Air energy spraying and baking chamber

A paint booth and air energy technology, which is applied in the paint spray booth, injection device, pretreatment surface, etc., can solve the problems of inability to utilize waste heat, inability to use heaters, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

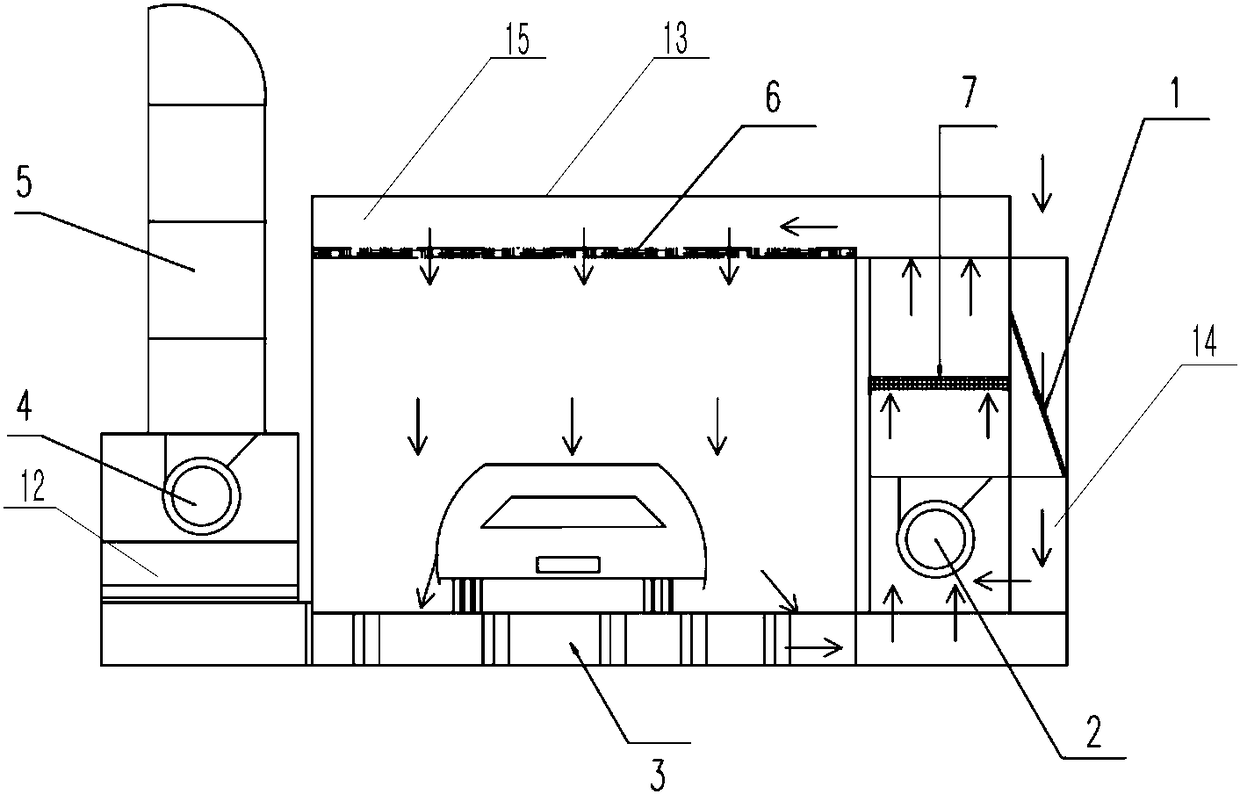

[0027] Such as figure 1 As shown, the present invention includes an air inlet pipe arranged on one side of the room body, primary filter cotton is fixedly installed (drawer-type installation) in the air inlet pipe, the air inlet pipe is connected with the air inlet duct, and a suction fan is installed in the air inlet duct, There is an exhaust pipe on the other side of the body, and the exhaust pipe is connected with the air cylinder. There is a bottom plate with a leak hole at the bottom of the room body. There is a return air duct under the bottom plate. A heating device is provided above, an exhaust fan is arranged in the exhaust pipe, a plurality of air inlets are provided on the top of the air inlet pipe extending to the roof part, and a high-efficiency filter cotton is arranged at the air inlet, and the heating device It is a heat pump condenser, and the cold air pipe of the heat pump condenser extends out of the room.

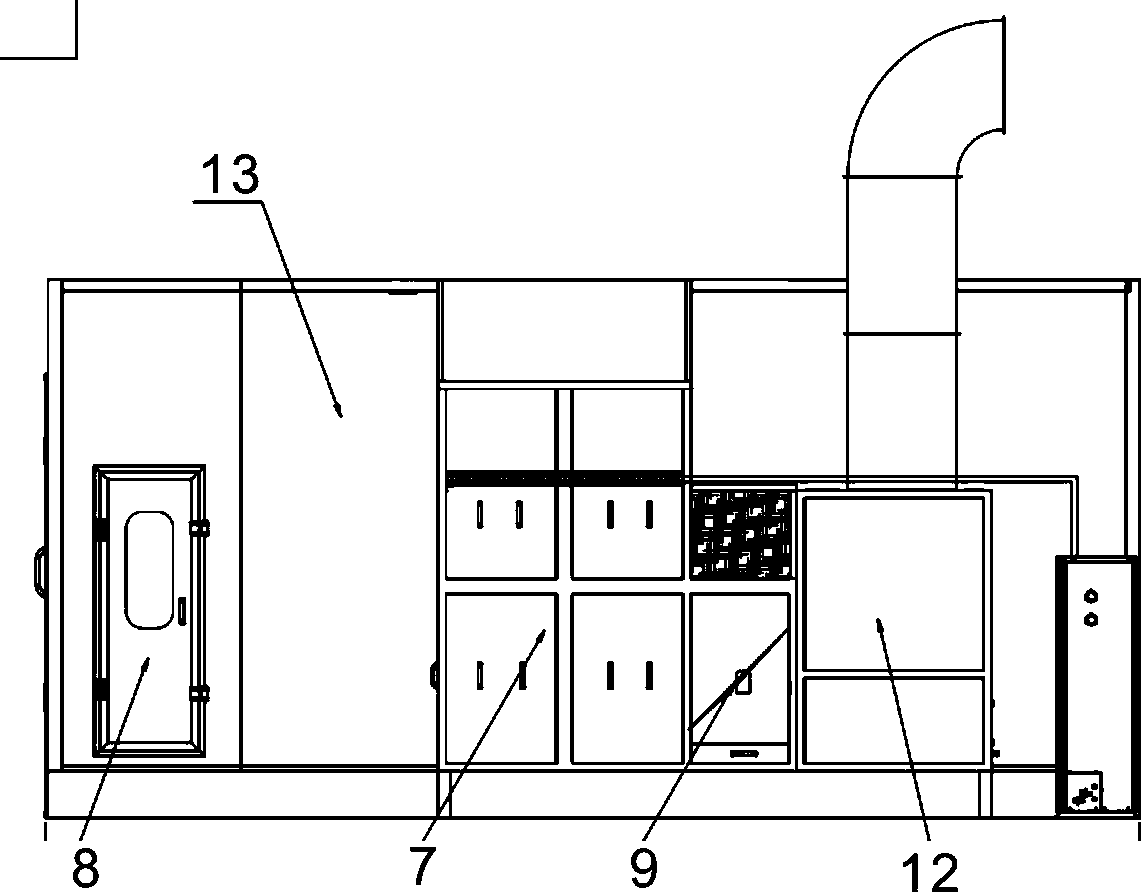

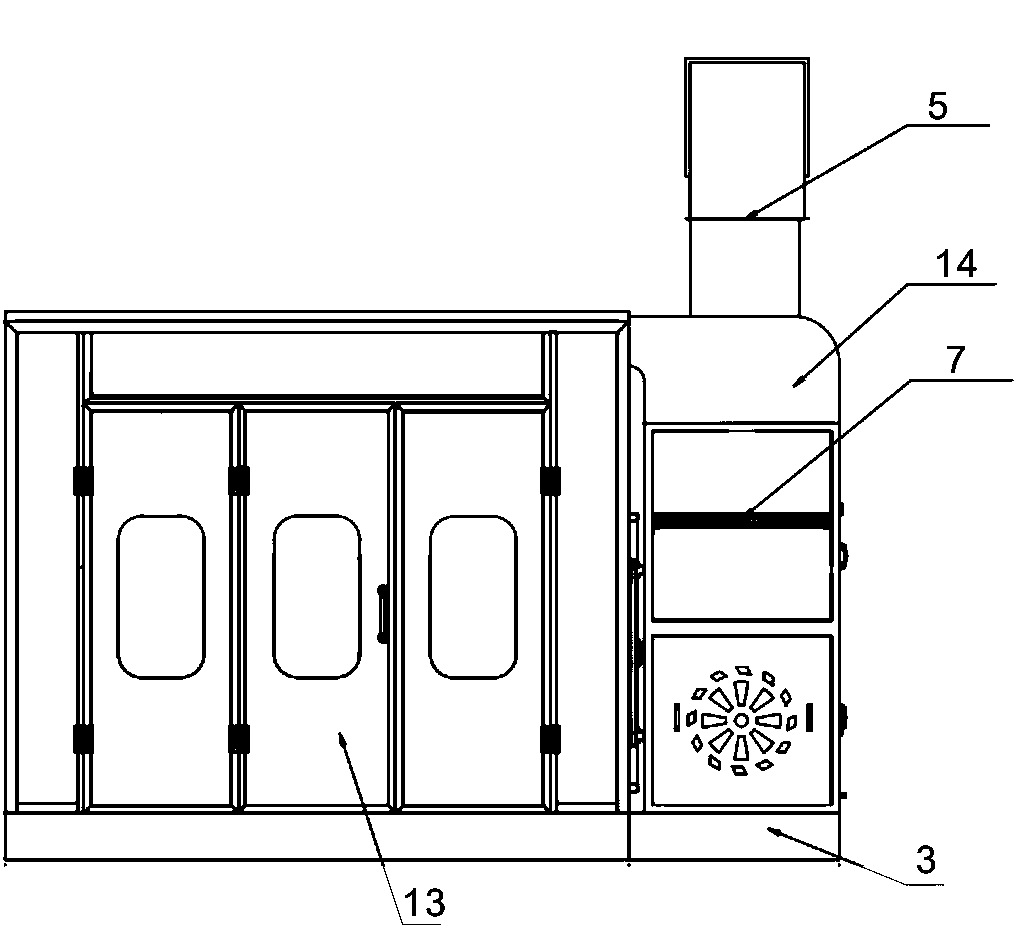

[0028] Such as figure 2 and image 3 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com