Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Uniform hardening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

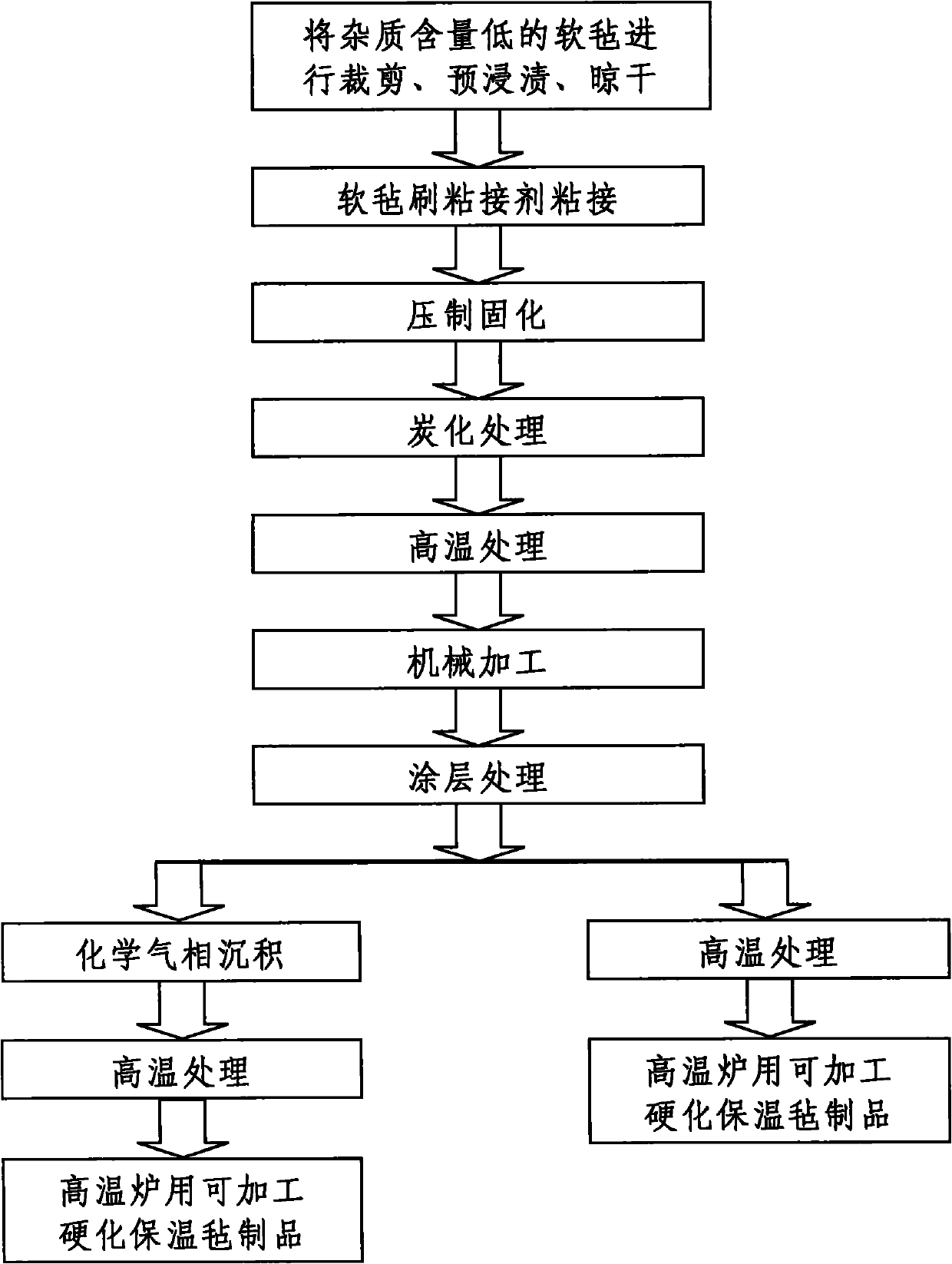

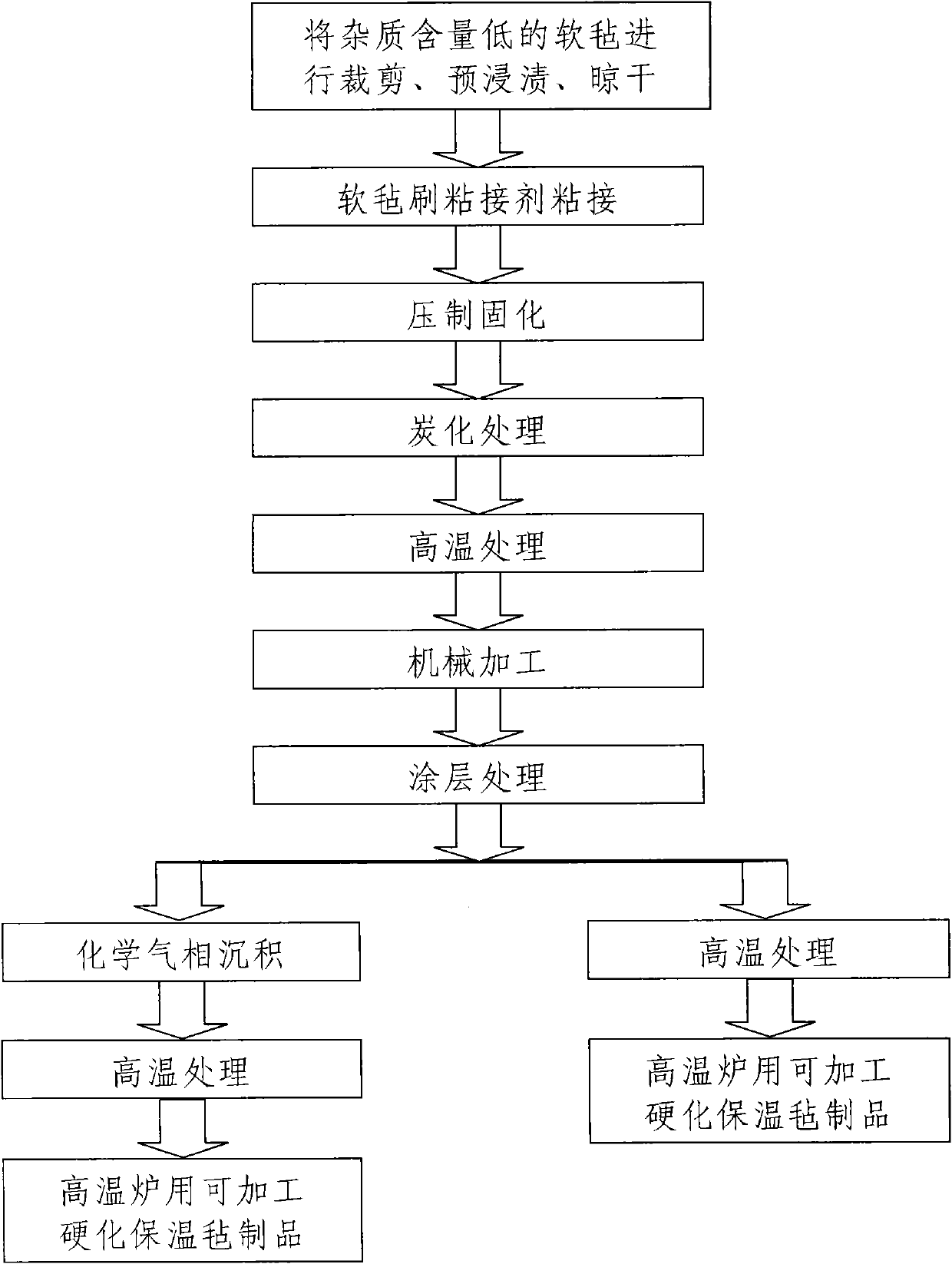

Method for preparing work hardening insulation quilt for high temperature furnace

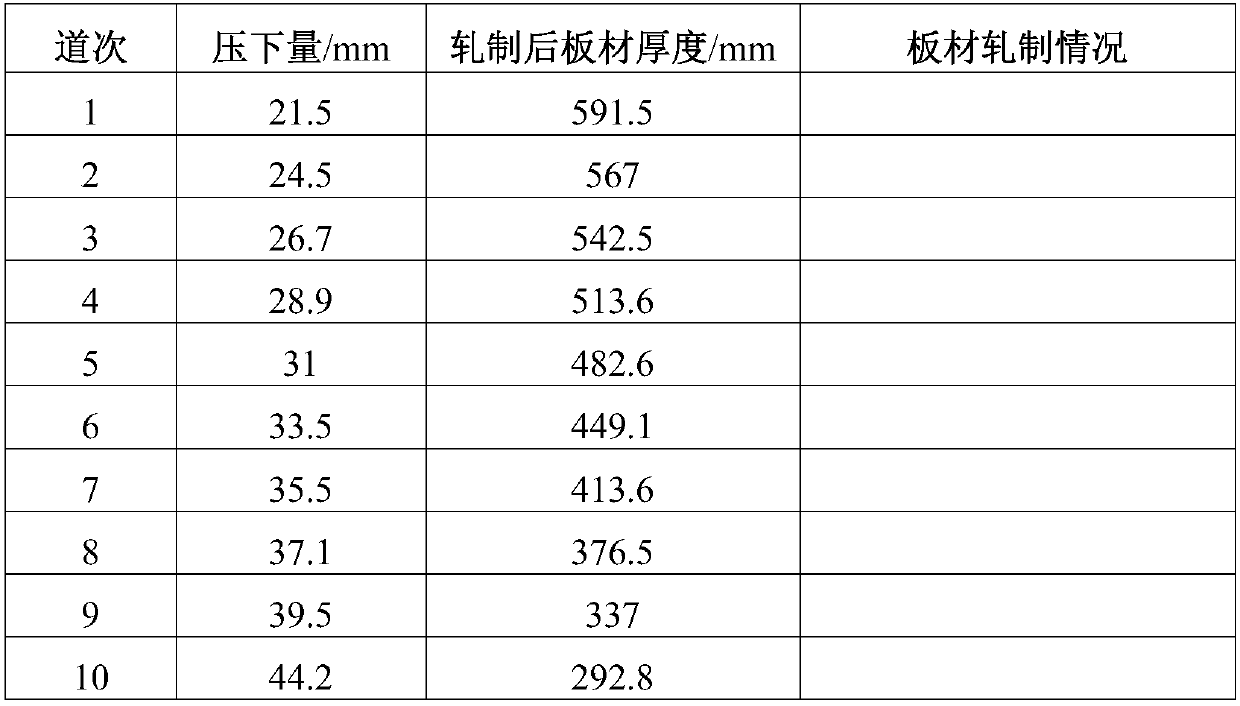

The invention relates to a method for preparing a work hardening insulation quilt for a high temperature furnace, which comprises the following steps of: 1, cutting, pre-impregnating and airing a soft quilt; 2, adhering the soft quilt by using an adhesive; 3, pressing and curing for forming; 4, performing carbonization treatment; 5, performing high temperature treatment; 6, machining; 7, performing coating treatment; and 8, performing chemical vapor deposition treatment and high temperature treatment, or directly performing high temperature treatment to obtain the work hardening insulation quilt for the high temperature furnace. The method has the advantages of simple technological process and suitability for mass production; and the prepared work hardening insulation quilt has the heat conductivity of less than or equal to 0.5W / m.K, the ash content of less than or equal to 2,000ppm, high mechanical properties and high-temperature dimensional stability and excellent processability, does not generate volatile matters when used in the high temperature furnace, cannot pollute the product, and has important significance for prolonging the service life of the insulation quilt in the high temperature furnace.

Owner:XIAN CHAOMA SCI TECH

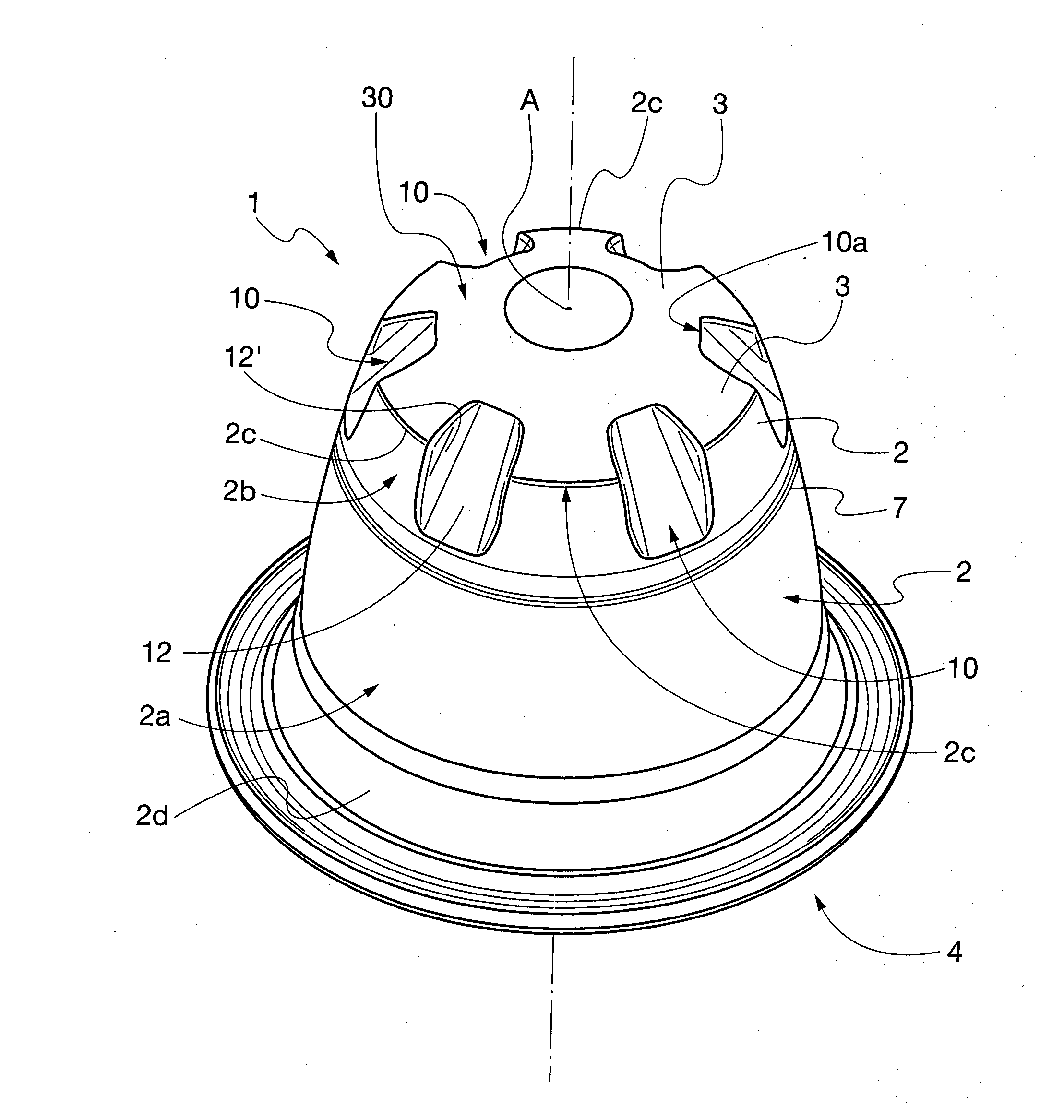

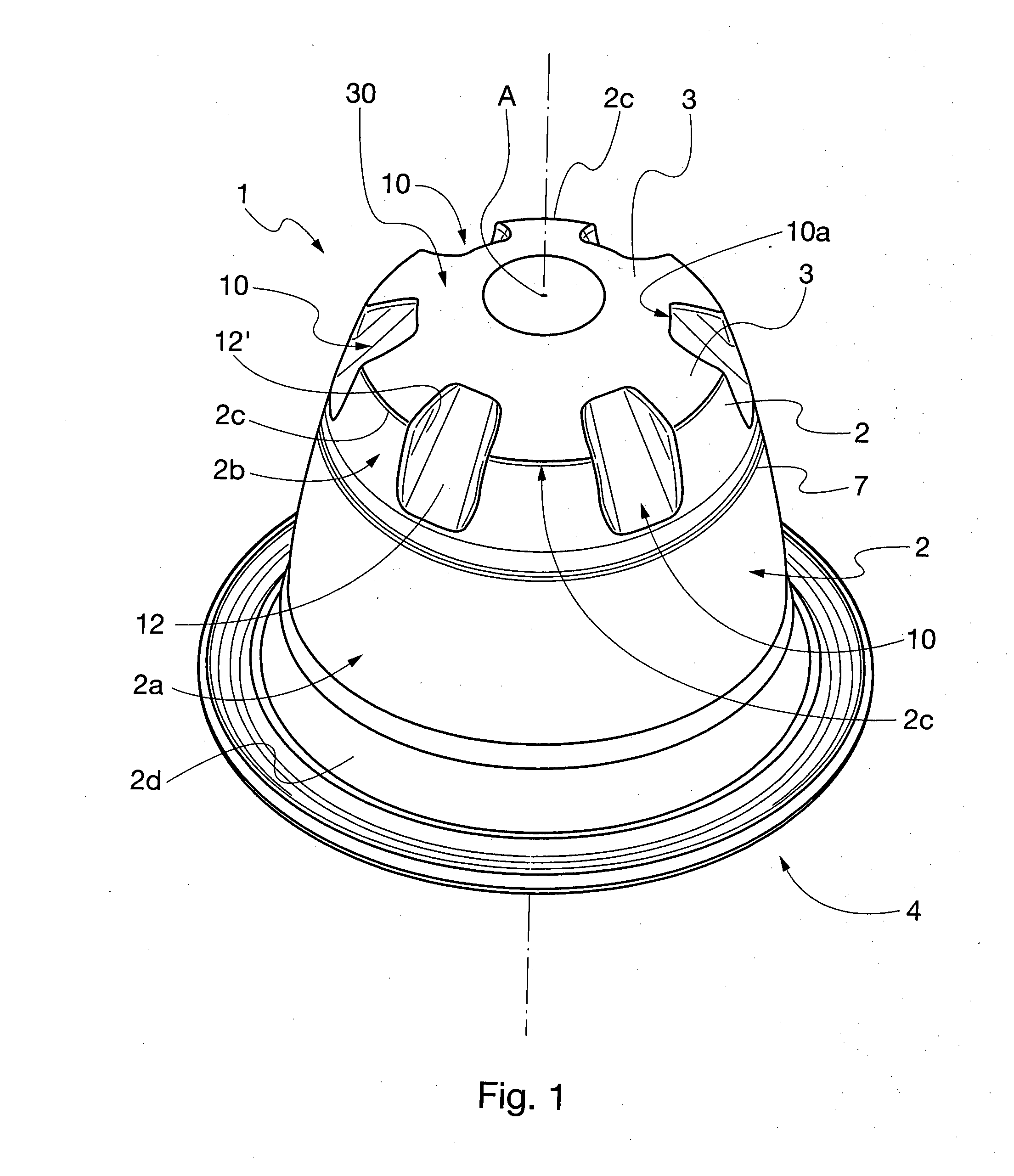

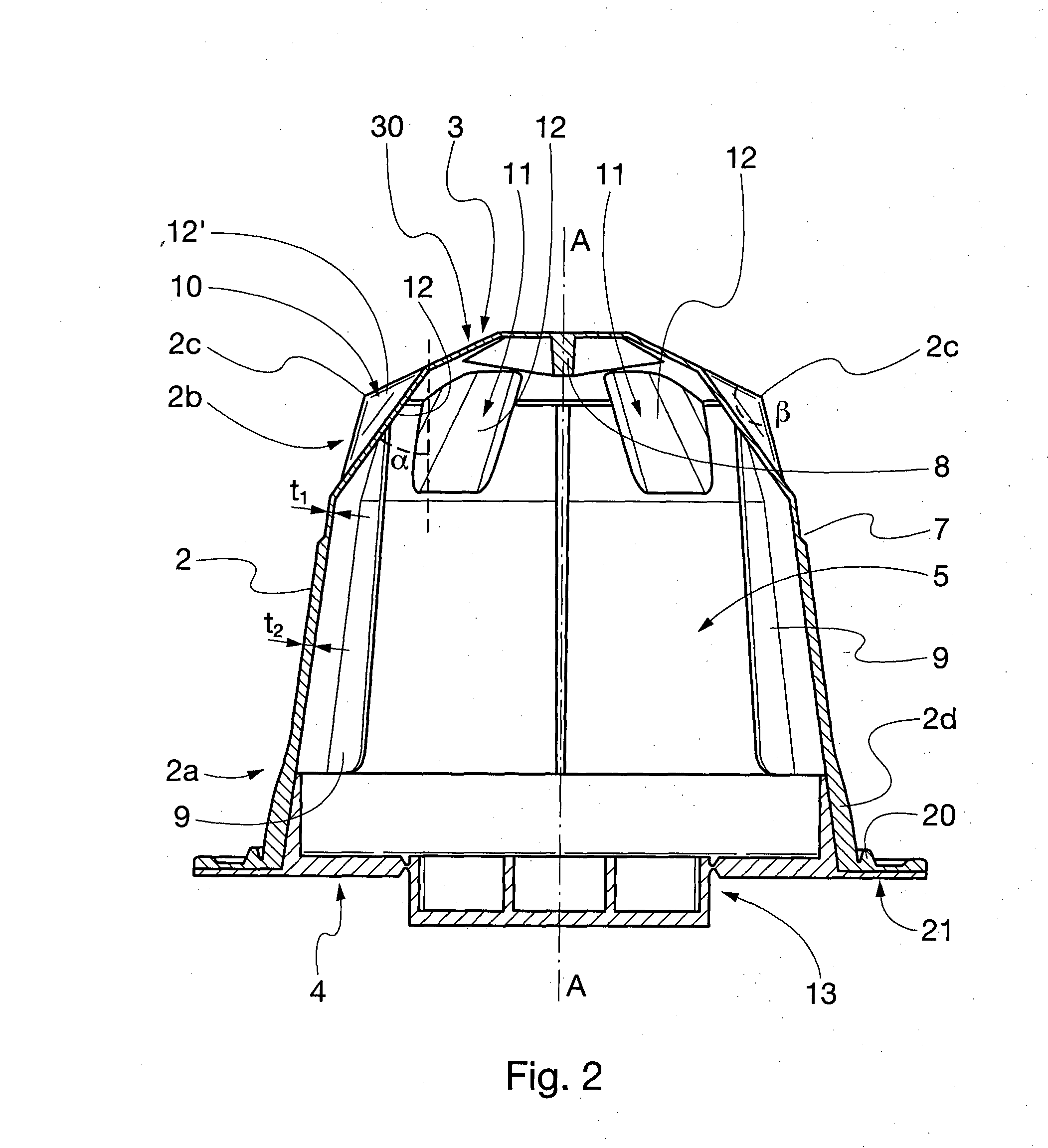

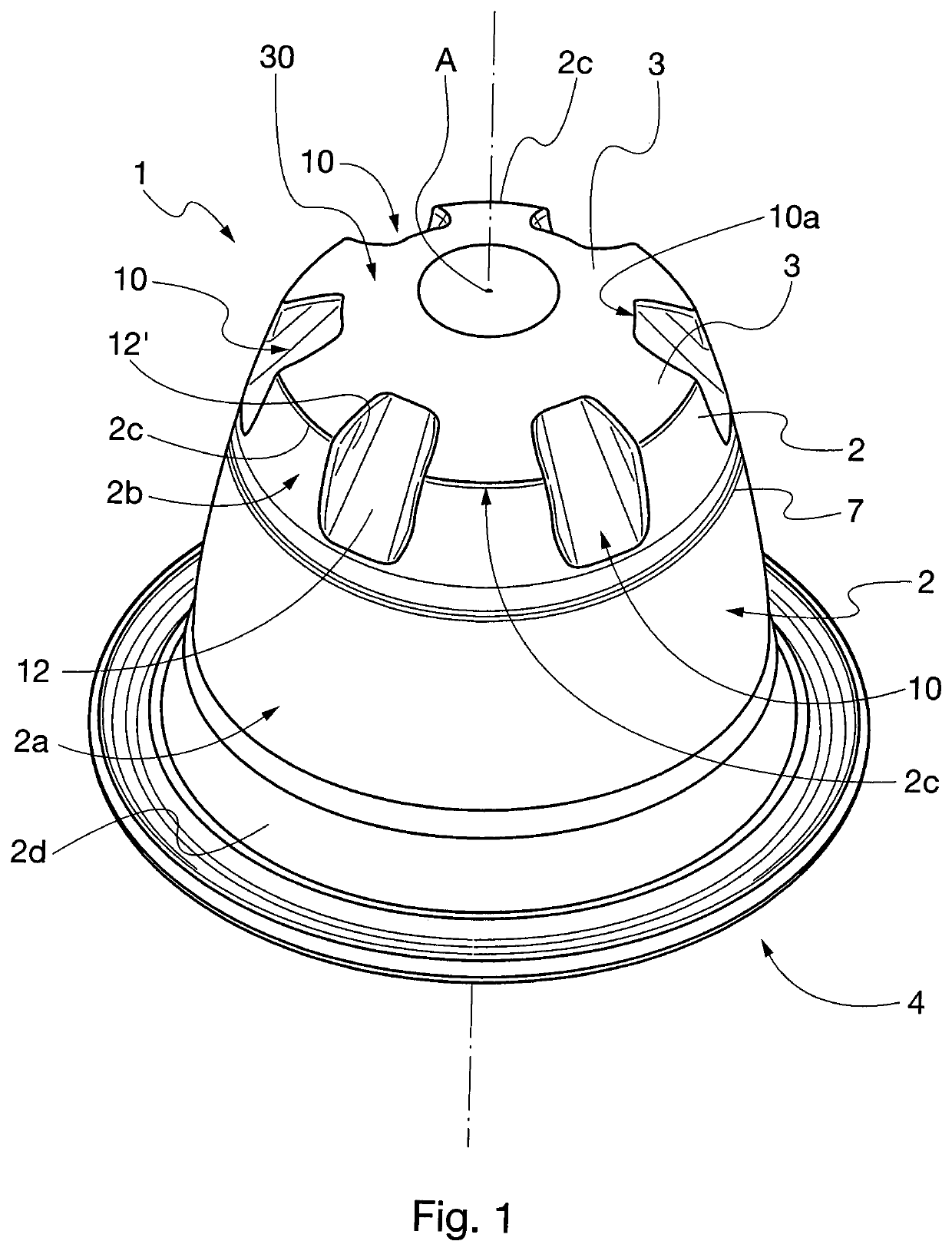

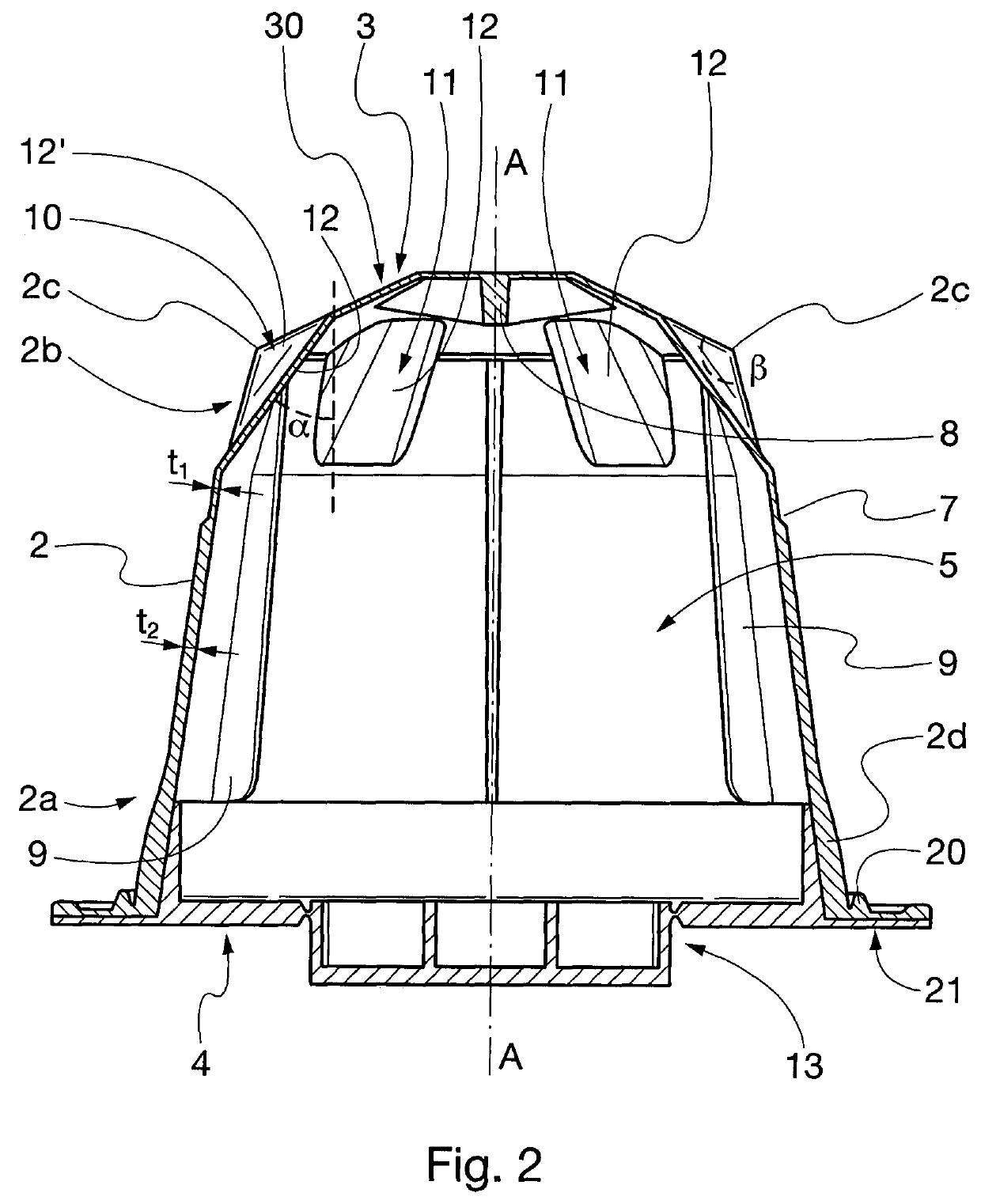

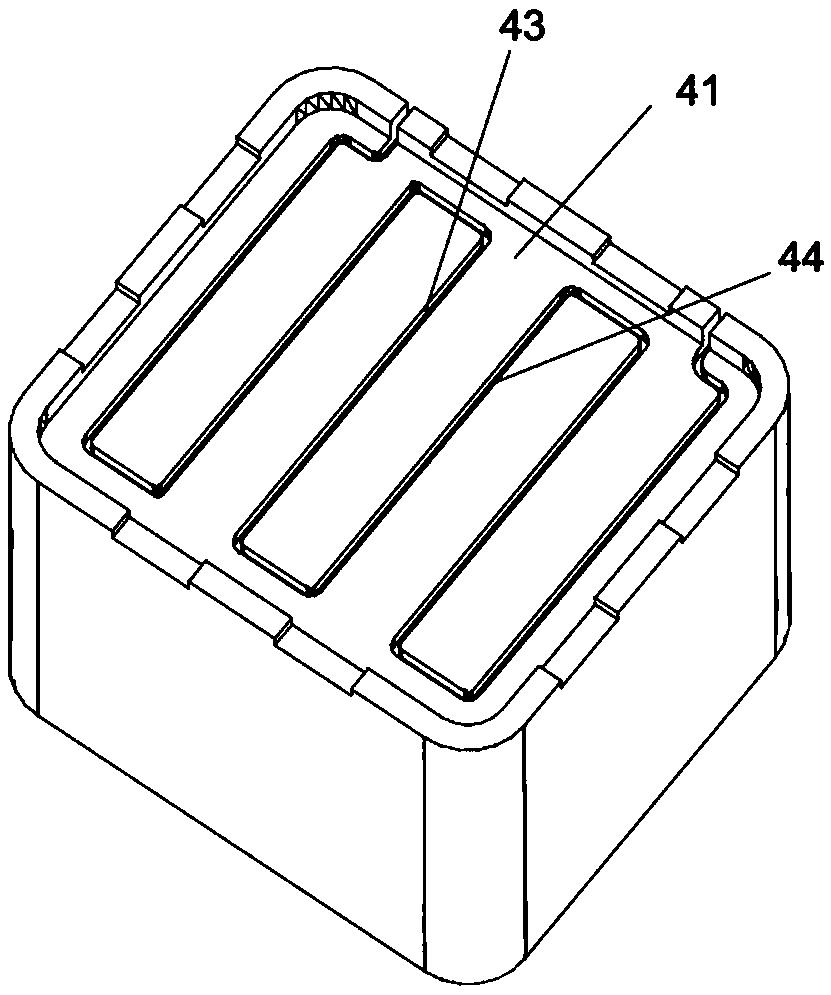

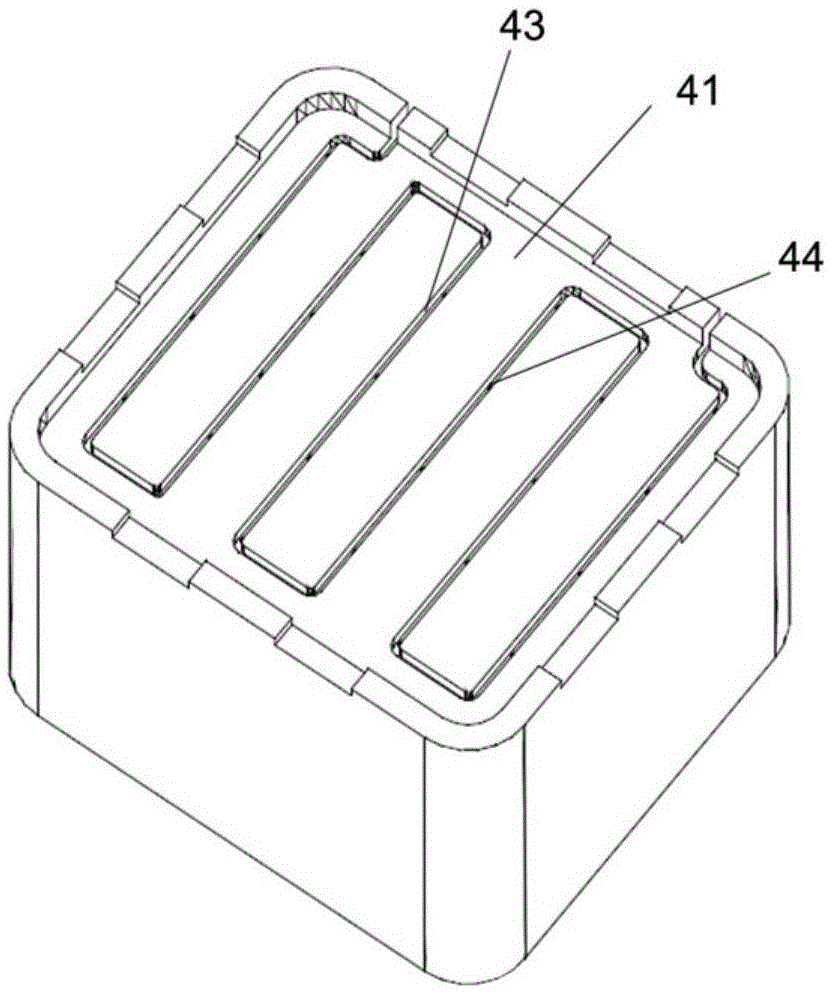

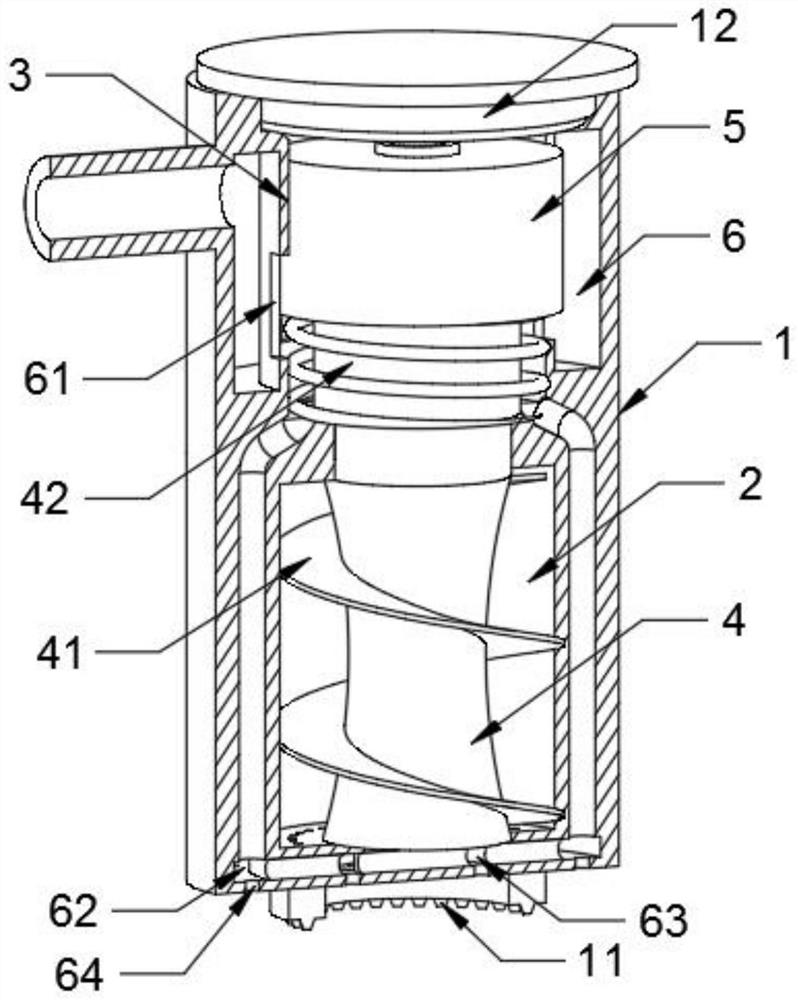

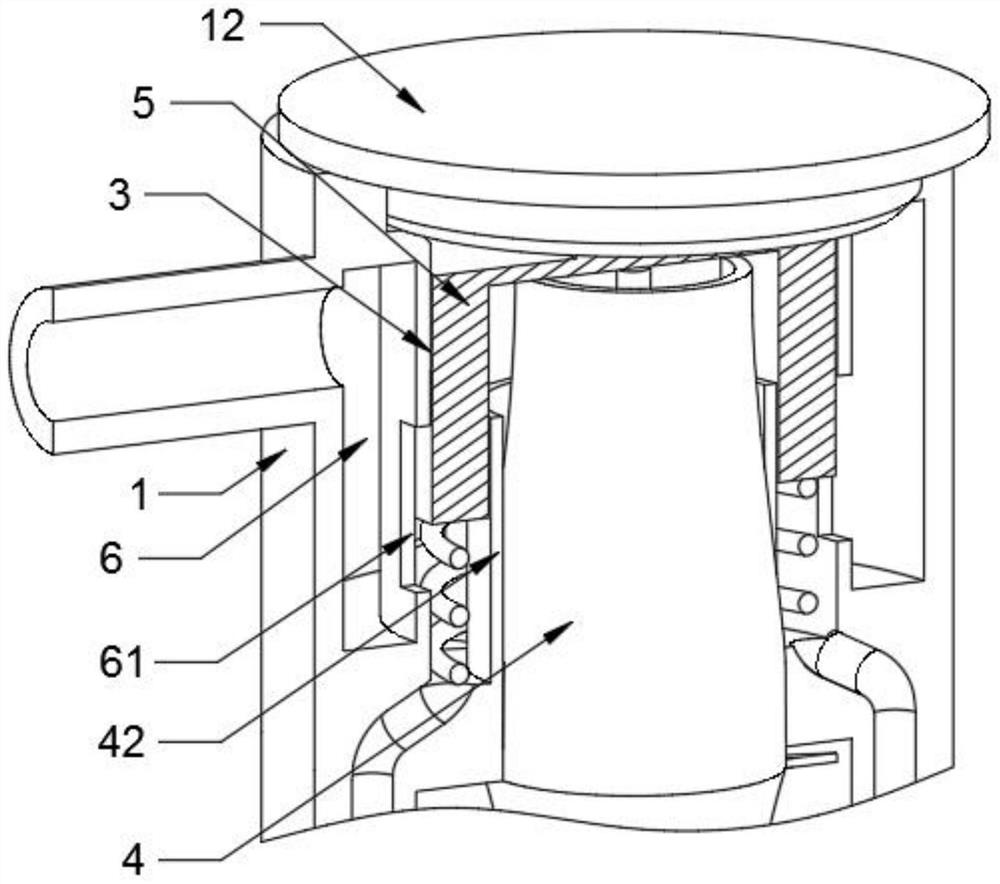

Capsule and system for beverage preparation

ActiveUS20140318380A1Easy feedingEfficient extractionReady-for-oven doughsBeverage vesselsEngineering

A capsule for the preparation of a beverage comprises a lateral wall, an inlet wall and a lower wall forming a hollow body having a substantially central axis, the inlet wall extends from a peripheral end of the lateral wall towards said central axis and a plurality of sunken portions are extending on both lateral and inlet walls across the edge between said walls each portion connecting together the lateral wall and the inlet wall.

Owner:TUTTOESPRESSO SRL

Method for hardening sand mold by CO2 blowing

InactiveCN1701875AEfficient and uniform hardeningReduce gas usageFoundry mouldsFoundry coresProduct gasLayer thickness

This invention relates to blowing with CO2 and hardening sand mould method. on one side wall of casting box or casting frame, set location holes according to given certain size and amount; when preparing sand mould, for different mould shapes, insert round bars crossed horizontally mould top to nearby of another side wall to wall holes accorded with blowing hole diameter and amount; on the base that ensures keep certain sand layer thickness between bar and mould surface and certain distance between its top and another side of sand box, fall moulding sand, ram and locate; after forming, draw out bar, form blowing air hole; cover plant plate on sand box top, blow CO2 till sand mould change to hard. This invention can fit to all cavities variety request; the product has advantages of well quality, even harden, easy to demould and convenient to convey.

Owner:鑫工艺(上海)材料科技有限公司

Self-hardening sand bonding agent for casting and preparation method and using method thereof

ActiveCN102139341ARaw materials are readily availableSimple equipmentFoundry mouldsFoundry coresBoiling pointSelf hardening

The invention relates to a bonding agent for casting, in particular to a self-hardening sand bonding agent for casting and a preparation method and a using method thereof. The self-hardening sand bonding agent for the casting comprises resin and a curing agent, wherein the resin consists of the following components in part by weight: 100 parts of castor oil, 40 to 90 parts of glycerol, 0.1 to 0.2part of calcium oxide, 50 to 90 parts of phthalic anhydride, 5 to 9 parts of dimethylbenzene, 120 to 200 parts of high-boiling point arylhydrocarbon; and the curing agent is prepared by mixing 100 weight parts of isocyanate and 20 to 40 weight parts of high-boiling point arylhydrocarbon. The bonding agent has readily available raw materials and is environment-friendly, equipment required by a synthetic process is simple, and a process condition is easy to control; the bonding agent has high sand mulling flowability, low gas forming amount, high gas forming speed, stable sizes of sand cores / sand molds and smooth surfaces, is convenient to store, and has the excellent effects of resisting sand burning and deformation; and the sand molds are hardened integrally and uniformly, castings have high size accuracy, and sand can be recycled, so the bonding agent is suitable for the production of large-scale steel-casting sand molds.

Owner:NINGXIA UNIVERSITY +1

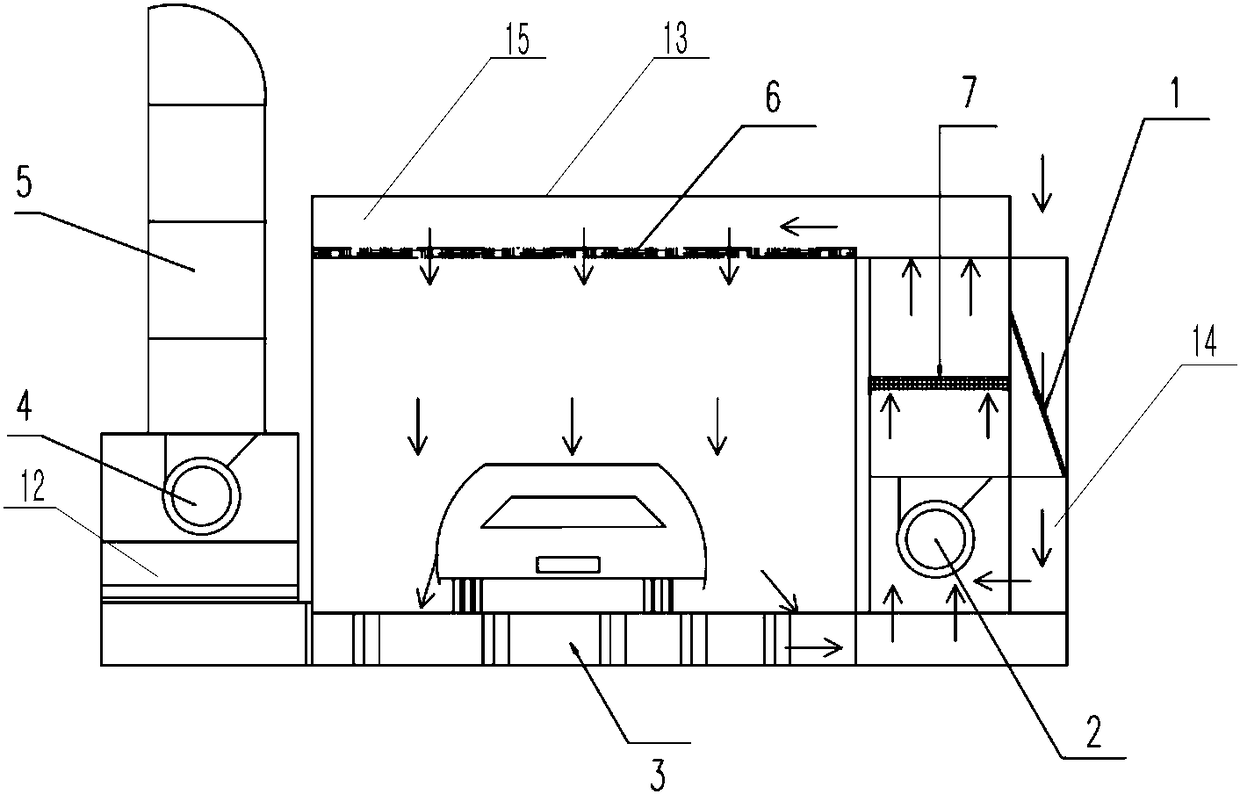

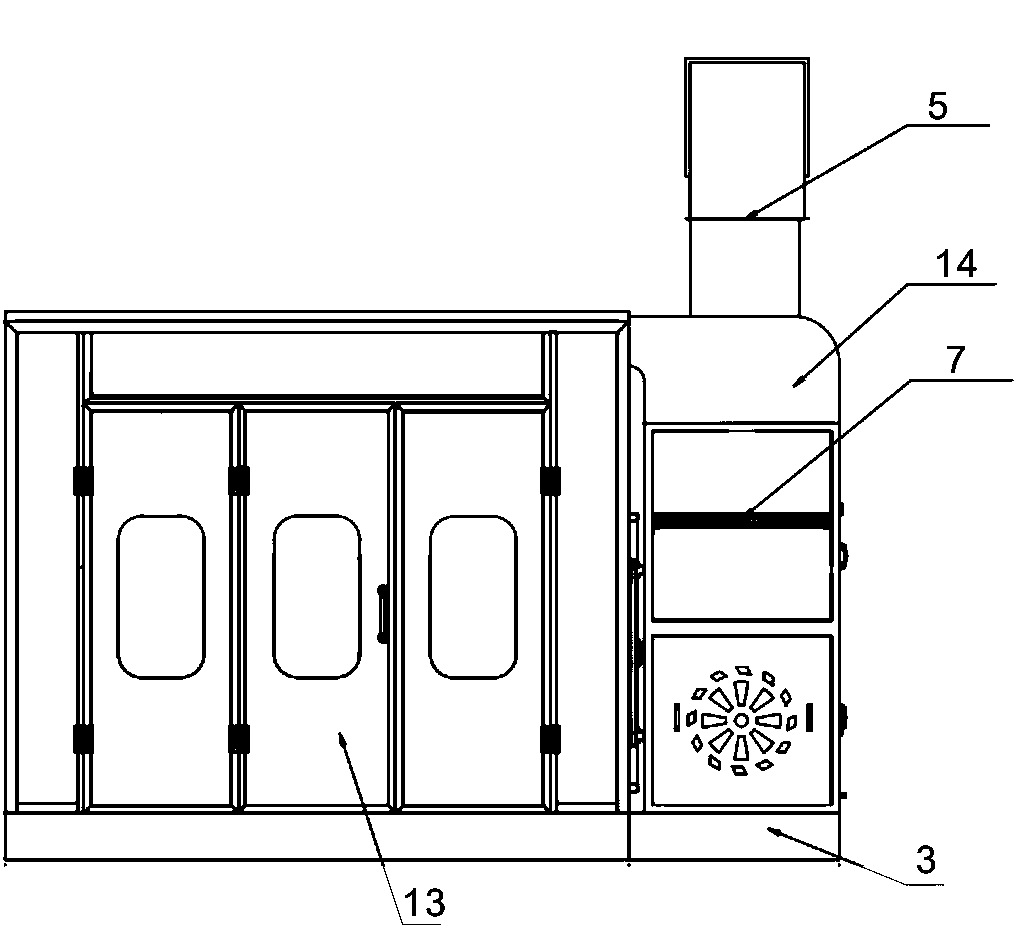

Air energy spraying and baking chamber

PendingCN108499821AControl temperature and humidityEasy to usePretreated surfacesCoatingsElectricityWater based

An air energy spraying and baking chamber comprises an air inlet pipe arranged on one side of a chamber body. Primary filter cotton is fixedly mounted in the air inlet pipe. The air inlet pipe communicates with an air inlet duct. A suction ventilator is mounted in the air inlet duct. An exhaust pipe is arranged on the other side of the chamber body and communicates with a blow dryer. A bottom plate with leaking holes is arranged at the bottom of the chamber body. An air return duct is arranged under the bottom plate and communicates with the air inlet duct. During baking, the air energy spraying and baking chamber is more environmentally friendly than oil type baking chambers, free of smoke pollution and safer than the oil type baking chambers, the oil type baking chambers are liable to start fires, the air energy spraying and baking chamber saves more energy than electric heating type baking chambers, about two thirds of electric energy is saved, in addition, baked parts can be evenlyhardened through baking, the temperature and humidity in the spraying and baking chamber can be controlled, and both oil-based paint and water-based paint can be better used.

Owner:邵锦文

Method for producing casting cold-box resin

The invention relates to a method for producing resin, and particularly relates to a method for producing casting cold-box resin. The method comprises the following steps: adding dissolved industrial phenol to a reaction kettle; starting an agitator; adding solid paraformaldehyde, a regulator and 0.08-0.12% of metal ion catalyst; opening a steam valve, slowly heating up, and heating up to 105 DEG C within 40-50 minutes; keeping constant temperature at 105-108 DEG C for 30 minutes; heating up to 112 DEG C within 10-20 minutes, and keeping constant temperature at 112-115 DEG C for 50 minutes; continuing to heat up and dewatering under normal pressure after heat preservation is finished; timing constant temperature when the temperature inside the kettle ascends to 120 DEG C, and keeping constant temperature at 120-123 DEG C for 30 minutes; after constant temperature is finished, vacuumizing and continuing to dewater; stopping dewatering when the total dewatering amount achieves 60% of formaldehyde amount; adding a polar dibasic acid ester, nonpolar high-boiling point solvent oil and a modifier; agitating for 60 minutes; adding an enhancer when cooling to below 40 DEG C; evenly agitating, detecting and packaging. The casting cold-box resin which is low in viscosity, and high in casting sand strength, can be used for a long period of time, and meets core-making production in batches is provided by the invention.

Owner:共享新材料(山东)有限公司

Composite foam mortar, and preparation and construction method thereof

ActiveCN101412608AWater retentionFunctionalSolid waste managementCeramicwareCrack resistanceMicrosphere

The invention relates to a composite foam mortar, which is prepared from the components by the following weight percentage through mechanically and evenly stirring: 20 to 30 percent of ordinary Portland cement, 5 to 8 percent of white lime, 8 to 10 percent of fly ash, 15 to 20 percent of light aggregate, 30 to 40 percent of heavy aggregate, 1.6 to 2.0 percent of foam initiator, and 3.0 to 5.0 percent of strength-keeping rubber powder, wherein the light aggregate is an inorganic vitrification hollow microsphere material; the heavy aggregate is a mixture of sand and coarse whiting powder; and the foam initiator is a mixture of an anionic surfactant and a foam stabilizer. The 30 to 50 weight percent of composite foam mortar is diluted by water, is constructed on a wall surface by a mortar mixer with instant mixed spray coating, and is scraped evenly by a running rule or a putty knife. The composite foam mortar can be constructed by adopting a mechanical guniting technology, thus the construction efficiency and the construction quality are improved, the material dosage on a unit area is reduced, and the cost is reduced. The composite foam mortar also has the advantages of water resistance and heat insulation, improved crack resistance, good compatibility with base layer brickworks, and simple and practical process; besides, the composite foam mortar is applicable to waterproof and heat insulation decoration engineering on the inner and outer surfaces of the outer walls of all buildings, in particular to the moist environments with high requirements on water resistance and heat insulation in south China.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

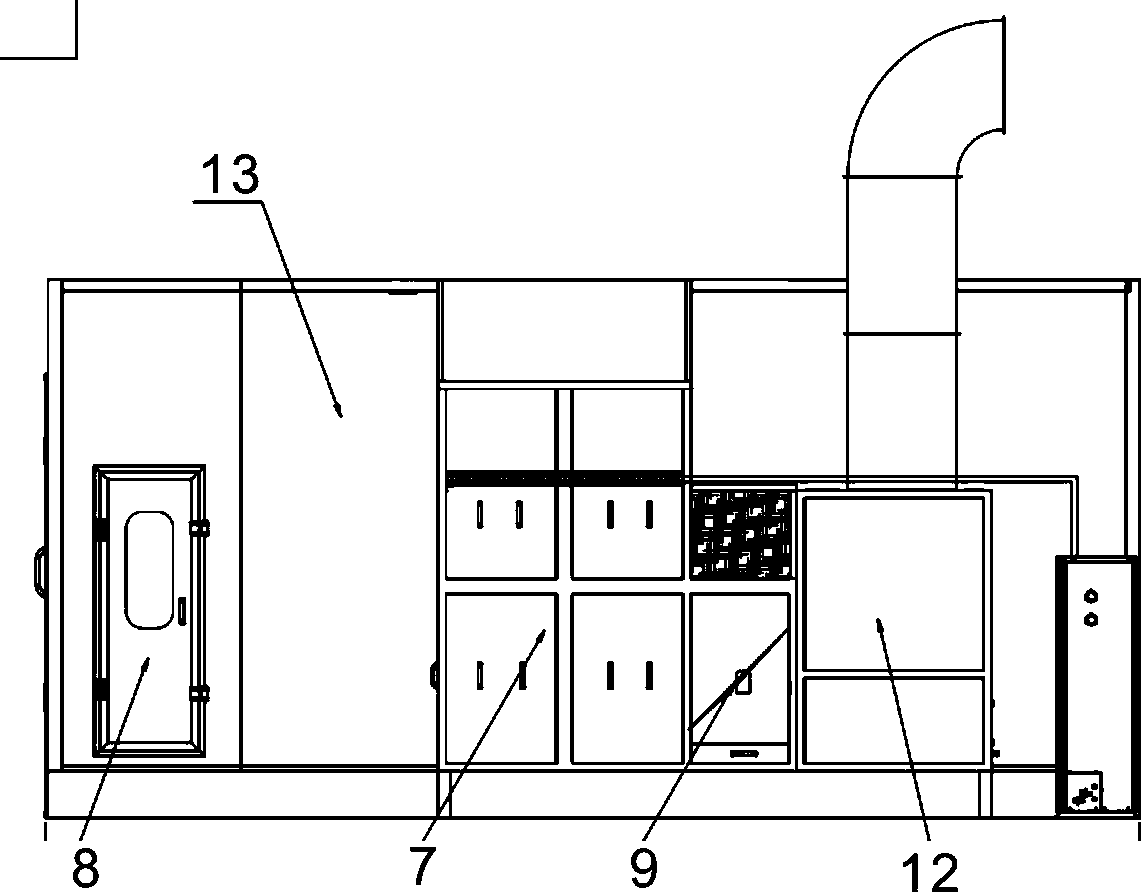

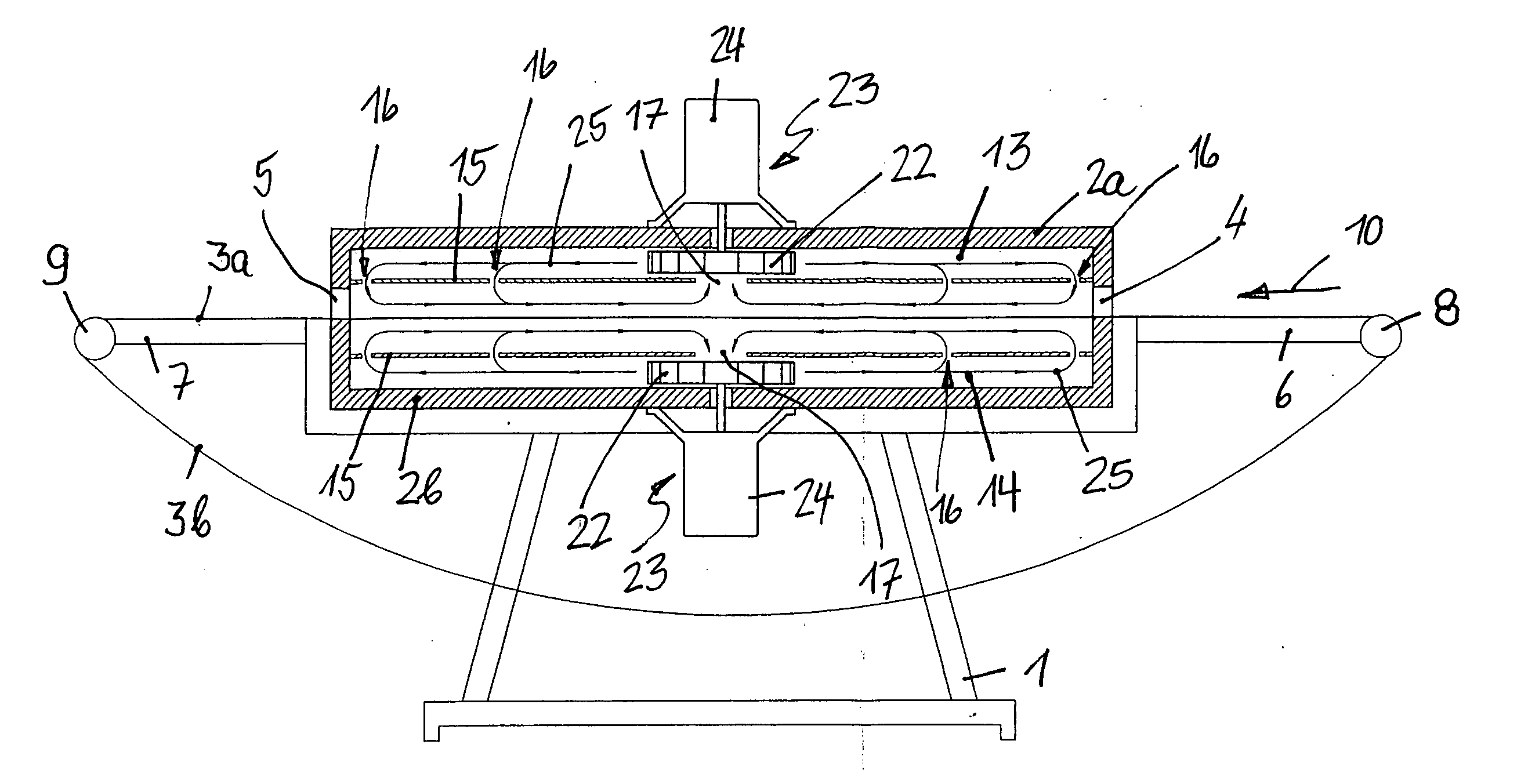

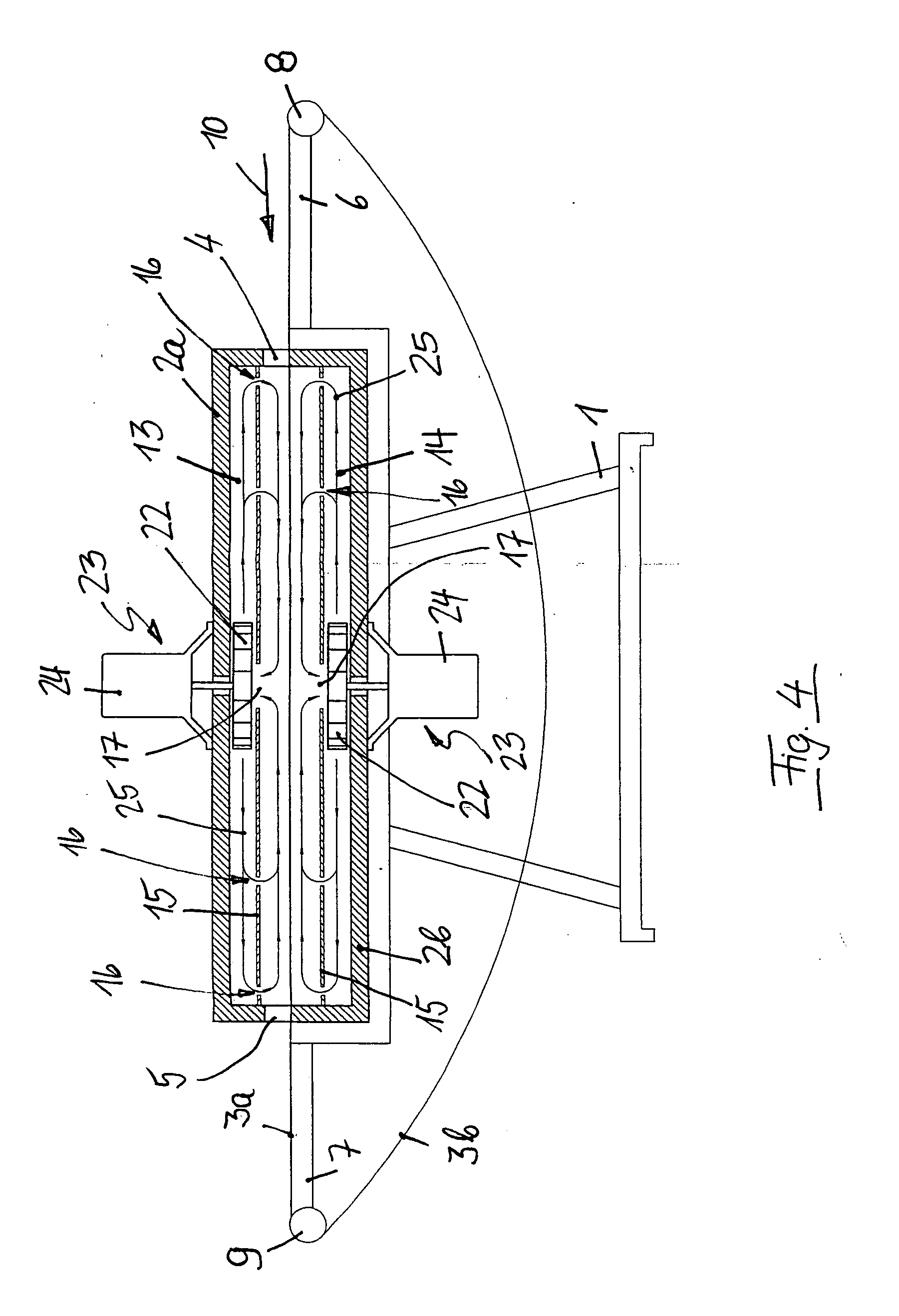

Device for heat-treating a coating of flat-bed offset printing plates

InactiveUS20060096480A1Avoid unevennessUniform hardeningSemiconductor/solid-state device manufacturingMaintainance of heating chambersEngineeringMechanical engineering

The present invention provides a device for heat-treating a coating of flat-bed offset printing plates by application of hot air upon the flat-bed offset printing plates, comprises an upper hot-air chamber: a lower hot-air chamber, arranged at a distance from the upper hot-air chamber below the latter; an air-permeable endless conveyer belt having a carrying run, which extends between the upper and the lower hot-air chambers; a first air diffuser provided on the bottom of the upper hot-air chamber, and a second air diffuser provided on the top of the lower hot-air chamber. The two air diffusers are provided with air outlet openings that face the conveyer belt and at least one air inlet opening which is connected with the intake side of one or more blowers. The space between the two hot-air chambers, except for an entry opening for the carrying run and an exit opening for the carrying run for the conveyer belt, is closed.

Owner:TECHNO GRAFICA

Machining technology of ultrawide 6061 aluminum alloy panel for military test detection platform

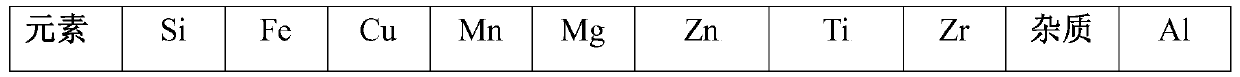

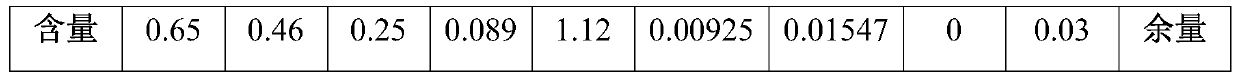

The invention belongs to the technical field of aluminum alloy, and relates to a machining technology of an ultrawide 6061 aluminum alloy panel for a military test detection platform. Aluminum alloy is prepared from, by weight percentage, 0.63-0.69% of Si, 0.45-0.55% of Fe, 0.2-0.3% of Cu, 0.08-0.12% of Mn, 1.05-1.15% of Mg, 0-0.1% of Zn, 0.013-0.02% of Ti, 0-0.05% of Zr, 0-0.05% of single impurities, and the balance Al, wherein the total weight percentage of the above raw materials except Al is smaller than or equal to 0.15%. The lost pass is added in the hot rolling process, during shallow pass, by cooling the panel with rolling mill air-blowing equipment, the purpose of uniformly and slowly lowering the finish rolling temperature is achieved, arching of the back of the panel due to theexcessive width is avoided, and the problems that for the ultrawide 6061 aluminum alloy panel prepared through an existing machining technology, the contradiction between the width and flatness of thepanel and the machining deformation is prominent, and it is hard to meet customer needs are solved.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

Method for preparing work hardening insulation quilt for high temperature furnace

Owner:XIAN CHAOMA SCI TECH

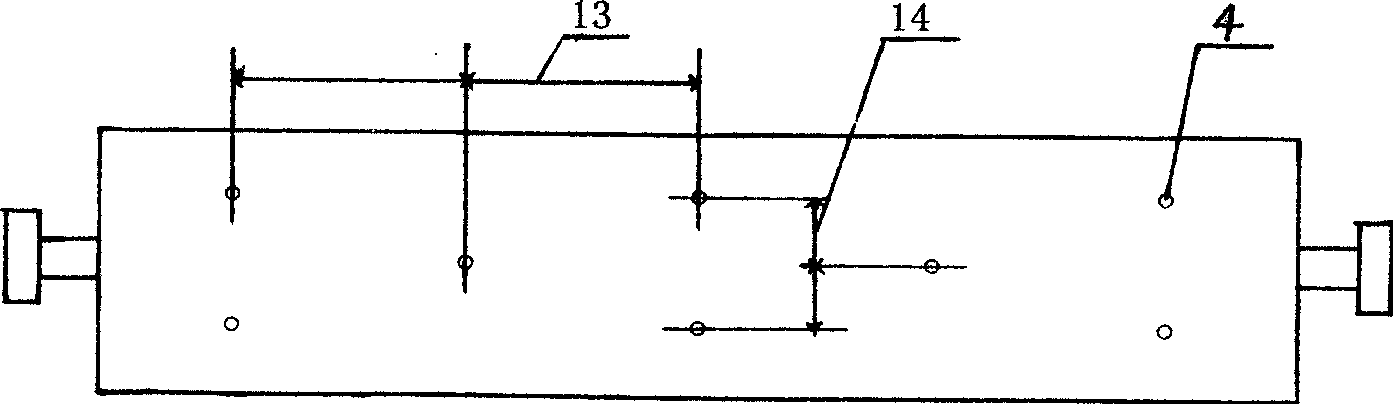

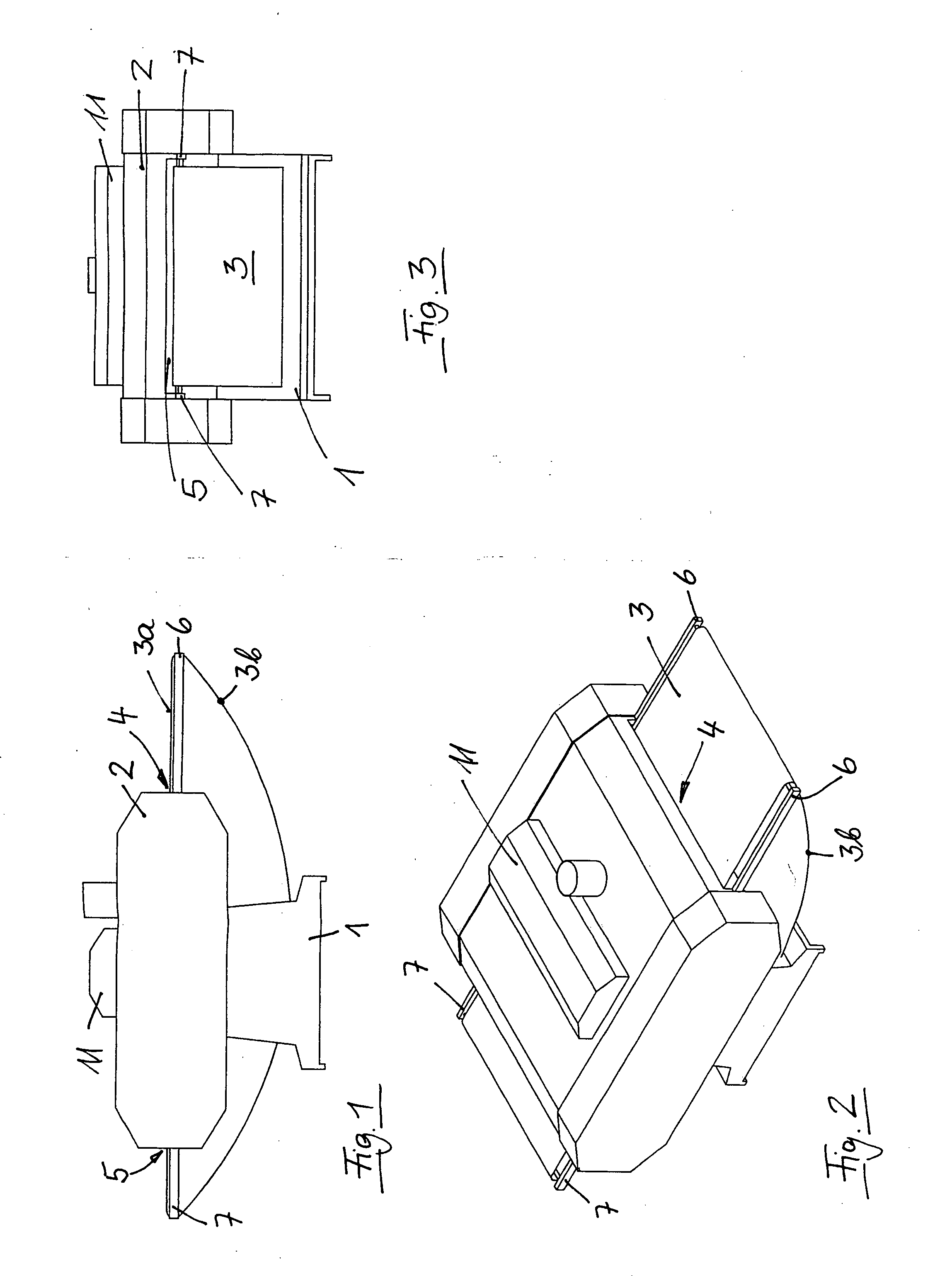

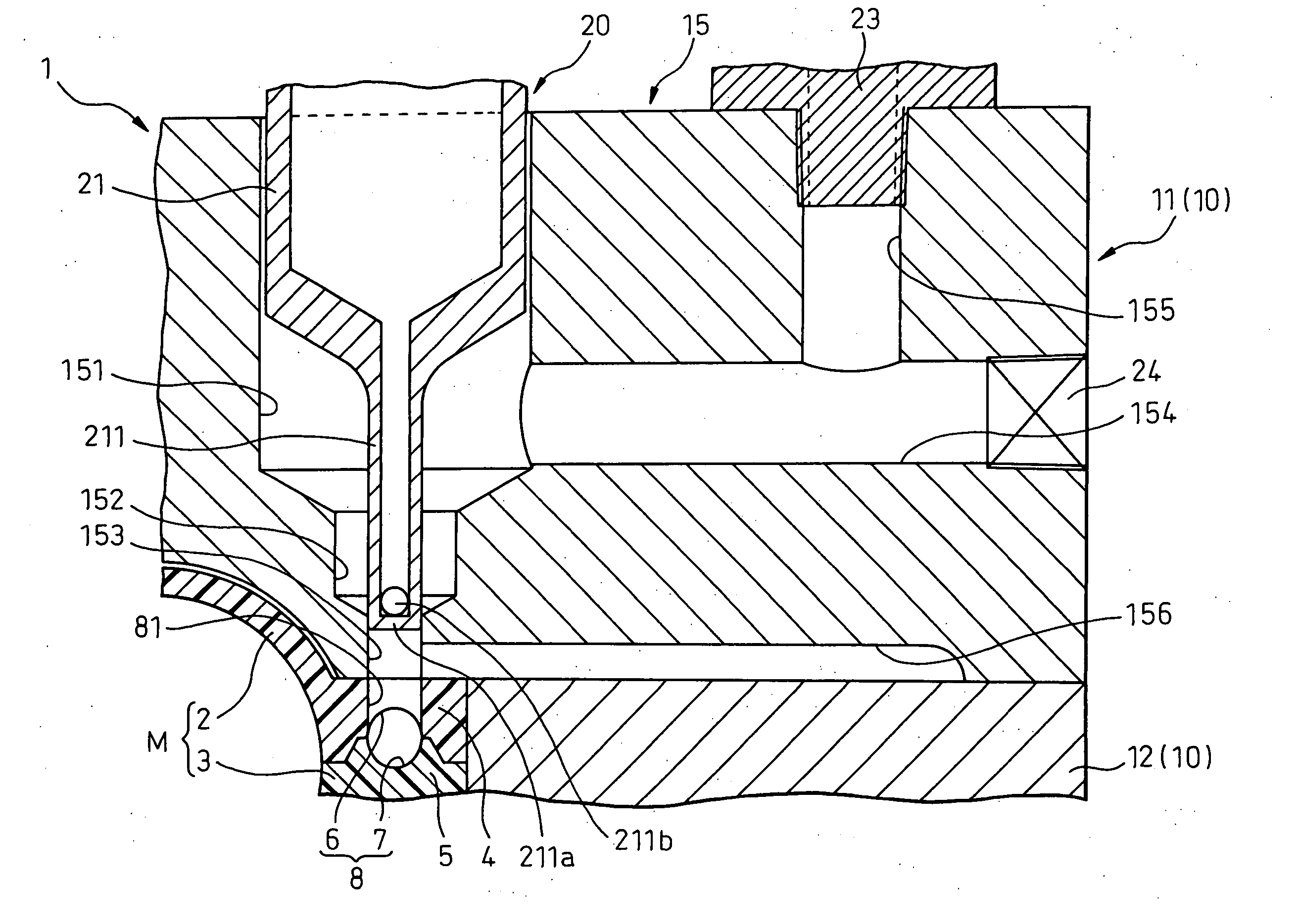

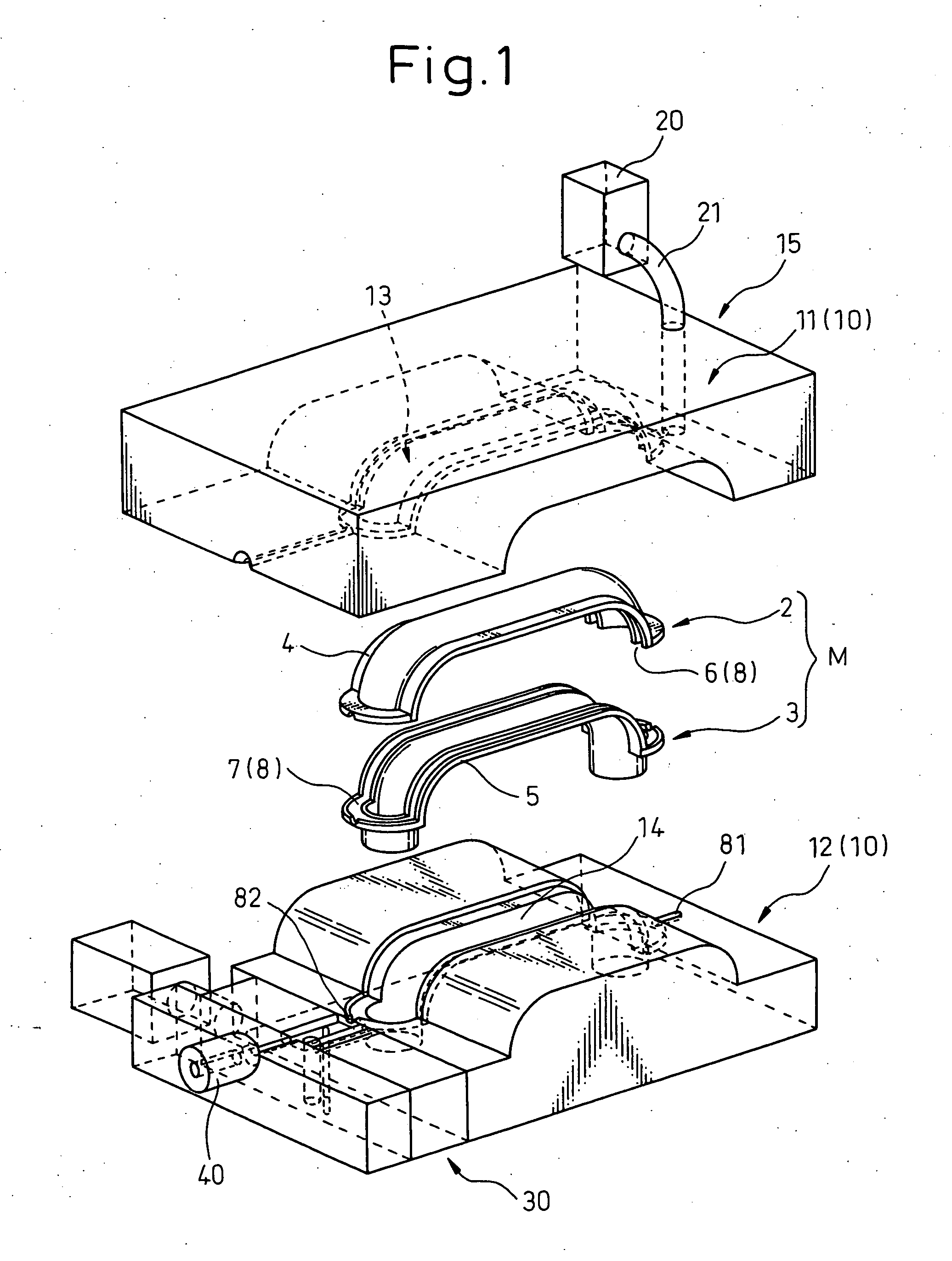

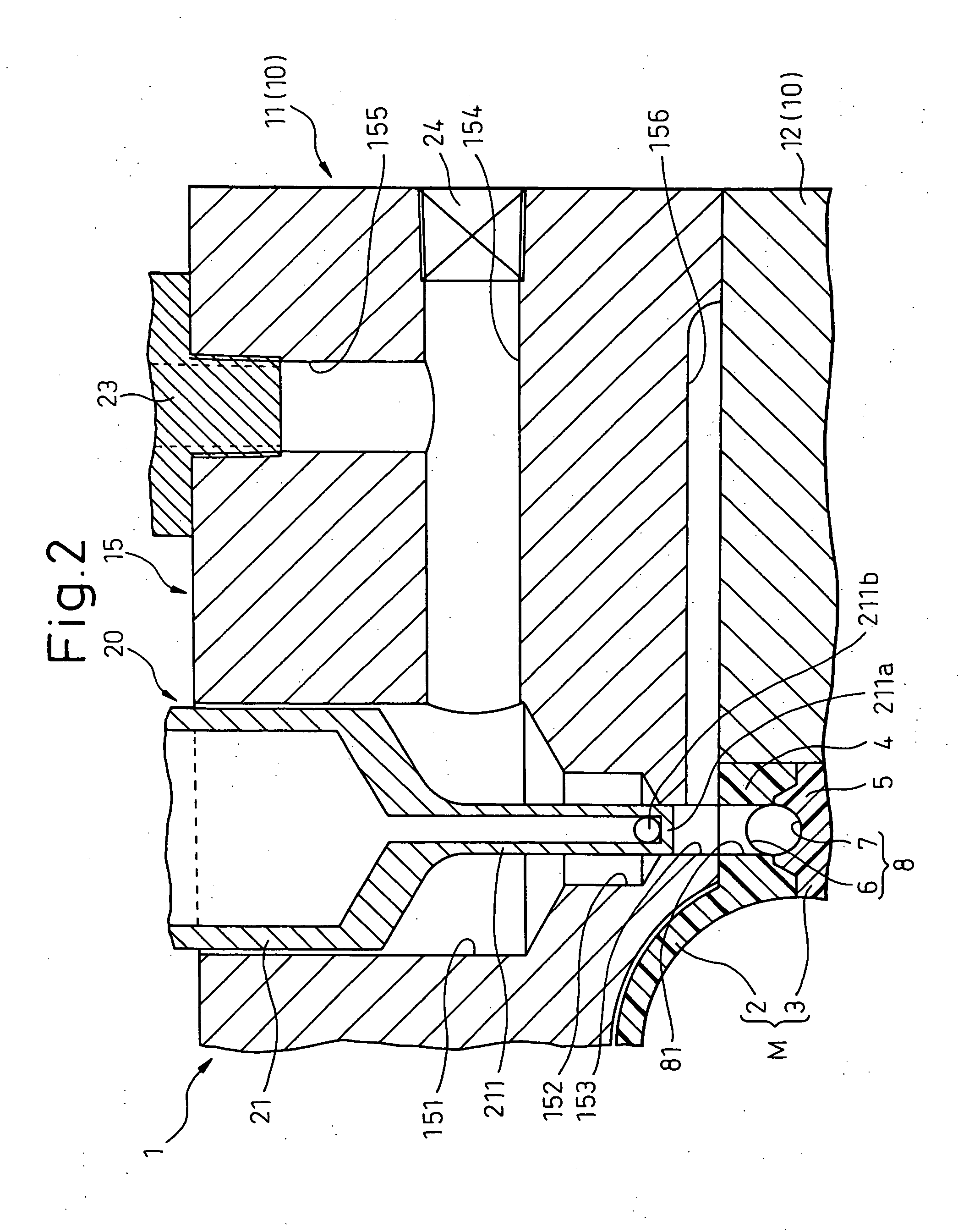

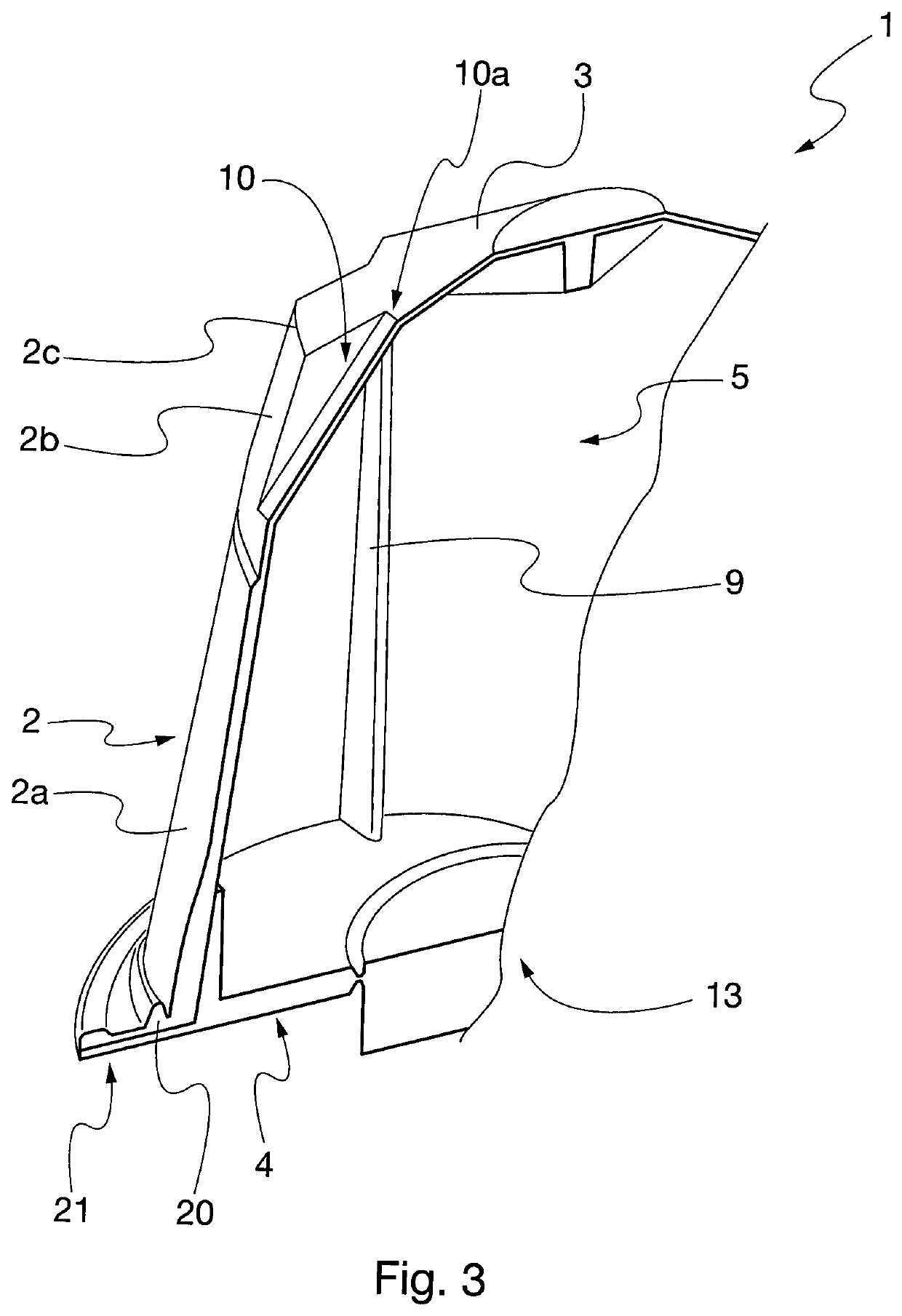

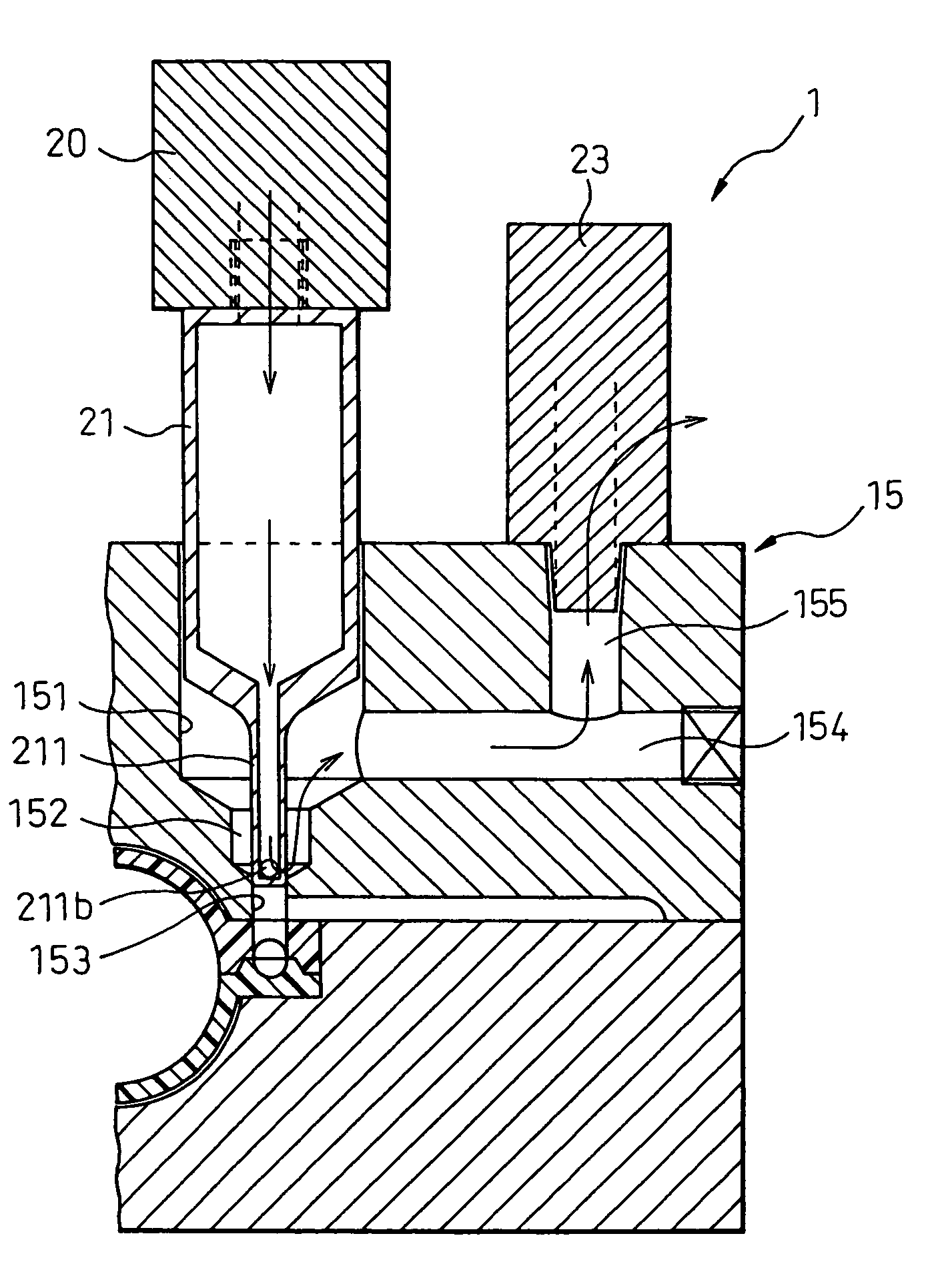

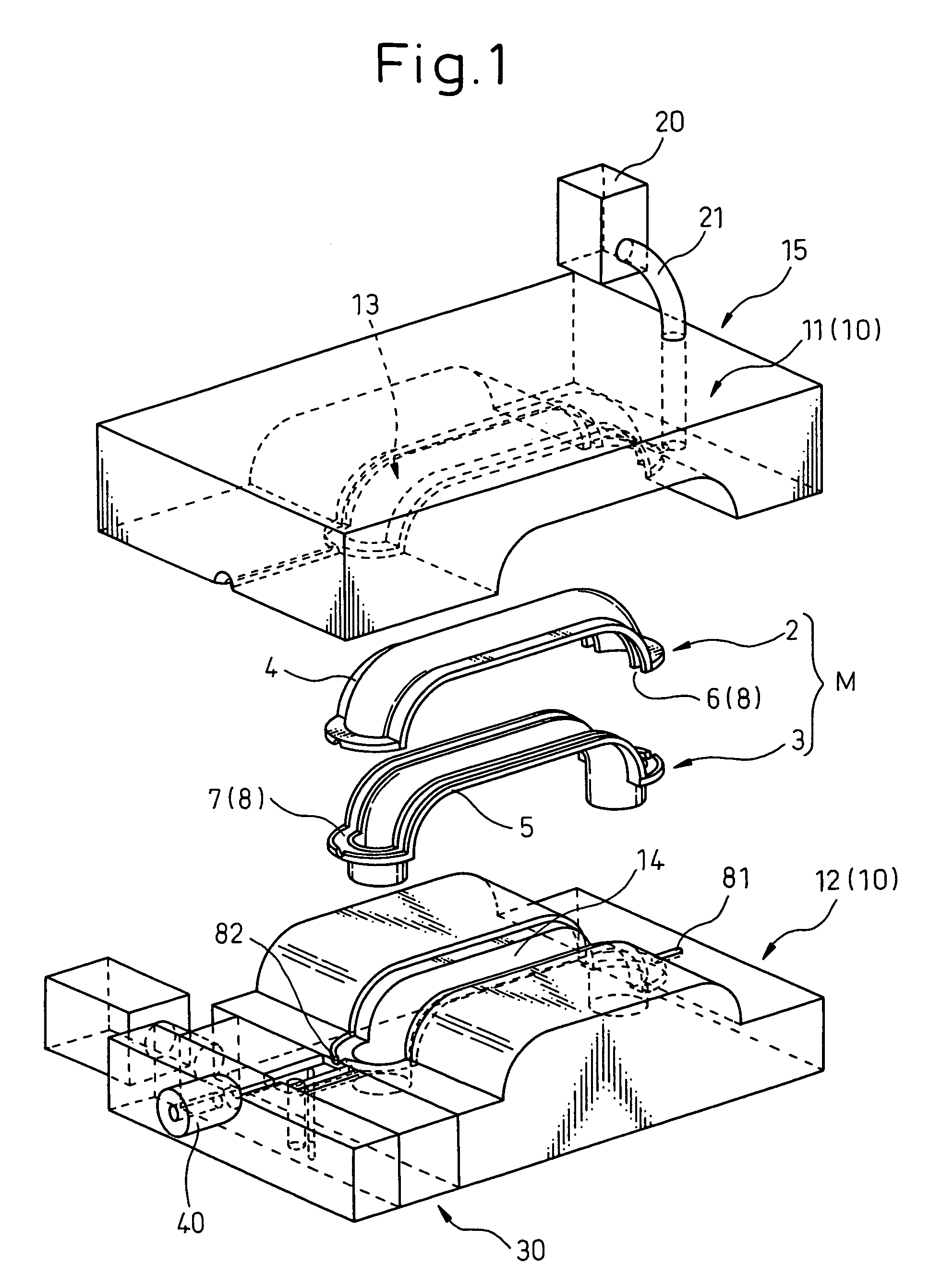

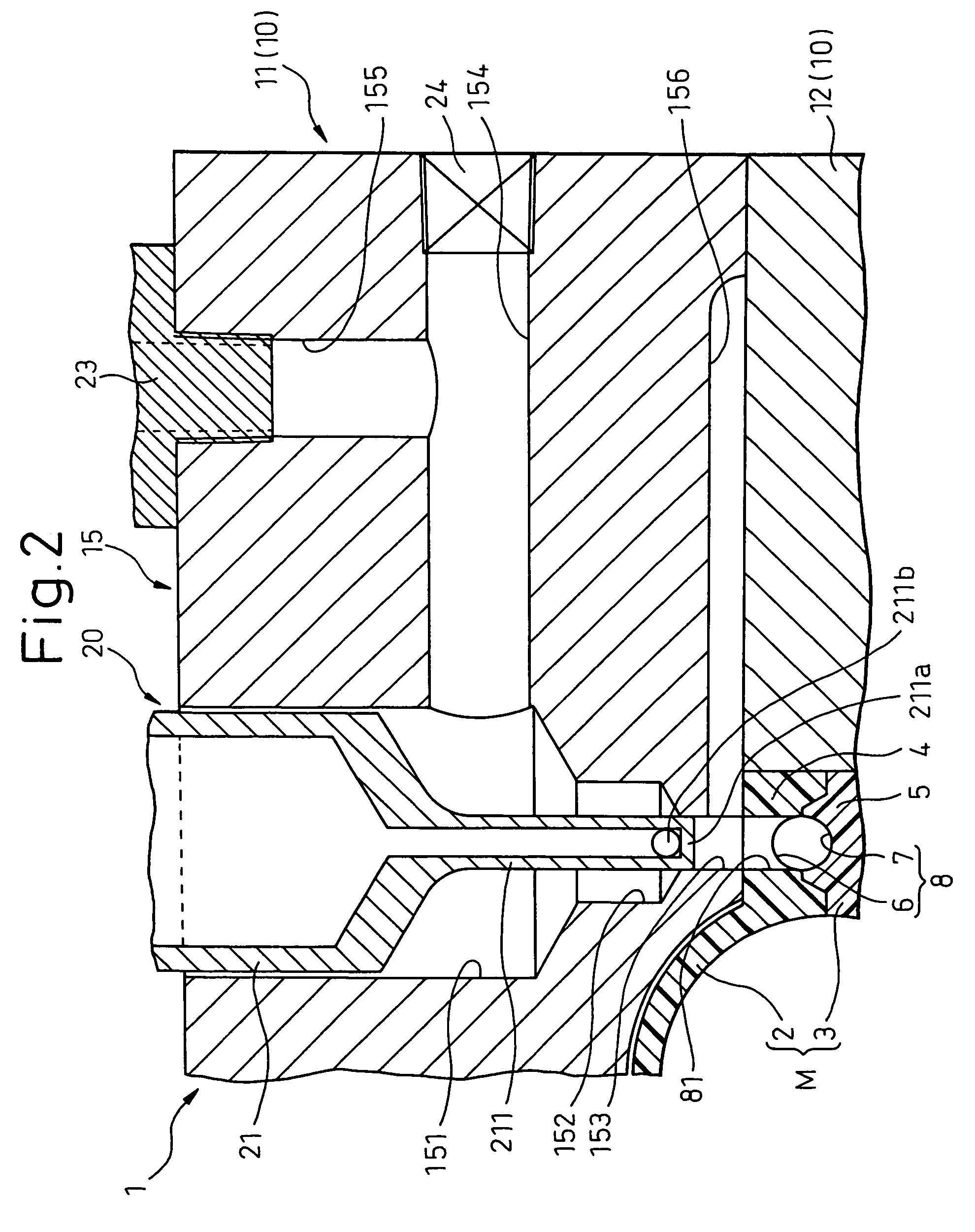

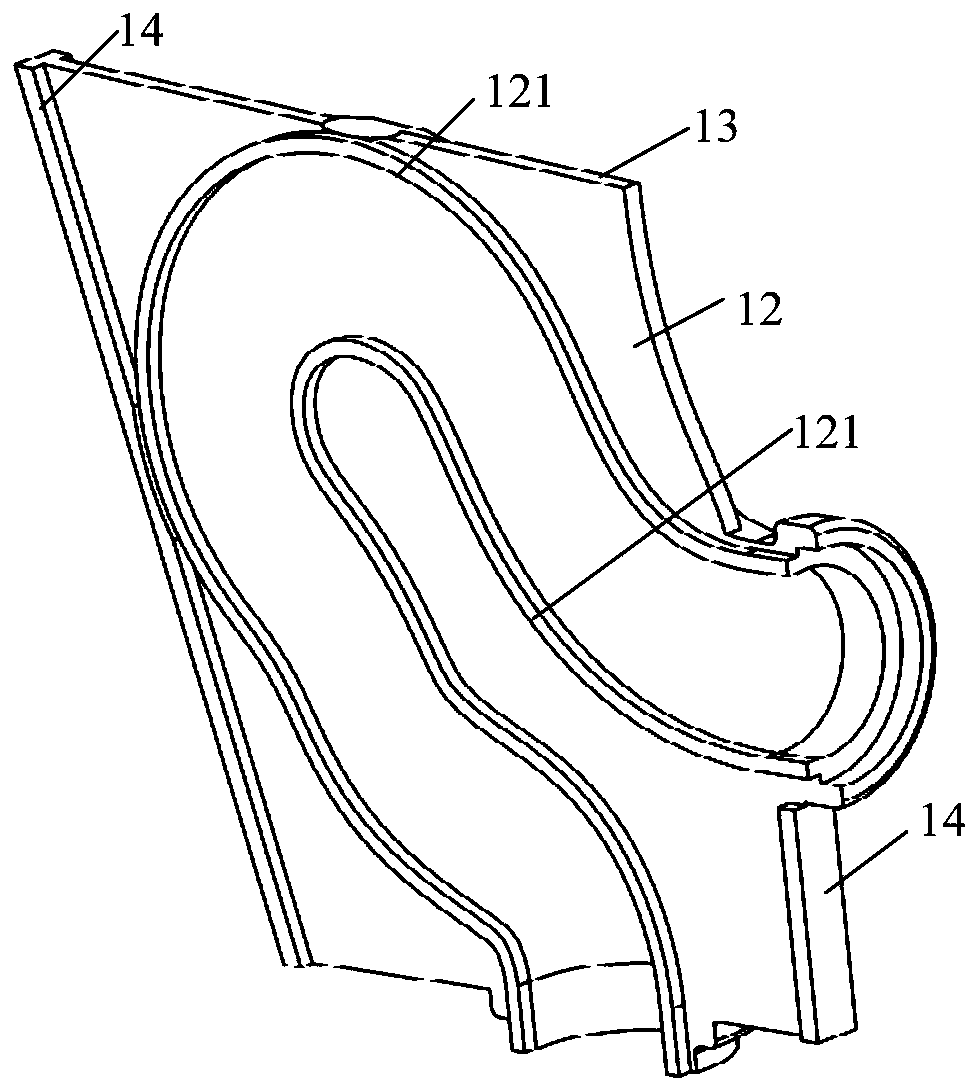

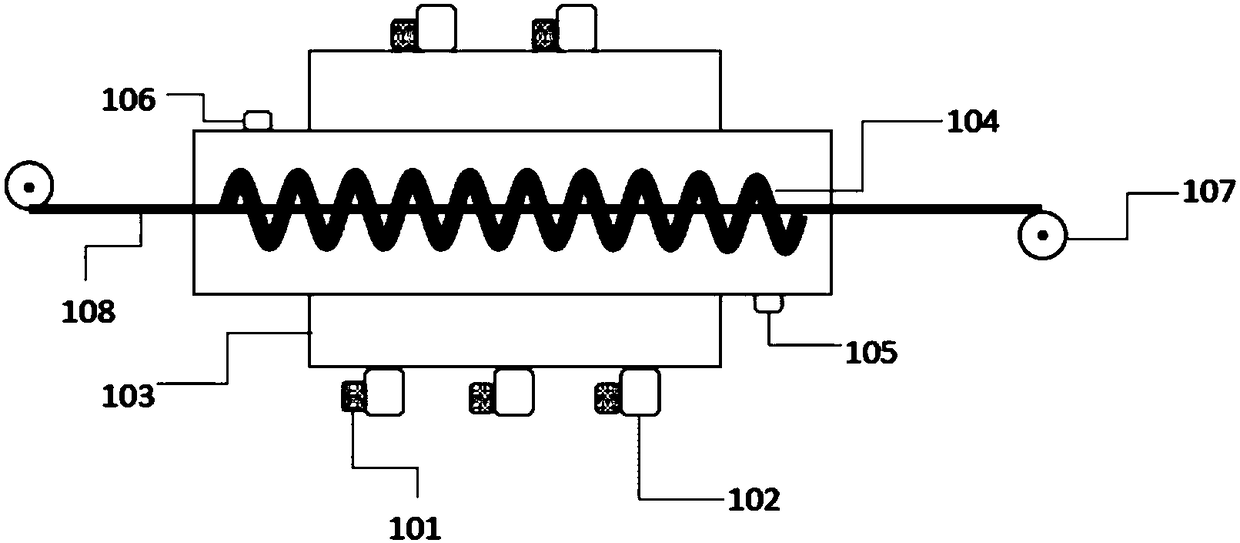

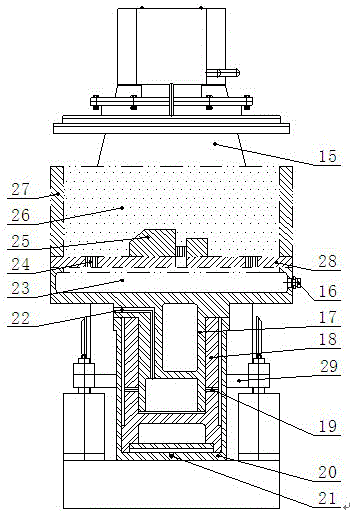

Heated medium supplying method and structure for secondary molding of resin molding component

A hot-air supply structure (1) comprises a hot air generator (20) and a housing (15) formed in the neighborhood of a hot-air inlet (81) of a molded component M in a die (10). A nozzle (21) is formed at the forward end of the hot-air generator, and an ejection port (211b) is formed on the side wall portion of the forward end needle unit (211) of the nozzle. The housing includes a support hole (151) in the nozzle, a relief hole (152), a flow path communication passage (153) and a bypass (154). The ejection port is movable between a first position to discharge the cool or warm air into the atmosphere through the bypass from the relief hole and a second position to introduce hot air into the flow path (8) of the molded component through the inlet (81) and the passage (153).

Owner:DENSO CORP

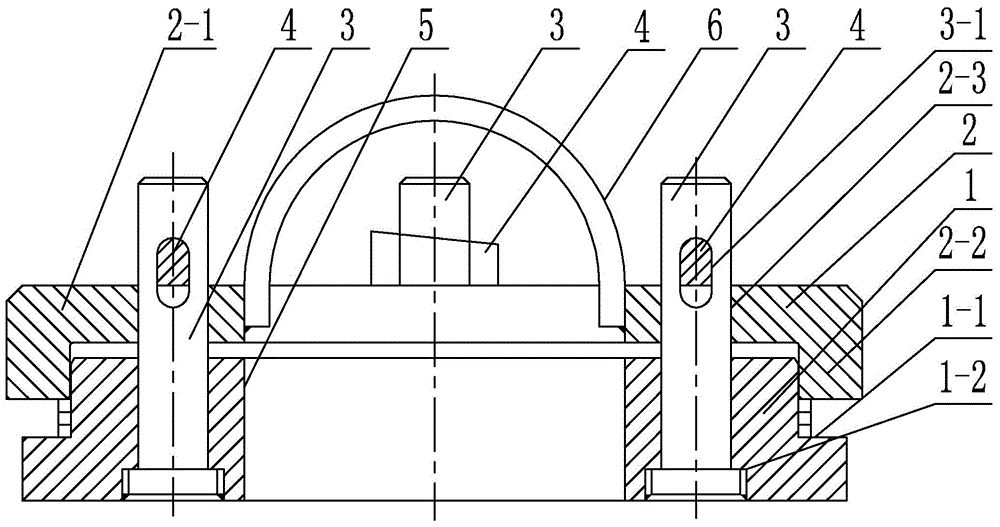

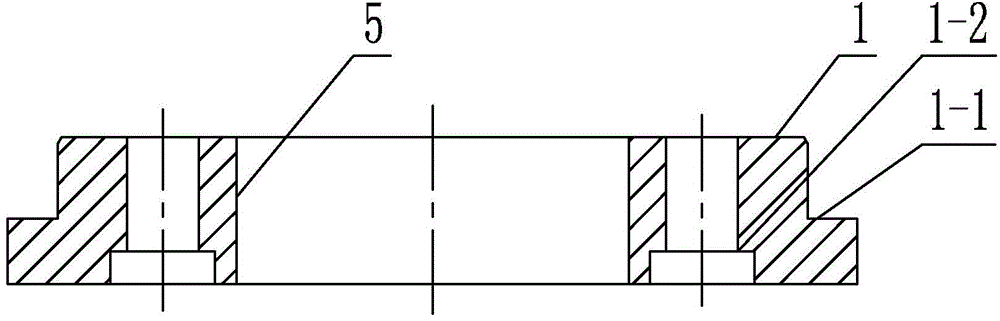

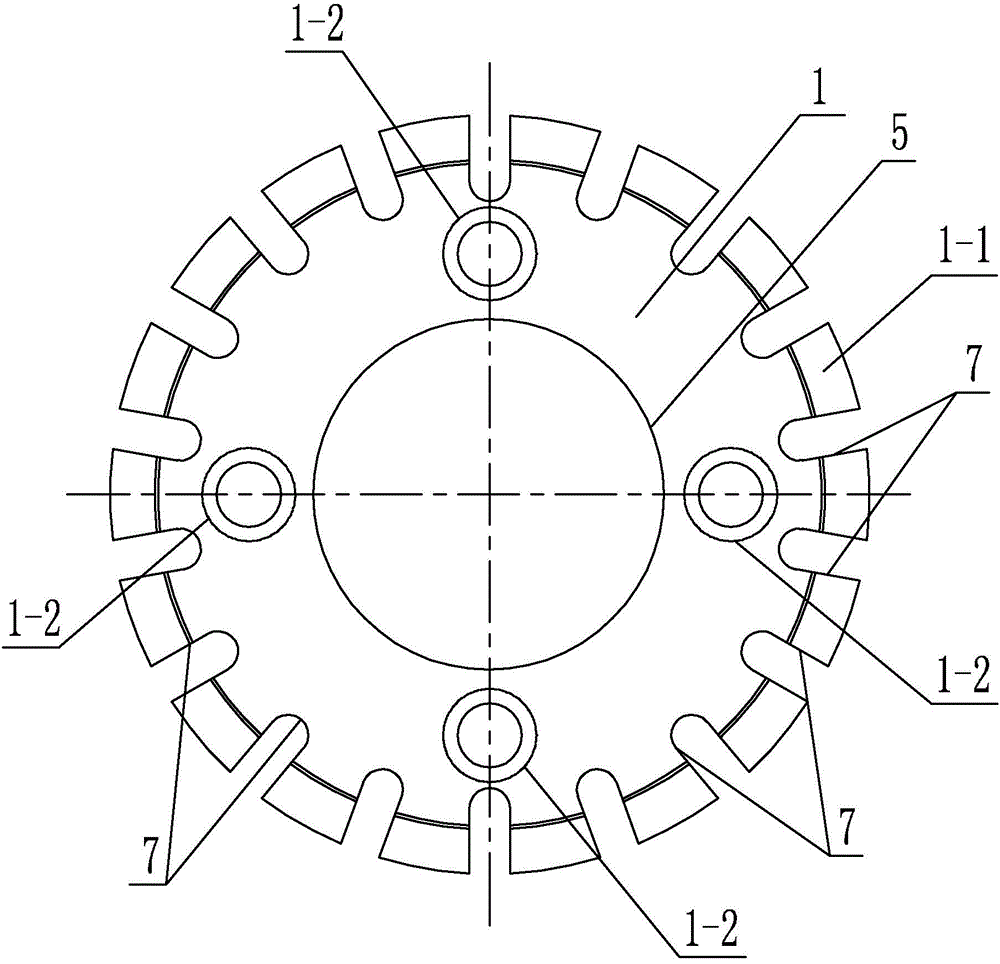

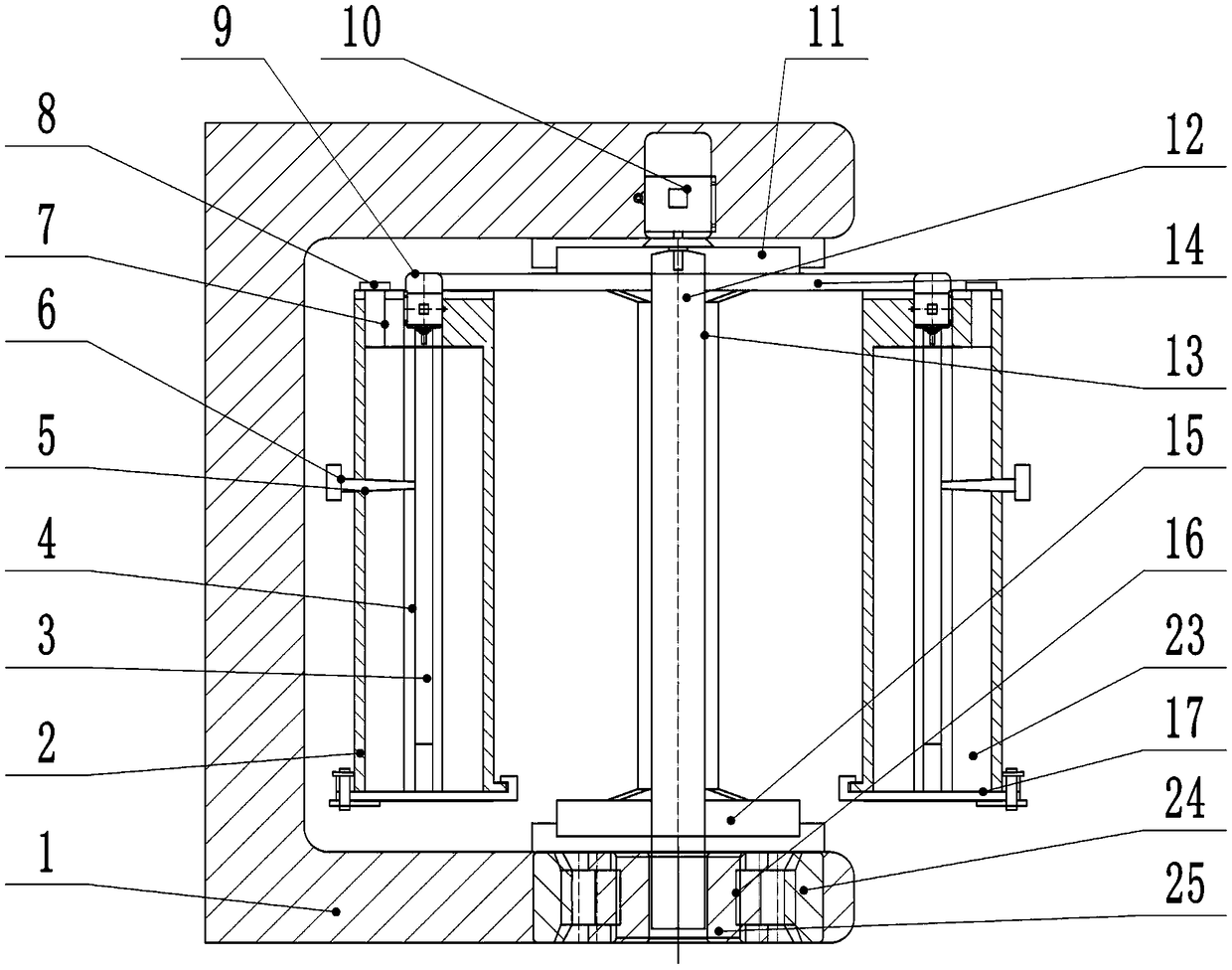

Quench hardening shaping fixture for metal-material super-thin opening annular element

InactiveCN103952526AIncrease contact areaGuaranteed opening sizeFurnace typesHeat treatment furnacesMetallic materialsLarge deformation

The invention discloses a quench hardening shaping fixture for a metal-material super-thin opening annular element, relates to a shaping fixture, and aims to solve problems that because an opening annular element forms larger stress in quenching and tempering processes, the opening annular element has large deformation and the opening size of the opening annular element cannot be guaranteed. A shoulder is processed on a base plate; the diameter of the upper part of the base plate is smaller than the diameter of the lower part of the base plate; the press plate is composed of a press plate main body and a press ring; the press ring is fixedly mounted on the outer edge of the lower end face of the press plate main body; the press plate main body and the press ring are made into a whole; a press plate covers the upper end face of the base plate; the press ring is sleevedly mounted on the upper end part of the base plate; the base plate and the press plate are each provided with 16-24 U-shaped grooves along the circumferential direction in a processing mode, and the U-shaped grooves are processed in an up-and-down corresponding mode; a strip-shaped through hole is processed on each of locking shaft pins; the base plate and the press plate are locked tightly through the locking shaft pins; each strip-shaped through hole is provided with a wedge block; central through holes are correspondingly respectively processed on the base plate and the press plate, and the central through hole of the press plate is provided with a hinge. The fixture is used for quench hardening shaping of the metal-material super-thin opening annular element.

Owner:HARBIN TURBINE

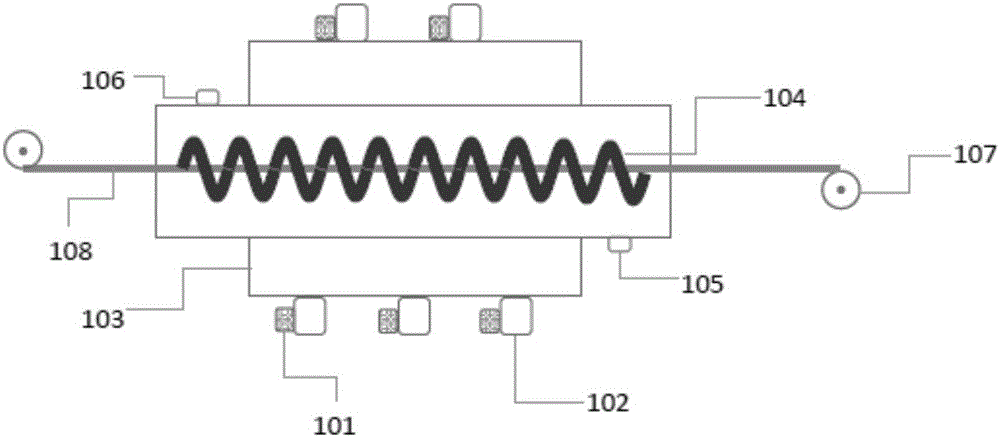

Method for curing diamond resin line by microwave-ultraviolet combined use type

ActiveCN105797664AShorten drying timeUniform hardeningEnergy based chemical/physical/physico-chemical processesProcessing typeMicrowave

The invention discloses a method for curing a diamond resin line by microwave-ultraviolet combined use type. The method comprises the following steps of arranging the diamond resin line in a microwave and ultraviolet-containing curing device, and curing, wherein the diamond resin line comprises a diamond-containing resin coating layer and a metal core layer; the resin is a mixed resin which comprises a thermosetting resin and a photocuring resin. The method has the advantages that industrial microwave heating and ultraviolet curing techniques are applied into the production of the diamond resin line, the traditional processing type of the diamond resin line is changed by utilizing the advantages of microwave heating and ultraviolet curing, the resin drying time is shortened, the curing of the resin line is more uniform, the holding force of diamond on the line is enhanced, and the cutting efficiency is improved; the traditional coating type of the resin line is changed, the exposure speed of the diamond on the line is high, and the defect of exposure only by removing the surface coating layer of the diamond in the preliminary stage is overcome.

Owner:广东烯王科技有限公司

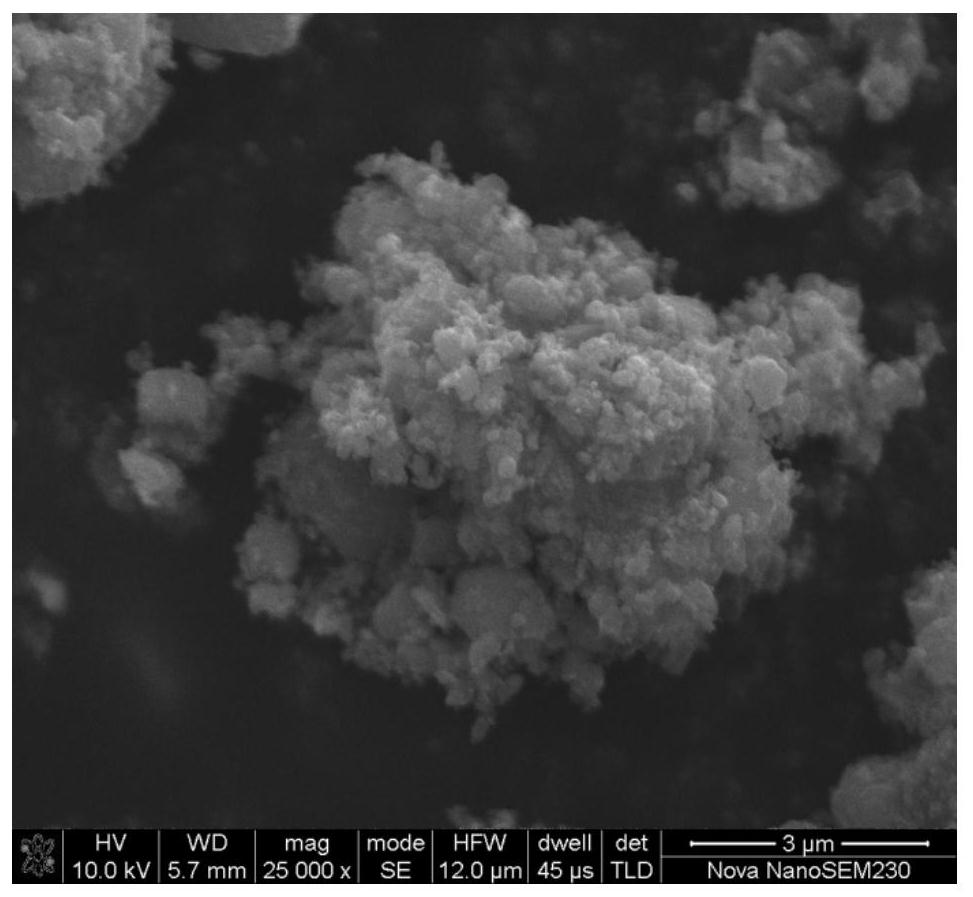

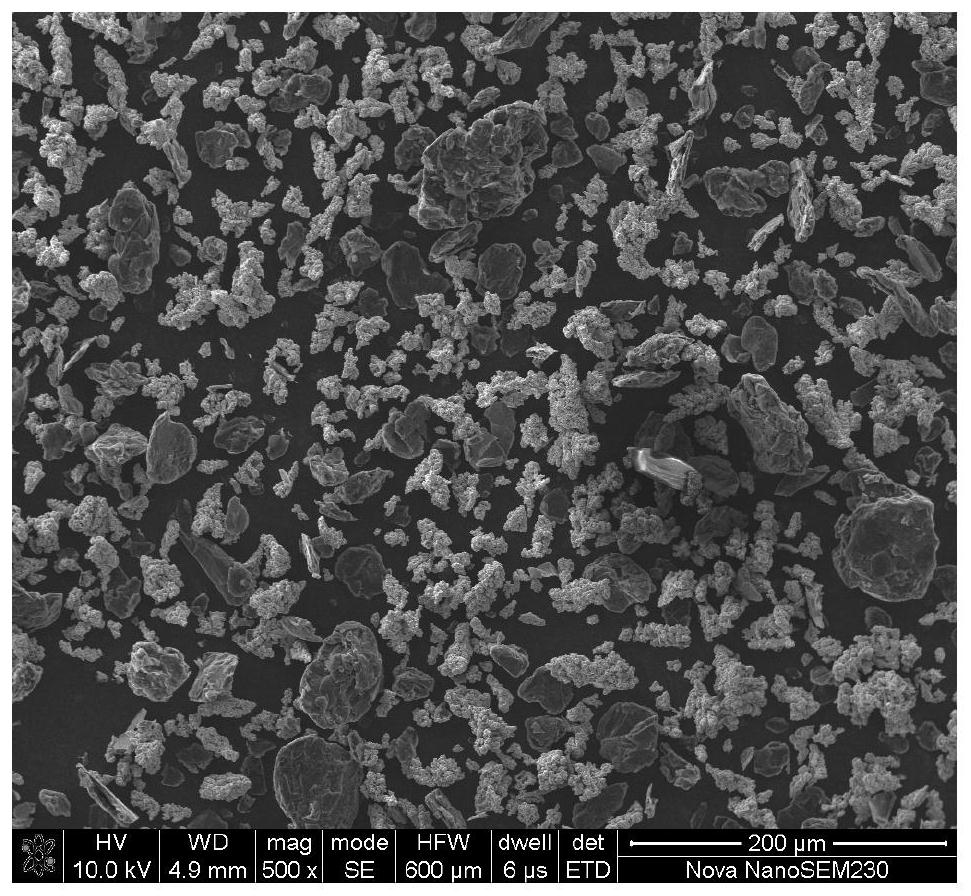

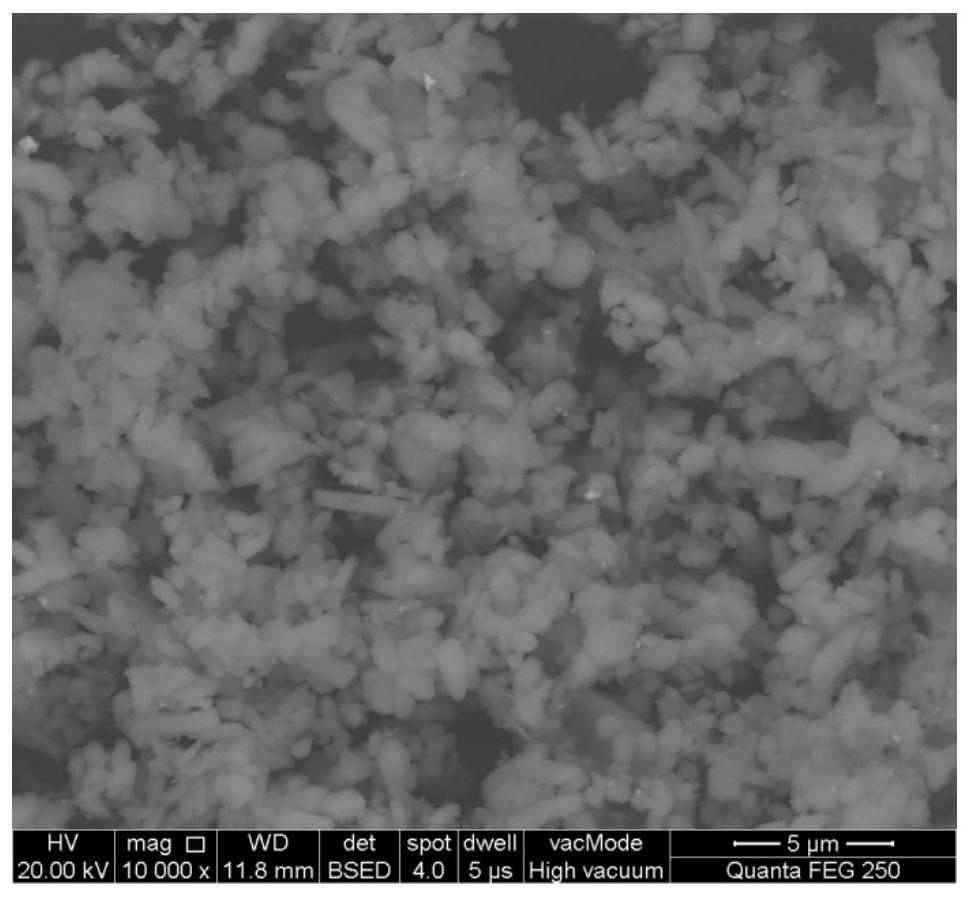

Application of phenolic resin coating treatment technology to preparation of powder metallurgy material with ball milling method

PendingCN112091222AWell mixedUniform hardeningTransportation and packagingMetal-working apparatusResin coatingUltimate tensile strength

The invention relates to an application of a phenolic resin coating treatment technology to preparation of a powder metallurgy material with a ball milling method, and belongs to the technical field of powder. According to the application, phenolic resin is introduced as a control agent for the strength of the powder metallurgy material and a dispersant for various added substances, so that the problem of difficult pressing and sintering possibly caused by matrix work hardening in the ball milling process is successfully solved, and meanwhile, the problems that the various added substances aredifficult to uniformly disperse and the structural integrity of the added substances is obviously damaged in the crushing process are solved, and the strength of the material in the subsequent high-temperature use process is maintained. According to the application, for the hardness difference of soft and hard materials, in order to realize dispersion of substances having the relatively-large hardness difference in metal, different phenolic resin coating treatment is utilized, so that the influence of obvious work hardening brought by matrix ball milling on subsequent pressing and sintering is reduced while uniform dispersion is realized. The preparation technology is simple, the cost is low, and large-scale industrial application is facilitated.

Owner:CENT SOUTH UNIV

Capsule and system for beverage preparation

ActiveUS10752431B2Avoid deformationReliable reinforcementBeverage vesselsPackagingEngineeringStructural engineering

A capsule for the preparation of a beverage comprises a lateral wall, an inlet wall and a lower wall forming a hollow body having a substantially central axis, the inlet wall extends from a peripheral end of the lateral wall towards said central axis and a plurality of sunken portions are extending on both lateral and inlet walls across the edge between said walls each portion connecting together the lateral wall and the inlet wall.

Owner:TUTTOESPRESSO SRL

Efficient producing drying device for assembling type building

The invention discloses an efficient producing drying device for an assembling type building. The device comprises a supporting arm, a drying cabin shell, a connecting plate and a lower baffle; the drying cabin shell is fixedly arranged on the lower portion of the connecting plate through a bolt set, a feeding channel is arranged on the outer side of the upper portion of the drying cabin shell, adrying cavity is formed in the drying cabin shell, a limiting pin is arranged in a limiting thread hole, the tail end of the limiting pin is fixedly provided with a limiting pin handle, the lower baffle is arranged on the bottom of the drying cabin shell, a limiting hole is formed in the upper end of a fixed shaft, a limiting pin is arranged in the limiting hole in a close fit manner, and a lowerbaffle fixing plate is designed in a lengthened manner, and is fixedly connected to the lower end of the lower baffle. The dual-rotation structure is adopted in the device, multiple concrete columns can be dried at a time, drying is uniform, efficiency is obviously improved, due to a roller type drying structure, setting of the concrete columns is more uniform and compact, and problems appearing in natural setting are solved.

Owner:CHONGQING REAL ESTATE COLLEGE

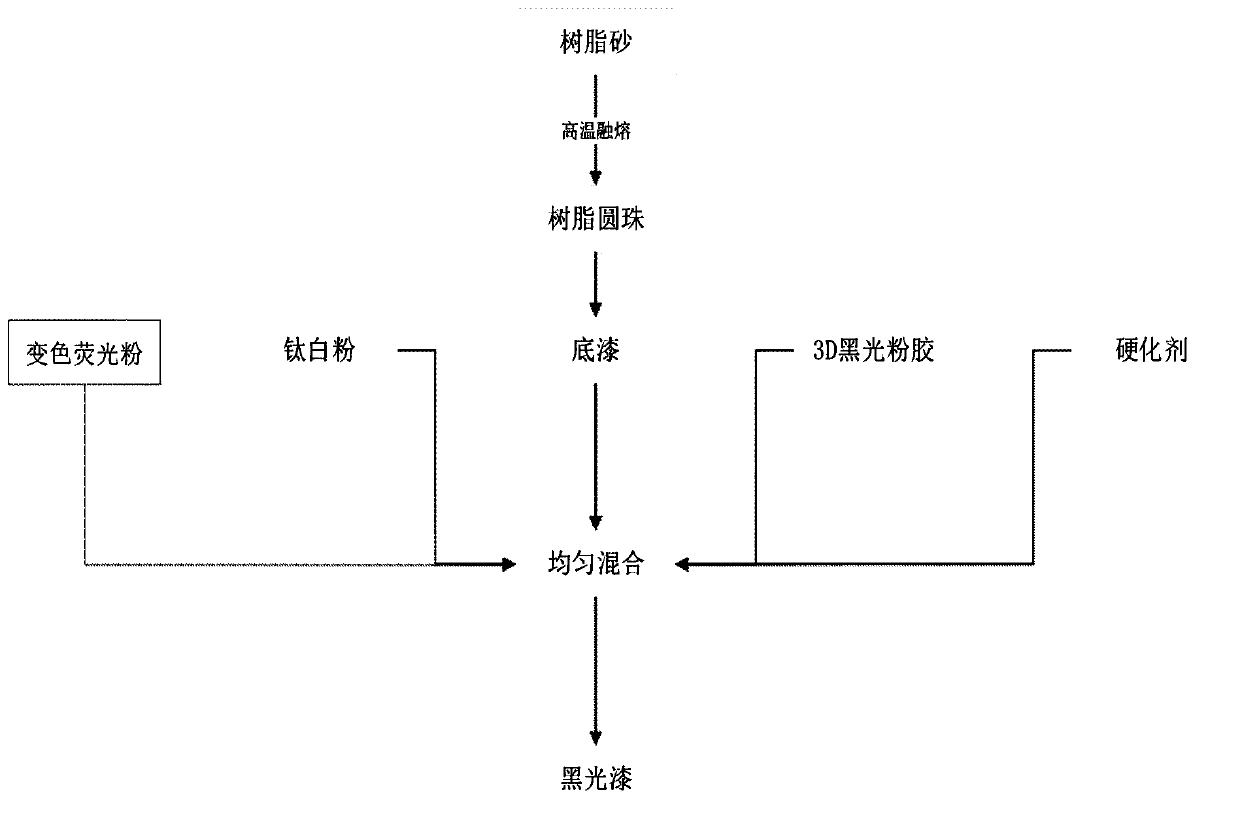

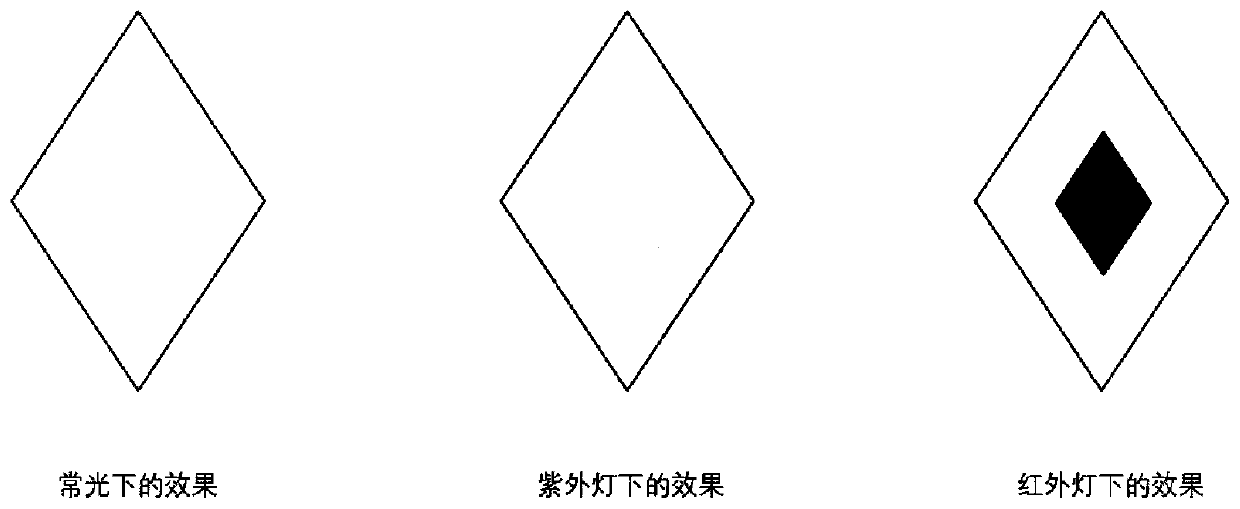

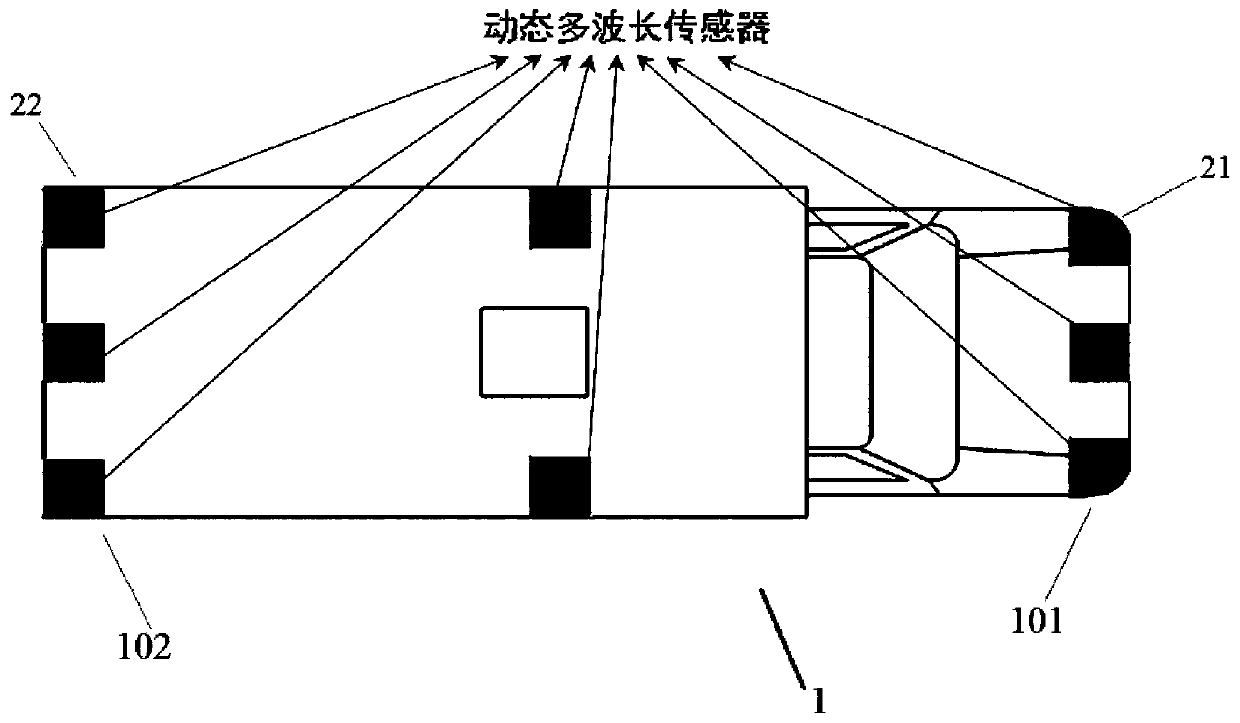

Multi-vision fluorescent paint surface marked navigation system and multi-vision fluorescent paint surface marked navigation device

InactiveCN109705644AUniform dispersionUniform hardeningInstruments for road network navigationLuminescent paintsFluorescencePhosphor

The invention belongs to the technical field of unmanned driving, and concretely relates to a multi-wavelength optical flow navigation system and a multi-wavelength optical flow navigation device. Thesystem comprises a multi-vision paint surface used for carrying out traveling adjustment on a driverless car, and the multi-vision paint surface comprises a phosphor, titanium dioxide, a priming paint and a hardener, wherein the phosphor comprises a photochromic phosphor. The priming paint and titanium dioxide are used in the multi-vision paint surface as dispersants to make the phosphor uniformly dispersed and hardened, so the heat dissipation capability and the aging resistance of the multi-vision paint surface are improved. The navigation system can powerfully ensure the optical flow adjustment of the driverless car in the traveling process at any time, and can adjust the heading direction of the car at any time to achieve safe driving.

Owner:深圳市数聚天源人工智能有限公司

Heated medium supplying method and structure for secondary molding of resin molded component

InactiveUS7459118B2Improve deposition qualityInhibition strengthFood shapingTubular articlesAtmospheric airNozzle

A hot-air supply structure (1) comprises a hot air generator (20) and a housing (15) formed in the neighborhood of a hot-air inlet (81) of a molded component M in a die (10). A nozzle (21) is formed at the forward end of the hot-air generator, and an ejection port (211b) is formed on the side wall portion of the forward end needle unit (211) of the nozzle. The housing includes a support hole (151) in the nozzle, a relief hole (152), a flow path communication passage (153) and a bypass (154). The ejection port is movable between a first position to discharge the cool or warm air into the atmosphere through the bypass from the relief hole and a second position to introduce hot air into the flow path (8) of the molded component through the inlet (81) and the passage (153).

Owner:DENSO CORP

High-strength closestool and manufacturing method thereof

PendingCN110000894AConsistent densityStable supportWater closetsMould separation apparatusSlurryEngineering

The invention discloses a high-strength closestool and a manufacturing method thereof. The high-strength closestool comprises a closestool main body, a bent pipe and a side wall, wherein the closestool main body and the side wall are separately and integrally formed; the bent pipe comprises a first half pipe and a second half pipe, and the first half pipe and the second half pipe are bonded to form the bent pipe; and the first half pipe and the second half pipe are of a double-sided slurry structure. The strength of the closestool can be improved, and the yield of closestools can also be improved.

Owner:SHUNDE AREA FOSHAN LEHUA CERAMIC SANITARY WARE

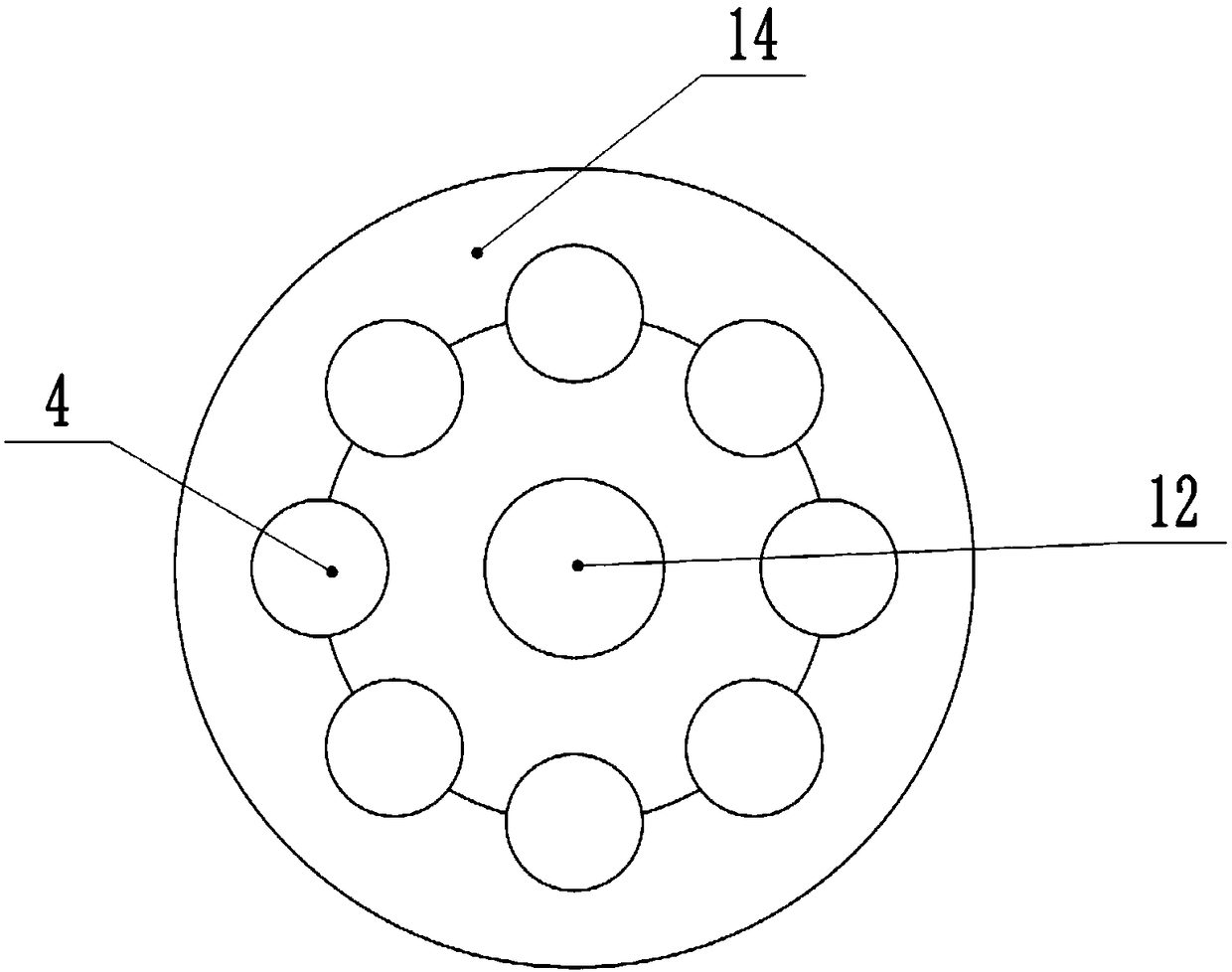

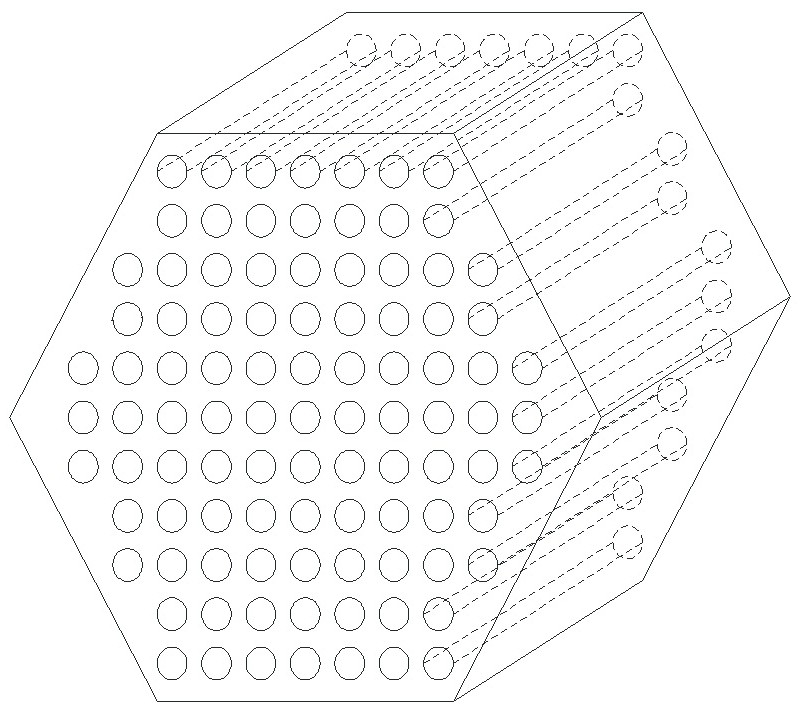

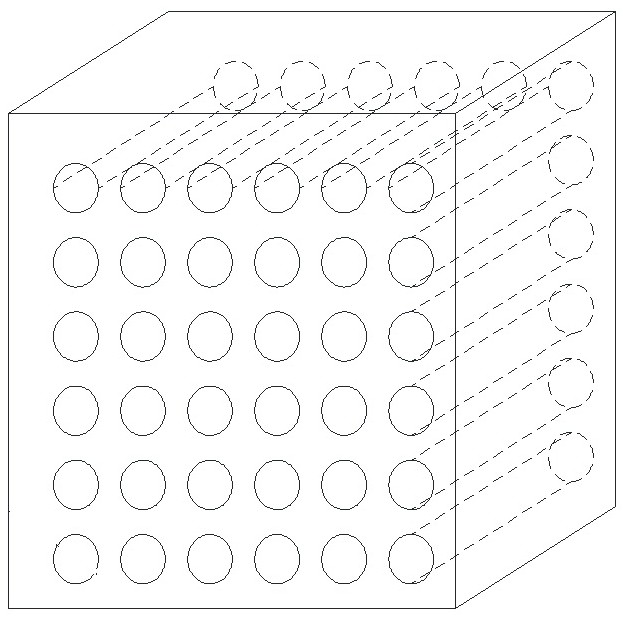

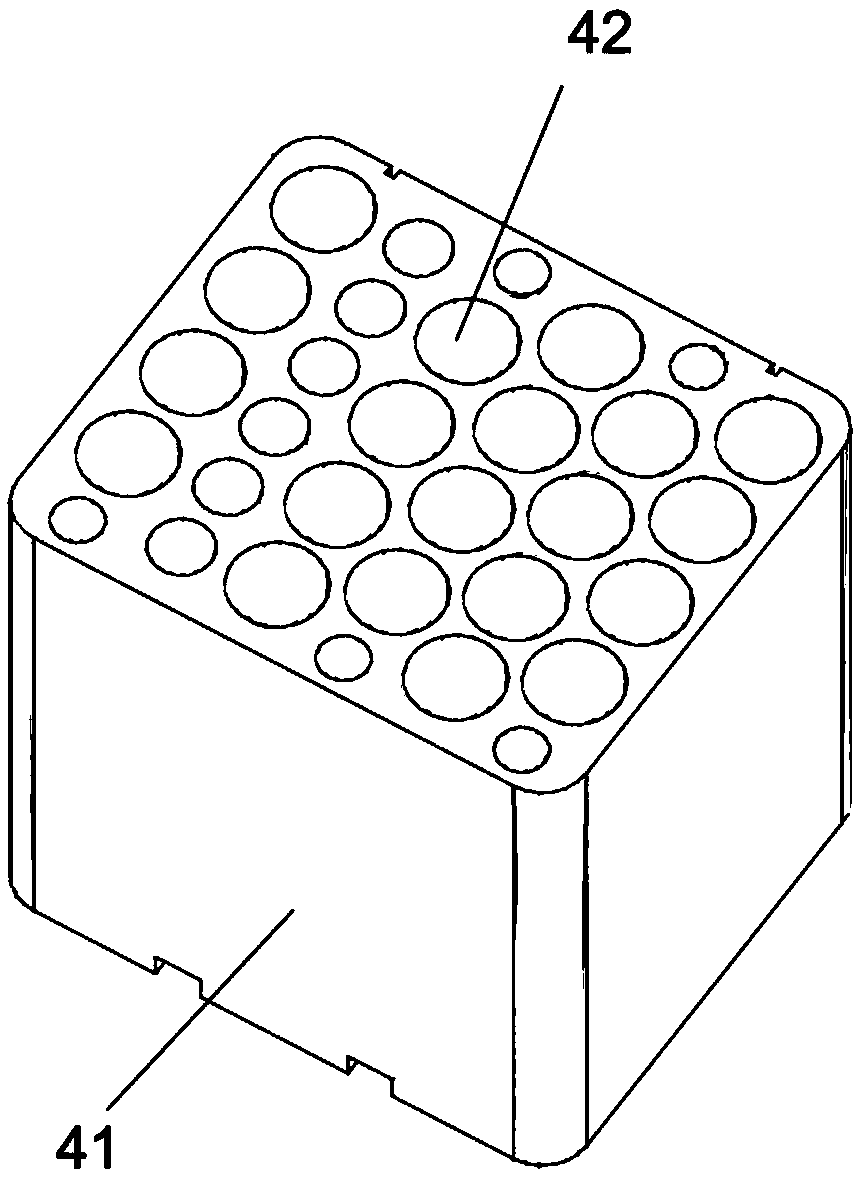

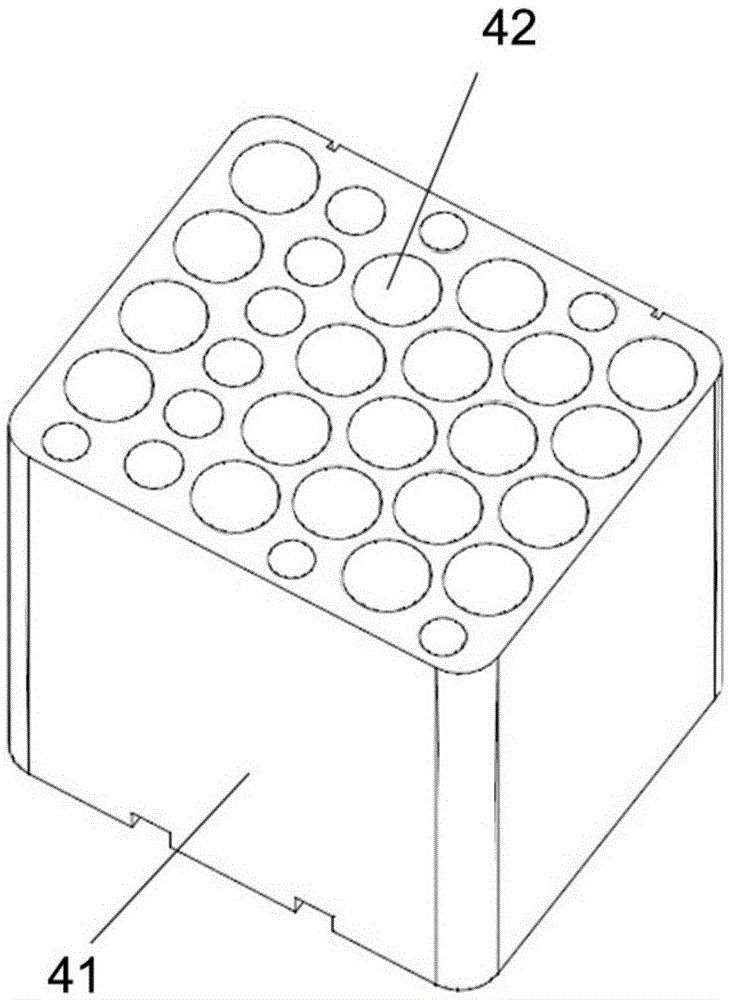

Preparation method of novel microorganism high-enrichment filler

PendingCN112456872AHigh porosityHigh strengthCeramic shaping apparatusCement mixing apparatusBiotechnologyMicroorganism

The invention discloses a preparation method of a novel microorganism high-enrichment filler, the structure of the filler is in a regular polyhedron shape, the cross section of the filler is square orregular hexagonal, regular porous channels are arranged in the filler, and the pore section is circular. The side length of the section of the microorganism high-enrichment filler is about 100 mm, the length is about 100 mm, and the diameter of the filler hole-shaped channel is about 10-20 mm. The filler is used by combining various section shapes, and has the characteristics of high porosity, low possibility of blockage, small flow resistance, convenience in cleaning and the like. The filler is a sintering-free filler and is integrally formed by pressing through a mold. The preparation method has the characteristics of high filler strength, low preparation cost, long service life and the like.

Owner:NANJING WONDUX ENVIRONMENTAL PROTECTION TECH CO LTD

A kind of production method of cold box resin for casting

The invention relates to a method for producing resin, and particularly relates to a method for producing casting cold-box resin. The method comprises the following steps: adding dissolved industrial phenol to a reaction kettle; starting an agitator; adding solid paraformaldehyde, a regulator and 0.08-0.12% of metal ion catalyst; opening a steam valve, slowly heating up, and heating up to 105 DEG C within 40-50 minutes; keeping constant temperature at 105-108 DEG C for 30 minutes; heating up to 112 DEG C within 10-20 minutes, and keeping constant temperature at 112-115 DEG C for 50 minutes; continuing to heat up and dewatering under normal pressure after heat preservation is finished; timing constant temperature when the temperature inside the kettle ascends to 120 DEG C, and keeping constant temperature at 120-123 DEG C for 30 minutes; after constant temperature is finished, vacuumizing and continuing to dewater; stopping dewatering when the total dewatering amount achieves 60% of formaldehyde amount; adding a polar dibasic acid ester, nonpolar high-boiling point solvent oil and a modifier; agitating for 60 minutes; adding an enhancer when cooling to below 40 DEG C; evenly agitating, detecting and packaging. The casting cold-box resin which is low in viscosity, and high in casting sand strength, can be used for a long period of time, and meets core-making production in batches is provided by the invention.

Owner:共享新材料(山东)有限公司

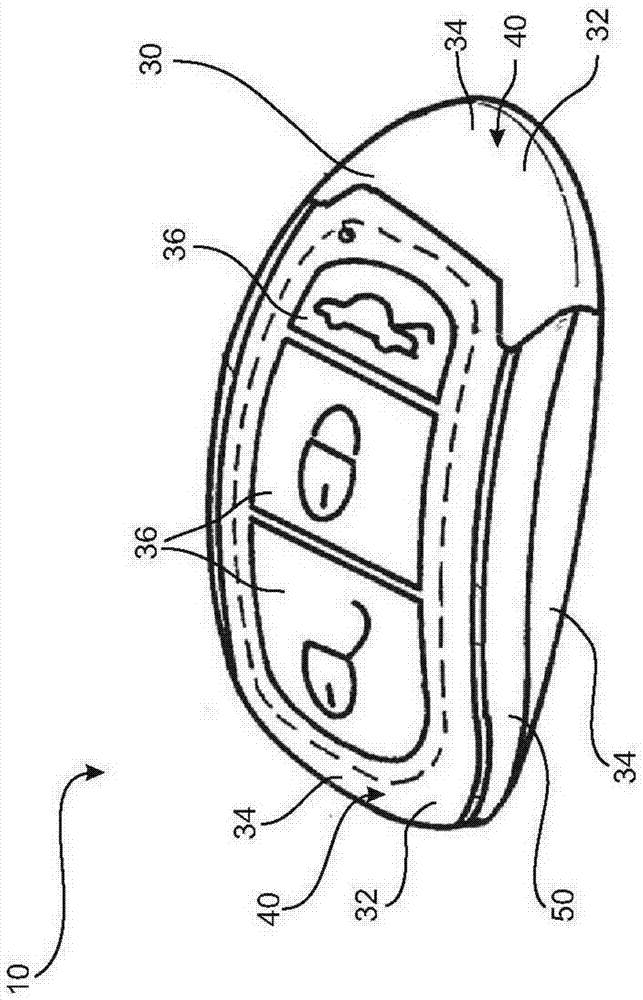

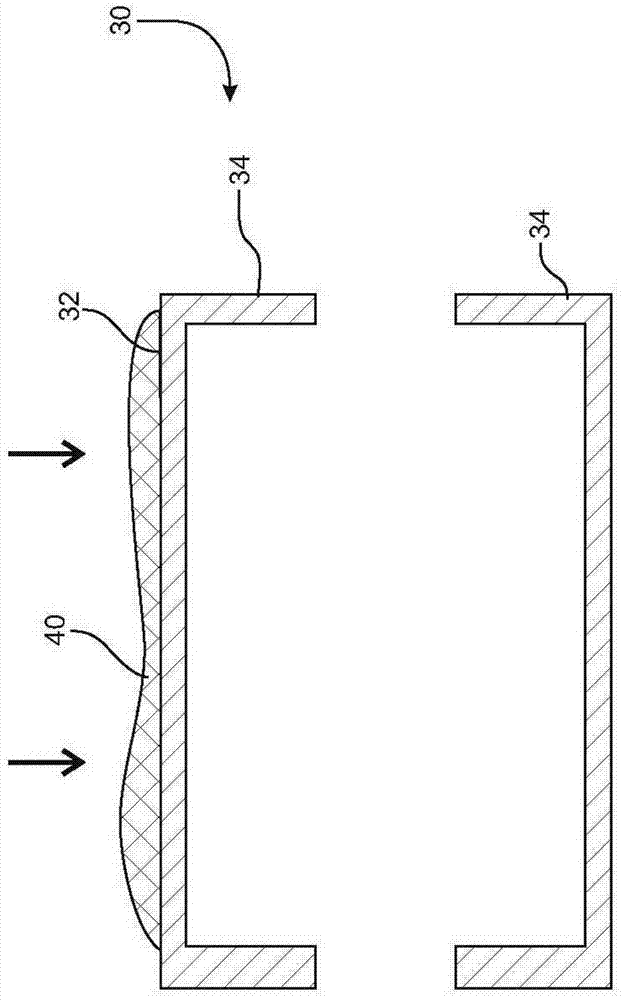

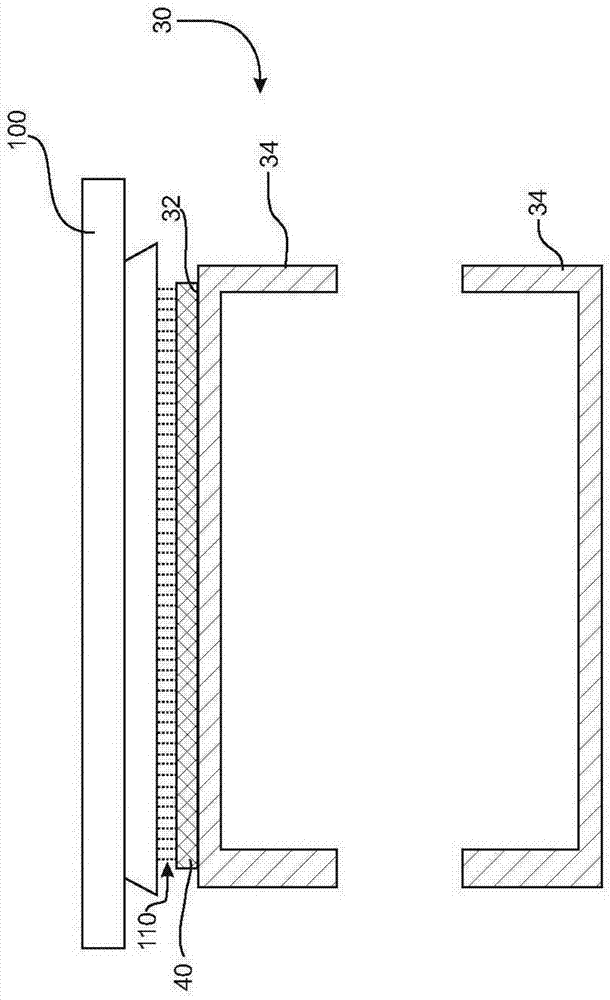

ID transmitter for an access control system

InactiveCN104852954AReduce frictionFree from damageAnti-theft devicesElectric switchesControl systemMedia access control

The invention relates to an ID transmitter (10) for an access control system, in particular an ID transmitter (10) for an access control system for a vehicle. The ID transmitter comprises an electronic module (20) for communication with the access control system and a housing (30) in which the electronic module (20) at least partially disposed. The housing (30) has a protective layer (40) over at least a outwardly directed surface portion (32).

Owner:HUF HULSBECK & FURST GMBH & CO KG

Self-hardening sand bonding agent for casting and preparation method and using method thereof

ActiveCN102139341BGood sand mixing fluidityLow gas productionFoundry mouldsFoundry coresGlycerolSteel casting

The invention relates to a bonding agent for casting, in particular to a self-hardening sand bonding agent for casting and a preparation method and a using method thereof. The self-hardening sand bonding agent for the casting comprises resin and a curing agent, wherein the resin consists of the following components in part by weight: 100 parts of castor oil, 40 to 90 parts of glycerol, 0.1 to 0.2part of calcium oxide, 50 to 90 parts of phthalic anhydride, 5 to 9 parts of dimethylbenzene, 120 to 200 parts of high-boiling point arylhydrocarbon; and the curing agent is prepared by mixing 100 weight parts of isocyanate and 20 to 40 weight parts of high-boiling point arylhydrocarbon. The bonding agent has readily available raw materials and is environment-friendly, equipment required by a synthetic process is simple, and a process condition is easy to control; the bonding agent has high sand mulling flowability, low gas forming amount, high gas forming speed, stable sizes of sand cores / sand molds and smooth surfaces, is convenient to store, and has the excellent effects of resisting sand burning and deformation; and the sand molds are hardened integrally and uniformly, castings have high size accuracy, and sand can be recycled, so the bonding agent is suitable for the production of large-scale steel-casting sand molds.

Owner:NINGXIA UNIVERSITY +1

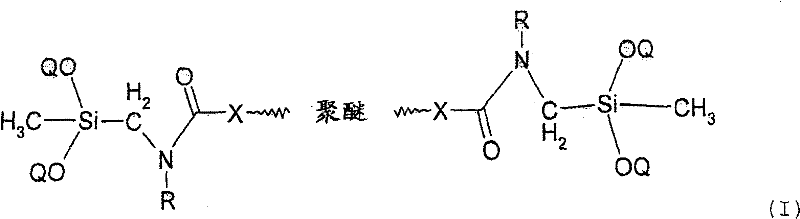

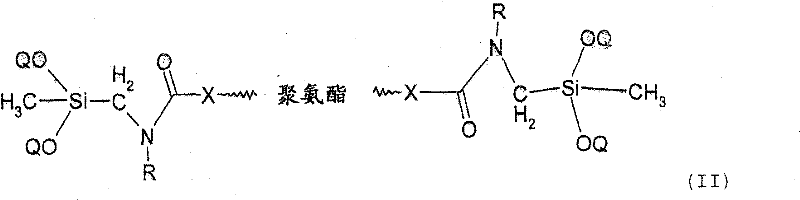

Foam systems , packages and their applications

Foam systems and / or foam kits each have 2 or more components, including component(s) containing alkoxysilane-terminated prepolymers (I) and other component(s), such that reactants (II) that can form a gas in contact with one another are in not less than 2 separate components before mixing. Independent claims are included for (1) use of 2 or more (II) in the production of foam from mixtures containing (II) and (I); (2) use of (I) and (II) for producing a foam system and / or kit; (3) process for producing foam from these systems and / or kits.

Owner:FISCHERWERKE ARTUR FISCHER GMBH & CO KG

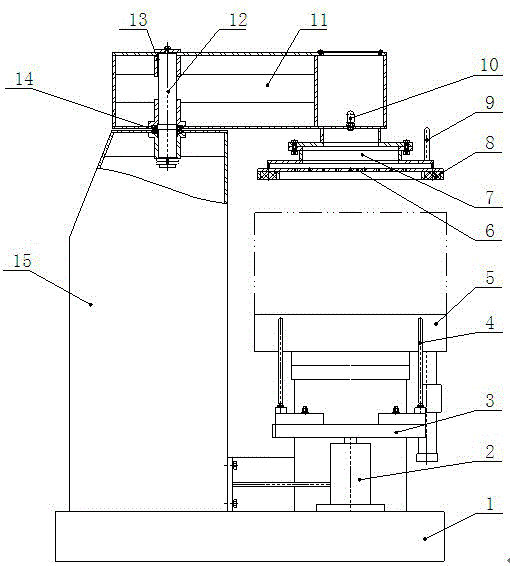

A kind of preparation method and production equipment of fireworks barrel

The invention discloses a firework cylinder manufacturing method and production equipment. The firework cylinder manufacturing method is characterized by including the following steps that a, raw materials are manufactured, wherein the raw materials include plant fibers, padding and a setting and hardening material, and the setting and hardening material is an air hardening cementing material or a water hardening cementing material or a mixture of the air hardening cementing material and the water hardening cementing material; b, the raw materials are put into a forming mould; c, high-frequency vibration is applied to the raw materials in the forming mould through 20KHZ-50KHZ ultrasonic waves, at the same time, an upper mould body and a lower mould body of the forming mould are matched and exert 2t-8t pressure to extrude the raw materials, and the raw materials are extruded into a firework cylinder basic finished product; d, the firework cylinder basic finished product is taken out from the forming mould. The firework cylinder manufacturing method shortens the forming time of the raw materials in the mould, improves demoulding quality, reduces the content of moisture, shortens later drying time, shortens a production cycle of the product, and improves production efficiency of the product.

Owner:汤华荣

A method for curing diamond resin wire by microwave-ultraviolet light combination

ActiveCN105797664BImprove gripFastEnergy based chemical/physical/physico-chemical processesProcessing typeMicrowave

The invention discloses a method for curing a diamond resin line by microwave-ultraviolet combined use type. The method comprises the following steps of arranging the diamond resin line in a microwave and ultraviolet-containing curing device, and curing, wherein the diamond resin line comprises a diamond-containing resin coating layer and a metal core layer; the resin is a mixed resin which comprises a thermosetting resin and a photocuring resin. The method has the advantages that industrial microwave heating and ultraviolet curing techniques are applied into the production of the diamond resin line, the traditional processing type of the diamond resin line is changed by utilizing the advantages of microwave heating and ultraviolet curing, the resin drying time is shortened, the curing of the resin line is more uniform, the holding force of diamond on the line is enhanced, and the cutting efficiency is improved; the traditional coating type of the resin line is changed, the exposure speed of the diamond on the line is high, and the defect of exposure only by removing the surface coating layer of the diamond in the preliminary stage is overcome.

Owner:广东烯王科技有限公司

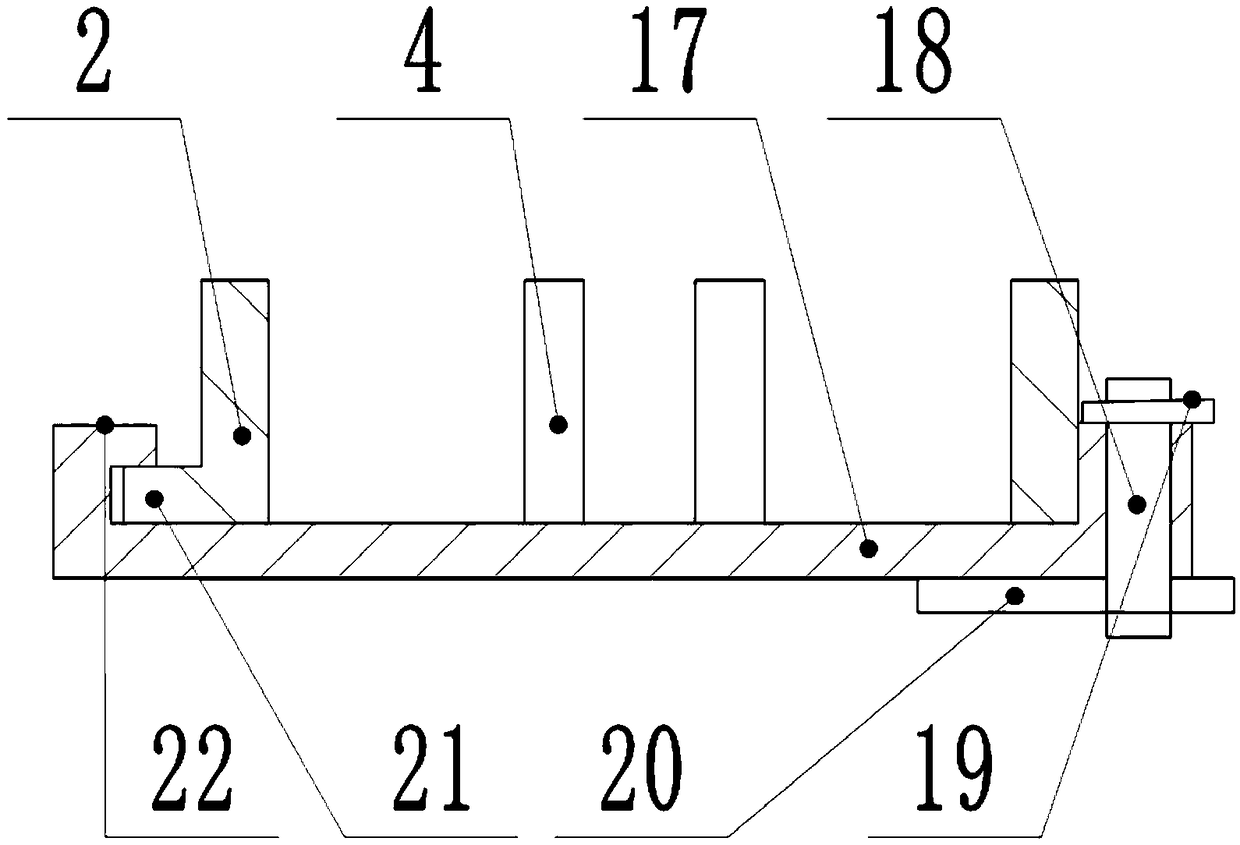

A kind of mold and production equipment for fireworks cylinder body

InactiveCN104501664BReduce manufacturing costSmooth demouldingDischarging arrangementFeeding arrangmentsChemical reactionFireworks

The invention discloses a firework barrel forming mold and production equipment. The firework barrel forming mold comprises a mold base, an upper mold and a lower mold. A forming cavity which is used for accommodating raw materials is arranged on the lower mold, ultrasonic vibration heads which are used for transmitting ultrasonic waves to the forming cavity are arranged on the lower mold, the upper mold comprises an upper mold plate and an upper mold cylinder, the upper mold cylinder is used for driving the upper mold plate to move up and down, the lower mold comprises a cavity, the forming cavity, a lower mold plate and a lower mold cylinder, the forming cavity is arranged on the cavity, the lower mold plate is arranged in the forming cavity, the lower mold cylinder is used for driving the lower mold plate to vertically move up and down in the forming cavity, and the ultrasonic vibration heads are fixed onto the cavity. The firework barrel forming mold and the production equipment have the advantages that the raw materials in the forming mold can be vibrated at high frequencies, accordingly, the internal chemical reaction speeds of the raw materials can be increased, the compactness of products and the quality of the products can be improved, drying degrees of the products can be upgraded, the strength of the products stripped from the forming mold can be improved, the products are difficult to break and are easy to carry, and the time required by drying or natural drying in later periods can be shortened.

Owner:汤华荣

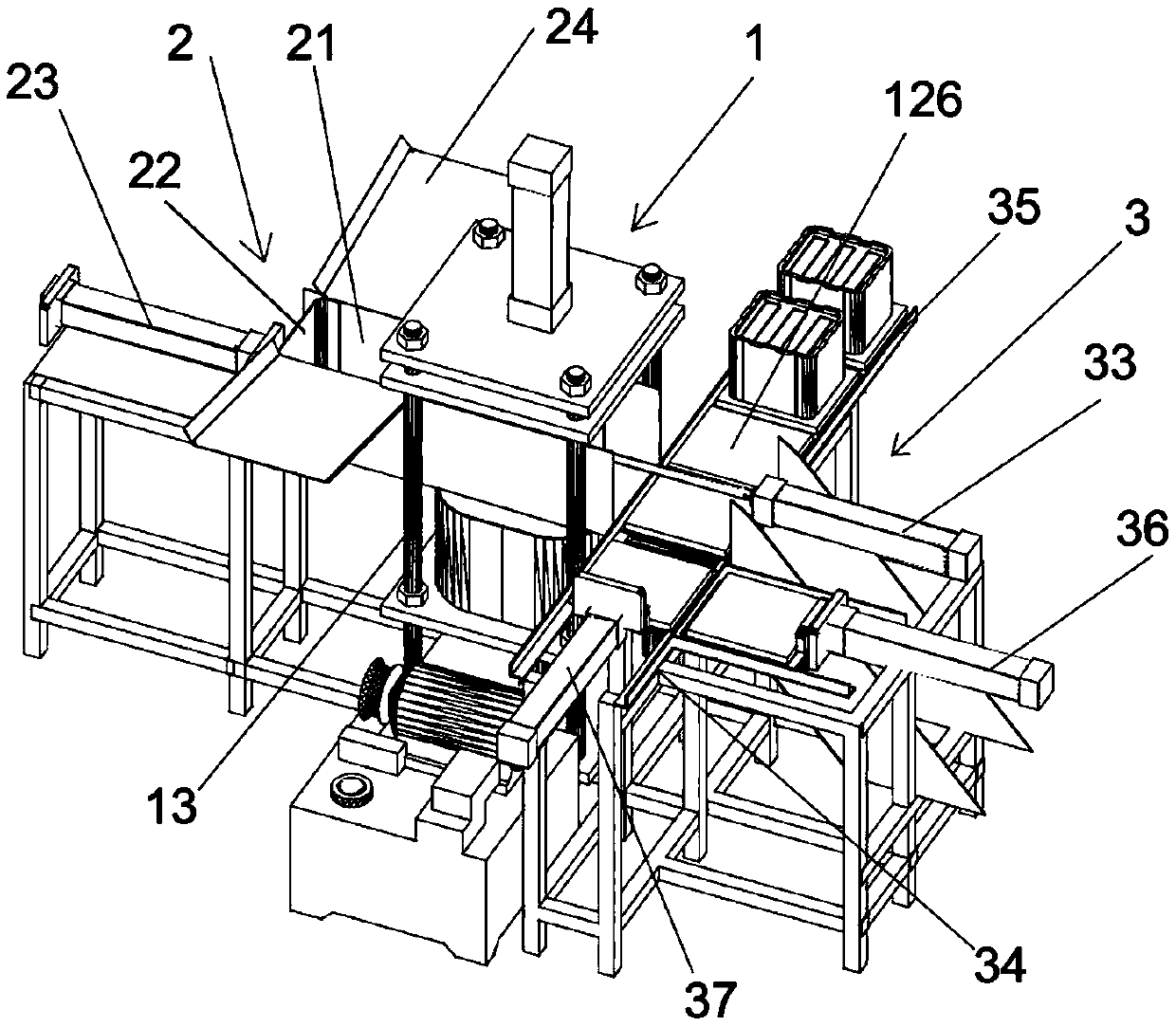

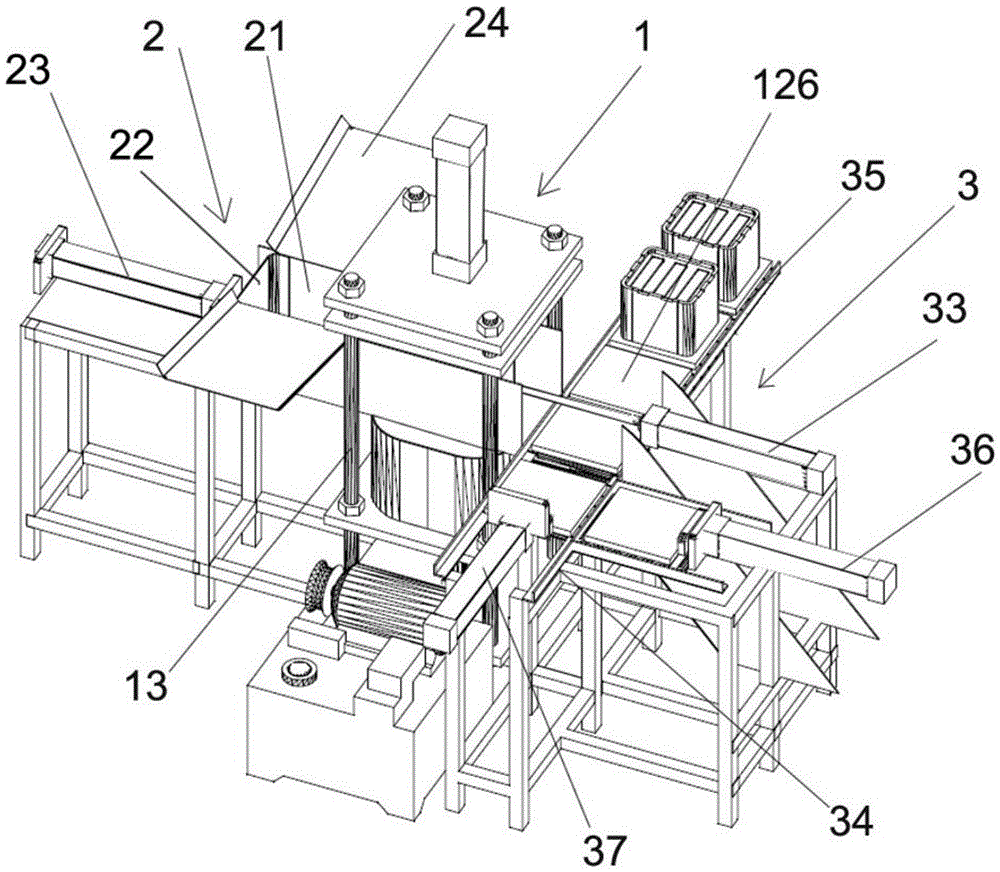

Single-column sodium silicate-bonded sand molding machine and molding technology thereof

ActiveCN103273015BUniform hardeningRealize stand-alone mechanizationMoulding machinesMolding machineEngineering

The invention discloses a single-column sodium silicate-bonded sand molding machine and a molding technology thereof. The molding machine comprises a base and a frame, wherein a pattern drawing mechanism, a lifting mechanism and a vibrating mechanism are arranged on the base; a rotary arm is arranged at the upper end of the frame; a work bench is arranged on the vibrating mechanism; the upper surface of the work bench sinks to form a cavity; a template arranged at the upper end face of the work bench and the work bench form a vacuum chamber; the vacuum chamber is connected with a vacuum system; and a CO2 blowing device is arranged on the rotary arm. The single-column sodium silicate-bonded sand molding machine has the beneficial effects that stand-alone mechanization of sodium silicate-bonded sand molding can be achieved; the technological operation is simple; the labor intensity of working personnel is reduced; and the labor productivity is improved.

Owner:SHANDONG JIANZHU UNIV

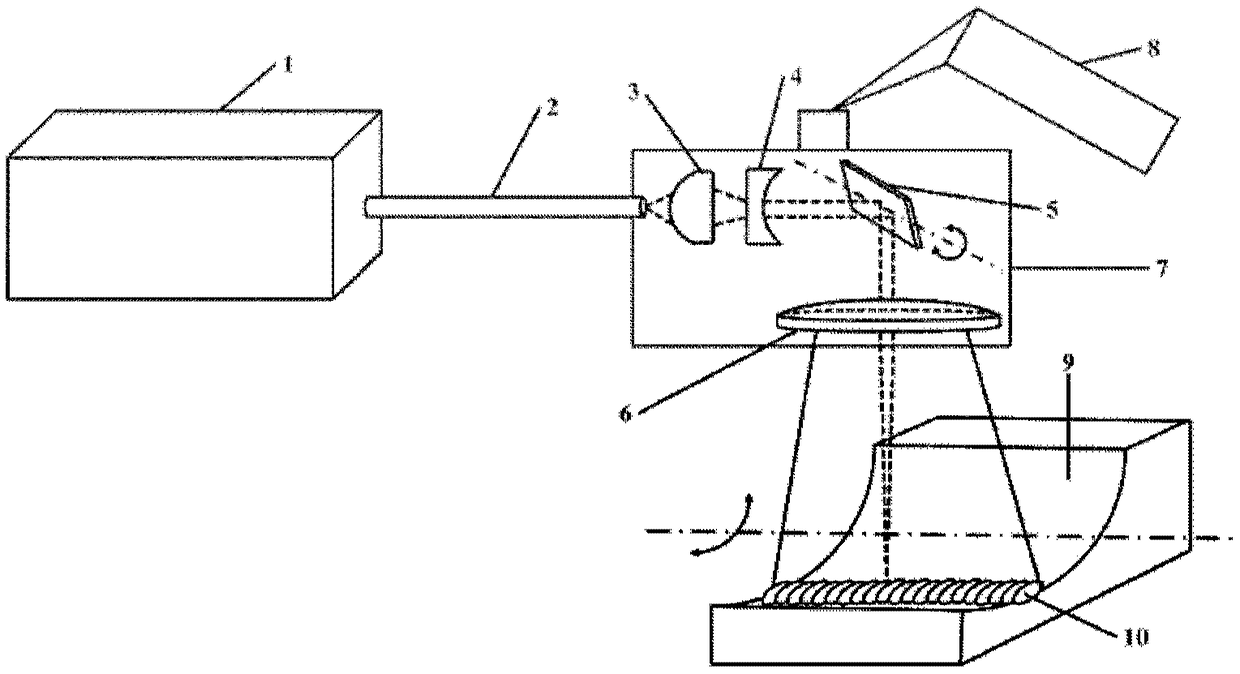

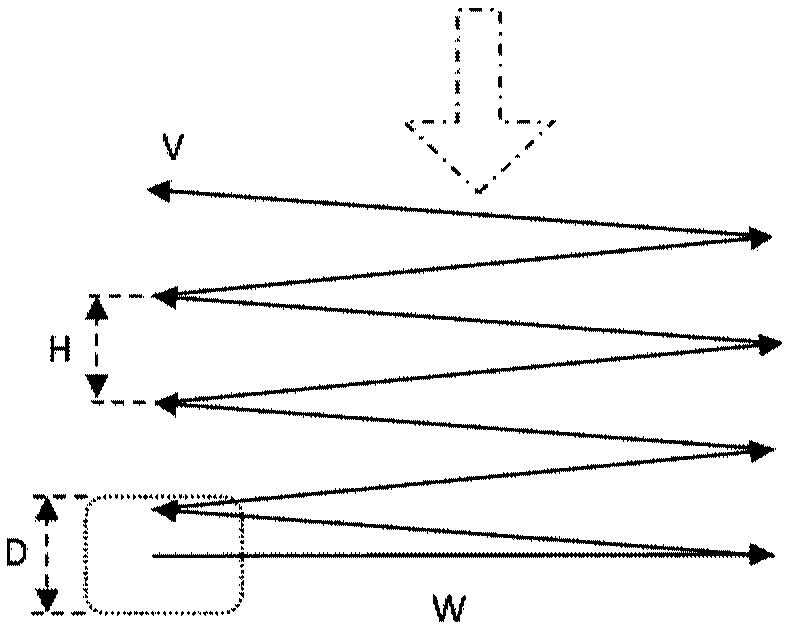

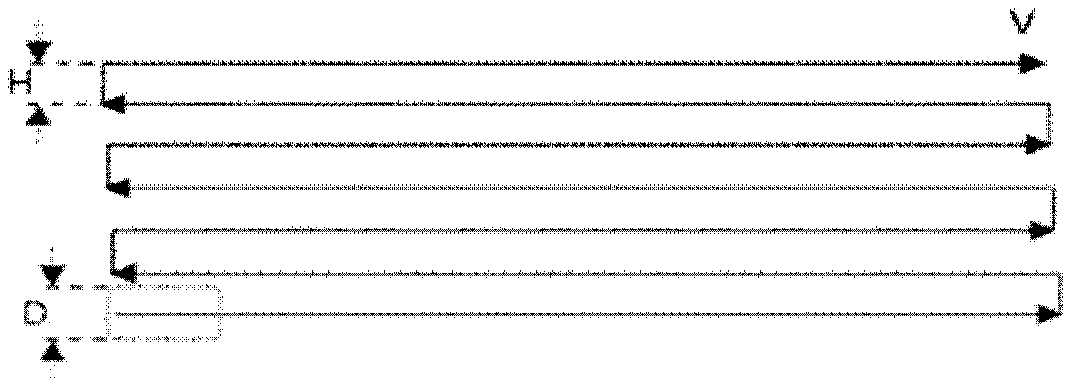

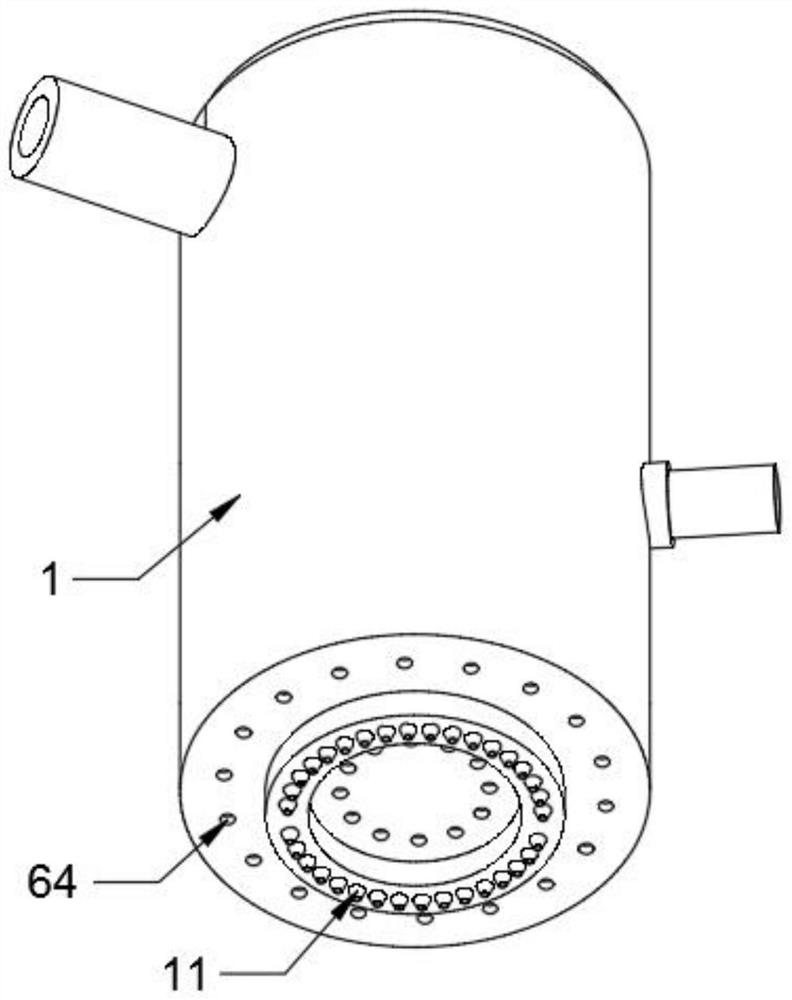

Laser quenching device and method for non-tempered soft zone on bearing surface

ActiveCN106755756BQuality improvementRapid quenchingFurnace typesHeat treatment furnacesLaser quenchingLaser processing

The invention discloses a laser quenching device and method without a tempering soft belt on a bearing surface. The device comprises a laser unit, a light beam transmission system, a laser processing head and a mechanical arm, wherein a laser beam emitted by the laser unit sequentially passes through the light beam transmission system and the laser processing head to reach a bearing workpiece; the mechanical arm controls the laser processing head to horizontally move and rotate, so that laser spots which reach the bearing workpiece can cover the surface of the workpiece; the laser processing head comprises a first lens, a second lens, a scanning galvanometer and a flat field focusing lens, wherein after entering the laser processing head through the light beam transmission system, the laser beam emitted by the laser unit sequentially passes through the first lens and the second lens in the laser processing head to reach the scanning galvanometer, and reaches the bearing workpiece through the flat field focusing lens after being reflected by the scanning galvanometer to change the direction. Laser directly scans and irradiates the bearing surface by virtue of modes of laser beam reshaping and scanning galvanometer scanning and processing, so that the quenching purpose is reached, and therefore, the effects of no tempering soft belt, and a deep and wide size of an ultra-hardened layer can be realized.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Production process of novel high-performance bio-based textile material

ActiveCN114369879AUniform fiber qualityPrecise proportional speed regulationSpinnerette packsArtificial thread manufacturing machinesChemistryProcess engineering

The invention relates to the field of bio-based material production, in particular to a production process of a high-performance bio-based textile new material, which comprises the following steps: introducing a sodium alginate solution into a spray head through pressurization, spraying the sodium alginate solution out of a spinneret orifice, arranging an air bag in contact with the pressurized sodium alginate solution in a wrapping manner in the spray head, one end, which is not wrapped, of the air bag is a free deformation end, a flow channel for discharging a calcium chloride solution is arranged in the spray head, the calcium chloride solution is guided into the flow channel in a pressurized manner and is sprayed out from the water spraying holes, and a check ring for controlling the size of an opening of the flow channel is arranged in the calcium chloride solution flow channel in a sliding manner. And the other end of the through groove is changed to different degrees under different pressures so as to change the adjustment of the blocking area of the through groove by the check ring, so that the discharge speed of the calcium chloride solution is synchronously increased or reduced along with the discharge speed of the sodium alginate solution, and the quality of the produced bio-based fiber is relatively uniform.

Owner:安徽迪惠新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com