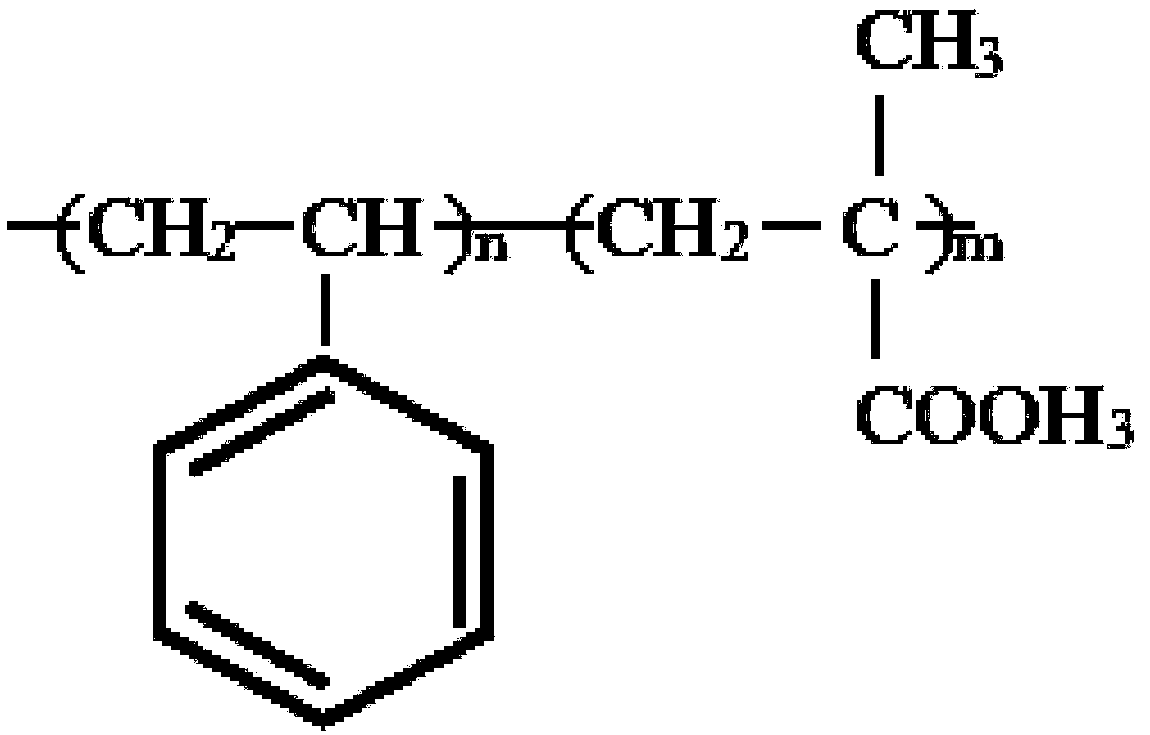

STMMA large-size full mold casting plate evanescent mode and preparation method thereof

A technology of solid mold casting and lost foam, applied in casting and molding equipment and other directions, can solve the problems of casting quality decline, pouring back spray, not easy thermal decomposition, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] A method for preparing the lost foam of STMMA large-size solid casting plate, comprising the following steps:

[0064] (1) Selection of beads: select STMMA with a larger size between 0.7mm and 0.90mm as the original beads;

[0065] (2) Pre-foaming: add the above-mentioned STMMA beads to the SPJ1500 automatic intermittent pressurized quantitative pre-foaming machine for pre-foaming, the pressure of the feeding furnace is 0.013-0.018Mpa; the main steam pressure is 0.66-0.72Mpa, The steam adjustment pressure is 0.030-0.040Mpa, the temperature of the steam introduced is between 105-110°C, the pre-foaming temperature of STMMA is 105°C, because the glass transition temperature of STMMA is 100-105°C, the pre-foaming temperature Only when it reaches 105°C and above can STMMA complete pre-foaming. The steam enters the pre-foaming machine through the gas storage tank to accelerate the pre-foaming time of the steam, and is continuously stirred by the agitator in the pre-foaming r...

Embodiment 2

[0072] A method for preparing the lost foam of STMMA large-size solid casting plate, comprising the following steps:

[0073] (1) Selection of beads: select STMMA with a larger size between 0.7mm and 0.90mm as the original beads;

[0074] (2) Pre-foaming: add the above-mentioned STMMA beads to the SPJ1500 automatic intermittent pressurized quantitative pre-foaming machine for pre-foaming, the pressure of the firing furnace is 0.013-0.018Mpa; the main steam pressure is 0.66-0.72Mpa, The steam regulating pressure is 0.030-0.040Mpa, and the temperature of the water steam is between 105-110°C. The steam enters the pre-foaming machine through the gas storage tank to accelerate the pre-foaming time of the steam, and is continuously stirred by the agitator in the pre-foaming room, so that the original STMMA beads to be foamed are in a liquid state or the viscosity reaches a plastic state before foaming , the pre-foaming time is 150-165s per 28kg of STMMA beads;

[0075] (3) Drying ...

Embodiment 3

[0081] A method for preparing the lost foam of STMMA large-size solid casting plate, comprising the following steps:

[0082] (1) Selection of beads: select STMMA with a larger size between 0.7mm and 0.90mm as the original beads;

[0083] (2) Pre-foaming: add the above-mentioned STMMA beads to the SPJ1500 automatic intermittent pressurized quantitative pre-foaming machine for pre-foaming, the pressure of the feeding furnace is 0.013-0.018Mpa; the main steam pressure is 0.66-0.72Mpa, The steam regulating pressure is 0.030-0.040Mpa, and the temperature of the water steam is between 105-110°C. The steam enters the pre-foaming machine through the gas storage tank to accelerate the pre-foaming time of the steam, and is continuously stirred by the agitator in the pre-foaming room, so that the original STMMA beads to be foamed are in a liquid state or the viscosity reaches a plastic state before foaming , the pre-expansion time is 150-165s per 28kg of STMMA beads; from the cross-sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com