Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

173 results about "Evanescent mode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Evanescent mode (cutoff mode) (1) (wave-guides) A field configuration in a wave-guide such that the amplitude of the field diminishes along the waveguide, but the phase is unchanged. The frequency of this mode is less than the critical frequency. See wave-guide.

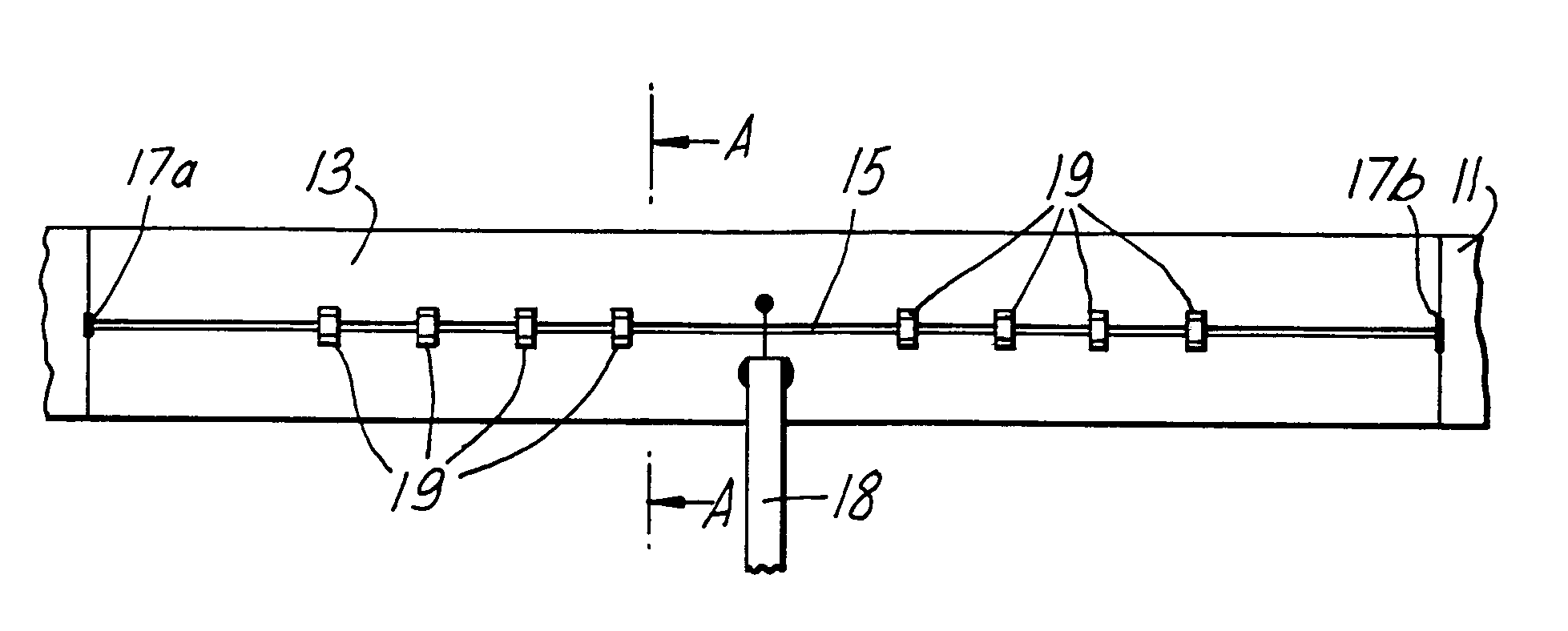

Sea surface antenna

InactiveUS7123200B1Antenna adaptation in movable bodiesSubaqueous/subterranean adaptionCapacitanceMetallic materials

A sea surface antenna comprises a cylindrical tube of metallic material 13 on a dielectric former. The tube has a longitudinal slot shorted at each end and coupled at its midpoint to a coaxial feed. The slot is bridged by two groups of capacitances each group being distributed along a respective half of the slot. The length of the antenna is less than 0.25 λ and the diameter of the antenna is less than 0.02 λ, where λ is the free space wavelength at the operating frequency. The antenna is dimensioned so as to operate in an evanescent mode at a resonant frequency less than the cut-off frequency.

Owner:NORTEL NETWORKS LTD

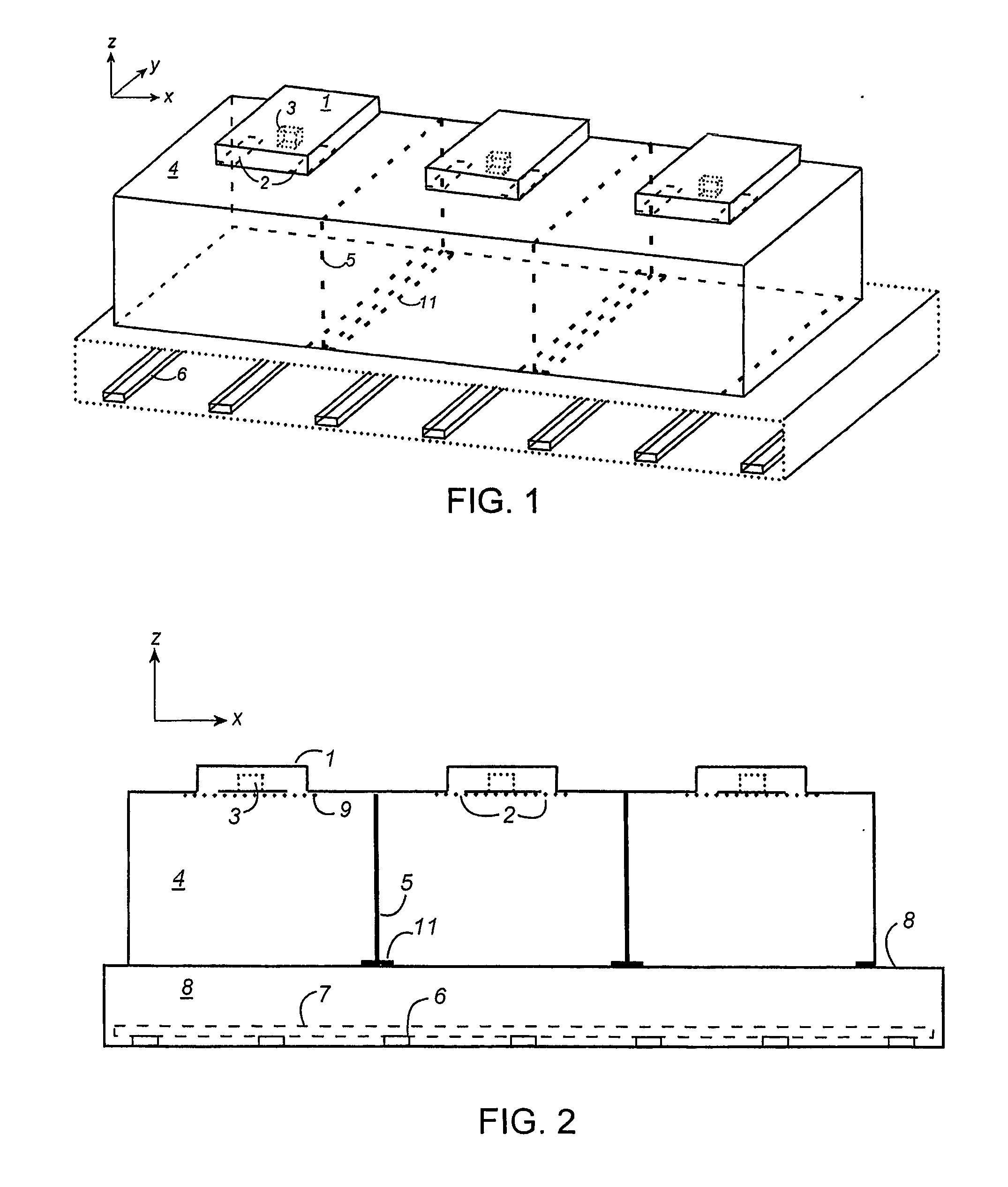

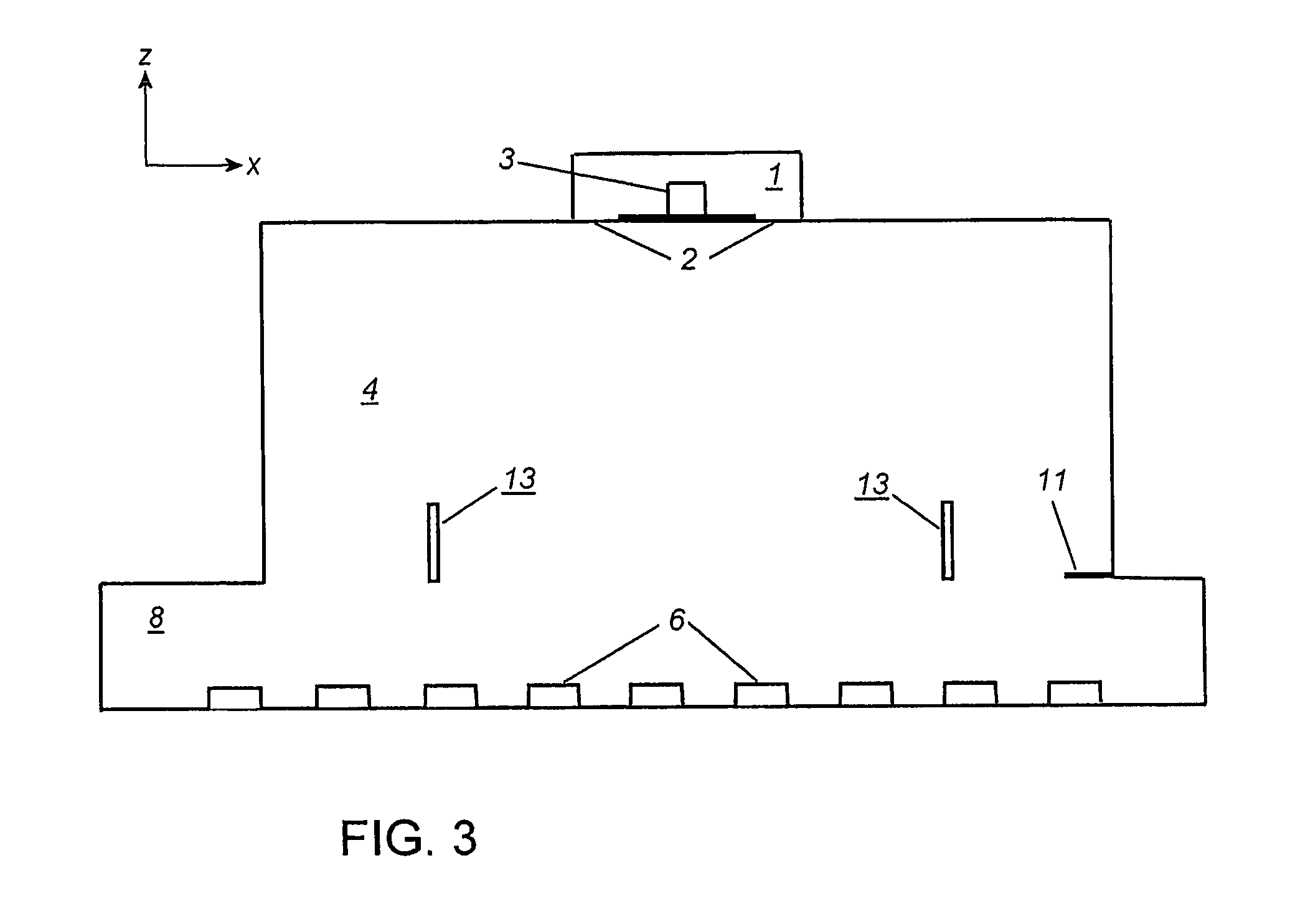

Evanescent Mode Resonator Including Tunable Capacitive Post

An evanescent mode resonator including a cavity formed in a substrate of semiconductor material. The resonator includes a capacitive post positioned within the cavity, and a tuning element positioned within the wall of the cavity proximate to the capacitive post, where a gap between the flexible element and the post sets the tuning of the resonator.

Owner:PACIFIC COAST FEATHER COMPANY +1

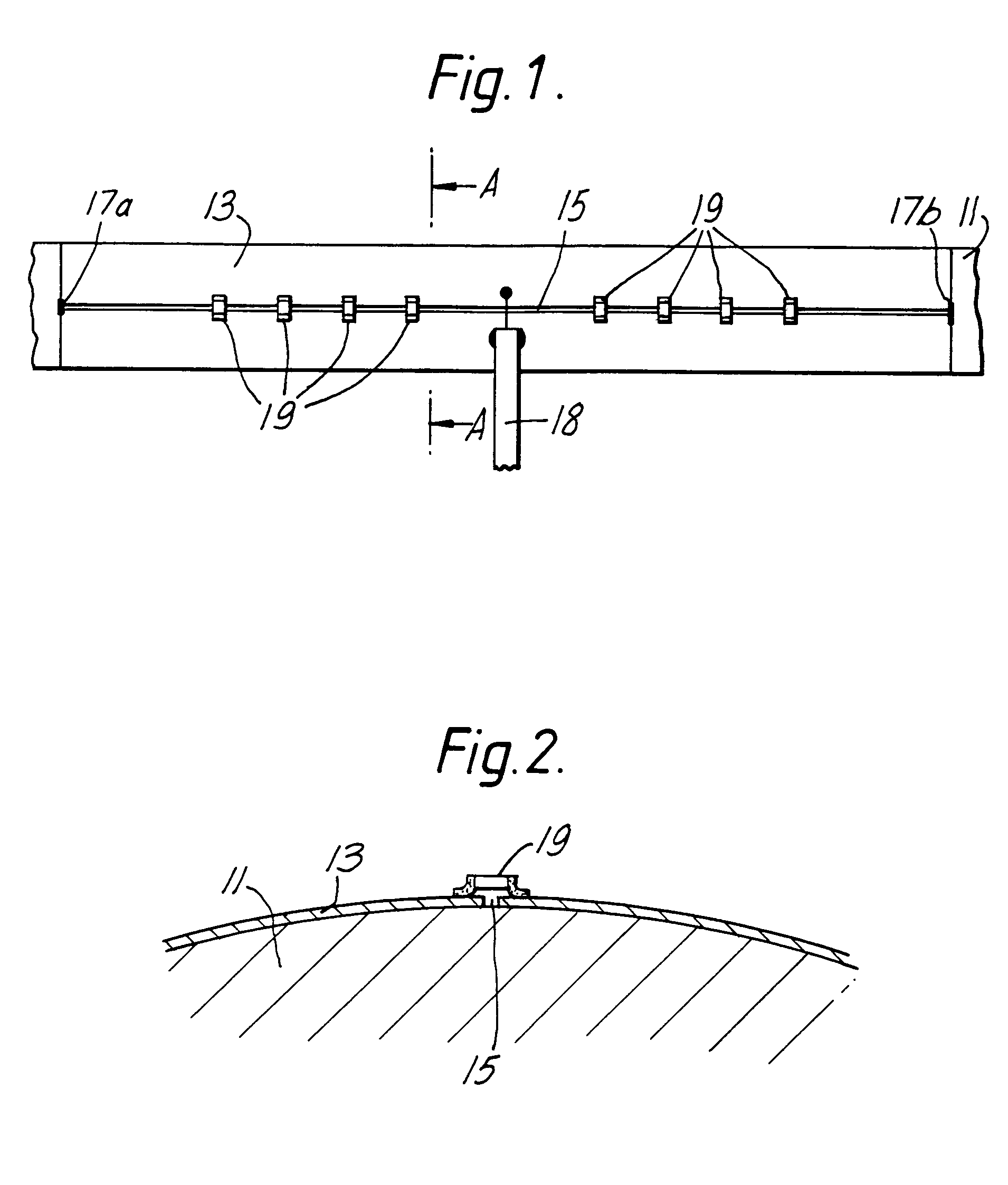

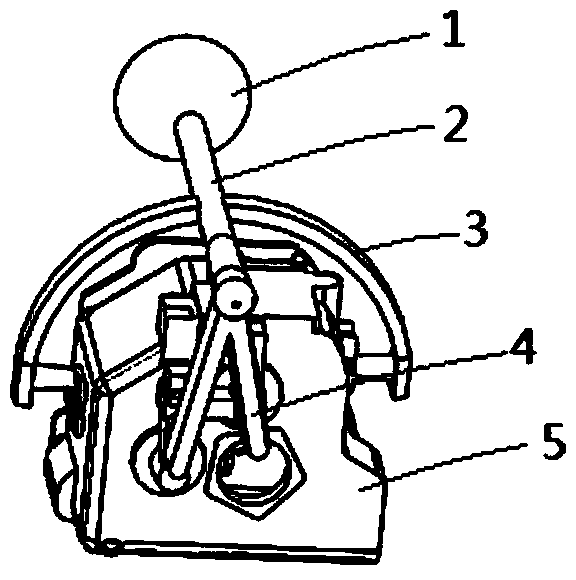

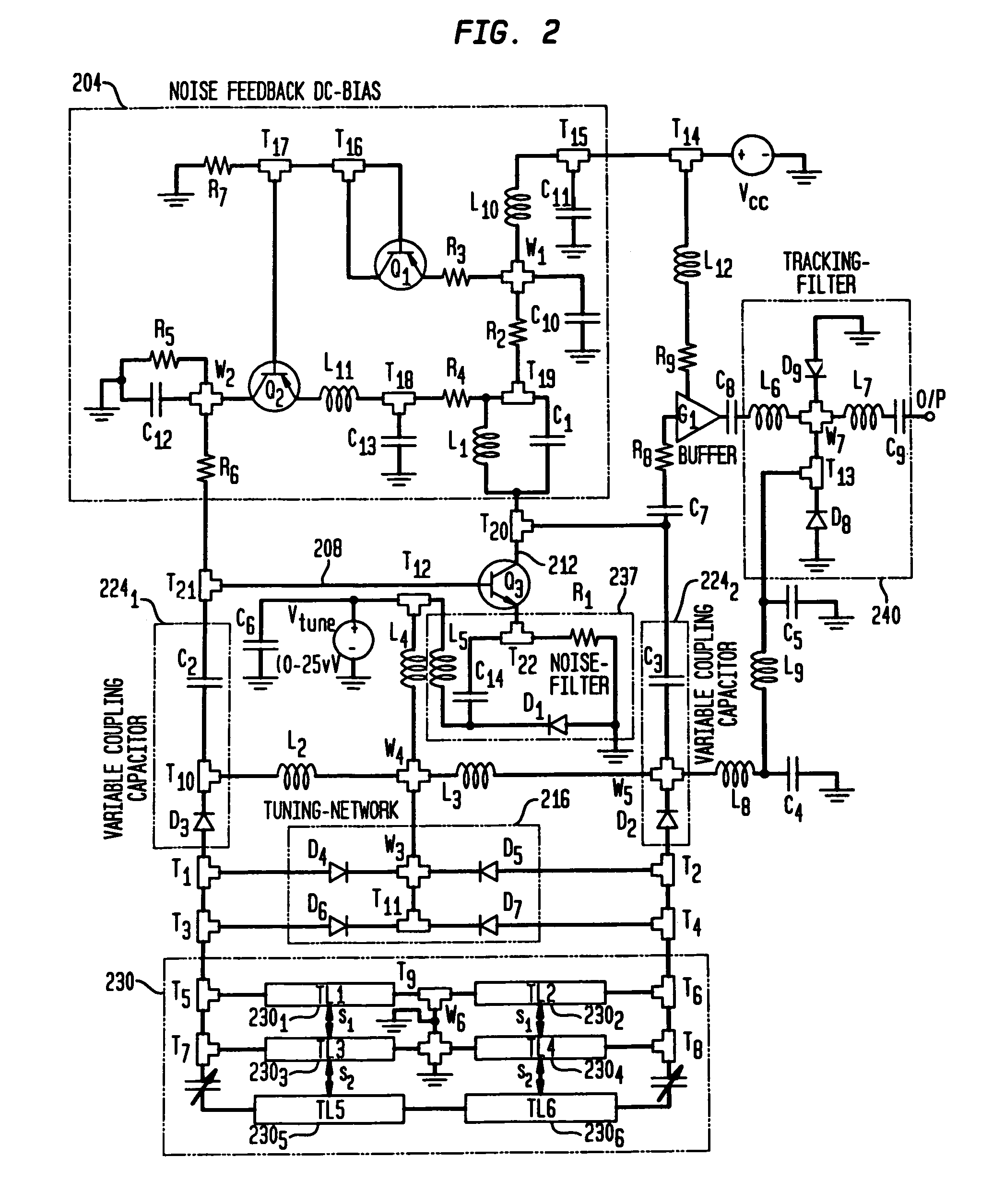

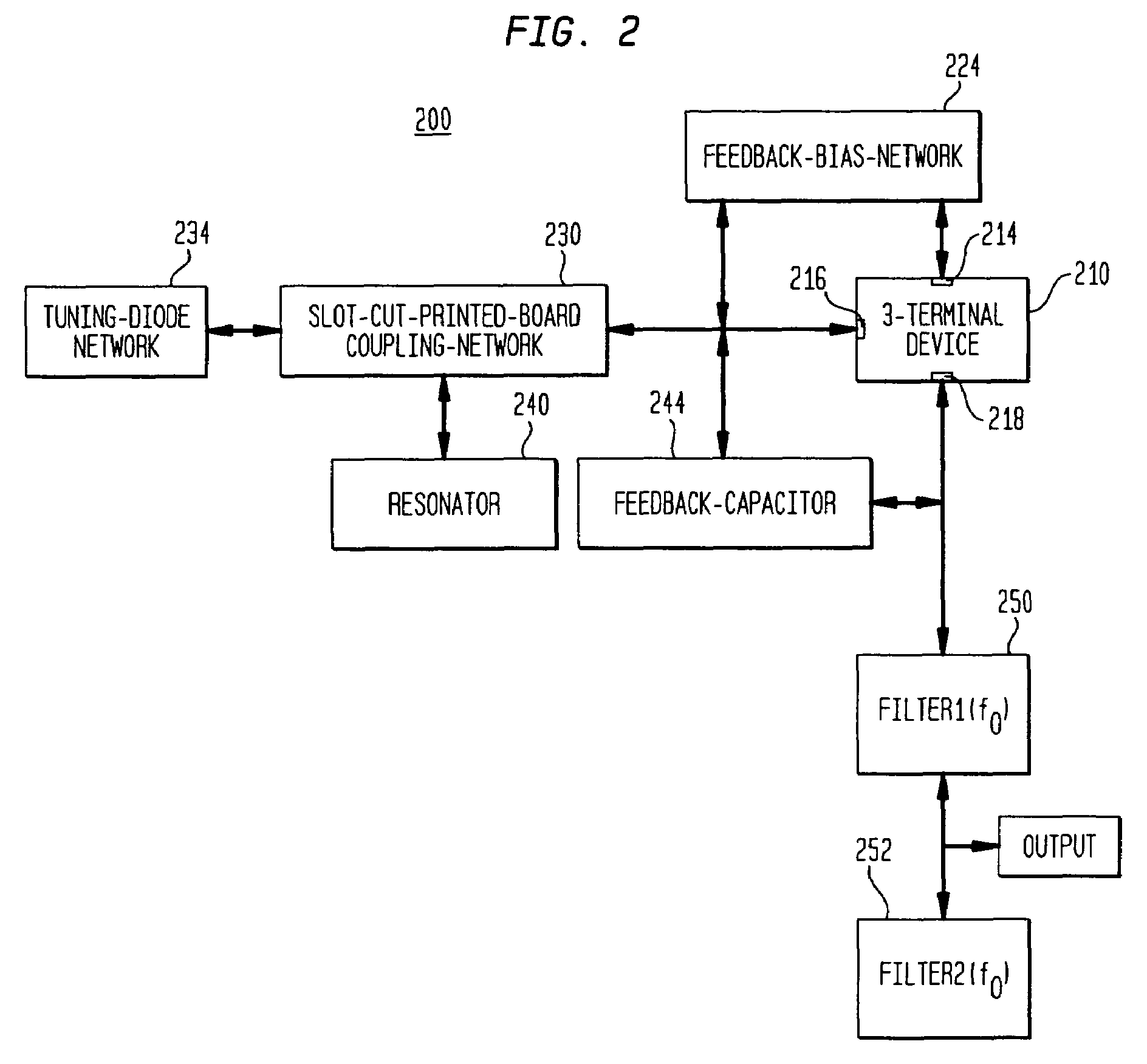

Wideband voltage controlled oscillator employing evanescent mode coupled-resonators

ActiveUS20050242896A1Increase working frequencyUniform resistanceOscillations generatorsEngineeringEvanescent mode

In one aspect, the present invention includes a voltage controlled oscillator comprising an active device having a plurality of resonators coupled across two terminals of the device and at least one resonator coupled across the plurality of resonators. The at least one resonator preferably operates as an evanescent mode buffer capable of storing a select amount of energy present in the oscillator.

Owner:SYNERGY MICROWAVE CORP

Tunable evanescent-mode cavity filter

A tunable filter having an electronically tunable center frequency and dynamic bandwidth control over a large tuning range. High-Q continuously tunable evanescent-mode cavity resonators and filters using reliable RF MEMS actuators. One embodiment is a 3.4-6.2 GHz (1.8:1 tuning ratio) continuously tunable electrostatic MEMS resonator with quality factor of 460-530, with a volume of 18×30×4 mm including the actuation scheme and biasing lines. A tunable resonators is also disclosed with a 2.8:1 (5.0-1.9 GHz) tuning ratio, and Q of 300-650.

Owner:PURDUE RES FOUND INC

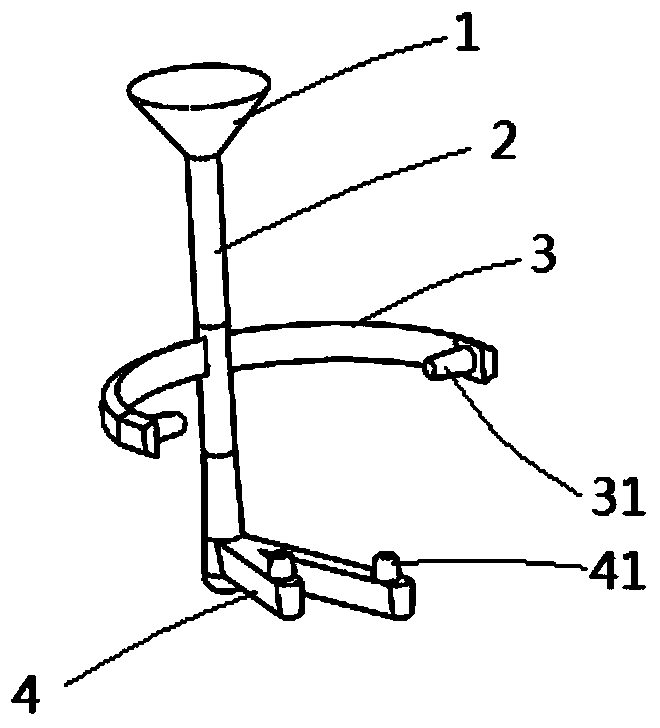

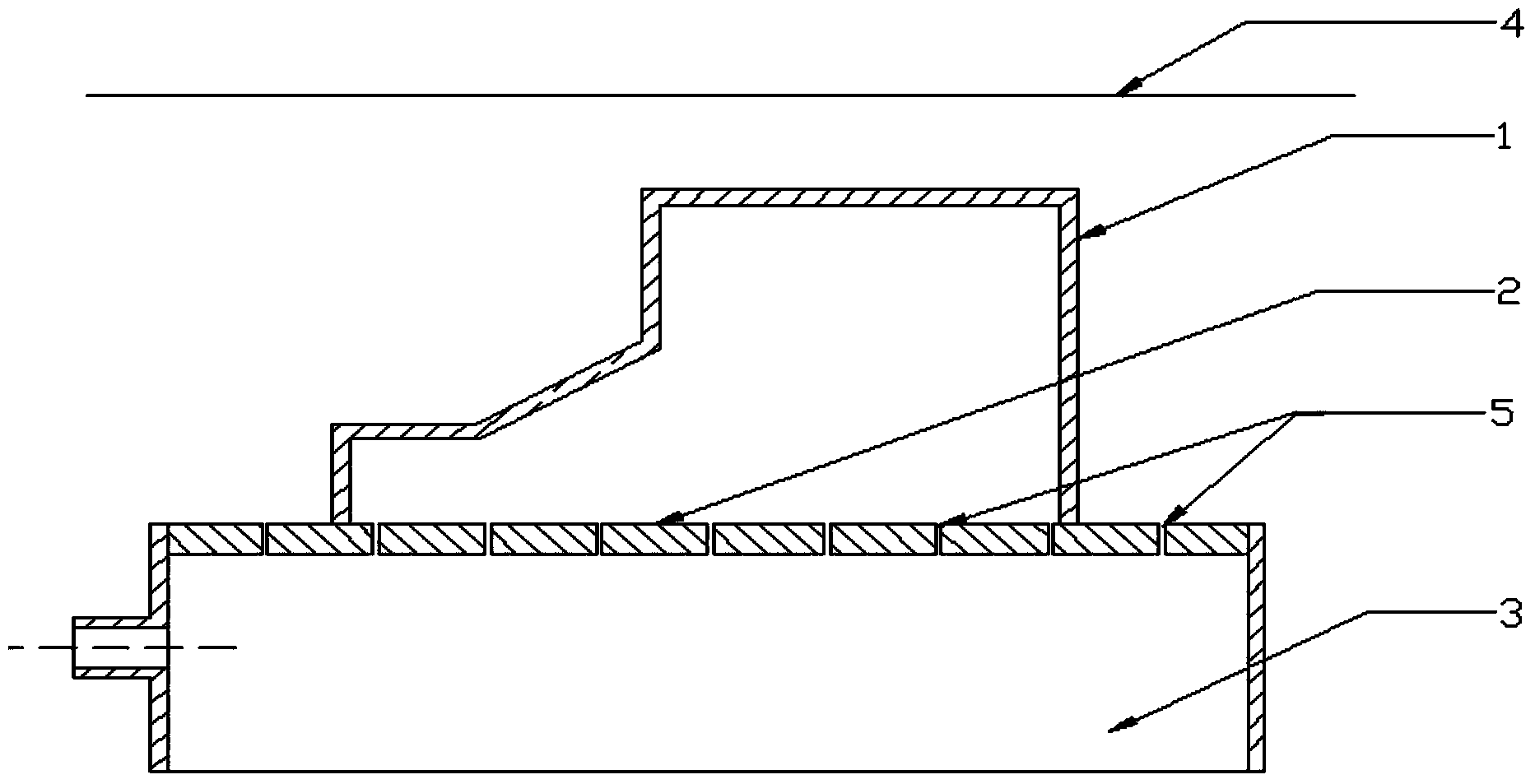

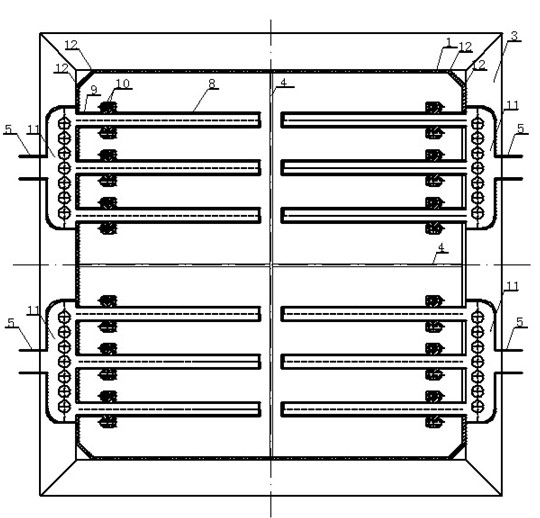

Evanescent mode pouring system of speed changing box body

The invention discloses an evanescent mode pouring system of a speed changing box body. The evanescent mode pouring system is provided with a sprue, wherein the sprue is sequentially communicated with a pouring cup, a first cross gate and a second cross gate from top to bottom, and the first cross gate and the second cross gate are respectively communicated onto the sprue along the radial direction of the sprue; the end part, away from of the sprue, of each of the first cross gate and the second cross gate is respectively provided with a first inner gate pouring port and a second inner gate pouring port. The pouring system is adopted for pouring a casting, so that the mold filling time is shortened, and the heat loss is reduced; moreover, the shrinkage porosity and cavity weakness can be greatly reduced, and the casting quality can be effectively improved.

Owner:HEFEI UNIV OF TECH

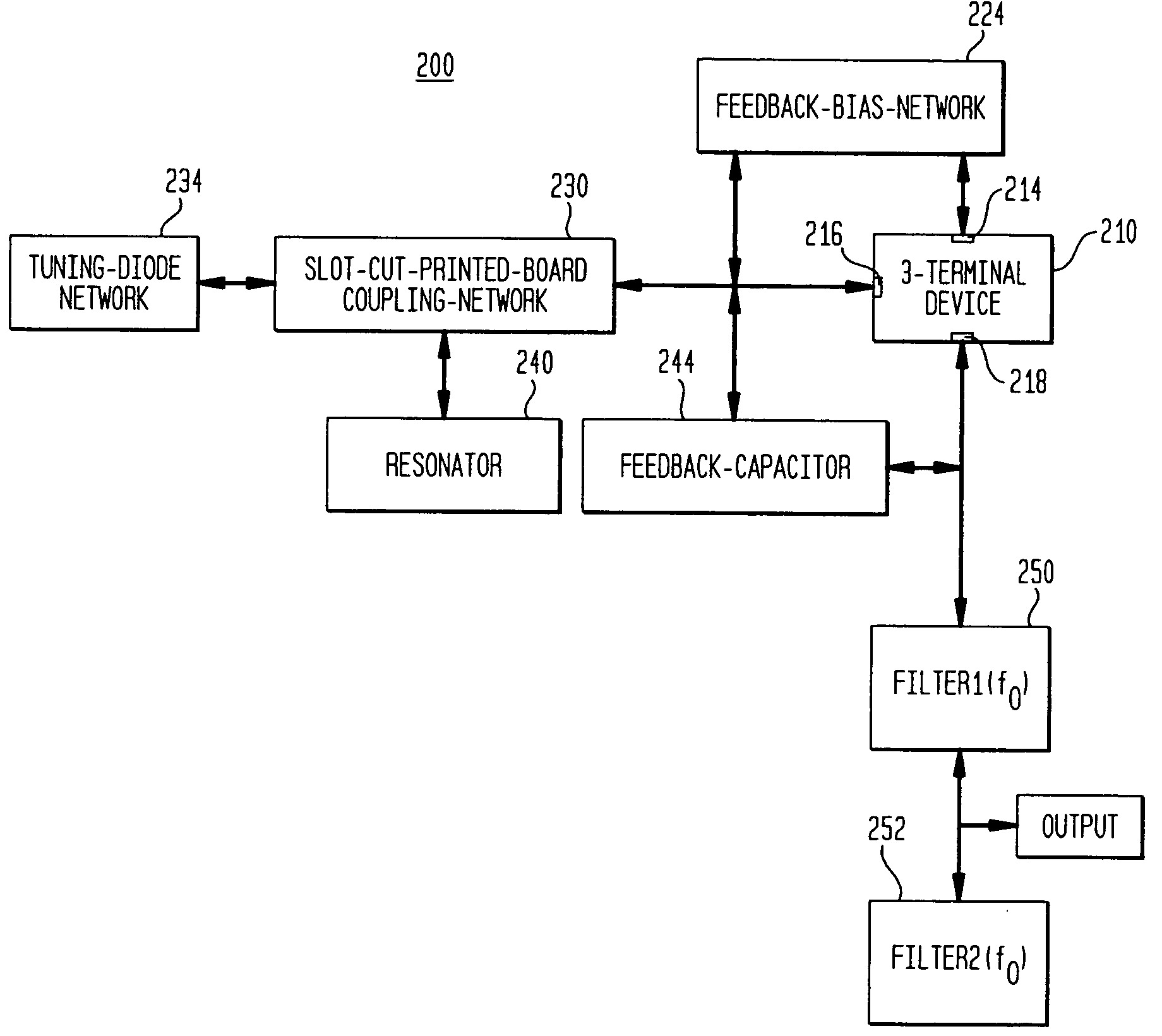

Low thermal drift, tunable frequency voltage controlled oscillator

ActiveUS20050280478A1Pulse automatic controlSemiconductor/solid-state device detailsCapacitanceCascode

An oscillator comprising a cascode configured device having first, second and third terminals, a plurality of resonators and first circuitry coupled between the plurality of resonators and the second terminal of the cascode configured device. The first circuitry is preferably operable as an evanescent mode buffer to compensate for changes in the capacitance of the oscillator during operation.

Owner:SYNERGY MICROWAVE CORP

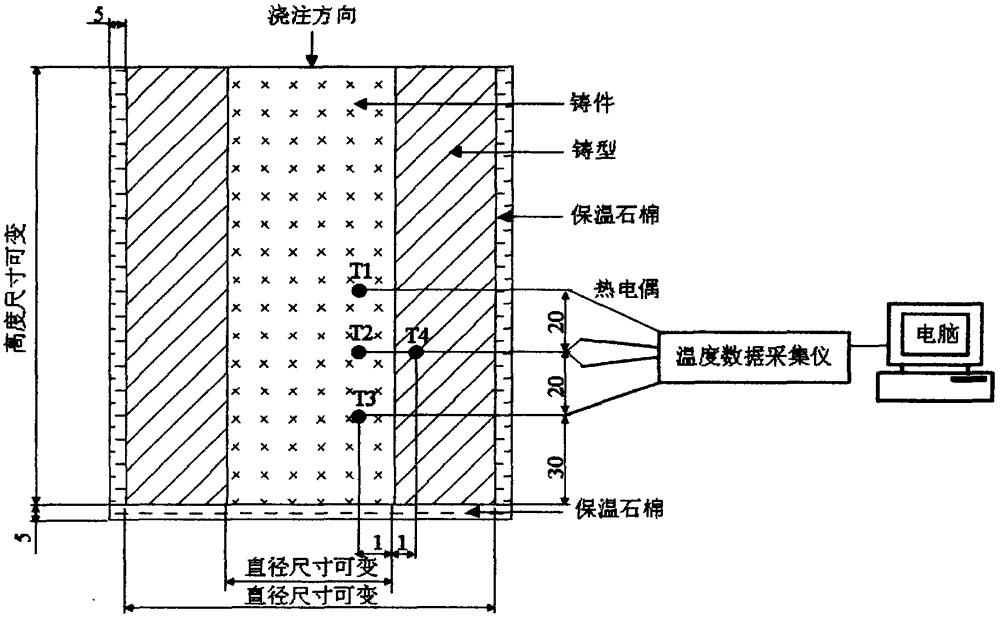

Determination method for interface heat transfer coefficient in casting process

InactiveCN104698030AShort response timeAccurate temperature test resultsMaterial heat developmentMeasurement pointData acquisition

The invention discloses a determination method for an interface heat transfer coefficient in a casting process. The determination method for the interface heat transfer coefficient in the casting process comprises the following steps that K type thermal couples with the diameter being 0.1 mm-0.5mm are arranged on the positions, 1 mm-5mm away from the cast mold surface, of a cast mold and a cavity respectively, the K type thermal couples are inserted into one end in the casting mold and one end in the casting mold cavity and protected by ceramic tubes with the diameter being 2.0 mm-10 mm, and the other ends of the casting mold and the casting mold cavity are connected to a computer; the interface heat transfer coefficient of a casting piece in the process of cooling and solidfication can be obtained by using a heat transfer recognition software according to the temperature changing data of casting piece measuring points and casting mold inner measuring points. The injection mold cold runner casting system structure is suitable for special casting processes including sand casting, die casting, evanescent mode casting, metal mold casting and pressure casting for aluminium alloy, steel, iron and other different materials.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Powder evanescent mode casting paint and application method and application thereof

InactiveCN106694798AGood bonding performance at room temperatureImprove breathabilityFoundry mouldsFoundry coresPhosphatePolyvinyl alcohol

The invention discloses powder evanescent mode casting paint and an application method thereof. The powder paint comprises the following components in percentage by weight: 88.9-89.7% of refractory aggregate, 3.7-4.5% of sodium base bentonite, 0.78-1.23% of polyethyl alcohol, 0.82-1.85% of aluminum dihydrogen phosphate, 0.32-0.44% of sodium carboxymethylcellulose, and 3.8-4.8% of expanded graphite. During preparing, all powder is added in a mixer for dry mixing to reach an uniform state to obtain the finished powder evanescent mode casting paint. Water by 23.5-37 weight% of the powder paint is firstly added in the mixer; the mixer is started; the powder paint is slowly added in the mixer; after materials are added, the stirring is continued by 1-2 hours; and then, an evanescent mode can be coated by the paint. The paint can achieve the effect of long-time storage without deteriorating by adding no formaldehyde in the raw materials; no surface active agent is added in the raw materials to prevent the trouble of adding a defoaming agent to defoam in subsequent use; the finished product is higher in strength at normal temperature or high temperature; and the paint is excellent in permeability, and cannot release poisonous substances.

Owner:HUBEI UNIV OF TECH

Wideband voltage controlled oscillator employing evanescent mode coupled-resonators

ActiveUS7180381B2Increase working frequencyAngle modulation by variable impedenceGenerator stabilizationEngineeringEvanescent mode

Owner:SYNERGY MICROWAVE CORP

Evanescent mode production process of engine cylinder body

ActiveCN103372630APrevent water leakageImprove pass rateFoundry moulding apparatusWater leakageEvanescent mode

The invention discloses an evanescent mode production process of an engine cylinder body, belonging to the technical field of evanescent mode production processes. The evanescent mode production process comprises the steps of: S1, a bead pre-frothing process; S2, a white mode forming process; S3, a drying treating process for drying a white mode; S4, a mode sticking process; S5, a coating dip-coating process; S6, a drying process after dip-coating; and S7, a modeling and casting process. According to the evanescent mode production process, phenomena of sand burning and water leakage can be effectively prevented, and thus the qualified rate of produced engine cylinder bodies of automobiles is increased.

Owner:河北瑞丰科技有限公司

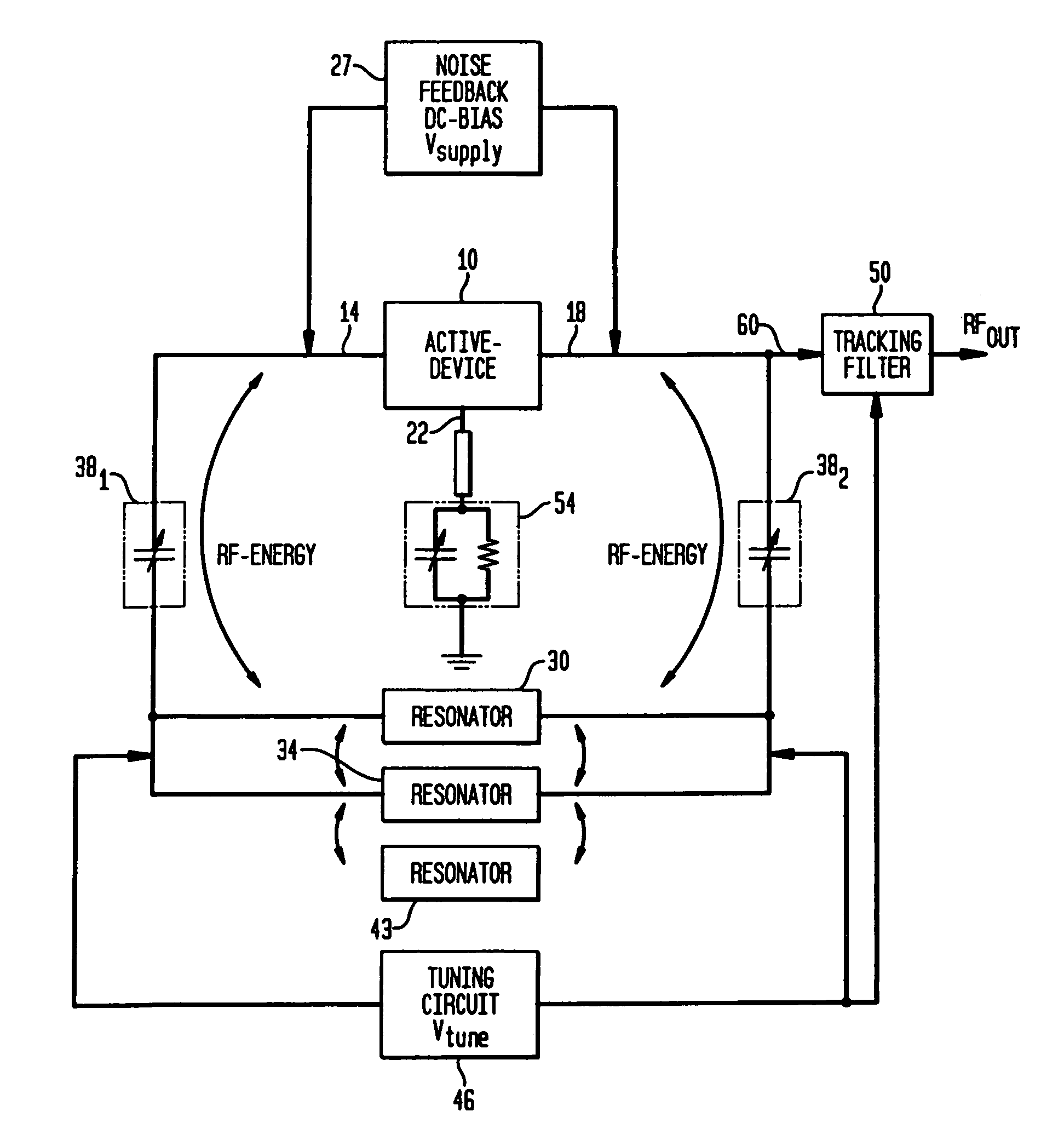

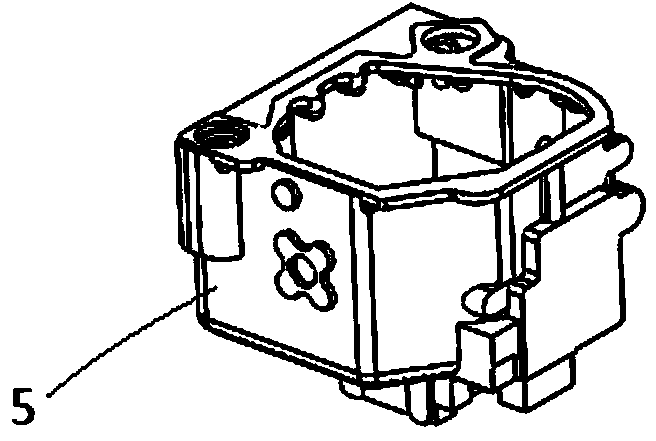

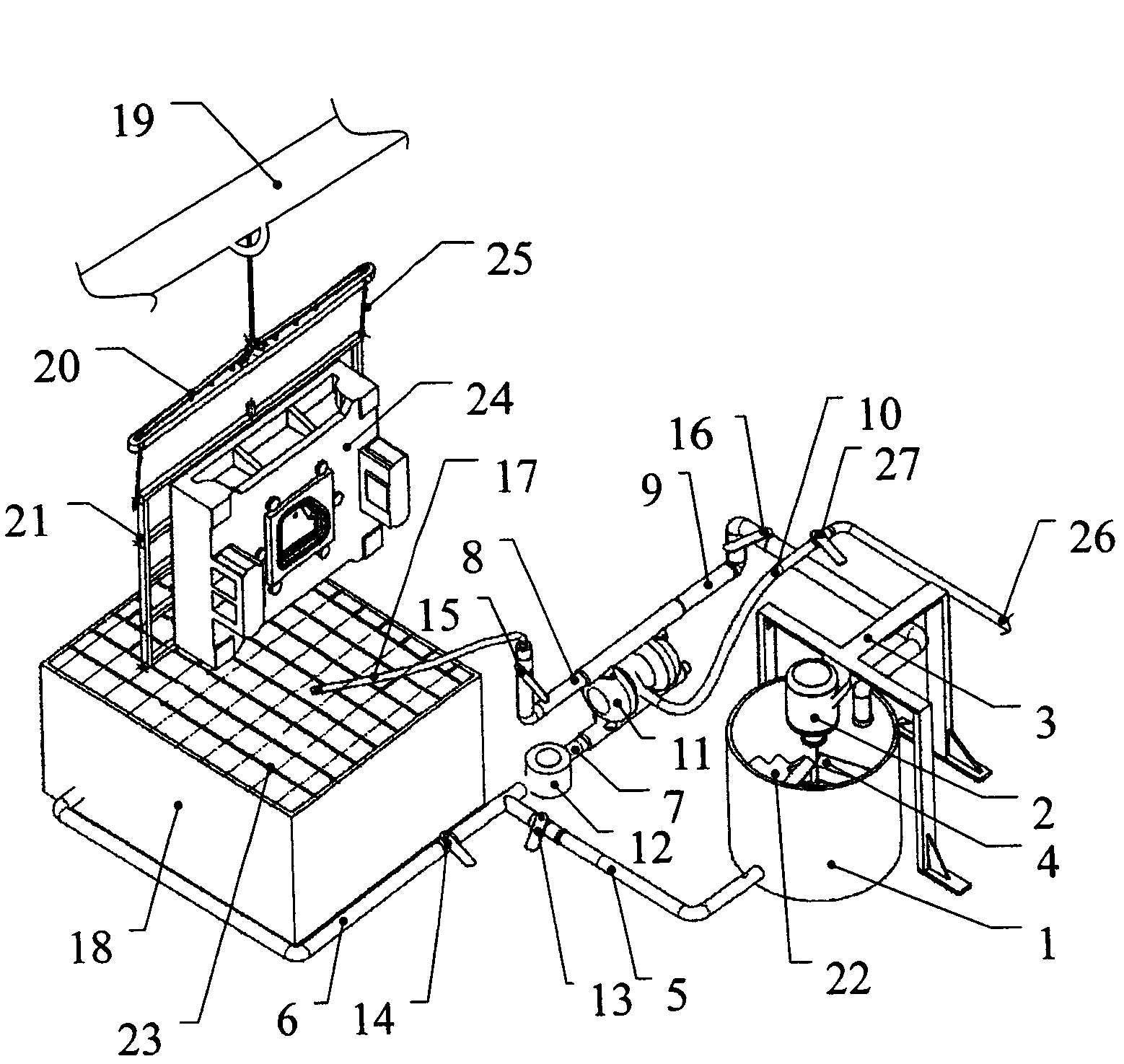

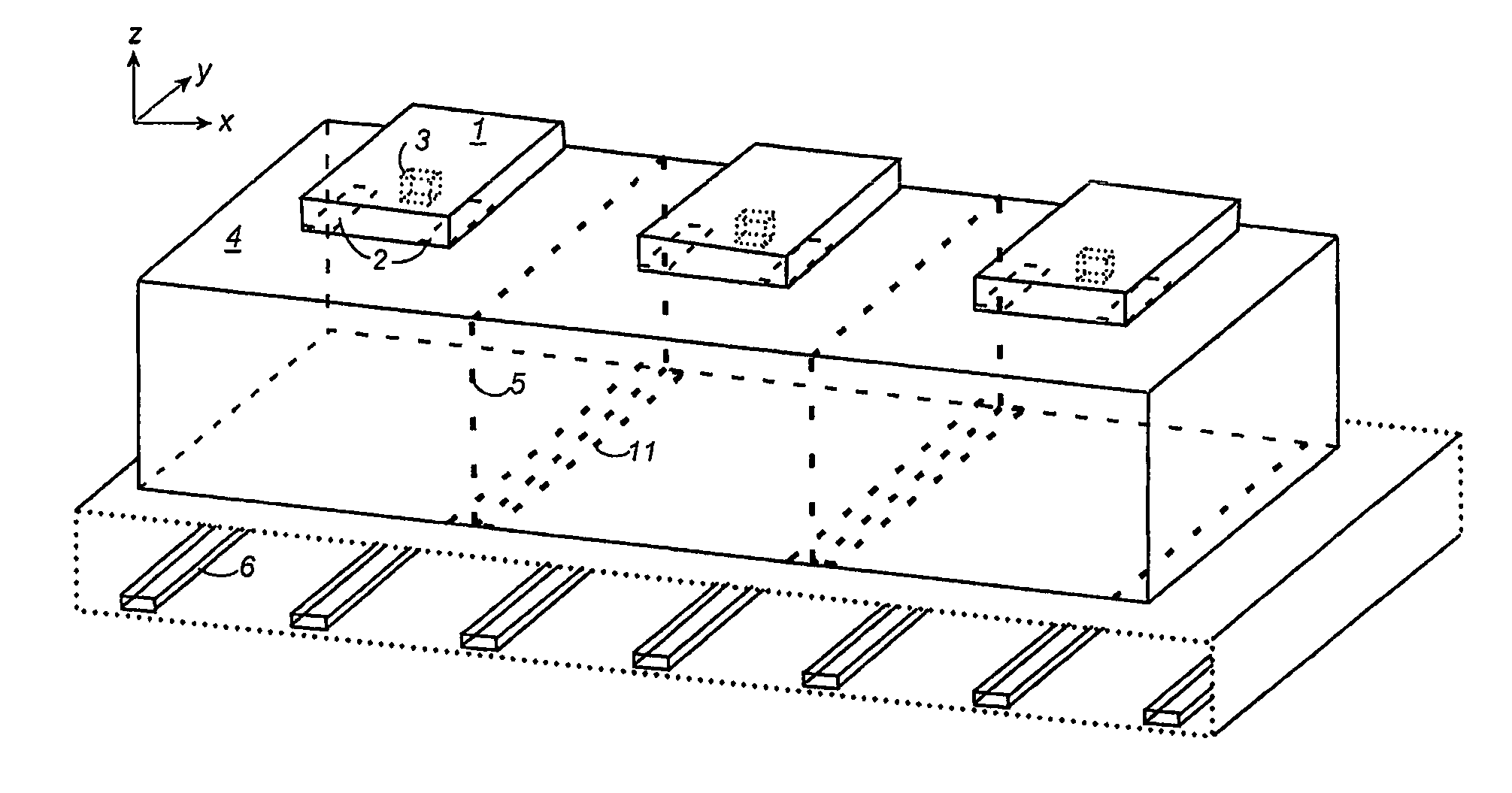

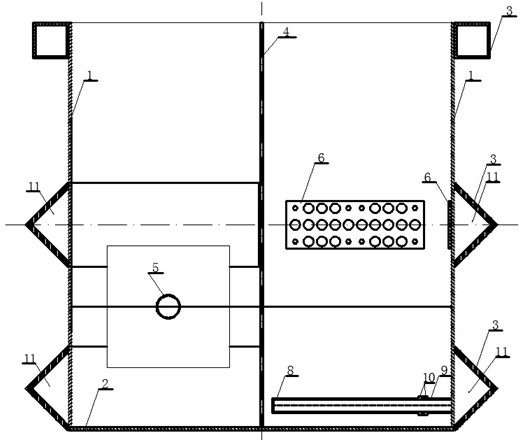

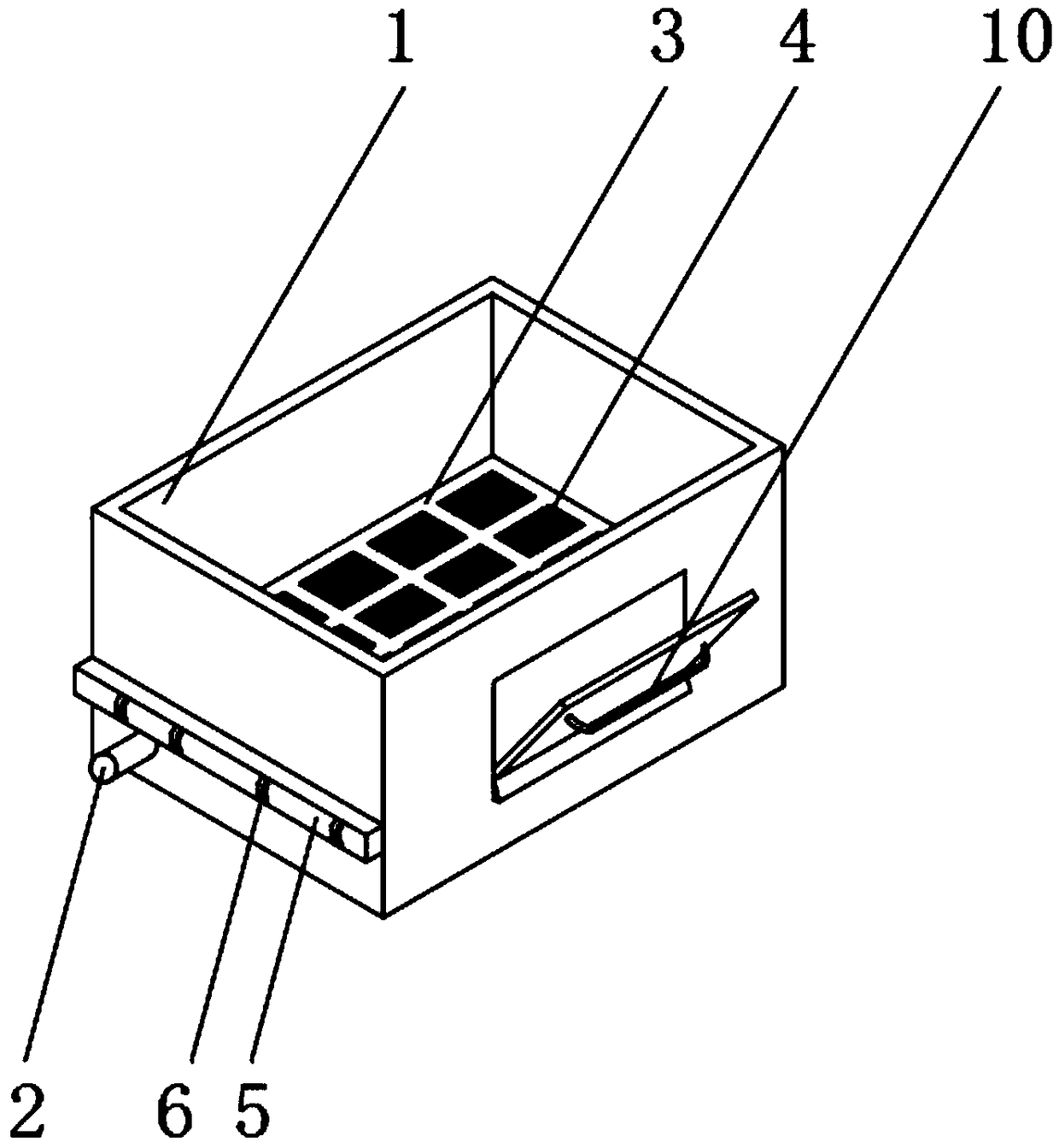

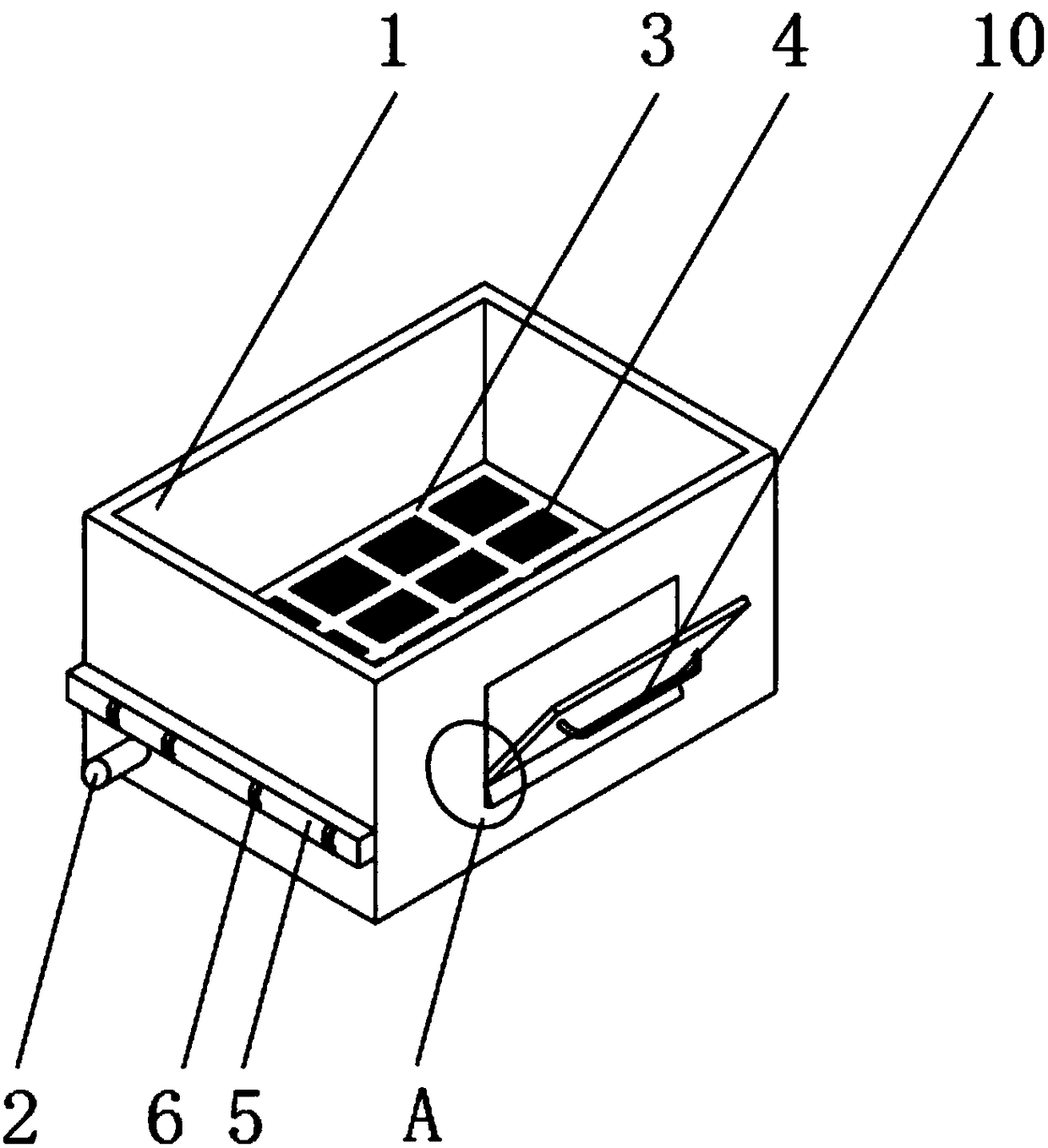

Evanescent mode coating spraying system

InactiveCN102641990AProtect against deformationAvoid damageMoulding toolsFoundry mouldsDiaphragm pumpImpeller

The invention discloses an evanescent mode coating spraying system which comprises a storage vat (1), a motor (2), a motor bracket (3), a stirring impeller (4), a feed delivery pipe (5), a return pipe (6), a connecting pipe (7), an output pipe (8), a feedback pipe (9), an air pipe (10), a pneumatic diaphragm pump (11), a magnetic filter (12), a first control valve (13), a second control valve (14), a third control valve (15), a fourth control valve (16), a spray pipe (17), a storage tank (18), a crown block (19), a lifting frame (20), a mounting rack (21), an evanescent mode coating (22), a mesh enclosure (23) and a fifth control valve (27). The evanescent mode coating spraying system has the advantages and effects that: during the evanescent mode coating process of the system, manpower and material resources as well as time are saved, the coating is uniformly coated, and cannot be limited by an evanescent mode structure, and deformation during the evanescent mode coating process is avoided.

Owner:枣庄市同捷汽车模具有限责任公司

Vacuum seal modeling method for refrigerator cold closet plastic uptake mould casting

ActiveCN103658527AIncrease freedomHigh dimensional accuracyFoundry mouldsFoundry coresNumerical controlEvanescent mode

The invention relates to a vacuum seal modeling method for a refrigerator cold closet plastic uptake mould casting, and relates to the technical field of casting. The method comprises the following steps: 1) drawing up a cold closet solid model on three-dimensional software, and then utilizing a numerically-controlled machine tool to automatically process a polyurethane model; 2) putting the polyurethane model in the middle position of a template, coating a heated and softened plastic film on the surfaces of the template and the polyurethane model, and vacuumizing in an aspirating chamber; 3) putting an aspirating sand box on the polyurethane model and the template coated with the plastic film, sticking a gating system made of evanescent mode foam material on the polyurethane model, adding dry sand to ram-jolt, vacuumizing the aspirating sand box; 4) drawing, overturning the aspirating sand box, removing a supporting plate in the model, adding resin sand in the inner chamber of the model, and manufacture resin sand core; 5) orderly putting a normal sand box on the aspirating sand box, adding clay sand in the normal sand box to compact, and forming a sprue; 6) lifting the normal sand box, enabling the normal sand box to be separated from the aspirating sand box, removing the model, performing mould assembling, and waiting to pour. Through the adoption of the structure that the model is manufactured by three-dimensional drawing numerical control machining, the freedom degree of the model is improved, the stability of the size is kept, the labor is saved, and the pollution to the environment is low.

Owner:CHUZHOU JINNUO INDAL

3D printing forming casting method for large-scale complex thin-wall high-temperature metal component

InactiveCN107598095ASolving the Difficulties of Investment Casting Shell ManufacturingAchieve rapid productionAdditive manufacturing apparatusFoundry mouldsWaxInvestment casting

Owner:安徽恒利增材制造科技有限公司

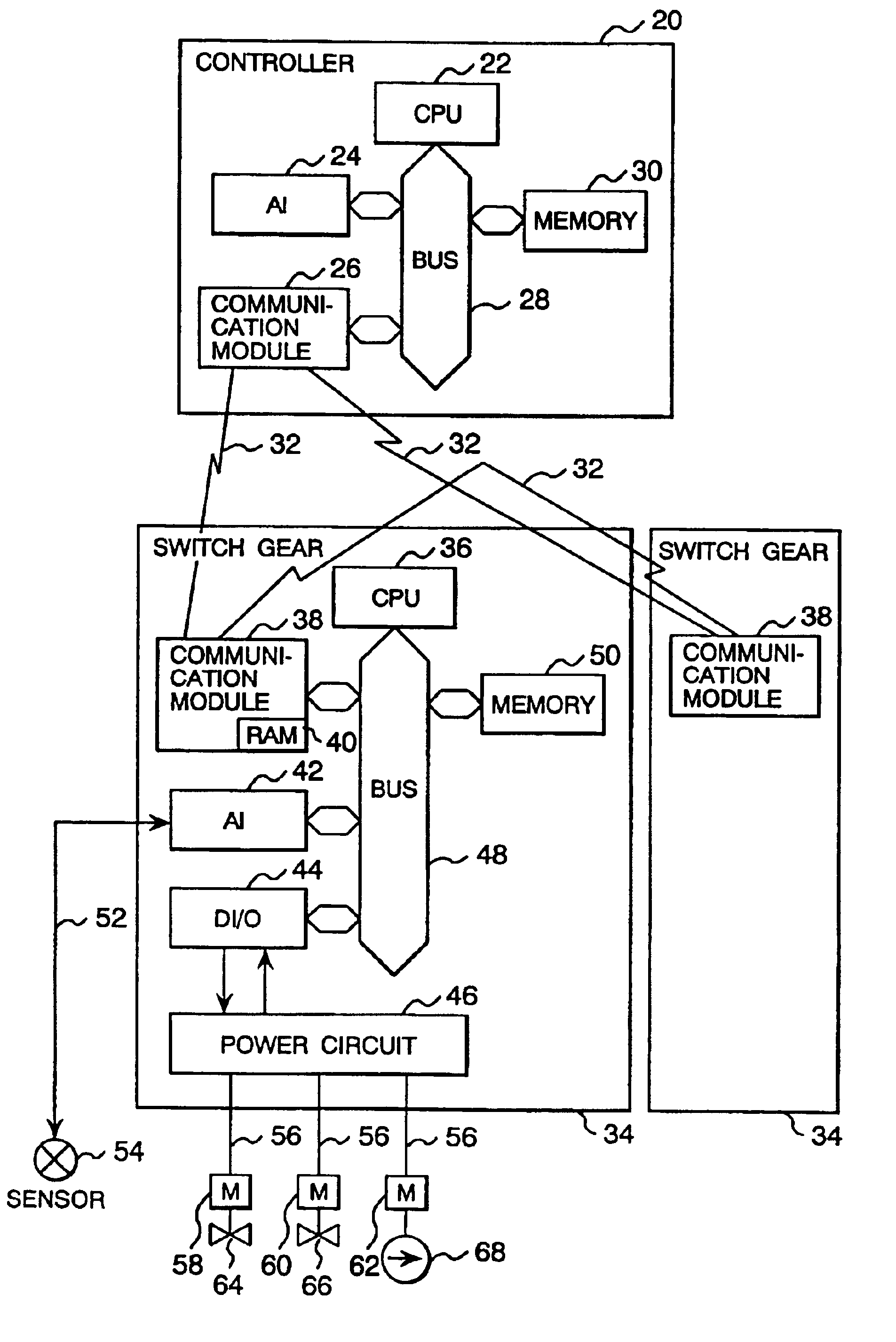

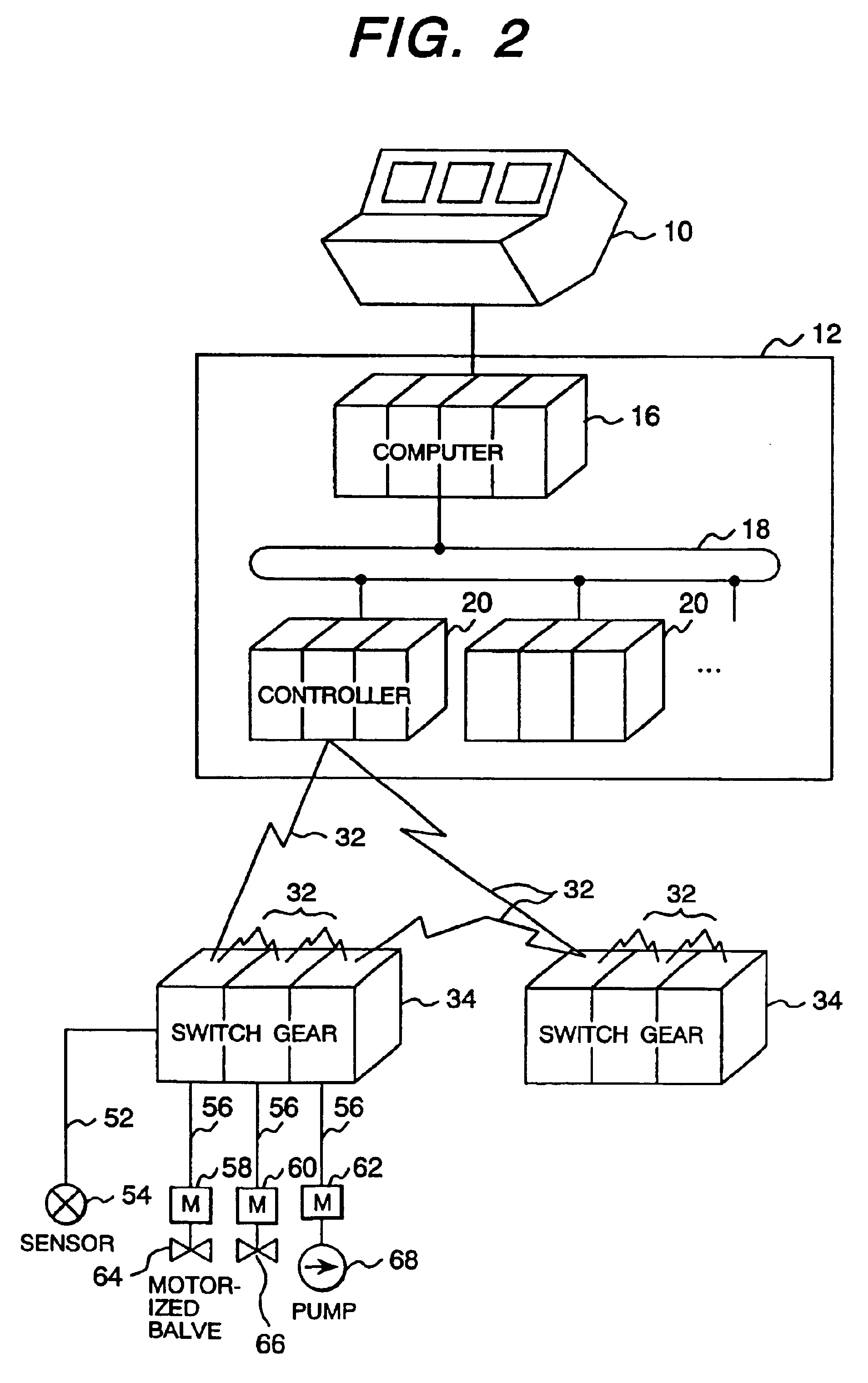

Power distribution panel switch gear and a monitoring and control system having a distribution panel switch gear

InactiveUS6947813B2Scale upKeep for a long timeMechanical power/torque controlLevel controlDiagnostic dataSwitch box

A monitoring and control system is provided having a control device, arranged in a central controller room, which provides commands to power distribution panel switch gear located in the field. The switch gear transmits and receives controlling and monitoring signals through wireless communication applying an evanescent mode. The switch gear has a power circuit connected to a plurality of devices to be operated. The switch gear is a panel comprising metal and non-metal surfaces, so that a portion of wireless waves in the evanescent mode travel out of the panel. A receiver is provided for monitoring the wireless waves that travel out of the panel. The wireless signals are compared with information stored in a diagnostics database, and are diagnostically evaluated to determine whether the signals are within a known normal operating range.

Owner:HITACHI LTD

Casting technique of V12-type engine cylinder block

InactiveCN103273007AHigh precisionQuality improvementFoundry mouldsFoundry coresEvanescent modeCylinder block

The invention discloses a casting technique of a V12-type engine cylinder block. The casting technique comprises the following steps of: manufacturing a foam model, modeling under vibration, pouring under vacuum and cooling and cleaning, wherein a sand mould is subjected to air exhaust during a pouring process and before and after the pouring step, an air exhausting pipeline is arranged at the lower end of the sand mould, an iron pillow for dispersing force is arranged on a pouring cup, a layer of water glass sand is coated on a film, a vibrating platform is started before pouring, and a sand box can continuously vibrate in the pouring process. The V12-type engine cylinder block with a complicated structure is manufactured by adopting an improved evanescent mode casting technique and a vibrating-while-pouring compact strengthening casting method, shape-position dimensional accuracy and internal-external surface quality of the V12-type engine cylinder block are further improved by the allowance-free and accurate forming evanescent mode technique, an ideal compact organization structure is obtained by virtue of the vibrating-while-pouring compact strengthening casting method, and the performance of the V12-type engine cylinder block can be guaranteed and improved.

Owner:重庆汉华汽车零部件制造有限公司

WCp/EPS evanescent mode pattern and WCp/Fe composite preparation

The invention discloses a WCp / EPS evanescent mode pattern and a WCp / Fe composite evanescent mode cast forming process, and belongs to the technical field of metal forming. A preparation method of theWCp / EPS evanescent mode pattern includes the following steps that WC particles, rare earth powder, EPS beads and an adhesive are weighed by volume parts and mixed to be uniform, and a mixture is prepared; a die is preheated, and when the temperature of the die reaches the working temperature of 100 DEG C, filling is started; the die is filled with the mixture through compressed air, and hot steamis introduced; and after the hot steam is relieved, water is sprayed to the back face of the die for cooling, the temperature of the pattern is rapidly cooled to 40-50 DEG C, the temperature is reduced below the softening temperature, and after the pattern is shaped, the die is stripped. According to the process method, alloy particles and a substrate are firmly bound, the particles are uniformlydispersed, the comprehensive mechanical performance of the product is improved, and large WCp / Fe composite parts with complex shapes can be manufactured through evanescent mode casting.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Evanescent mode casting technology

InactiveCN104439075AIncrease productivitySave investmentFoundry mouldsFoundry coresWater basedEvanescent mode

The invention belongs to the field of metal casting, and discloses an evanescent mode casting technology. The technology comprises the following steps: producing a foam mode sample or a pouring system with a metal foaming mold in a shaping machine; cementing the mode sample and a pouring channel to form a mode truss module; soaking water-based paint on the mode truss module with a coating machine; stoving the paint, and drying the stoved mode truss module with an air exhauster in a stoving chamber; putting the dried mode truss module into a sand box, and filling dry sand; performing vibration molding on a swing table so as to fill the dry sand into the lumen of the sand box and compact the dry sand, sealing the sand box with a plastic film, and placing a pouring cup; performing pouring so as to gasify and disappear a foam mode sample in the sand box to form a cast, and pumping air in a vacuum manner during the pouring; after the cast is cooled, taking out the cooled cast, performing shakeout and cutting out and cleaning a pouring head. The technology has the advantages that the cost is reduced, the property is steady, and the efficacy is high.

Owner:LIUZHOU ZHENGLONG MACHINERY MFG

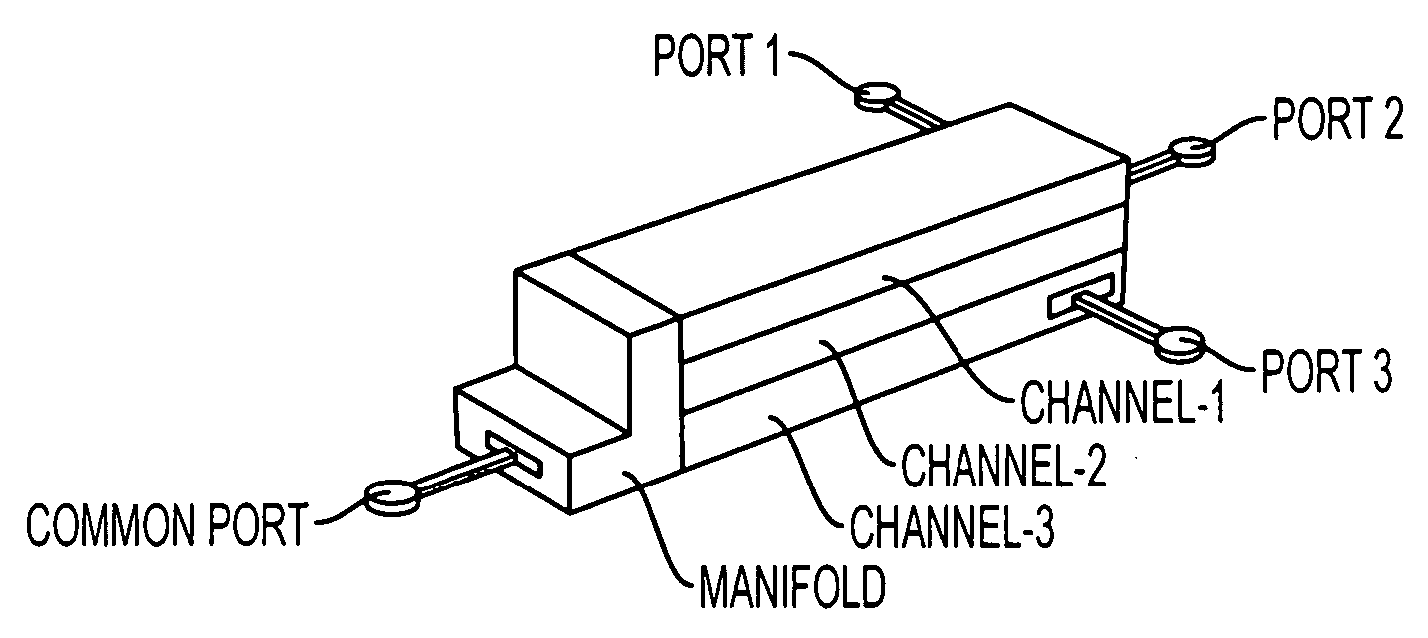

Low-loss filter and frequency multiplexer

InactiveUS20060186969A1Raise the cutoff frequencyWide upper stopbandsCoupling devicesCost effectivenessMultiplexer

A waveguide filter with a signal input port at a first end and a signal output port at a second end includes a dielectric core of moldable material where the outer surface of its periphery has a metal layer with nonmetallized openings positioned at opposite ends of the filter to accommodate the input and output ports. The filter's periphery is configured to provide a cascade connection of a plurality of metal-bounded ridge-waveguide sections with interspersed metal-bounded evanescent-mode coupling regions. The filter can be joined through a manifold to realize a frequency-multiplexer, with the manifold containing a cascade connection of electrically short waveguide segments and quasi-lumped waveguide circuit components, such as irises. The filter and multiplexer are amenable to the application of cost-effective injection molding techniques to manufacture the dielectric core.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Manufacturing technique for duplex metal compound crusher hammerhead

The invention relates to the technical field of wear-resistant metal materials and discloses a manufacturing technique for a duplex metal compound crusher hammerhead. The manufacturing technique for the duplex metal compound crusher hammerhead comprises the steps of smelting, wearing layer casting, hammer handle casting, hammerhead evanescent mode casting, pouring, cooling, heat treatment and the like. According to the manufacturing technique for the duplex metal compound crusher hammerhead, a wearing layer is welded at the front end of the hammerhead, the abrasive resistance of the crusher hammerhead is improved, the service life of the hammerhead is prolonged, and the requirements of impact resistance on the hammerhead by a crusher are met. The manufacturing technique for the duplex metal compound crusher hammerhead is simple, a hammer handle is closely connected with the hammerhead, the hammerhead is not prone to falling off when used, and the hammerhead is good in hardness, high in intensity and good in toughness.

Owner:盐城支点机械制造有限公司

Microwave heating applicator

InactiveUS20070068937A1Good impedance transformationDifficult to eliminateMicrowave heatingElectric power transmissionElectric force

A new type of microwave applicator has been disclosed. The applicator according to an embodiment of the invention makes use of an evanescent main power-transferring mode. This evanescent mode is complemented by a second mode, which is a propagating mode that has the purpose of providing a counter-directed magnetic field in the y-direction at the horizontal, y-directed applicator wall opening. The effect of the cooperation of the two applicator modes is that the field pattern extends over a significant distance below the applicator opening, such that a load placed below the applicator opening is heated by a field pattern of the mode combination.

Owner:EXH LLC

Evanescent mode sand processing system

InactiveCN102886492AReduce the temperatureLow ashMould handling/dressing devicesProgrammable logic controllerMagnetic separator

The invention relates to an evanescent mode sand processing system, belonging to the field of an evanescent mode pouring technology. The evanescent mode sand processing system comprises a drum sand sieving machine, a vibration conveyor trough, a belt-type suspended magnetic separator, a heat-resistant bucket elevator, two intermediate sand bins, a dust removing device, a transitional sand hopper, a pneumatic conveyor, two sand hoppers above a swing table, and a rain-type sand feeder, wherein the vibration conveyor trough and the belt-type suspended magnetic separator are arranged at the rear side of the drum sand sieving machine; the heat-resistant bucket elevator is arranged at the rear sides of the vibration conveyor trough and the belt-type suspended magnetic separator; the two intermediate sand bins are arranged at the rear side of the heat-resistant bucket elevator; the dust removing device is arranged at the rear sides of the intermediate sand bins; the transitional sand hopper is arranged at the rear side of the dust removing device; the pneumatic conveyor is positioned at the rear side of the transitional sand hopper; the sand hoppers above the swing table are arranged at the rear side of the pneumatic conveyor; and the rain-type sand feeder is arranged at the rear sides of the sand hoppers above the swing table. The evanescent mode sand processing system is characterized by further comprising a programmable logic controller (PLC) system and a dust removing system; the dust removing device is a boiling bed cooling dust removing device and comprises a cold water circulating system and a high-pressure centrifugal fan; and a central sand bin is arranged between the transitional sand hopper and the pneumatic conveyor. Due to the dust removing device and the dust removing system, the evanescent mode sand processing system is good in effect, reasonable in design, convenient and reliable to control and use and high in working efficiency.

Owner:ANHUI REDSTAR VALVE

Low thermal drift, tunable frequency voltage controlled oscillator

An oscillator comprising a cascode configured device having first, second and third terminals, a plurality of resonators and first circuitry coupled between the plurality of resonators and the second terminal of the cascode configured device. The first circuitry is preferably operable as an evanescent mode buffer to compensate for changes in the capacitance of the oscillator during operation.

Owner:SYNERGY MICROWAVE CORP

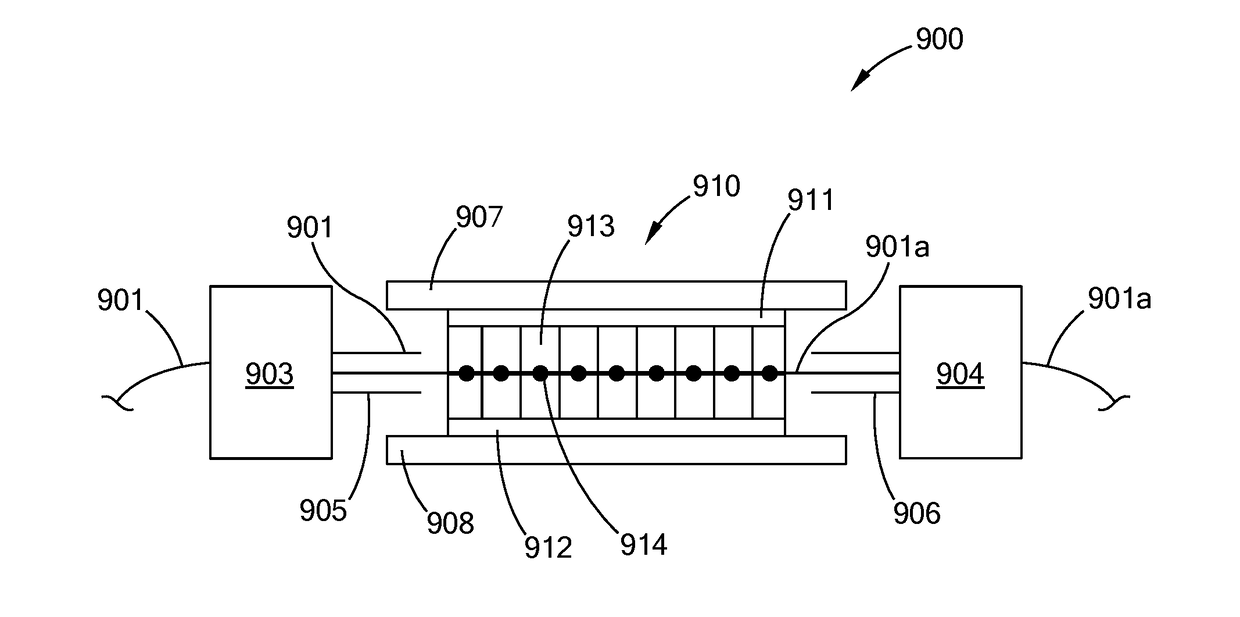

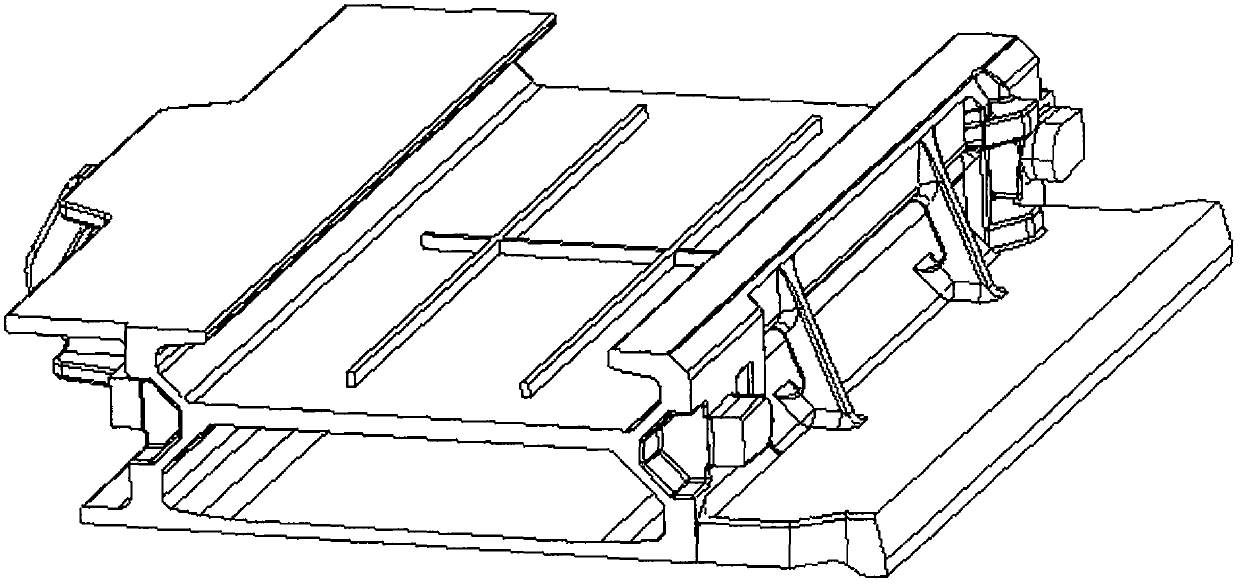

Tunable evanescent-mode cavity filter

A tunable filter having an electronically tunable center frequency and dynamic bandwidth control over a large tuning range. High-Q continuously tunable evanescent-mode cavity resonators and filters using reliable RF MEMS actuators. One embodiment is a 3.4-6.2 GHz (1.8:1 tuning ratio) continuously tunable electrostatic MEMS resonator with quality factor of 460-530, with a volume of 18×30×4 mm including the actuation scheme and biasing lines. A tunable resonators is also disclosed with a 2.8:1 (5.0-1.9 GHz) tuning ratio, and Q of 300-650.

Owner:PURDUE RES FOUND INC

Multifunctional sand box for casting

InactiveCN102581235AEasy to replaceLower barriers to entryMoulding flasksProduction linePressure system

A multifunctional sand box for casting comprises box walls at the peripheries and a box bottom. Structural steels for strengthening are installed on the peripheries of the box walls, vertical separating boards are arranged in the sand box to separate the sand box into small sand boxes which are not communicated, and an independent vacuumizing interface is arranged on the lateral face or / and the bottom face of each small sand box. The separating boards are added in the sand box, so that the sand box is separated into the small sand boxes, and reasonable size of the small sand boxes can be adjusted according to different casting pieces. Each small sand box has the independent vacuumizing interface, air between small sand boxes is not communicated, an independent negative pressure system guarantees that negative pressure in the small sand boxes does not influence on others, the negative pressure can be adjusted according to different requirements, cast production manufacturers do not need customize large-size sand box in order to give consideration to manufacture different casting pieces, generality of a production line is improved, overlapping investment of the production line is effectively avoided, and an evanescent mode induction doorsill is reduced.

Owner:湖南省津市市嘉城汽车部件制造有限公司

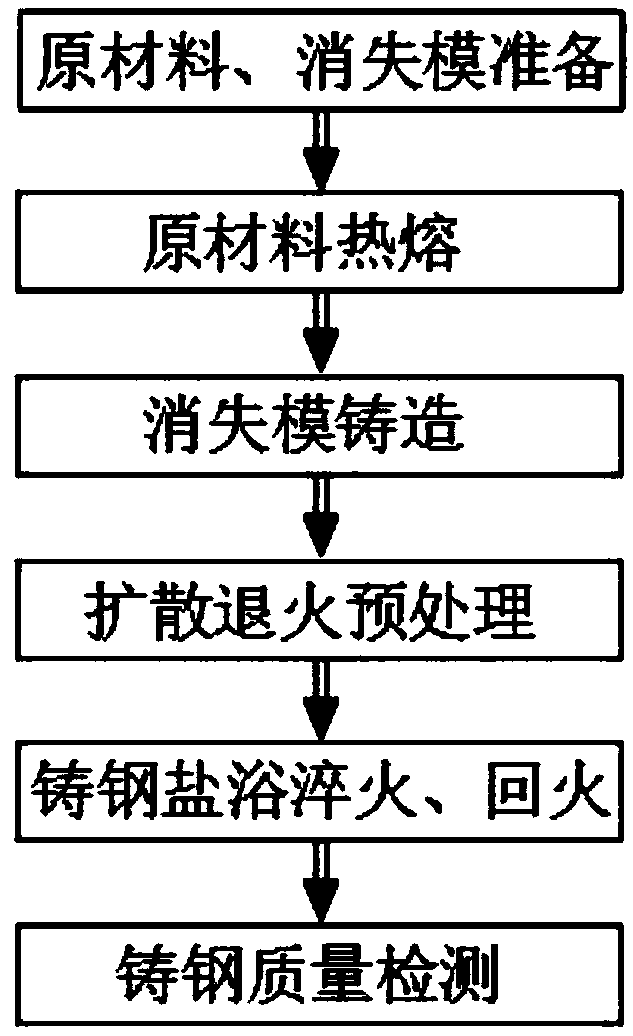

High-strength high-wear-resistant bainite cast steel used for block cast middle groove, and preparation technology thereof

ActiveCN109252098AExtended service lifeHigh strengthFoundry mouldsFoundry coresWear resistantQuenching

The invention discloses high-strength high-wear-resistant bainite cast steel used for a block cast middle groove, and a preparation technology thereof. The preparation technology comprises the following technical steps: preparing raw materials and evanescent modes, carrying out raw material hot melting, casting the evanescent modes, carrying out diffusion annealing preprocessing, carrying out caststeel salt bath quenching and tempering and detecting cast steel quality. The bainite cast steel used for the middle groove has the characteristics of high strength and high wear-resistant performance, the middle groove is subjected to integral casting forming, and the problem that all positions have inconsistent wear resistance is avoided. When a work surface is turned, maintenance is not required, the current work surface is directly turned to a next work surface, and the coal mining efficiency is improved. Meanwhile, since the materials of different positions are different, so that the effect of new goods are traded for old goods is realized, waste middle groove can be recovered and recast, waste is recycled, and the fully mechanized mining cost of users is greatly lowered, thus realizing an important meaning for the energy and material saving, the circular economy and the sustainable development of coal production.

Owner:JIKAI HEBEI MECHATRONICS TECH CO LTD

High average power optical fiber cladding mode stripper, methods of making and uses

Nano-particle based mode strippers for removing undesirable laser energy for laser systems. Nano-particle mode strippers having matched indices of refraction to the outer cladding remove cladding light converting it into heat. There are provided fibers having evanescent mode strippers having annular outer cores and claddings.

Owner:FORO ENERGY

Integral casting method for middle groove of scraper conveyer

PendingCN107598086ALow costSimple processFoundry mouldsFurnace typesVolumetric Mass DensityHigh intensity

The invention relates to an integral casting method for a middle groove of a scraper conveyer, and belongs to the field of low-alloy high-strength cast steel sand mould casting. The integral casting method comprises the following casting steps that a middle groove casting structure is designed according to the characteristics of the sand mould casting technology, and a bottom plate is provided with a square hole; an anti-deformation tie bar is arranged on the middle plate, after model core setting, a sand mould checking sample plate is used for detecting the size of components, and box combining is conducted after qualification is checked; and a low-alloy cast steel material with qualified components is smelted, and oblique pouring is conducted. Si and Mn serve as main alloy elements of the adopted low-alloy and high-strength cast steel material, the content of C is smaller than or equal to 0.35%, the content of Si and Mn is smaller than or equal to 2.5%, a trace of B, Ti, Nb and otherelements are added, the carbon equivalent CE is smaller than or equal to 0.68%, welding and repairing can be conducted, the material is subjected to normalizing, quenching and low-temperature tempering heat treatment, and after normalizing, the anti-deformation tie bar on the middle plate is removed. According to the material performance, the tensile strength Rm is larger than or equal to 1,300 MP, the impact toughness KV2 is larger than or equal to 25J, and the abrasion resistance is superior to that of an imported abrasion resisting plate Hardox400. The sand mould casting technology solvesthe problem that an evanescent mode technology is adopted at present to integrally cast a middle groove casting, deformation is large, and density is low; and the production technology is relatively simple, materials can be welded and repaired, and the integral manufacturing cost of the middle groove is reduced.

Owner:CHINA COAL ZHANGJIAKOU COAL MINING MACHINERY

Reconfigurable bridge filter network based on SIW evanescent mode resonators

The invention discloses a reconfigurable bridge filter network based on SIW evanescent mode resonators. The reconfigurable bridge filter network comprises an SIW substrate and evanescent mode resonators formed on the substrate, and the network comprises four groups of evanescent mode resonators; the four groups of evanescent mode resonators are arranged in a rectangular array position and are formed on the SIW substrate in an axial symmetry and central symmetry mode, and the central symmetry center is located in the symmetry center of the rectangular array position; the network comprises an inter-stage coupling unit connected between adjacent resonators, and the inter-stage coupling unit is used for providing inter-stage coupling connection between the resonators. The network is a microwave passive device, and the gap bridge coupler and the band-pass filter are integrated on one device. According to the scheme, a cognitive radio technical solution is realized, so that the wireless communication equipment has the capabilities of discovering a 'frequency spectrum cavity' and reasonably utilizing the discovered 'cavity', and a frequency spectrum manager can manage precious frequency spectrum resources in a more flexible manner.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

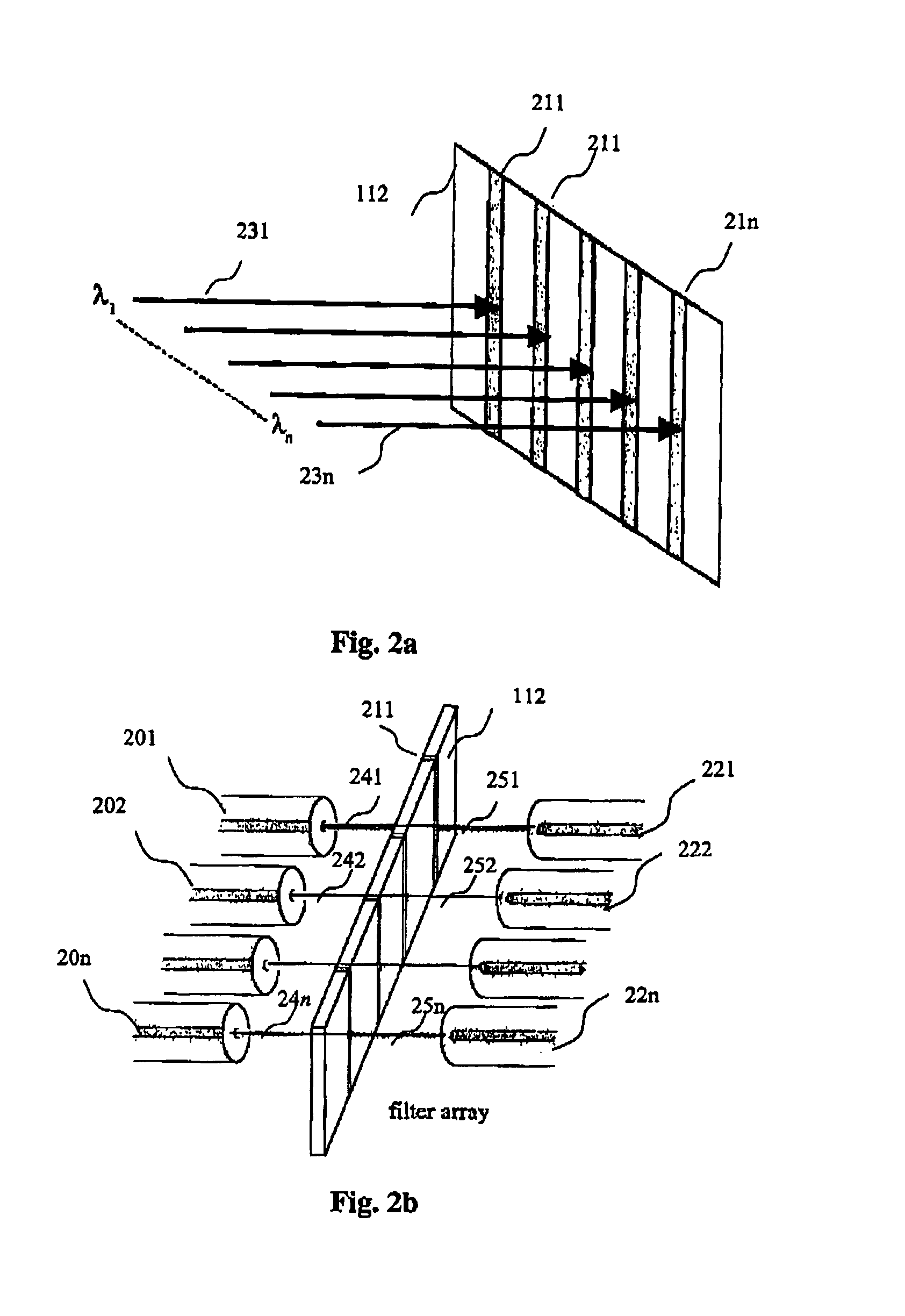

Spatial phase filter for light beams, system and corresponding method

InactiveUS20050259917A1Small sizeEasy to decoupleOptical filtersCoupling light guidesRegular distributionPhase filter

The invention relates to a spatial phase filter capable of receiving an incident light beam so as to transmit it to a single mode output fibre comprising a spatially variable phase profile and being adapted to excite the evanescent modes of the output fibre. The profile has: an adjustable pattern with a phase distribution substantially corresponding to a combination of at least one quantile of normal distribution on at least one dimension (301); and a phase shifting zone support (320) limited in relation to the incident beam according to the dimension(s). The invention also relates to a system implementing several filters and a method for filter calculating.

Owner:OPTOGONE

Method for preparing evanescent mode by using 3DP printing technology

InactiveCN107790624AImprove adhesionOvercome speedAdditive manufacturing apparatusFoundry moulding apparatusShrinkage rateParaffin oils

The invention belongs to the technical field of 3D printing, and discloses a method for preparing an evanescent mode by using a 3DP printing technology. The computer three-dimensional modeling is performed according to the structural shape and size of an evanescent mode to be printed, and a three-dimensional model is divided into two-dimensional sections; PMMA powder is flatly paved in a 3DP printing platform; a binding agent-liquid phenolic resin is sprayed on the PMMA powder plane according to section information provided by the two-dimensional sections to finish printing of one layer; the height of the printing platform is lowered by one layer; a layer of PMMA powder is continuously and flatly paved on the surface of the printed layer; then, the binding agent is sprayed; the powder pavement and the spraying are repeated like this; the layers are superposed; a semi-finished model is obtained after printing; redundant powder around the semi-finished model is removed; and then, the semi-finished model is dipped in molten paraffin by 15-30 min, and is taken out for airing to obtain the evanescent mode. The evanescent mode with high molding precision and low product shrinkage rate can be obtained by the 3DP printing technology within shorter time.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com