Powder evanescent mode casting paint and application method and application thereof

A lost-foam casting and coating technology, which is applied to casting molding equipment, coatings, casting molds, etc., can solve the problems of deteriorating coating performance, low drying strength, and poisonous formaldehyde, and achieve low packaging and transportation costs and reduce gas defects. , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

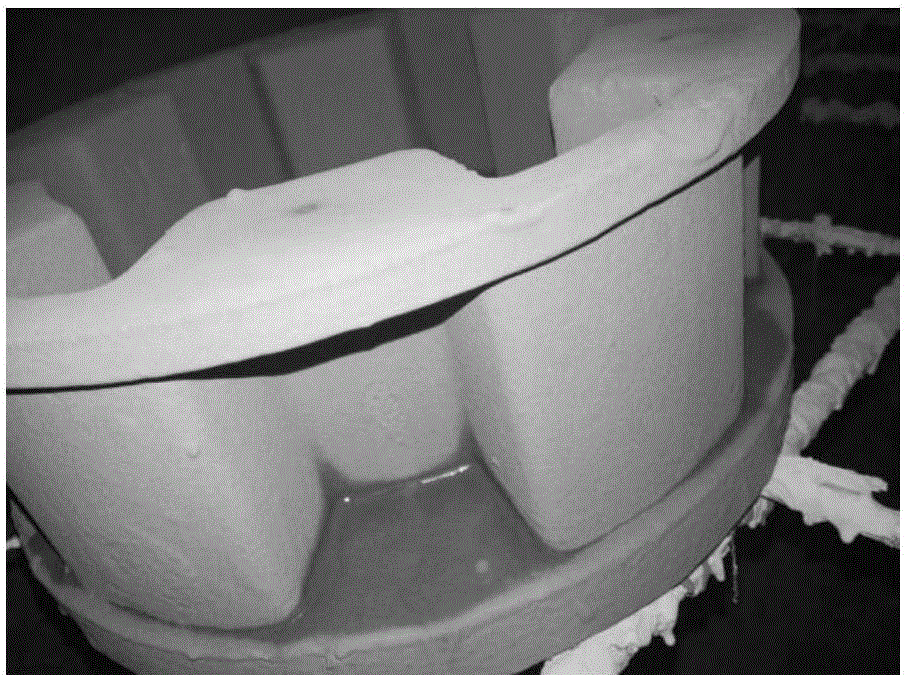

Image

Examples

Embodiment 1

[0028] (1) Prepare 65 kilograms of refractory powder zircon powder for subsequent use;

[0029] (2) Prepare 3 kilograms of sodium bentonite, 0.58 kilograms of polyvinyl alcohol, 0.6 kilograms of aluminum dihydrogen phosphate, 0.32 kilograms of sodium carboxymethyl cellulose, and 3.5 kilograms of expanded graphite, for subsequent use;

[0030] (3) Add the powder prepared in step (1) and step (2) into the blender and dry mix for 10 minutes until uniform, to obtain the finished powdery lost foam casting coating;

[0031] When in use, add water accounting for 37% by weight of the powdery paint into the mixer, start the mixer, slowly add the paint into the mixer, and continue stirring for 1 hour after adding the powder, and then it can be used.

[0032] After coating the surface of the foam model with paint, put it in a 50°C drying oven to dry for 3 hours, take it out, the surface of the coating is smooth and smooth, the coating has high strength at room temperature, and it cannot ...

Embodiment 2

[0034] (1) Prepare 70 kilograms of refractory powder zirconium powder for subsequent use;

[0035] (2) Prepare 3.5 kilograms of sodium bentonite, 0.61 kilograms of polyvinyl alcohol, 0.64 kilograms of aluminum dihydrogen phosphate, 0.25 kilograms of sodium carboxymethyl cellulose, and 3 kilograms of expanded graphite for subsequent use;

[0036] (3) Add the powder prepared in step (1) and step (2) into the blender and dry mix for 15 minutes until uniform, to obtain the finished powdery lost foam casting coating;

[0037] When in use, add water accounting for 28.2% by weight of the powder coating into the mixer, start the mixer, slowly add the powder coating into the mixer, and continue stirring for 1.5 hours after adding the powder to obtain the coating in use.

[0038] After coating the surface of the foam model with paint, put it in a 50°C drying oven to dry for 3 hours, take it out, the surface of the coating is smooth and smooth, the coating has high strength at room tempe...

Embodiment 3

[0040] (1) Prepare 72 kilograms of refractory powder zirconium powder for subsequent use;

[0041] (2) Prepare 3 kilograms of sodium bentonite, 1 kilogram of polyvinyl alcohol, 1.5 kilograms of aluminum dihydrogen phosphate, 0.3 kilograms of sodium carboxymethyl cellulose, and 3.2 kilograms of expanded graphite for subsequent use;

[0042] (3) Add the powder prepared in step (1) and step (2) into the blender and dry mix for 20 minutes until uniform, to obtain the finished powdery lost foam casting coating;

[0043] When in use, add water accounting for 23.5% by weight of the powder coating into the mixer, start the mixer, slowly add the powder coating into the mixer, and continue stirring for 2 hours after adding the powder to obtain the coating in use.

[0044] After coating the surface of the foam model with paint, put it in a 50°C drying oven to dry for 3 hours, take it out, the surface of the coating is smooth and smooth, the coating has high strength at room temperature, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com