Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

204 results about "Dying processes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Design-specific on chip variation de-rating factors for static timing analysis of integrated circuits

InactiveUS8336010B1Reduce running timeDesign specificationComputer aided designSoftware simulation/interpretation/emulationTime informationDying processes

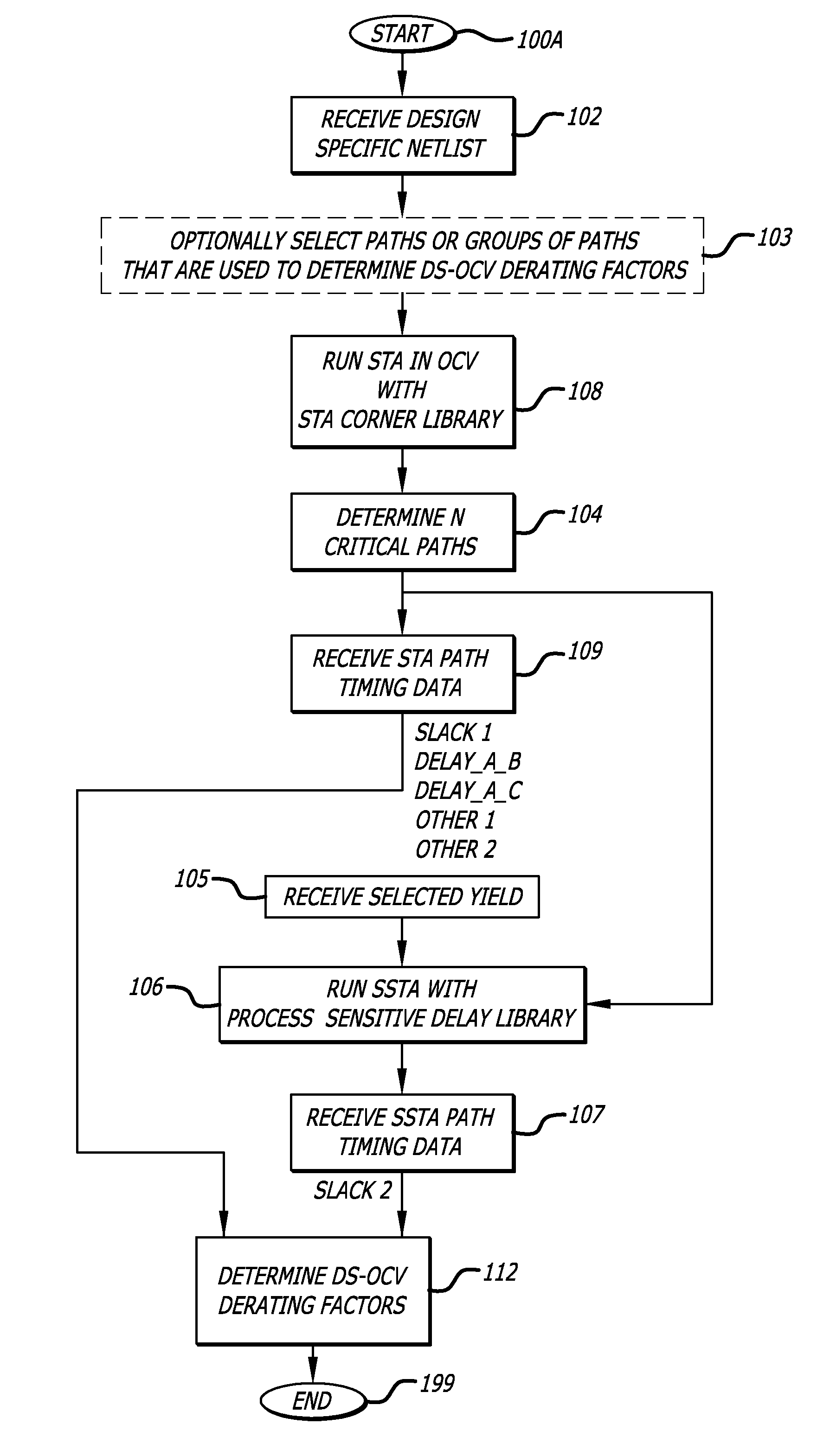

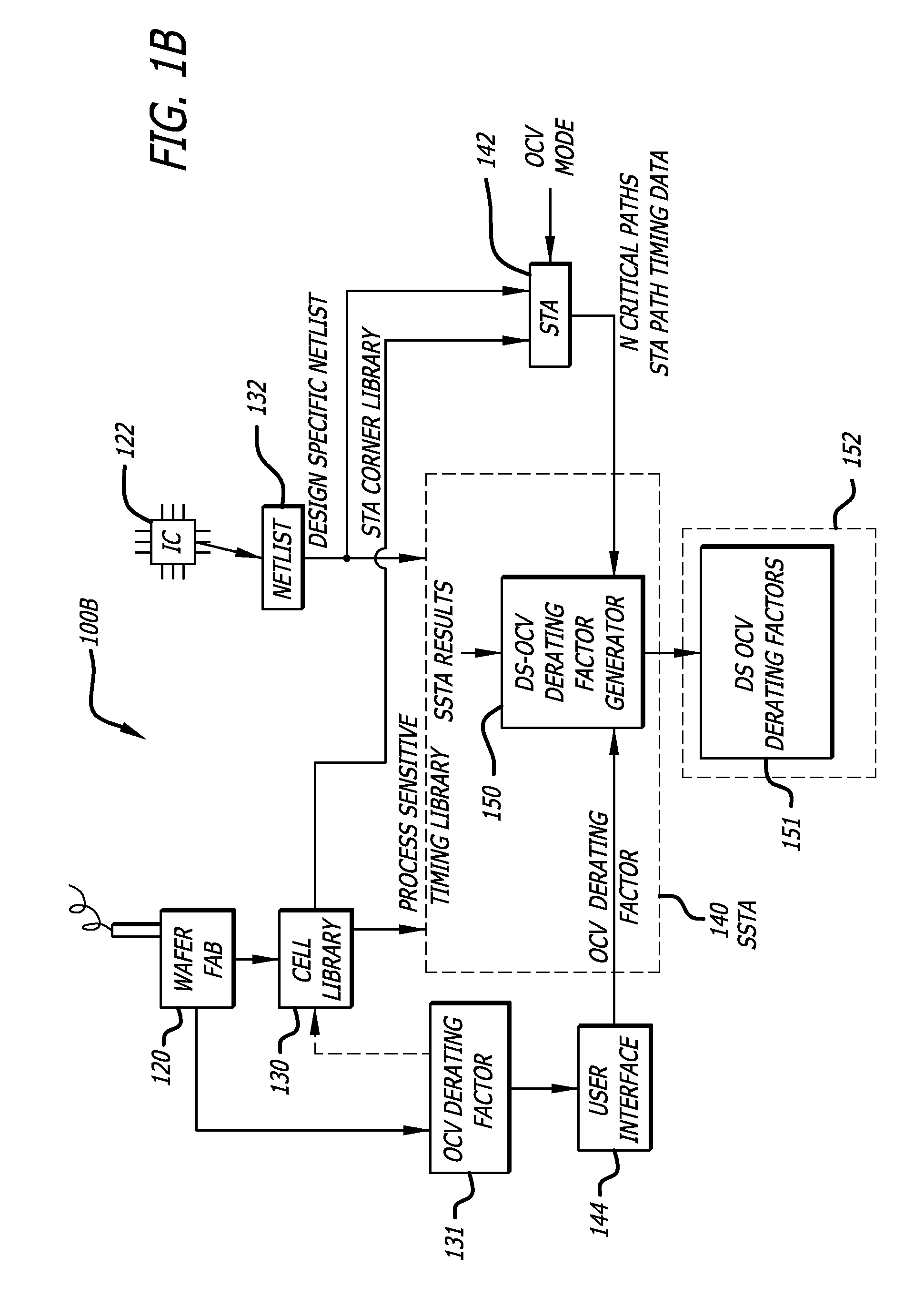

In one embodiment of the invention, a method of analysis of a circuit design with respect to within-die process variation is disclosed to generate a design-specific on chip variation (DS-OCV) de-rating factor. The method includes executing a static timing analysis (STA) in an on-chip variation mode using a process corner library. Collecting timing information of the top N critical timing paths. Executing a statistical static timing analysis (SSTA) on the N critical timing paths using timing models characterized for SSTA with sensitivities of delays to process variables. Compare the two timing results and deriving DS-OCV de-rating factors for the clock / data paths to be used in a STA OCV timing analysis to correctly account for the effects of process variations. A user may select to specify DS-OCV de-rating factors for paths or groups of paths and achieve an accurate timing analysis report in a reduced amount of run-time.

Owner:CADENCE DESIGN SYST INC

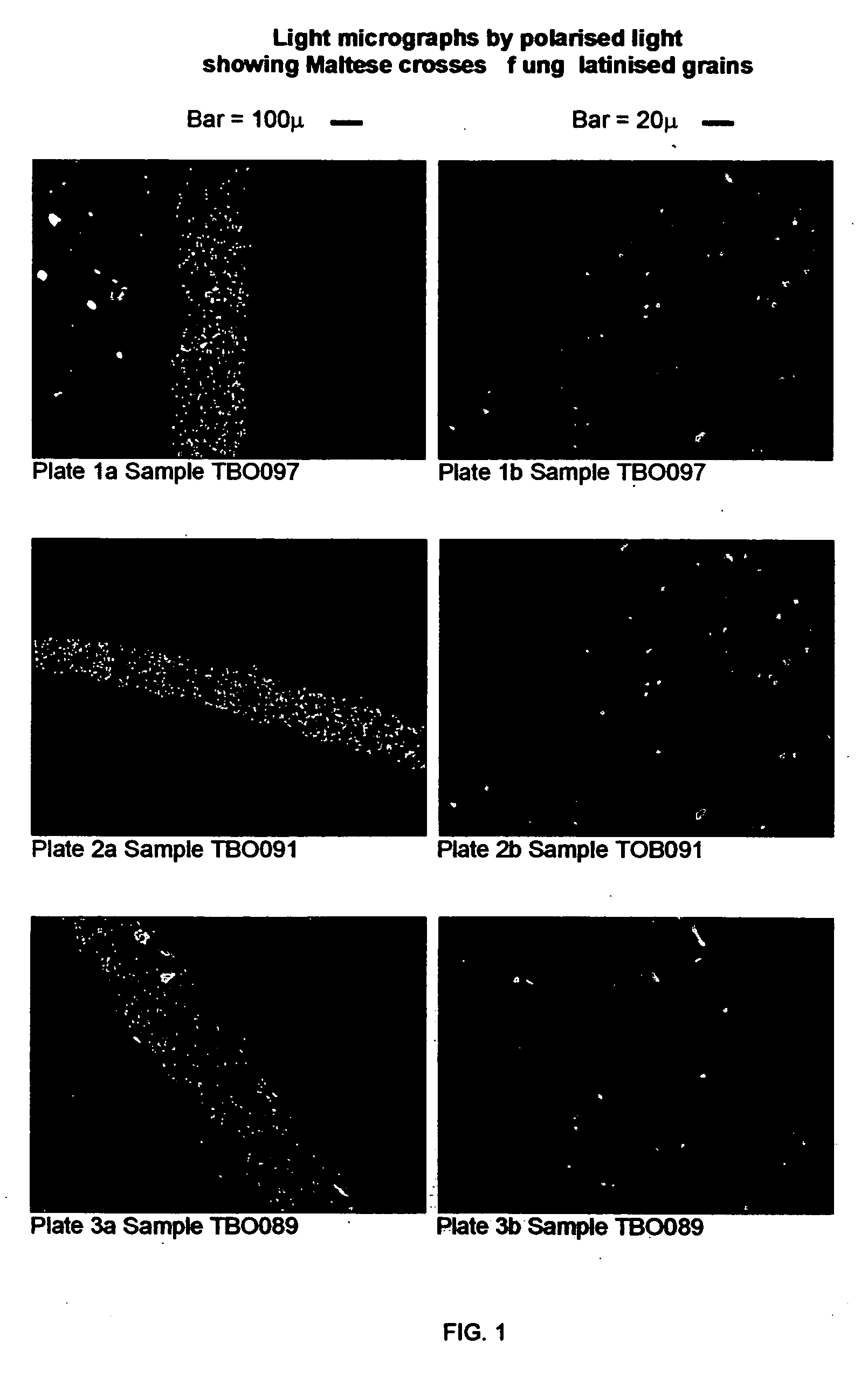

Chewable soft capsules containing ungelatinized starch

A soft chewable capsule film suitable for medicament or foodstuff encapsulation, and a method of fabricating capsules from such a film. Such capsules demonstrate fast rupture in the oral cavity, good mouth feel and chewability, and rapid dissolution of the shell components. In particular, the modified starch is substantially ungelatinized, due at least in part to the processing temperature, and may act as a water retention agent to promote hydration. Additionally, gelatins are selected for bloom strengths that result in a robust capsules that may be fabricated at a thinner wall thickness than previously experienced in the art. Accordingly, such thin capsules have a smaller mass than traditional capsules of the same size and dissolve more quickly than chewable capsules having greater thicknesses. The capsules may be fabricated by a rotary die process at speeds greater than those generally known for soft chewable capsules.

Owner:R P SCHERER TECH INC

Vacuum evanescent die casting process

InactiveCN102974762AHigh precisionNo uneven wall thicknessFoundry mouldsFoundry coresModel compositionAfter treatment

The invention discloses an evanescent die process. The evanescent die process is characterized by comprising the following steps of: selecting foaming plastic beads, manufacturing a model; enabling the beads to expand to be in a certain size through hot water pre-frothing, steam pre-frothing and vacuum pre-frothing, curing and frothing forming; clustering model composition, coating a model; vibrating and shaping; pouring and displacing; and cooling and cleaning, wherein the full mold casting ramoff is simple, a casting piece can be hoisted out when a sand box is inclined or can be directed hoisted out form the sand box, the casting piece and dried sand are naturally separated, and the separated dried sand is reused after treatment. According to the process, a die is not required to be taken out, and a parting plane and a sand core are not required, and thus the casting piece has no flash, no burrs and no pattern tapers, and the dimension error caused by core combination is reduced; and compared with the conventional sand casting method, for the evanescent die process, the 40%-50% machining time is reduced.

Owner:CHANGTU COUNTY JIPAI MACHINERY CASTING

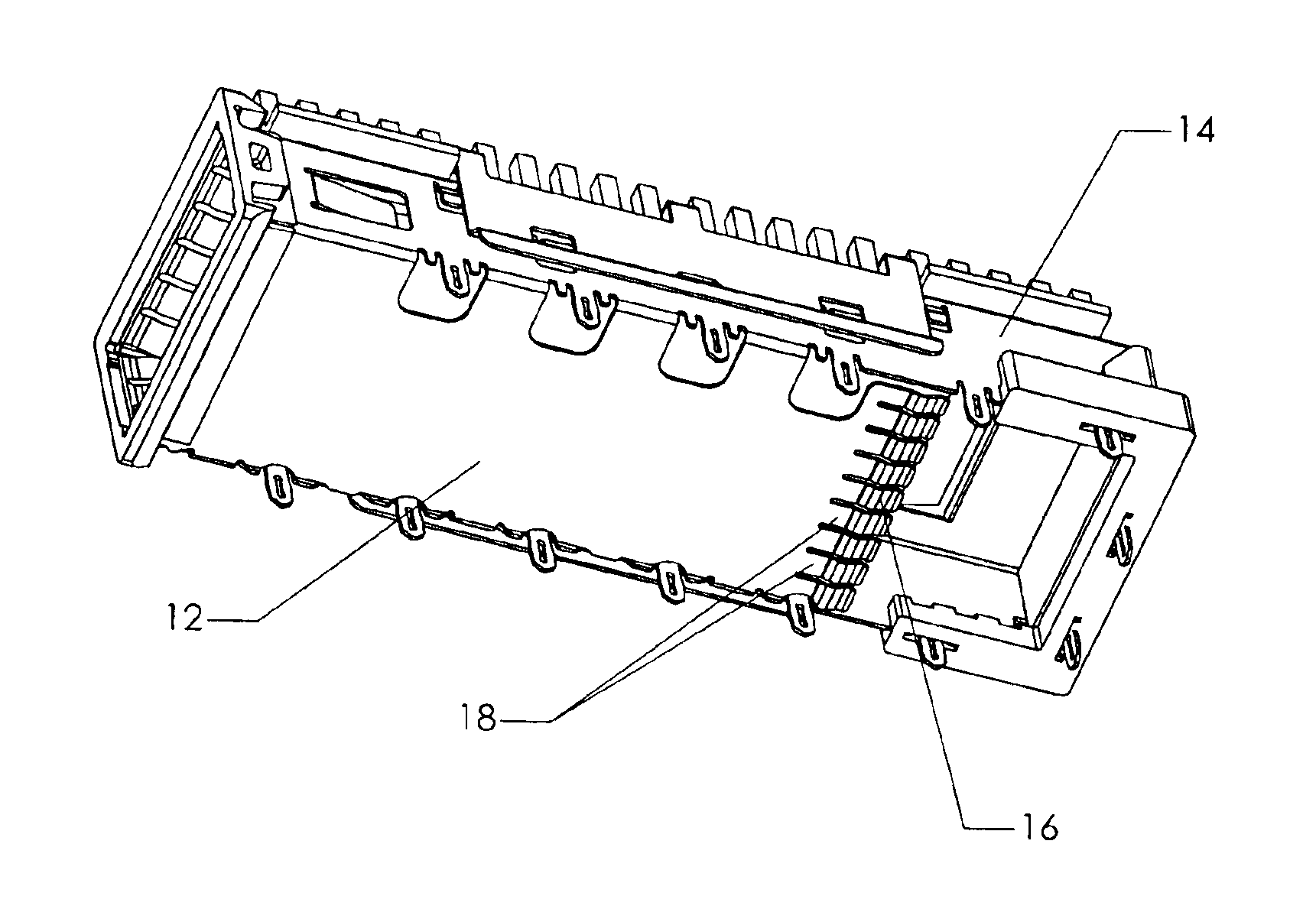

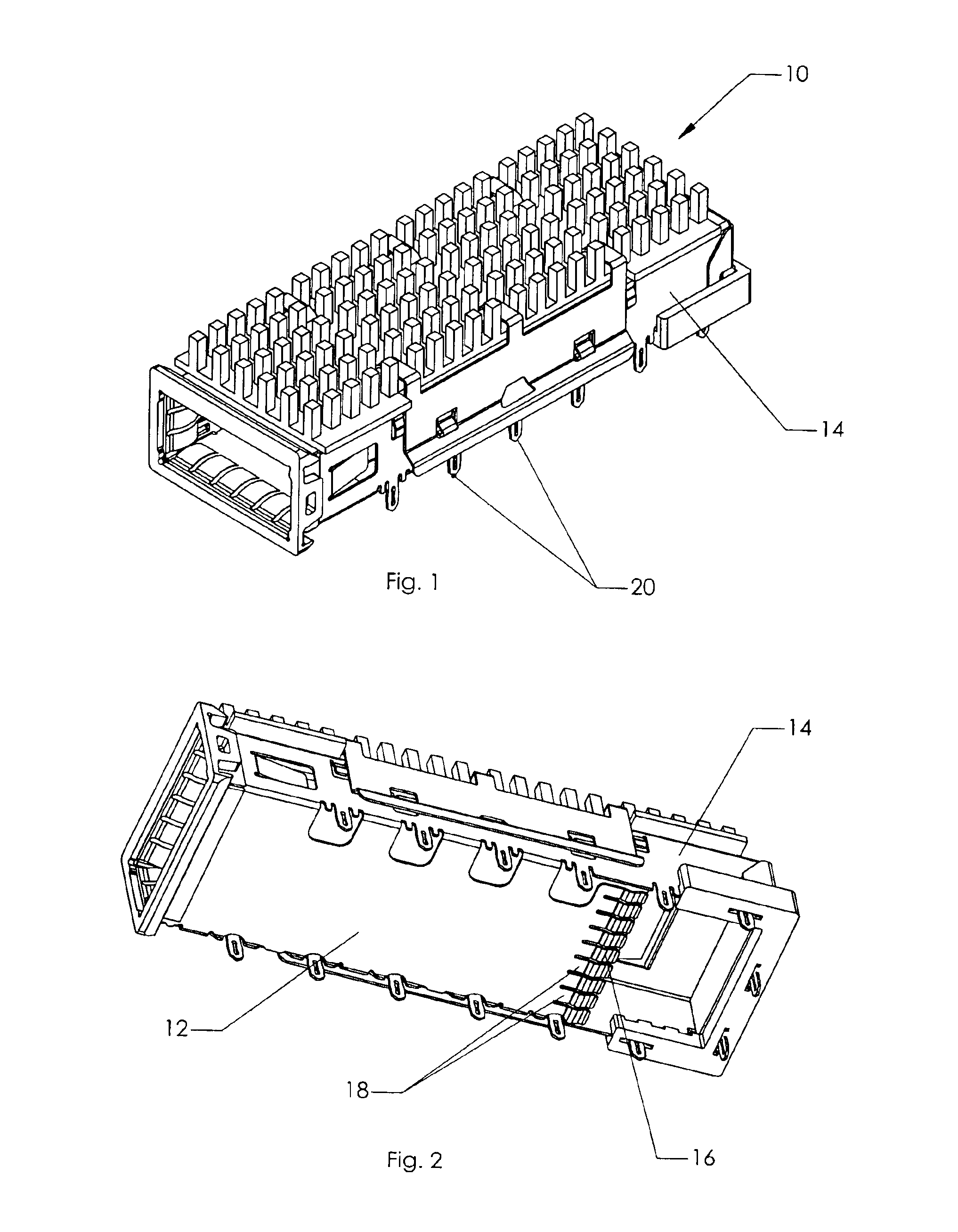

Fiber optic transceiver package with integral EMI gasket

InactiveUS6875056B1Low costShorten the timePrinted circuit assemblingPrinted circuit aspectsFiberTransceiver

A package for a fiber optic transceiver that integrates the intermediate rear gasket into the lower body of the transceiver package. As such, the EMI fingers are much thicker than current art EMI fingers, 0.010″ thick as compared to current art 0.002″ thick. In current art devices, providing such robust EMI fingers is not possible. The connecting pins that secure the transceiver cage to the PCB are self-centering press-fit pins formed from a plurality of legs. At least one of the legs provides an electrical connection point for the transceiver on which the pins are used. The connecting pin is formed so that the legs act as leaf springs to securely hold the connector in place in the proper installation hole in the board on which the transceiver is installed. The pins are stamped from sheet metal with a progressive die process. By changing the amount of flexion in the legs of the pin, the pressure required to insert the pin into a connection hole, and hence the retaining pressure, can be varied.

Owner:FOURTE INT SDN BHD

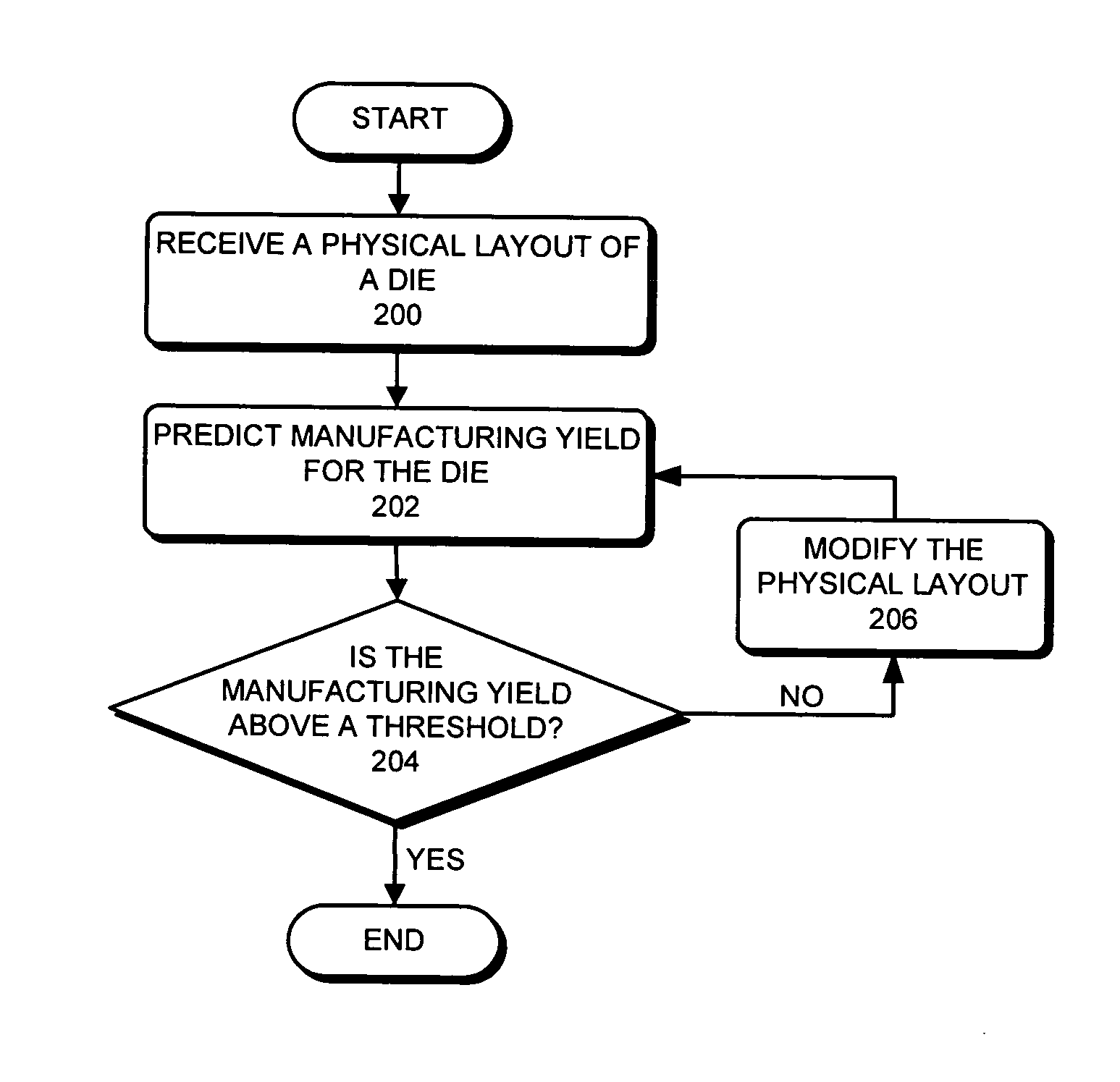

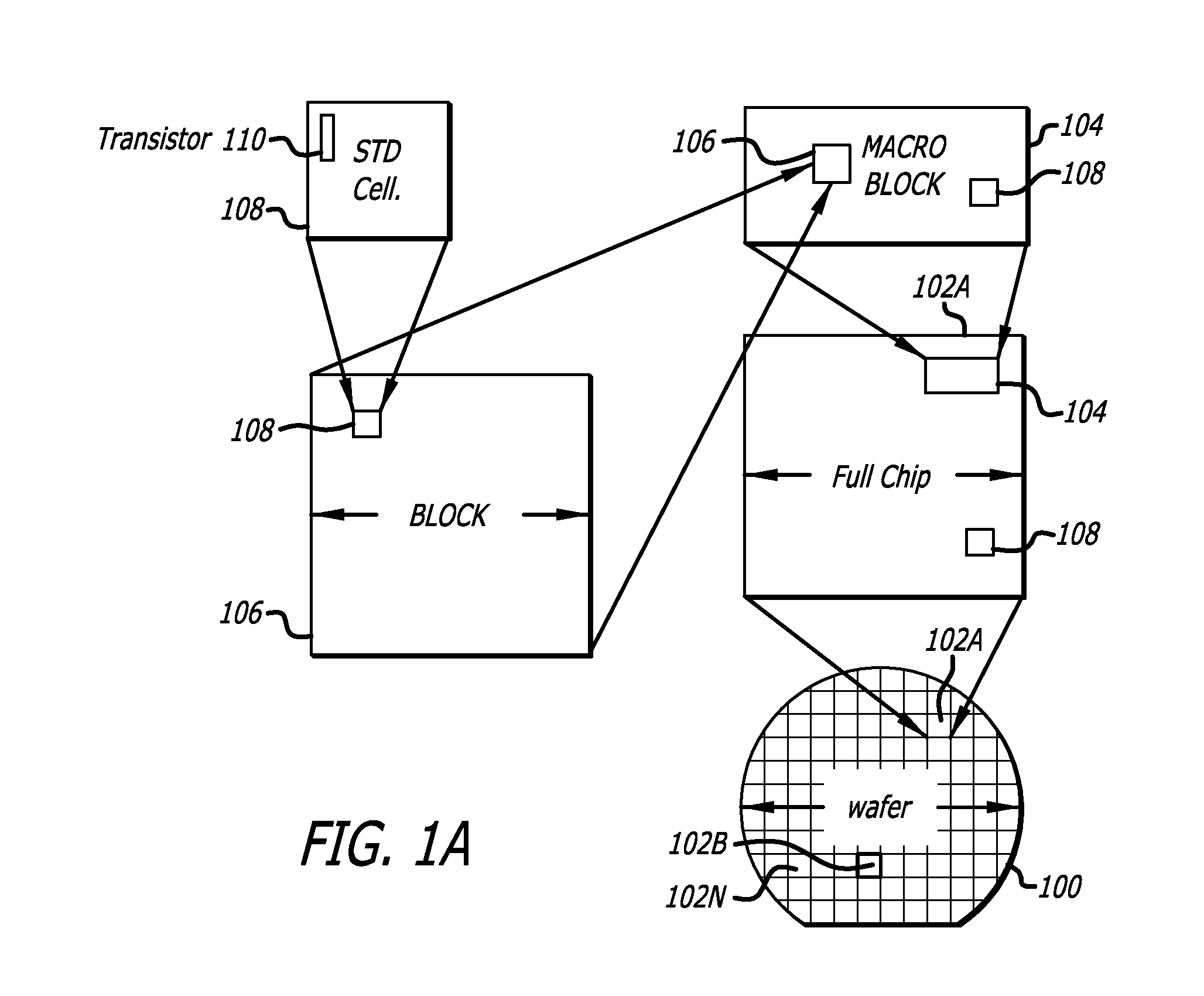

Predicting IC manufacturing yield by considering both systematic and random intra-die process variations

ActiveUS20070174797A1Reduce complexityProgramme controlSemiconductor/solid-state device detailsSystematic variationDying processes

One embodiment of the present invention provides a system that predicts manufacturing yield for a die within a semiconductor wafer. During operation, the system first receives a physical layout of the die. Next, the system partitions the die into an array of tiles. The system then computes systematic variations for a quality indicative value to describe a process parameter across the array of tiles based on the physical layout of the die. Next, the system applies a random variation for the quality indicative parameter to each tile in the array of tiles. Finally, the system obtains the manufacturing yield for the die based on both the systematic variations and the random variations.

Owner:SYNOPSYS INC

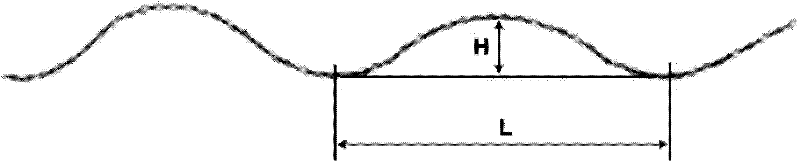

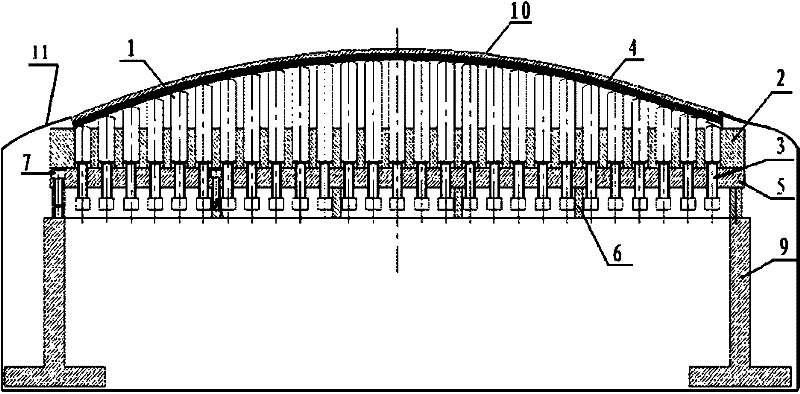

A metal creep forming die

The invention discloses a metal creep forming die. The metal creep forming die comprises an ejector rod, a threaded rod, an ejector rod fixing plate, a threaded rod fixing plate, a reinforcing rib, a height adjusting cushion block and a molded surface base plate, wherein the ejector rod is arranged in a cylindrical hole of the ejector rod fixing plate; the threaded rod is arranged in a threaded hole of the threaded rod fixing plate and is used for controlling the height of the ejector rod to form the required molded surface array; the reinforcing rib is arranged at the bottom of the fixing plate so as to enhance deformation resistance of the die; the height adjusting cushion block is arranged at the bottom of the reinforcing rib so as to adjust the horizontal height of the die; one layer of molded surface base plate is paved above the ejector rod array and is used for transitioning the discrete dot matrix surface into the required smooth curved surface; and the molded surface base plate may be an aluminum plate, a steel plate or a steel aluminum composite plate. In the die provided by the invention, the molded surface base plate can contact with all the ejector rod dot matrixes, so that the waviness of a creep formed member is less than 0.005 and good member molded surface quality is achieved; and the die process cost caused by that a fixed curvature characteristic integrated type structure die and a rib plate type split structure die are required to be modified repeatedly is avoided, so that die trial cost can be greatly reduced.

Owner:CENT SOUTH UNIV

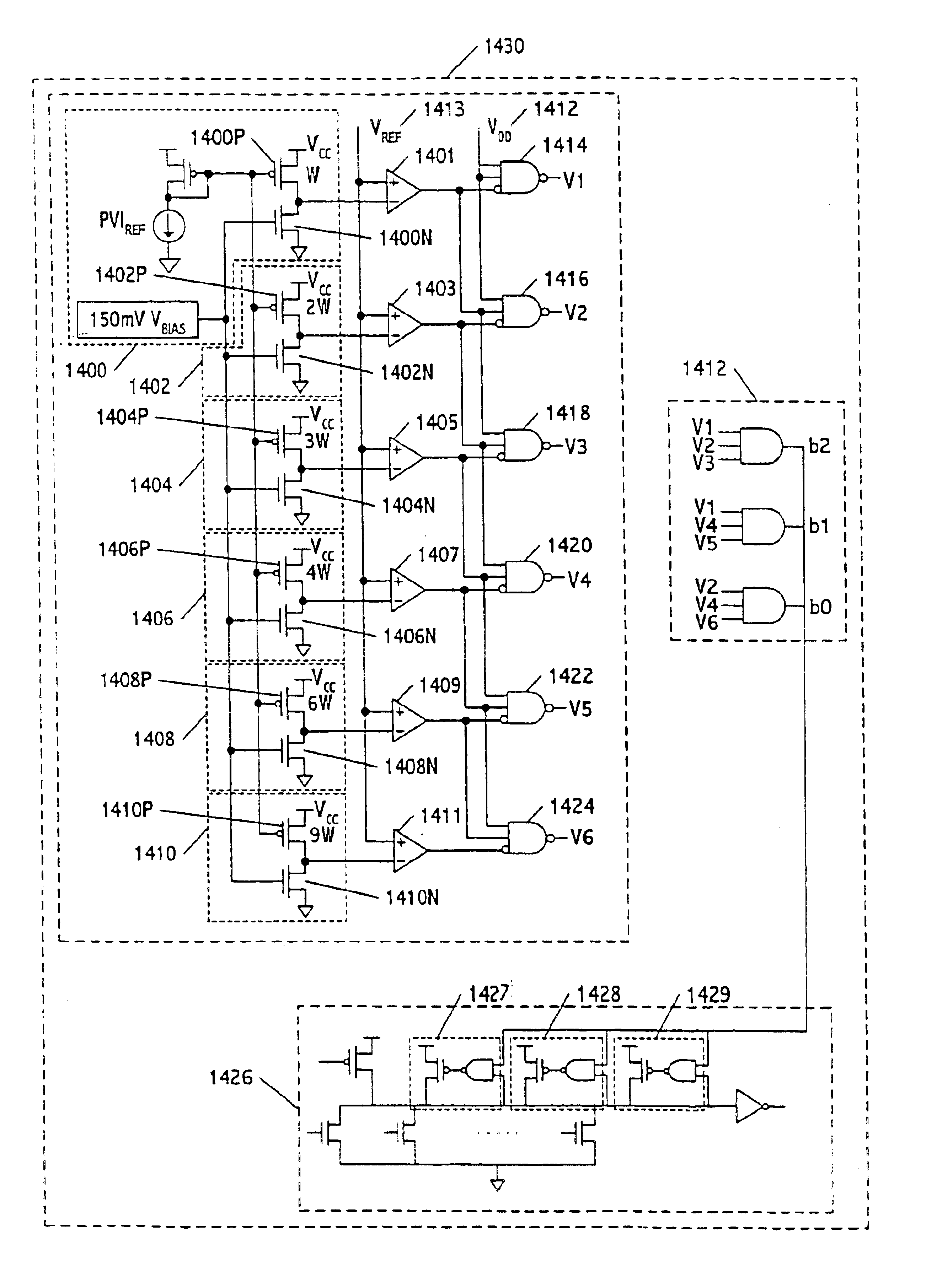

Current mirror based multi-channel leakage current monitor circuit and method

A current mirror multi-channel leakage monitor circuit and method measures die leakage and generates digital keeper control bits to control a process compensated dynamic circuit. The leakage monitor enables high resolution on-chip leakage measurements in multiple locations on a die, thereby saving test time and enabling both die to die and within die process compensation.

Owner:INTEL CORP

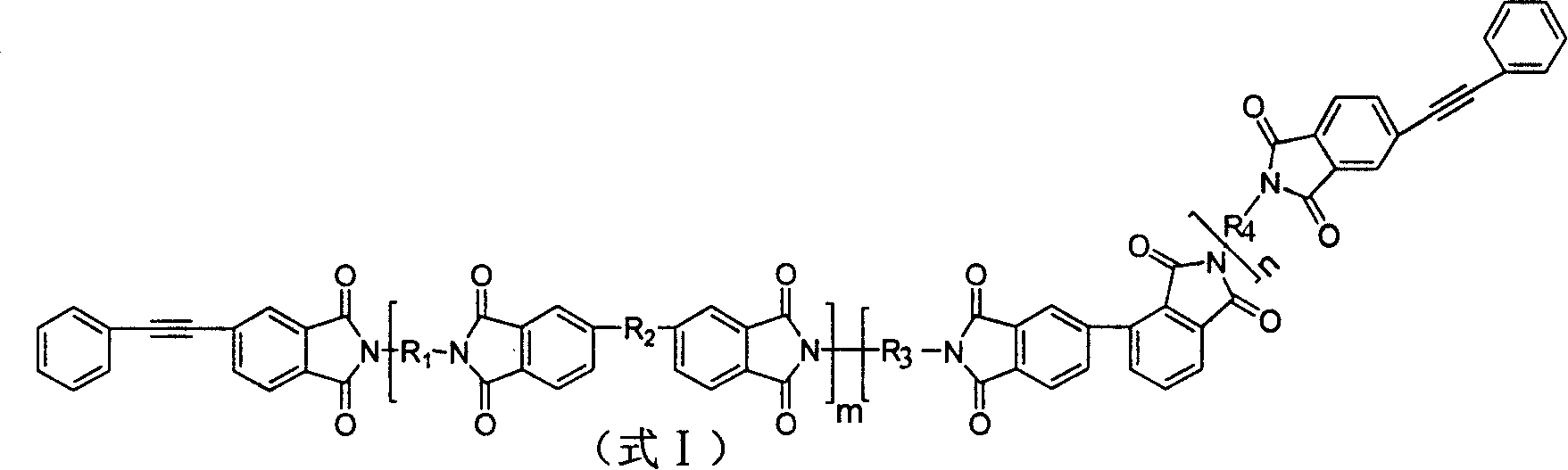

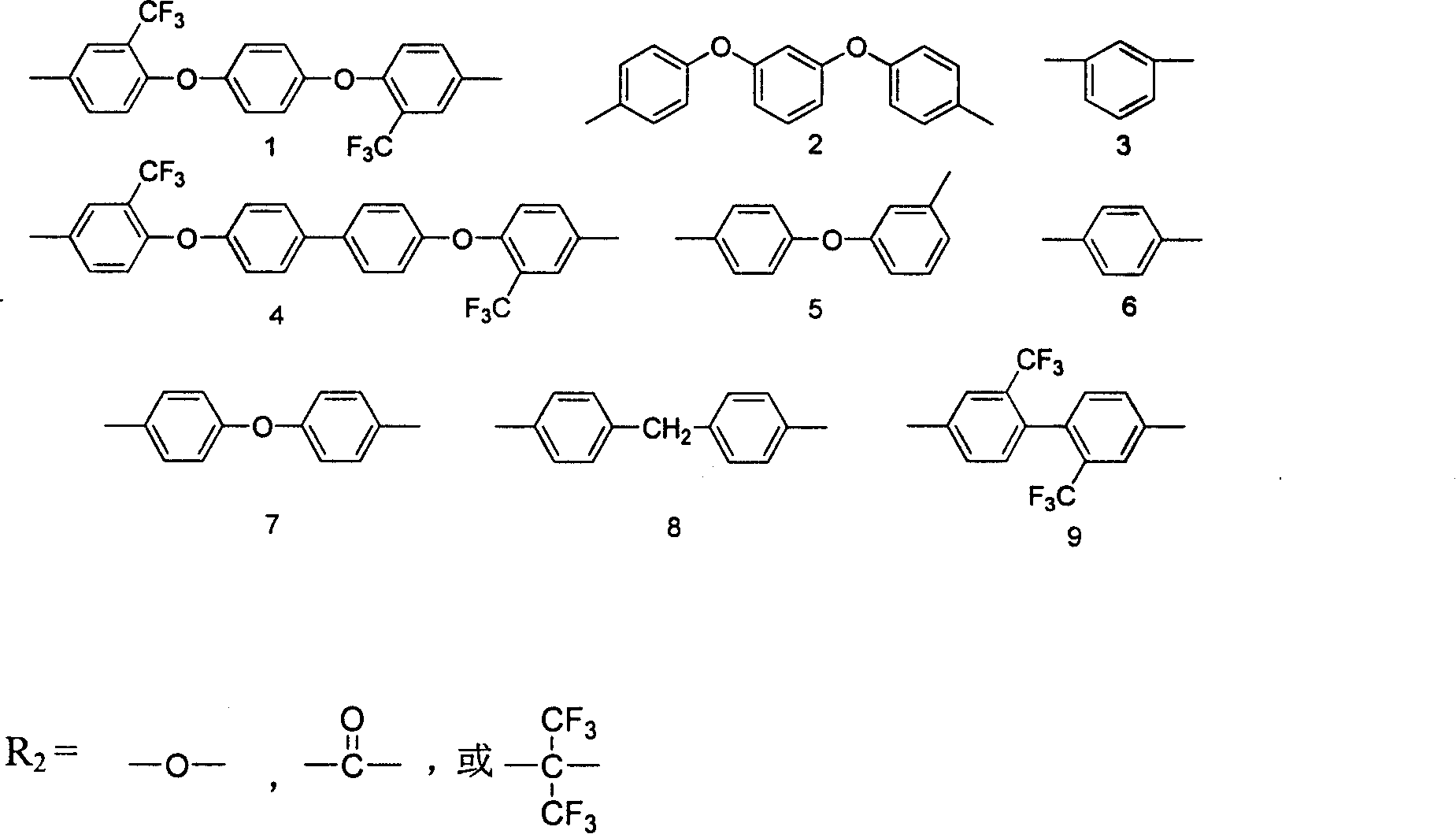

Polyimide resin and preparation method thereof

The invention discloses polyimide resin and a preparation method thereof. The polyimide resin is polymer having molecular structural formula as shown in formulation I. The resin employs aromatic dianhydride, aromatic diamine and reactivity blocking agent as raw materials and is prepared by adopting a PMR method. The process of preparing the invention is that the aromatic dianhydride, the aromatic diamine and the reactivity blocking agent are heated, refluxed and mixed so as to prepare resin solution. The polyimide resin matrix of the invention can directly compounded with enhanced body to prepare resin matrix composites, or the resin solution is die processed after heat treatment to obtain resin molded parts. The polyimide resin matrix solution of the invention is characterized by high solid content, low viscosity, good stability of storage, etc., and the resin molded parts and the resin matrix composites prepared has low porosity, excellent heat resistance, and high mechanical property, and have potential applying value in high-technology field such as spaceflight, aviation, space technology, etc. when being taken as light weight, high-temperature resistant structure components or secondary structure components.

Owner:INST OF CHEM CHINESE ACAD OF SCI

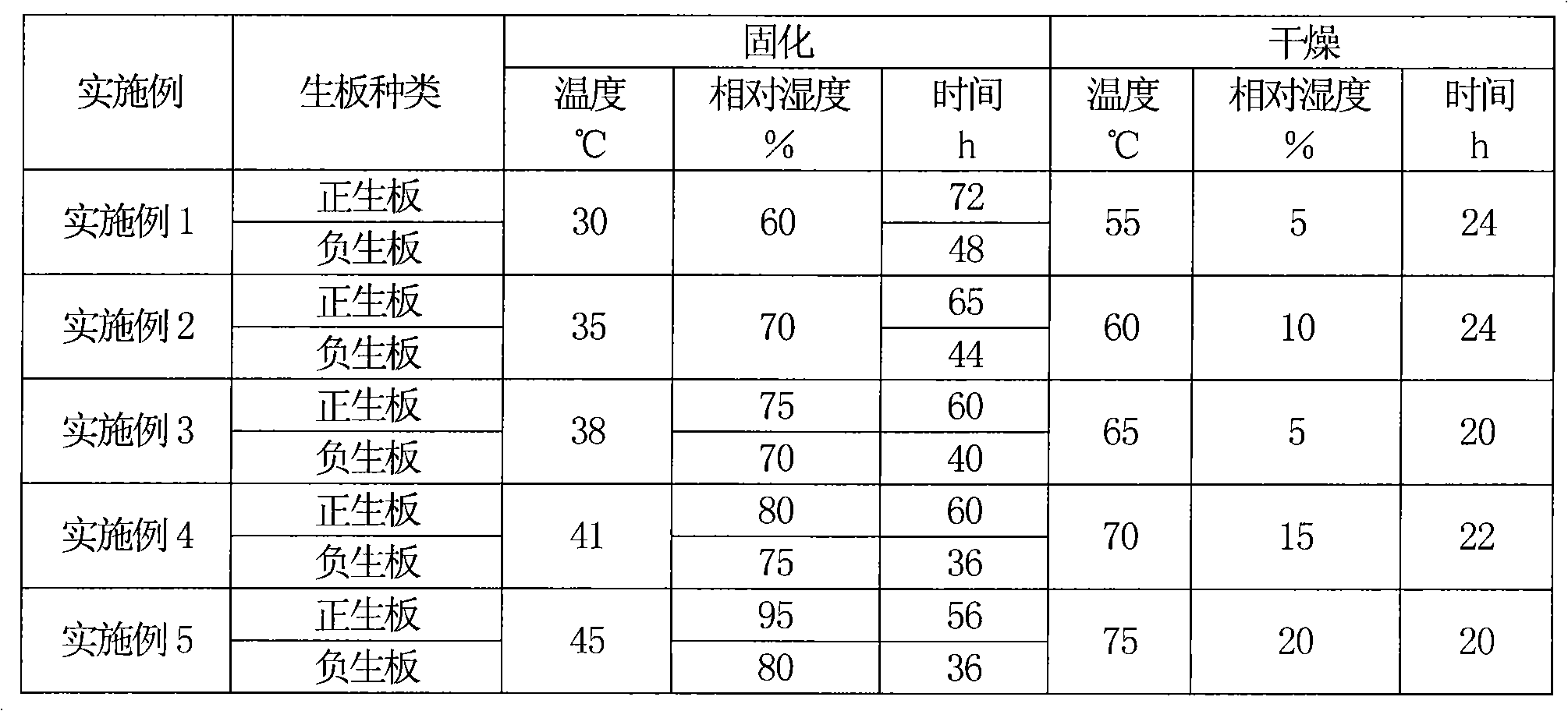

Growth plate curing and dying process of lead-acid accumulator

InactiveCN101345305AExtended service lifeHigh hardnessLead-acid accumulator electrodesDying processesWater vapor

The invention provides a lead-acid accumulator raw plate solidification drying process which is used for solving the problems that the raw plate active matter is easy to occur argillization, and be desquamated, etc. The technical proposal of the invention is that the procedure is carried out in a solidification drying chamber, with the process parameters as follows: 60 to 95 percent of solidification relative humidity of positive raw plate, 30 to 45 DEG C of solidification temperature thereof, 56 to 72 hours of solidification time thereof; 60 to 80 percent of solidification relative humidity of negative raw plate, 30 to 45 DEG C of solidification temperature thereof and 36 to 48 hours of solidification time thereof. The process of the invention is beneficial for reducing the free lead content in the raw plate, obviously improves the adhesion of the lead paste and the grid plate, prolongs the service life of the accumulator, and reduces the generation of rust plate and the dosage of water vapor during the solidification. The comparison detection indicates that the service life of the accumulator prepared by the raw plate which is processed by the process of the invention is prolonged by about 20 percent compared with the original process.

Owner:FENGFAN

Aging method after dying of all-cotton knitting clothes

InactiveCN101008140AGood hygroscopicityImprove breathabilityPhysical treatmentDyeing processAge methodDying processes

A method for aging the clothes after dying process comprises that: cleaning the dyed clothes; selecting pumex and putting some pumex into strong oxidant solution to be immerged, taking out and drying, to obtain wet pumex; putting dry and wet pumexes into the chamber of grinder; putting clothes into chamber, grinding and taking out clothes to obtain the grinded aged clothes; washing that washing clothes in washing machine, leading in clean water, heating, adding oxalic acid or sodium thiosulphate to wash and adjust pH value, discharging water, leading in water, adding sodium thiosulphate, neutralizing and washing, controlling pH value, softening, dewatering, drying, cleaning to obtain the final product. The inventive clothes have soft, flexile and wet-adsorption properties.

Owner:CHANGSHU HONGQIAO SAND WASH

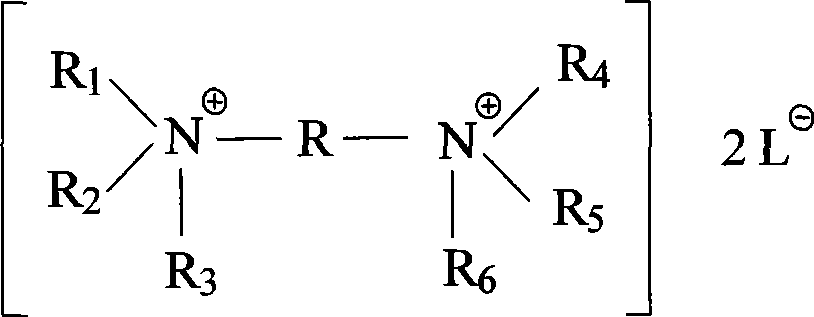

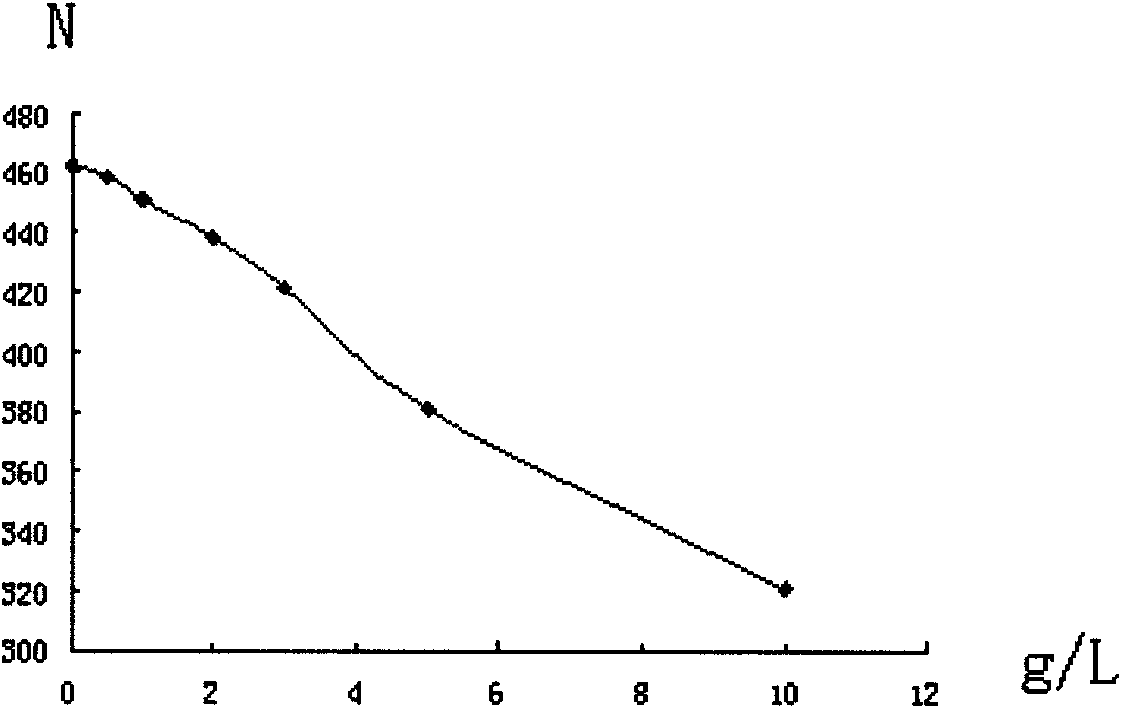

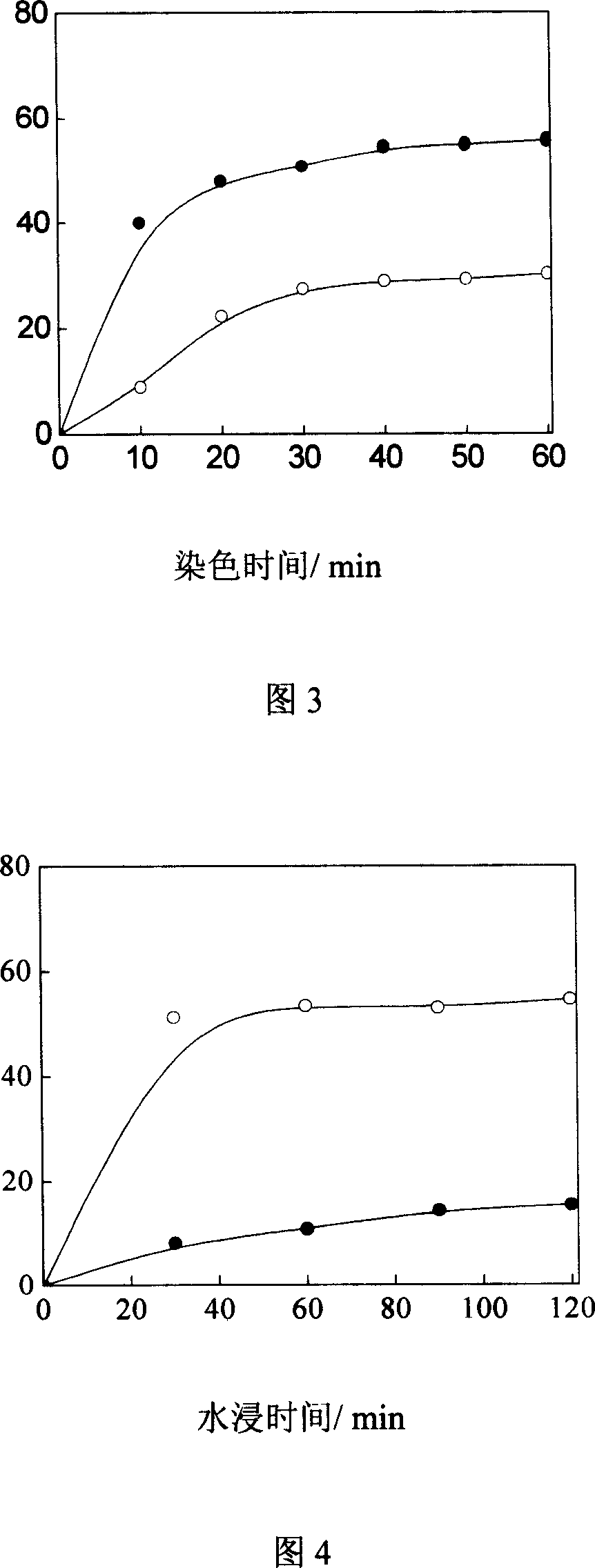

Reactive dye salt-free dying process of cotton fabric

InactiveCN103526606APlay a protective effectImprove dyeing effectDyeing processGraft reactionSalt free

The invention relates to a reactive dye salt-free dying process of cotton fabric. The reactive dye salt-free dying process of the cotton fabric comprises the following steps: (1) performing grafting reaction on glycidol trimethyl ammonium chloride and an amino-terminated hyperbranched compound to obtain amino-terminated hyperbranched compound quaternary ammonium salt; (2) placing the cotton fabric in the solution of the amino-terminated hyperbranched compound quaternary ammonium salt, performing dipping treatment at 20 to 90 DEG C for 20 to 80 minutes, taking out the cotton fabric and completely washing the cotton fabric for later use; (3) placing the modified cotton fabric into reactive dye and dyeing at normal temperature; and (4) washing after dyeing is finished, adding soap flakes of 3 g / L, performing soap boiling at 90 to 100 DEG C for 5 to 10 minutes and airing. The reactive dye salt-free dying process of the cotton fabric has the benefits that after the cotton fabric is modified, the dyeing property is obviously improved, the dyeing ratio is increased, the amount of dyeing waste water is reduced, and the environment is protected. Compared with the unmodified cotton fabric subjected to traditional salt dyeing, the cotton fabric has higher K / S value and achieves better effects on color fastness to rubbing and color fastness to washing.

Owner:KUNSHAN P&X GARMENTS

All-in-one machine for tea enzyme deactivation and tea screening

The invention discloses an all-in-one tea cleaning and screening machine, which comprises a base, a foot, a fixed plate, a drying cylinder, a feeding port, a cover plate, a handle, a collection box and a top plate; a drying cylinder is arranged above the base, and the base The left end of the seat is fixedly connected with a fixed plate, the side wall of the fixed plate is hinged with a first motor, the shaft extension end of the first motor is fixedly connected with a left rotating shaft, the right end of the left rotating shaft is fixedly connected with a first bevel gear, and the left rotating shaft is sleeved There is a left half gear, a partition is set on the right side of the left shaft, and a right shaft runs through the middle of the partition. The right end of the right shaft is fixedly connected with an electric heating plate, and the first motor drives the electric heating plate to rotate to dry the tea leaves. Heating is more uniform; during the drying process, use the scraper to clean the bottom of the drying cylinder, and at the same time use the scraper to turn the tea at the bottom of the drying cylinder, so that the tea is heated more evenly and the drying effect is further improved; drying The barrel rotates forward and backward alternately, so that the tea is heated more evenly and the screening efficiency is improved.

Owner:刘志坚

Low temperature dyeing method for wool fibre

The invention discloses a method for dyeing wool fibers at low temperature, which is characterized by comprising the following steps: increasing one or more than one Gemini cationic surfactant in the process of the prior wool acid dye dyeing or wool active dye dyeing, and then dyeing at specified temperature, wherein usually, the added weight of the Gemini cationic surfactant is 0.1 to 1.0 percent of that of the wool fibers, and the dyeing time is 40 to 90 minutes at a temperature of between 75 and 85 DEG C. The method can improve dyeing quality of the wool fibers and simultaneously reduce energy consumption in the dying process.

Owner:ZHANGJIAGANG CHENCHEN TEXTILE

Coating And Extruding Method For Producing Starch Softgel Capsules

InactiveUS20150119473A1Improve security levelBiocideLamination ancillary operationsSoftgelDying processes

The invention discloses a method for preparing starch-based softgel capsules, which, specifically, includes the following 2 steps: 1, Extrude the starch-based premixed material into starch-based extrusion film, 2, Apply the gel solution coating to the extrusion film to form composite starch film, 3) Process two composite starch films into starch-based softgel capsules by rotary die process.

Owner:ZHONGSHAN CAPSULE STARCH MATERIAL TECH

Mixing and extruding method for preparing starch softgel capsules

The invention discloses an extrusion method for preparing starch-based softgel capsules, which, specifically, includes the following 2 steps: 1, co-extruding the starch premix and gel solution to form composite starch film. 2, processing two composite starch films into starch-based softgel capsules by rotary die process.

Owner:ZHONGSHAN CAPSULE STARCH MATERIAL TECH

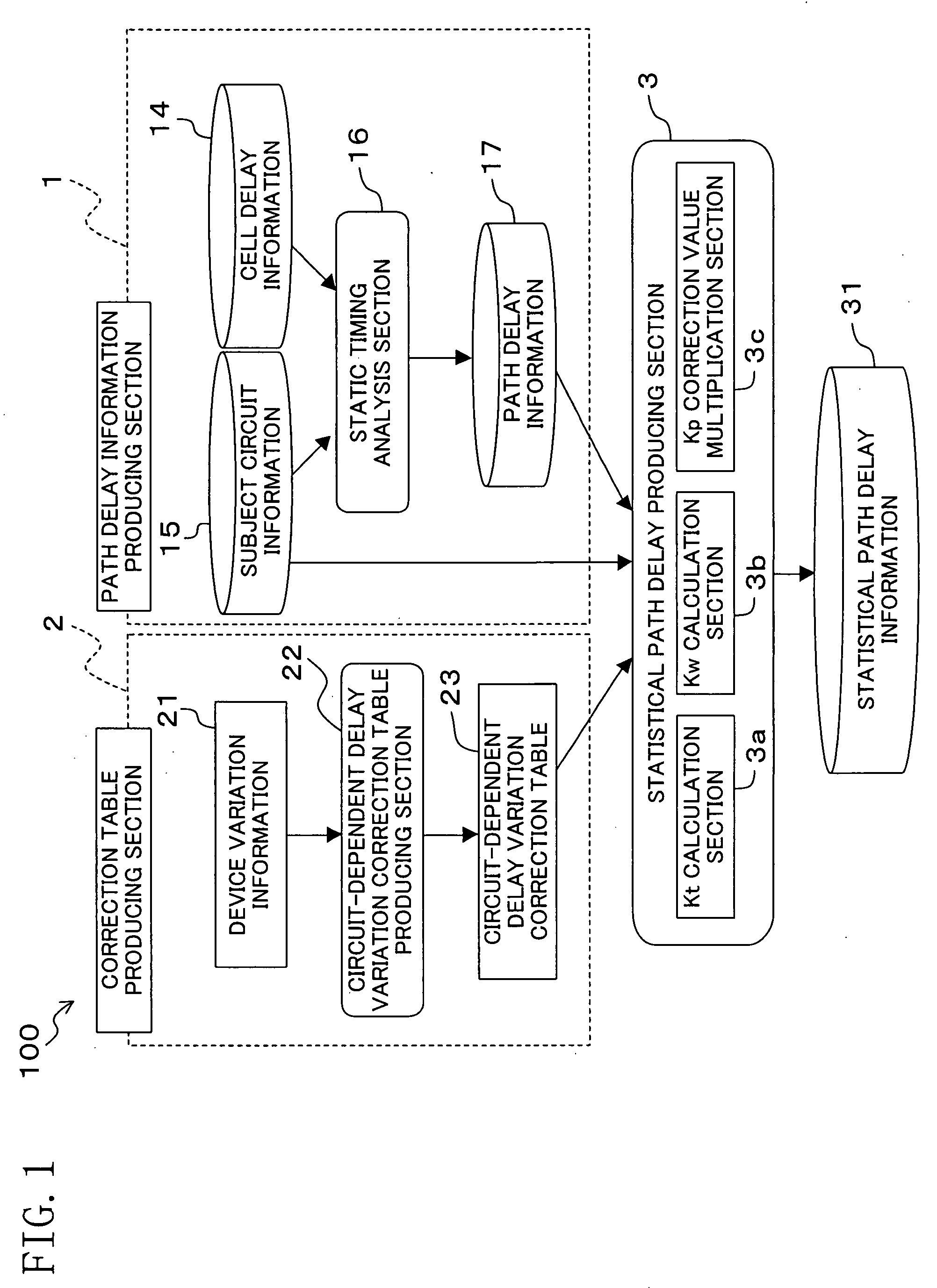

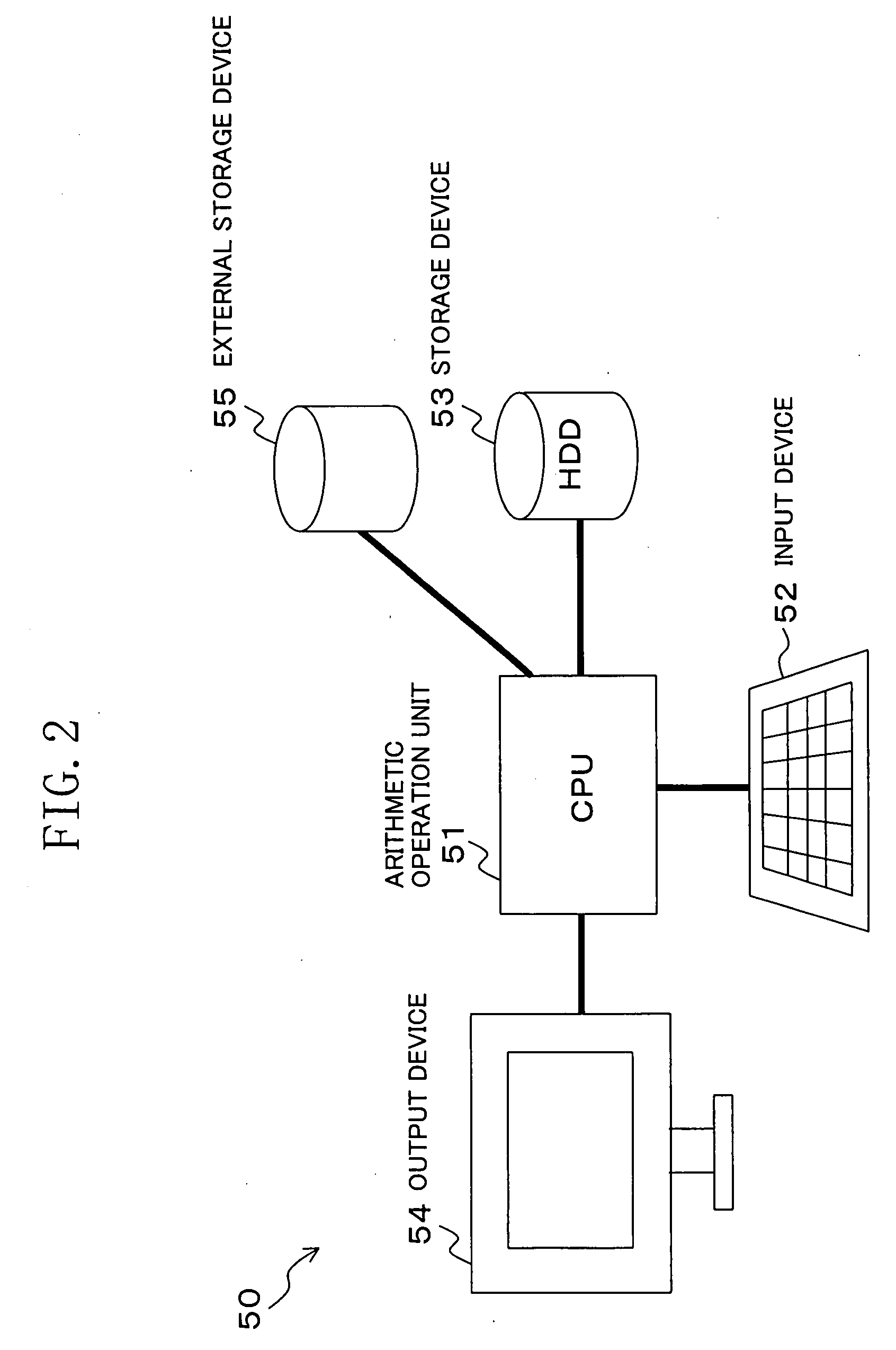

Apparatus and method of static timing analysis considering the within-die and die-to-die process variation

InactiveUS20070226671A1Quickly and precisely fluctuationQuickly and precisely calculatingComputer aided designSoftware simulation/interpretation/emulationStatic timing analysisDying processes

In a method and apparatus for designing semiconductor integrated circuit, a path delay information producing section produces path delay information by performing a static timing analysis based on delay information of a cell and subject circuit information. A correction table producing section calculates circuit-dependent delay variation for each combination of circuit parameter values based on variation information of an element, and stores the calculated circuit-dependent delay variation in a delay correction table. A statistical path delay producing section calculates the circuit parameters for a path based on the subject circuit information and the path delay information, obtains the corresponding circuit-dependent delay variation based on the circuit-dependent delay variation correction table, and calculates and outputs statistical path delay information based on the circuit-dependent delay variation and the corresponding path delay information. Thus, it is possible to obtain a value close to an actual path delay worst value with only a little addition of calculation time.

Owner:PANASONIC CORP

Precision casting technique of ceramic shell lost foam

InactiveCN101412076AGood dimensional stabilityHigh strengthFoundry mouldsFoundry coresDying processesIntermediate frequency

The invention relates to a precise casting process for a ceramic shell lost die. The process comprises the following steps: materials are foamed once and injected in a die cavity; after dry forming, and the materials are assembly welded by spraying glue and hot melt glue to form a die set; the die set adopts quick drying silicasol to prepare a shell and is pre-roasted, the die set after pre-roasting is placed in a furnace for roasting in the shortest time so as to be dried; after the roasting of the die shell, the die shell is filled in a sand box and pumped out and compacted, waste steel and alloy steel material are placed in an intermediate frequency furnace for melting, the compositions of the molten steel are adjusted to be the same as those of the cast product, after casting, cooling and forming, the remained sand on the surface is removed; after a riser and an ingate of the cast product are removed, the cast product is placed in a heat treatment furnace for heat treatment; the sand grain and oxide skin on the surface of the cast product are removed, the riser platform is processed to be smooth, and the surface defects of the cast product are eliminated. The process has the advantages of realizing the production of cast steel products which can not be realized by the conventional lost die process, having extremely high hardness, and avoiding the problems that the carbon penetration and gas holes on the cast product are easily generated.

Owner:安徽应流铸业有限公司

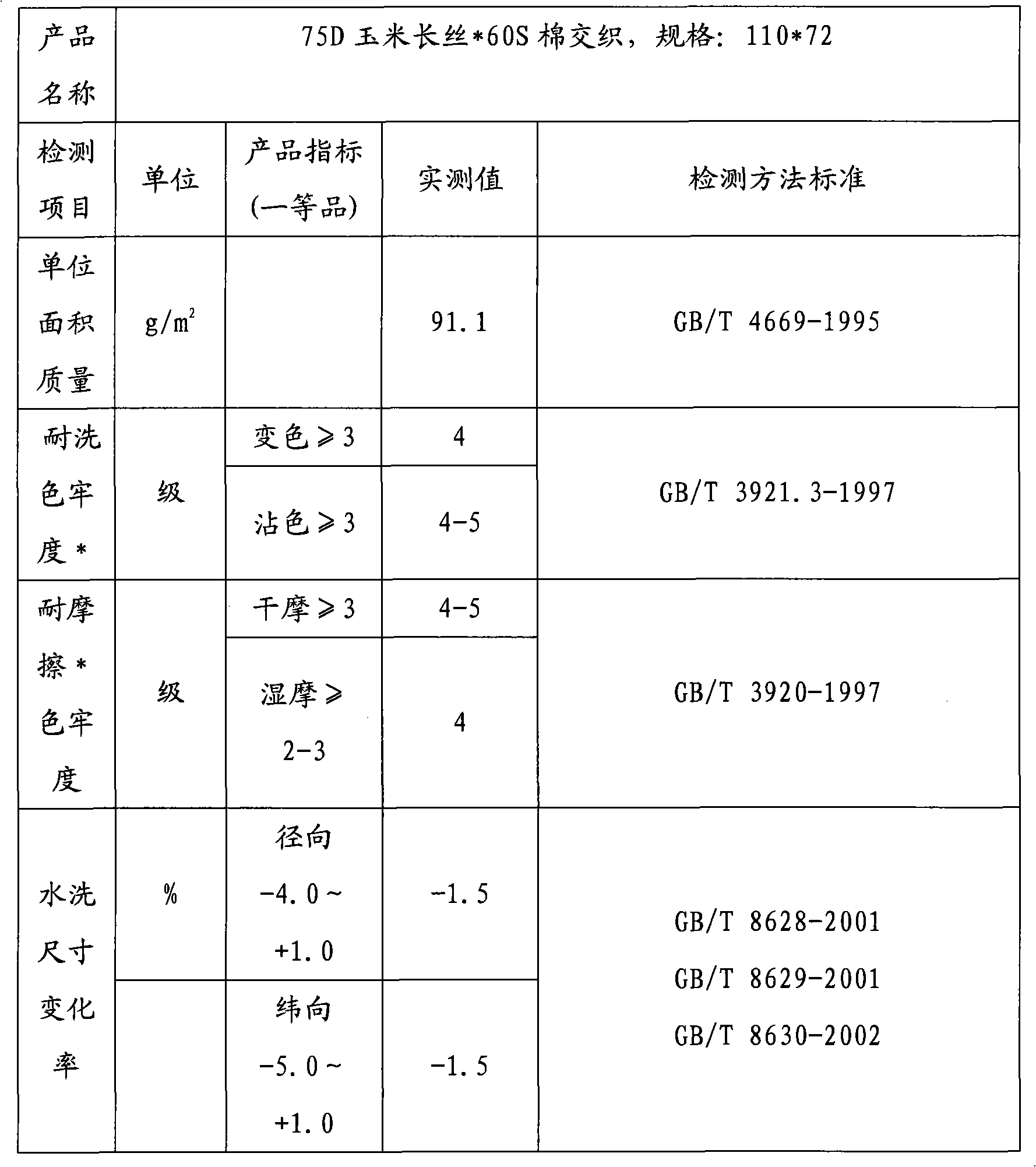

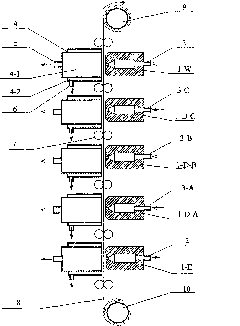

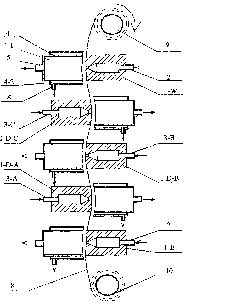

Dyeing and finishing process of corn fibers and cotton blending and mixed fabrics

ActiveCN101671947ASufficient sourceNo need for petrochemical resourcesBiochemical fibre treatmentHeating/cooling textile fabricsDisperse dyeDying processes

The invention discloses a dyeing and finishing process of corn fibers and cotton blending and mixed fabrics, comprising the following steps: end stitching of greige cloth, pre-setting, pre-treatment,dyeing, dehydration, post finishing, and warehouse entry inspection. In the pre-setting process, the temperature is 120-130 DEG C and the time is 30-45 minutes; in the pre-setting process, the presetfabrics are placed in an overflow dying machine to conduct desizing and remove the hairiness on the surface of the fabrics; in the dying process, the corn fibers adopt middle temperature type and lowtemperature type dispersing dyes to conduct dying; and in the post finishing process, the dyed fabrics are placed in a 8-12g / L of hydrophilic amino-silicone softener for padding, and then the padded fabrics are dried and stentered and set at 100-120 DEG C. The dyeing and finishing process of corn fibers and cotton blending and mixed fabrics has good coloring rate, ensures the strength and feel ofcorn fibers, and also has significant impact on the industrial development of the textile industry.

Owner:安徽三宝棉纺针织投资有限公司

Supercritical fluid spray-dyeing device

InactiveCN101798735ASimple structureOperational securityTextile treatment machine partsSolvent treatment with solvent recoveryDying processesSpray nozzle

Owner:SHANDONG UNIV

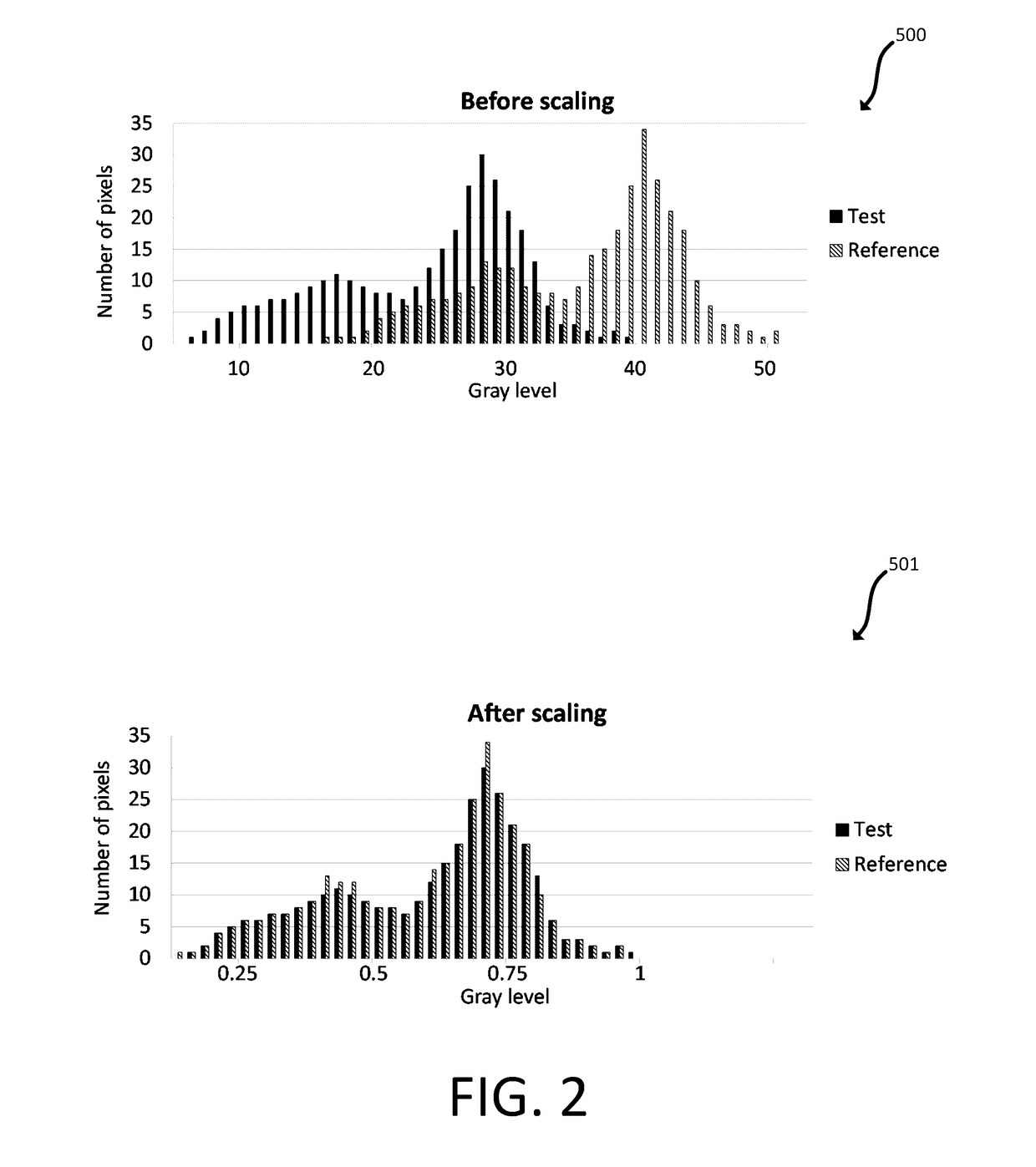

Defect signal to noise enhancement by reducing die to die process noise

Gray level histograms for a test image and a reference image are adjusted by histogram scaling. Parameters from the histogram scaling are applied to the test image and the reference image. After the parameters are applied, the reference image and the test image are compared to produce a difference image, such as by subtracting the reference image from the test image. Noise in the difference image can be reduced, which improves defect identification in the difference image. In addition, noisy structures in the difference image which are elongated in vertical or horizontal direction can be found. If the noise exceeds a certain threshold, the structures may not be inspected.

Owner:KLA CORP

Dry rice noodle and manufacturing method thereof

InactiveCN104187389AWhite and bright appearanceFlexible textureFood shapingFood preparationDying processesEngineering

The invention discloses a manufacturing method of dry rice powder. The method comprises the steps as follows: rice selection, soaking, milk grinding, filter pressing, smashing, accessory adding, rice dough kneading, pressing, threading, aging, loosing and dying processes. Compared with the prior art, the method is characterized by further comprising the milk grinding, stock screening, dewatering, filter pressing and smashing steps. According to the method, after dewatering, an accessory is added, so that compared with conventional dry rice powder, the manufactured dry rice powder is white and bright in surface, flexible in texture, not prone to be burnt by poaching and uneasy to break by dry cooking; and compared with fresh wet rice powder, the dry rice powder is smooth in texture, fragrant, flavorful and good in taste.

Owner:GUILIN QUANZHOU MILANXIANG FOOD

One-way wet-guiding and absorbing and quick-drying type cotton/nylon composite knitting fabric

ActiveCN103696110AFeel goodHigh glossWeft knittingHeating/cooling textile fabricsDying processesEngineering

The invention relates to a one-way wet-guiding and absorbing and quick-drying type cotton / nylon composite knitting fabric. The fabric adopts a double-sided plain weave structure, the cotton with higher wet-absorbing capability and poorer wet-guiding capability is weaved into an inner layer of the fabric by a circular knitting machine, and the superfine denier nylon long yarns with good wet-guiding and absorbing capability are weaved into an outer layer of the fabric. The dying process of the one-way wet-guiding and absorbing and quick-drying type cotton / nylon composite knitting fabric adopts the conventional dying process, and comprises the following processing steps of weaving of fabric blanks, preshaping, fiber opening, dyeing, cleaning, hydrophilic softening and arranging and shaping. The fabric has the advantages that the wet can be quickly absorbed and diffused to the outer layer of the fabric, the continuous dryness in the clothes can be maintained, and the fabric is an ideal and environment-friendly type one-way wet-guiding and quick-drying material.

Owner:广东广纺检测技术股份有限公司

Flashing frazil ice corduroy fabric

The invention belongs to the machine weaving category in the weaving field, which adopts flat polyester super fine denier filaments (either FDY or DTY)with a straight shape section as warp-wise and weft-wise raw material, the specification of the raw material is casually selected, the denier is normally required over 100D, the density of single filaments (dpf) is required to be smaller or equal to 0.5D. The finished clothes should be firstly treated by alkali, and then is treated by the process of desizing, brushing, singeing, bleaching and dying; or the finished clothes of corduroy is treated by the polishing process finally after the process of velvet cutting, printing, stentering and brushing; or the finished clothes of corduroy is treated by the process of velvet cutting, brushing, dying, drying and setting; only a pressing procedure is increased necessarily after the dying process, namely a special pressing and embossing machine is adopted to execute the pressing treatment on the frontal surface of the weave so as to produce a flashing ice crystal effect and to form a strong level of 3D beauty. The Pique stripes of the corduroy are smooth and enriched; the floss is wear-resistant with thick quality, soft handle feeling and good heat insulation performance. The invention is mainly used for clothes, shoes and hats of male, female, elder and child, and also is used for decorative clothes, handcraft products, toys, etc.

Owner:SHENGHONG GRP CO LTD

Colored union yarn containing cashmere and processing method thereof

The invention discloses a colored union yarn containing cashmere and a processing method thereof, wherein the union yarn comprises viscose fibers with weight ratio of 50 %, 45% lustre wool fibers and 5% cashmere fibers, wherein at least part of or the whole of one of the fibers is dyed, the dyed fiber and unfinished fibers are spun into the colored union yarn containing cashmere after mixing through spinning procedures. The process method comprises that dying the fibers, then spraying oil solution on the dyed fibers to stew for tens of hours, and mixing the fibers in different colors and different proportions after weighing, and installing the fibers on a spinning machine to be spun into the colored union yarn. The technical scheme of the invention can reduce the pollution of the dying process to environment, can enrich the color of the union yarn, and reduces the cost required by the finishing process after dying.

Owner:江阴市茂达棉纺厂有限公司

Method for dyeing cotton/pashm blended yarn

The invention provides a dying method for cotton / cashmere blended yarn, which sequentially comprises pre-treatment, dying, post-treatment and oven-drying. The method is characterized in that the pre-treatment process comprises enzyme scouring treatment and oxygen bleaching treatment, and the dying process is achieved by bath dying using an active dye. The invention can effectively solve the problems of influencing the dying quality of cotton / cashmere blended product, such as dyeing defect and poor level dyeing property occurred in bath dying process as well as poor homochromatic property in cotton and cashmere dying, thus achieving better effect.

Owner:LUTAI TEXTILE

Modified one-bath dyeing technology of polyester/rayon fabric dispersed microcapsule/active dye

The invention belongs to the technical field of spinning dying and particularly relates to a modified one-bath dyeing technology of polyester / rayon fabric dispersed microcapsule / active dye. The dispersed microcapsule slow release dacron assistant-free dyeing process and the fabric modified salt-free and alkali-free dying process are combined for replacing the traditional dispersed / active two-bath method and the dispersed / active one-bath method dying process in recent years, the problems of low production efficiency, great water, electricity and steam consumption and great sewage discharge quantity of the two-bath method are solved, the problems of dye hydrolysis deep dying difficulty and poor dying color fastness of the one-bath method adopting a great number of dispersing agents, uniform dying agents, salt and alkali are solved, the active dying rate is improved, the reduction soaping is omitted, the dying period is shortened, the water is saved, the energy is saved, the sewage is reduced, the clean production is reached, and greater social and economic benefits are realized.

Owner:绍兴董氏纺织印染技术开发中心

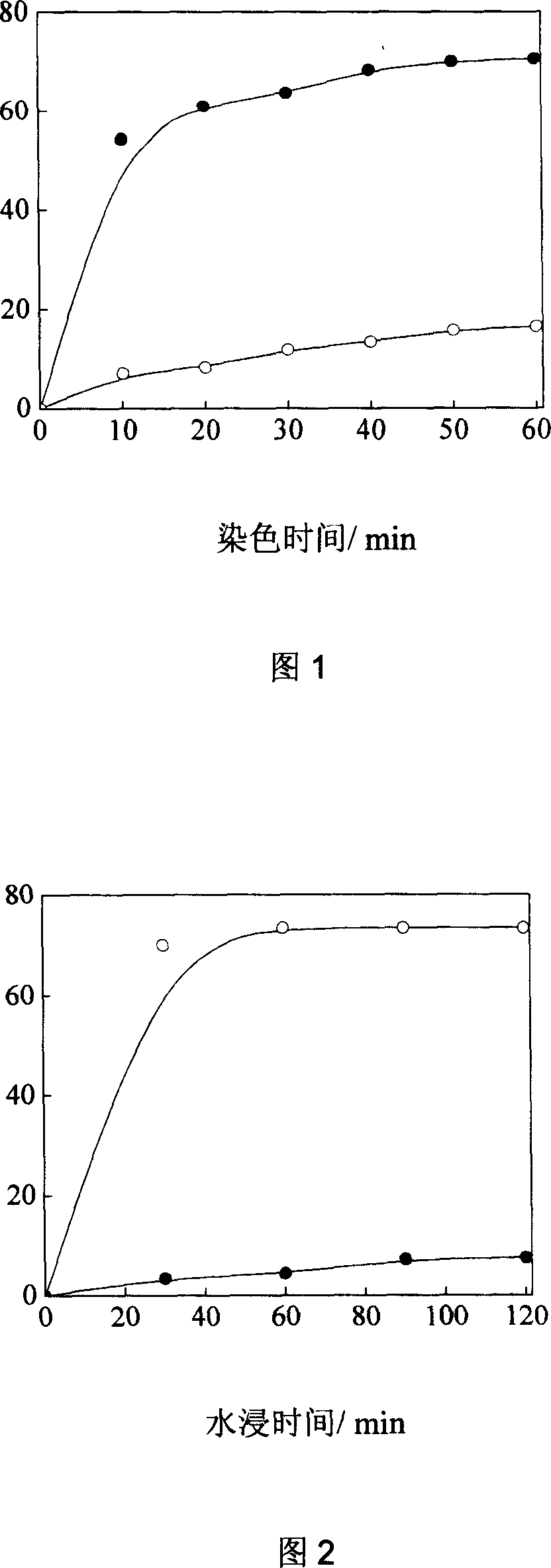

Fibroin protein coating fabric dying method

InactiveCN101008157AReduce pollutionImprove dyeing qualityFibre treatmentDyeing processSocial benefitsDying processes

The invention relates to a method for dying the fabric with fibroin coat, which utilizes the cation dye and acid dye to dye the rear cotton, nylone and terylene. The inventive method comprises that 1, treating the coat that furnishing the fabric in fibroin / silicon dioxide nanometer sol, drying at 40-80Deg. C, treating with methanol and drying, baking at 100-150Deg. C for several minutes, washing in water and drying; 2, pretreatment before dying comprises that 1, wetting the fabric and preparing the anion dye which is 0.1-2.0% of object mass, while the bath ratio is 1:50-1:100, and using acetate to adjust the pH value to 4.0-8.0; 2, wetting the fabric and preparing the acid dye at 0.1-2.0% of object mass, while the bath ration is 1:50-1:100, using acetate to adjust the pH value to 2.0-3.5; 3, dying process comprises that 1, dying with anion, 2, dying with acid dye; 4, drying and ironing the object. The invention has simple process, dye-uptake and high color stability, without other agents and pollution, but high economic and social benefits.

Owner:DONGHUA UNIV

Self-centering press-fit connector pin used to secure components to a receiving element

InactiveUS6764318B1Easy to disassembleConvenient meanPrinted circuit assemblingPrinted circuit aspectsDying processesPrinted circuit board

A self-centering press-fit pin that is typically used to secure components to a printed circuit board (PCB). The device includes more than one leg, the legs providing connection points for the component on which the pins are installed. The pin is formed so that the legs act as leaf springs to securely hold the connector in place in the proper installation hole in the board on which the component is installed. The pins are stamped from sheet metal with a progressive die process. By changing the amount of flexion in the legs of the pin, the pressure required to insert the pin into, and remove the pin from, a connection hole can be varied.

Owner:FOURTE INT SDN BHD

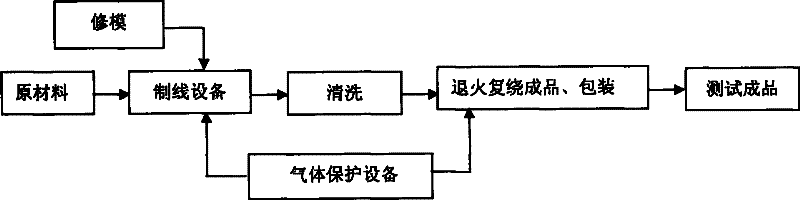

Single crystal copper bonding lead and preparation method thereof

InactiveCN102637657AHigh strengthHigh elongationSemiconductor/solid-state device detailsSolid-state devicesCopper wireDying processes

The invention discloses a single crystal copper bonding lead and a preparation method thereof, relating to the field of production of microelectronic materials. The production technology integrates a metal material preparation process, a heat treatment process and a diamond die process, ensures the production consistency and reliability and realizes the large-scale production. The adopted production process comprises the steps of providing die repair and gas protection equipment, smelting, wiredrawing, cleaning, and compounding, packaging and testing a finished product. The single crystal copper bonding lead has the beneficial effects that as a signal crystal copper material has a compact solidification structure, lateral crystal boundaries are eliminated, the casting defects of shrinkage cavities, pores and the like are avoided, the plastic working performance, the mechanical performance, the electric performance and the like of the signal crystal copper material are obviously higher than those of the conventional oxygen-free copper, the defects of more end breakage, low quality and low productivity in the wiredrawing process of the conventional copper wire are overcome, and an electronic packaging bonding wire with the wire diameter reaching 0.015m, high strength, high elongation and stable performance can be prepared.

Owner:宋东升

Accelerated characterization of circuits for within-die process variations

In one embodiment of the invention, a method for electronic circuit design is disclosed. The method includes analyzing a netlist of a subcircuit to determine one or more input pins and one or more output pins; forming an arc graph of the subcircuit including one or more timing arcs between the one or more input pins and the one or more output pins; and reducing the number of transistors to perturb to perform a sensitivity analysis for within die process variations over the one or more timing arcs to reduce the number of simulations to characterize the subcircuit.

Owner:CADENCE DESIGN SYST INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com