Construction method for dismounting sandwich linings of operating high-speed rail tunnels

A construction method and interlayer technology, applied in the construction field of dismantling and operating the interlayer lining of high-speed railway tunnels, can solve problems such as hindering the development of regional economy, increasing the burden on surrounding lines, affecting national travel, etc., to achieve fast and effective cutting, improve cutting efficiency, ensure safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

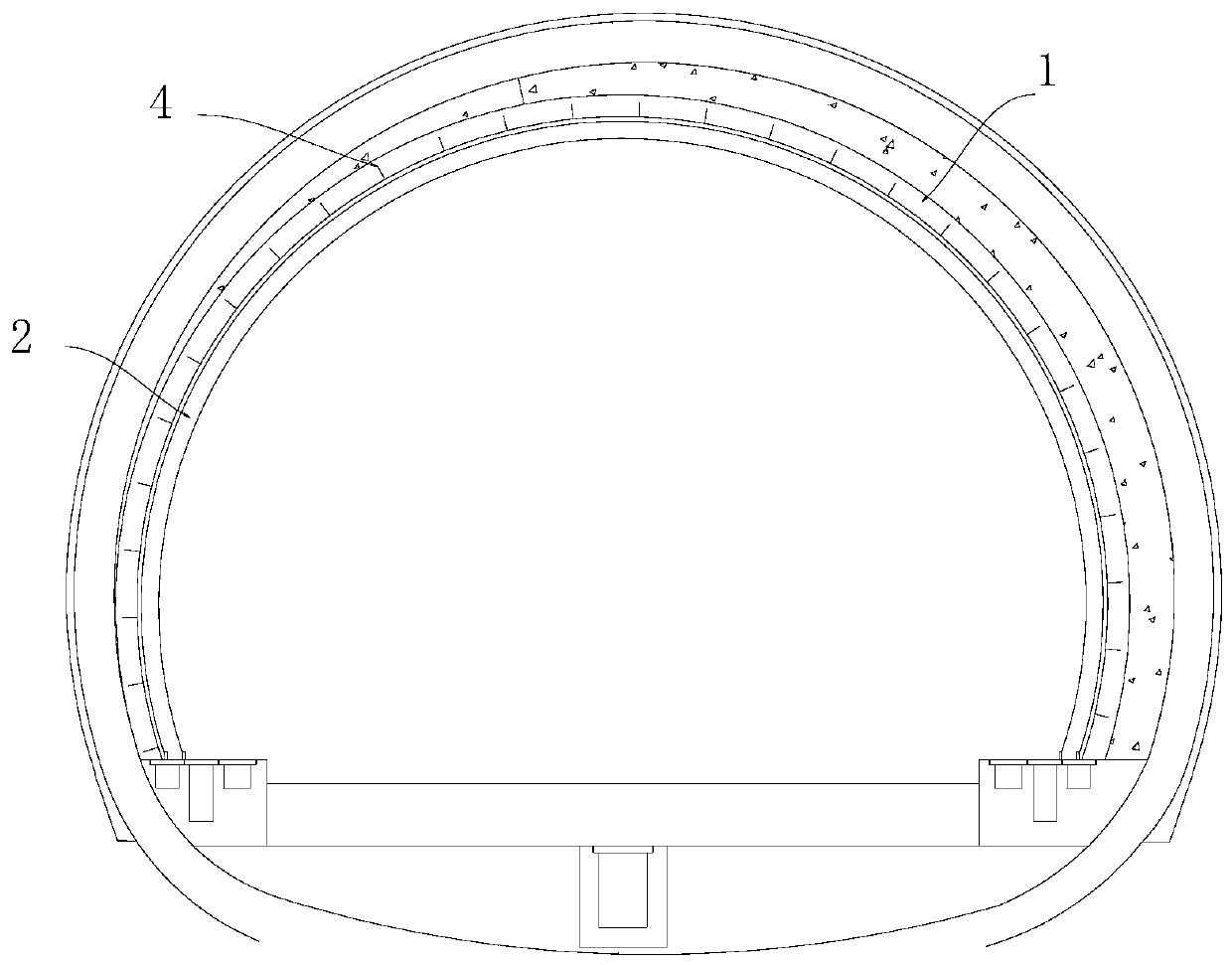

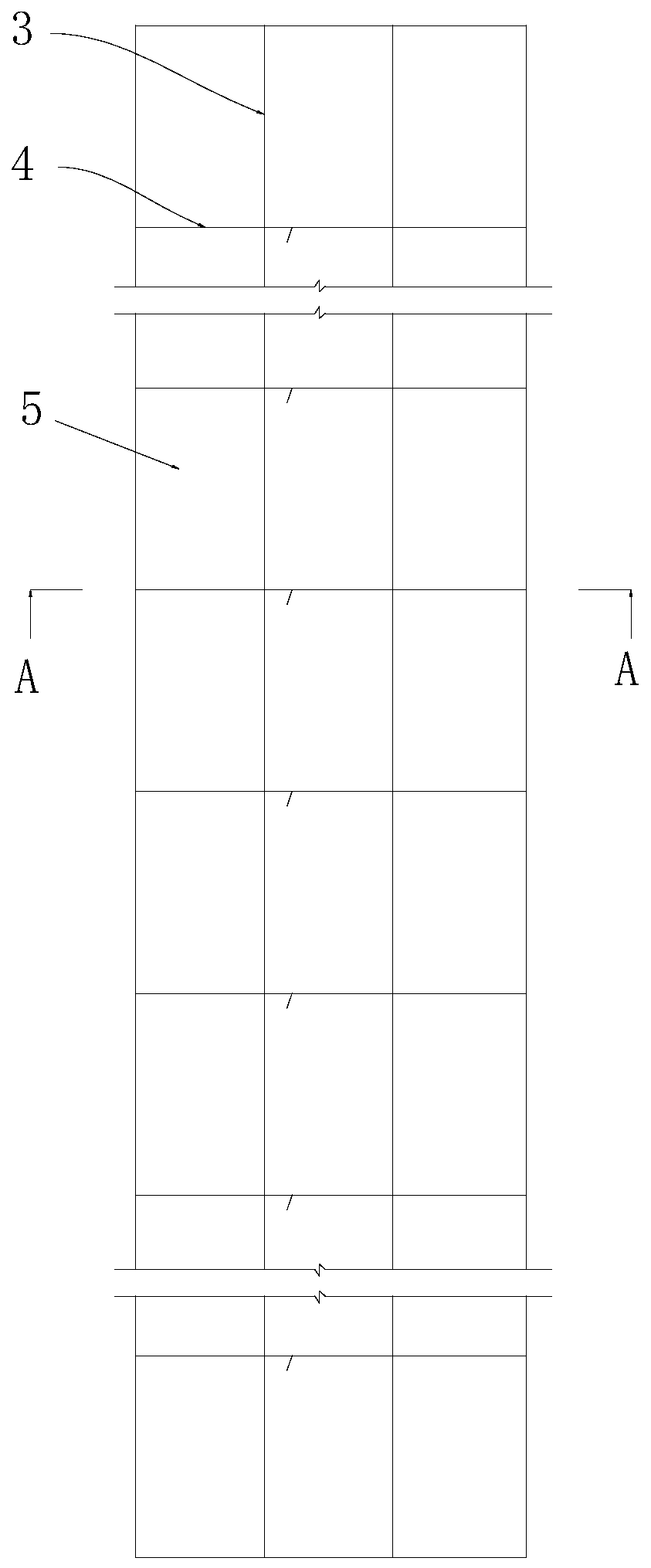

[0037] see Figure 1 to Figure 4 , the invention provides a construction method for dismantling the interlayer lining of a high-speed rail tunnel in operation, which comprises the following steps in turn:

[0038] (S1): Determine the removal area of the interlayer lining and erect a temporary protective frame under the interlayer lining to be removed; isolate the high-speed rail traffic passage and the reserved space for construction, and remove the interlayer lining without affecting the existing traffic operation . The temporary protective frame includes a steel frame, a protective plate arranged on the steel frame, and pulleys arranged at both ends of the steel frame, and the temporary protective frame should avoid the position of the circumferential slit when erected. The present invention adopts the movable temporary protective frame to isolate the traffic passage and the reserved space for construction. After the removal of the interlayer lining in one stage is comple...

Embodiment 2

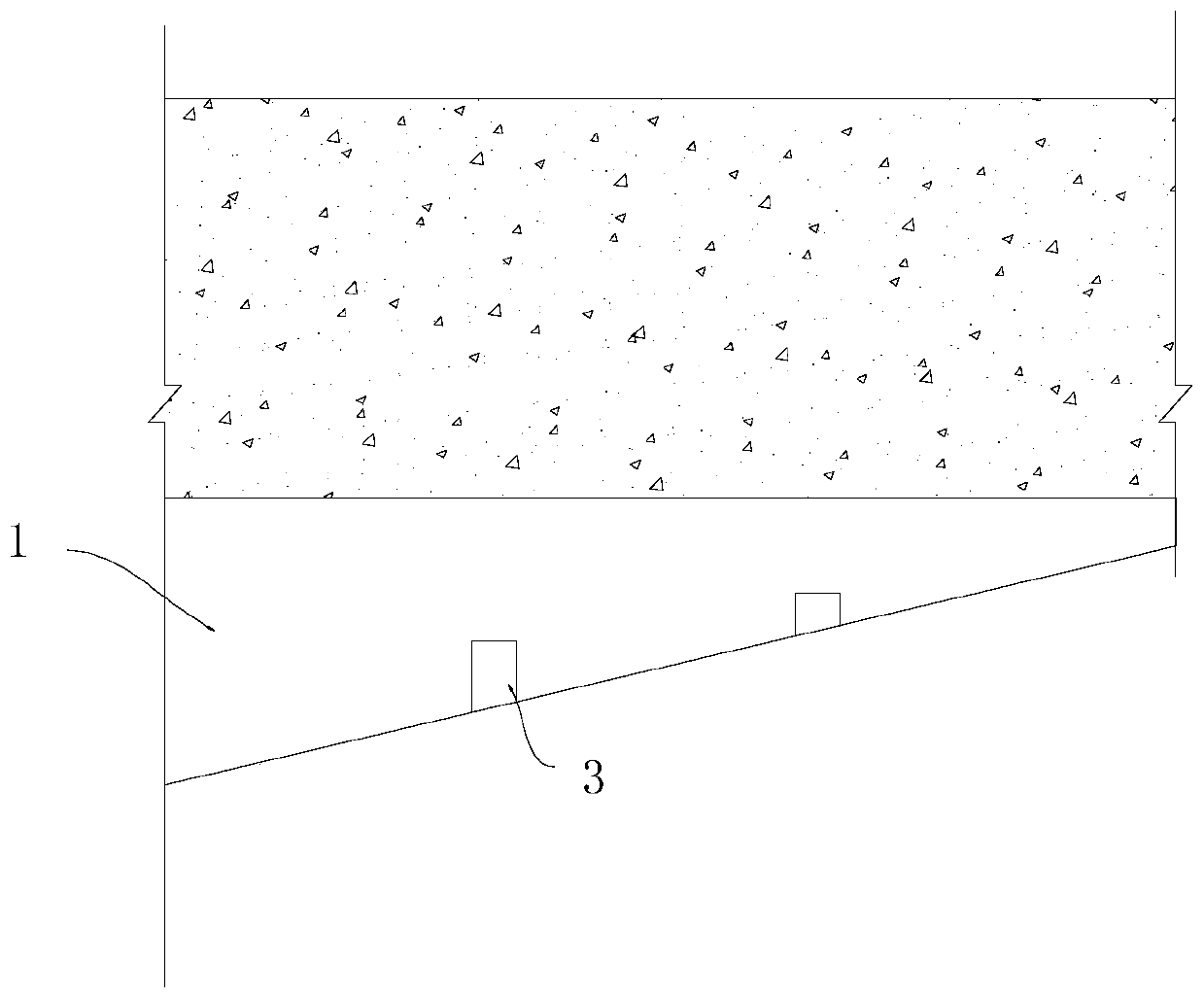

[0046] The construction method for dismantling the interlayer lining of the high-speed railway tunnel in operation in this embodiment is basically the same as that of Embodiment 1, the difference is that in the step (S2), when the thickness of the interlayer lining is relatively large, it needs to be cut in stages, which includes the following steps in turn:

[0047] (s1): Use a cutting machine to cut and form two circumferential or longitudinal slits on the surface of the interlayer lining, and then chisel away the concrete between the two slits to form a cutting groove. The distance between the two slits is greater than the width of the cutting tool and the margin is not less than 2cm to ensure that the cutting machine has operating space in the groove formed by chiseling.

[0048] (s2): Use a cutting machine to perform a second cut in the cutting groove until the depth of the cut is the same as the thickness of the interlayer lining. The present invention adopts the step-by-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com