Concentric centripetal sliding bearing formed by using interface slippage

A sliding bearing and sliding technology, which is applied in the direction of bearings, shafts, bearings, mechanical equipment, etc., can solve problems such as the lack of bearing capacity of the radial sliding bearing, the reduction of the concentricity of the shaft and the hole in the bearing, and the low thickness of the lubricating oil film of the bearing. , to achieve significant technical effects, high concentricity, and high precision bearing support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

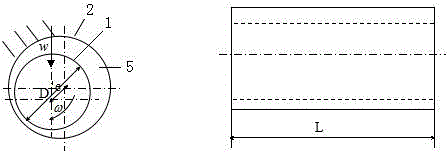

[0038] The embodiment is a concentric-to-central sliding bearing formed by interfacial sliding, formed by a rotating shaft 1 and a stationary bearing hole 5 , or formed by a rotating bearing hole 5 and a stationary shaft 1 . In the embodiment, the shaft 1 is concentric with the bearing hole 5, and there is a gap between the shaft 1 and the bearing hole 5, and the gap is filled with fluid. Figure 4 The bearing of the present invention is illustrated.

[0039]The bearing lubricating area of the present invention is divided into two sub-areas, that is, "I" sub-area and "II" sub-area, and the central angles of these two sub-areas are respectively and . In the bearing of the present invention, by coating a certain coating on the static contact surface of the "I" sub-region, the interface shear strength between the fluid and the coating is very low, so that the fluid can slip on the coating surface. The fluid does not slip on the remaining stationary contact surfaces of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com