Preparation method of novel microorganism high-enrichment filler

A microorganism and enrichment technology, which is applied to the treatment of granular microorganism carriers, clay preparation devices, chemical instruments and methods, etc., can solve the problems of high preparation cost, waste of land resources, and low microbial adhesion, and achieves low preparation cost, Long service life and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

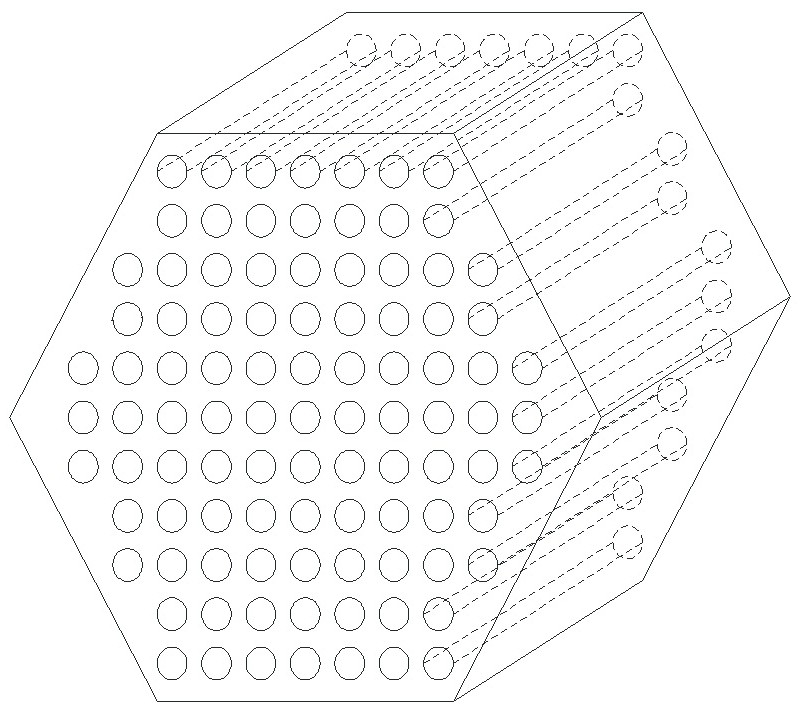

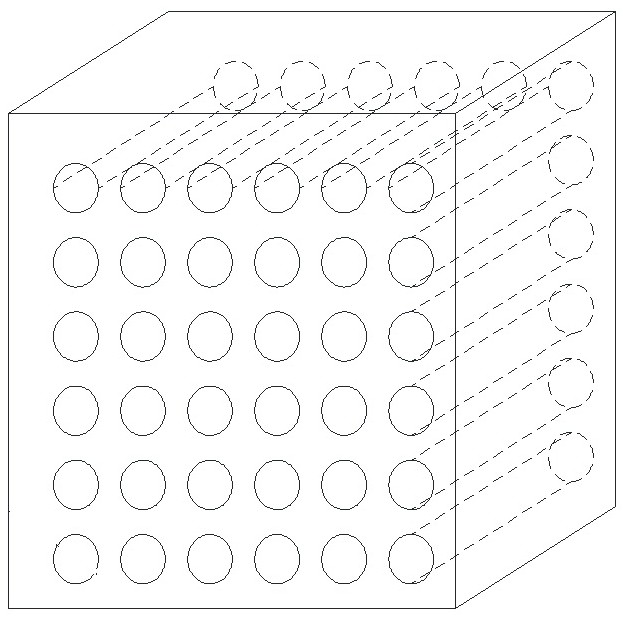

Embodiment 1

[0022] Example 1: The preparation method of the new microbial high-enrichment filler, the steps are as follows: (1) After the dewatered sludge dried at 105°C is pulverized by a ball mill, it is passed through a 100-mesh sieve, and the dewatered sludge, calcium oxide , cement, fly ash, additives and other raw materials are mixed according to the ratio of 15:5:25:55, in which the additive is aluminum powder, and its addition amount is 0.02%. The aluminum powder additive is used to improve the void structure of the filler and increase the specific surface area. Add 30%~35% water per unit mass of raw material, and stir evenly; (2) Use a mold to press the mixed raw material into a prefabricated shape, including the outer contour and internal hole-like channel; (3) The formed filler is in the Curing with wet gauze at room temperature (25°C) for 12 hours, so that the hydration reaction of the various raw materials inside the filler will continue, and more gelled hydration products wil...

Embodiment 2

[0026] Example 2: The preparation method of a new type of microbial high-enrichment filler, the characteristic steps are as follows: (1) After the dewatered sludge dried at 105 ° C is pulverized by a ball mill, it is passed through a 100-mesh sieve, and the dehydrated sludge, calcium oxide , cement, fly ash, additives and other raw materials are mixed according to the mass ratio of 15:5:25:55, in which the additive is aluminum powder, and its addition amount is 0.02%. The aluminum powder additive is used to improve the void structure of the filler and increase the specific surface area . Add 30%~35% water per unit mass of raw material, and stir evenly; (2) Use a mold to press the mixed raw material into a prefabricated shape, including the outer contour and internal hole-like channel; (3) The formed filler is in the Curing with wet gauze at room temperature (25°C) for 12 hours, so that the hydration reaction of the various raw materials inside the filler will continue, and mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com