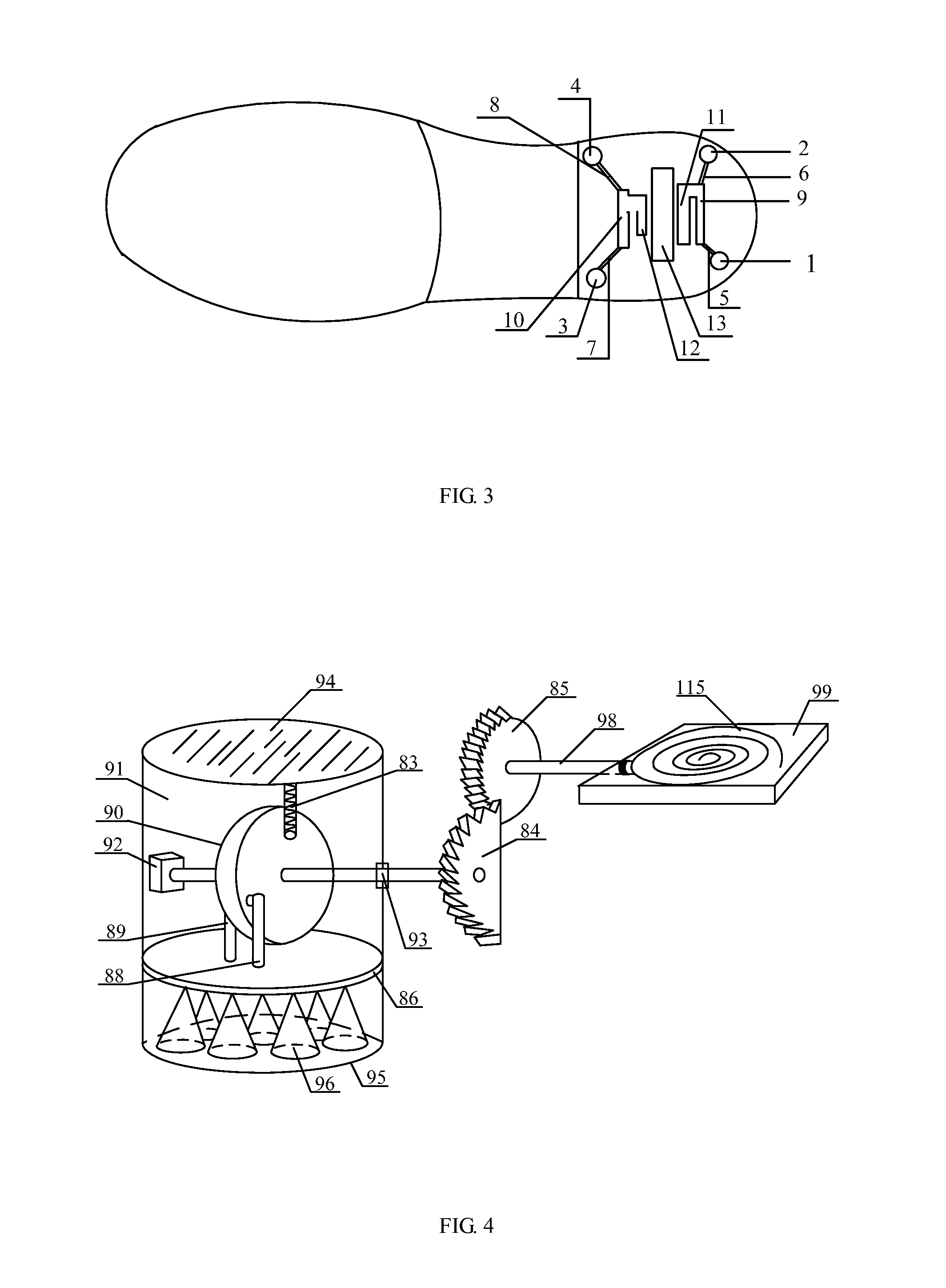

Disease testing and therapeutic device and remote monitoring shoes

ActiveUS20150088057A1Small sizeGuaranteed strongAutomatic syringesMedical devicesDiseaseTherapeutic Devices

The invention discloses a detection and therapeutic device and remote monitoring shoes. The detection and therapeutic device comprises a power supply module (a) which is connected with modules with electricity needs and used for powering the modules, a main processor module (b) which is used for collecting and processing signals from sensors and controlling working status of an automatic injection module (d), a detection sensor module (c) which comprises a plurality of sensors in connection with the main processor module (b) and is used for examining nerves, organs or secretions and sending back the results to the main processor module (b), an automatic injection module (d) which comprises a plurality of automatic injectors in connection with the main processor module (b) and is used for administrating according to signals for controlling from the main processor module automatically. The detection and therapeutic device can be used independently or can be paired with daily goods, such as shoes and the like. According to this arrangement, health condition can be detected at any time and automatic therapies can be achieved as sudden illnesses occur, and therefore, health risks can be reduced.

Owner:SU BO

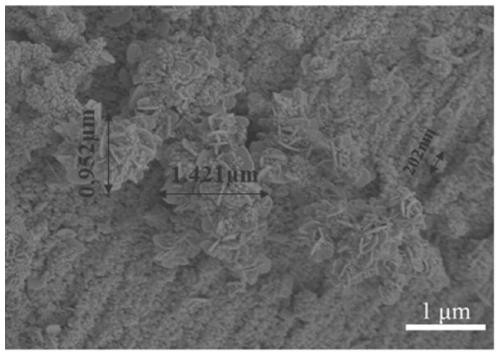

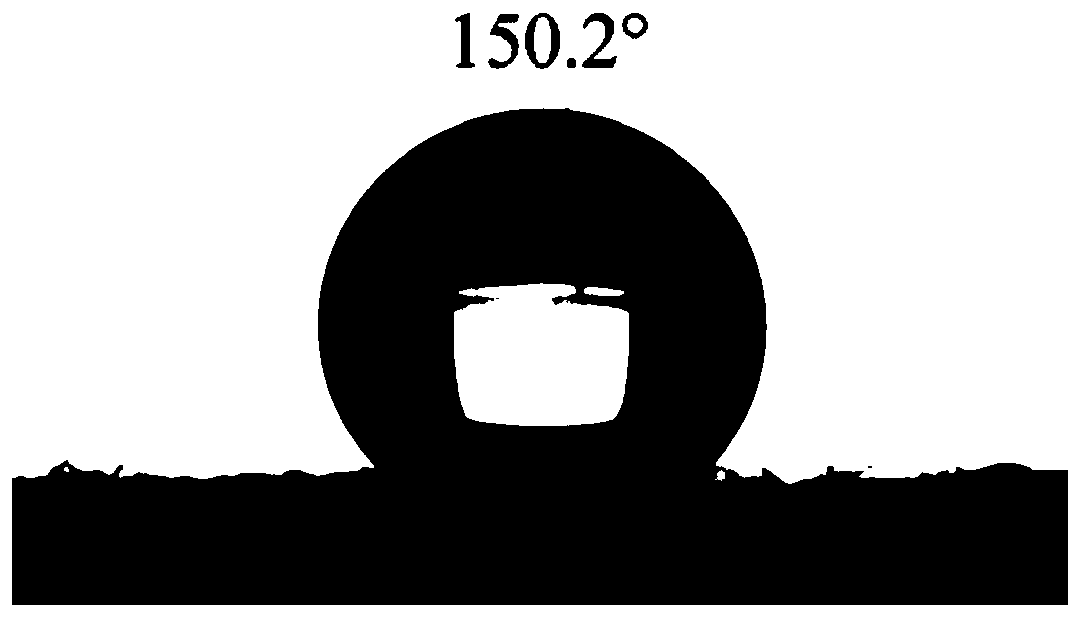

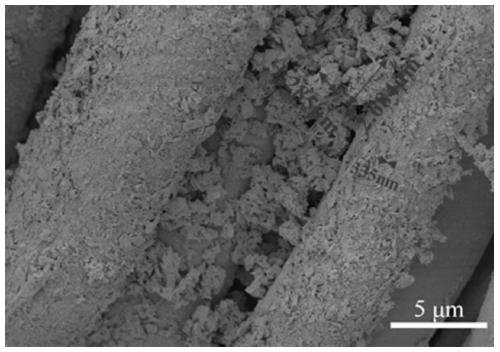

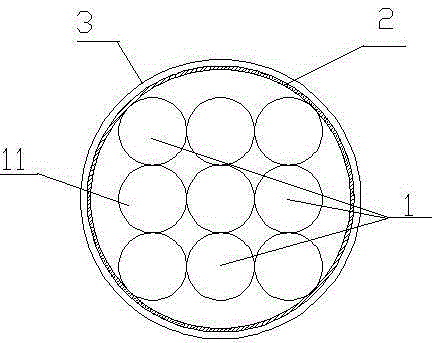

Waterproof cloth surface flexible composite material and preparation method thereof

ActiveCN111593570AExcellent durabilityGuaranteed strongSynthetic resin layered productsLiquid repellent fibresFiberPolymer science

The invention discloses a waterproof cloth surface flexible composite material and a preparation method thereof. The waterproof cloth surface flexible composite material is characterized in that one surface of a super-hydrophobic fabric is bonded with a plastic film by using an adhesive to obtain the washable waterproof cloth surface flexible composite material. The preparation method comprises the following steps of diazotizing a fluorine-containing alkyl aniline monomer in a dilute acid solution of sodium nitrite to form fluorine-containing alkyl benzene diazonium salt; carrying out reduction reaction on the fluorine-containing alkylbenzene diazonium salt under the action of a reducing agent to obtain a fluorine-containing alkylbenzene free radical monomer; and carrying out in-situ single-electron free radical covalent graft polymerization reaction on the fluorine-containing alkylbenzene free radical monomer in the fabric fiber to obtain the super-hydrophobic fabric. As the super-hydrophobic fabric obtained through chemical grafting, the fiber surface coating is combined with the fiber through covalent bonds, so that the super-hydrophobic fabric has excellent fastness, the flexibility and the hand feeling of the fabric are not influenced, and the problems of poor fastness and poor hand feeling of the super-hydrophobic fabric obtained through methods such as the coating are solved.

Owner:SUZHOU UNIV

Preparation method for euphausiid protein regenerated cellulose fibers

ActiveCN103741256AStrong and goodGuaranteed strongConjugated cellulose/protein artificial filamentsChemistryRegenerated cellulose

The invention relates to the field of chemical fiber materials and discloses a preparation method for euphausiid protein regenerated cellulose fibers. The preparation method comprises the following steps: preparing a mucilage glue solution for later use; preparing a pre-cross-linked euphausiid protein solution: sequentially adding a sodium hydroxide solution, euphausiid protein and lignin sulfamic acid; agitating at 50-70 DEG C for 4-6 hours; cooling to 35-45 DEG C, keeping the heat and filtering to obtain a filtering solution, namely the euphausiid protein solution; adding a cross-linking agent into the euphausiid protein solution and keeping the heat at 35-45 DEG C to react for 0.4-0.6 hour to prepare the pre-cross-linked euphausiid protein solution; and mixing the mucilage glue solution, the pre-cross-linked euphausiid protein solution and the cross-linking agent and spinning. The fibers prepared by the preparation method have good strength; the strength of the fibers is enhanced; meanwhile, the hand feeling and the luster of the fibers are improved and the fibers can be used as raw materials of a textile industry.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

Dyeing and finishing process of bamboo-cotton blended fabric

InactiveCN105780545ALow consumption costReduce dosageDyeing processVegetal fibresSodium carbonateDyeing

The invention discloses a dyeing and finishing process of a bamboo-cotton blended fabric. The dyeing and finishing process comprises the following steps: boiling and bleaching, namely preparing boiling and bleaching liquid, and boiling and bleaching the bamboo-cotton blended fabric in the boiling and bleaching liquid; dyeing, namely adjusting the pH value of the boiling and bleaching liquid to 7, taking out the bamboo-cotton blended fabric, putting the bamboo-cotton blended fabric and dyeing liquid into a dyeing machine, adding 10-15g of sodium carbonate into every litre of dyeing liquid, firstly heating the dyeing liquid to 90-95 DEG C, maintaining the temperature for 20-30 minutes, then heating the dyeing liquid to 95-130 DEG C, maintaining the temperature for 30-40 minutes, then cooling to 65-70 DEG C, and carrying out slow fixation; cleaning and reduction, namely adding cleaning liquid into the dyeing machine, and washing for 25-30 minutes at the temperature of 55-70 DEG C; and after treatment, namely putting the cleaned and reduced bamboo-cotton blended fabric into glacial acetic acid bath, and treating for 10-15 minutes at the temperature of 40-45 DEG C. The bamboo-cotton blended fabric processed by the dyeing and finishing process disclosed by the invention has original good bacteriostasis rate and bacteriostasis value of bamboo fiber, and also maintains original breathability, absorbency and elasticity of cotton fabric.

Owner:PAIDE DOWN FEATHER HOME TEXTILE NANTONG CO LTD

Bamboo fiber fabric dyeing and finishing process

InactiveCN105887514AStrong damageGuaranteed strongDry-cleaning apparatus for textilesBleaching apparatusFiberEngineering

The invention discloses a bamboo fiber fabric dyeing and finishing process. The bamboo fiber fabric dyeing and finishing process comprises the following steps of: scouring and bleaching, namely scouring and bleaching a bamboo fiber fabric with a bamboo fiber fabric solution and drying; after drying, pre-shaping; pre-treating, namely desizing a pre-shaped textile; dyeing, namely immersing the fabric with 75wt% ethanol; adding the bamboo fiber fabric solution into an active dyestuff to prepare a dyeing solution; immersing the bamboo fiber fabric with the dyeing solution; putting the dyed bamboo fiber fabric into a reducing washing solution to be subjected to reduction and washing; washing the bamboo fiber fabric with clean water; after-finishing, namely putting the dyed textile into a hydrophilic amino silicon softening agent and padding; after padding, adding bamboo-vinegar liquor to prepare a finishing solution and then carrying out after-finishing; and tentering, namely drying the textile subjected to the after-finishing and tentering and shaping. By improving a scouring and bleaching method and a formula of the scouring and bleaching solution, strength damages of fibers are reduced; the pre-treatment has desizing and scouring effects and the strength of the bamboo fibers does not have relatively large loss; a dyeing process guarantees good dyeing effect and dyeing fastness and the surface of the finally produced textile is flat; the color and luster are uniform and the dyeing fastness of the dyestuff is high.

Owner:NEWSEGA TEXTILE NANTONG CO LTD

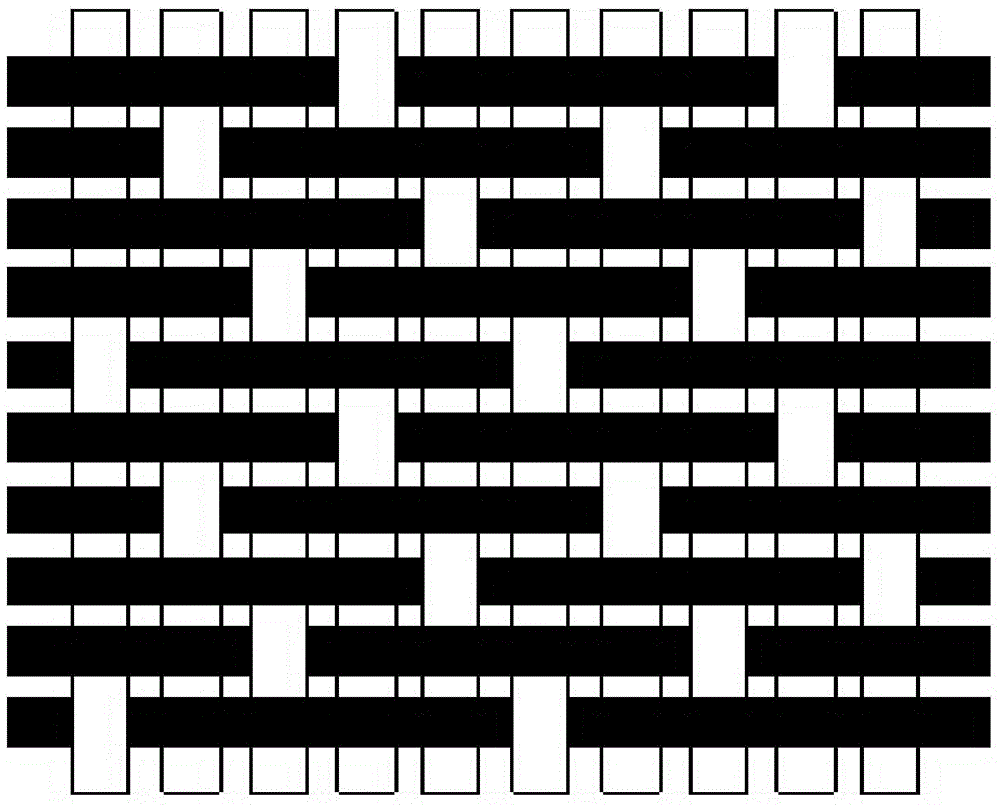

Production method of high-strength plastic woven bag

InactiveCN106319728AGuaranteed strongHigh strengthFilament/thread formingArtificial filament heat treatmentEngineeringPolypropylene

The invention relates to a production method of a high-strength plastic woven bag. The production method comprises the following steps: firstly, preparing polypropylene primary flat filaments, polypropylene primary flat filaments and polypropylene filament yarns; secondly, performing hot stretching and hot setting to obtain polypropylene finished flat filament and polypropylene finished flat filaments; weaving on a circular weaving machine to obtain woven drum fabric; thirdly, performing coextrusion and two-way stretching on special two-way stretching level polypropylene materials to obtain a cylindrical polypropylene inner coating film, and enabling the cylindrical polypropylene inner coating film to penetrate through and sleeve the inner part of the woven plastic woven drum fabric; enabling the woven plastic woven drum fabric to enter a heating baking oven; performing pressing fit, lifting and winding to obtain the plastic woven bag with the polypropylene inner coating film. According to the production method disclosed by the invention, the high-strength polypropylene finished flat filament, the polypropylene finished flat filament and polypropylene filament yarns are respectively adopted in a warp direction and a weft direction for weaving, so that the strength of woven base cloth is guaranteed; in addition, the inner part of the woven bag is coated with a polypropylene thin film, so that the strength of the plastic woven bag is improved; the plastic woven bag is suitable for packaging powdery small particle objects.

Owner:TIANJIN XUHUIHENGYUAN PLASTIC PACKAGING CORP

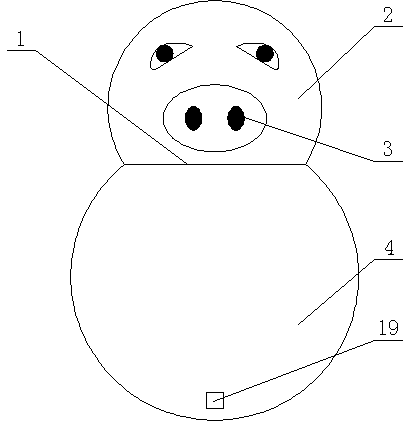

Welfare toy for pig

InactiveCN103999795ASave spaceSimple structureTaming and training devicesLivestock breedingEconomic benefits

The invention belongs to the field of livestock breeding welfare facilities, and particularly relates to a welfare toy for a pig. The welfare toy comprises a toy body which is in a calabash shape, the diameter of the upper portion of the toy body is smaller than that of the lower portion of the toy body, the upper portion is communicated with an inner cavity of the lower portion, a balance weight device is arranged at the bottom of the inner cavity of the lower portion, a storage battery, a stand column and a music mainboard are arranged on the balance weight device, an LED color change lamp is fixedly arranged at the upper end of the stand column, the LED color change lamp is connected with the storage battery through a first power supply line, and a first vibrating switch is arranged on the first power supply line. The music mainboard is connected with the storage battery through a second power supply line, a second vibrating switch is arranged on the second power supply line, the music mainboard is connected with a loudspeaker through a music output line, and the loudspeaker is arranged on the inner wall of the upper portion of the calabash shape. A power socket is formed in the lower portion of the calabash shape. The toy is easy to place and take out, production management personnel can move in a colony house conveniently, the life of swinery is enriched, production stress is reduced, welfare breeding is improved, and economic benefits are created.

Owner:INST OF ANIMAL SCI & VETERINARY MEDICINE SHANDONG ACADEMY OF AGRI SCI

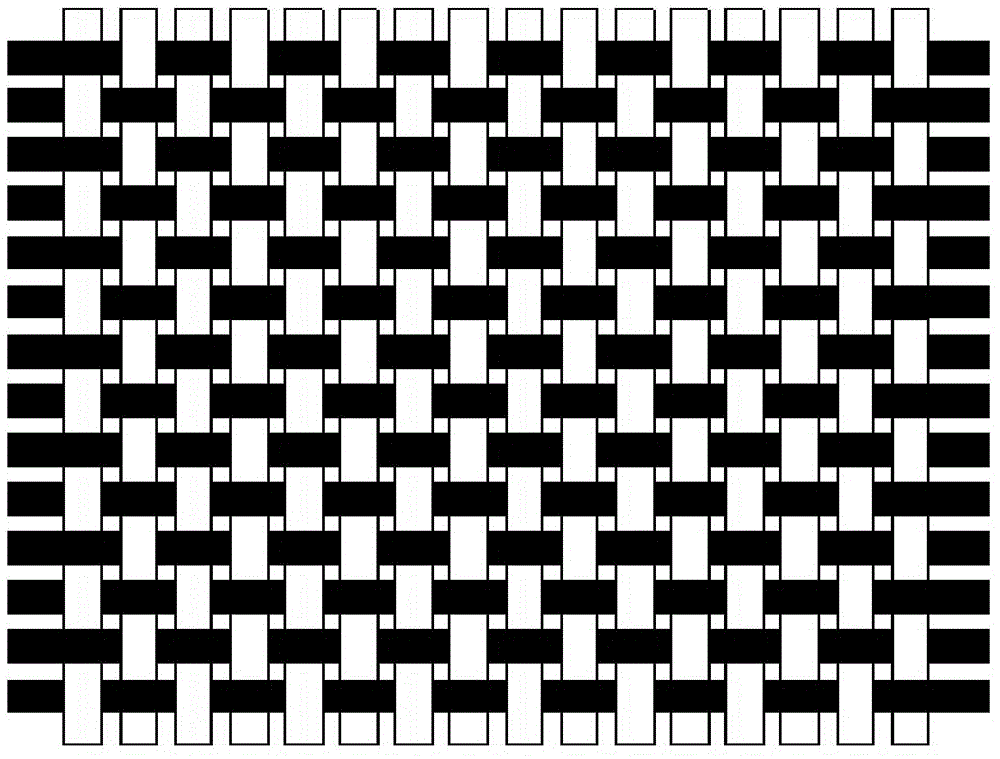

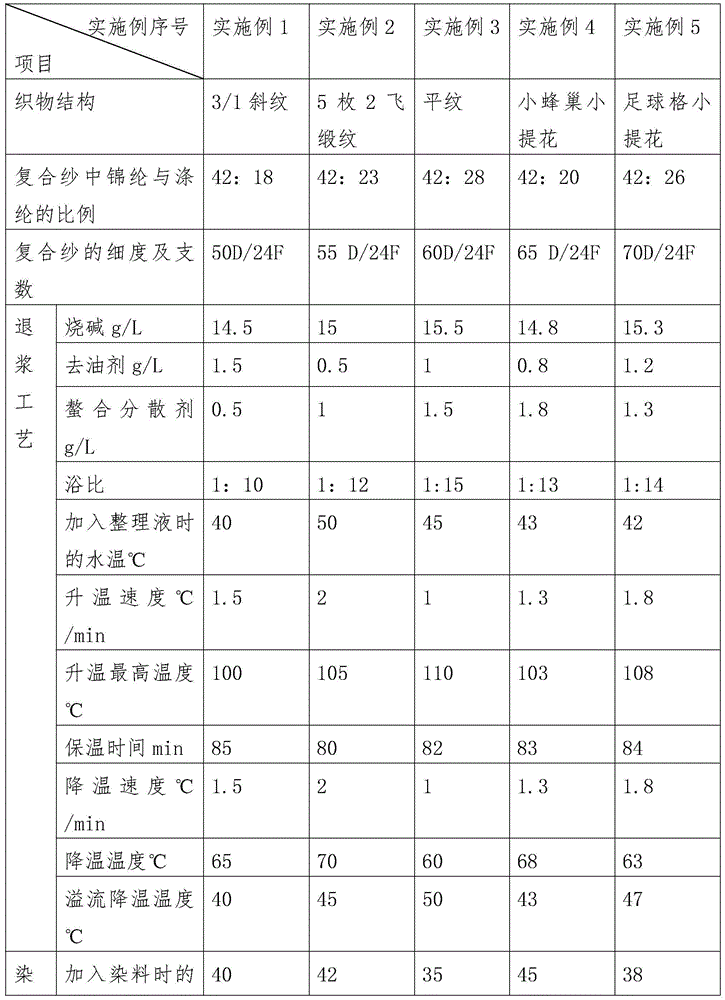

Velvet fabric blank, velvet fabric and preparing method of velvet fabric

ActiveCN104562374ALess power lossFeel goodSucessive textile treatmentsDry-cleaning apparatus for textilesWeft yarnDyeing

By aiming at the defects of low strength and poor velvet effect of the velvet fabric in the prior art, the invention provides a strong-velvet-effect and good-strength velvet fabric blank, a velvet fabric and a preparing method of the velvet fabric. The velvet fabric blank is formed by interweaving warp yarns and weft yarns, wherein the warp yarns and the weft yarns have comparative tissue floating points, or one side of the fabric is mainly provided with warp yarn tissue floating points, the other side of the fabric is mainly provided with weft yarn tissue floating points, the warp yarns are chinlon, the weft yarns are composite yarns of modified high-shrinkage chinlon and ordinary dacron, the velvet fabric is prepared from velvet fabric blank through the steps of a, desizing, b, dyeing and c, drying and hot shaping. The velvet fabric prepared by adopting the method provided by the invention has the advantages that the high-shrinkage chinlon and dacron composite yarn monofilament F number is sufficiently untwisted into 16F, so that the 50D / 384F to 75D / 384F microfiber composite fiber is obtained. In the dyeing process, the fiber microfiber ingreidnets are subjected to sufficient shrinkage, and the finally obtained fabric has good velvet effects and good strength.

Owner:ZHEJIANG TAIHUA NEW MATERIAL +1

Engine oil filter element end cover non-woven fabric material and manufacturing process thereof

ActiveCN108018652AHigh strengthHigh bonding strengthSingeingHeating/cooling textile fabricsPolyesterWork in process

The invention discloses an engine oil filter element end cover non-woven fabric material and a manufacturing process thereof. The engine oil filter element end cover non-woven fabric material comprises a first polyester staple fiber web layer, polyester reinforced cloth and a second polyester staple fiber web layer, all of which are sequentially fixed. The manufacturing process includes the following steps that S1, the polyester reinforced cloth and 100% polyester staple fibers are provided; S2, the 100% polyester staple fibers serve as raw materials to be fed into a bale opener for bale opening, are subjected to coarse opening through a coarse opener and subjected to cotton blending through a cotton blending box, enter a fine opener for fine opening, pass parallel cotton feeding box to enter a carding machine, and are dually carded through the carding machine, a single layer of polyester staple fiber web is made, the web is subjected to dual cross lapping through a cross lapper, multiple layers of polyester staple fiber webs are formed, meanwhile, the middle of the polyester reinforced cloth is fed to the position between the two polyester staple fiber web layers, needling web fixing is carried out through a pre-needling machine, a main-needling machine and a face repairing needling machine, and the parts are wound into semi-finished coil materials; S3, after calendering, shaping and mirror surface singeing are carried out, the semi-finished coil materials are coiled into coil materials; S4, the coil materials are slit and packaged into finished coil materials.

Owner:广东华滤净化技术有限公司

Polyester-cotton brushed fabric processing technology

InactiveCN109183328AGuaranteed strongConsider comfortSucessive textile treatmentsHeating/cooling textile fabricsFiberPolyester

The invention relates to the technical field of textile, in particular to a polyester-cotton brushed fabric processing technology. The technology includes the following steps: S1, selecting a piece ofembryo fabric; S2, carrying out cold batching on the embryo fabric; S3, washing the embryo fabric in open width; S4, pre-shaping the embryo fabric; S5, carrying out carbon brushing on the embryo fabric; S6, dyeing the embryo fabric; S7, dehydrating the dyed embryo fabric and drying the dyed embryo fabric in open width; S8, neatening and shaping the embryo fabric; and S9, inspecting the finished embryo fabric. The beneficial effects are as follows: the longitudinal and latitudinal tear strength and fastness of the polyester-cotton treated by the technology can be greater than 15N, and the fastness to acid perspiration of six kinds of fibers, the fastness to alkali perspiration of six kinds of fibers and the fastness to water of six kinds of fibers can reach the corresponding indexes; the polyester-cotton brushed fabric has both velvety and mousse effects, and the quality and style remain unchanged; and comfort and looseness are both achieved while the strength is guaranteed.

Owner:佳纺国际纺织品(无锡)有限公司

Anti-mist wet wiping cloth for automotive glass and preparation method of wet wiping cloth

InactiveCN106184134AImprove water absorptionGuaranteed feelNon-ionic surface-active compoundsLens cleaning compositionsMentholAlcohol

The invention discloses anti-mist wet wiping cloth for automotive glass. The anti-mist wet wiping cloth comprises a glass anti-mist emulsion and an emulsion carrier, wherein the glass anti-mist emulsion is prepared from components in parts by mass as follows: 30-40 parts of deionized water, 25-30 parts of flavorless alcohol, 2-8 parts of menthol, 1-3 parts of essence, 30-40 parts of EDI pure water, 10-20 parts of ethanol, 2-5 parts of decyl glucoside and 5-10 parts of propylene glycol. The wet wiping cloth can have sterilization and cleaning functions and can promote the surface of the glass to form a glossy film capable of realizing lasting mist prevention, the hand feeling and the strength of the wet wiping cloth are guaranteed while the water-absorbing property of the finished product, namely, the wet wiping cloth, is improved, the essence can be adjusted according to different demands, and comfortable fragrant enjoyment is brought while the wet wiping cloth realizes the cleaning and anti-mist functions.

Owner:ZHEJIANG YOUQUAN CARE PROD TECH CO LTD

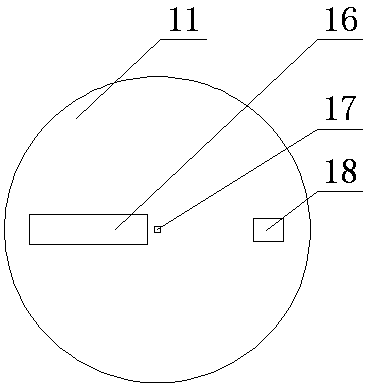

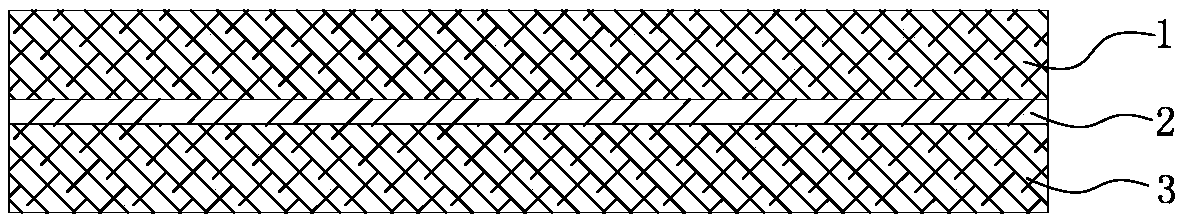

Three-layer composite marine rope and manufacture method thereof

ActiveCN105256620AReduces direct friction damageGuaranteed strongCoatingsTextile cablesPolyesterWear resistant

The invention discloses a three-layer composite marine rope and a manufacture method thereof, and relates to the field of ropes. The three-layer composite marine rope comprises a main rope (1), a sand prevention protection layer (2) and a wear-resistant layer (3), wherein the main rope (1) is formed by knitting a plurality of ultra-high molecular weight polyethylene fiber sub ropes (11) in parallel; the sand prevention protection layer (2) is a piece of non-woven fabric and wrapped on the main rope (1); the wear-resistant protection layer (3) is arranged to be a protection cover formed by knitting polyester fibers and wrapped at the external part of the sand prevention protection layer (2). The three-layer composite marine rope is simple in manufacture process, convenient to operate, high in strength, low in elongation, corrosion-resistant and long in service life.

Owner:SHANDONG ROPE TECH CO LTD

Dyeing and finishing technology for deep-color cotton-polyester elastic yarn-dyed fabric

InactiveCN108505358ALower the dyeing temperatureGuaranteed flexibilityDry-cleaning apparatus for textilesDyeing processDisperse dyeYarn

The invention discloses a dyeing and finishing technology for deep-color cotton-polyester elastic yarn-dyed fabric. The technological process comprises steps of slack winding, dyeing, rewinding, warping, slashing, weaving and after-finishing, wherein the dyeing process comprises steps of scouring and bleaching, carrier treatment, dyeing, reduction clearing and softening treatment; the after-finishing process comprises steps of singeing, desizing, mercerizing, high-temperature setting, desizing washing, setting tentering and preshrinking. The dyeing and finishing technology has the advantages that a disperse-dye low-temperature carrier dyeing process is adopted and combined with a specific soaping agent, a high-temperature high-tension rapid setting process is adopted in the after-finishingprocess, high-temperature setting time is shortened, disperse dyeing heat transfer amount is reduced, soaping is performed after setting for removing surface dyeing, and the problem of poor color fastness of deep-color cotton-polyester elastic varieties is solved.

Owner:张家港市金陵纺织有限公司

Method for processing fabric of surgical gown with permeability-resisting protection function

ActiveCN103451918AImprove function and effectGuaranteed strongPhysical treatmentSurgical GownsPre treatment

The invention discloses a method for processing the fabric of a surgical gown with a permeability-resisting protection function. The method comprises the steps of nano-sol pretreatment, low-temperature normal-pressure air plasma treatment, chemical permeability resisting agent treatment and ultraviolet radiation. The fabric processed by the method disclosed by the invention achieves the effects of resisting the permeability of blood, alcohol, water and the like, and meets the protection requirements of the fabric of the surgical gown: the water repellency level is 8, the oil repellency level is 7, the alcohol repellency level is 10, the blood contact prevention angle is 126.2 DEG, the strong retention rate is 92.6%, and the permeability retention rate is 95.3%.

Owner:江苏联泰纺织有限公司

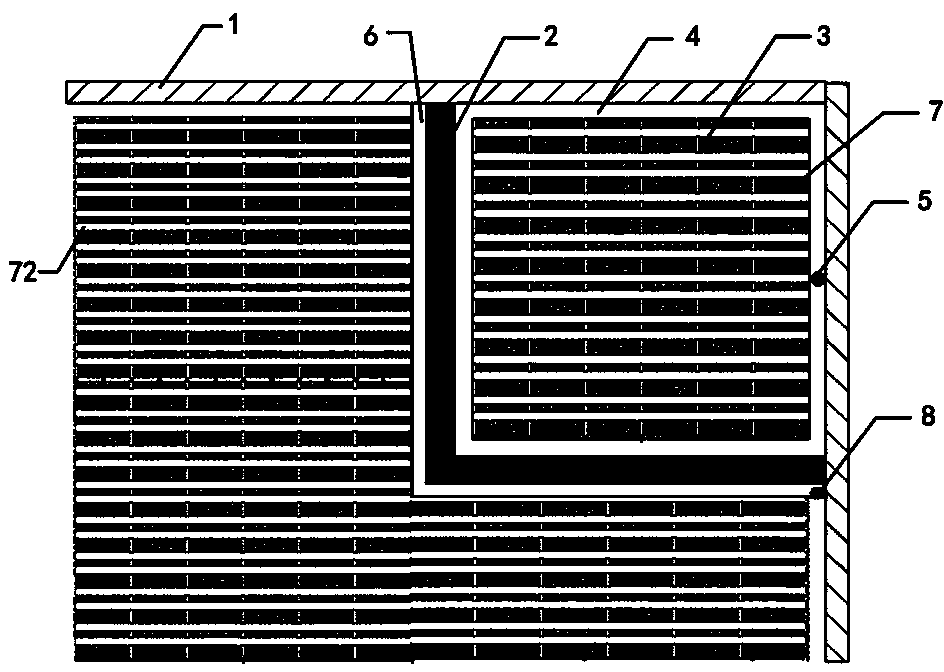

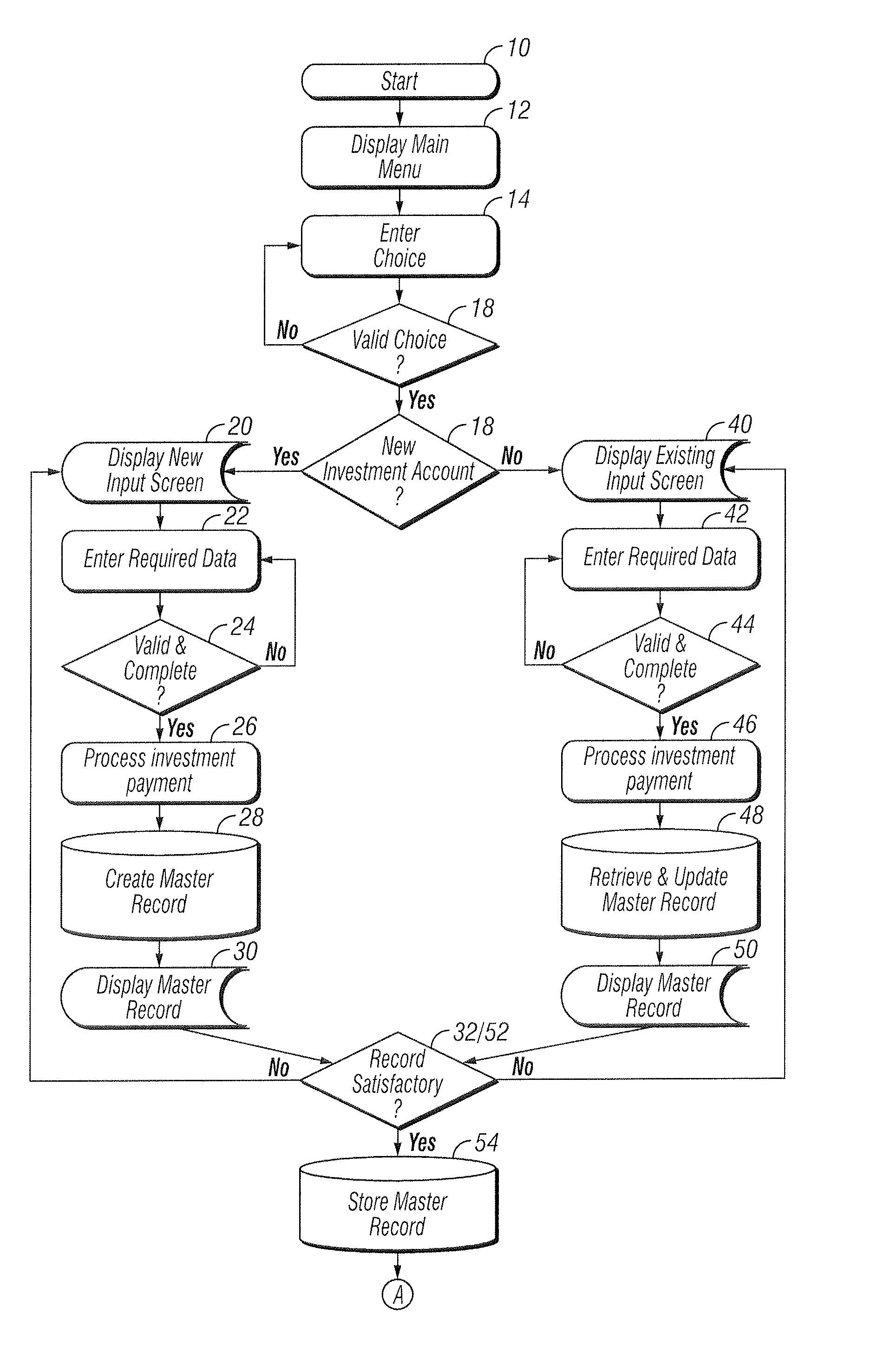

Shower room floor drainage skid resistance structure

ActiveCN104196198APrevent spillageImprove skid resistanceSewerage structuresFlooringMechanical engineeringShower

The invention discloses a shower room floor drainage skid resistance structure which comprises a wall body (1) and a partition (2). A shower room is separated out in a rest room through the partition (2), a shower floor (3) is arranged in the shower room, and annular drainage ditches (4) are arranged between the shower floor (3) and the wall body (1) and between the shower floor (3) and the partition (2). The annular drainage ditches (4) are internally provided with floor drains, and a water blocking ditch (6) is further formed outside the partition (2). The water blocking ditch (6) is also internally provided with a standby floor drain (8), and skid resistance floor tiles (7) are laid on the shower floor (3) and floors, outside the shower room, of the rest room. The laying direction of the skid resistance floor tiles (7) is that drainage grooves (72) face the floor drain (5) in a unified mode. The shower room floor drainage skid resistance structure has the high water accumulation preventing capability, can effectively drain and resist skid and is safe to use and convenient to clean.

Owner:QINGDAO HOUKE INFORMATION ENG

Dyeing and finishing processing method for real silk/cotton interweaved fabric

InactiveCN106283454AProtected growthStrong reachSucessive textile treatmentsBleaching apparatusCellulose fiberChemistry

The invention provides a dyeing and finishing processing method for real silk / cotton interweaved fabric. The method includes the procedures of fabric turning, enzyme desizing, enzyme refining, enzyme polishing, blanching, printing or dyeing, washing, softening and shaping, calendaring and preshrinking on gray fabric in sequence. In the enzyme refining procedure, cellulosic fiber refining enzymes and silk protein refining enzymes need to be added; in the enzyme polishing process, cellulose polishing enzymes need to be added. According to the dyeing and finishing processing method, the processing process of the cellulosic fiber refining enzymes, the silk protein refining enzymes and the cellulose polishing enzymes is adopted, the obtained real silk / cotton interweaved fabric is good in cloth cover glossiness, low in strength damage, natural and comfortable in hand feeling and good in dimensional stability and napping and pilling performance.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

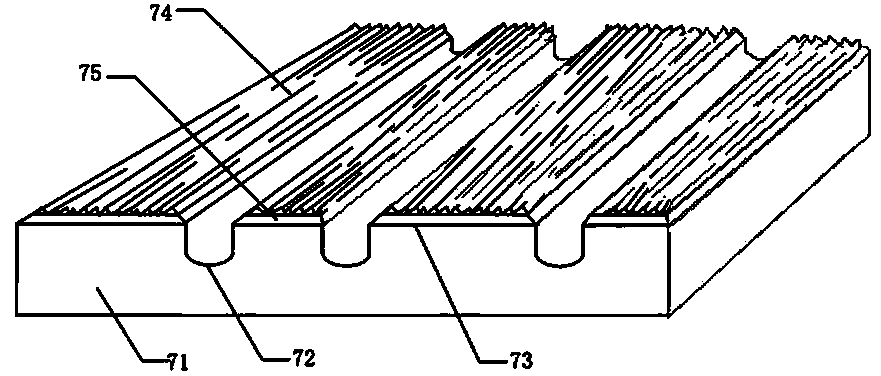

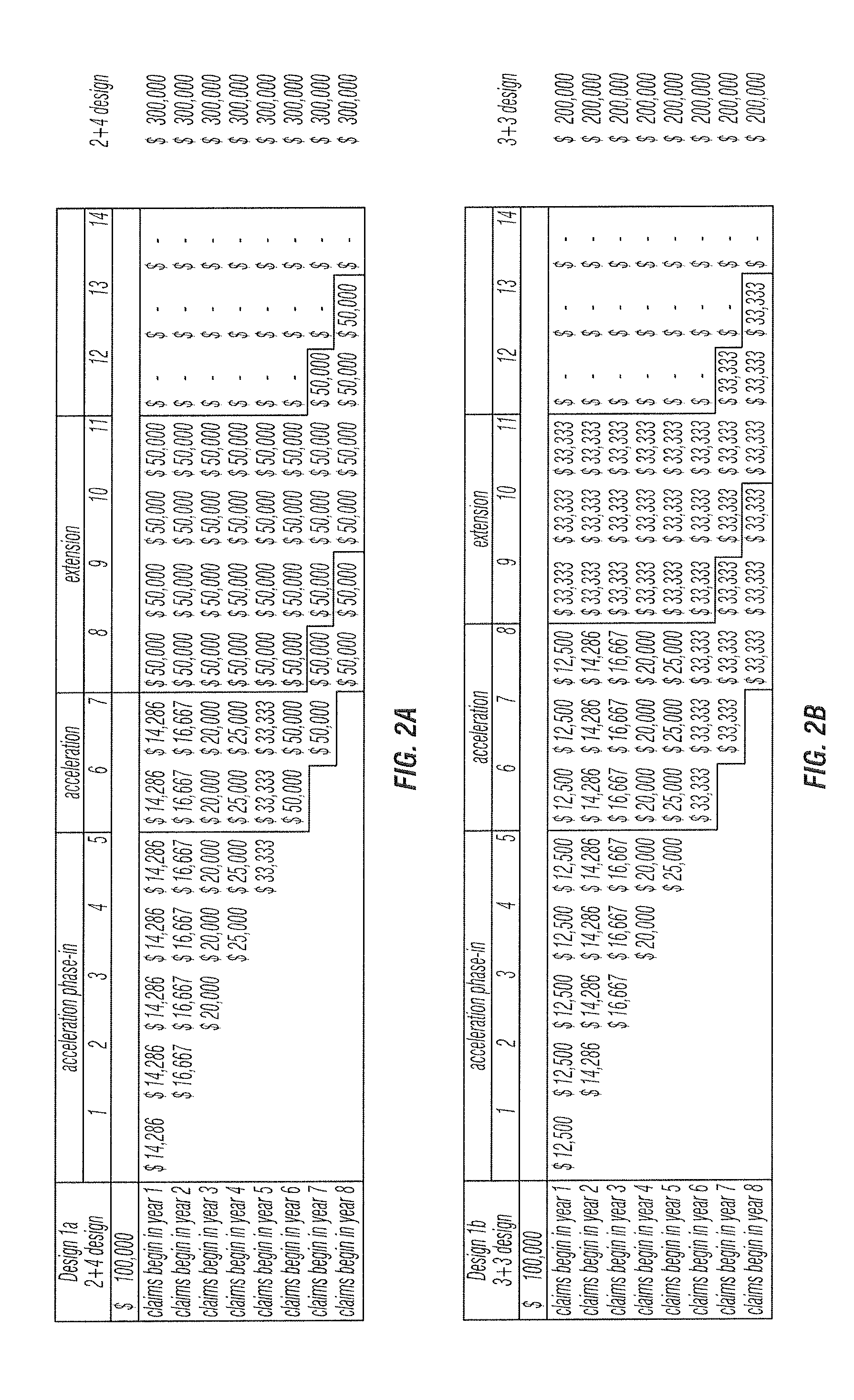

Computer Method and System for Administering Investment Account

InactiveUS20100191548A1Effectively and efficiently administeringNeed can be addressedFinancePaymentLong-term care

A computerized method for administering an investment account having an income or withdrawal guarantee and long term care guarantee includes the steps of establishing an investment account having an account balance, allocating a first portion of the account balance to fund a periodic long term care benefit having a long term care benefit guarantee, allocating a second portion of the account to fund a periodic income or withdrawal benefit having an income or withdrawal benefit guarantee, determining an amount of a periodic long term care benefit available for payment of a long term care benefit claims under the long term care benefit guarantee, and determining an amount of a periodic income or withdrawal benefit available for distribution under the income or withdrawal benefit guarantee. The long term care benefit guarantee may include an acceleration of benefits guarantee and an extension of benefits guarantee. A computer system which includes a processor and a program for causing the processor to perform certain steps is also disclosed.

Owner:LINCOLN NAT LIFE INSURANCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com