Single crystal copper bonding lead and preparation method thereof

A technology for bonding wires and single crystal copper, which is applied in the field of microelectronic material production, can solve problems such as difficulty in being used, and achieve the effects of eliminating lateral grain boundaries, stable performance, and overcoming many broken ends.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

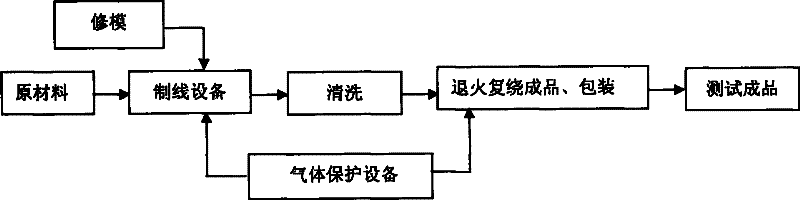

[0015] Embodiment: Step 1: Use ultrasonic mold repairing equipment to trim molds as needed, and use high-purity argon protection equipment with a purity of over 99.99% in the process of wire making and annealing and rewinding finished products; Step 2: The equipment is the key Lead wire drawing machine, the vacuum degree is 10-104MPa High-vacuum furnace melts high-purity copper with a purity higher than 99.995%, heats up to 1100-1180°C, and refines for 60-120 minutes. The entire melting process uses high-purity copper with a purity of more than 99.99%. Pure argon protection, and directional solidification method to draw Φ4 ~ Φ8mm single crystal copper rod; the third step: the equipment is bonding wire medium drawing machine, small drawing machine, fine drawing machine, micro drawing machine. The drawn high-purity single crystal copper rod is cold processed to Φ0.95~Φ1.102mm, the drawing processing rate of each pass is 15~25%, and the drawing speed is controlled at 40~60m / min; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com