Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

952results about How to "Low ash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

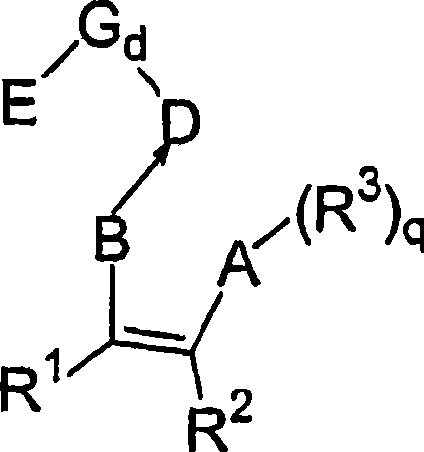

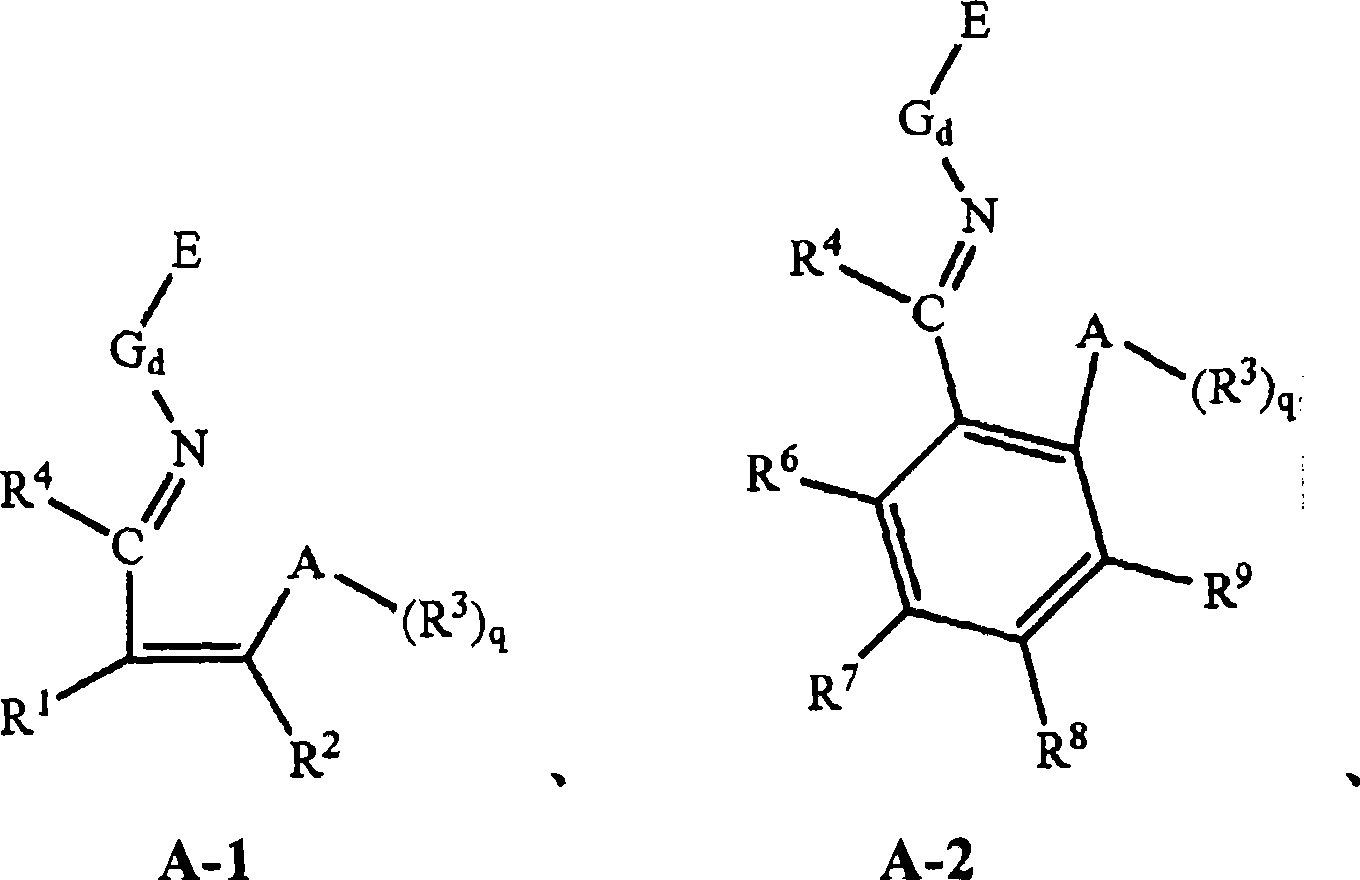

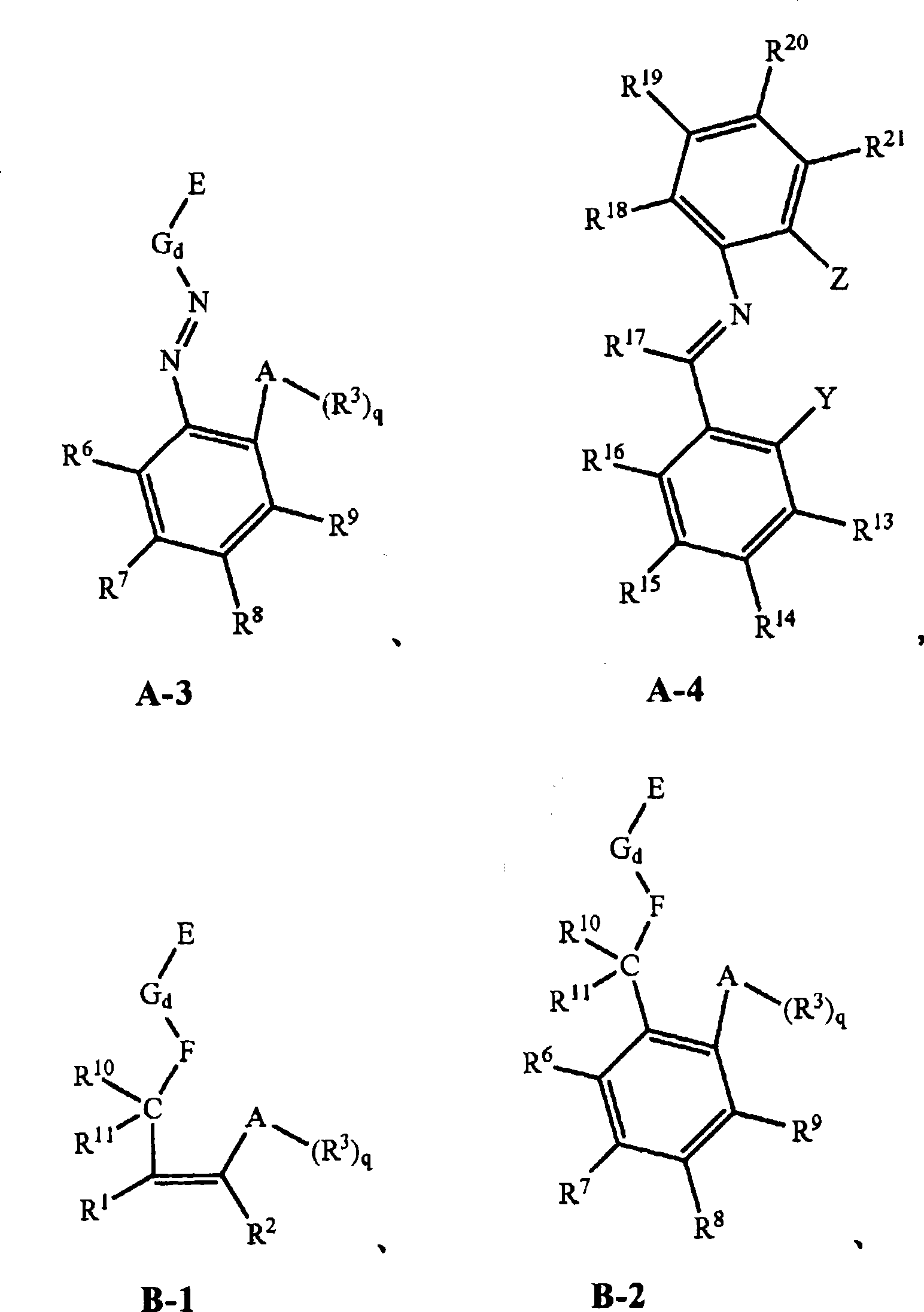

Magnesium compound load type non-metallocene catalyst and preparation thereof

The invention relates to a magnesium compound supported non-metallocene catalyst, which is obtained by directly contacting a compound of catalytic active metal and a magnesium compound containing a non-metallocene ligand through an in-situ supporting method. The preparation method for the magnesium compound supported non-metallocene catalyst has simple, feasible and flexible process, and has more adjustable parameters to the polymerization activity of the catalyst. When the supported non-metallocene catalyst and a catalyst promoter are adopted to form a catalytic system for the homopolymerization / copolymerization of olefins, the obtained polymer has high bulk density and low ash, and the molecular weight distribution of the polymer has wide adjustable range.

Owner:SINOPEC YANGZI PETROCHEM

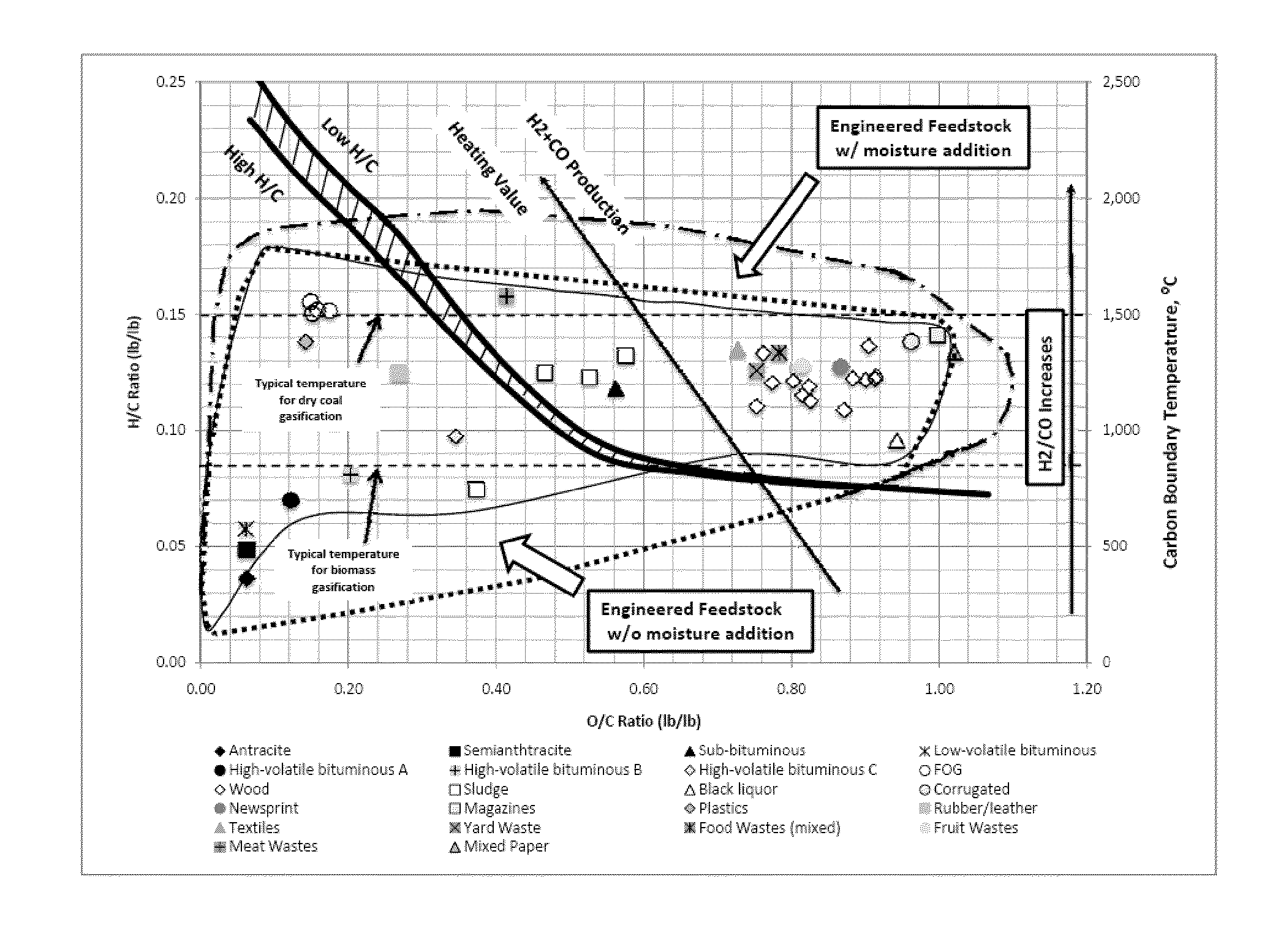

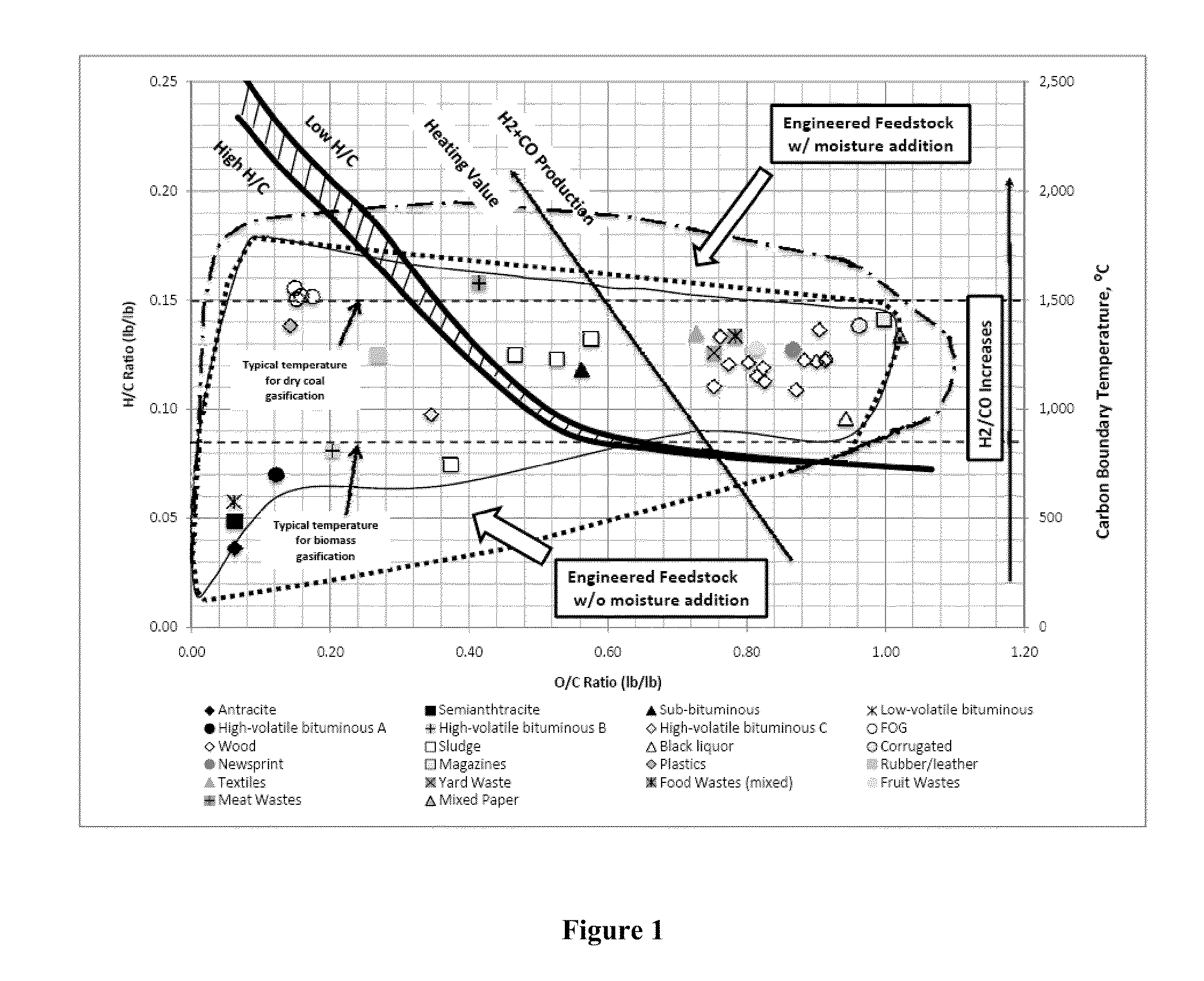

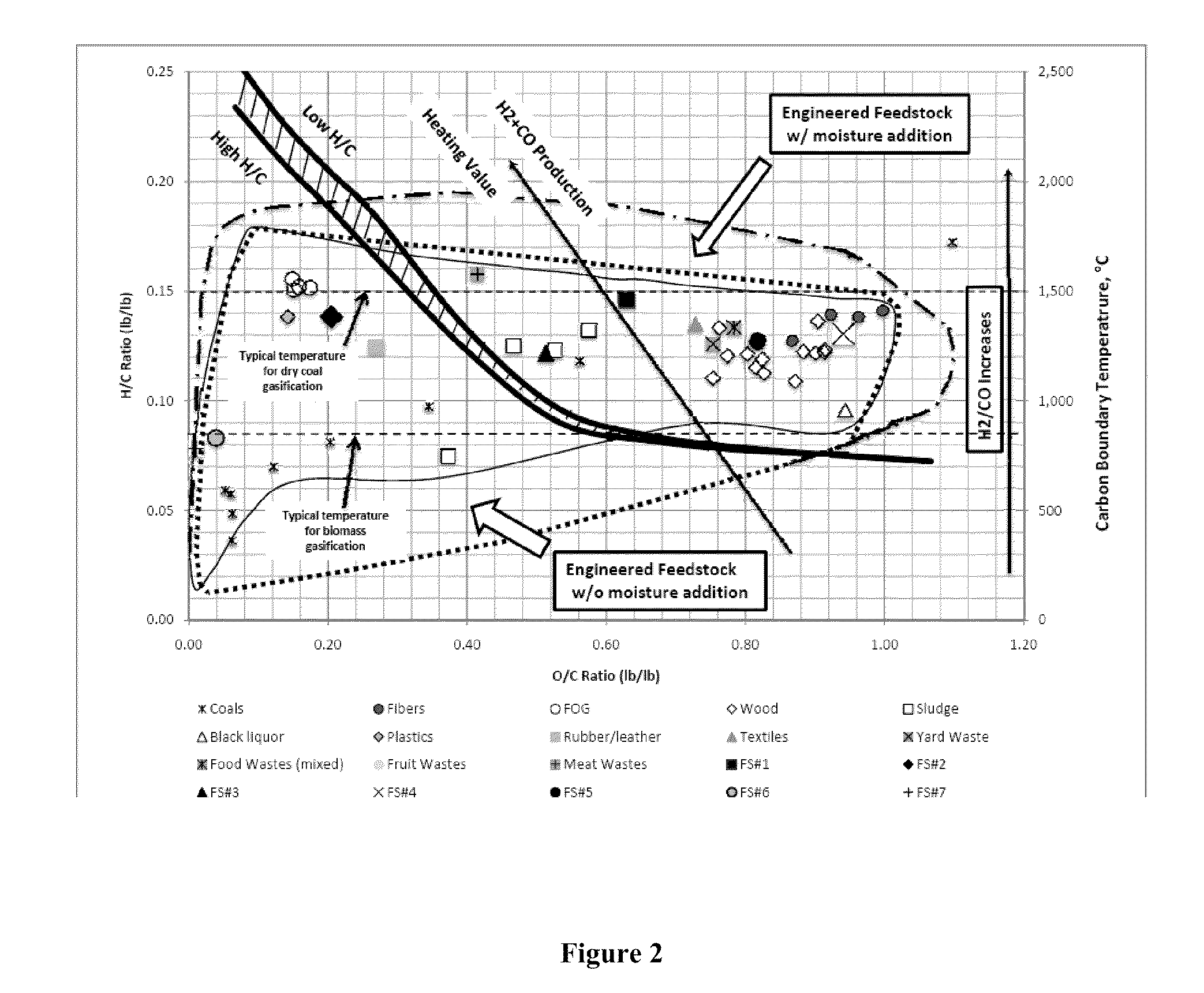

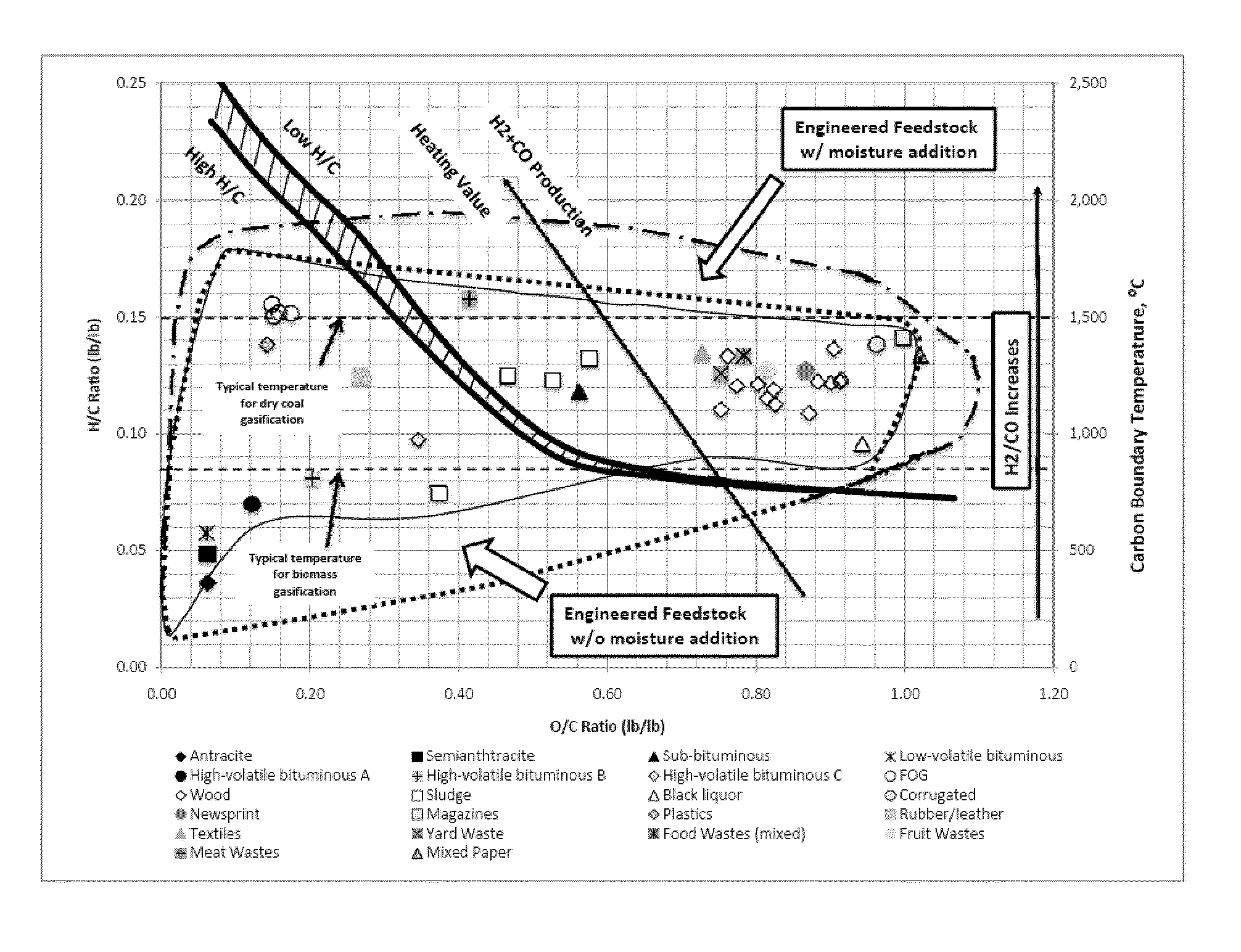

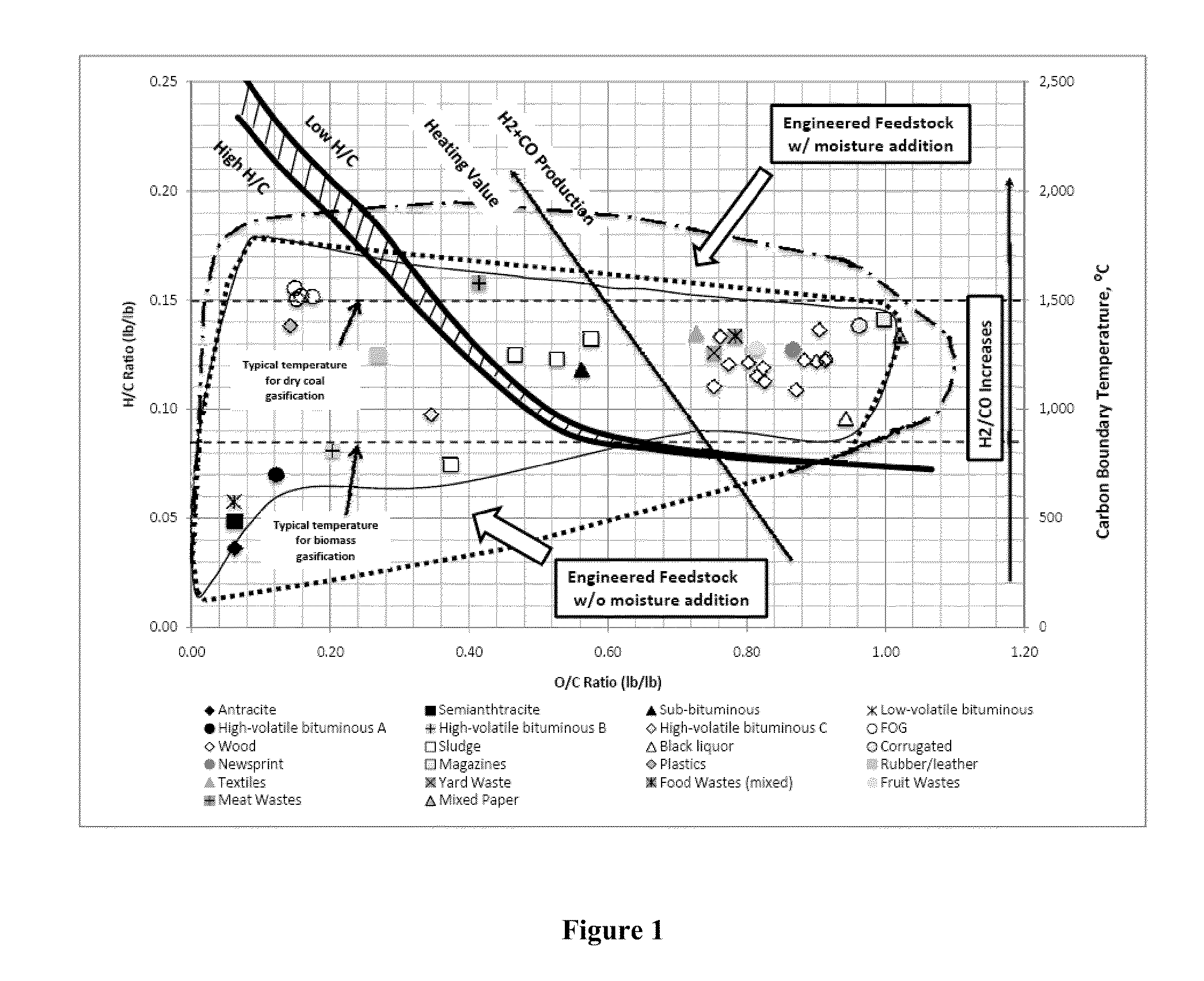

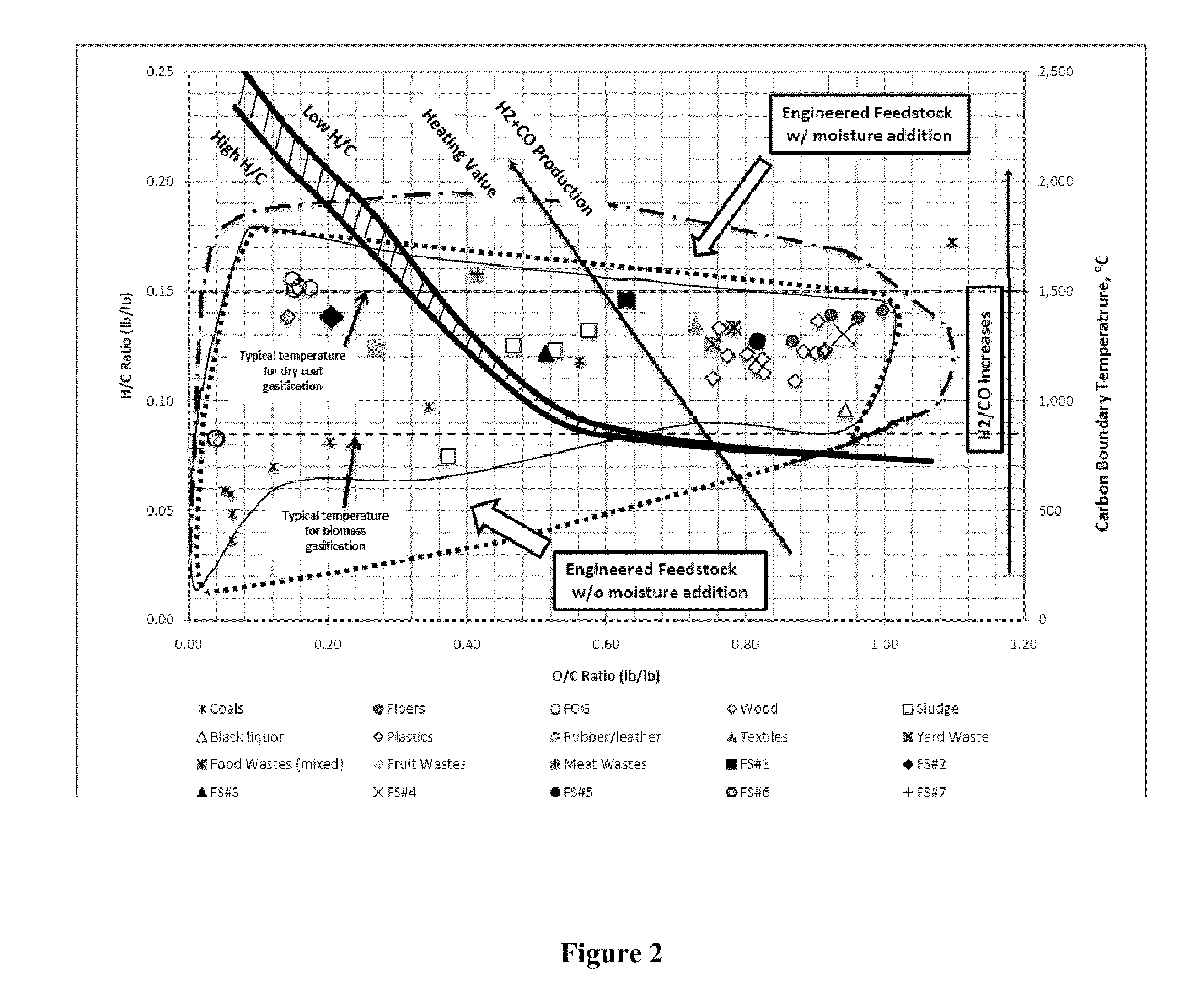

Engineered fuel feed stock useful for displacement of coal in coal firing plants

ActiveUS20100031560A1Reduce harm to the environmentQuality improvementMechanical working/deformationBiofuelsEngineeringCoal fired

Disclosed are novel engineered fuel feed stocks, feed stocks produced by the described processes, and methods of making the fuel feed stocks. Components derived from processed MSW waste streams can be used to make such feed stocks which are substantially free of glass, metals, grit and noncombustibles. These feed stocks are useful for a variety of purposes including co-firing with coal and as substitutes for coal.

Owner:REPOWER IP LLC

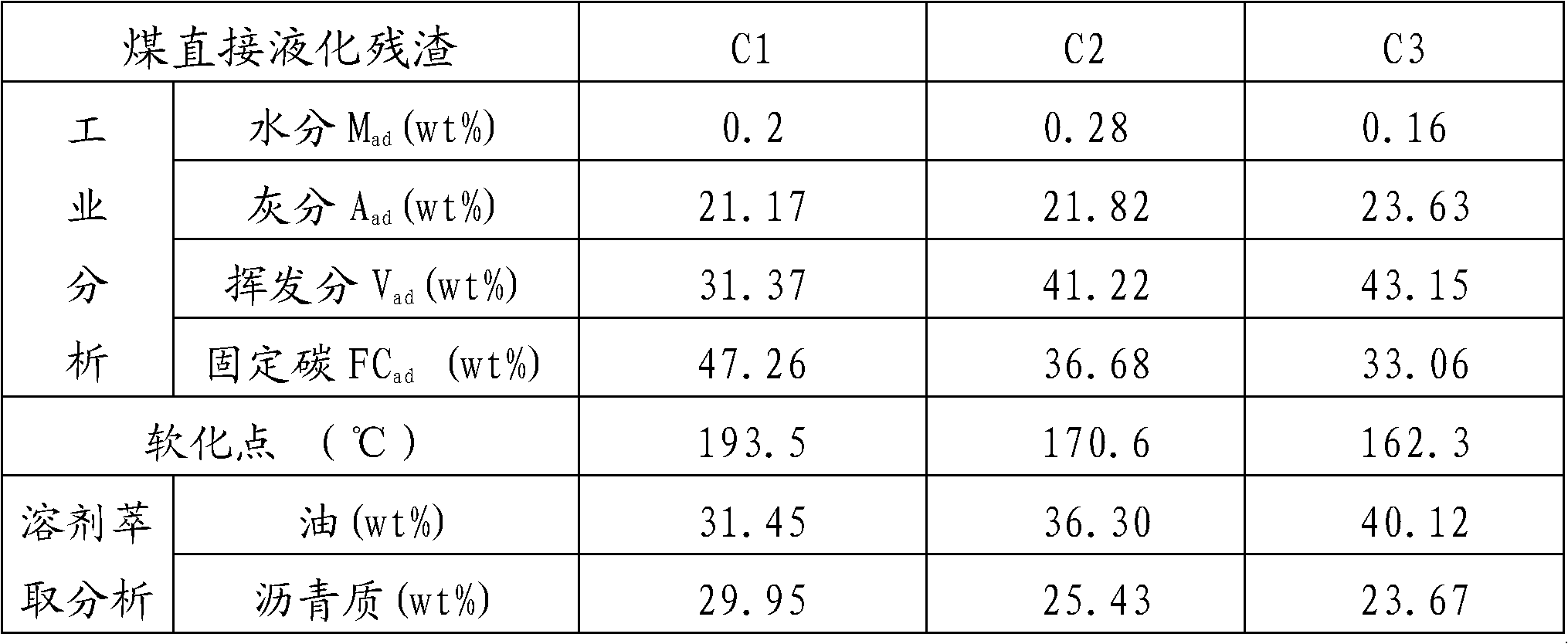

Method for preparing mesophase asphalt by coal liquefaction residue

ActiveCN101580729AHigh C/H atomic ratioLow ashWorking-up pitch/asphalt/bitumen by chemical meansSolventChemistry

The invention relates to a method for preparing mesophase asphalt by coal liquefaction residue. In the method, the coal liquefaction residue is ground, screened and dried, and is extracted at certain temperature for certain time by using organic solvent as extracting solvent; the extracted mixed liquor is filtered, purified and evaporated; the extracting solvent in the extract liquor is evaporatedto obtain refined coal liquefaction oil asphalt, thus obtaining the mesophase asphalt by charring for 4-10 hours in a high-pressure autoclave under the conditions of 410-460 DEG C, 3-4MPa of constantpressure and stirring. The method has simple process and convenient and safe operation, the mesophase asphalt with high quality is prepared and can be used as raw materials of high power and ultra high power graphite electrode, carbon fiber and the like.

Owner:CHINA COAL RES INST +1

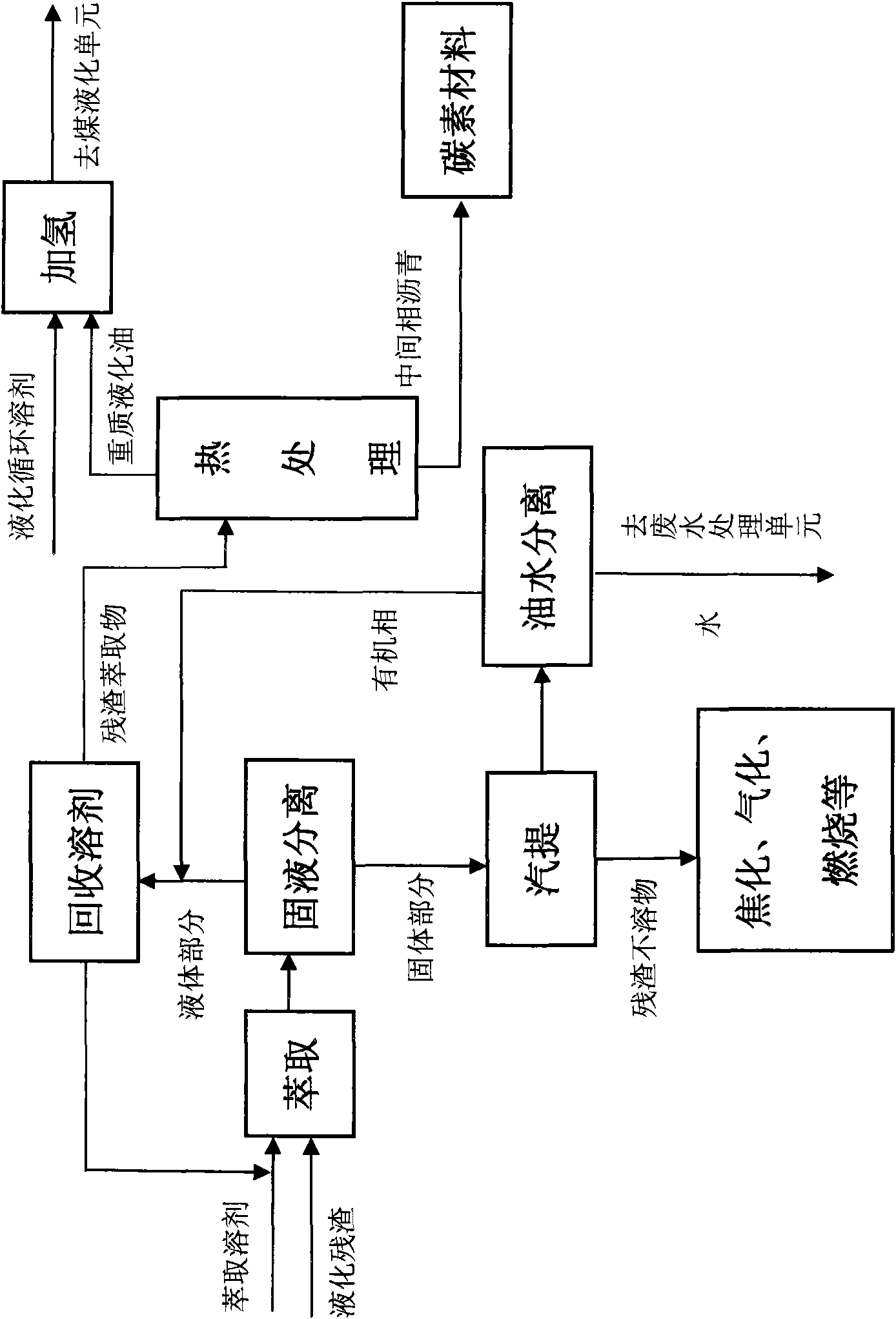

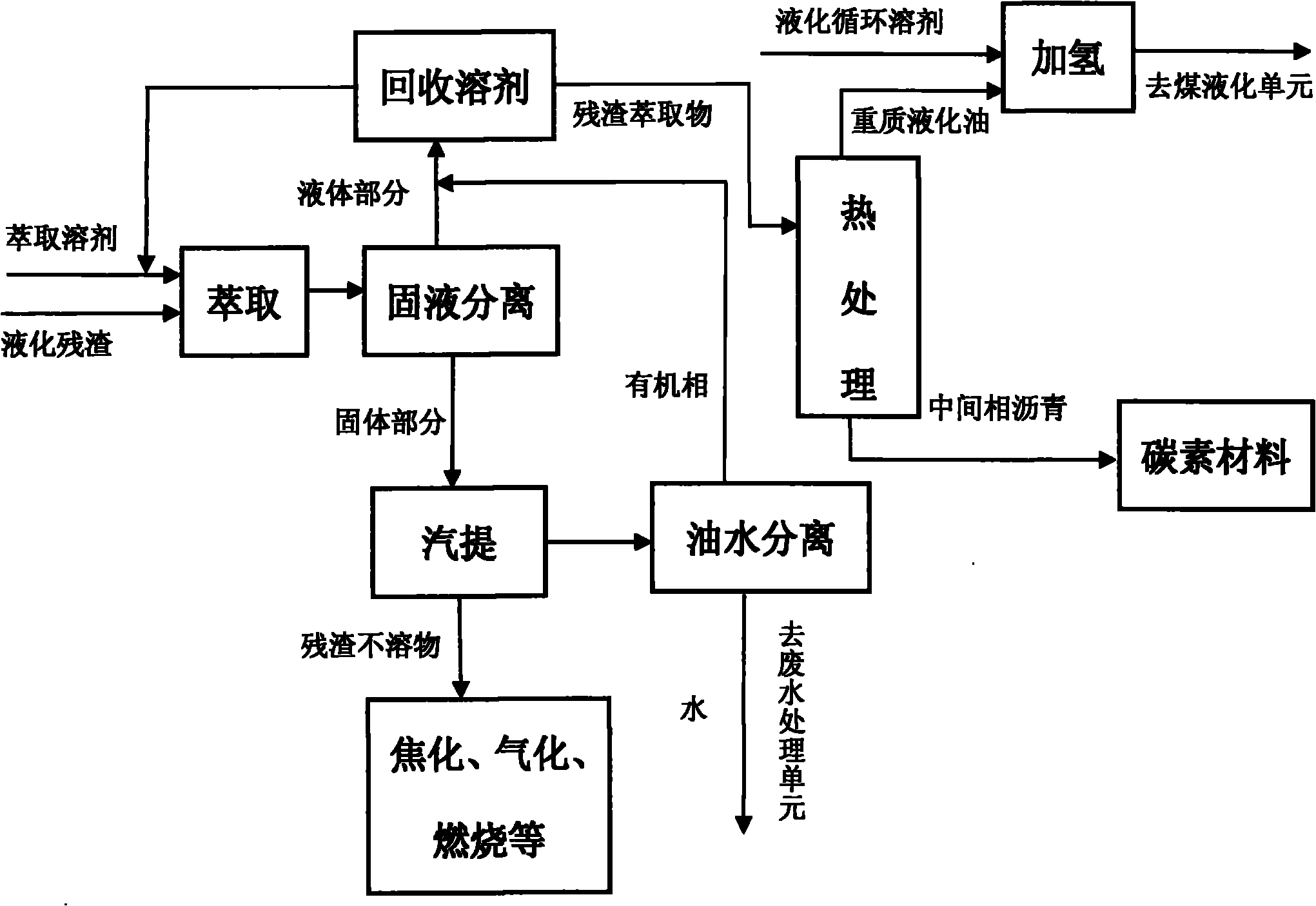

Method for extracting heavy liquefaction oil and intermediate-phase bitumen matter from coal liquefaction residuals and application thereof

ActiveCN101885976ARealize rationalityRealization of high value-added utilizationThermal non-catalytic crackingWorking-up pitch/asphalt/bitumen by selective extractionEvaporationOil water

The invention provides a method for extracting heavy liquefaction oil and an intermediate-phase bitumen matter from coal liquefaction residuals and application thereof. The method comprises the following steps of: adding coal liquefaction residual powder and an extraction solvent to a stirring kettle together for extraction to obtain extraction liquid and extraction residues; carrying out solid-liquid separation on the obtained extraction liquid and extraction residues; carrying out steam stripping on the obtained extraction residues, and recovering an organic phase after oil-water separation; mixing the extraction liquid with the organic phase, and then delivering into a solvent recovery unit; recovering the extraction solvent for recycling use or being returned to a liquefaction productprocessing unit by using a distillation method and / or an evaporation method, wherein residuals obtained after the extraction solvent is recovered are liquefaction residual extractives; delivering theobtained liquefaction residual extractives into a heat treatment unit, and separating the heavy liquefaction oil from the intermediate-phase bitumen matter by using a heating dry distillation method;and adding the obtained heavy liquefaction oil and other recycling solvents in a direct liquefaction process to a coal liquefaction solvent hydrogenation unit together.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Engineered fuel feed stock useful for displacement of coal in coal firing plants

ActiveUS8349034B2Less-harmful emissionEmission reductionMechanical working/deformationBiofuelsWaste streamEngineering

Disclosed are novel engineered fuel feed stocks, feed stocks produced by the described processes, and methods of making the fuel feed stocks. Components derived from processed MSW waste streams can be used to make such feed stocks which are substantially free of glass, metals, grit and noncombustibles. These feed stocks are useful for a variety of purposes including co-firing with coal and as substitutes for coal.

Owner:REPOWER IP LLC

Method for preparing carbon molecular sieve adsorbent

InactiveCN101596445ALow costReduce pollutionOther chemical processesAdsorption purification/separationPolymer scienceSorbent

The invention discloses a method for preparing a carbon molecular sieve adsorbent. The steps are as follows: (1) solidification: polymer is used as a raw material and is arranged in a thermostatic drying oven to be solidified; (2) dry distillation: the solidified macromoleclar polymer is pulverized by a pulverizer and then is processed by dry distillation; (3) fine pulverization: the macromoleclar polymer which is pulverized and processed by dry distillation is further processed by fine pulverization in the premise that the particle diameter of the macromoleclar polymer does not meet the requirement, and ball milling or gas milling is used for preparing micro-particles; (4) molding: the macromoleclar polymer which is processed by fine pulverization is mixed and uniformly stirred with agglomerant by mass ratio, and the mixture obtained is pressed and molded by an oil hydraulic press and then is dried; (5) carbonization and activation: under the state of N2 protection, temperature is raised for carbonization so as to increase the CMS surface area; and (6) carbon precipitation and hole adjustment: the hole adjustment agent is decomposed in the carbon molecular sieve for carbon deposition, the particle diameter is shortened and is enabled to be uniform, and the carbon molecular sieve product can be obtained after cooling. The carbon molecular sieve has the advantages of high CH4 adsorbing capacity, high selectivity factor of adsorption, favorable strength, low cost and no pollution, and the performance achieves or surpasses the standard of a sample of Japan carbon molecular sieve.

Owner:ANHUI UNIV OF SCI & TECH

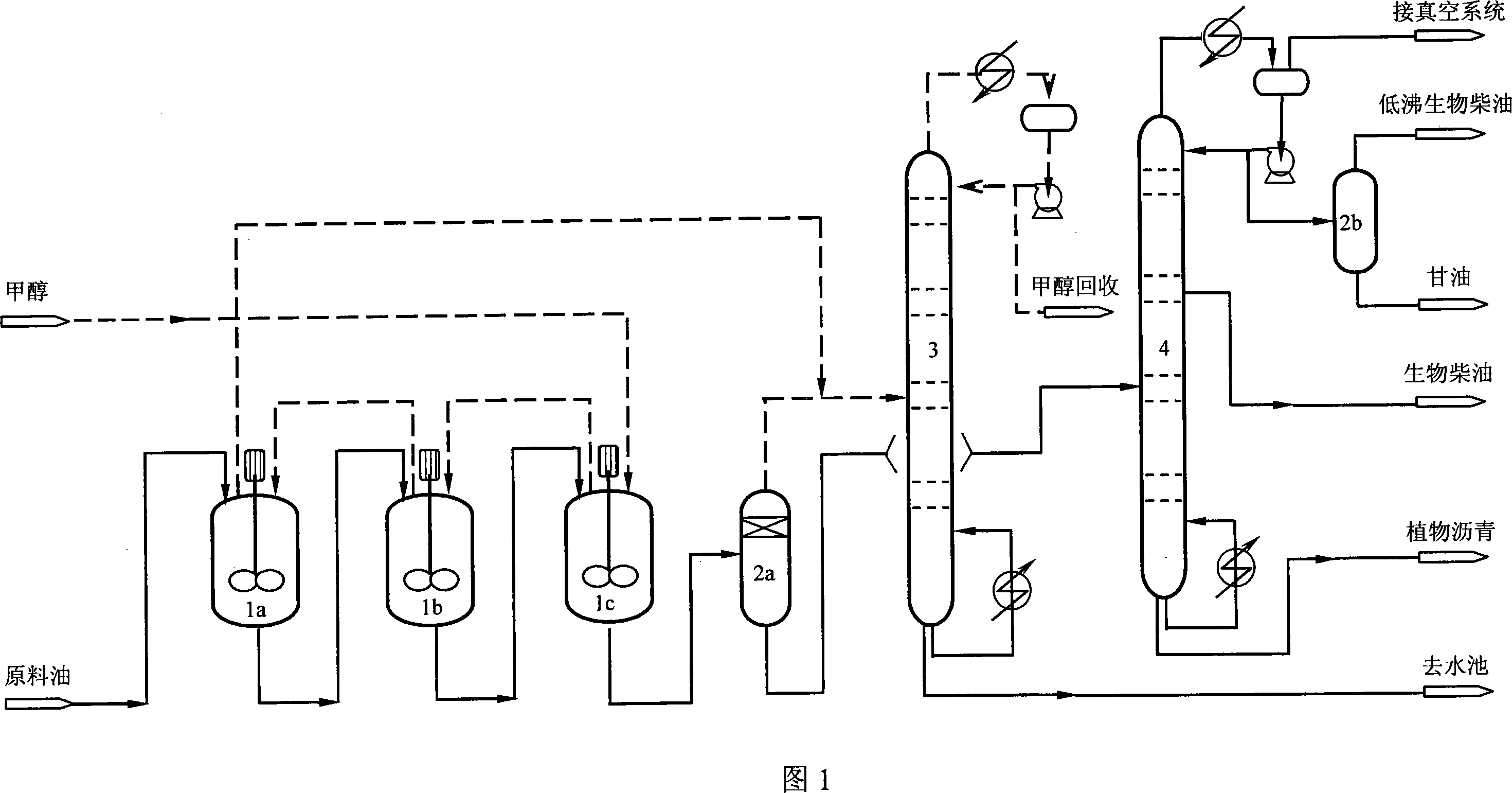

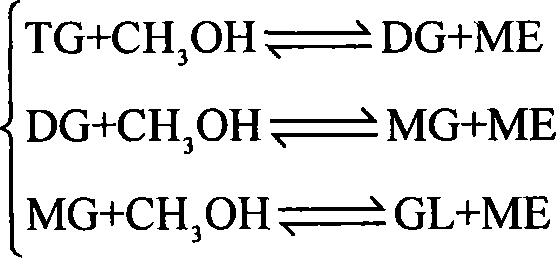

Solid catalysis process of preparing biodiesel oil continuously with high acid value material

InactiveCN101067091AHigh activityLow costPhysical/chemical process catalystsFatty acid esterificationOil and greaseRenewable energy technology

The present invention is solid catalysis process of preparing biodiesel oil continuously with high acid value material, and belongs to the field of grease chemistry and regenerable energy source technology. The process includes following four steps: material pre-treating, reaction, methanol rectifying recovery and vacuum rectification of fatty acid methyl ester; and features the high acid value material, such as acidified oil, waste edible oil, etc. The present invention has the advantages of low material cost, high activity and easy separation of the solid catalyst, high esterification efficiency, high product purity, high yield, less waste, no pollution, etc.

Owner:TSINGHUA UNIV +1

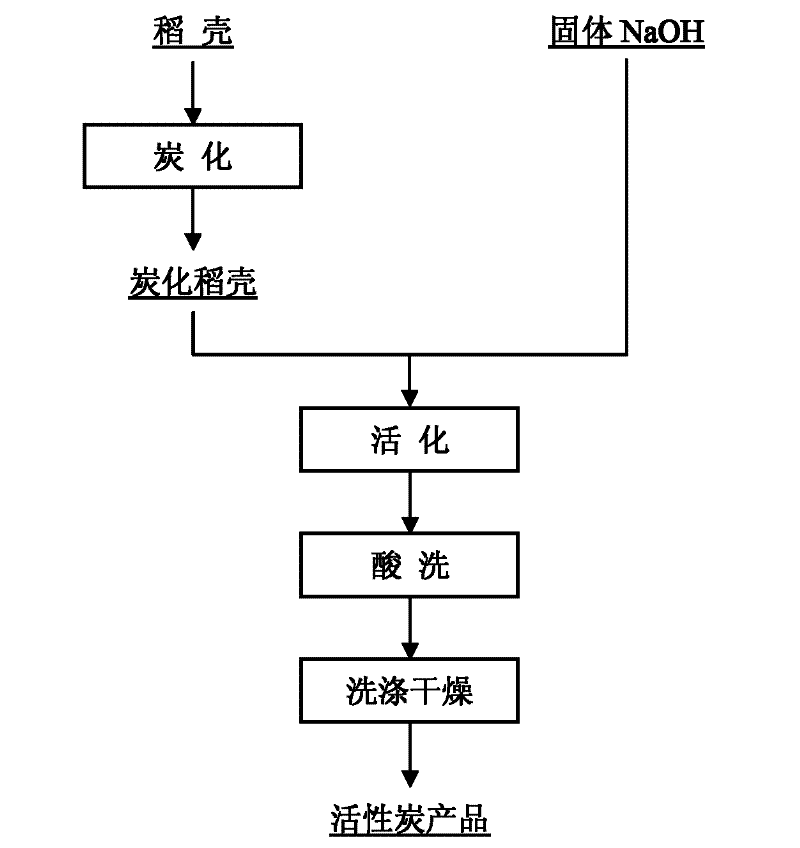

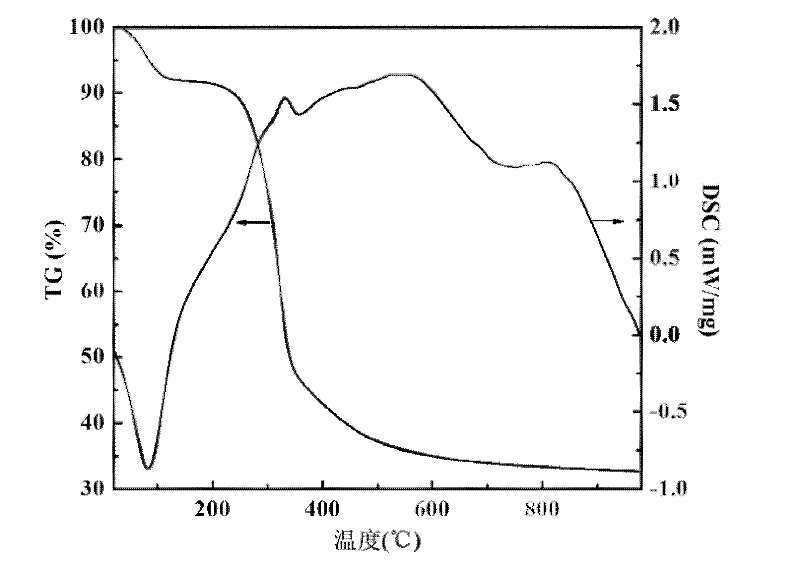

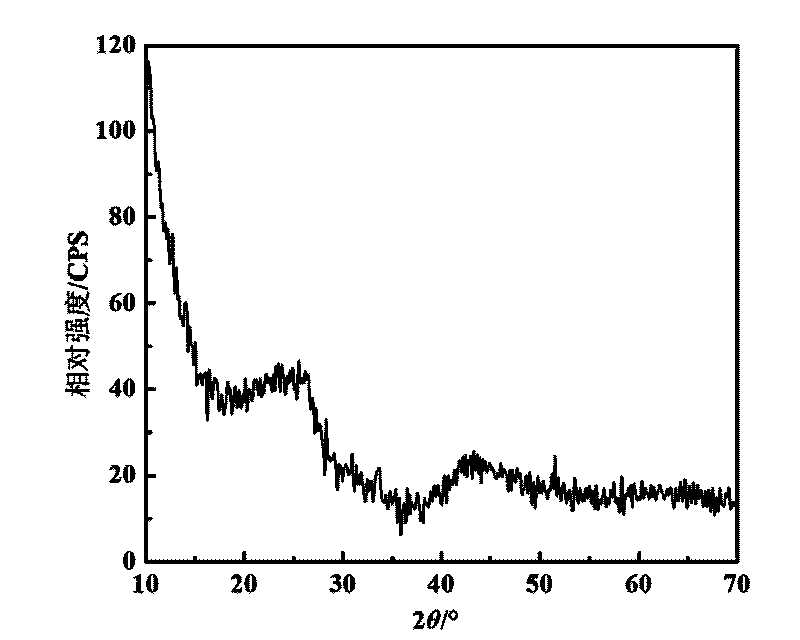

Method for preparing activated carbon

The invention relates to a method for preparing activated carbon. In the method, rice husks are taken as a raw material, NaOH is taken as an activator, and an activated carbon product is prepared through high temperature carbonization and activation, has high specific surface area, low ash content, a large number of distributed micropores, and high adsorption property, and is an ideal adsorption material, an ideal electrode material, an ideal hydrogen storage material and an ideal catalyst carrier. Alkaline solution is not required to be used for impregnation and activation, and the obtained product has a small particle size, has the characteristics of wide raw material source, low cost and simple process, is suitable for popularization, and has certain economic significance and environment-friendly significance.

Owner:CENT SOUTH UNIV

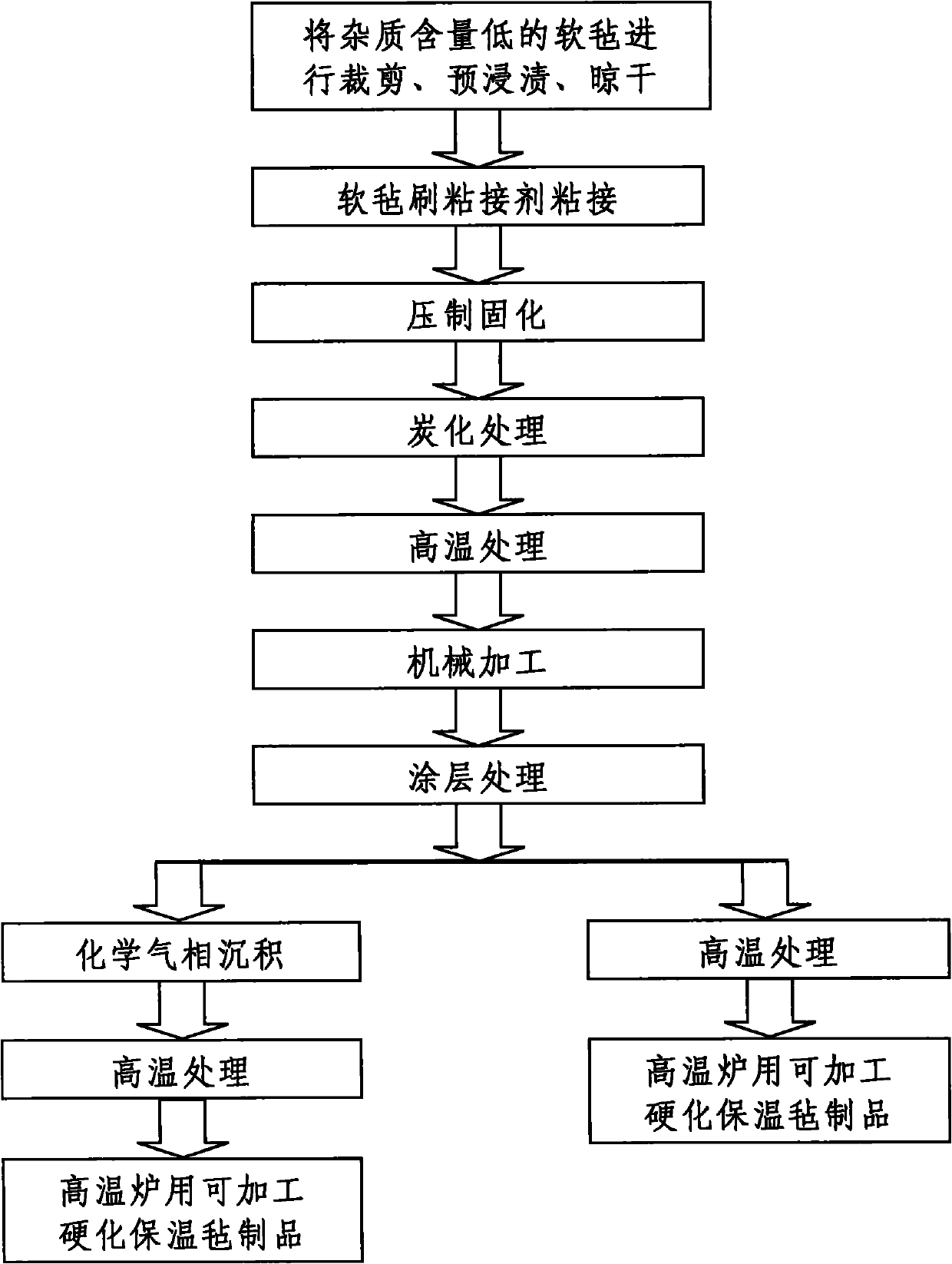

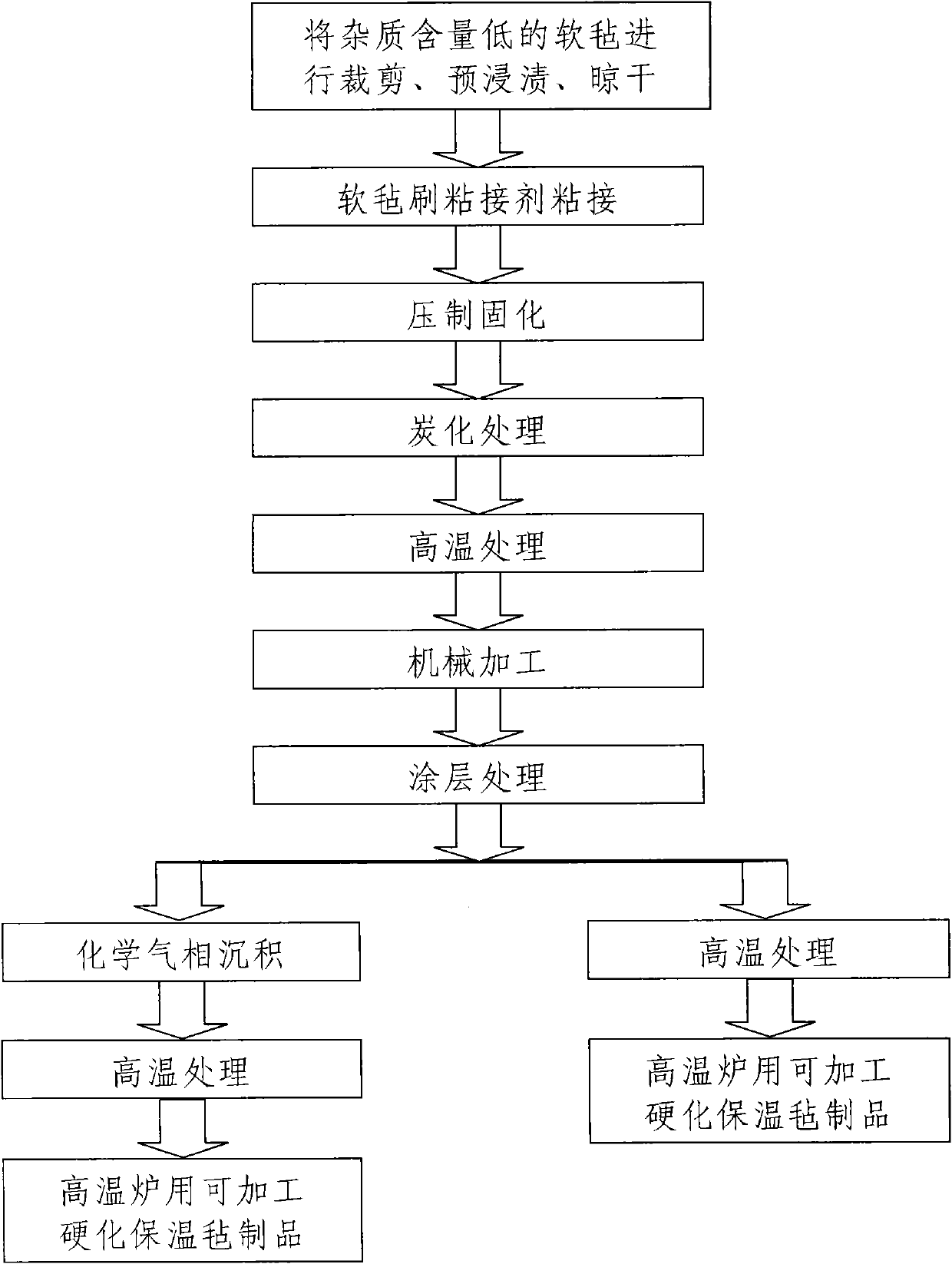

Method for preparing work hardening insulation quilt for high temperature furnace

The invention relates to a method for preparing a work hardening insulation quilt for a high temperature furnace, which comprises the following steps of: 1, cutting, pre-impregnating and airing a soft quilt; 2, adhering the soft quilt by using an adhesive; 3, pressing and curing for forming; 4, performing carbonization treatment; 5, performing high temperature treatment; 6, machining; 7, performing coating treatment; and 8, performing chemical vapor deposition treatment and high temperature treatment, or directly performing high temperature treatment to obtain the work hardening insulation quilt for the high temperature furnace. The method has the advantages of simple technological process and suitability for mass production; and the prepared work hardening insulation quilt has the heat conductivity of less than or equal to 0.5W / m.K, the ash content of less than or equal to 2,000ppm, high mechanical properties and high-temperature dimensional stability and excellent processability, does not generate volatile matters when used in the high temperature furnace, cannot pollute the product, and has important significance for prolonging the service life of the insulation quilt in the high temperature furnace.

Owner:XIAN CHAOMA SCI TECH

High-proportion coal blending and coking method

ActiveCN101942315ALow ashLow sulfurSpecial form destructive distillationProcess engineeringVitrinite

The invention relates to a high-proportion coal blending and coking method, wherein the coal blending varieties for coking used in the method comprises gas coal, fat coal, coking coal, lean coal and one third of coking coal. The coking method comprises the following steps: A. crushing raw coals separately, wherein crushed particle grade is less than 3mm, and the coal with particle size being lessthan 2mm accounts for more than 60% of the raw coal; and B. carrying out basic coal blending coking on the raw coals obtained in step A, wherein anhydrous ash-free basis volatile matter (Vdaf) of thebasic coal blending quality is 26.0-30.0%, the averagely maximum reflectance (MMR) of vitrinite is 1.0-1.1%, ash content (Ad) is less than 10.1%, total sulfur (St, d) is less than 1.1%, caking index (G) is more than 74, maximum thickness of a gelatine layer is more than 18mm and ratio between active components and inert components is 1.7-1.8. The coal blending coking method of the invention can enlarge coking coal source, lower ash content, sulfur content and phosphorus content in coke, reduce production cost of enterprises, increase economic benefit, improve competitiveness of enterprises, and achieve good comprehensive benefit.

Owner:CHINA SHENHUA ENERGY CO LTD +2

Precisive ornament casting moulding material

ActiveCN101074320AHigh hardnessLow shrinkageFoundry moulding apparatusMINERAL WAXMicrocrystalline wax

A precision-casting mold material for ornament consists of hydrogenated microcrystalline wax, paraffin, petroleum resin, high-molecular polymer, mineral wax and animal and vegetable wax. It has better bending strength, surface hardness, thermal stability, fluidity, reutilization and less linear shrinkage rate. It can be used for gold and silver ornaments.

Owner:CHINA PETROLEUM & CHEM CORP +1

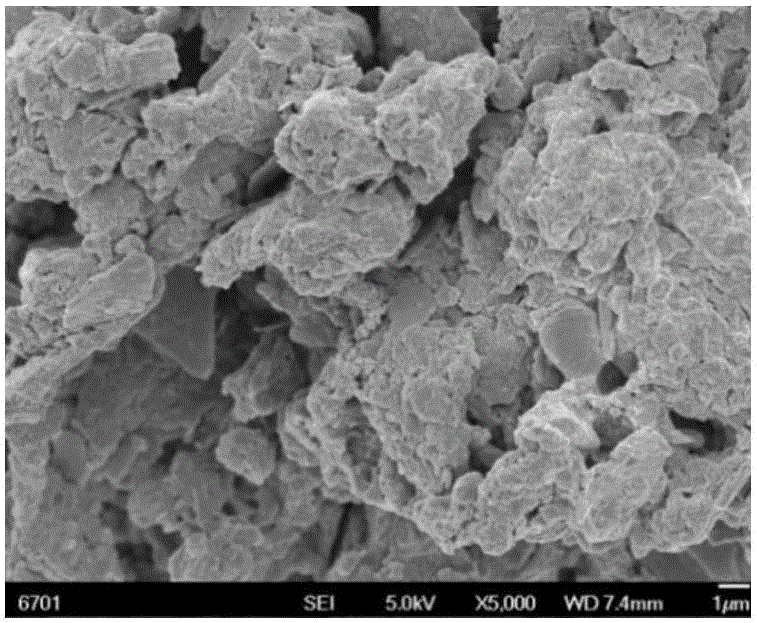

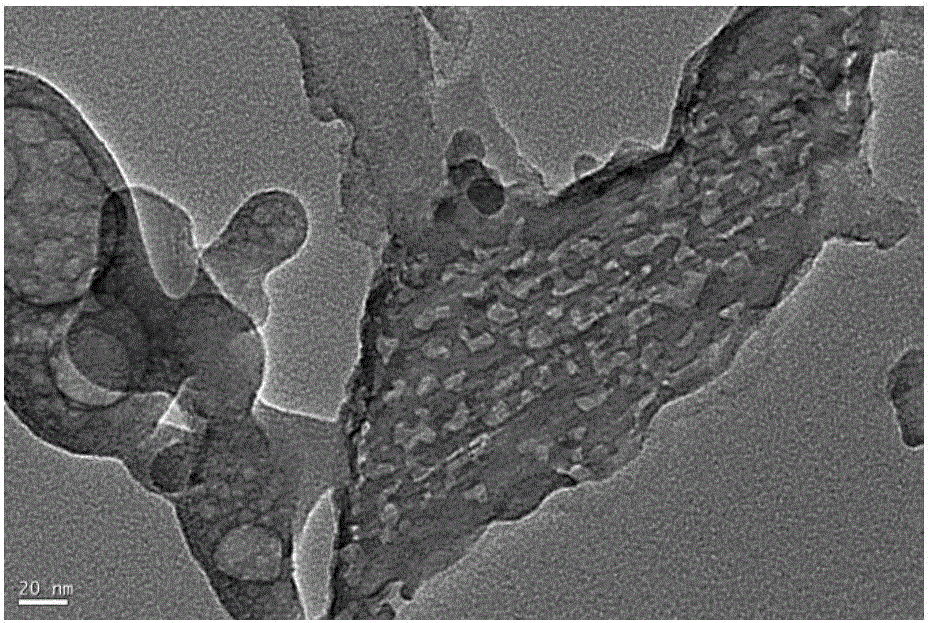

Method for preparing activated carbon by utilizing direct coal liquefaction residue

InactiveCN102153081AExpand sourceImprove coal liquefaction technologySolid waste disposalAcid washingCarbonization

The invention provides a method for preparing activated carbon by utilizing direct coal liquefaction residue as a raw material. The method includes the steps as follows: (1) adding smashed direct coal liquefaction residue together with KNO3, KOH and absolute alcohol into water, stirring to be uniform under room temperature, and later drying the obtained mixture to obtain a dry material; (2) placing the prepared dry material in a carbonization furnace, conducting preoxidation in the atmosphere of air, conducting carbonization-activation in the atmosphere of inertia gas, and then obtaining coarse activated carbon; and (3) acid-washing and deashing the prepared coarse activated carbon to obtain finished activated carbon. The method is simple in preparation process route, uses conventional equipment and has universality to the raw material. The obtained activated carbon has not only characteristics of high specific surface area, developed micropores and low ash content, but also controllable output, higher productivity, suitability for production in batches, and better technological and economic benefits.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Agricultural fibre fuel pellets

A method of preparing fuel pellets includes the steps of providing a feedstock in the form of agricultural hull fibres having a moisture content of about 10 to about 16%; and compressing and extruding the agricultural fibre feedstock through a die to obtain fuel pellets in the form of small cylinders having a diameter of about ⅜ inch to ¾ inch or more, said pellets having an ash content of about 1.1% to about 20% by weight and a calorific value of about 7,000 BTUs per pound of fuel on a dry basis. The agricultural hull fibres may be derived from all whole grains and seeds. For example, are comprised of at least one of corn bran fibre, rye bran fibre; oat bran fibre, rice bran fibre, soy bran fibre, canola bran fibre and wheat bran fibre. The method may include the step of pre-treating the agricultural whole grain and seed hull fibre feedstock with high temperature steam before being formed into pellets at a sufficient temperature and sufficient time to activate hemicellulose within the fibre as a binding agent. The method may include the step of mixing the agricultural whole grain and seed hull fibre feedstock with a sequestering agent before being formed into pellets for sequestering alkali metal vapors and raising the fusion point of the inorganic elements during combustion of the pellets. The sequestering agent may be calcium carbonate added in amounts up to about 0.5% by weight. The pellets contain additives comprised of ammonium nitrate, calcium, manganese, magnesium, aluminum, barium, iron, potassium and amorphous silicate, which sequester potassium and chlorides and alter the fusion point of the inorganic elements present in the fuel.

Owner:EVERGREEN BIOFUELS

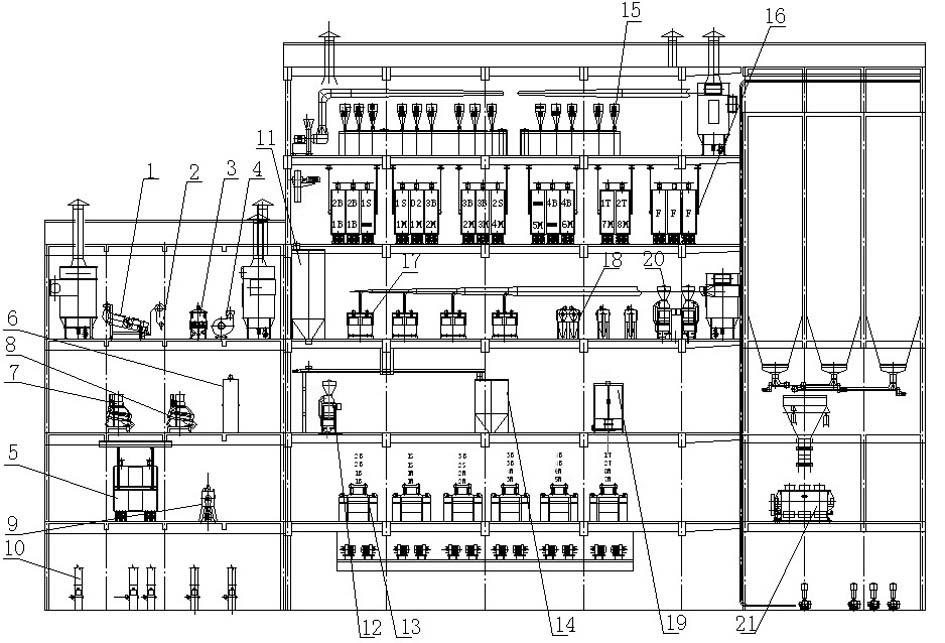

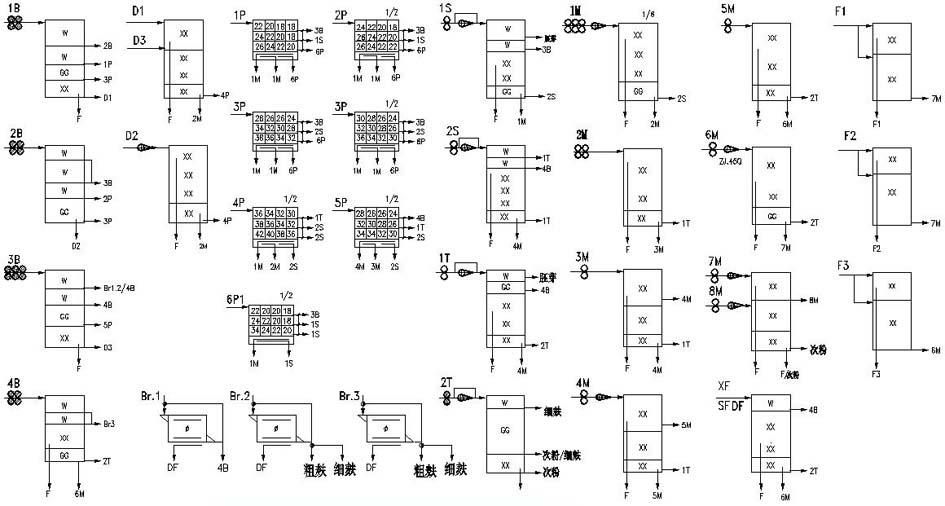

Wheat cleaning and classifying process for flour milling of stone grinder

InactiveCN101342502AReduce bran starLow ashGas current separationGrain millingFood safetyEngineering

The invention relates to a grading technique for cleaning wheat-grains during the process of flour milling by a stone mill. The technical process includes that the wheat grains in compliance with the flour processing quality are processed by a wheat-grain receiving system, a coarse wheat-grain clearing system, a tempering system and a wheat-grain cleaning system. A graded specific-gravity stoner, a suction separator and a screening device are used to clean and process the wheat-grains in a graded manner according to the quality, the lightweight and heavyweight of the wheat grains. Compared with the traditional cleaning techniques, the invention can effectively separate the heavy-weight and light-weight wheat grains; separate the epidermises and the matters attached on the wheat grains to the largest extent; lower the residue of pesticide and microorganism in the flour, and reduce the bran quantity and dust content in the flour; as a result, the purity of the milled material is ensured, the milling effect and flour yield are improved, and the flour processing precision and food safety are enhanced.

Owner:宁夏长湖实业有限公司

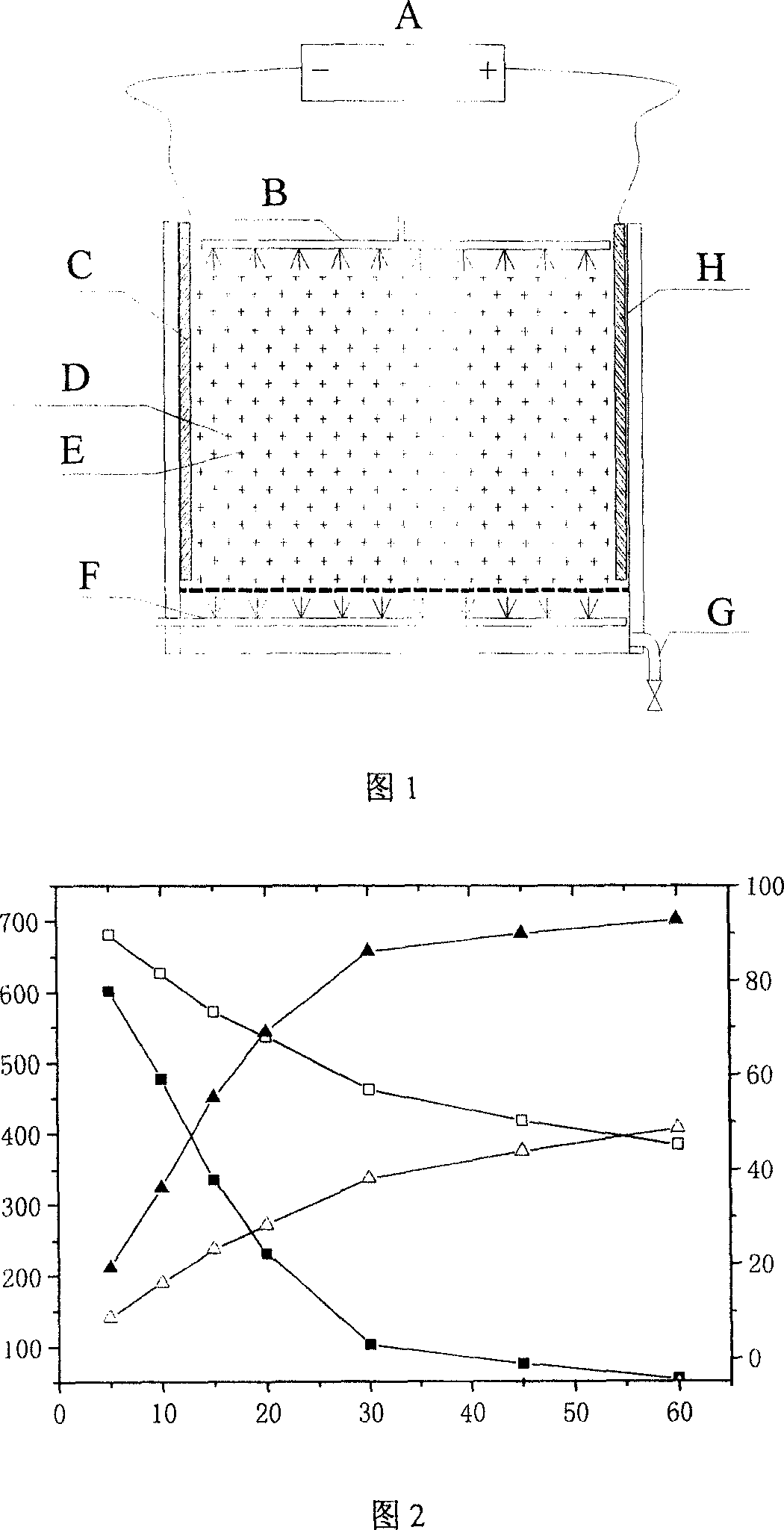

Granular electrode catalyst stuffing for 3D electrode reactor and its preparing method

InactiveCN1986434ALow ashLarge specific surface areaOther chemical processesWater/sewage treatment by electrochemical methodsFilm-coated tabletWater quality

The present invention is granular electrode catalyst stuffing for 3D electrode reactor and its preparation process. The electrode catalyst stuffing consists of modified active carbon 60-70 wt% and film coating active carbon 40-30 wt%. The modified active carbon is prepared with active carbon through acid or alkali modification, oxidizing modification and metal supporting modification; and the film coating active carbon is prepared with active carbon through acid or alkali modification and soaking in cellulose acetate solution. The 3D granular electrode stuffing is used in waste water treatment, and has the advantages of great adsorption capacity, fast reaction speed, stable treating effect, etc.

Owner:NANJING UNIV OF TECH

Grinding material for precision casting

The invention relates to a precise casting mold material, which comprises: petroleum wax, petroleum resin, high polymer, mineral wax and animal-plant wax. This product has high bending strength, superficial hardness, small linear shrinkage and ash, and well other properties, overcomes opposite in prior art, and fits to manufacture large-scale thin-wall integral fine-casting structure part.

Owner:CHINA PETROLEUM & CHEM CORP +1

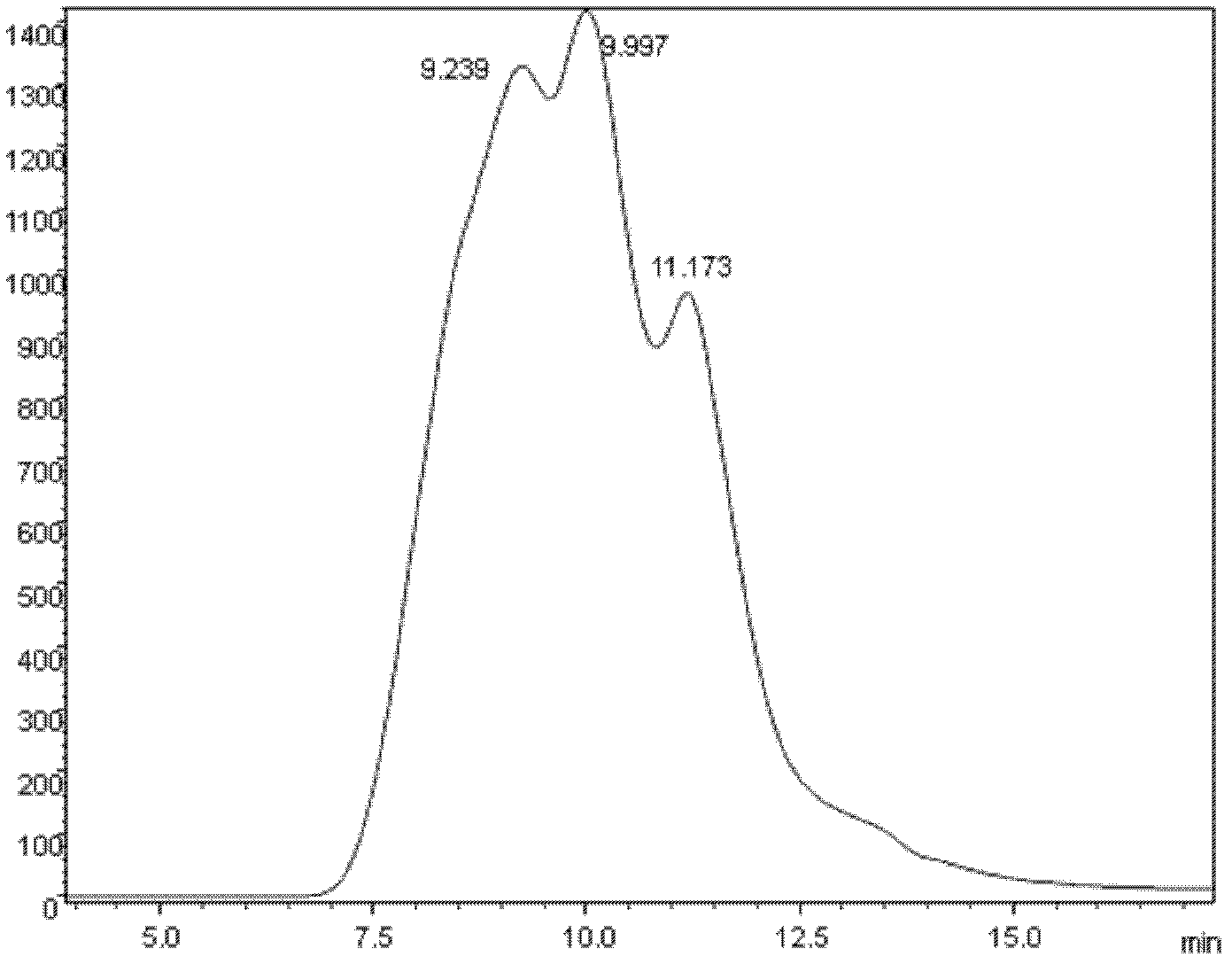

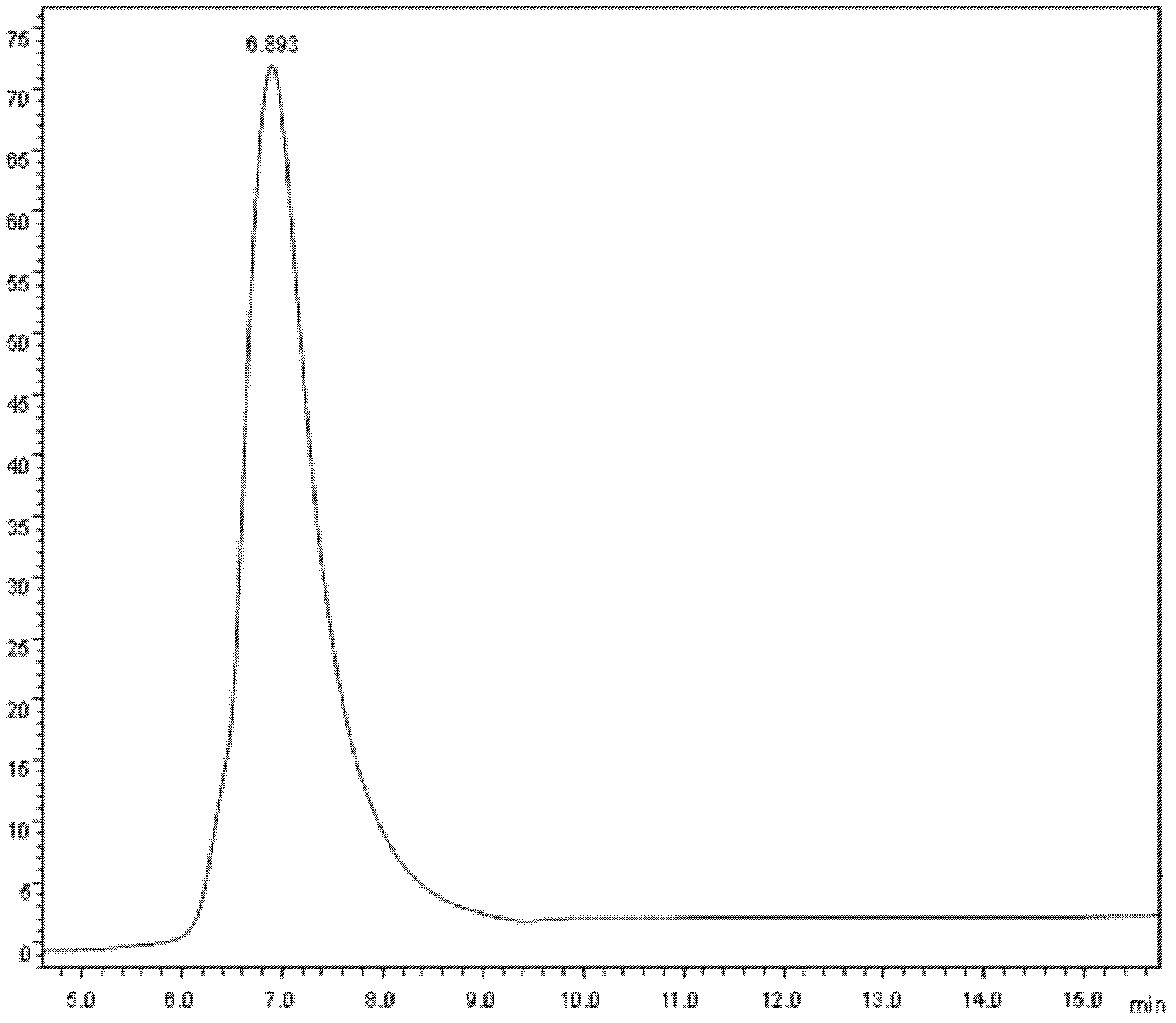

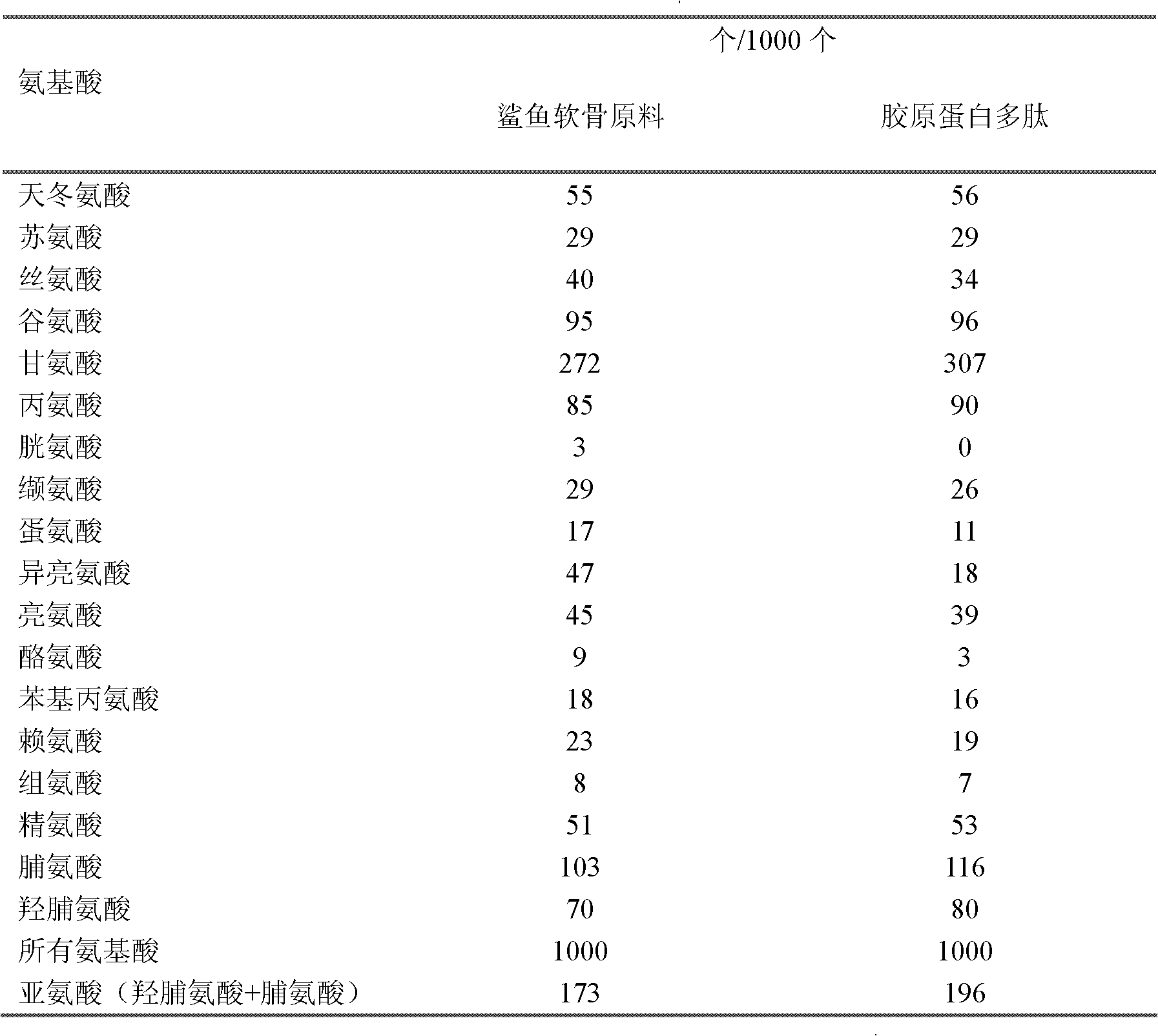

Method for preparing chondroitin sulfate and collagen polypeptide from animal cartilages

ActiveCN102533915ARealize high-value utilizationEfficient separation and extractionPeptide preparation methodsFermentationAlcoholUltrafiltration

The invention discloses a method for preparing chondroitin sulfate and collagen polypeptide from animal cartilages, which comprises the following steps: crushing animal cartilage materials to obtain cartilage powder; hydrolyzing the cartilage powder with protease, and then carrying out ultrafiltration and concentration to obtain a concentrated solution; passing the concentrated solution through an anion exchange resin column, and collecting an effluent solution A; eluting with pure water, and collecting a water washing solution B; merging the effluent solution A and the water washing solution B, carrying out ultrafiltration and concentration, and carrying out spray drying to obtain the collagen polypeptide; and eluting the anion exchange resin column with an NaCl solution, carrying out ultrafiltration and concentration on the eluent solution, carrying out alcohol precipitation, dehydrolyzing, and drying to obtain the chondroitin sulfate. The invention realizes the high-valued utilization of cartilage resources, can simultaneously and efficiently extract and separate the chondroitin sulfate and the collagen polypeptide, increases the added values of the products and reduces the environment pollution.

Owner:ZHEJIANG UNIV OF TECH

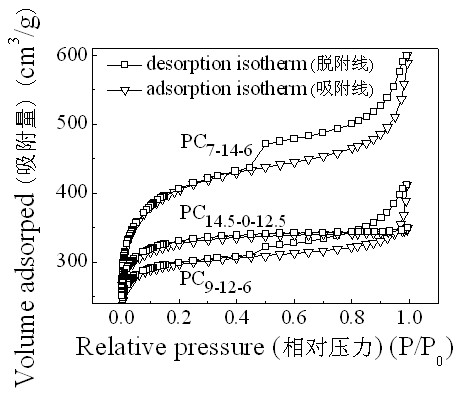

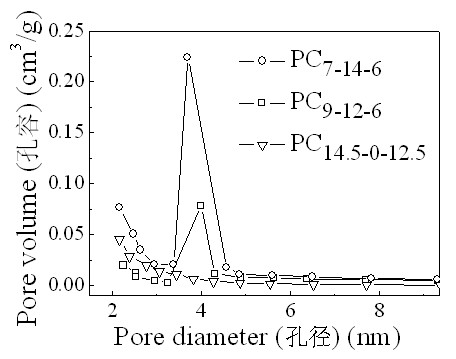

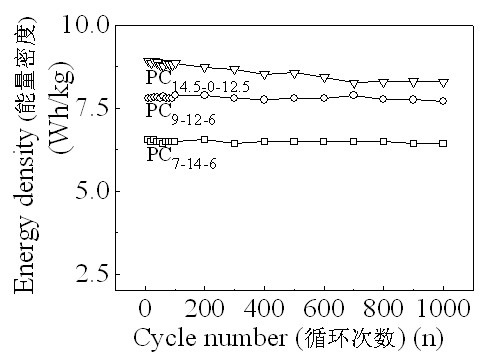

Method for preparing porous carbon material by using magnesium oxide template in cooperation with activation of potassium hydroxide

The invention discloses a method for preparing a porous carbon material by using a magnesium oxide template in cooperation with the activation of potassium hydroxide, and belongs to the technical field of carbon materials and microwave chemistry. The method comprises the following steps of: grinding coal tar pitch serving as a carbon source, nano magnesium oxide serving as a template and the potassium hydroxide serving as an activating agent; transferring the mixture to a corundum crucible; and putting into a microwave reactor, performing one-step microwave heating activation, and thus obtaining the porous carbon material for an electrochemical capacitor, wherein the specific surface area of the obtained porous carbon material is between 439 and 1,394m<2> / g, the total pore volume is between 0.23 and 0.94cm<3>, the average pore size is between 1.95 and 3.36mm, the ratio of the volume of a non-micro pore to the total pore volume is between 26.1 and 86.2 percent, and the porous carbon yield is between 37.8 and 84.9 percent. The invention has the advantages that: the method is quick and energy-saving; and the prepared porous carbon is used as an electrode material of the electrochemical capacitor and has extremely high stability and high comprehensive performance.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Modified blue-green algae biochar composite and application thereof to treatment of electroplating wastewater

ActiveCN110272085AHigh carbon contentLow ashWater treatment compoundsWater contaminantsBlue green algaeElectroplating wastewater

The invention discloses a modified blue-green algae biochar composite and application thereof to treatment of electroplating wastewater, and belongs to the technical field of preparation of biochar composite preparation. Blue-green algae in Taihu lake are dried, ground and sieved, then mixed with an activating agent and then subjected to thermal cracking to obtain modified blue-green algae biochar; the modified blue-green algae biochar is soaked in an iron-containing solution for further modification to obtain the modified blue-green algae biochar composite. The prepared modified blue-green algae biochar composite has the adsorption and catalysis capacity. The composite can efficiently remove metal ions in the wastewater through adsorption and Fenton-like reaction during the treatment of the electroplating wastewater. The composite is high in stability and can be repeatedly used.

Owner:JIANGNAN UNIV

Grouper bait and method for making same

InactiveCN1602723AStrong attractant effectStrong physical stimulationAnimal feeding stuffAccessory food factorsBiotechnologyBetaine

The invention pertains a kind of phagostimulant to rockfishes and other fishes, and its produce way. Materials by weight: animal protease 70-85%, nucleotide 2-10%, sulphocompound 0.4-3%, complex aminoacid 5-15%, betaine 2-20%, pigment 0.5-5%, oxidation preventive 0.1-0.5%. Production way: add animal protease after enzymolysis in oxidation preventive of 0.5-3% of fresh animal protease by weight; add by rate nucleotide, sulphocompound, complex aminoacid, betaine, pigment, oxidation preventive, mix and dry them, then the phagostimulant is made over. This phagostimulant can absorb sober of water animal effectually, promote growing, increase the ability of defeat disease, and increase the rate of living.

Owner:SUN YAT SEN UNIV

High-efficiency clean process for cleaning and graded milling of wheat

The invention relates to a food processing method, in particular to a high-efficiency clean process for cleaning and graded milling of wheat. The process comprises a wheat graded-cleaning process and a wheat graded-milling process. The wheat graded-cleaning process comprises two-pass stone removal, two-pass screening, one-pass air-suction separation and one-pass regrading. The wheat graded-milling process comprises four-pass breaking, seven-eight pass reduction, two-pass scratching, one-two pass tailing, and three-pass bran finishing. The invention has low investment, low energy consumption, high yield of high-quality flour and good sealability, and greatly improves the environment of wheat cleaning and milling workshops. The product has high whiteness, low ash content, and high competitiveness.

Owner:ZHEJIANG HENGLE GRAIN CO LTD

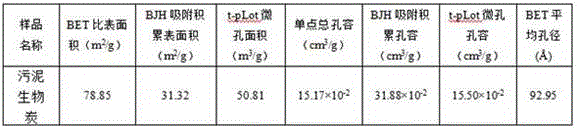

Sludge charcoal for repairing heavy metal contaminated soil and preparation method of sludge charcoal

InactiveCN106010542ASolve secondary pollutionSolve disposal problemsBiofuelsSpecial form destructive distillationSludgeSoil heavy metals

The invention belongs to the technical field of in-situ repair of heavy metal contaminated soil. Municipal sludge is used for preparing sludge-based charcoal through thermophilic thermolysis. The charcoal can be used as a repairing agent for the heavy metal contaminated soil. The sludge charcoal repairing agent comprises thickened sludge and palygorskite. A final black product namely the sludge-based charcoal is produced through the steps of performing biological and physical anhydration on sludge, then mixing the sludge after the biological and physical anhydration with the palygorskite, performing feeding into an atmosphere furnace, and then performing thermophilic thermolysis. The sludge charcoal is produced from the following components of 5-10% of the palygorskite and the balance of thethickened sludge. According to the sludge charcoal disclosed by the invention, the municipal sludge is subjected to decrement and harmless treatment, so that the municipal sludge can enter cycle of material and energy in natural environment again, and the difficult problem of treating and disposing the sludge is solved. The sludge charcoal is added to the heavy metal contaminated soil, so that heavy metal contaminated substances can be effectively solidified, the purposes of being durable and stable in repairing effect and being free from secondary pollution are realized, and the sludge charcoal is an ideal soil heavy metal contamination repairing agent with low cost.

Owner:LANZHOU JIAOTONG UNIV

Post-treatment process for preparing super-capacitor active carbon with super-low ash content

The invention relates to a post-treatment process for preparing super-capacitor active carbon with super-low ash content. According to the invention, by combining high-temperature and high-pressure characteristics of a hydrothermal technique, a method including the steps of alkali washing, acid washing and water washing is adopted, so that the content of ash content impurities in the active carbon is greatly reduced and the active carbon becomes a high-performance electrode material which is high in electrical conductivity and strength and is applicable to a super capacitor. A buckle type super capacitor which is manufactured by the active carbon refined by the post-treatment process has the advantages of low resistance, small leakage current and long cycling life.

Owner:CENT SOUTH UNIV

Active carbon used for adsorbing and removing sulfides in gasoline, and preparation method thereof

ActiveCN102188954AHighly selective adsorptionLow ashOther chemical processesHydrocarbon oils refiningHydration reactionAdhesive

The invention relates to active carbon used for absorbing and removing sulfides in gasoline, and a preparation method thereof. The active carbon is composed of the following components in percentage by weight: 40-70% of petroleum coke, 10-50% of coal, 10-30% of adhesive, 0.1-10% of pore forming agent and 0.1-10% of amodifier, wherein the ash content of the petroleum coke is less than 1%; the coalis anthracite or bituminous coal with volatile content less than 35%; the adhesive is one of or the mixture of coal pitch, coal tar, vacuum residue, coked condensed oil, ethylene cracked residue, catalytic slurry, petroleum pitch and petroleum pitch oxide; the pore forming agent is one of or the mixture of carbon black containing active functional groups and active elements, furfural residue, ferrocene, furfuryl alcohol and potassium; and the modifier is a hydrate nitrate of Cr, Fe, Co, Ni, Mo, Ti, Cu or Zn. The active carbon has the characteristics of low ash content, high strength, high selectivity, excellent adsorption performance and the like.

Owner:PETROCHINA CO LTD

Coal blending and coking method for metallurgical coke

The present invention relates to coal blending and coking method for metallurgical coke, and especially the coal blending and coking method with thermal coal and weakly caking coal. The present invention adopts conventional coking process and the coal consists of weakly caking coal 0-15 wt%, thermal coal 0-10 wt%, gas coal 13-45 wt%, fatty coal 9-20 wt% and coking coal 40-45 wt%. The produced coke has dropping strength M40 of 77-78.5 %, abrasion resistance strength M10 <8.6 %, reactivity of 35-37 %, thermal state strength of 45-55 %, and granularity of 25-40 mm and 40-80 mm, and meets the requirement for iron smelting in blast furnace of 1000 cubic meter or larger. The present invention has expanded coal variety range for coking, and lowered coking cost.

Owner:武钢集团有限公司

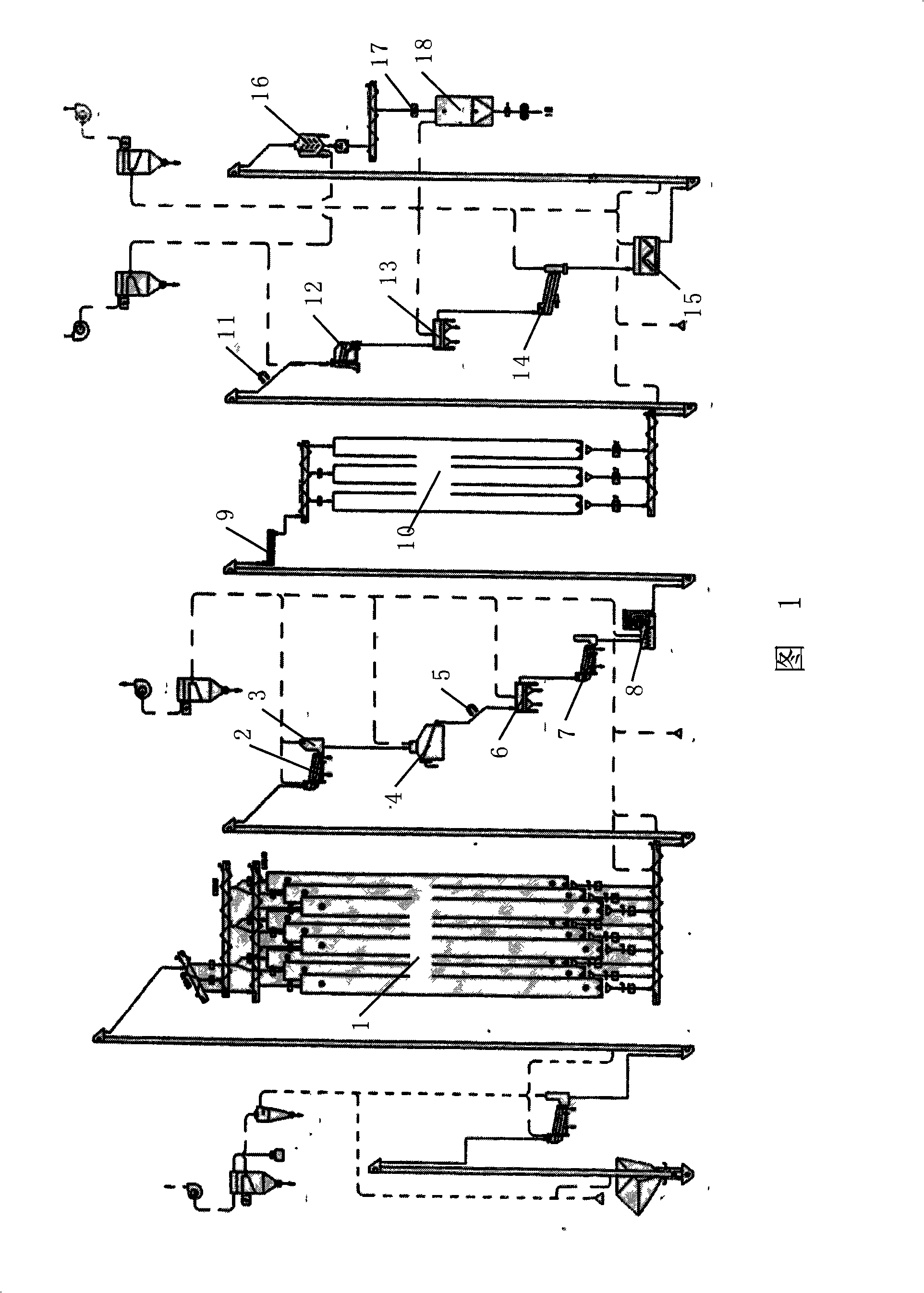

Method for manufacturing integral heater for carbon/carbon polycrystalline silicon ingot furnace

InactiveCN101905977AReduce consumptionMeet production requirementsSilicon compoundsCarbon compositesCarbonization

The invention discloses a method for manufacturing an integral heater for a carbon / carbon polycrystalline silicon ingot furnace. The method comprises the following steps of: winding carbon cloth or needled carbon felts on which resin is painted on a steel mold core layer after layer to obtain a prefabricated body; performing pressurized curing, carbonization and chemical vapor deposition densification treatment until the density of a heater product is more than or equal to 1.50 g / cm<3>; performing machining to achieve a shape and a size required by a customer; and performing high temperature purification treatment through a chemical vapor deposition (CVD) silicon carbide protective layer to obtain the integral heater for the carbon / carbon composite polycrystalline silicon ingot furnace. Compared with the conventional carbon material heater, the raw material consumption of the integral heater is lowered by over 90 percent; and a CVD surface deposition silicon carbide protective layer is formed on the surface of the product, so that corrosion of silicon steam, oxygen and the like on the product is blocked and service life is prolonged by at least more than one time.

Owner:HUNAN NANFANG BOYUN NOVEL MATERIAL

Purification process for vulcanization accelerator 2-mercaptobenzothiazole

The invention relates to a purification process for vulcanization accelerator 2-mercaptobenzothiazole, which includes that crude 2-mercaptobenzothiazole molten pulp prepared through high-temperature high-pressure condensation is directly led into an extraction kettle filled with organic solvents after complete replacement with nitrogen in advance; impurities are removed by conducting liquid-liquid extraction reaction; the temperature of the extraction kettle is kept no more than 50 DEG C in the process of extraction; mass ratio of the organic solvents to the crude 2-mercaptobenzothiazole molten pulp is (2-10) : 1; after extraction is finished, mixture inside the extraction kettle is filtered; obtained filter cakes are dried so as to obtain the vulcanization accelerator 2-mercaptobenzothiazole; the organic solvents recycled by distilling obtained filter liquor can be reused; and organic solvents evaporated in the extraction process condensate and flow back, and non-condensable gas is recycled by using active carbon to absorb the non-condensable gas. The purification process has safe extraction, shortens process flow, saves labor, material resources and energy sources, and can obtain high-purity vulcanization accelerator 2-mercaptobenzothiazole.

Owner:山东戴瑞克新材料有限公司

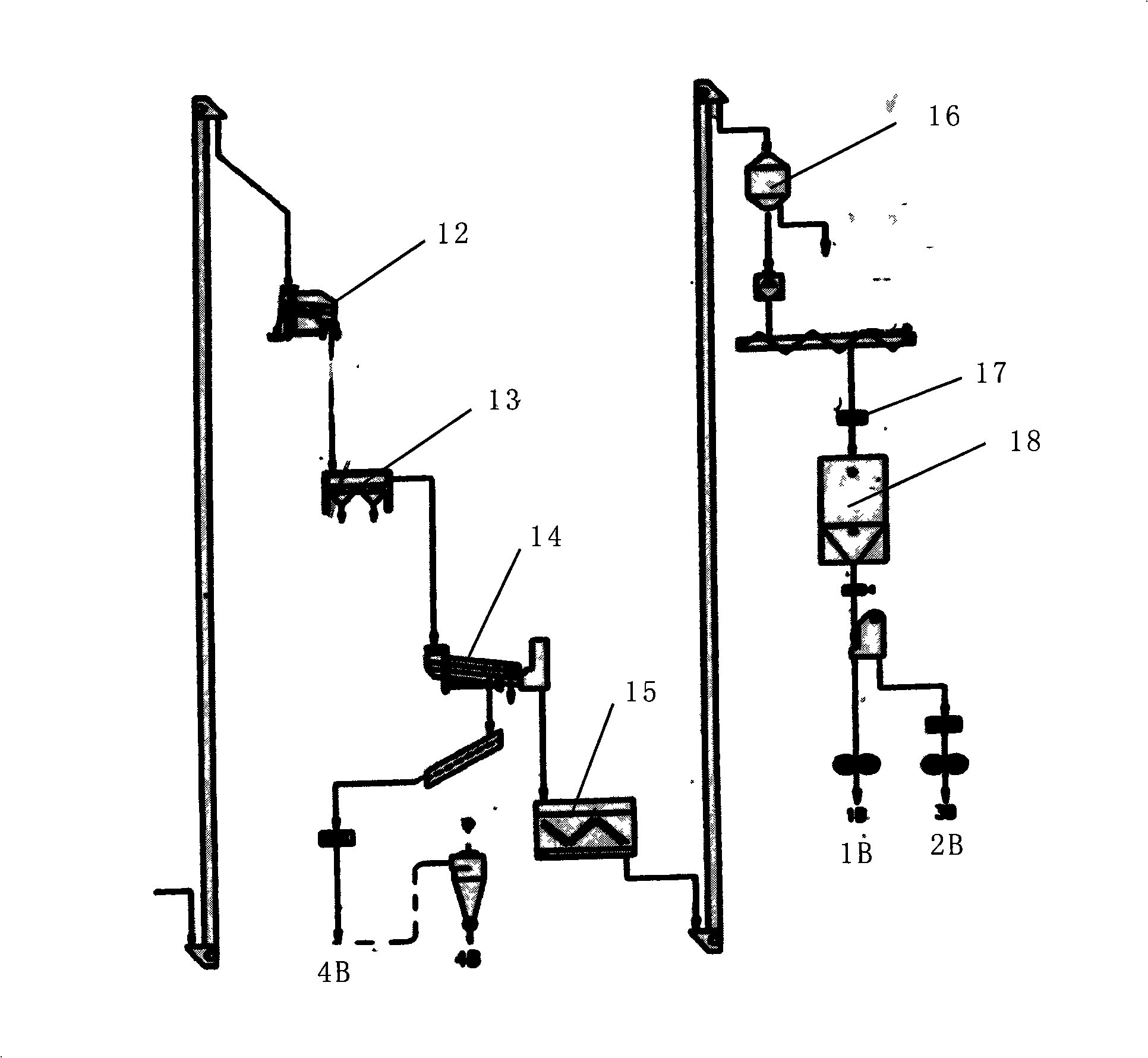

Continuous production device for poly-p-phenylene terephthamide resin

ActiveCN102838744AReduce continuous metering errorsQuality improvementContinuous measurementPolymer science

The invention provides a continuous production device for a poly-p-phenylene terephthamide resin, which belongs to the field of high molecular materials and relates to a high molecular material manufacturing technology. The continuous production device is characterized by comprising a p-phenylenediamine melt and solvent mixing and cooling device, a pre-polycondensation double-screw reactor, a combined second-order polycondensation double-screw reactor and a water washing device. After the continuous production device provided by the invention is used, the p-phenylenediamine and paraphthaloyl chloride are both fed as melts, so that continuous measurement errors are reduced and degrees of influences of flow fluctuation and solvent concentration on the mol ratio of the p-phenylenediamine and the paraphthaloyl chloride are reduced; and the obtained poly-p-phenylene terephthamide resin has the advantages of stable mass, narrow molecular weight distribution and low ash content and is suitable for industrially and continuously preparing the poly-p-phenylene terephthamide resin on a large-scale.

Owner:SHANGHAI HUIBO NEW MATERIAL SCI & TECH

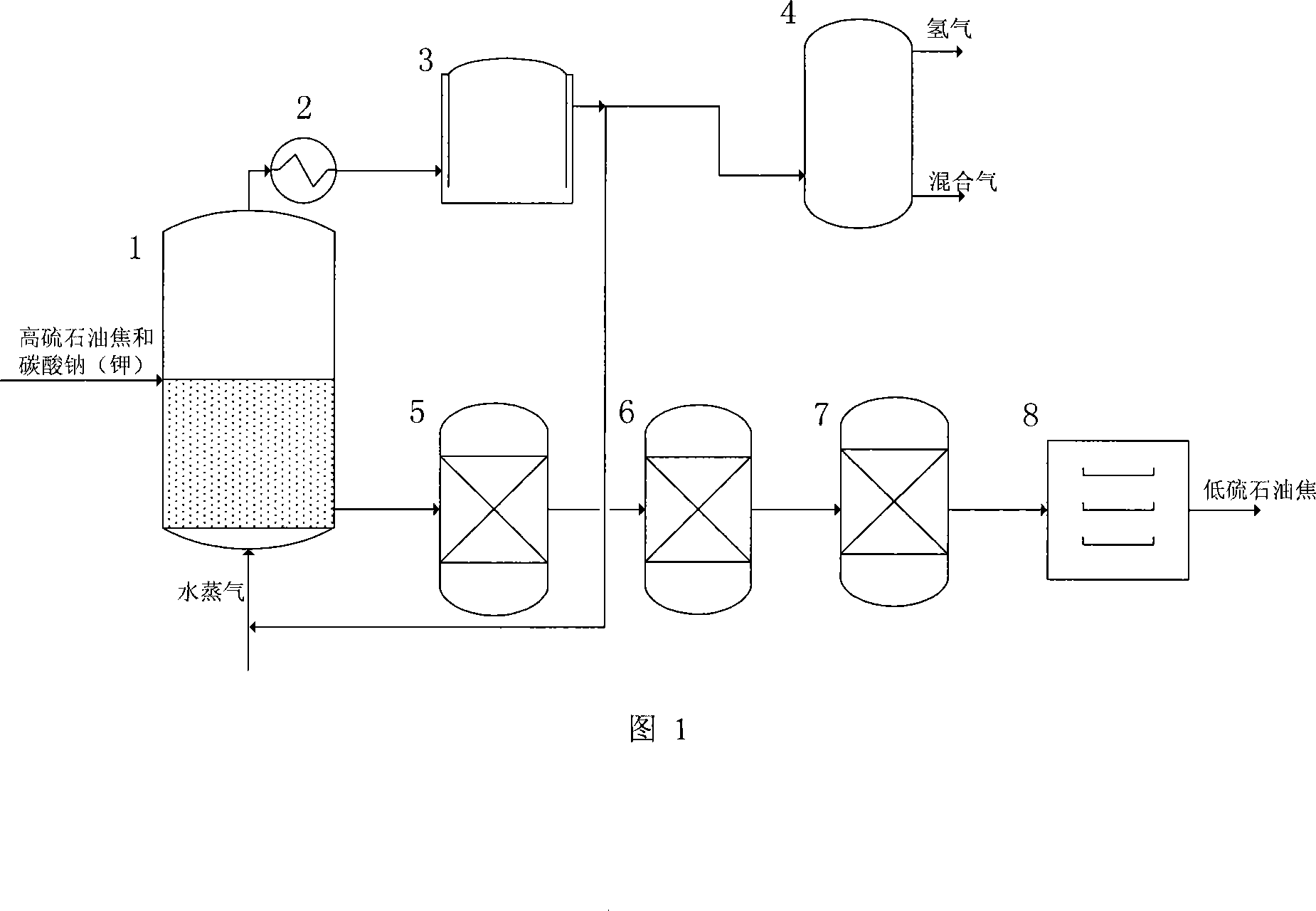

Coupling method between making hydrogen and desulfurizing petroleum coking gas

InactiveCN101020854AReduce sulfur contentOff promotionSolid fuelsGas purification by catalytic conversionSodium carbonateChemistry

The present invention discloses method of coupling the hydrogen making reaction and desulfurizing reaction of gasifying petroleum coke. The present invention features that the mixture of petroleum coke and sodium carbonate or potassium carbonate is added into the reactor and gasified with the introduced water vapor to obtain synthesized gas with high hydrogen content, and of the synthesized gas, part is returned to the reactor through the water vapor inlet for hydrogenating and desulfurizing while the rest is further purified. After some time of gasification reaction, the rest solid product is exhausted for acid pickling, water washing and drying to obtain petroleum coke with low sulfur content.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Low sulfur, low ash, and low phosphorus lubricant additive package using an alkylamine salt of dialkylmonothiophosphate

InactiveUS20050026791A1Minimal sulfurLow phosphorus contentOrganic chemistryLiquid carbonaceous fuelsSulfurLubricant

The present invention provides an oil soluble lubricant additive package comprising at least one alkylamine salt of a dialkylmonothiophosphate. Further, the present invention provides lubricating oils based on the lubricant additive package and methods of use.

Owner:AFTON CHEM INTANGIBLES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com