Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69 results about "Full-mold casting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Full-mold casting is an evaporative-pattern casting process which is a combination of sand casting and lost-foam casting. It uses an expanded polystyrene foam pattern which is then surrounded by sand, much like sand casting. The metal is then poured directly into the mold, which vaporizes the foam upon contact.

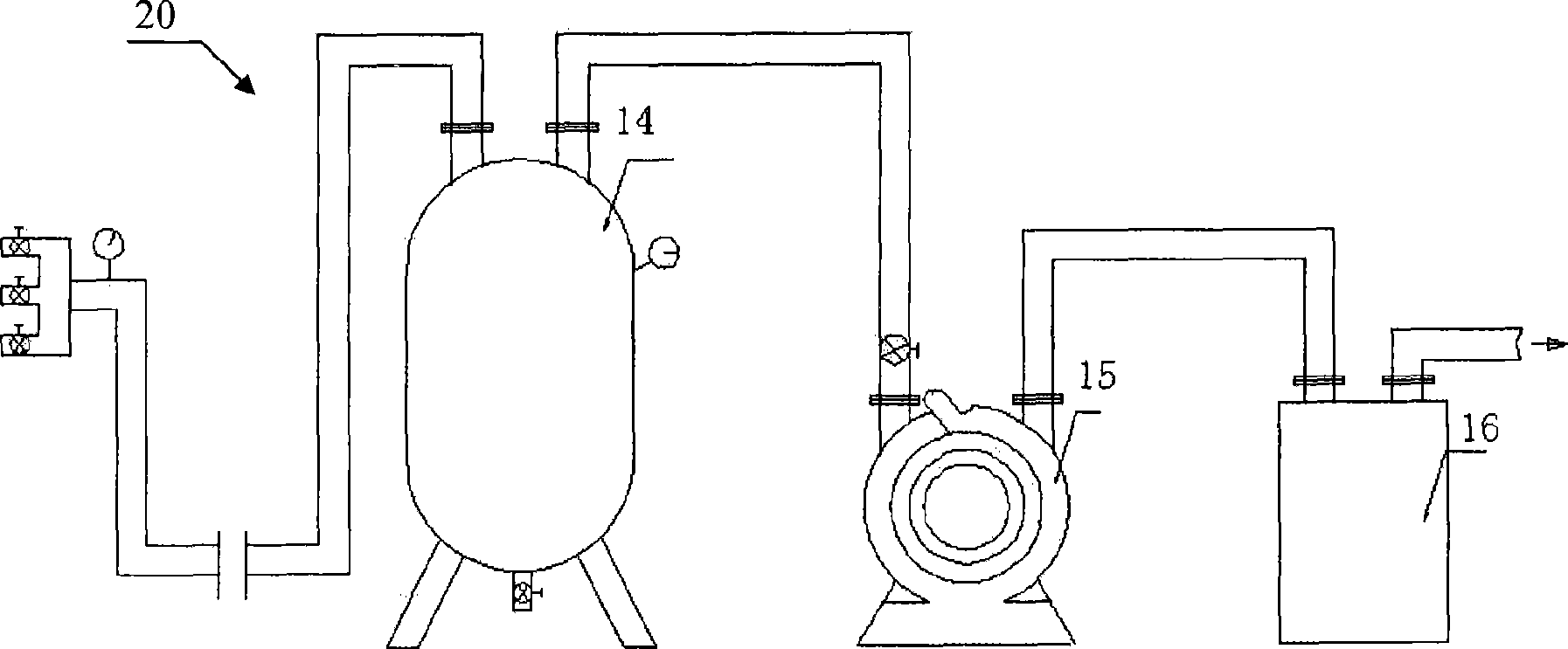

Vacuum evanescent die casting process

InactiveCN102974762AHigh precisionNo uneven wall thicknessFoundry mouldsFoundry coresModel compositionAfter treatment

The invention discloses an evanescent die process. The evanescent die process is characterized by comprising the following steps of: selecting foaming plastic beads, manufacturing a model; enabling the beads to expand to be in a certain size through hot water pre-frothing, steam pre-frothing and vacuum pre-frothing, curing and frothing forming; clustering model composition, coating a model; vibrating and shaping; pouring and displacing; and cooling and cleaning, wherein the full mold casting ramoff is simple, a casting piece can be hoisted out when a sand box is inclined or can be directed hoisted out form the sand box, the casting piece and dried sand are naturally separated, and the separated dried sand is reused after treatment. According to the process, a die is not required to be taken out, and a parting plane and a sand core are not required, and thus the casting piece has no flash, no burrs and no pattern tapers, and the dimension error caused by core combination is reduced; and compared with the conventional sand casting method, for the evanescent die process, the 40%-50% machining time is reduced.

Owner:CHANGTU COUNTY JIPAI MACHINERY CASTING

Full mold casing coating

ActiveCN102397983AImprove performanceIncrease stiffnessFoundry mouldsFoundry coresSodium BentonitePolyvinyl alcohol

The invention discloses a full mold casting coating, which consists of the lower components in part by weight: 70-80 parts of quartz powder, 10-15 parts of olivine powder, 10-15 parts of alundum powder, 4-6 parts of sodium bentonite, 1-2 parts of lignosulfonic acid, 2-3 parts of dextrin powder, 0.8-1.5 parts of sodium carboxymethylcellulose, 0.4-0.6 part of sodium benzoate, 1-2 parts of hollow glass microsphere, 7-9 parts of aluminum sulfate, 4-6 parts of polyvinyl alcohol, 5-6 parts of silica sol, 0.5-0.8 part of brown iron oxide, 0.04-0.06 part of n-octyl alcohol and 15-25 parts of water.

Owner:南通市通州区俊朗建筑工程有限公司

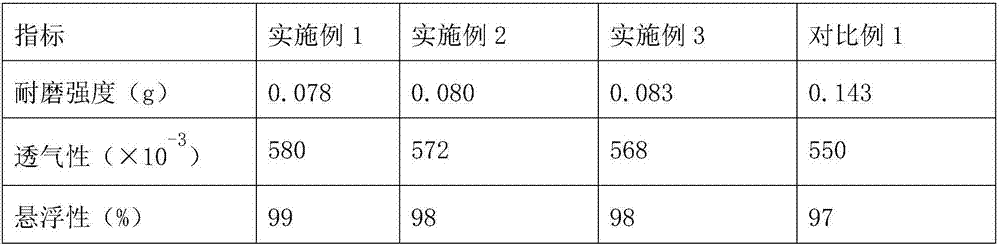

Method for preparing full-mold casting coating

ActiveCN102500745AImprove performanceIncrease stiffnessFoundry mouldsFoundry coresHigh surfaceTemperature resistance

The invention discloses a method for preparing a full-mold casting coating. The full-mold casting coating prepared by the method is high in anti-burn-on capacity and capable of improving rigidity and high-temperature resistance of molds, while cost is reduced to the utmost extent. A high-current rheological fluid is formed by optimizing blending of aggregates and various additives, and has betterwettability and brushing property to foamed plastic molds. According to practices, the coating thickness of the coating can be at least 1.7mm after the coating is brushed by twice and is capable of meeting requirements for anti-burn-on capacity and transporting of large-size castings. The full-mold casting coating has excellent suspended property, thixotropy, breathabililty and higher surface strength, the method for preparing the full-mold casting coating is simple, convenient in operation and low in cost, and raw materials for preparing the full-mold casting coating are rich. In addition, surfaces of the full-mold castings produced by the full-mold casting coating are smooth and bright and free of defects of wrinkles, carbon black and the like, and coating layers on the surfaces are easy to be stripped and convenient to be cleaned.

Owner:南通市通州区俊朗建筑工程有限公司

Full-mold casting technique of resin-bonded sand

InactiveCN101462160ANo pollutionEvenly filledFoundry mouldsFoundry coresDental Casting TechniqueCasting defect

The invention provides a process for resin sand full mold casting. The process comprises the following steps: manufacturing a model by a foam materiel; coating paint on the surface of the model, and drying the model; modeling, namely, putting the dried model into a sand box, laying a pouring channel, filling resin sand into the sand box to model, and providing a shrink head on the model; and pouring, sand shaking and cleaning, namely, pouring molten iron into the sand box, opening the box to shake sand after the molten iron is cooled, and cleaning the cast, wherein during pouring, the sand box keeps a vacuum state. According to the process for the resin sand full mold casting, because the sand box keeps the vacuum state during pouring, large amount of waste gas and smoke generated by the foam model can be taken away by a vacuum system and subjected to uniform treatment, so that the waste gas and the smoke are not discharged into a workshop and can not cause pollution; and because the waste gas is taken away by the vacuum system in time, the molten iron can be filled smoothly, so as to avoid casting defects that filling is not full, air holes are generated, and the like.

Owner:BYD CO LTD

Full mold casting technique for diesel engine cylinder body

InactiveCN105618680AControl pre-blown densityImprove qualityFoundry mouldsFoundry coresResidual carbonVolumetric Mass Density

The invention relates to casting methods, in particular to a full mold casting technique for a diesel engine cylinder body. The full mold casting technique for the diesel engine cylinder body comprises the following steps that a, prefoaming is conducted; b, curing is conducted; c, foam forming is conducted; d, models are combined into a cluster; e, the models are coated; f, a mold bed is prepared; g, a full mold model is placed; h, sand filling is conducted; i, sealing and shaping are conducted; j, pouring and displacing are conducted; and k, cooling and cleaning are conducted. The full mold casting technique for the diesel engine cylinder body has the beneficial effects that firstly, excellent foam plastic beads are used for further reducing the amount of residual carbon; secondly, the reasonable bead prefoaming density is effectively controlled, so that the situation that a white mold deforms and even breaks due to the fact that the strength of the white mold is insufficient is avoided, and the defects, such as pores and carbon defects, of castings are also avoided; and thirdly, the problem that the quality of the castings is low is solved, and thus volume production of diesel engine cylinder bodies is achieved.

Owner:CHANGZHOU CHANGXIE DIESEL ENGINE BLOCK CO LTD

Preparation method of anti-burnt-on sand full-mold casting coating

InactiveCN103100650AImprove performanceHigh anti-sand sticking abilityFoundry mouldsFoundry coresCarboxymethyl celluloseGraphite

The invention discloses a preparation method of an anti-burnt-on sand full-mold casting coating. The coating comprises the following components in parts by weight: 56-70 parts of quartz powder, 5-7 parts of plant ash, 1-2 parts of hollow glass beads, 10-15 parts of sodium silicate, 10-15 parts of graphite powder, 4-6 parts of nano attapulgite, 1-2 parts of lignosulfonic acid, 2-3 parts of polyving akohol, 0.8-1.5 parts of sodium carboxymethyl cellulose, 0.4-0.6 part of sodium benzoate, 1-2 parts of nano ceramic powder, 0.5-0.8 part of ferric oxide powder and 525-535 parts of water. The coating is a full-mold casting coating with strong abrasion resistance, high adhesiveness, excellent air permeability and rapid drying capability in both high temperature and low temperature environments, so that the requirements of production of large-sized casts are met.

Owner:BAZHONG SHENBANG BUILDING MATERIAL CO LTD

Full-mold casting paint and preparation method thereof

InactiveCN107052232ASolve the problem that cannot meet the production requirements of large castingsImprove wear resistanceFoundry mouldsFoundry coresPolyvinyl alcoholOlivine

The invention provides a full-shape casting coating and a preparation method thereof, relating to the field of casting. The full-shape casting coating includes the following raw materials in parts by weight: quartz powder, olivine powder, corundum powder, sodium bentonite, lignin sulfonic acid, and dextrin powder , sodium carboxymethyl cellulose, sodium benzoate, hollow glass microspheres, aluminum sulfate, polyvinyl alcohol, silica sol, iron oxide powder, n-octanol, graphite powder, zircon powder, attapulgite, water reducing agent and water The preparation method comprises the following steps: (1) weighing raw materials, (2) preparing each mixed solution in turn, and (3) adding to a reaction kettle and stirring in turn. The invention solves the problem that the existing solid casting coatings generally have strong wear resistance, high adhesion, excellent air permeability and quick drying under high temperature and low temperature environments, which makes them unable to meet the production requirements of large castings. question.

Owner:安徽华飞机械铸锻有限公司

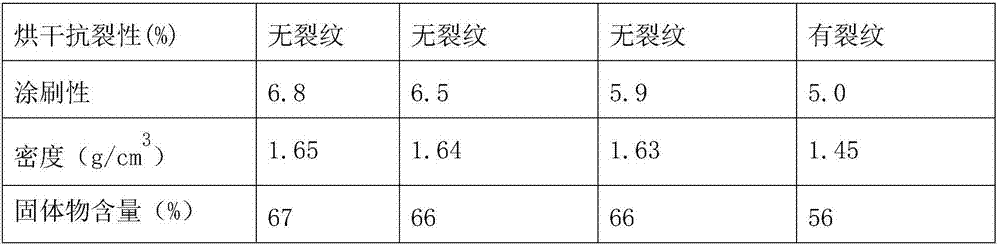

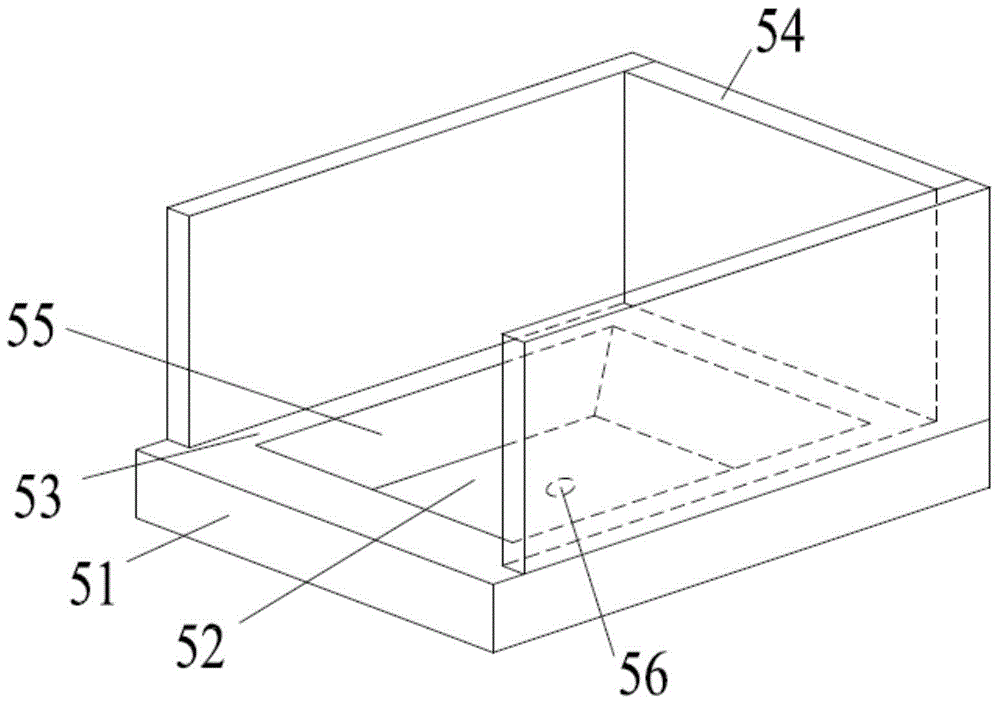

Full mold casting coating curtain coating device

ActiveCN104139165AImprove work efficiencyReduce labor intensityMoulding toolsDie castingSpray coating

The invention discloses a full mold casting coating curtain coating device which comprises a coating supply device, a spray gun connected with the coating supply device and a curtain coating pool used for accommodating a blank die cast. The curtain coating pool comprises a base and a surrounding plate vertically arranged on the base. The base is provided with a storing face used for storing the blank die cast and an inclined flow guide face which is connected to the edge of the storing face. According to the full mold casting coating curtain coating device, the coating supply device and the spray gun are combined to spray coating on the surface of the blank die cast in the curtain coating pool, manual painting is replaced, so that work efficiency of coating the blank die cast is improved, time and labor are saved, and labor intensity is lowered.

Owner:WUHU RUYHOO CASTING

Full mold casting method for large grinder bed

InactiveCN107737873AFully vaporizedStable mass productionFoundry mouldsFoundry coresSlagCarbon deposition

The invention discloses a full mold casting method for a large grinder bed. The large grinder bed is machined by the steps of lost foam pattern manufacturing, lost foam pattern coating, lost foam pattern drying, casting bed manufacturing, design of a pouring system, smelting and pouring, casting taking-out and the like. An annular pouring gate is used in the pouring system which is an open type non-pressure gating system, four sprues are used, two of the four sprues are positioned at two ends of a lost foam pattern and are connected with a pouring cup at the upper end, the other two sprues stretch across the middle of the lost foam pattern and are connected with the bottom of a pouring cup at the upper end, a cross gate surrounds the periphery of the lost foam pattern, the upper part of the outer wall of the cross gate communicates with the sprues, a plurality of ingates are arranged below the cross gate at intervals, and the lower ends of the ingates are bent inwards and go deep intothe bottom of the lost foam pattern. The multi-pouring-gate open type gating system is used, and it can be ensured that slag blowholes are not formed in a casting guide track; a riser-free and exposed-air-hole-free process is adopted, sufficient gasification of the lost foam pattern is ensured, carbon deposition is avoided, the appearance is attractive, and smoke does not exist; and by a special coating brushing method, it can be ensured that sand does not adhere to castings.

Owner:芜湖久弘重工股份有限公司

Full-mold casting paint and preparation method thereof

InactiveCN107052231AImprove high temperature resistanceImprove conductivityFoundry mouldsFoundry coresFiberSurface-active agents

The invention discloses full-mold casting paint, and belongs to the technical field of casting paint. The full-mold casting paint comprises, by weight, 15-17 parts of crystalline flake graphite, 10-15 parts of cyanite powder, 20-24 parts of spodumene powder, 8-10 parts of ceramic fibers, 6-9 parts of zirconium silicate powder, 14-15 parts of aluminum powder, 4-7 parts of forsterite powder, 0.5-0.8 part of iron oxide powder, 17-20 parts of phenolic resin, 1-2 parts of methyl alcohol, 0.01-0.05 part of a surface active agent, 4-6 parts of a defoaming agent, 1-2 parts of an anticorrosive agent, 0.5-1 part of a carbon adsorbing agent, and 24-26 parts of water. The invention further discloses a preparation method of the full-mold casting paint. The full-mold casting paint is environmentally friendly, resistant to corrosion, excellent in high-temperature resistance and fire resistance and high in mechanical strength.

Owner:安徽华飞机械铸锻有限公司

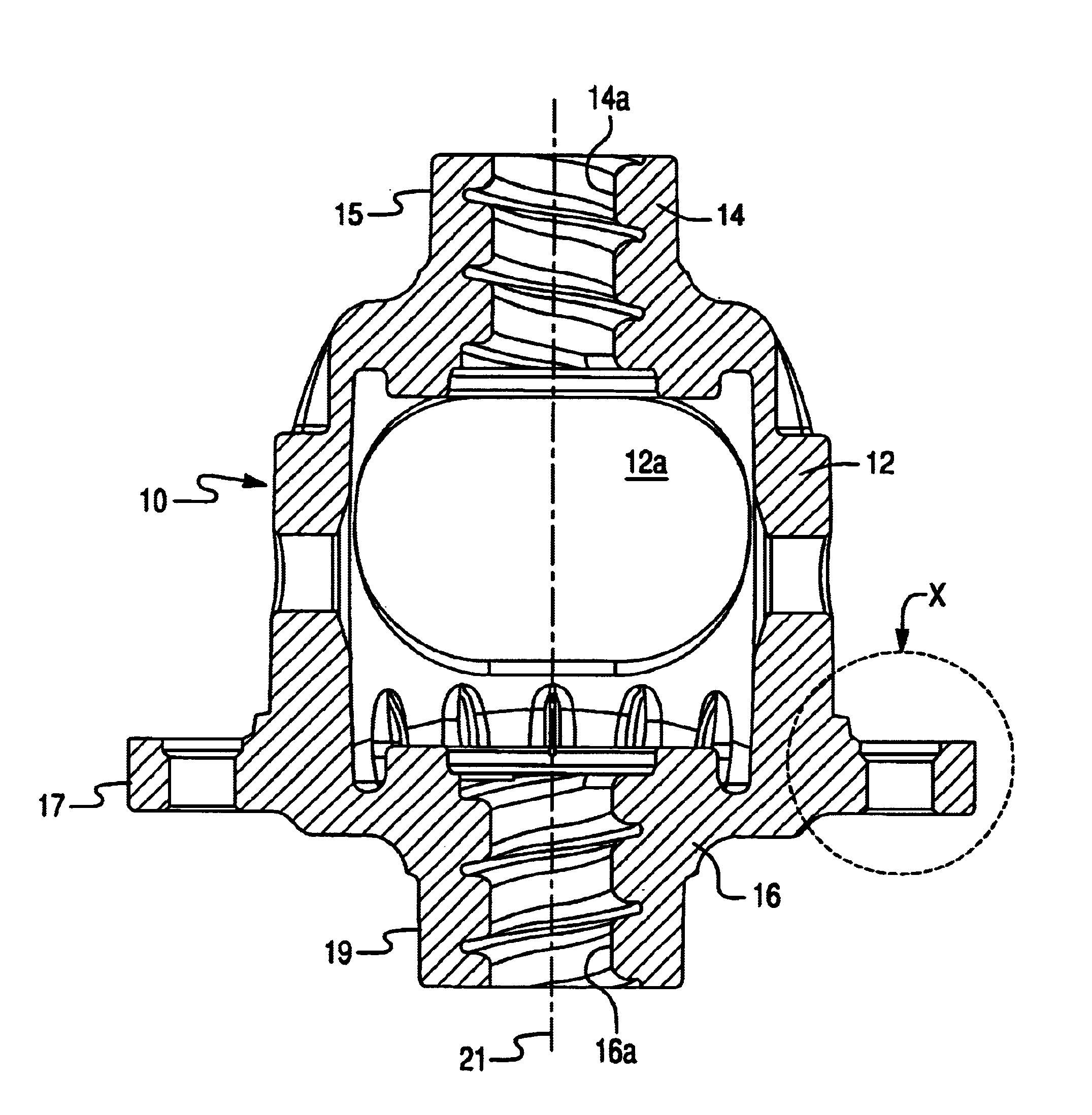

Full mold casting process and device for a differential case with cast-in bolt holes

InactiveUS6889742B1High densityReducing and eliminating damageFoundry mouldsFoundry coresMachining processControl theory

A peripheral flange formed on a differential case for mounting a ring gear and the peripheral flange is provided with a plurality of cast-in bolt holes for bolting up the ring gear to the differential case using the lost foam casting process for making the differential case. A method of making a gear case eliminates the process of machining of the bolt holes in the differential case casting, thus reducing cost of manufacturing the differential case.

Owner:DANA AUTOMOTIVE SYST GRP LLC

Full mold casting process

InactiveCN105964917AGood molding effectReduce manufacturing costFoundry mouldsFoundry coresSand blastingPolystyrene

The invention discloses a full-shape casting process, which uses the full-shape casting technology to process automobile cover molds, selects polystyrene foam to make a casting mold, and uses water glass sand to make a full-shape casting mold, which is poured, cooled, and punched. Box, cleaning, sandblasting, cutting off the riser, to obtain the formed casting. The solid mold casting process of the present invention has the characteristics of good formability, low production cost, short processing time, high wear resistance, fatigue resistance and strong crack growth resistance.

Owner:池州埃美柯水表铸造有限公司

Preparation method of high-strength full mold casting coating

ActiveCN103100654AImprove performanceHigh anti-sand sticking abilityFoundry mouldsFoundry coresCarboxymethyl cellulosePolyvinyl alcohol

The invention discloses a preparation method of a high-strength full mold casting coating. The high-strength full mold casting coating comprises the following components in parts by weight: 63-70 parts of high-alumina bauxite clinker, 5-7 parts of plant ash, 10-12 parts of water glass, 10-12 parts of sodium bentonite, 4-6 parts of nano-attapulgite, 1-2 parts of lignosulfonic acid, 2-3 parts of polyvinyl alcohol, 0.8-1.5 parts of sodium carboxymethyl cellulose, 0.4-0.6 part of sodium benzoate, 1-2 parts of nano-scale ceramic powder, 0.5-0.8 part of iron oxide red powder and 525-535 parts of water. The coating disclosed by the invention is of the full mold casting coating with strong corrosion resistance, high adhesiveness, excellent air permeability and quick-drying property under high-temperature and low-temperature environments, and can meet the production requirements of large-scale casts.

Owner:南京辉腾机械铸造有限公司

Cavity-pasting full-mold casting method

InactiveCN104028695ASolve the deformationSolve Exhaust ProblemsFoundry mouldsFoundry coresPre embeddingSodium silicate

A disclosed cavity-pasting full-mold casting method comprises: (1) preparing a frame mold and enabling the core-space contour structure of the frame mold to be corresponding to the exterior contour structure of a casting; (2) employing a ground pit for molding, firstly filling pit-bed sand on the bottom of the ground pit, then paving a layer of clay sodium silicate sand, leveling, and hardening with carbon dioxide, putting the frame mold, taking the inner-side edges of the frame mold as a basis, pre-embedding a pouring pipe, filling the outer periphery of the frame mold with sand and strickling the inner side at the same time; (3) employing carbon dioxide to harden the sand mold, and then taking out the frame mold; (4) preparing a foam mold plate according to the wall thickness of the casting, taking a mold hole as a basis, pasting the foam mold plate on the mold holes, and during molding of the foam mold plate, embedding a resistance wire into a segment, from an ingate to an open riser, in the foam mold plate; (5) putting the open riser, and filling the core space of the casting with sand; (6) employing carbon dioxide to blow and harden the core-space mold sand, then accessing the resistance wire with a power supply, and fusing the foam mold plate under electric heating; and (7) pouring, solidifying, cooling and cleaning.

Owner:GUANGZHOU RONGZE MOLD

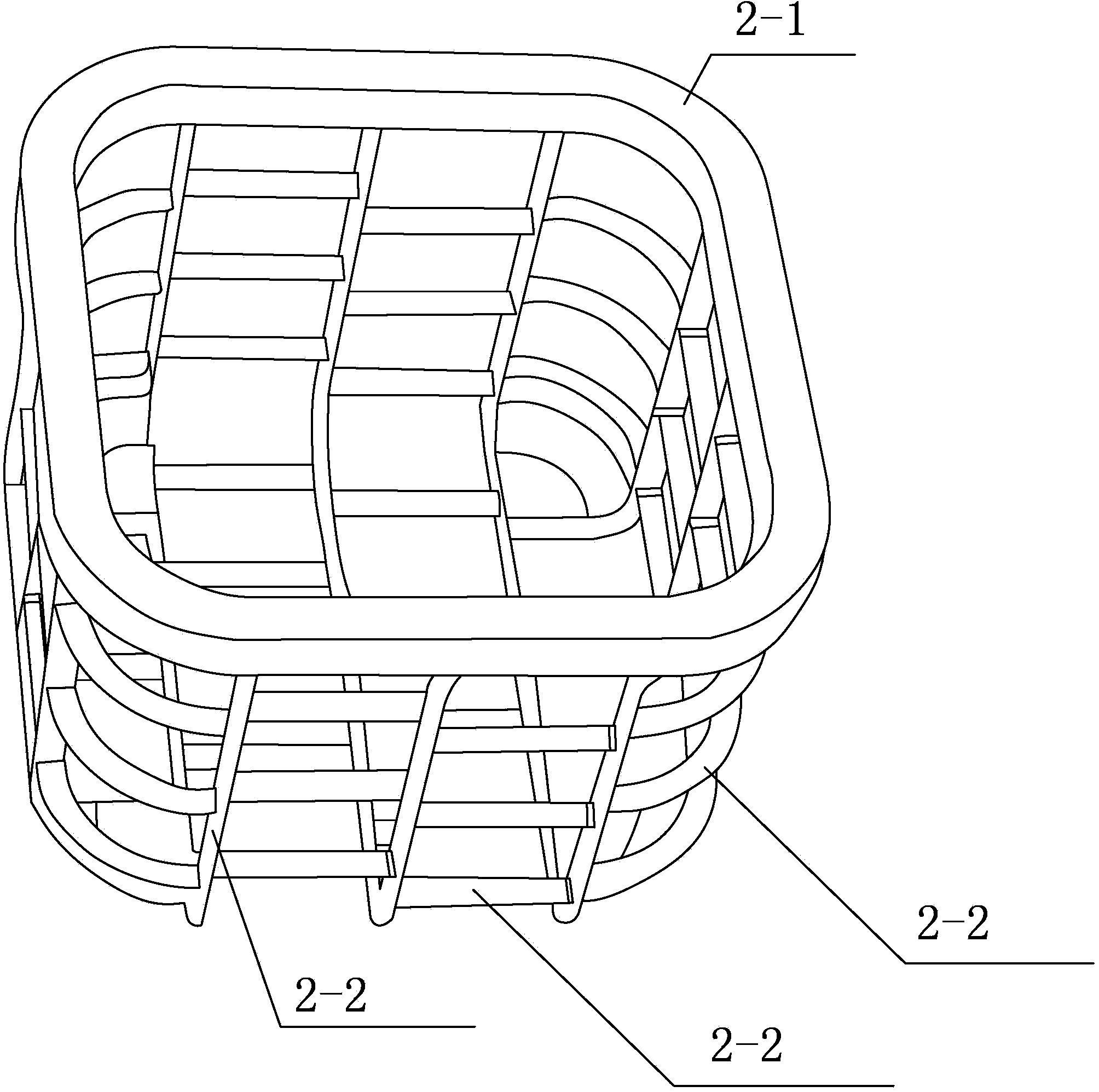

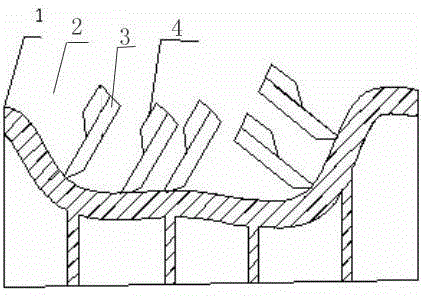

Full mold casting molten iron introducing type chill

InactiveCN104942225AReduce manufacturing costEliminate casting defectsFoundry mouldsFoundry coresPolystyreneCasting defect

The invention provides a full mold casting molten iron introducing type chill. The full mold casting molten iron introducing type chill comprises a casting full mold, wherein mold sand of an inner cambered surface of the casting full mold is provided with a plurality of polystyrene foam bars; pig iron is pressed on the middle upper parts of the polystyrene foam bars; the foam bars and a casting model body are in seamless connection, and the foam bars can form iron casting bars after pouring; the polystyrene foam bars have the length of 200-400mm, have the width of 30-100mm, have the thickness of 10-30mm, and are distributed in the mold sand with an oblique array interval of 30-150mm, and the installation oblique angle is 5-45 degrees; the included angle of the inner cambered surface of the casting full mold is 15-120 degrees. By utilizing the full mold casting molten iron introducing type chill, the manufacturing cost of the chill is reduced; the casting defect that a thermal joint of a casting is probably easy to shrink is eliminated; the quality of a casting is ensured. The full mold casting molten iron introducing type chill has the characteristics of low manufacturing cost, simple structure, convenience and reliability in clamping, and good effects.

Owner:SHIYAN LONGGANG CASTING

Special coating for full mold casting

InactiveCN101444826AImprove adhesionImprove breathabilityFoundry mouldsFoundry coresPorosityLiquid product

A special coating for full mold casting is characterized in that the coating is prepared by mixing and stirring components consisting of sodium borate, phosphoric acid, silica sol, ethyl acetate, polypropylene acyl carboxy, carboxymethyl cellulose sodium and absorbent according to the weight ratio of 10:2-3:6-9:8-10:8-10:2-6:5-8. The special coating for full mold casting has the advantages that the coating property and thixotropy are quite strong, and the casting can effectively absorb liquid products produced by foam plastic model pyrolysis during the using process, thus reducing the porosity of a casting part below 0.2 percent, greatly improving the precision of the size of the casting part, and reducing the finishing allowance of blanks of the casting part.

Owner:大连核心铸造技术工程研究所

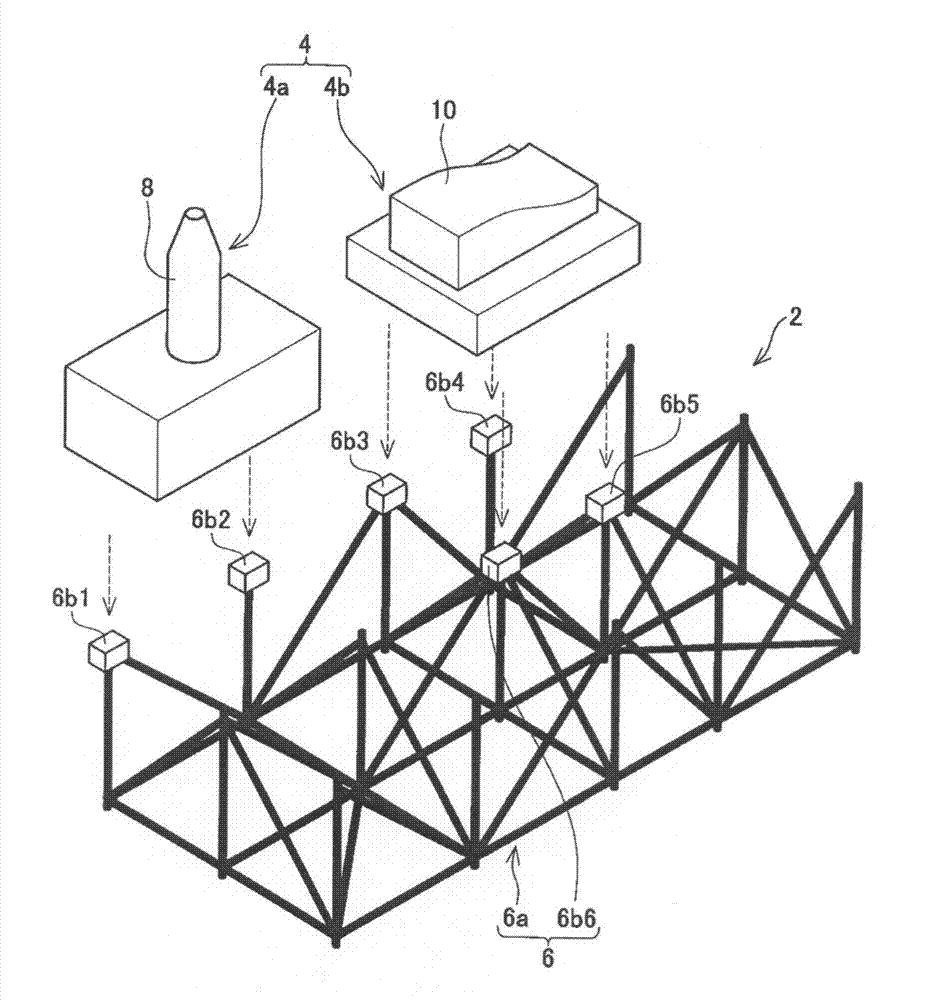

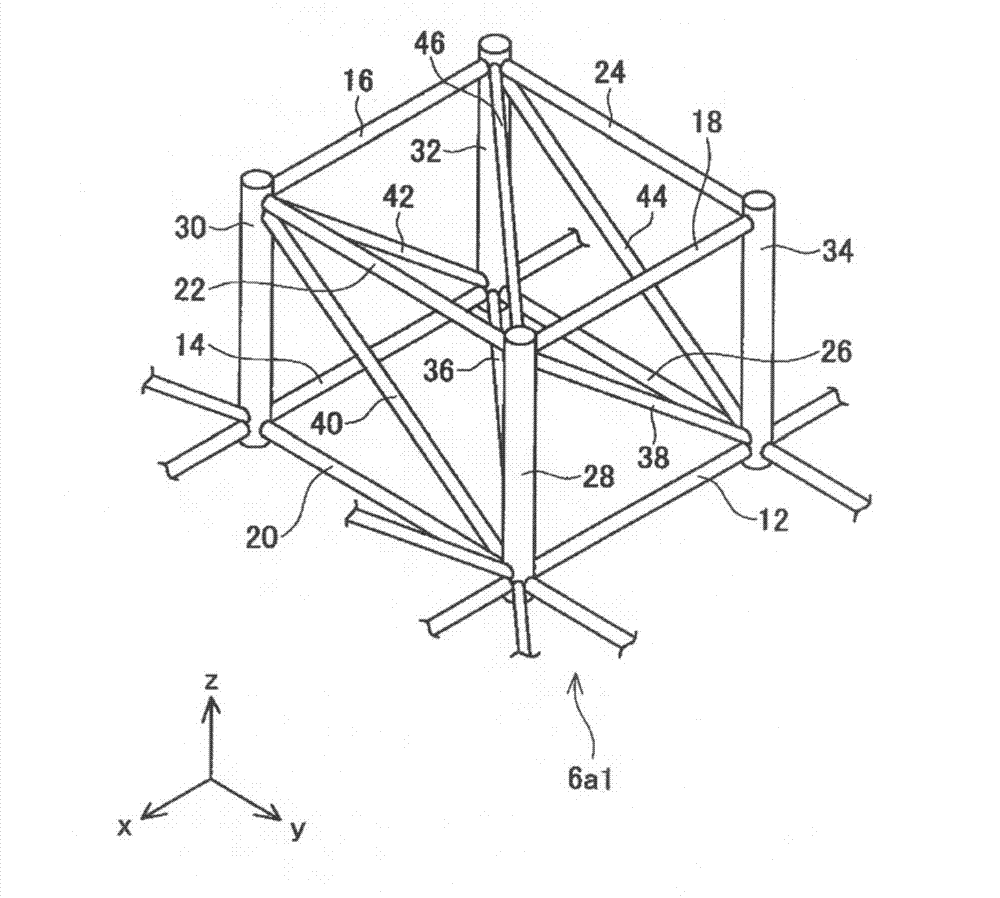

Lost pattern, method for producing lost pattern, and method for producing die using lost pattern

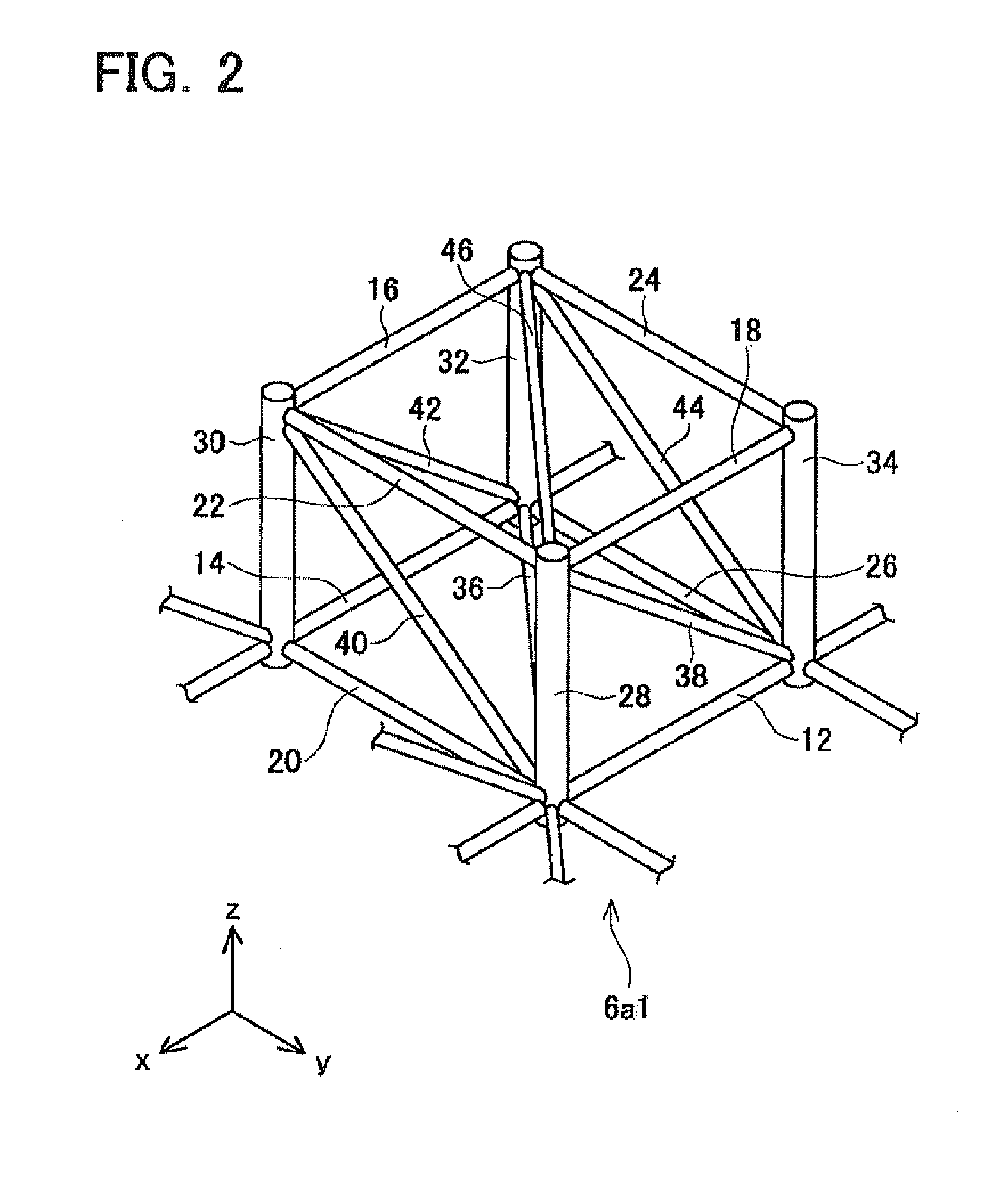

InactiveCN102958628AManufacturable light weightShaping toolsFoundry mouldsThree-dimensional spaceMechanical engineering

A light-weight die exhibiting necessary rigidity is obtained. First, an original pattern for a lost pattern is produced by cutting a lump of a quenchable material. The original pattern is provided with: a three-dimensional reticule structure which has a plurality of bar members, and in which the connecting points where the ends of the bar members are connected are dispersed within a three-dimensional space; and a plurality of block members, the relative positional relationship of which being secured by means of the reticule structure. Subsequently, at least a section of some of the bar members forming the original pattern is removed and is replaced with a tube member. Then, a full mold casting process is performed by using the lost pattern in which a section of some of the bar members are replaced with the tube members as mentioned above. The positional relationship between the block members on which the necessary molding surfaces of a die are formed is secured by means of the three-dimensional reticule structure, thereby ensuring necessary rigidity. The weight of the die is reduced because a three-dimensional reticule structure is used. Moreover, the amount of gas produced during the full mold casting process is reduced and the quality of the cast is not impaired because a section of some of the bar members are replaced with tube members.

Owner:TOYOTA JIDOSHA KK

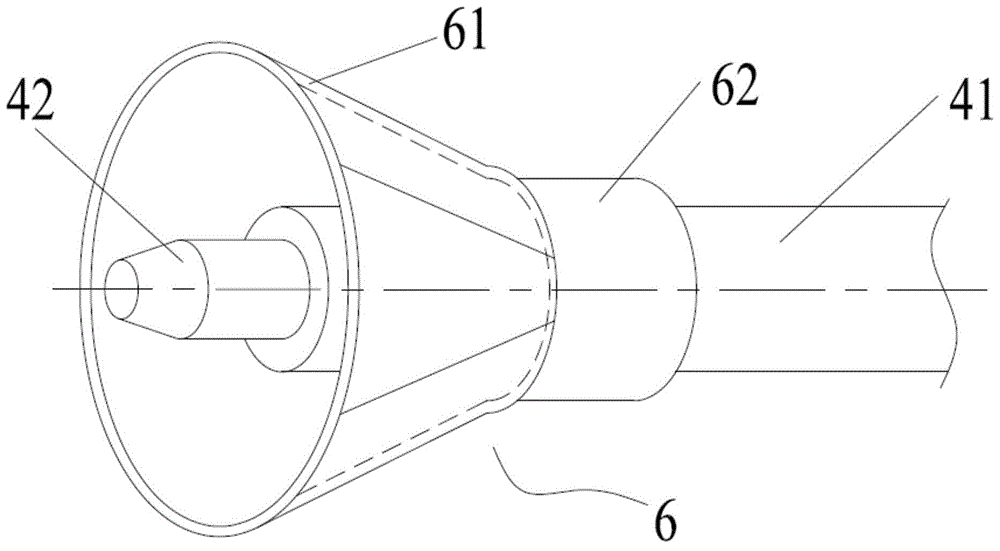

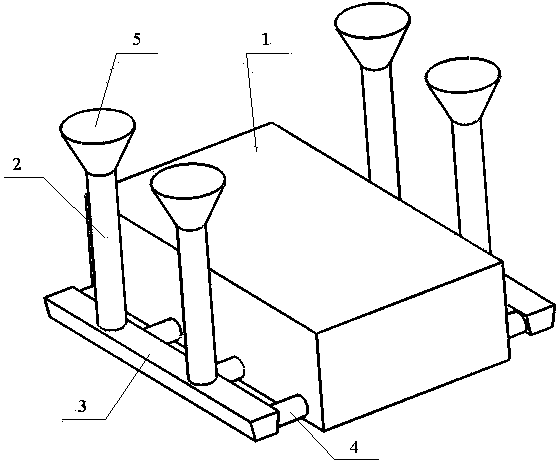

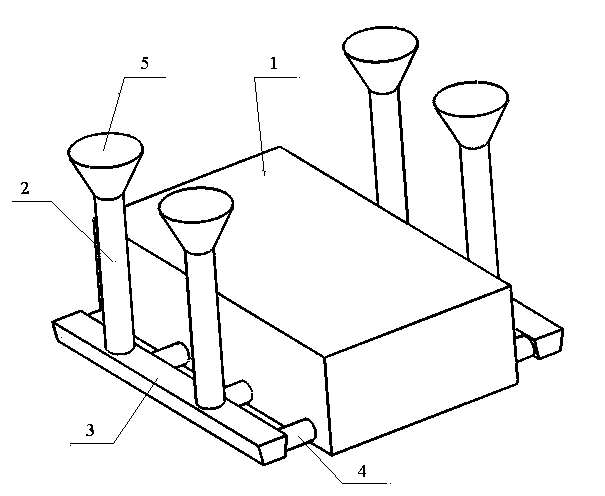

Full-mold casting method of resin sand without dead head

InactiveCN103639361AReduce injection volumeDid not enterFoundry mouldsFoundry coresFlue gasPollution

The invention discloses a full-mold casting method of resin sand without a dead head. The full-mold casting method comprises the steps of manufacturing a pattern and a casting system, molding, smelting casting, forming and cleaning, wherein working allowance is preset on the upper surface of the manufactured pattern, and no dead head is arranged in the molding step; the casting system comprises a plurality of sprues with funnel-shaped pouring cups at the top ends, the volume of the pouring cup is more than that of the sprue, the bottom of the sprue is communicated with a cross gate, the lower end surface of the cross gate is leveled with the bottom surface of the pattern or is slightly higher than the bottom surface of the pattern, the length of the cross gate is 95% of the length of the pattern, and a plurality of ingates communicated with the pattern are arranged on the cross gate at intervals; and molten metal is poured by the plurality of pouring cups simultaneously during casting, and the speed of filling the molten liquid into each pouring cup can ensure the molten liquid in the pouring cup to close the sprues. According to the full-mold casting method, no dead head is arranged, no flue gas and no pollution are caused during production, the production steps are simplified and the cost is reduced.

Owner:BOTOU DONGJIAN CASTING

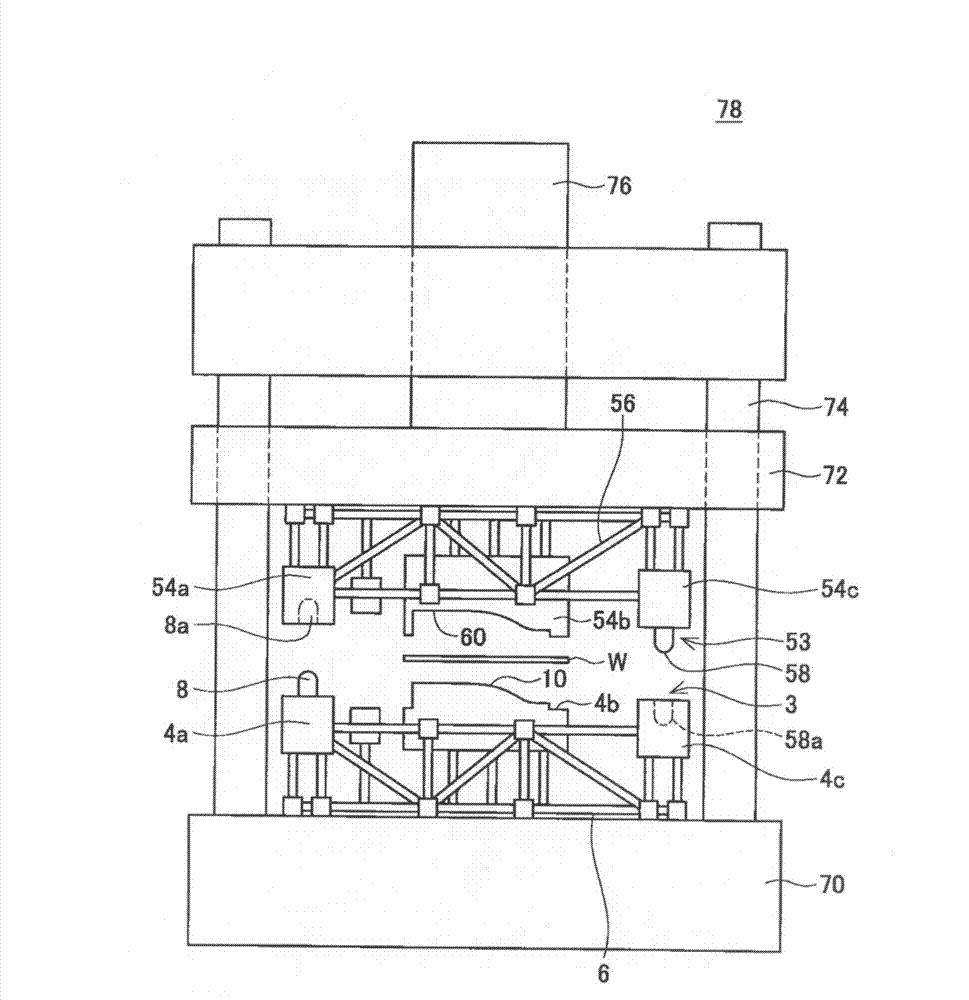

Method of manufacturing cast metal products, and manufacturing plant

Provided are a method of manufacturing cast metal products and a manufacturing plant that use self-hardening molds and allow, using a shared production line in a single factory, either full-mold casting or wooden-mold casting to be selected and performed depending on factors such as the type of product. This allows more efficient production of cast metal products. A combined multipurpose mold manufacturing line (1) is set up in a central area of the factory, said line being shared between full-mold casting and wooden-mold casting. A full-mold casting line and a wooden-mold casting line that include the mold manufacturing line (1) are set up in parallel, making it possible to switch between the full-mold casting line and the wooden-mold casting line on the basis of decision factors such as the shape, material, and production lots of the cast metal product to be manufactured.

Owner:ITEC FM

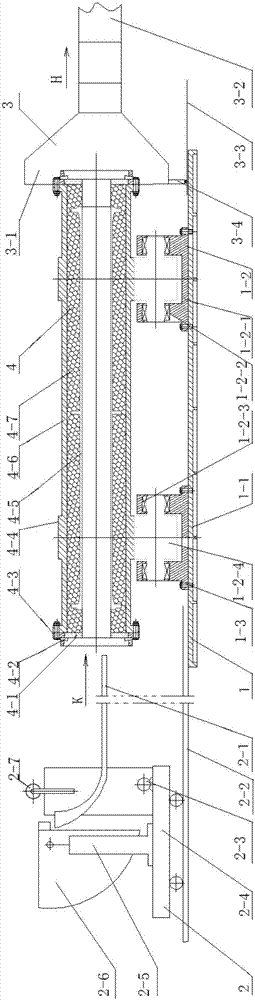

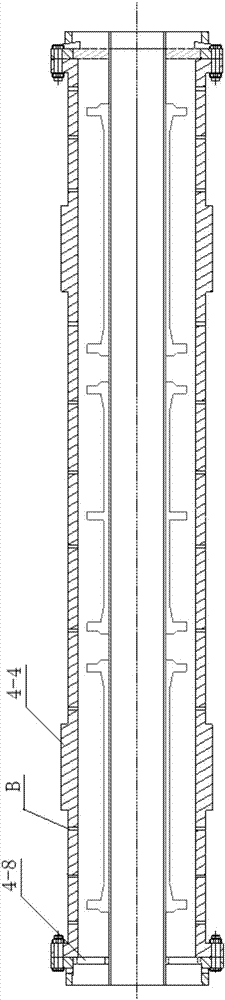

Device and method for full mold centrifugal casting of double-plate flange straight tube and wall flange straight tube

The invention relates to a device and method for full mold centrifugal casting of a double-plate flange straight tube and a wall flange straight tube. The device comprises a centrifugal machine system, a quantitative pouring system, a dust removal system and a full mold centrifugal casting die, wherein a base is a steel plate formed by casting; a centrifugal machine supporting wheel assembly, a catch wheel assembly and a direct-current speed regulation motor assembly are respectively mounted on the base; the centrifugal machine supporting wheel assembly is fastened on the base through bolts and is connected with the direct-current speed regulation motor assembly through a transmission triangular belt; the catch wheel assembly is arranged below the center of a pipe die and is fastened on the base; a catch wheel rotating plate is arranged on the catch wheel assembly; bearings are mounted at two ends of a supporting wheel, and the supporting wheel and the bearings are mounted on a supporting wheel bearing block together; and bearing caps are mounted on the supporting wheel bearing block. Flexibility of the full mold casting is high, various workpieces can be casted by a die, the full mold casting meets requirements of different length specifications, different flange pressure grades and different wall flange positions, the molding yield is increased, the production efficiency is high, and batch production is realized. The device is applied to the technical field of centrifugal casting.

Owner:营口经济技术开发区爱维尔铸业有限公司

High-manganese medium carbon steel wear-resisting chute lining plate

The invention relates to smelting of metal components on a chute, and provides a high-manganese medium carbon steel wear-resisting chute lining plate. Steel materials are smelted through an electric-arc furnace and then transferred into a finery, the component proportion of the molten steel is adjusted, and then the steel is discharged. The molten steel is subjected to vacuum degassing and then full mold casting, and an obtained casting is subjected to heat treatment including water quenching and oil quenching to obtain a finished part. The components of the molten steel include, by weight, 0.54-0.58% of C, 12-16% of Mn, 1.5-3.5% of Cr, 2.5-3.5% of Al, 0.15-0.25% of Nb, 0.60-0.80% of Ti, 0.5-2.5% of B, 0.05-0.07% of Zr, less than 0.04% of P, less than 0.5% of Si and the balance Fe.

Owner:ANHUI SANFANG NEW MATERIAL TECH CO LTD

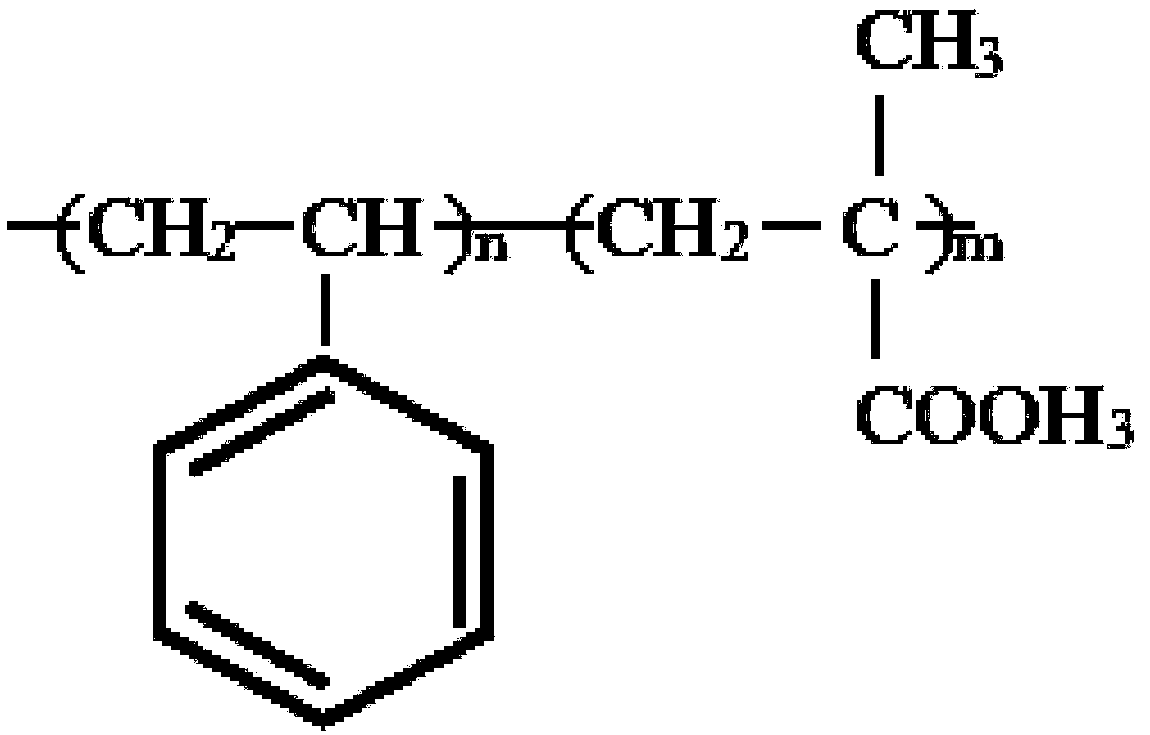

Process for improving full mold casting engine cylinder yield

The invention discloses a process for improving a full mold casting engine cylinder yield. The process comprises such steps as mode production, combination, coating, molding, shaping, casting, taking and detection. The process for improving the full mold casting engine cylinder yield adopts a foam model produced by expandable methyl methacrylate and styrene copolymerized resin beads to improve the casting yield, uses a sealing film and a vacuum pump for vacuum air extraction of a sand box to form negative pressure, increases viscosity between dry sand, guarantees uniform feeding of casting liquid, facilitates gas elimination, and improves the casting integrity; after the mold casting is finished, a vacuum air extraction device continuously extracts air to maintain 200-300 s vacuum, so that the casting stability and the casting molding yield are guaranteed to realize the advantages of reasonable matching, simple operation process and high reliability; and the process is higher in innovativeness, practicability and utilization value.

Owner:ANHUI QUANCHAI TIANHE MACHINERY

High adhesiveness full mold casting coating and preparation method thereof

InactiveCN108705028AStable in natureImprove wear resistanceFoundry mouldsFoundry coresMulliteSurface-active agents

The invention discloses a high adhesiveness full mold casting coating and a preparation method thereof, and relates to a full mold casting coating. The high adhesiveness full mold casting coating comprises the following raw materials according to parts by weight: 40-50 parts of mullite, 5-10 parts of cyanite, 4-9 parts of flake graphite, 5-10 parts of mica, 8-15 parts of modified bentonite, 3-6 parts of electric melting magnesium powder, 1-3 parts of hydroxymethyl cellulose, 2-5 parts of nanometer iron oxide, 1-3 parts of cryolite, 4-7 parts of binder, 0.6-1.2 parts of surface active agent, 0.4-0.8 part of deforming agent and 0.6-1.2 parts of preservative. The casting coating has a stable property under high temperature environments, good wearing resistance and high adhesion through the mutual coordination of the raw materials, and has an excellent protective effect on castings. The preparation method is simple and easy to operate.

Owner:ANHUI TONGSHENG RING

Evaporative pattern, method of forming an evaporative pattern, and method of forming a metal mold by using an evaporative pattern

InactiveUS20130295316A1Quality improvementHighly accurate shapeLayered productsFoundry mouldsThree-dimensional spaceMetal mold

A lightweight metal mold having a necessary rigidity is realized. Firstly, an original pattern of an evaporative pattern is formed by machining an evaporative material block. The original pattern includes a three-dimensional mesh structure including a plurality of bar-shaped parts and connecting points that connect ends of the bar-shaped parts and are distributed in a three-dimensional space, and a plurality of block parts having fixed relative positional relationship by being fixed to the three-dimensional mesh structure. Then, at least a portion of at least one or more of the bar-shaped parts composing the original pattern is removed, and replaced with a tube member. Then, a full-mold casting is performed by using the evaporative pattern having the replaced tube member. Positional relationship of the block parts in which surfaces, etc. necessary for the metal mold are formed is fixed by the three-dimensional mesh structure, and the necessary rigidity is secured. The metal mold is made lighter by using the three-dimensional mesh structure. Due to the replacement with the tube member, an amount of gas generated upon the full-mold casting is suppressed, and a decrease in casting quality is prevented.

Owner:TOYOTA JIDOSHA KK

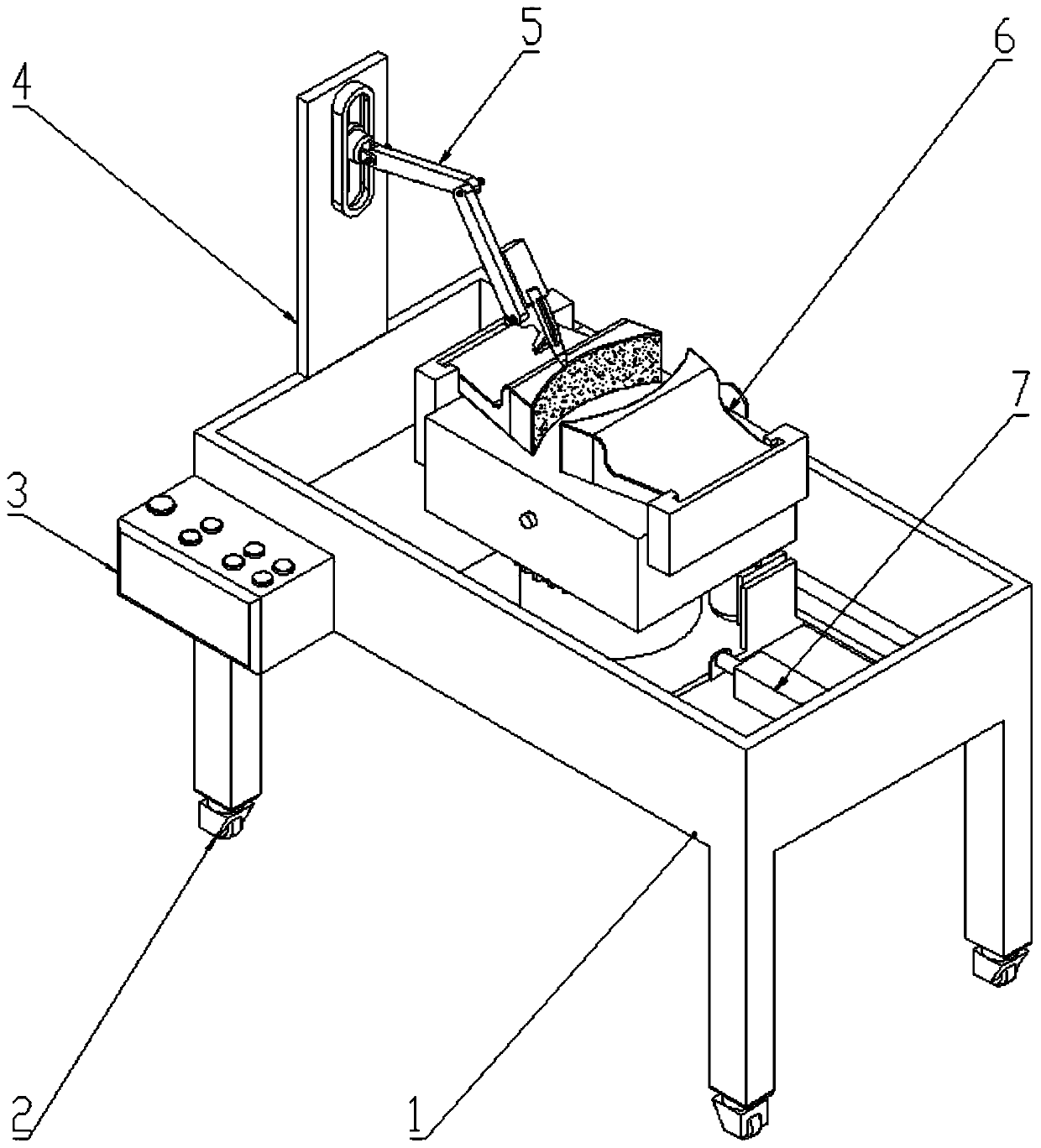

Automatic bonding device for full mold casting

The invention provides an automatic bonding device for a full mold casting, and belongs to the technical field of full mold casting bonding. The problem that irregular full mold casting bonding facesare difficult to be rapidly coated with hot glue for bonding is solved. The device comprises a base, universal brake trundles are fixed to the lower ends of four supporting legs of the base, a controlbox is fixed to the front end of the base, the side end of the base is fixedly provided with a glue injection mounting plate, a second adjusting sliding rail is fixed to the glue injection mounting plate, a glue injection mechanism is arranged on the second adjusting sliding rail, two first adjusting sliding rails are fixed to a bottom plate in the base, and are symmetrically distributed, rotating clamping mechanisms are arranged in the first adjusting sliding rails in a sliding manner, and adjusting push rods are arranged between the rotating clamping mechanisms and the base. Through cooperation of the rotating clamping mechanisms and the adjusting push rods, the full mold casting is clamped and driven to move, the irregular bonding face moves at the lower end of a glue outlet of a hot melt adhesive gun, the bonding face can be rapidly coated with the hot glue fully, and the application range is wide.

Owner:安徽兰翔纺机科技有限公司

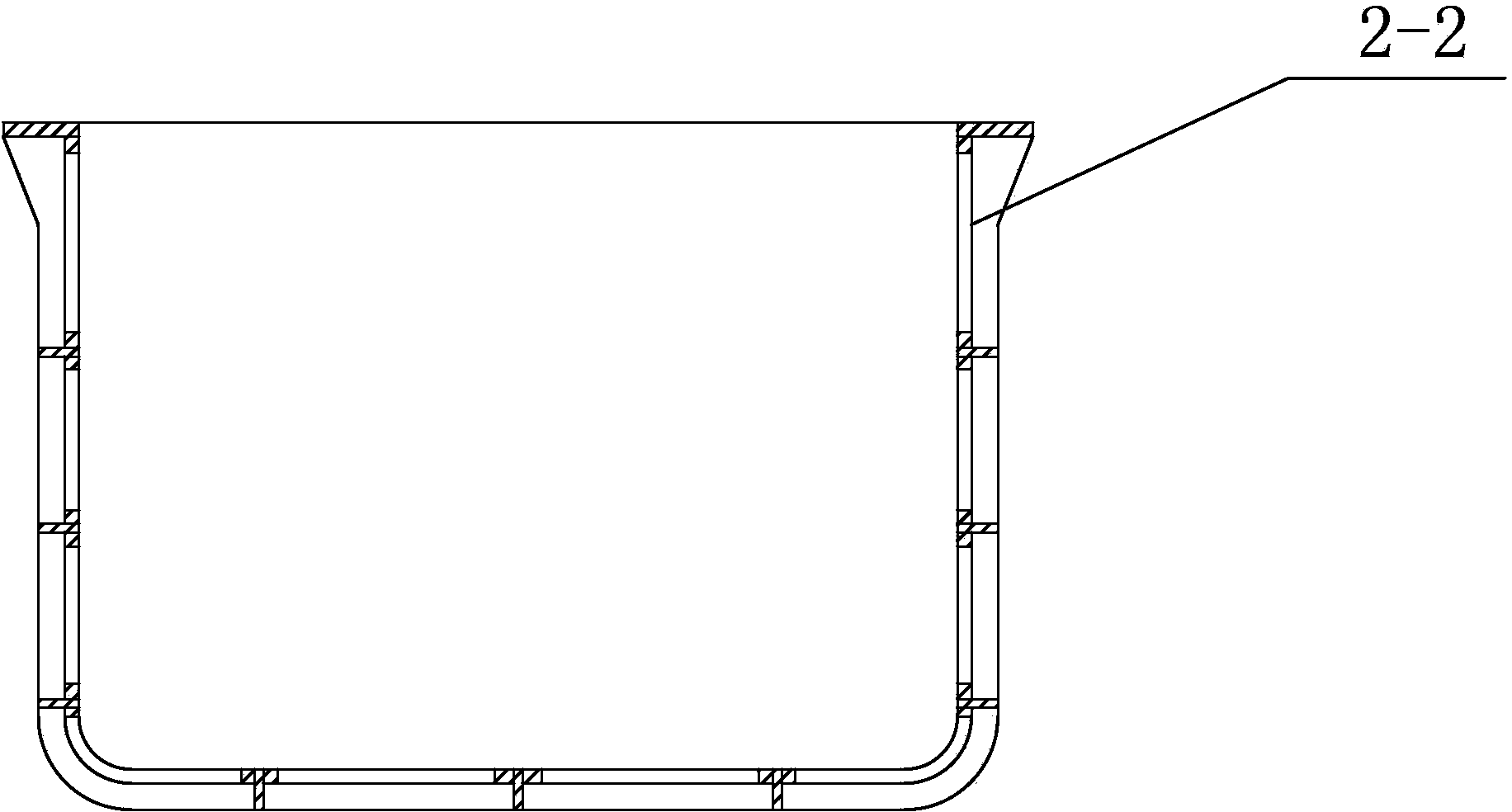

Full-mold casting method of resin sand without vent hole

InactiveCN103639362AImprove protectionImprove aestheticsFoundry mouldsFoundry coresMolten metalFull-mold casting

The invention discloses a full-mold casting method of resin sand without a vent hole. The full-mold casting method comprises the steps of manufacturing a pattern and a casting system, molding, smelting casting, forming and cleaning, wherein working allowance is preset on the upper surface of the manufactured pattern in the steps of manufacturing the pattern and the casting system, and no vent hole is formed in the molding step; the casting system comprises a plurality of sprues provided with pouring cups at the top ends and arranged vertically, the volume of the pouring cup is more than that of the sprue, the bottom of the sprue is communicated with a cross gate parallel to the length direction of the pattern, the lower end surface of the cross gate is leveled with the bottom surface of the pattern or is slightly higher than the bottom surface of the pattern, the length of the cross gate is 95% of the length of the pattern, and a plurality of ingates communicated with the pattern are arranged on the cross gate at intervals; and molten metal is poured by the plurality of pouring cups simultaneously during casting. According to the full-mold casting method, no vent hole is formed, pattern burning cannot happen during casting, no harmful gas is generated and the environment protection effect is achieved.

Owner:BOTOU DONGJIAN CASTING

Lost foam full mold casting process

ActiveCN110976758AImprove working environment conditionsImprove production conditionsFoundry mouldsFoundry coresWorking environmentProcess engineering

The invention discloses a lost foam full mold casting process, and the process is characterized by comprising the following steps: S1, selecting foam plastic beads; S2, manufacturing a lost foam; S3,coating a model; S4, preparing a casting rough blank; S5, performing post-processing. The invention further discloses a casting manufactured according to the lost foam full mold casting process. The process is simple and easy to implement, small in dependence on equipment, low in casting cost, high in casting efficiency and finished product percent of pass and suitable for continuous large-scale production, the working environment and production conditions of a casting production line can be greatly improved, the labor intensity is reduced, and energy consumption is reduced; a product obtainedthrough casting is higher in size precision and better in inner and outer surface quality, and has higher economic value, social value and ecological value.

Owner:ANHUI SOLID FOUNDRY CO LTD

STMMA large-size full mold casting plate evanescent mode and preparation method thereof

ActiveCN107552725AHigh bonding strengthFully integratedFoundry moulding apparatusCompression moldingEnvironmental resistance

The invention discloses an STMMA large-size full mold casting plate evanescent mode and a preparation method thereof. The method comprises the technique steps of bead selection, pre-foaming, drying curing, compression molding, cooling, demolding, plate drying and the like. The defects such as carbon black of the surfaces of nodular iron castings after casting can be overcome, gas evolution can beeffectively reduced, reverse ejection during casting is avoided, the shape of a manufactured and produced STMMA evanescent mode is prevented from being distorted, the bonding strength between beads isimproved, full combination of the beads is ensured, the structure strength of castings is improved, and the effects of saving raw materials, reducing cost and protecting environment are achieved, andthe yield of the castings is greatly increased; and the comprehensive production cost of the castings is further reduced.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE +2

Full mold casting method

InactiveCN104874734AReasonable designImprove the finishFoundry mouldsFoundry coresSurface finishDry sand

The invention relates to the field of the casting technology and in particular relates to a full mold casting method. The full mold casting method comprises the following steps: I. manufacturing a foam plastic pattern, combining a casting system, brushing and spraying special high-temperature paint on the surface of a gasified pattern and drying; II. arranging an interlayered sand box on a worktable, filling with dry sands, compacting, striking off, arranging the dried gasified pattern on base sand, fully filling with dry sands, slightly compacting for an appropriate time period, and striking off the opening of the sand box; III. covering a plastic film, placing a pouring cup, connecting a vacuum system for vacuumizing, securing the dry sand, forming, casting, gasifying the foam plastic pattern, and filling the position by molten metal; and IIIV. releasing vacuum, condensing a casting, overturning the box, and taking out the casting from loose dry sands. According to the full mold casting method, the process route design is reasonable, the surface finish of the produced casting is high, the size precision is high, the production procedure is simple, the metal utilization rate is high, used sand is completely recycled, and the molding cost is reduced.

Owner:LIUZHOU KEERTE FORGING MACHINERY

Full mold casing coating

ActiveCN102397983BImprove performanceIncrease stiffnessFoundry mouldsFoundry coresPolyvinyl alcoholOlivine

The invention discloses a full mold casting coating, which consists of the lower components in part by weight: 70-80 parts of quartz powder, 10-15 parts of olivine powder, 10-15 parts of alundum powder, 4-6 parts of sodium bentonite, 1-2 parts of lignosulfonic acid, 2-3 parts of dextrin powder, 0.8-1.5 parts of sodium carboxymethylcellulose, 0.4-0.6 part of sodium benzoate, 1-2 parts of hollow glass microsphere, 7-9 parts of aluminum sulfate, 4-6 parts of polyvinyl alcohol, 5-6 parts of silica sol, 0.5-0.8 part of brown iron oxide, 0.04-0.06 part of n-octyl alcohol and 15-25 parts of water.

Owner:南通市通州区俊朗建筑工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com