Integral casting method for middle groove of scraper conveyer

A scraper conveyor and integral casting technology, which is applied in the field of sand casting technology and low-alloy high-strength cast steel, can solve the problems of inability to promote production, low casting compactness, large deformation of the central groove of the entire casting, etc., and achieve comprehensive product mechanics Excellent performance, short production cycle, and solve the effect of large deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

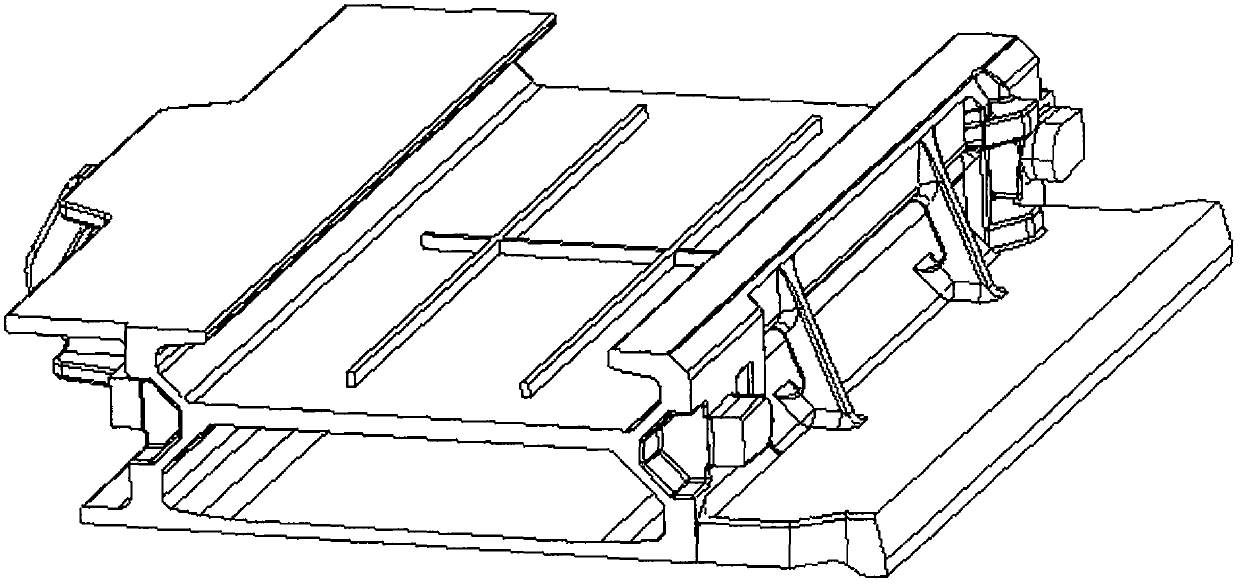

Image

Examples

Embodiment 1

[0013] (1) According to the characteristics of the sand casting process, the casting structure of the middle groove is designed. The bottom plate is provided with square holes, the number of which is 2, which is convenient for sand core fixing and exhaust, and is convenient for falling sand cleaning; the middle plate is provided with "H" shaped anti-deformation tie bars. Afterwards, the casting process design, pattern making, molding / core making are carried out. After the molding and core are completed, the sand mold inspection sample is used to test the dimensions of each part, and the box is assembled after passing the test.

[0014] (2) The smelting chemical composition is: 0.29% C, 1.31% Mn, 0.72% Si, 0.0043% B, trace Re, Ti, Nb.

[0015] (3) Before pouring, the sand mold is fixed on a platform at an angle of 8° to the ground, and poured obliquely.

[0016] (4) Casting normalizing pretreatment, the temperature is 920 ° C, heat preservation for 4 hours, air cooling, remove ...

Embodiment 2

[0019] (1) According to the characteristics of the sand casting process, the casting structure of the middle groove is designed, and the square hole is set on the bottom plate, the number is 3; the "H" shape anti-deformation tie bar is set on the middle plate. Afterwards, the casting process design, pattern making, molding / core making are carried out. After the molding and core are completed, the sand mold inspection sample is used to test the dimensions of each part, and the box is assembled after passing the test.

[0020] (2) The smelting chemical composition is: 0.30% C, 1.27% Mn, 0.76% Si, 0.0036% B, trace Re, Ti, Nb.

[0021] (3) Before pouring, the sand mold is fixed on a platform at an angle of 10° to the ground, and poured obliquely.

[0022] (4) Normalizing pretreatment of castings, temperature 900°C, heat preservation for 4 hours, air-cooling to room temperature to remove the process tie bars at the middle plate.

[0023] (5) Quenching treatment, temperature 900°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com