Machining technology of ultrawide 6061 aluminum alloy panel for military test detection platform

An aluminum alloy plate and detection platform technology, which is applied in the field of aluminum alloy manufacturing, can solve the problems of plate flatness, prominent processing deformation, difficulty in meeting customer needs, etc., achieve excellent mechanical properties, avoid sawing waste, and avoid waist collapse Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] A processing technology of ultra-wide 6061 aluminum alloy plate for military test and detection platform, including the following steps:

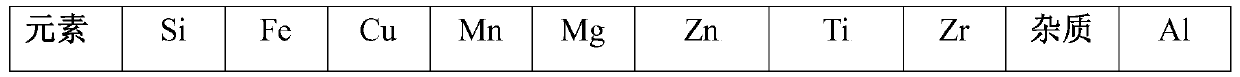

[0029] A. Ingredients: The aluminum alloy raw materials for preparing the aluminum alloy plate are mixed according to the weight percentage, namely

[0030]

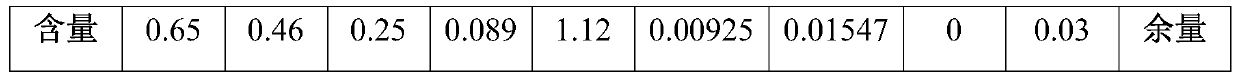

[0031]

[0032] B. Melting and casting: Put the configured aluminum alloy raw materials into the smelting furnace in turn for smelting, and use the flux for refining and covering. When the aluminum water appears in the furnace, start stirring, and smelt into liquid aluminum alloy after stirring evenly. The melting temperature is 730-750 ℃, pour the smelted aluminum alloy melt into a refining furnace for refining, the refining temperature is 720~740℃, the refining time is 20min, the refined aluminum alloy melt is allowed to stand at 720±5℃ for 20min, and the refined aluminum alloy The melt is passed into high-purity argon gas and the melt is stirred to remove the impurity gas in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com