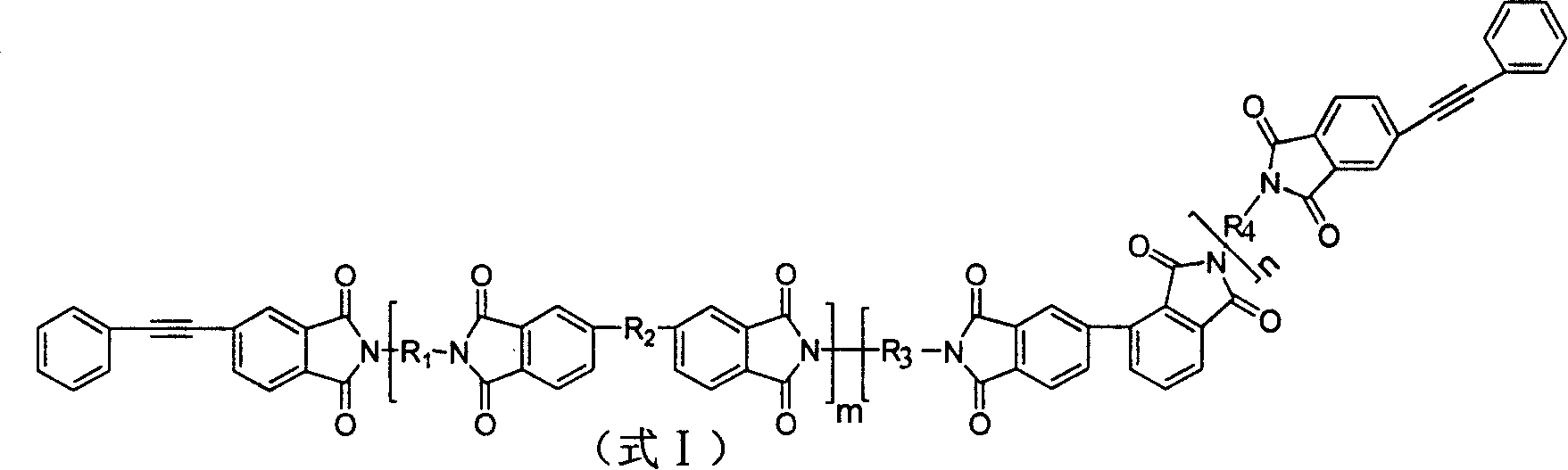

Polyimide resin and preparation method thereof

A polyimide resin and the same technology, applied in the field of polyimide resin and its preparation, can solve the problems of low open-hole compressive strength, unsatisfactory service temperature upper limit of composite materials, unsatisfactory toughness, etc., and achieve low porosity , high mechanical properties, excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

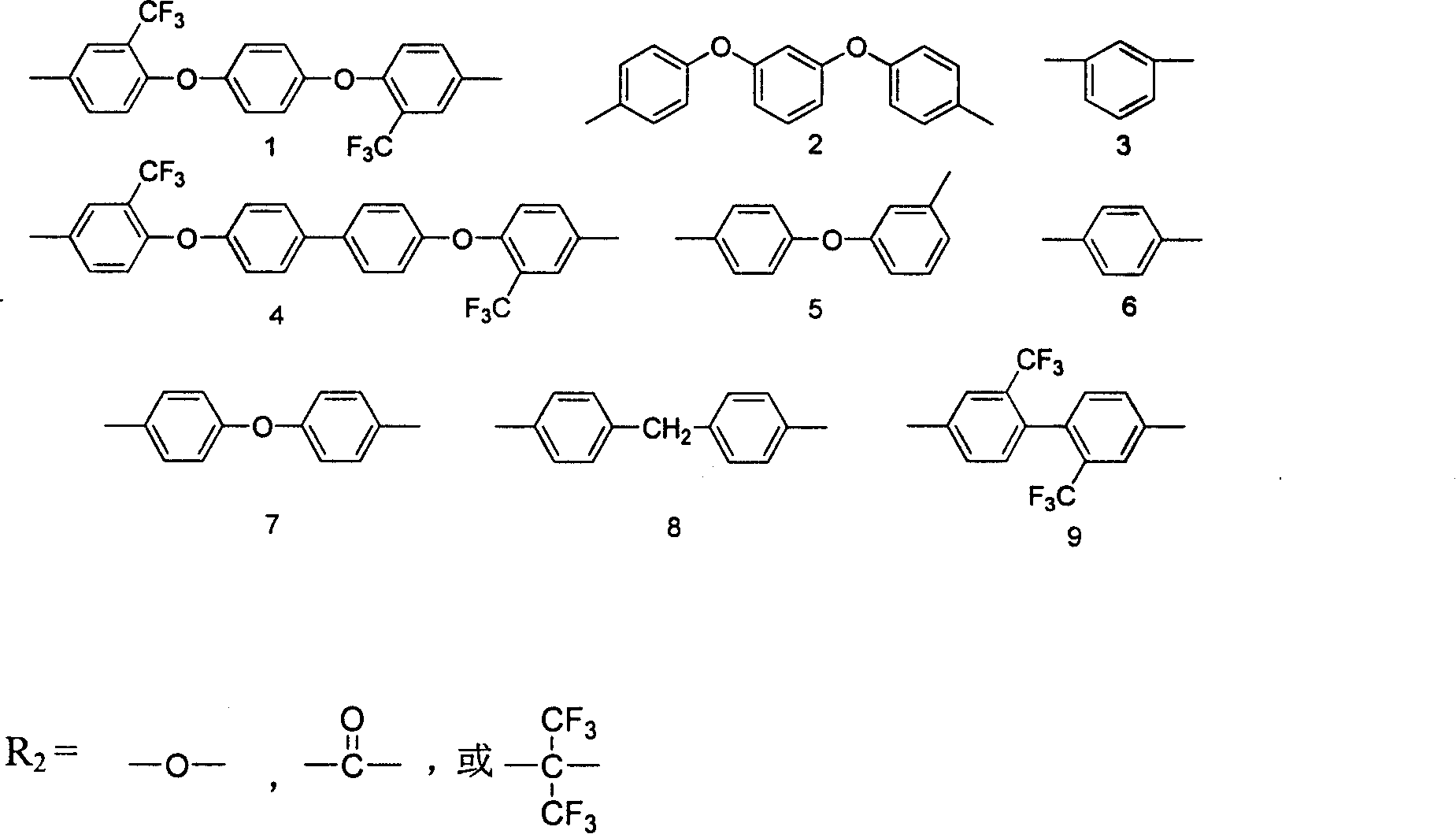

Method used

Image

Examples

Embodiment 1

[0031] 80 parts by weight of 2,3,3',4'-biphenyltetraacid dianhydride (a-BPDA) was heated under reflux in 100 parts by weight of ethanol for 1 hour to obtain an aromatic diacid diester (a-BPDE) solution. Heat reflux 42 parts by weight of end-capping agent-phenylacetylene phthalic anhydride in 66 parts by weight of ethanol for 5 hours to obtain monoacid monoester (PEPE) solution. Under the protection of nitrogen, dissolve the p-phenylenediamine (p-PDA) of 30 parts by weight in the ethanol of 40 parts by weight, add the PEPE and a-BPDE solution of above-mentioned preparation successively after stirring for half an hour; The mixture was stirred at 5° C. for 15 hours to obtain a polyimide resin matrix solution with a solid content of 42% (weight percent); its viscosity (25° C.) was 25-28 mPa.s. The resin solution has good storage stability at room temperature and 0°C, and at room temperature and 0°C, the infrared spectrum absorption peak and viscosity of the resin solution basicall...

Embodiment 2

[0034] 90 parts by weight of 2,3,3', 4'-biphenyltetraacid dianhydride (a-BPDA) was refluxed for 5 hours in 170 parts by weight of ethanol to obtain aromatic diacid diester (a-BPDE ) solution. Heat and reflux 45 parts by weight of end-capping agent-phenylacetylene phthalic anhydride in 60 parts by weight of ethanol for 1 hour to obtain monoacid monoester (PEPE) solution. Under the protection of argon, 72 parts by weight of diamine monomer p-phenylenediamine (p-PDA) and 8 parts by weight of m-phenylenediamine (m-PDA) were dissolved in 110 parts by weight of ethanol, and after stirring for half an hour The previously prepared PEPE and a-BPDE solutions were sequentially added, and the mixture was stirred at 50° C. for 2 hours to obtain a polyimide homogeneous resin solution with a solid content of 39% (weight percent). Its viscosity (25°C) is 24-27mPa.s. The resin solution has good storage stability at room temperature and 0°C, and at room temperature and 0°C, the infrared spect...

Embodiment 3

[0037] 220 parts by weight of 2,3,3',4'-biphenyltetraacid dianhydride (a-BPDA) was heated to reflux in 380 parts by weight of ethanol for 2 hours to obtain an aromatic diacid diester (a-BPDE) solution , 90 parts by weight of 3,3',4,4'-benzophenonetetraacid dianhydride (BTDA) was heated to reflux in 170 parts by weight of ethanol for 3 hours to obtain an aromatic diacid diester (BTDE) solution. Heat reflux 90 parts by weight of end-capping agent-phenylacetylene phthalic anhydride in 130 parts by weight of ethanol for 3 hours to obtain monoacid monoester (PEPE) solution. Under the protection of nitrogen, the diamine monomer p-PDA of 190 parts by weight is dissolved in 200 parts by weight of ethanol, and after stirring for half an hour, PEPE, a-BPDE and BTDE solutions prepared before are added successively, and the mixed solution is in Stirring at 25° C. for 8 hours to obtain a polyimide homogeneous resin solution with a solid content of 40% (weight percent). Its viscosity (25°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com