Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

281results about How to "Small circulation resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

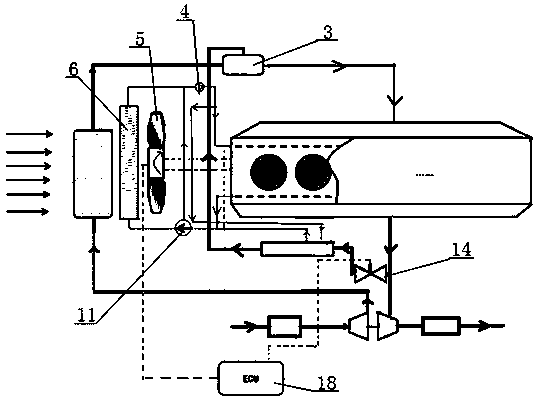

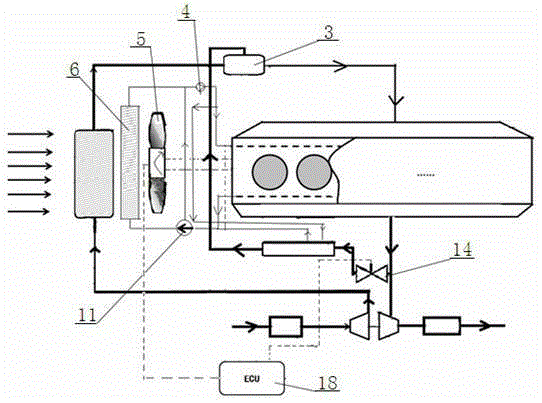

Supercharged diesel engine EGR (Exhaust Gas Recirculation) system intelligent cooling device

ActiveCN103775252AImprove dynamic response performanceSpeed up the warm-up processInternal combustion piston enginesNon-fuel substance addition to fuelExhaust fumesIntercooler

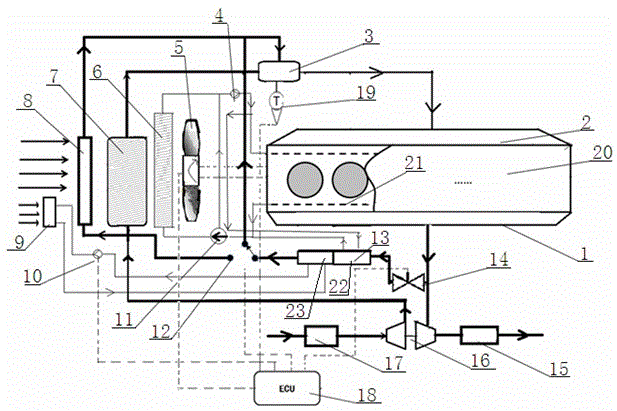

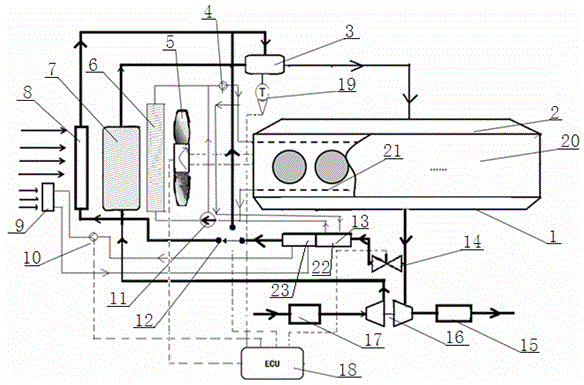

The invention discloses a supercharged diesel engine EGR (Exhaust Gas Recirculation) system intelligent cooling device, comprising an EGR mixer (3), a mechanical water pump (4), an electric control fan (5), a radiator (6), a thermolator (11), an EGR cooler (13), an electric control EGR valve (14), an engine ECU (Electronic Control Unit) (18), a temperature sensor (19), an exhaust gas intercooler (8) and an electric control two-position three-way valve (12), wherein an inlet of the electric control two-position three-way valve (12) is communicated with a gas outlet of the EGR cooler (13); outlets in two ends of the electric control two-position three-way valve (12) are respectively communicated with an exhaust gas inlet of the EGR mixer (3) and a gas inlet of the exhaust gas intercooler (8); a gas outlet of the exhaust gas intercooler (8) is communicated with the exhaust gas inlet of the EGR mixer (3); the electric control EGR valve (14), the electric control fan (5), the temperature sensor (19) and the electric control two-position three-way valve (12) are respectively connected with the engine ECU (18) electrically.

Owner:DONGFENG COMML VEHICLE CO LTD

Smoke damper door

The invention relates to an off-gas baffle door which comprises three flues and baffle doors arranged in the flues. The invention is characterized in that the baffle door has a single-piece single-shaft structure; a door shaft is positioned at the top of the baffle door and is arranged horizontally, and the baffle door can turn around the shaft in an angle between 0 and 90 degrees; double-layer elastic metal sheets which preserve a gap between layers and interlaced positioning of layers are respectively adopted around the two side faces of the baffle door; double-layer sealing boards corresponding to the elastic metal sheet are respectively arranged around the flue of a matching face of the baffle door, and the elastic metal sheet is matched with the sealing board to form a sealing face; a sealed cavity is formed in the middle of the sealing face. The baffle door adopts a hydraulic driving system comprising a hydraulic oil cylinder which is arranged at the two ends of the door shaft in a mode of double-side arrangement; an emergence closing loop is arranged in the system and an energy storing device is arranged in the loop. The fume flow passage of the invention has no obstacle with low flow resistance, the sealing rate can reach 100 percent and the driving of the hydraulic oil cylinder is stable with reliable capability.

Owner:HANGZHOU BOILER GRP CO LTD

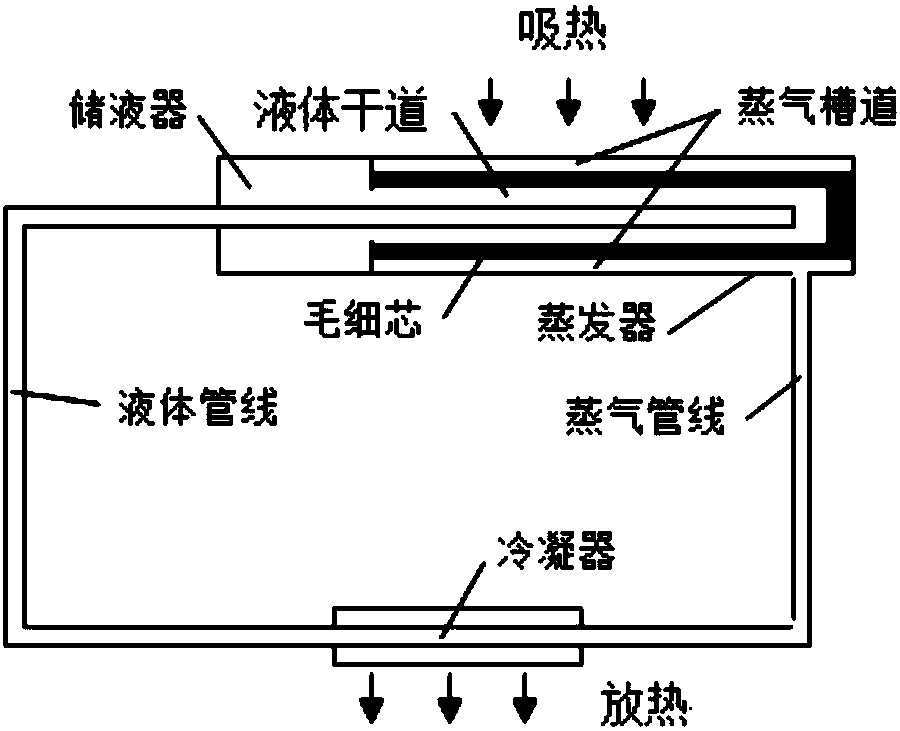

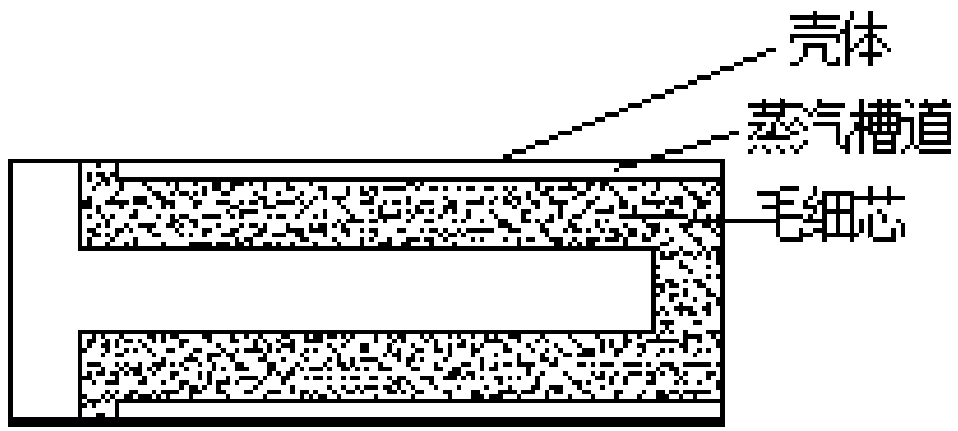

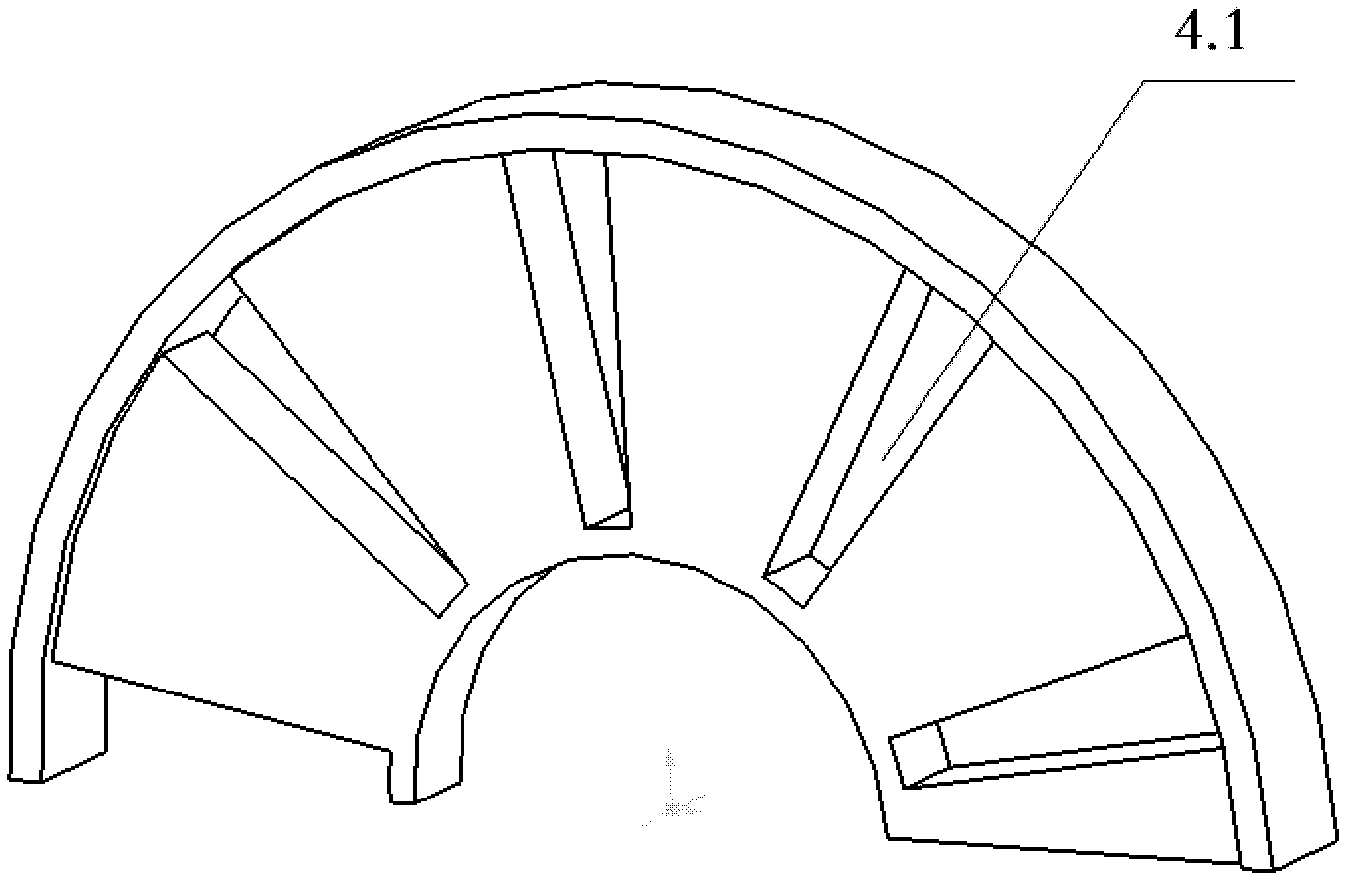

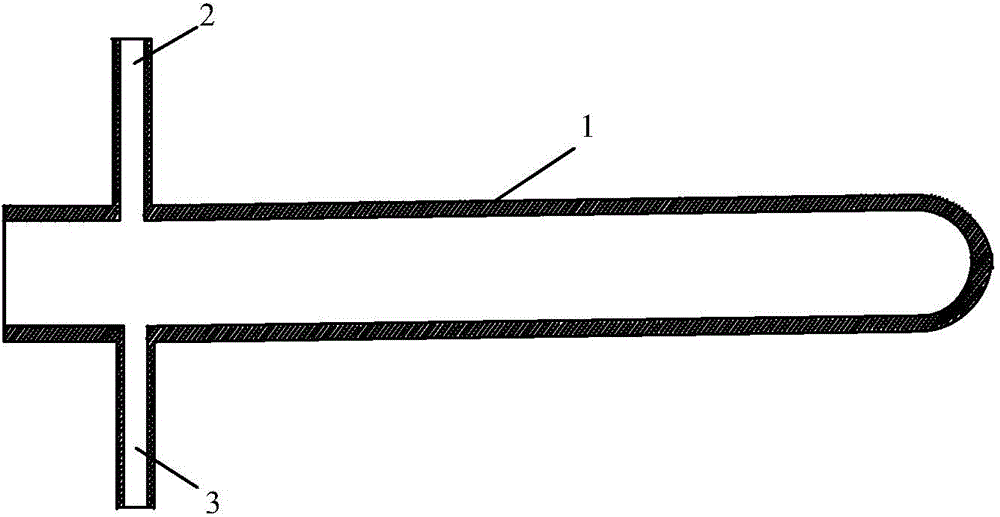

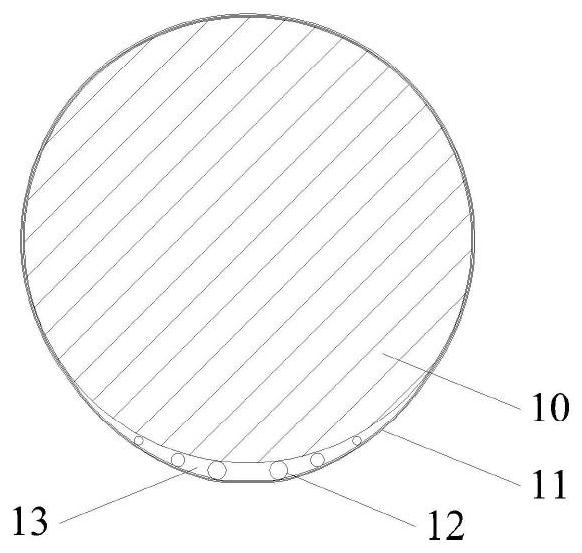

High-power flat evaporator resistant to positive pressure, processing method of flat evaporator and flat-plate loop heat pipe based on evaporator

ActiveCN107782189AHigh compressive strengthSuitable for positive pressure working mediumIndirect heat exchangersThermal insulationPositive pressure

The invention provides a high-power flat evaporator resistant to positive pressure, a processing method of the flat evaporator and a flat-plate loop heat pipe based on the evaporator and belongs to the technical field of spacecraft structures. The evaporator comprises a casing, reinforcing ribs and a capillary core, wherein the reinforcing ribs and the capillary core are located in the casing, andthe strength of the whole evaporator can meet the requirement of positive pressure resistance by means of arrangement of the reinforcing ribs; the capillary core is formed by combining an evaporationcore, a thermal insulation core, a sealing core and a transmission core, liquid supply with low flow resistance can be realized on the basis of high permeability of the transmission core, heat-transfer capability of the loop heat pipe is improved substantially, and the problems of long liquid supply path and high flow resistance of a large-area evaporator are solved; with adoption of the transmission core and the thermal insulation core with low thermal conductivity, the phenomenon of heat leakage from the evaporator to a liquid accumulator can be reduced, meanwhile, good permeability is achieved, flow resistance in the capillary core is reduced, and operating stability of a product is improved.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

Residual oil hydrotreating method

ActiveCN103773429AReduce differential pressureSmall circulation resistanceRefining to eliminate hetero atomsPtru catalystHydrogenation reaction

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of ceramic membrane supporting body

ActiveCN104014252AShorten the production cycleIncrease productivitySemi-permeable membranesAir atmosphereArgon atmosphere

The invention discloses a preparation method of a ceramic filtering membrane supporting body. The method comprises the steps of (1) preparing a raw material, wherein the raw material comprises mixing powder, namely alpha aluminium oxide powder (1) the purity of which is greater than or equal to 99.7% and alpha aluminium oxide powder (2) the purity of which is greater than or equal to 99.8%, the median particle diameter D50 of the alpha aluminium oxide powder (1) is 18-35mum, the median particle diameter D50 of the alpha aluminium oxide powder (2) is 0.8-2mum, and the dosage of the alpha aluminium oxide powder (2) is 2%-10% (weight) of that of the alpha aluminium oxide powder (1); (2), mixing the mixing powder with a water solution of cross-linking agent acrylamide and methylene double crylic acid ammonium to form a suspension, and carrying out gel casting on the suspension; heating a formed product to 40-55 DEG C in a microwave manner, drying for 1-3 hours, calcining the dried formed product for 4-8 hours under 500-800 DEG C in air atmosphere, placing a calcined product in vacuum or atmospheric hydrogen or argon atmosphere, carrying out heat preservation on the calcined product for 4-12 hours under the condition of 1800 DEG C-1950 DEG C so as to form a supporting body of a pure alpha phase aluminum oxide ceramic filtering membrane. The preparation method provided by the invention has the advantages that the porosity of a product is high, the flux is high, and the product is strong-acid-resisting and strong-alkali-corrosion-resisting.

Owner:SANDA FILM SCI & TECH XIAMEN

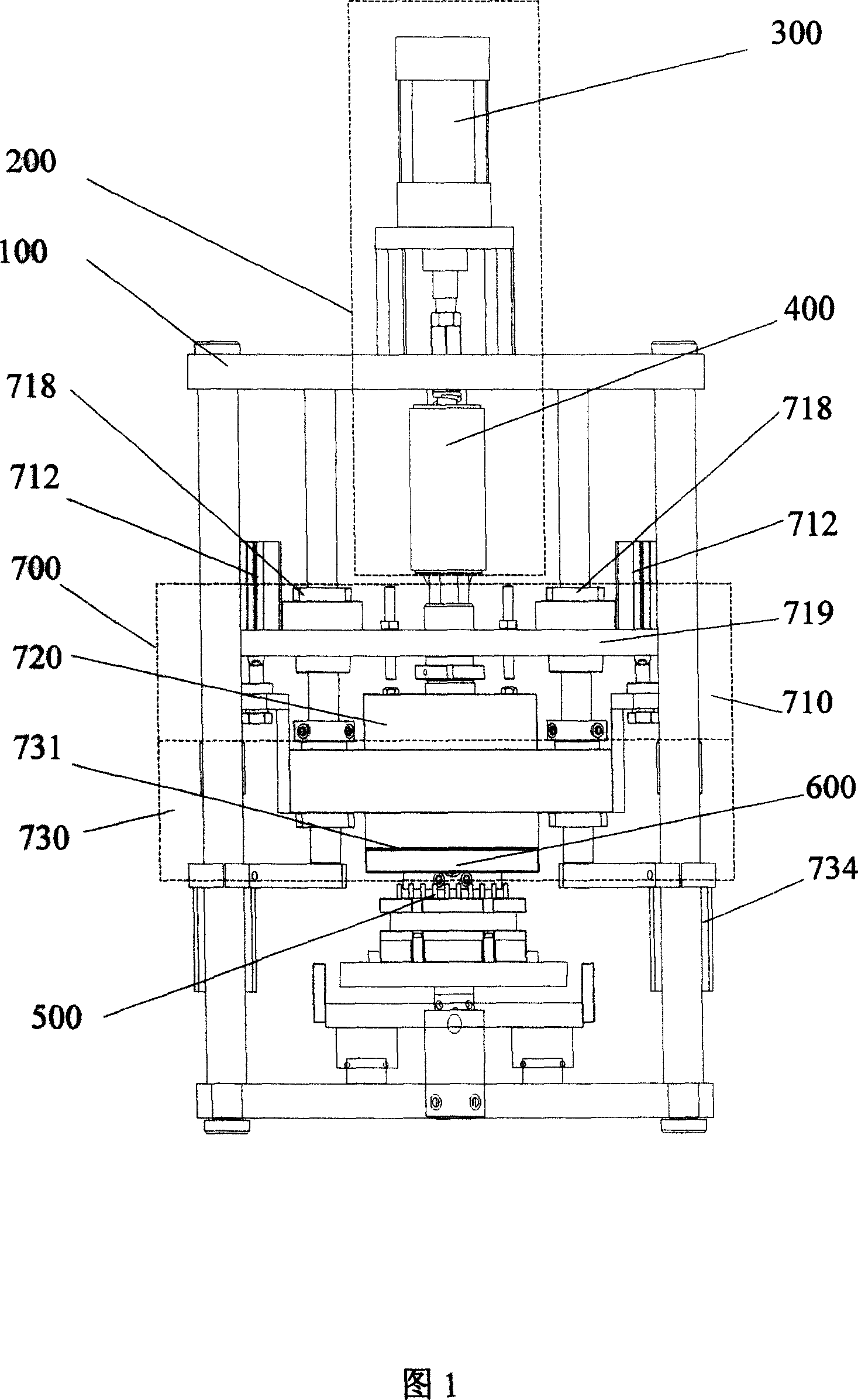

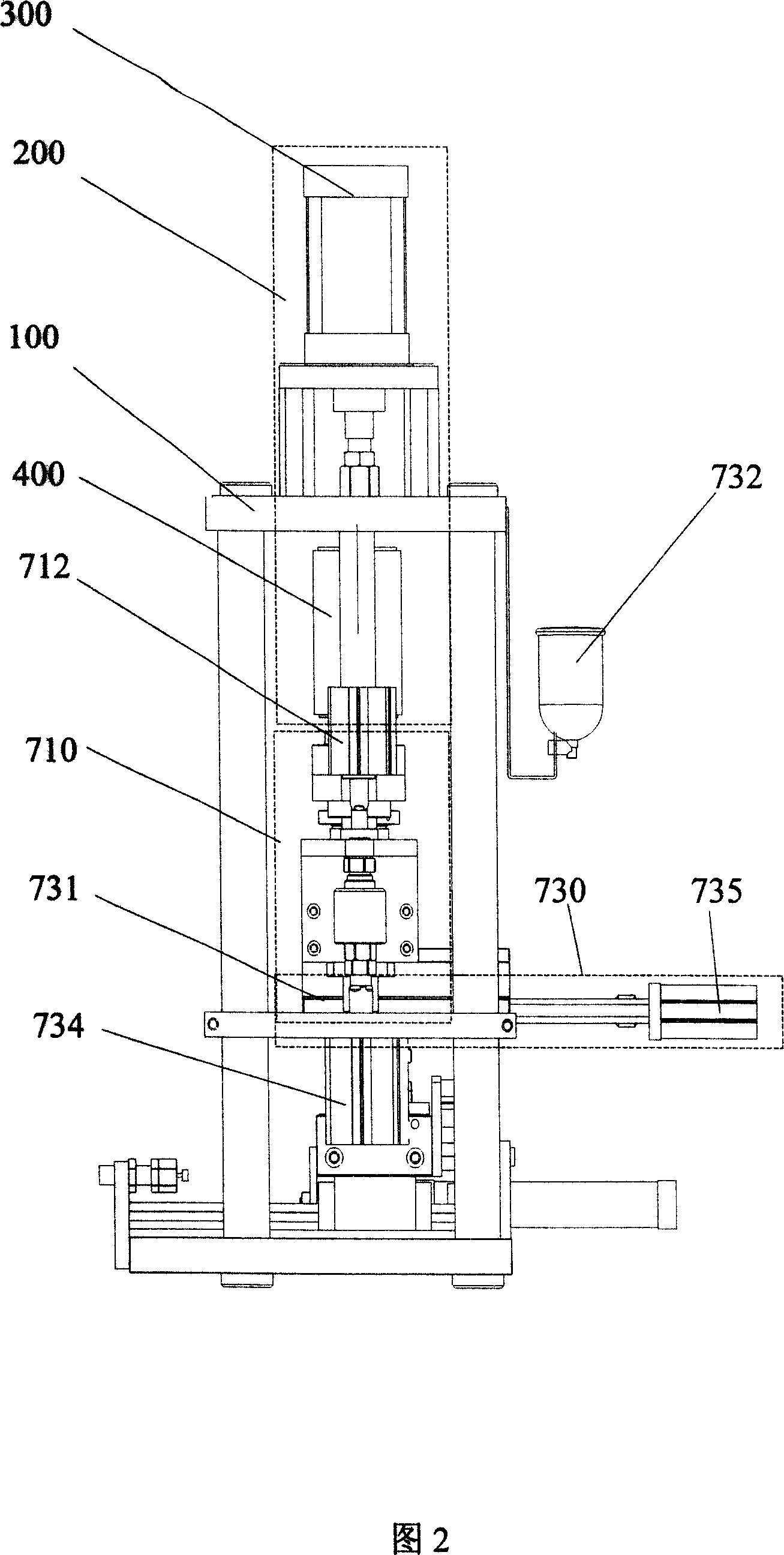

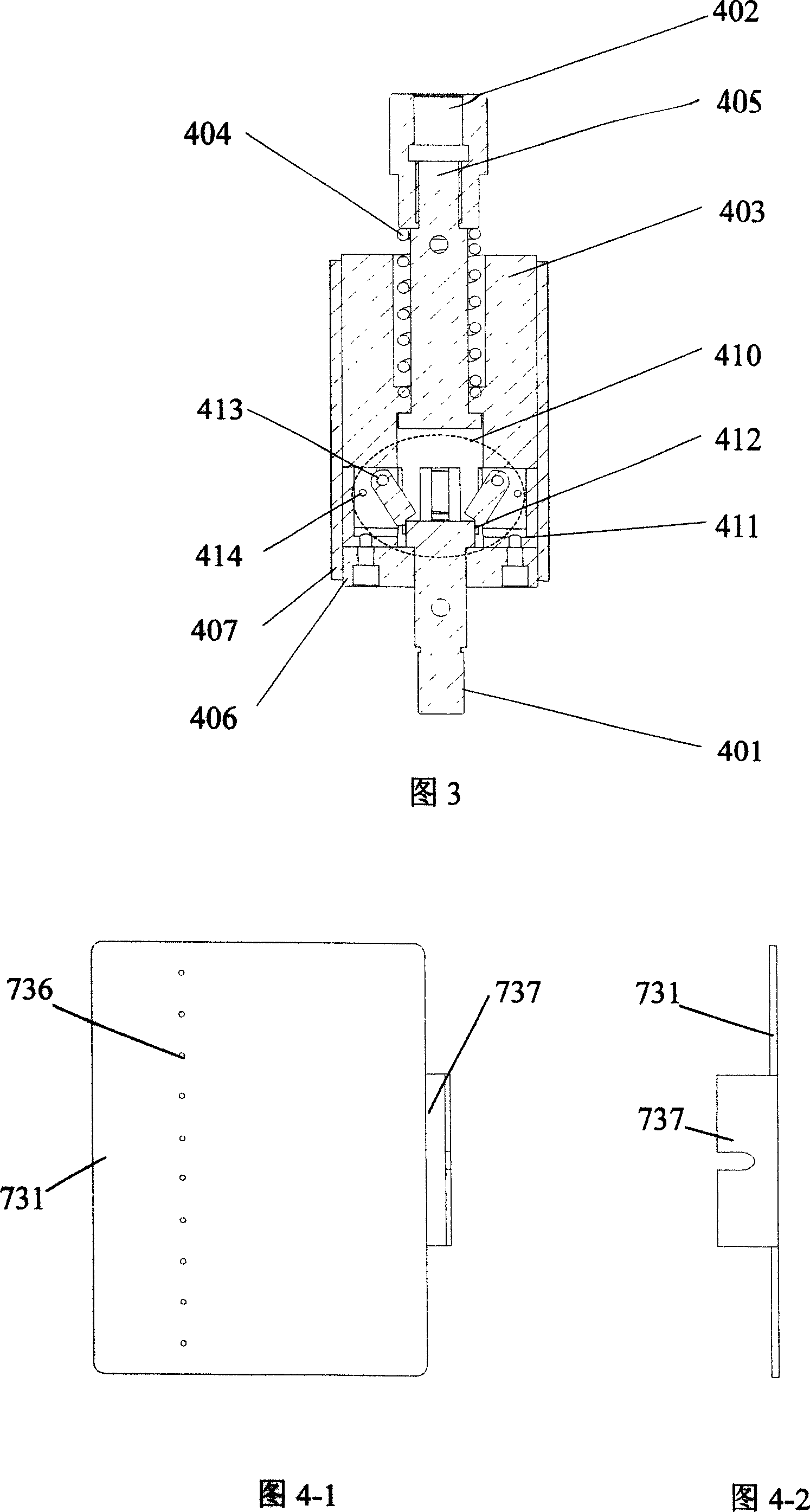

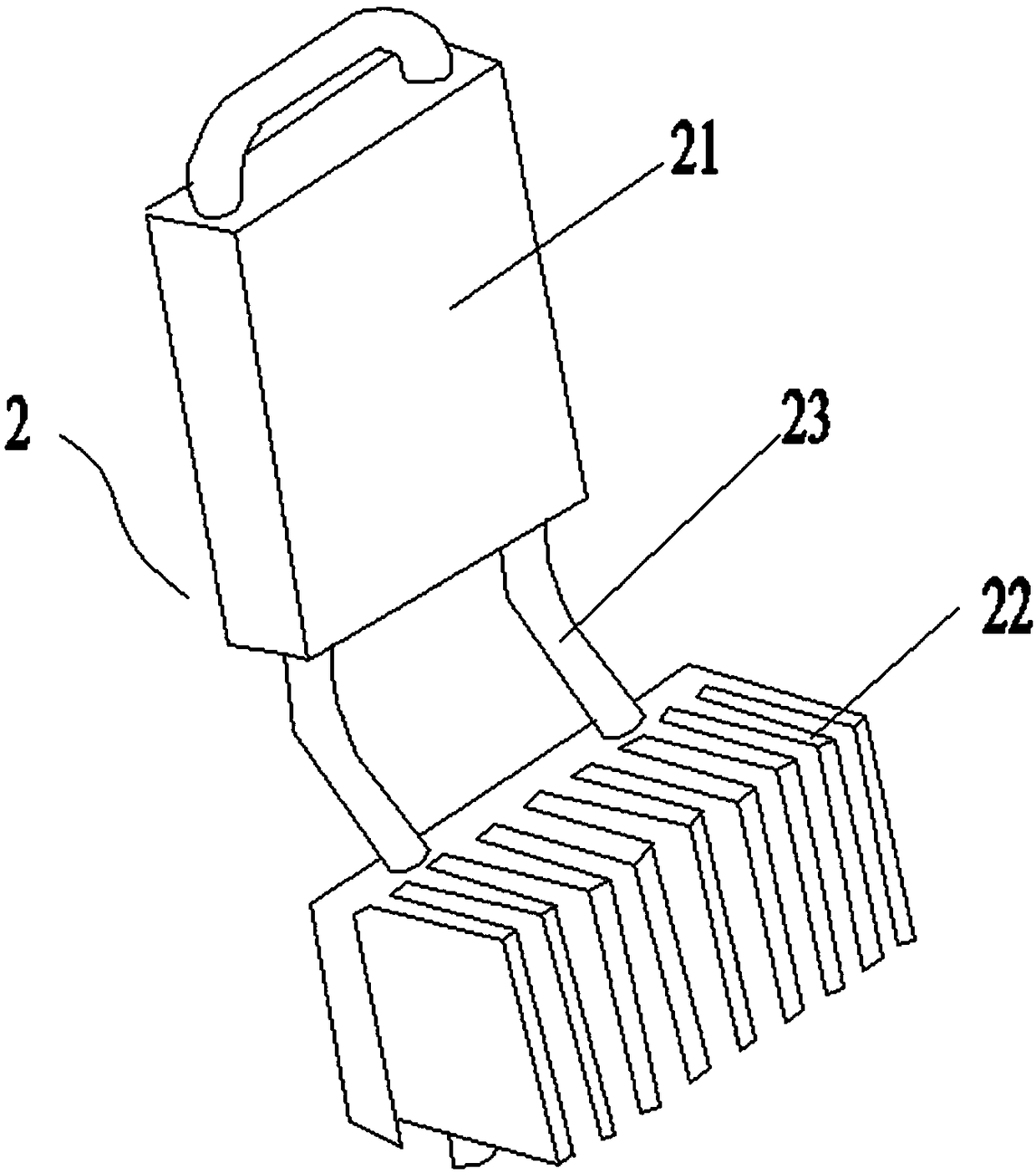

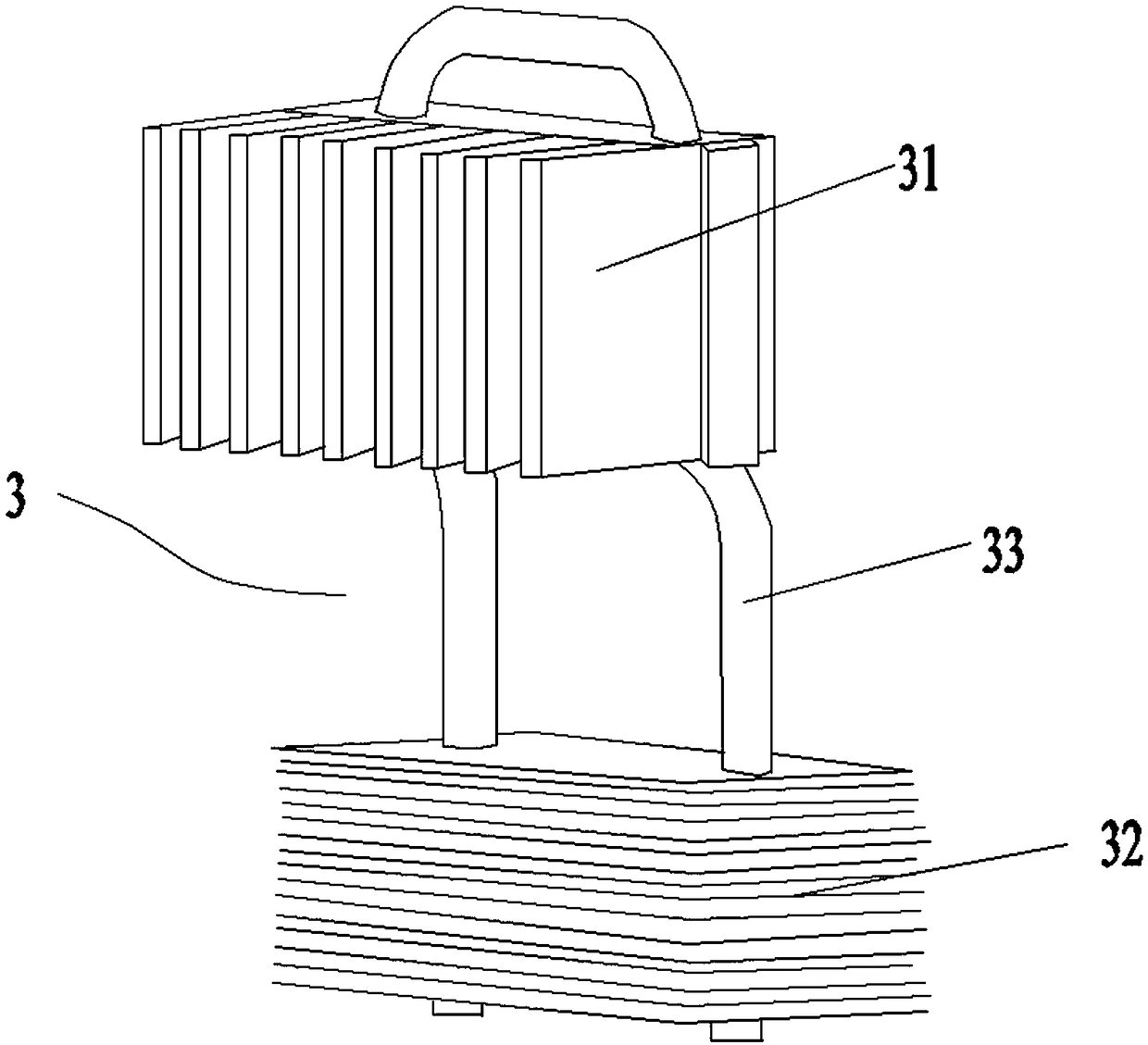

Fully automatic vacuum capper for square lithium ion battery and its capping method

InactiveCN101009366AImprove performanceIncrease vacuumFinal product manufactureCell component detailsSteel ballEngineering

The invention discloses a square type lithium cell full automation vacuum capper that includes rack, high speed pressure unit, cell clamp and steel ball distributing device which is between the high speed pressure unit and cell clamp; the steel ball distributing device includes pin guiding unit of the press pin and steel ball distributing unit; the pin guiding unit includes several press pins; the steel ball distributing unit includes giving ball plate which can horizontal shift, several steel ball holes which are corresponding with said press pins are set on the giving ball plate; the other limit position of the giving ball plate is that the steel ball holes are corresponding with steel ball storehouse mouth; the pin guiding unit, cell storehouse and the press pin are separately shift under the drive of movement unit; using the cell sealing craft of the capper, when the steel ball is given and the press pin is pressed to seal, the cell is always in vacuum condition. It avoids the phenomenon of rebound of cell thickness and tympanites, and guarantees perfect vacuum and reliable tightness.

Owner:天津丰泽科技有限公司

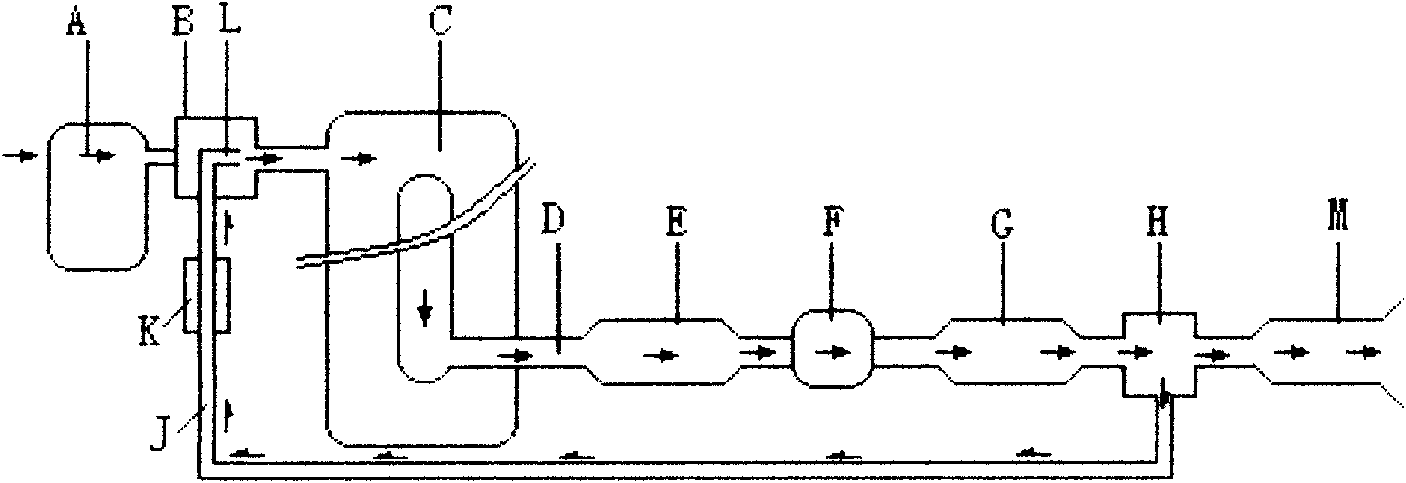

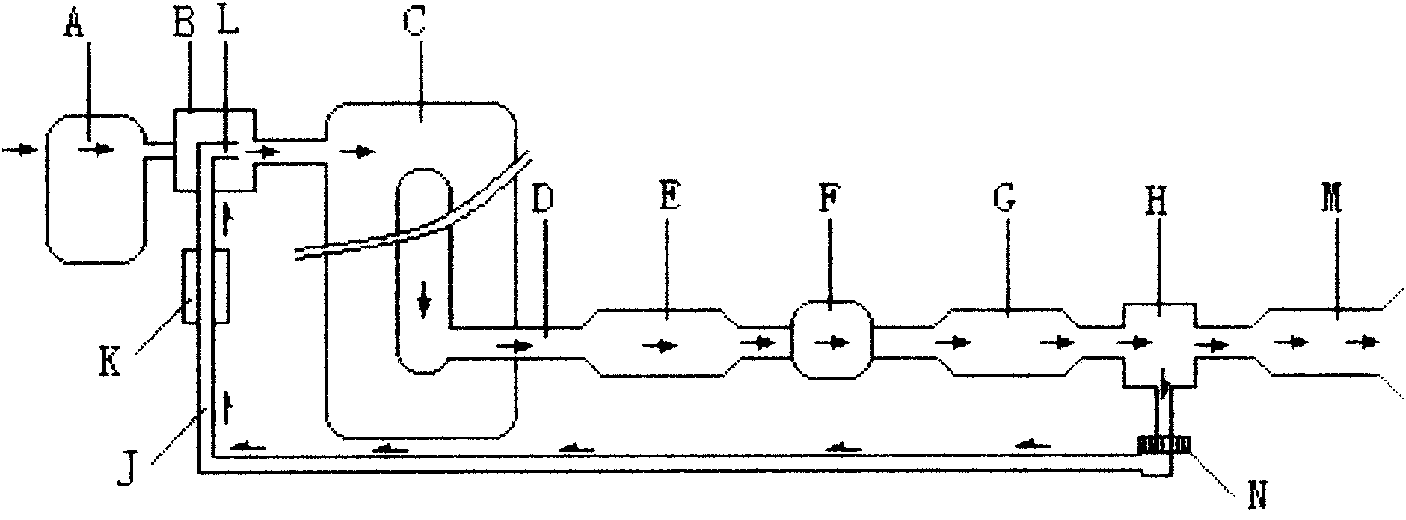

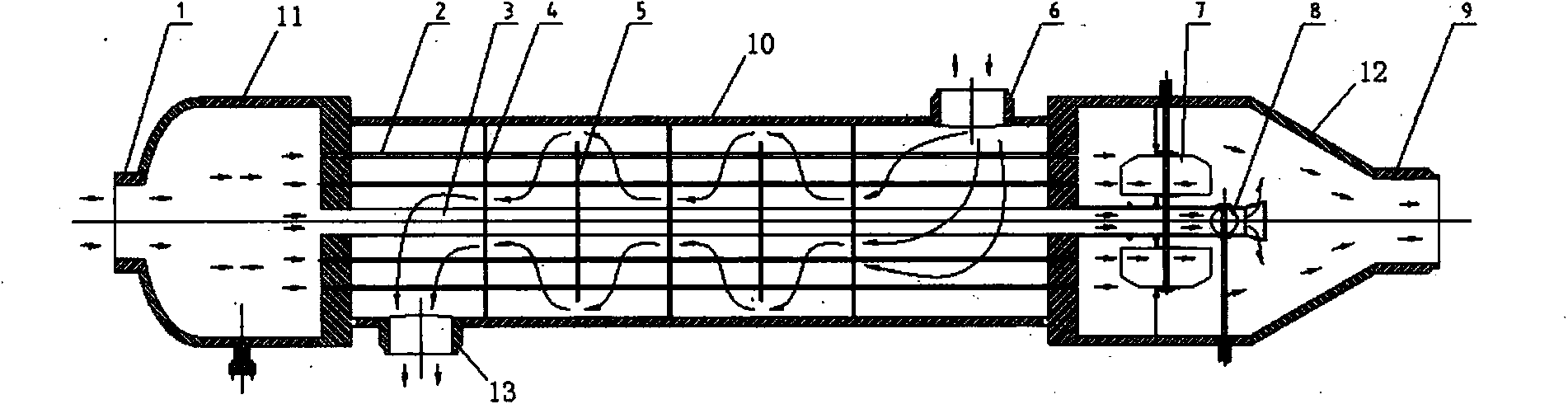

Waste gas recovery system device of noise elimination and air cooling static catalytic cracker of internal-combustion engine

InactiveCN101660468ADoes not affect flow characteristicsSpeed up chemical reactionsInternal combustion piston enginesNon-fuel substance addition to fuelInternal combustion engineRefrigerated temperature

The invention relates to a waste gas recovery system device of a noise elimination and air cooling static catalytic cracker of an internal-combustion engine, comprising a tail gas recycling device, atail gas recycling nozzle, a tail gas recycling connecting pipe, an engine exhaust system, an exhaust pipe, an air cooling static noise eliminator, an ozone generator, an air cooling static NOX catalyst, an exhaust flow divider, an air cooling NOX catalyst, a semiconductor refrigerator, an axial flow fan, an air cooling particle catcher and an air cooling static mixing catalyst. The waste gas recovery system device is connected with an air supplying system and an oil line system so as to form new external three systems. The invention is suitable for a plane, a steamship, a diesel engine generating set, an internal-combustion locomotive, a motorcycle, a gasoline car, a diesel car, an oil drilling diesel machine, an industrial boiler, a domestic gas cooker, and the like, has simple and convenient installation, i.e. an original system of the internal-combustion engine is taken down and replace with the new system, can save the oil by 15-30 percent without exhaust pollution, prolongs the service life of the internal-combustion engine, is a major energy-saving brainstorm project during the Eleventh Five-Year Plan and is the major breakthrough of the waste gas recovery system--the reformation of the external three-system of an engine in 21 century.

Owner:上海徕普太阳能科技有限责任公司

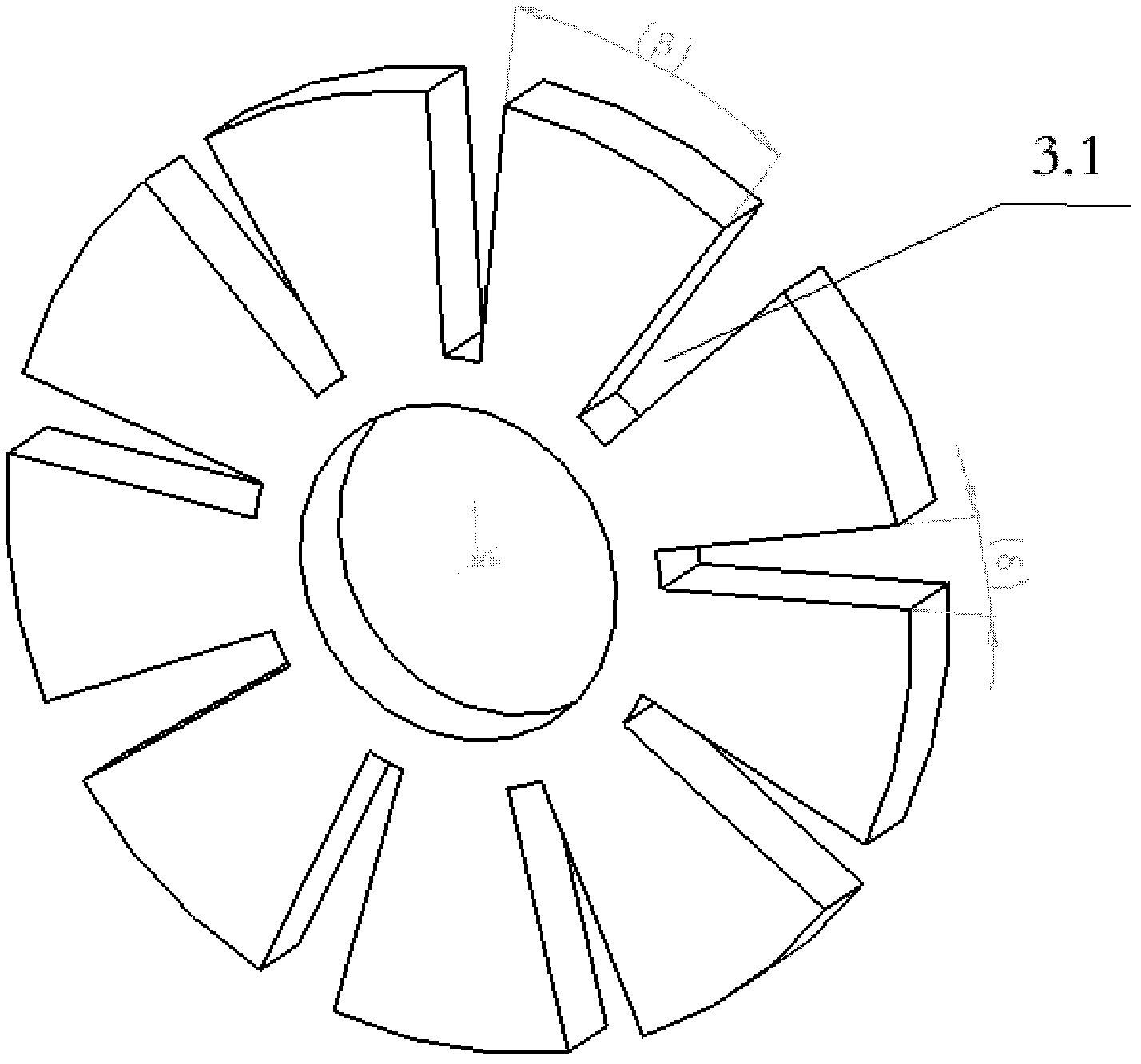

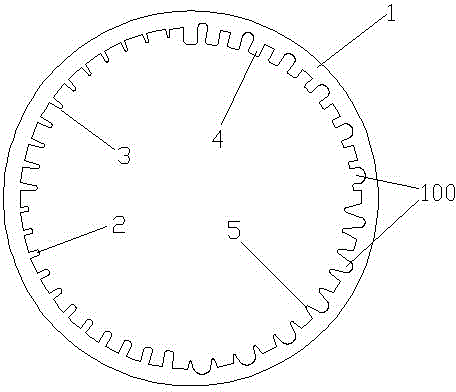

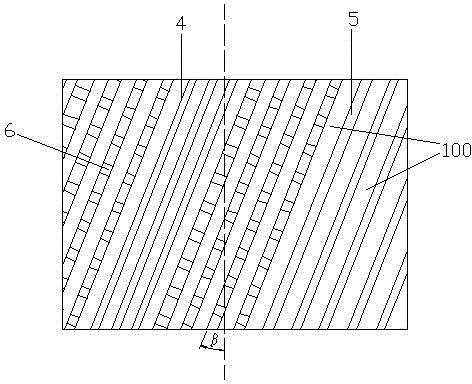

Combined impeller abrasive disk type extrusion plasticizing method and device

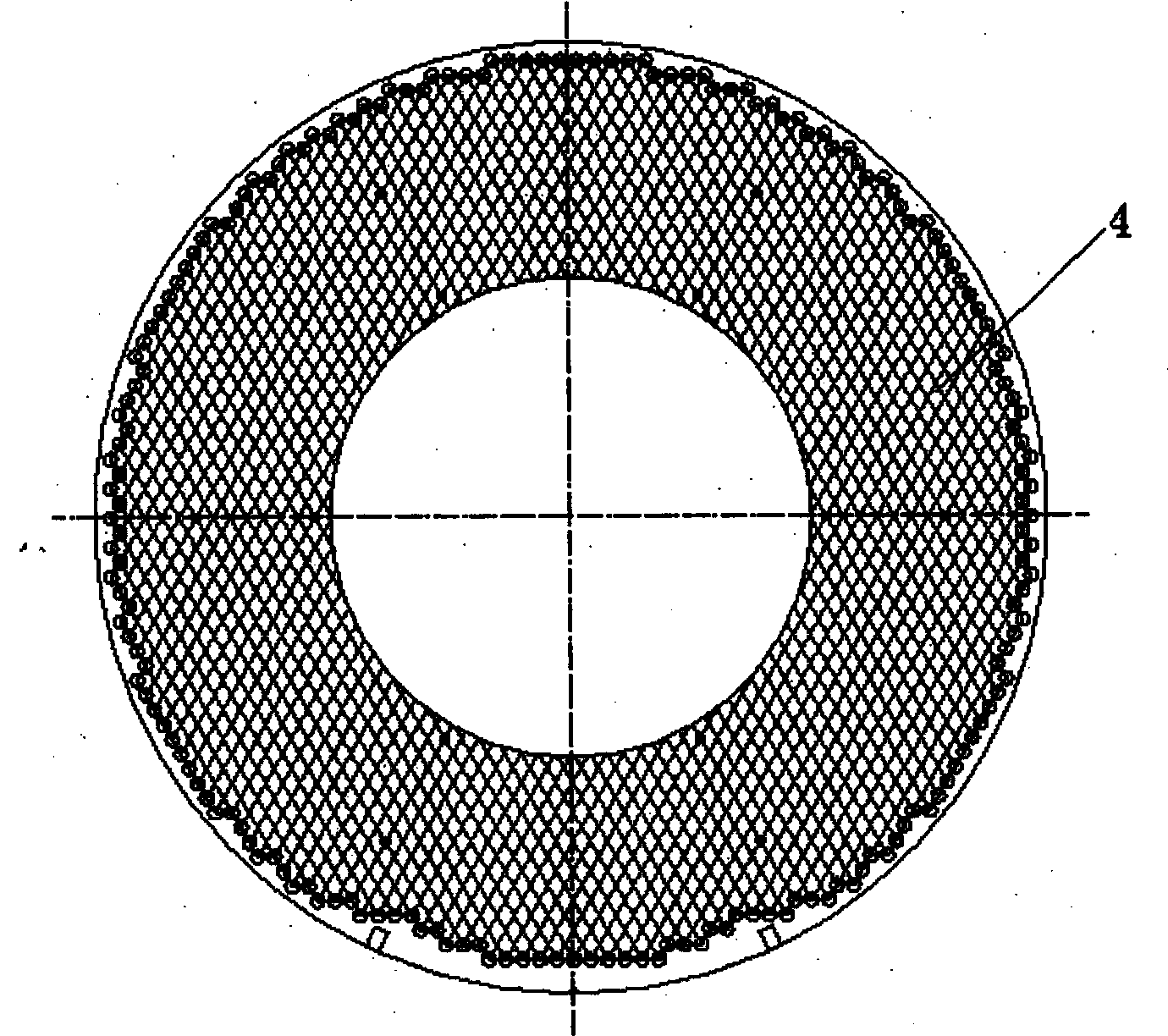

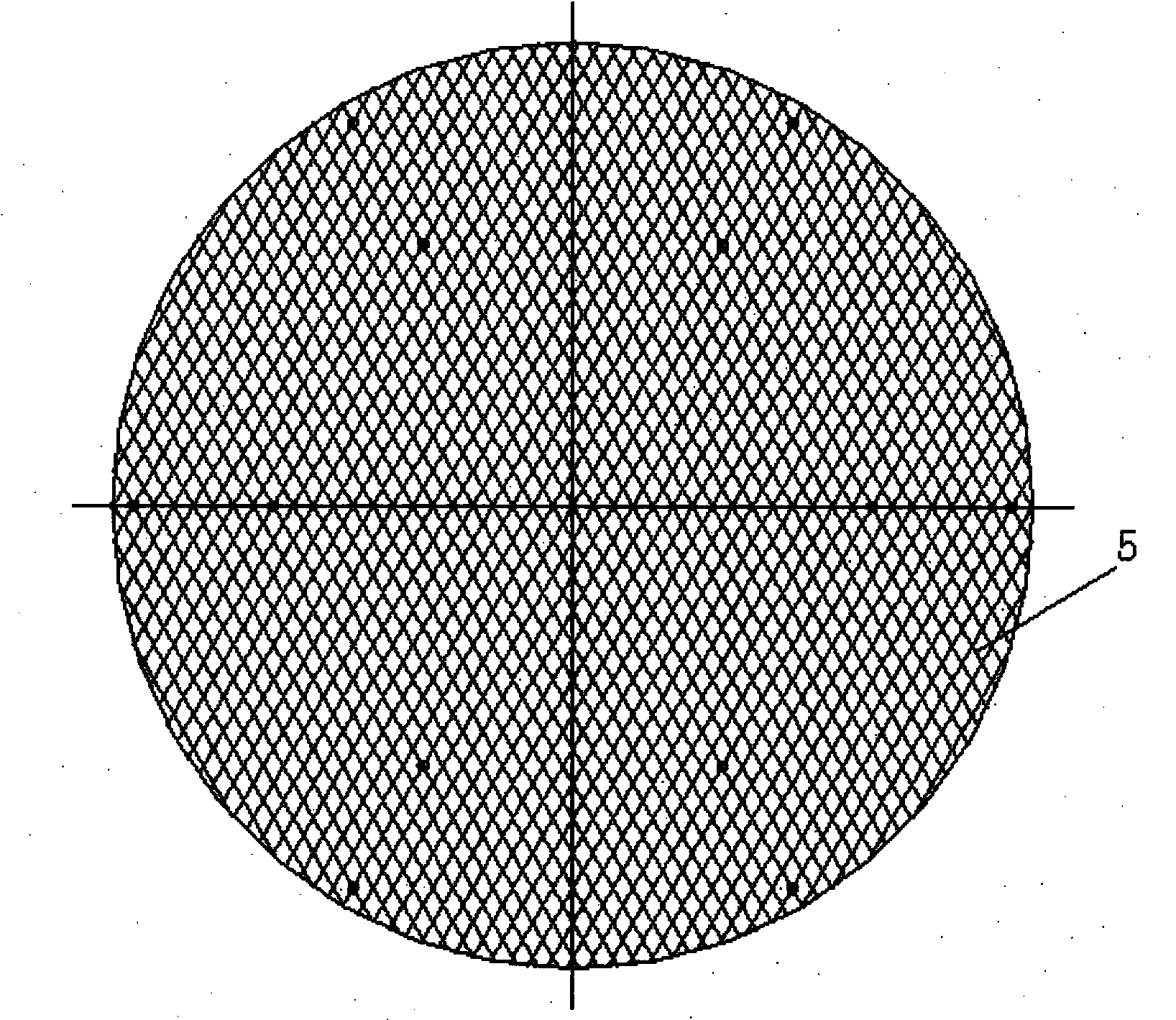

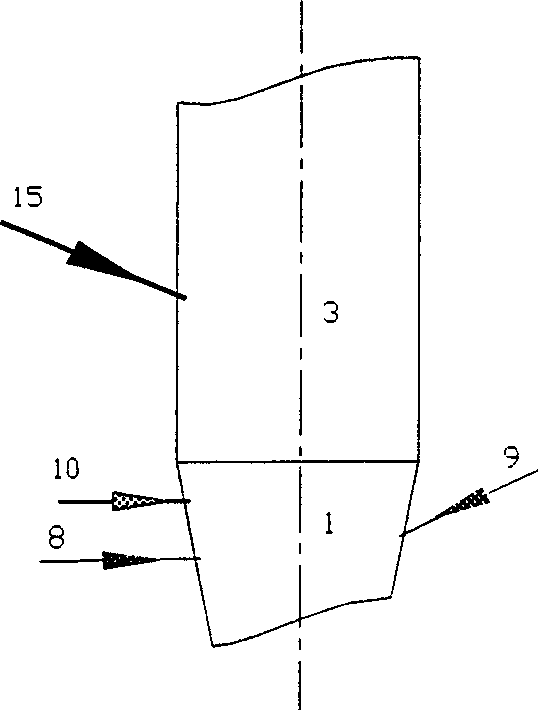

The invention discloses a combined impeller abrasive disk type extrusion plasticizing method and a combined impeller abrasive disk type extrusion plasticizing device. A fixed abrasive disk and a rotating abrasive disk are arranged in a charging barrel; the fixed abrasive disk is arranged on the charging barrel; and the rotating abrasive disk is arranged on a power shaft. The invention is characterized in that: the fixed abrasive disk and the rotating abrasive disk are designed to be impeller type abrasive disks are formed by making a plurality of material through grooves for allowing materials to pass through and mixing the materials on whole abrasive disks along a radial direction; impeller blades form abrasive surfaces, and channels are formed by the material through grooves between theblades of the impeller abrasive disks; a plurality of like fixed impeller abrasive disks and rotating impeller abrasive disks are overlapped alternately; the materials are forcefully pressed in from the front part of the inside of the charging barrel; then under the rotation of the rotating impeller abrasive disks relative to the fixed impeller abrasive disks, the materials pass through abrasive disk gap and blade material through grooves so as to be gradually mixed, crushed, ground, softened, subjected to heat exchange and plasticized in the constantly varying material through channels and the abrasive disk gaps; and finally, the materials are discharged from a discharge hole on the rear part of the inside of the charging barrel.

Owner:HUBEI UNIV OF TECH

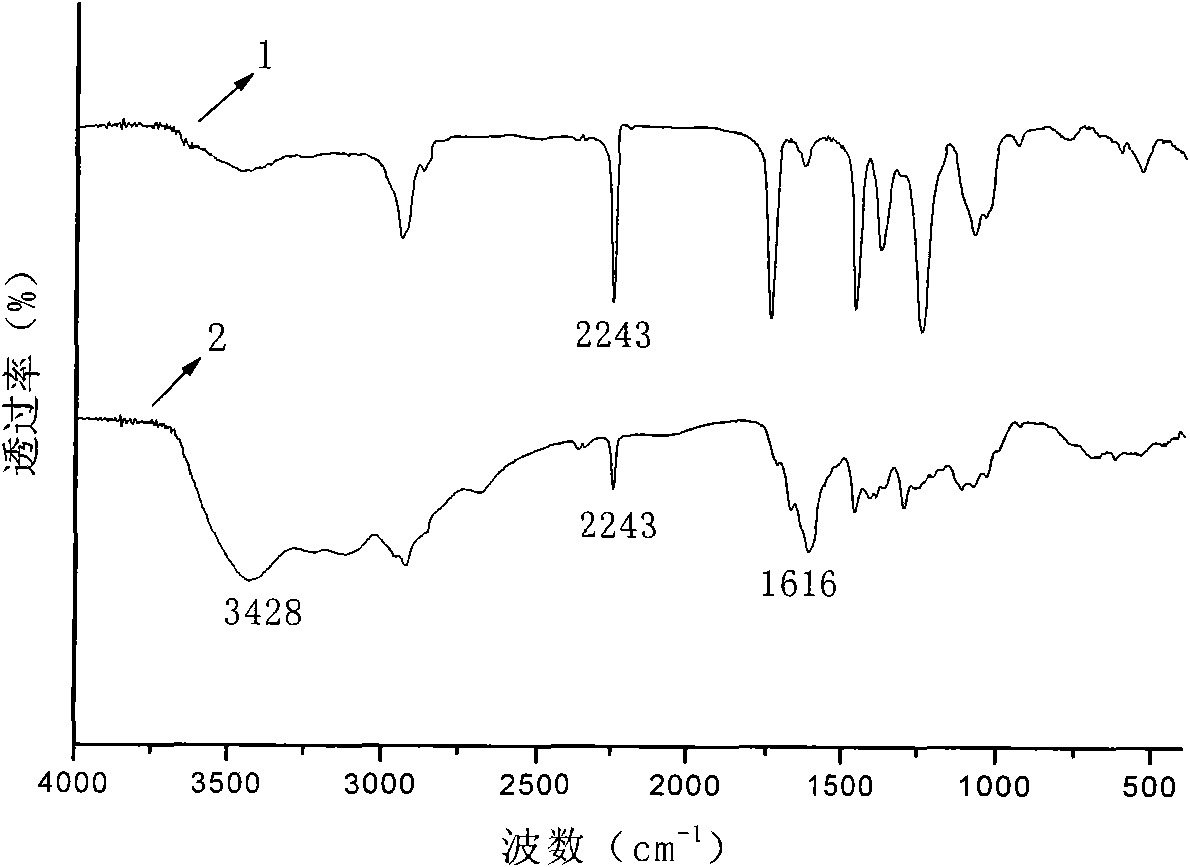

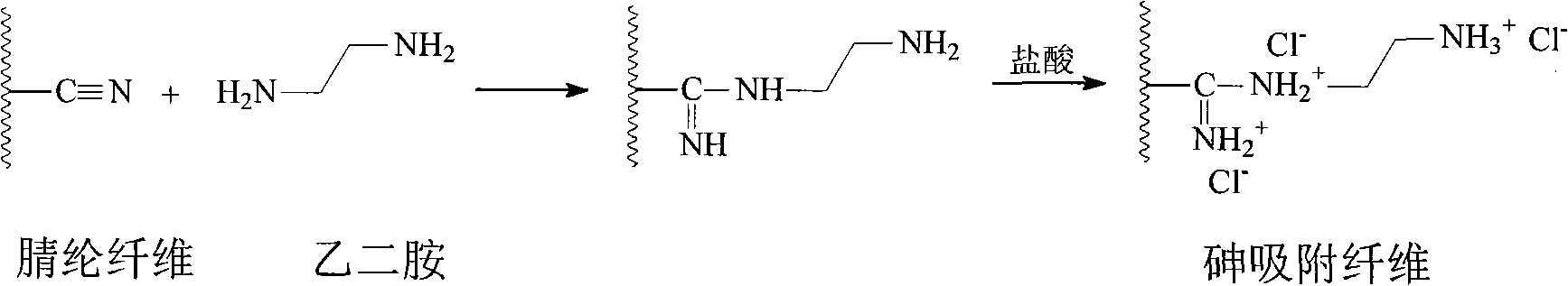

Arsenic adsorbing fiber and synthesizing method thereof

ActiveCN101569854ALarge specific surface areaSmall circulation resistanceOther chemical processesAlkali metal oxides/hydroxidesIon exchangeCarbon dioxide

The invention discloses an arsenic adsorbing fiber using acrylic fiber as a fundamental frame and a synthesizing method thereof, belonging to the technical field of polymer materials. In the structure of the fiber material, amido existing in a mode of hydrochloride is contained, and the amido can effectively adsorb arsenic radical in the water through an ion exchange reaction. The method for synthesizing the fiber is to lead the acrylic fiber to firstly perform a grafting reaction with a multi-amido compound to introduce amido, and the acrylic fiber reacts with the hydrochloric acid to transform the amido into the hydrochloride, and has simple reacting process and mild condition. The neutral fiber is stable in the air, cannot absorb carbon dioxide and other acid gases, and cannot affect the pH value of the water body when the arsenic adsorbing fiber is used in the water as an adsorbent.

Owner:HENAN ACADEMY OF SCI CHEM RES INST CO LTD

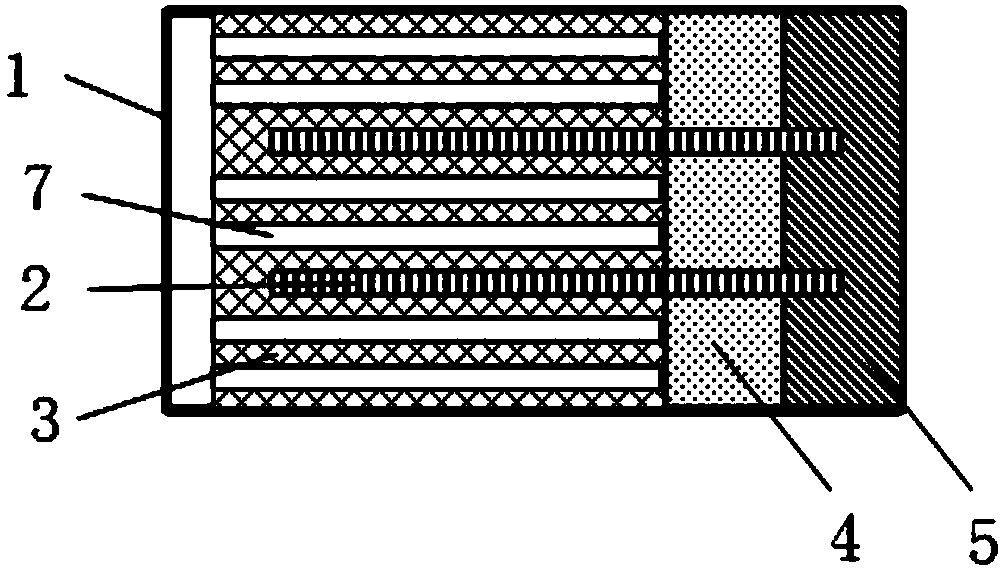

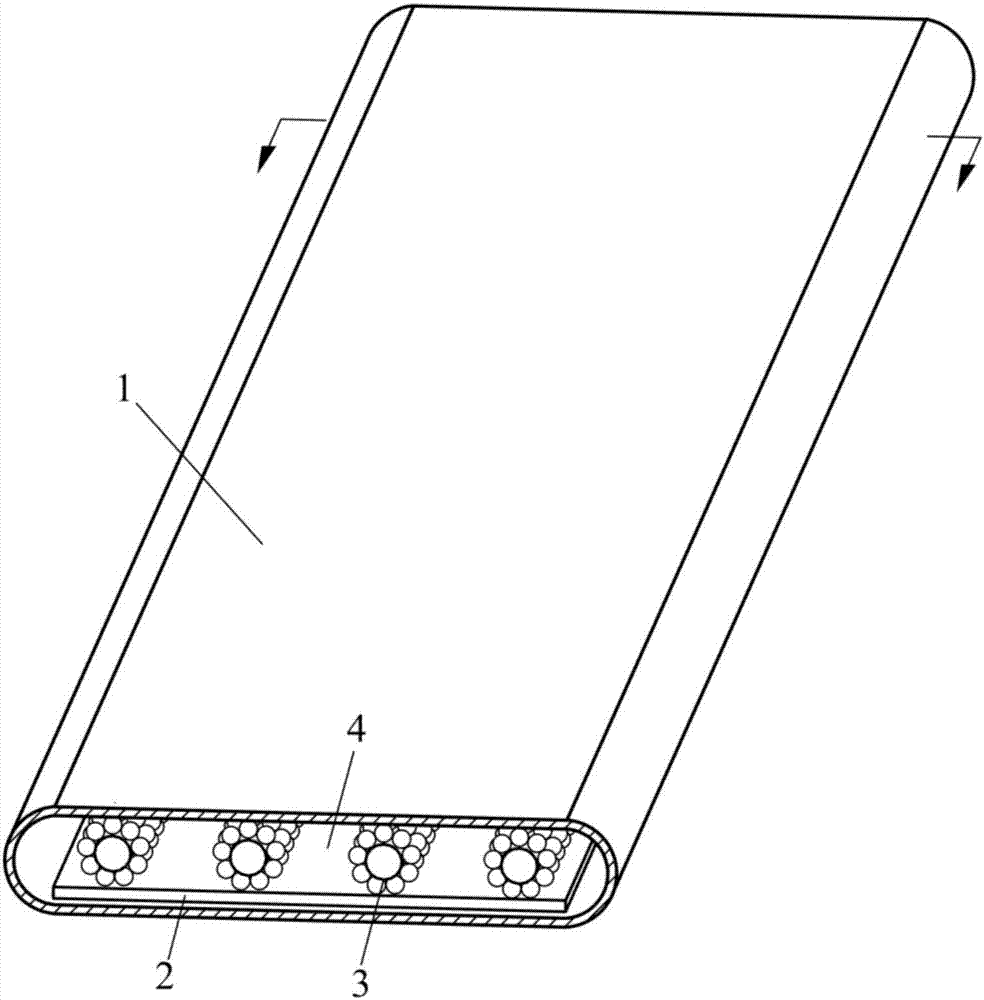

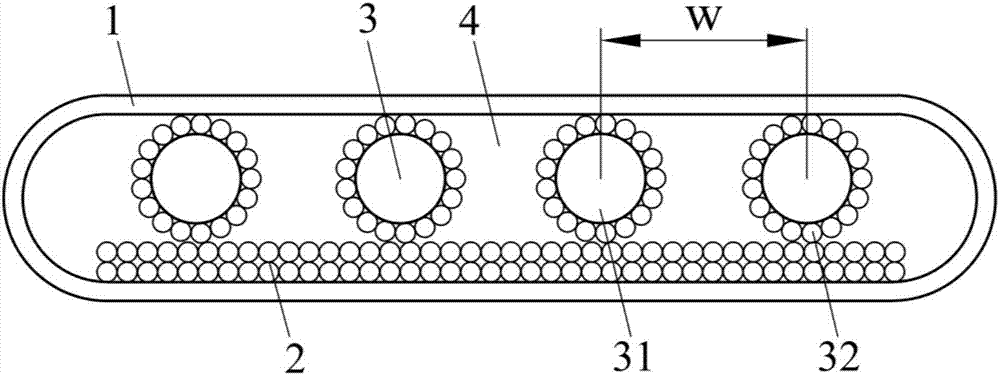

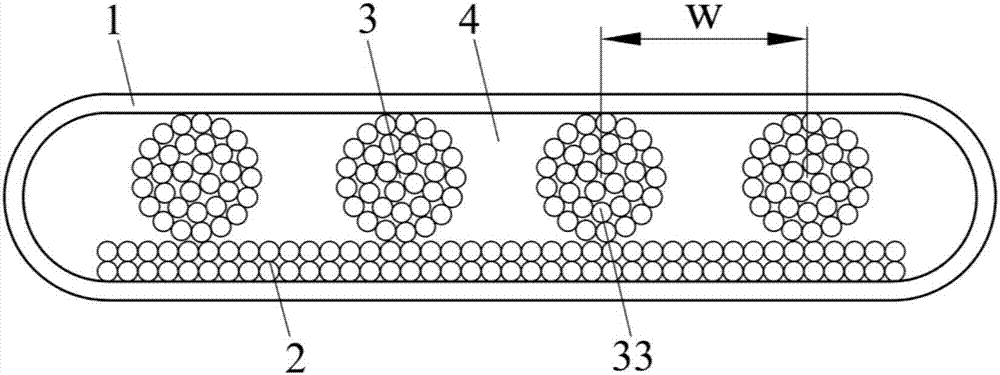

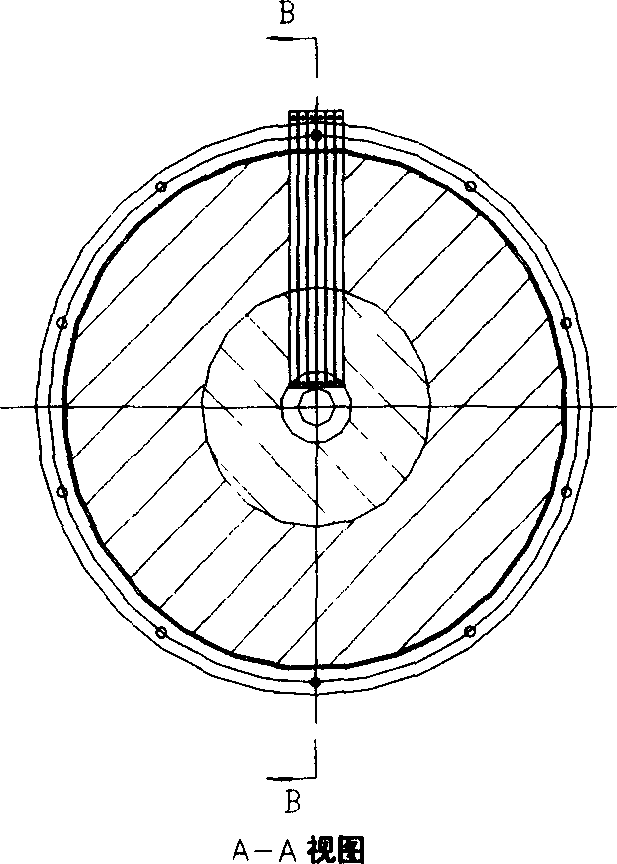

Ultra-thin flat panel heat pipe and manufacturing method thereof

ActiveCN107167008AEasy to moveIncrease heat transfer limitIndirect heat exchangersVapor liquidHeat flux

The invention relates to an ultra-thin flat heat pipe and a manufacturing method thereof. A wick comprises a porous medium bottom layer and a plurality of porous medium filaments arranged side by side; the porous medium filaments make contact with the top of a tube shell; the wick inside the heat pipe, a sharp angled area between the porous medium filaments and the upper surface of the tube shell, and a sharp angled area between the porous medium filaments and the porous medium bottom layer provide liquid return capillary driving force which is large enough in a limited space; spaces formed between the porous medium filaments provide steam flow channels, and the steam flow channels communicate with one another; and reasonable matching of vapor-liquid phase distribution is achieved, and steam and condensed liquid can flow easily. According to the ultra-thin flat heat pipe, efficient operation can be maintained at various angles, the performance of anti-gravity operation is excellent, the heat flux which can be borne by the heat pipe is high, and the heat transfer performance of the heat pipe is remarkably improved after further modification treatment.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

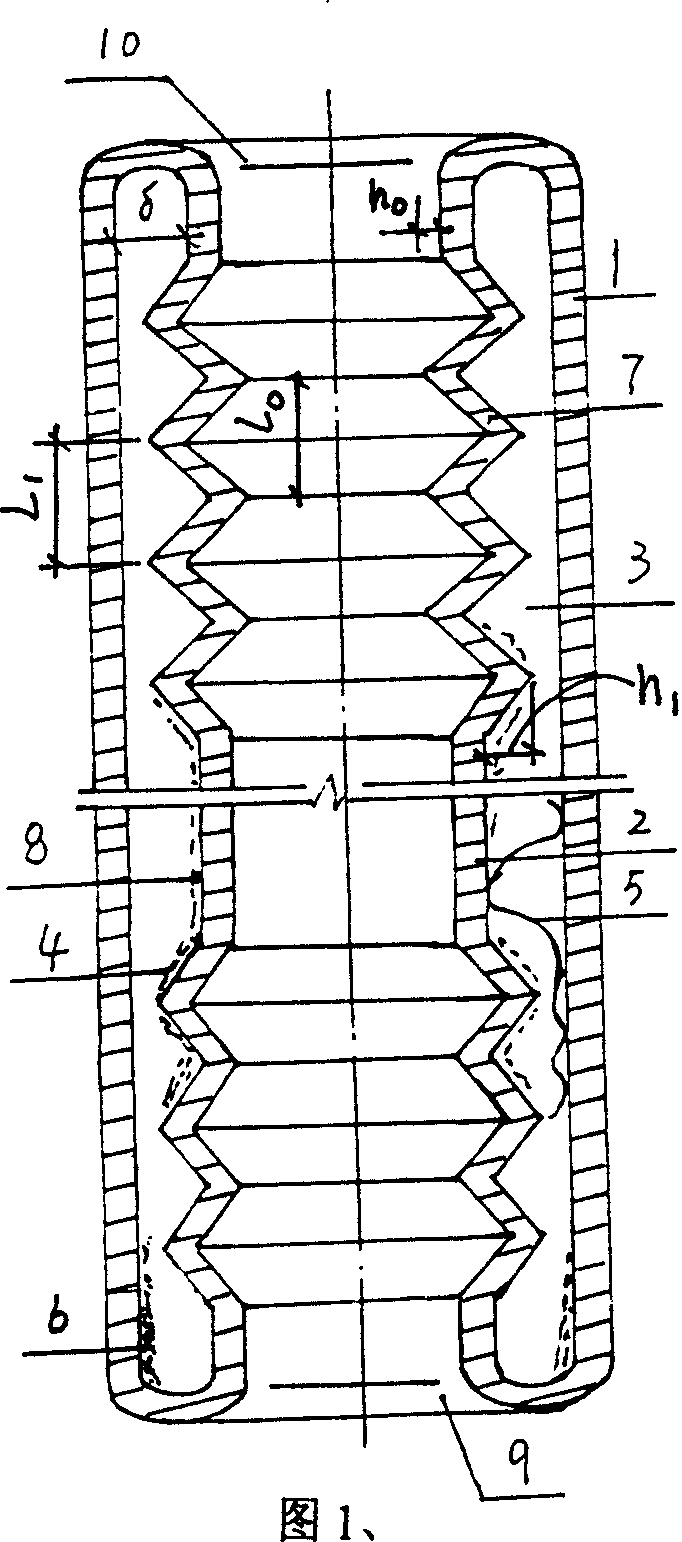

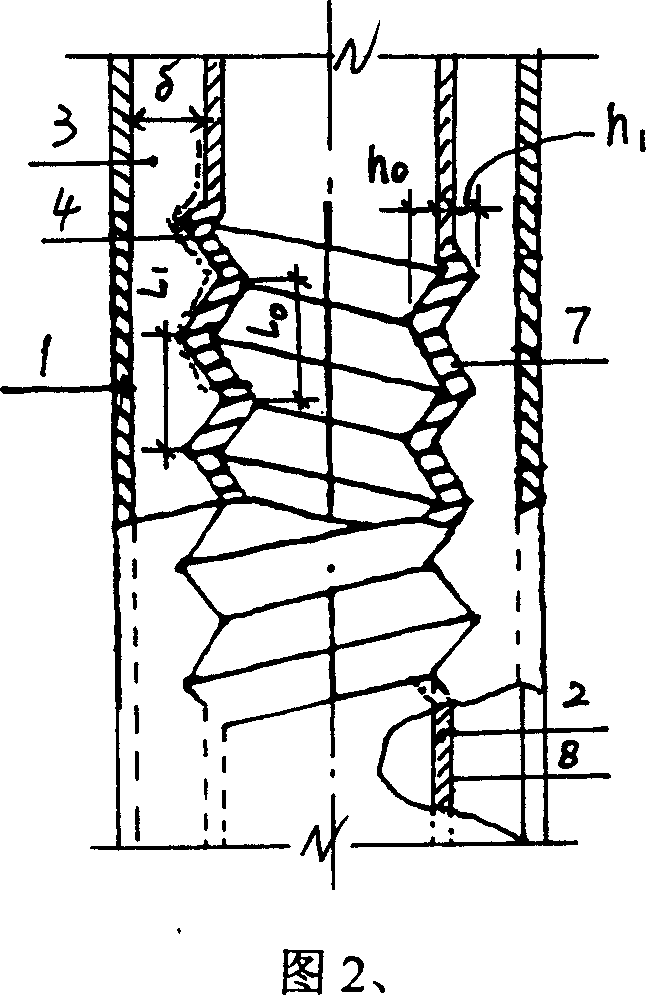

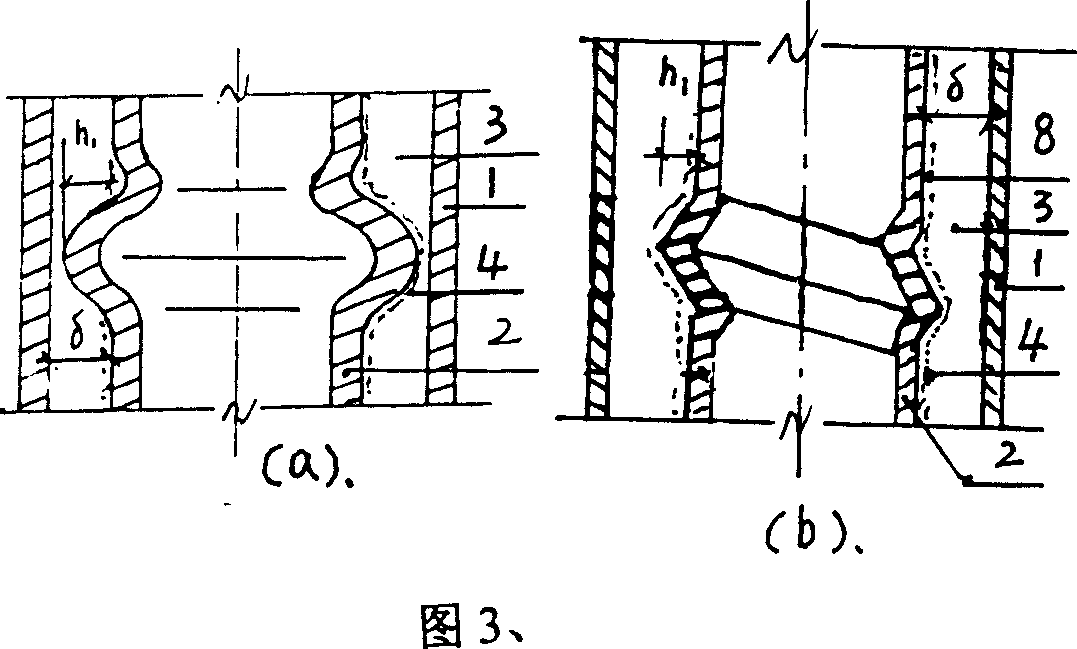

Two ends straight through type all glass vacuum heat collection tube of solar energy

InactiveCN1959293AGuaranteed working lifeTake advantage ofSolar heating energySolar heat devicesDegasserWave form

A glass vacuum solar heat collection tube of through two-end type consists of external glass tube, internal tube with corrugated body, absorption coated layer, elastic support and degasser. It is featured as setting space between two said tubes to be vacuum cavity, melt-jointing two ends of two said tubes to be an integral body for sealing two ends with each other and setting circular wave form ledges on internal tube to be distributed in mode of group wave ledges being not continuously set.

Owner:罗赞继 +2

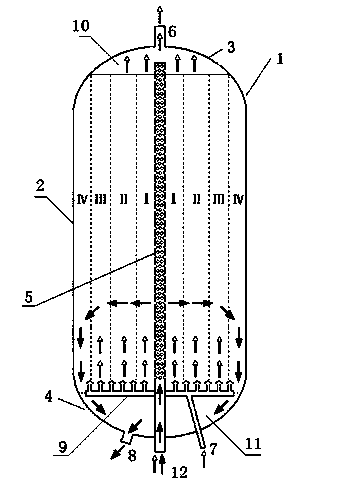

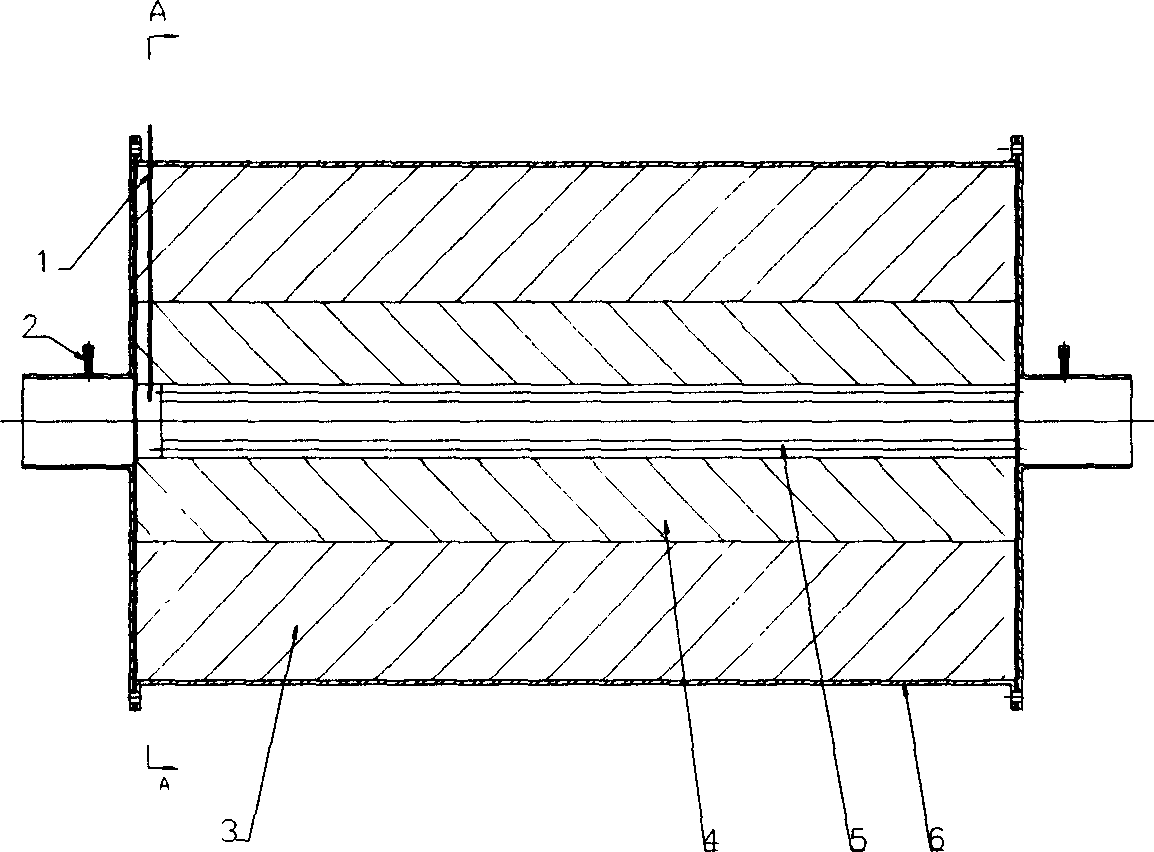

Fixed tube-sheet heat exchanger with temperature control function

InactiveCN103471431AImprove heat transfer coefficientReduce heat transfer areaHeat exchanger casingsStationary tubular conduit assembliesCircular discTemperature control

The invention relates to a fixed tube-sheet heat exchanger with a temperature control function. A head structure and a tail structure are respectively arranged at two ends of a shell, at least one heat exchange pipe is arranged in the shell, tube pass fluid flows out from a head cavity and flows in a tail cavity from the heat exchange pipe, a shell pass inlet and a shell pass outlet are arranged on the shell, the fixed tube-sheet heat exchanger with the temperature control function is characterized in that a central channel is also arranged in the shell, a heat-insulating layer is arranged on the inner wall of the central channel, the tube pass fluid flows out of the head cavity and flows in the tail cavity also by the central channel, the heat exchange between the tube pass fluid in the central channel and shell pass fluid can be isolated by the heat-insulating layer, at least one annular baffle plate and at least disc type baffle plate are also simultaneously arranged in the shell, and the tail cavity at least comprises one mixed cavity. The fixed tube-sheet heat exchanger with the temperature control function has the following beneficial effects that the heat exchange coefficient of the heat exchanger is effectively increased, the heat exchange area can be reduced, and the manufacturing cost of equipment can be lowered; the temperature control structure can ensure the running stability of the heat exchanger under variable working conditions, and guarantee the steady-state operation of downstream equipment of the heat exchanger.

Owner:SHANGHAI BOILER WORKS

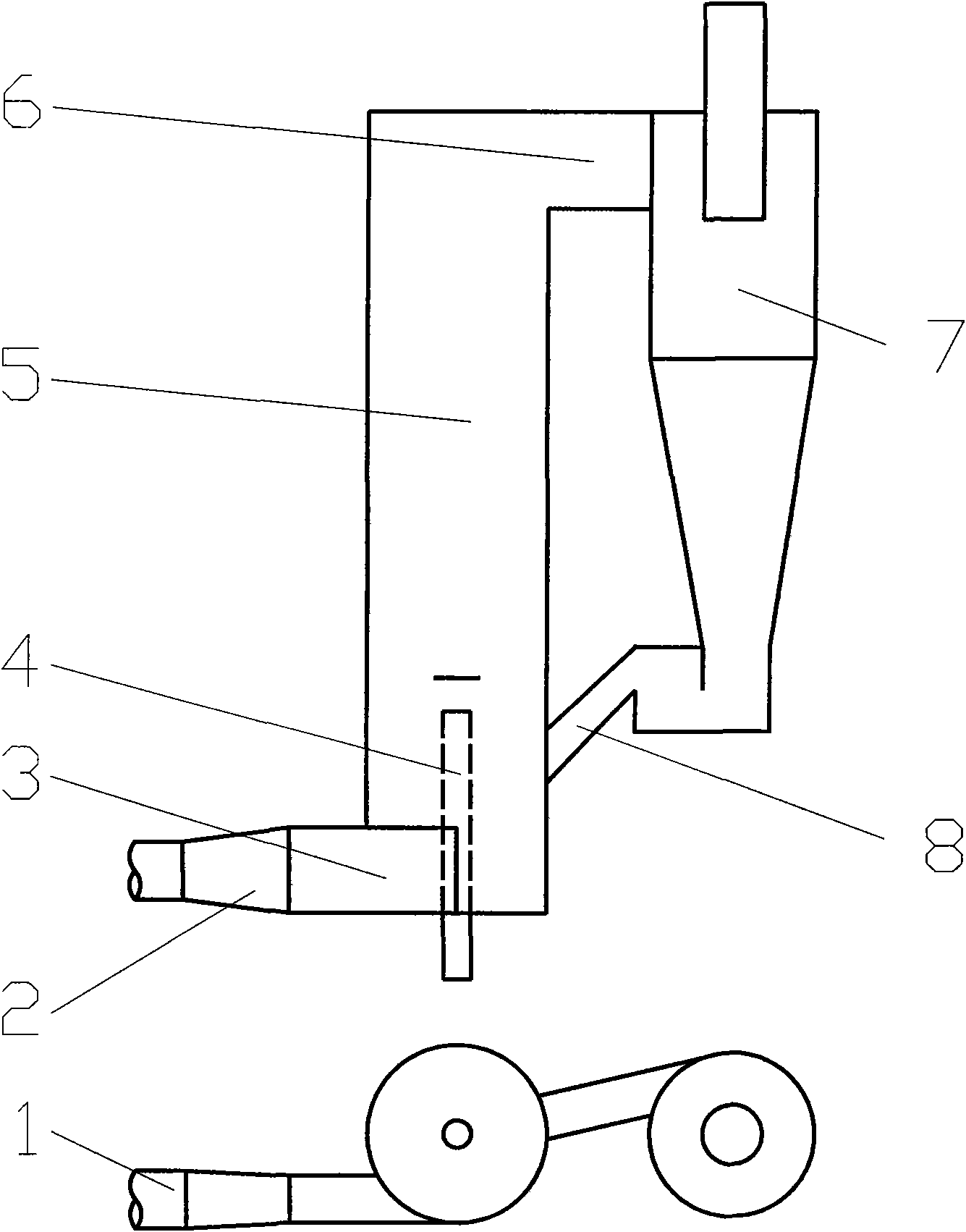

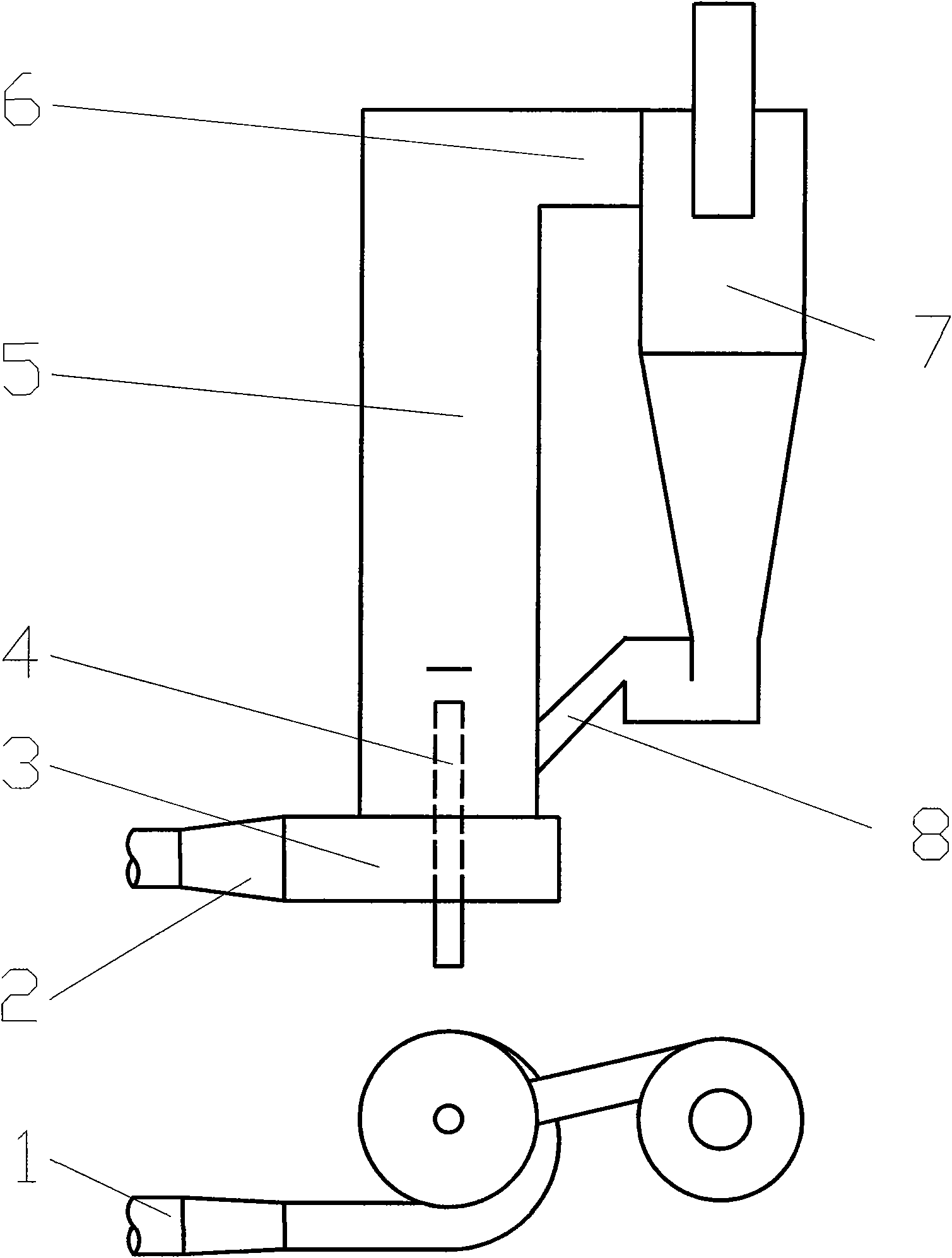

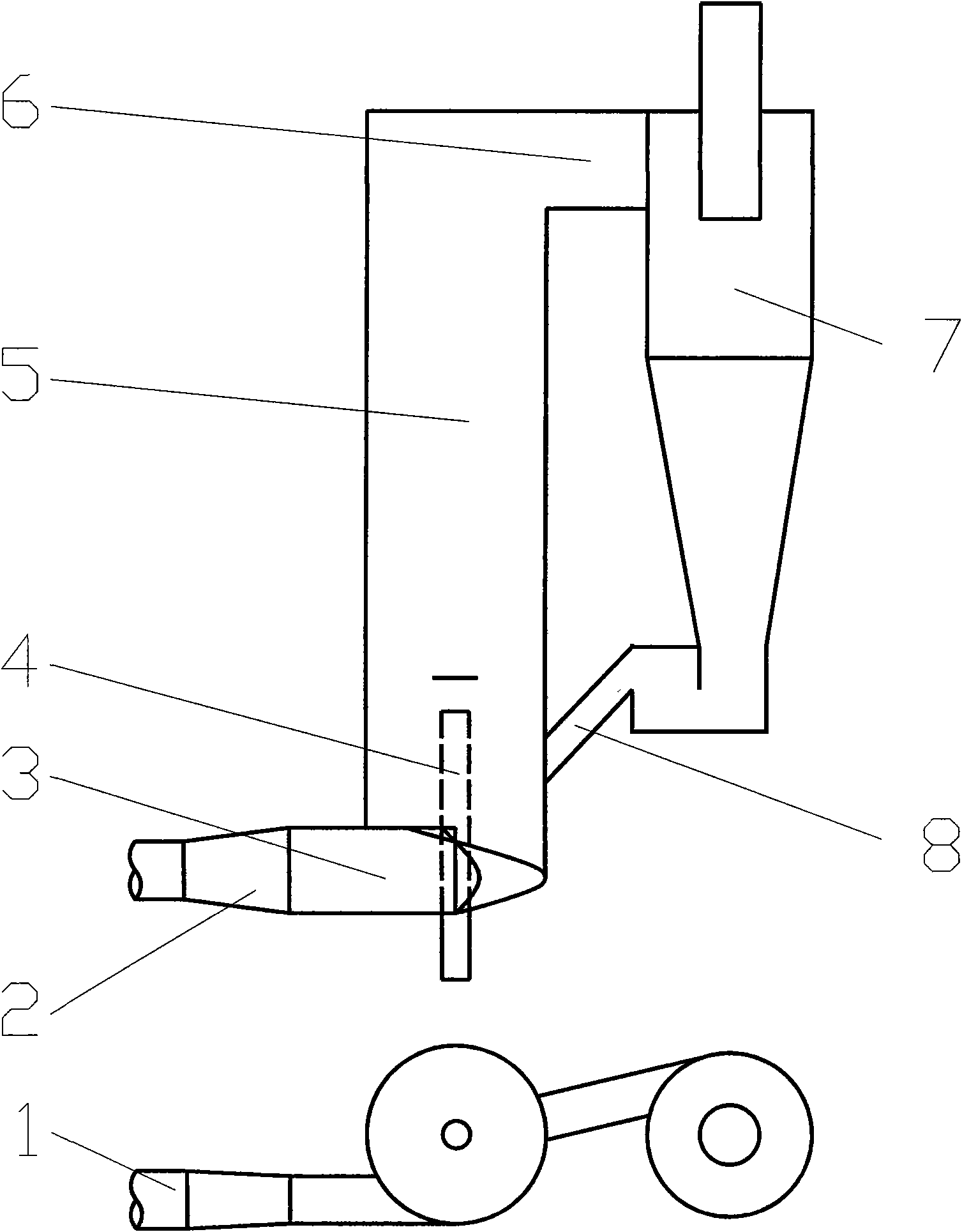

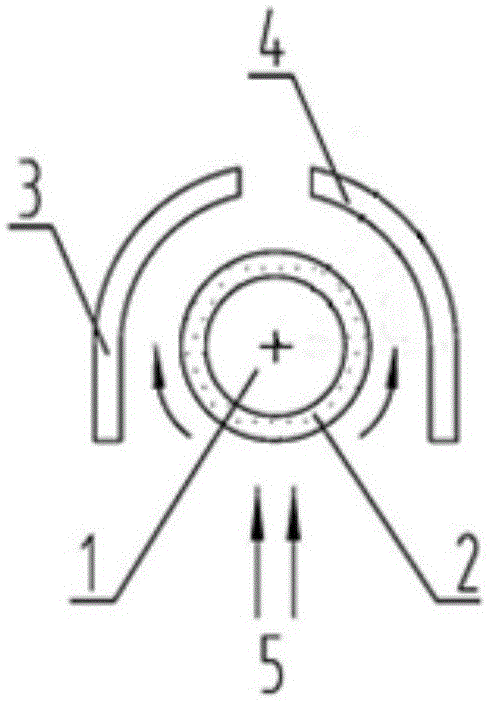

Dry-process flue gas desulfurizing method using combined gas jet

InactiveCN1488426ASmall circulation resistanceIncrease mixing intensityDispersed particle separationFlue gasEngineering

The invention discloses a drying smoke desulfurizing method by using combined smoke jet. The character is that it adds a smoke jet nozzle above the water nozzle and desulfurizing agent muzzle. It realizes the fully combination of gas, solid and liquid in the desulfurizing reaction tower, increases the desulfurizing efficiency.

Owner:WUHAN KAIDI ELECTRIC POWER CO LTD

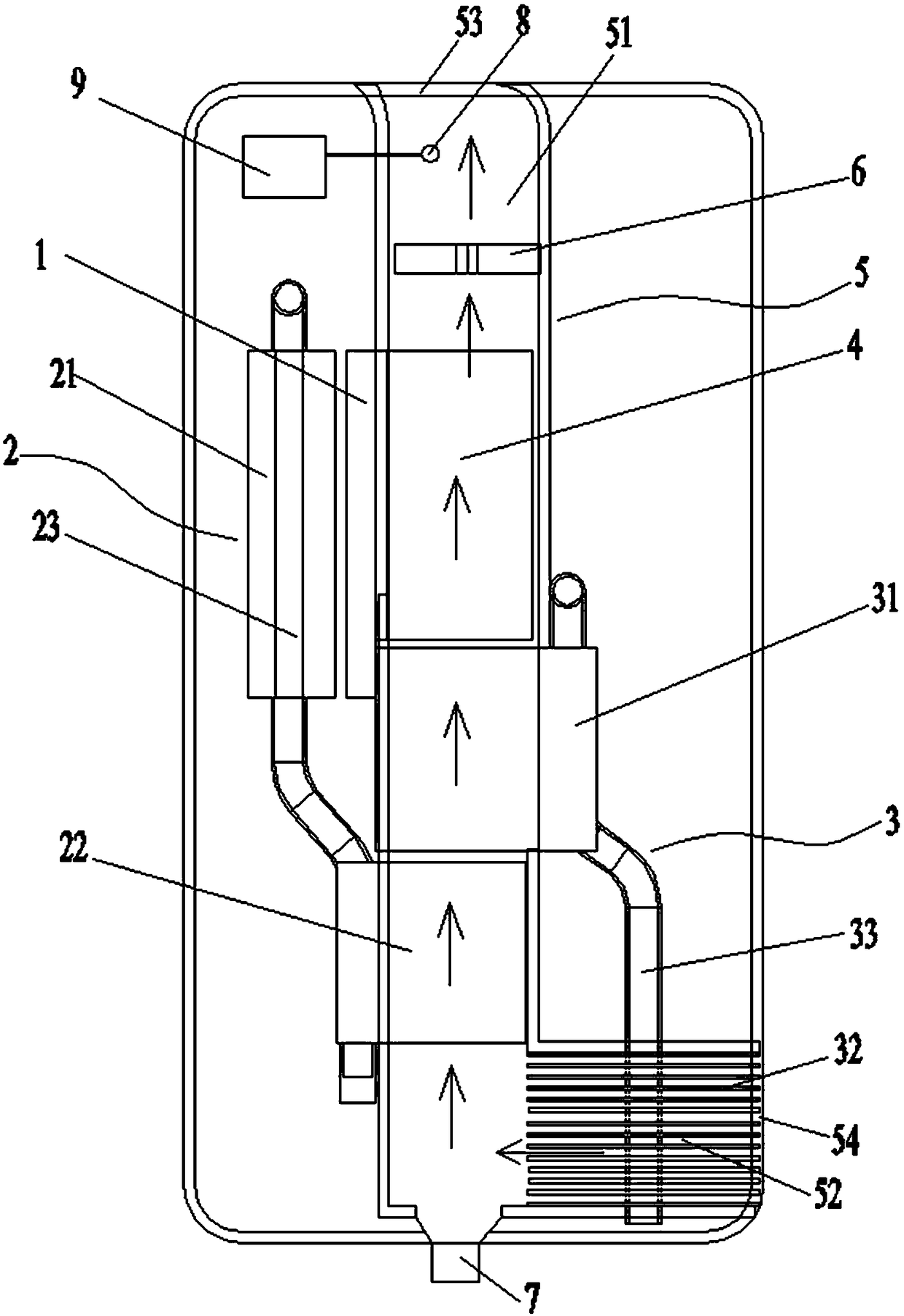

Semiconductor refrigeration dehumidifier and dehumidification method thereof

PendingCN108758882AImprove dehumidification efficiencySimple structural designMechanical apparatusSpace heating and ventilation detailsEngineeringCooling capacity

The invention provides a double-heat-pipe semiconductor refrigeration dehumidifier and a dehumidification method of the double-heat-pipe semiconductor refrigeration dehumidifier. The double-heat-pipesemiconductor refrigeration dehumidifier comprises a semiconductor refrigeration sheet, a first heat transfer device, a second heat transfer device, a third heat transfer device, an air flue, an exhaust fan and a water outlet. Heat exchange and dehumidification of air are performed through the arrangement of the three heat transfer devices, and the first heat transfer device can transfer the cooling capacity of the cold face of the semiconductor refrigeration sheet and performs secondary cooling on the air in an air-discharging channel through the absorbed cooling capacity of the cold face ofthe semiconductor refrigeration sheet. The third heat transfer device can transfer the heat of the hot face of the semiconductor refrigeration sheet and performs secondary heating on the air in the air-discharging channel, the air passes through the cold face for heat exchange in advance and then passes through the hot face for heat exchange without changing the direction, structural design of theair flue is simplified, the flowing pressure loss of the air in the air flue is reduced, and the dehumidification efficiency of the whole dehumidifier is improved.

Owner:AUX AIR CONDITIONING LTD BY SHARE LTD

Ventilation and rain-guard apparatus for radar antenna front

ActiveCN101309565ADistribute in timeImprove the rain protection rateCasings/cabinets/drawers detailsCooling/ventilation/heating modificationsFixed frameRadar

The invention provides a ventilating and rain retaining device used for a radar antenna array, which comprises a fixed frame and a louver, wherein, the louver comprises at least a leaf, each leaf of louver is installed in the fixed frame through a bending plate, the blade of the louver at the inner side of a wind inlet surface is horizontally installed, the blade of the adjacent louver is vertically installed, thus, the rain retaining rate is enhanced, cooling air can be entered and rain water can be retained whether being under the condition of forward direction and overturning 180 degrees, so that the heat generated by the electronic element and the immediate heat radiation are ensured; the blade with no installing surface can be conveniently installed, and can be firmly fixed; the circulating resistance of the air can be reduced through arranging a wing guiding surface, to increase the air disturbance, and to prevent the rain water from entering; the excessive entering amount of the rain water is effectively prevented through the rain wrapping surface; the rain retaining effect is further enhanced through the reasonable gap among the blades, therefore, the cost is saved. The device can effectively ventilate and retain the rain, to improve the safety performance of the electronic device, and prolong service life.

Owner:泰兴航空光电技术有限公司

Low flow resistance check valve with high sealing force

InactiveCN102563135AImprove sealingSmall flow resistanceCheck valvesValve housingsMagnetic tension forceCircular disc

The invention relates to a low flow resistance check valve with high sealing force. The low flow resistance check valve is characterized in that the low flow resistance check valve is provided with a valve body, a valve cap and a valve rod, wherein an inlet and an outlet are formed in the valve body; a central line of the inlet and a central line of the outlet of the valve body are arranged by 90 degrees; the valve cap is mounted on an outer plane of the valve body, which is opposite to the inlet; a permanent magnet is mounted in an inner hole of the valve cap; central lines of the valve cap, the valve rod and the inlet are consistent; the valve rod comprises rod parts arranged at two ends of the valve rod and disks positioned on the intermediate sections of the rod parts; the rod parts are respectively matched in holes of the valve cap and a guide plate of the inlet in a sliding way; the disks and corresponding annular blade edges of the valve body form a valve; and a spring is mounted on the valve rod between the disk and the valve cap. Due to the adoption of common action of a strong magnetic force and a spring force, the low flow resistance check valve has the characteristics of high sealing force and low flow resistance.

Owner:HANGZHOU CHUNJIANG VALVE

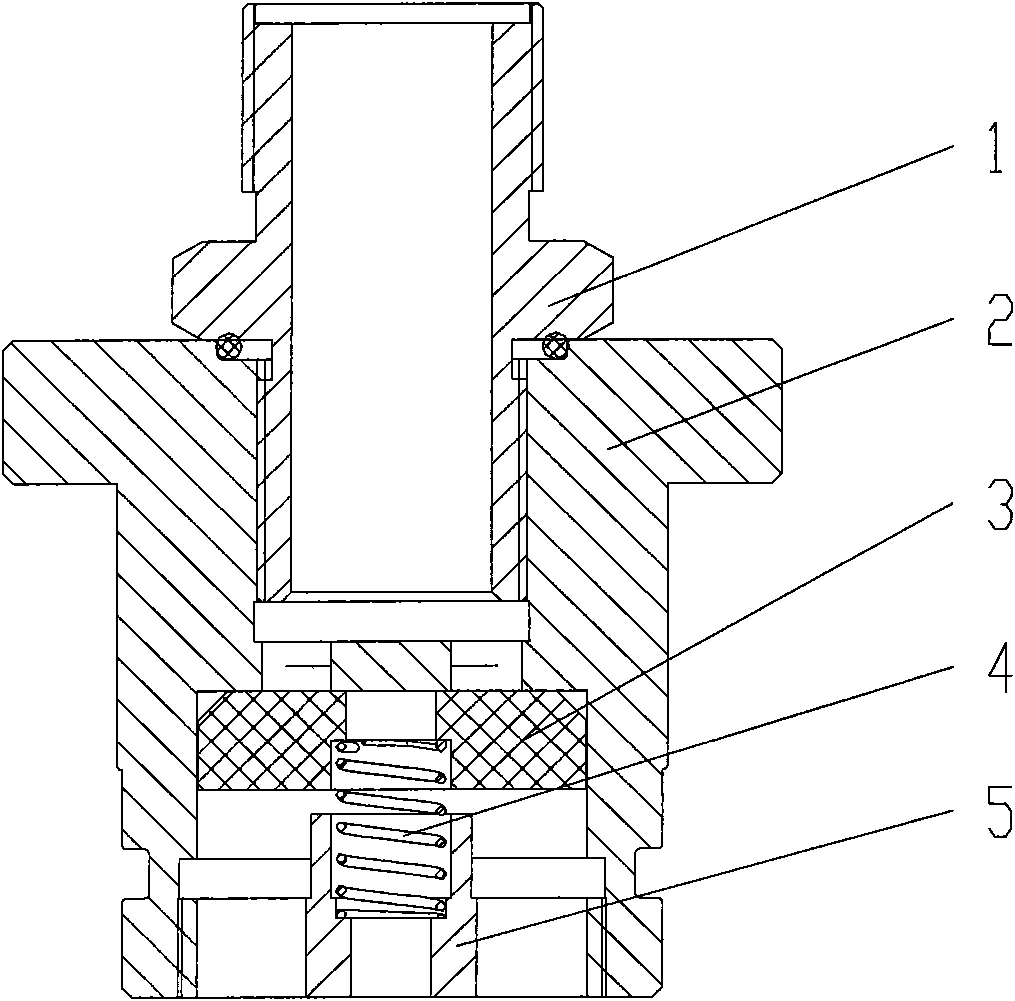

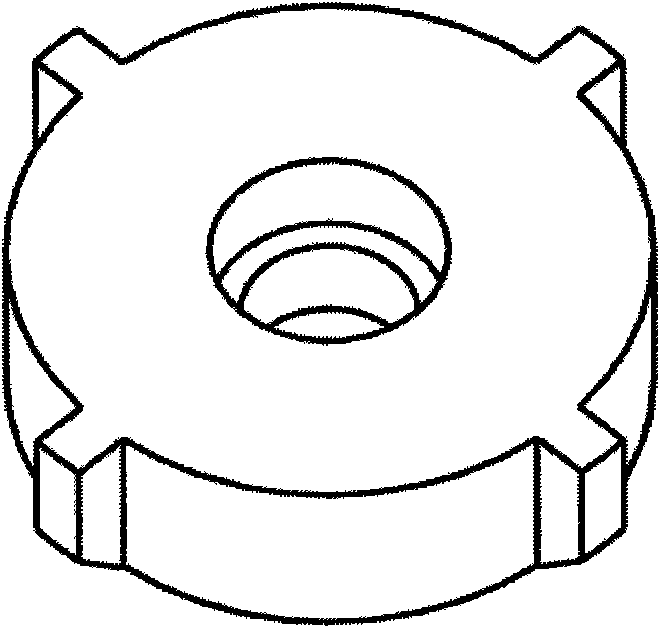

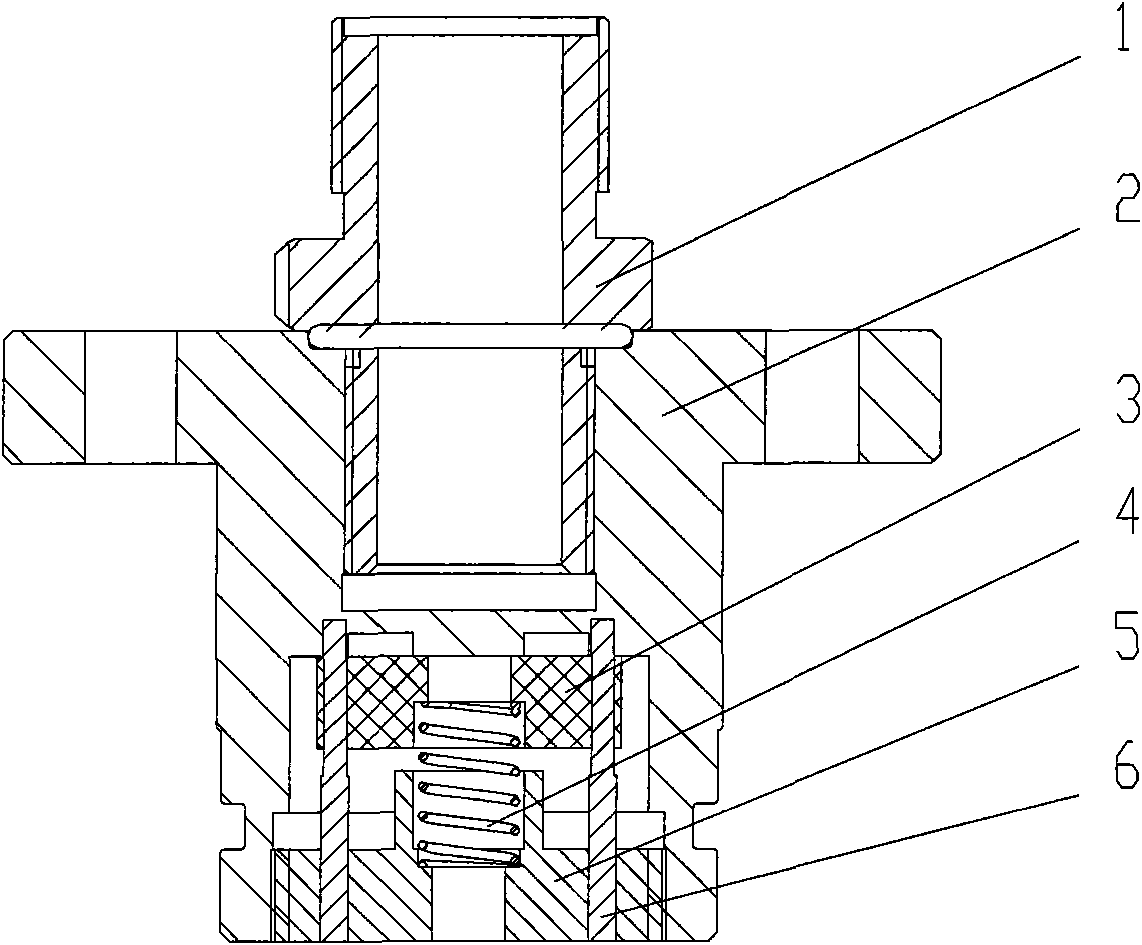

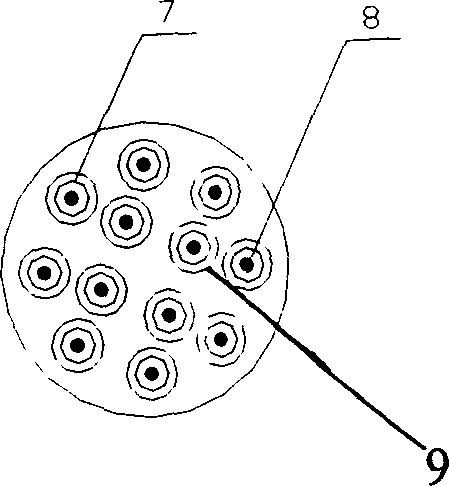

Air inlet and exhaust valve of compressor

ActiveCN101592145AReduce weightAvoid breakingPositive displacement pump componentsPositive-displacement liquid enginesExhaust valveReciprocating motion

The invention discloses an air inlet and exhaust valve of a compressor, which comprises a valve body, an air valve plate, a spring, a spring seat and an air inlet and exhaust connector, wherein the valve body is arranged on the valve seat; the spring applies a pretightening force during installation to press the air valve plate onto the valve seat tightly; seal is formed between the air valve plate and the valve seat to separate the channels positioned above and below the air valve plate; the air valve plate is made of an impact-resistance nonmetal material and is provided with a guide structure preventing the sidewise inclination of the air valve plate during reciprocal motion of the air valve plate; the valve body is provided with a structure matched with the guide structure; and the center of the air valve plate is provided with a central hole for reducing the weight of the air valve plate and increasing circulation area at the same time. The air valve has the advantages of compact arrangement, simple structure, small resistance to air flow, low vibration noise, high reliability and the like and is particularly suitable for use in medium and small flow reciprocating piston type compressors.

Owner:SHANGHAI MICROPOWERS

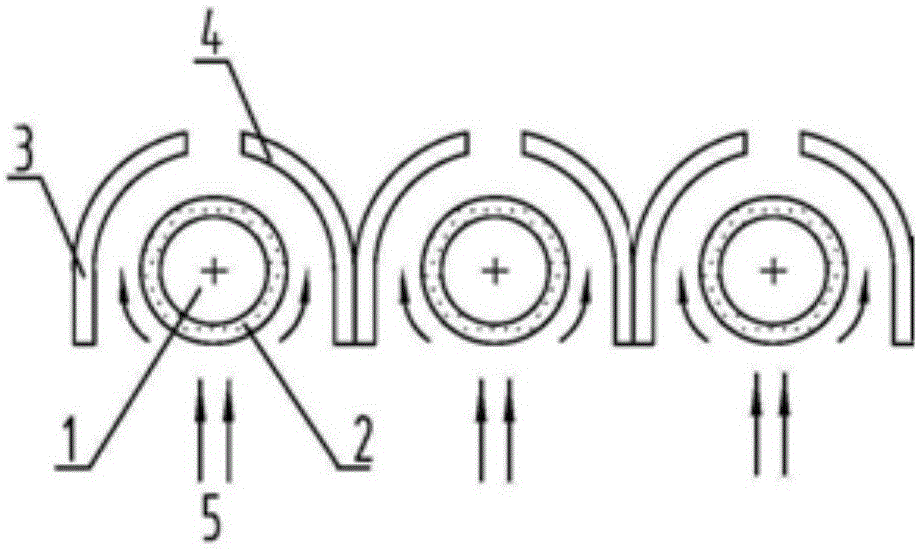

Tangential gas intake desulfurization tower of semi-dry circulating fluidized bed

InactiveCN101612523AUniform concentration distributionIncreased turbulence intensityDispersed particle separationChemical/physical processesFluidized bedFlue gas

The invention relates to a tangential gas intake desulfurization tower of flue gas desulfurization technology of a semi-dry circulating fluidized bed. The tower is characterized in that: a flue gas intake structure is tangentially connected with the desulfurization tower, a desulfurizer inlet is positioned at the central position of the bottom of the desulfurization tower, a feed back inlet is positioned at the lower part of the desulfurization tower and a flue gas outlet is positioned at the top of the desulfurization tower. The tangential gas intake desulfurization tower has the advantages of causing the flue gas to form strong rotating flow in the desulfurization tower, improving turbulent intensity of gas flow, maintaining full contact between a desulfurizer and the flue gas, and intensifying desulfurization reaction process and greatly improving the utilization ratio of the desulfurizer; and the tangential flue gas intake structure can help effectively lower pressure drop of the system.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Micro-miniature catalytic burner taking foam metal as catalyst structure substrate

ActiveCN104595899AOvercome lossOvercoming difficulties such as easy flameoutBurner material specificationsGaseous fuel burnerExhaust gasMixed fuel

The invention relates to a micro-miniature catalytic burner taking a foam metal as a catalyst structure substrate. The micro-miniature catalytic burner comprises an outer side sleeve, an inner side sleeve A and an inner side sleeve B. Pre-mixed fuels pass through a reactant inlet, a reactant inlet channel and an inlet of a catalytic combustion reaction chamber in sequence, and then enter the catalytic combustion reaction chamber so as to generate catalysis and combustion reaction on the surface of an integral catalyst taking the foam metal as the structure substrate; then, the pre-mixed fuels pass through a product channel inlet, a product channel, a backheating channel inlet, a backheating channel and a tail gas outlet. In a process of flowing a product mixture (high-temperature smoke gas) through the backheating channel, on one hand, most of heat is transmitted to a thermoelectric conversion material on the surface of the outer side sleeve, so that a process of converting heat into electricity is completed; on the other hand, part of heat is transmitted into a pre-mixed recant in the reactant inlet channel, so that microscale combustion stability is improved. The foam metal is taken as the structure substrate of the integral catalyst, so that the activity and the combustion stability of the catalyst are improved.

Owner:BEIJING UNIV OF TECH

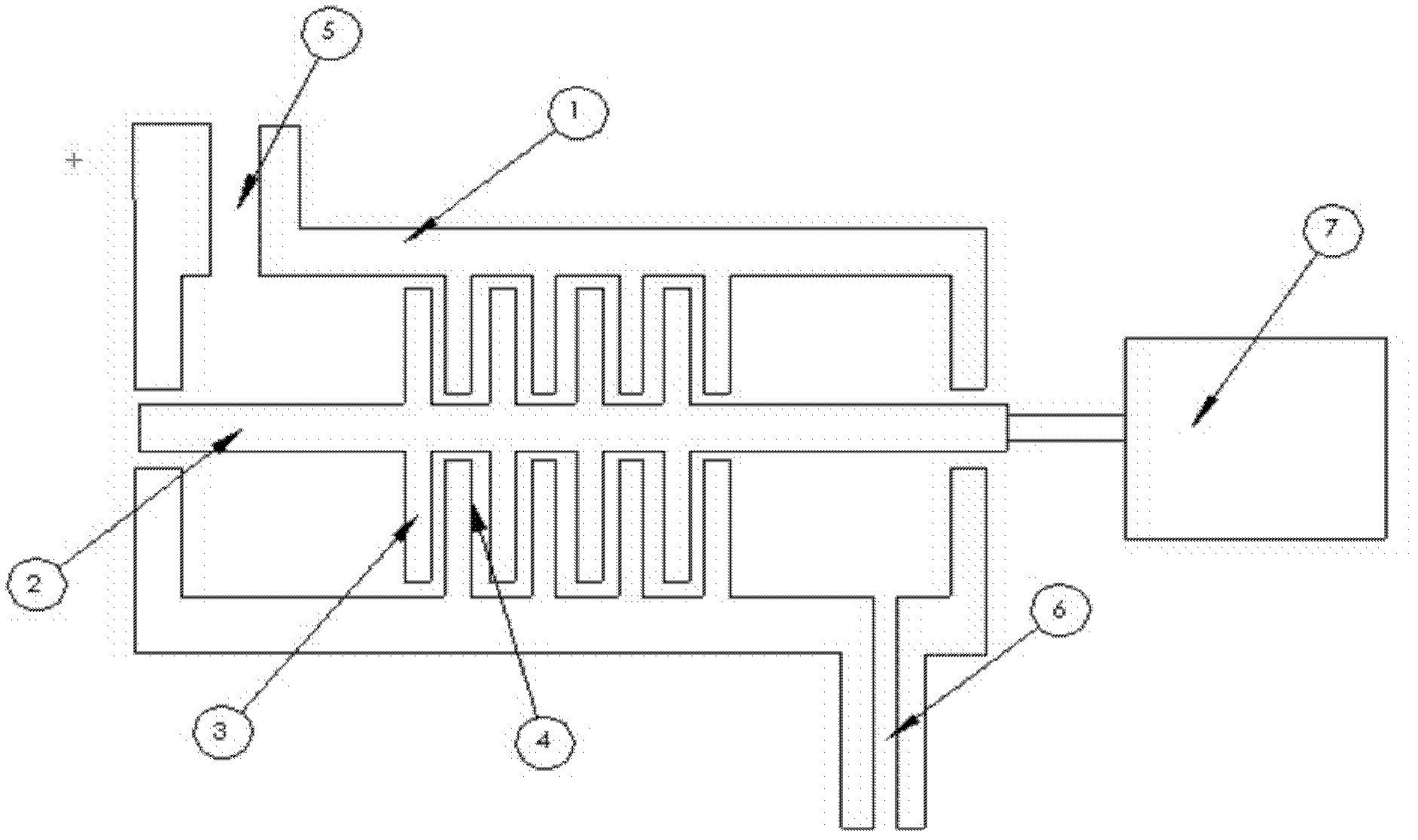

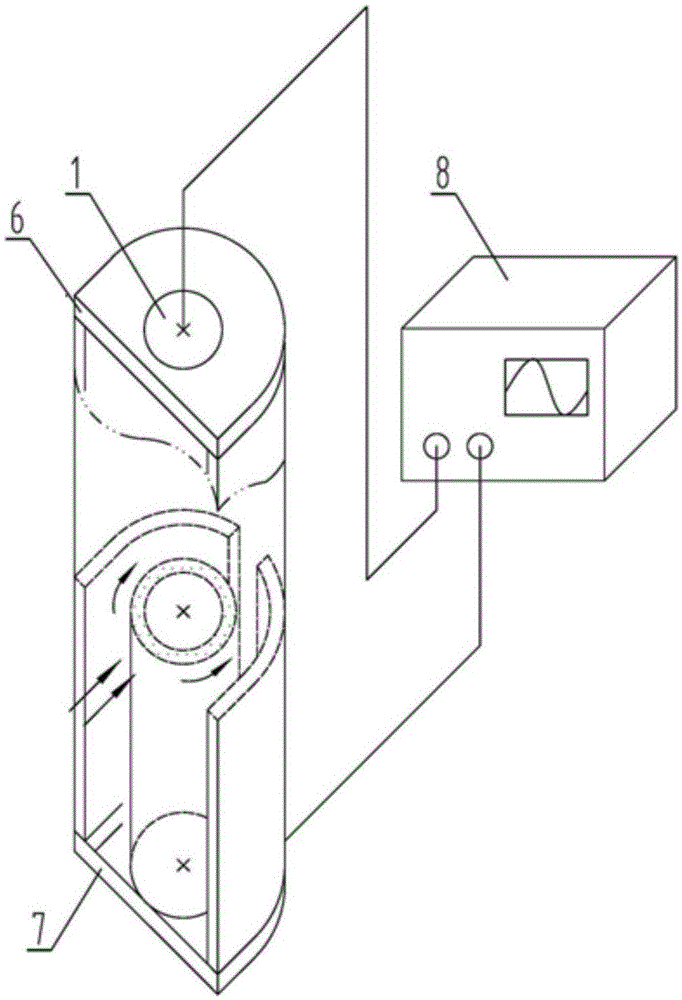

U-shaped plate type dielectric-barrier-discharge-based low-temperature plasma reactor and reactive system

ActiveCN105050304AFlow adjustableChange the size of the flow cross-sectional areaPlasma techniqueGas passingEngineering

The invention relates to a U-shaped plate type dielectric-barrier-discharge-based low-temperature plasma reactor and reactive system. The reactor comprises a core electrode, a U-shaped plate electrode housing, an insulating medium and a driving power. The core electrode is installed inside the U-shaped plate electrode housing; and gas outlet channel parallel to the core electrode is arranged at the arc position of the U-shaped plate electrode housing. The insulating medium is installed between the core electrode and the U-shaped plate electrode housing. The driving power is respectively connected with the core electrode and the U-shaped plate electrode housing. Gas enters the reactor through a U-shaped opening of the U-shaped plate electrode housing; and the processed gas leaves the reactor through the gas outlet channel. According to the reactor, large-flow gas can be processed; the gas disturbance can be enhanced and the plasma catalysis can be strengthened; the mixed uniform degree of several kinds of gas can be improved; the dielectric barrier discharge (DBD) breakdown voltage and discharging power are low and the waste gas treatment cost can be lowered; and the reactor can work separately or work in a matrix arrangement mode.

Owner:SHANDONG ELECTRIC POWER ENG CONSULTING INST CORP

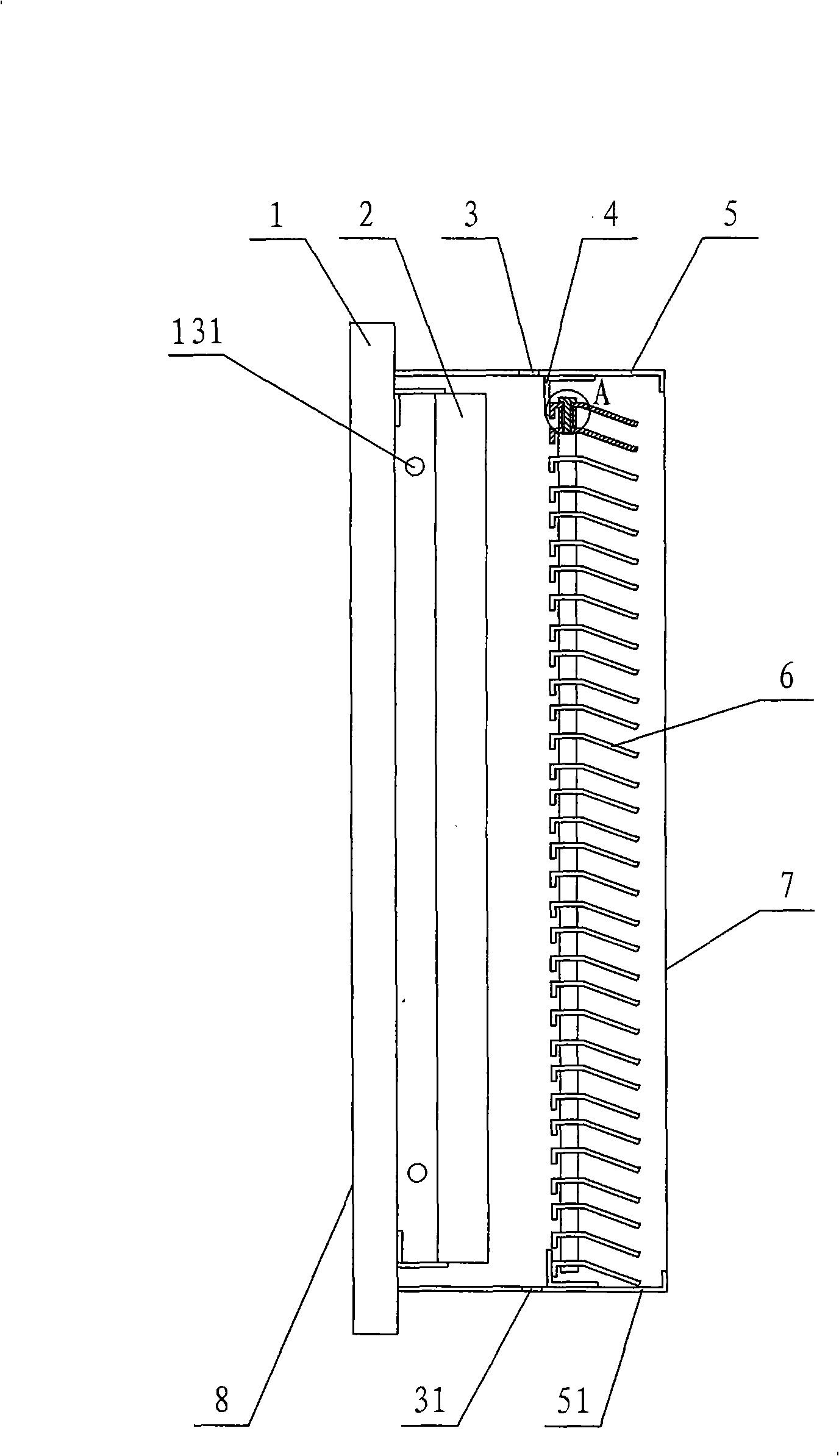

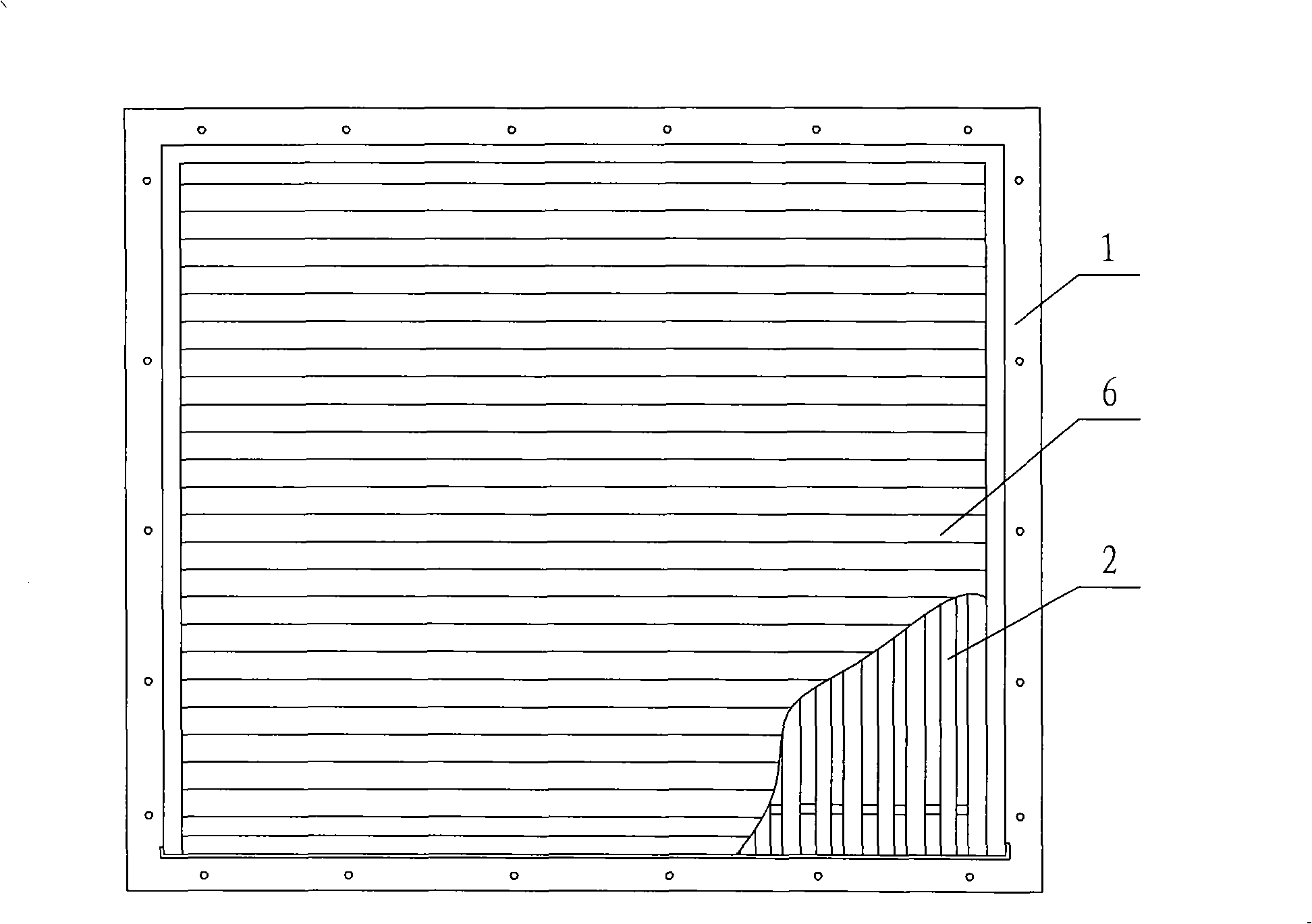

Microchannel heat exchanger, refrigerator and air-cooled refrigerator

InactiveCN106322850AImprove heat transfer effectSmall circulation resistanceEvaporators/condensersStationary conduit assembliesPipe layerRefrigerant

The invention discloses a microchannel heat exchanger, a refrigerator and an air-cooled refrigerator. The microchannel heat exchanger comprises two header pipes, multiple heat exchange pipes and fins. The two header pipes are arranged in parallel. The two ends of the multiple heat exchange pipes are connected with the two header pipes correspondingly. The multiple heat exchange pipes are bent in the length direction to form multiple pipe layers. The refrigerant circulation resistance of some heat exchange pipes is smaller than that of the rest of the heat exchange pipes. Each fin is arranged between every two adjacent pipe layers or arranged on the outer side of the outermost pipe layer. In the extending direction of the heat exchange pipes, each fin extends in a corrugate shape. In the extending direction of the heater pipes, each fin continuously extends. The fins are provided with air holes. According to the microchannel heat exchanger, the problem that a large amount of water is attached to fin surfaces and cannot be thoroughly drained is solved, and the phenomenon that dense ice is produced on the surface of the microchannel heat exchanger, and therefore heat exchange efficiency is affected can be prevented. In addition, the defrosting period can be prolonged, the refrigerant flow of the multiple heat exchange pipes is promoted to be uniform, and heat exchange performance is improved.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +2

Coke-removing and soot-cleaning combustion improver for boiler

InactiveCN101955818APromote combustionBurn safely and thoroughlyGaseous fuelsLiquid carbonaceous fuelsEngineeringSteam locomotive

The invention relates to a fuel additive, in particular to a coke-removing and soot-cleaning combustion improver for a boiler, suitable for various boilers, kilns, and other fuel furnaces using coal, oil, gas and natural gas as fuel, such as industrial boilers, civil boilers, ship boilers, drinking water boilers, steam locomotives, and the like. The coke-removing and soot-cleaning combustion improver is prepared from the following raw materials in percentage by weight: 12.5-30 percent of sodium nitrate, 17.50-25 percent of potassium nitrate, 5.50-11 percent of calcium nitrate, 15-19 percent of salt and 15-49.50 percent of borax. The coke-removing and soot-cleaning combustion improver can prevent the forming of new coke, is beneficial to the full combustion of the fuel, ensures that deposited chimney soot is fully combusted, reduces sticky carbon and carbide, plays a certain corrosion inhibition role to the boiler and prolongs the service life of the boiler.

Owner:吉林鑫聚源节能材料有限责任公司

High temperature air heater

InactiveCN1474111ASmall circulation resistanceImprove heat transfer efficiencyAir heatersTemperature controlThermocouple device

The present invention relates to one high temperature air heater comprising lotus root-shaped ceramic body, heat insulating layer, casing, thermocouple and containing wires. The ceramic body has several through holes, inside which there are ceramic rods wound with electrothermal wire. The ceramic body is set inside heat insulating layer and the thermocouple is set in one end of ceramic body. Air is made to enter the ceramic from one end and heated by electrothermal wire and the ceramic body. The heater has high heat efficiency, small volume, convenient temperature control and long servicelife.

Owner:TONGJI UNIV

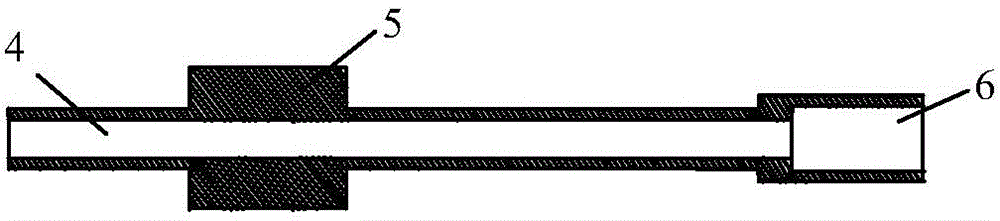

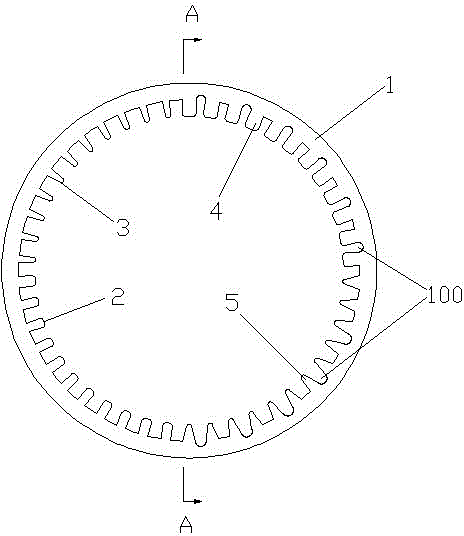

Internal threaded heat-transfer copper pipe

ActiveCN104654886ASmall circulation resistanceIncrease heat exchange rateEvaporators/condensersTubular elementsEngineeringScrew thread

The invention relates to the technical field of heat-transfer pipes, and discloses an internal threaded heat-transfer copper pipe. The internal threaded heat-transfer copper pipe comprises a copper pipe body, wherein the inner wall of the copper pipe body is sequentially provided with four groups of toothed ribs in a spiral distribution along the circumferential direction; the four groups of toothed ribs include toothed ribs A, toothed ribs B, toothed ribs a and toothed ribs b; on any cross section of the copper pipe body, the arc surface of each group of the toothed ribs A, the toothed ribs B, the toothed ribs a and the toothed ribs b occupies a central angle of 90 degrees; the cross section of each of the toothed ribs A and the toothed ribs a is rectangular; the cross section of each of the toothed ribs B and the toothed ribs b is triangular; the tooth width ratio of one toothed rib A to one toothed rib a is 1:1.2 to 1:1.6; the addendum angle of each toothed rib B is 8-20 degrees; the addendum angle of each toothed rib b is 25-40 degrees; the inner wall, corresponding to the toothed ribs a and the toothed ribs b, of the copper pipe body is further provided with heat radiating grooves; at least two toothed ribs are distributed between two adjacent heat radiating grooves. Therefore, the internal threaded heat-transfer copper pipe has the beneficial effects that the refrigerant flow resistance can be effectively reduced, and the heat exchange rate of refrigerants at different parts in the copper pipe body is improved.

Owner:JIANGXI NAILE COPPER IND

Dehumidification method for main cable of suspension bridge

ActiveCN111945562AReduce initial equipment investmentSmall circulation resistanceSuspension bridgeDrying gas arrangementsSystem maintenanceTower

The invention discloses a dehumidification method for a main cable of a suspension bridge. The surface of the main cable is sealed and wrapped by the wrapping tape, and the wrapping tape and the internal main cable steel wires form cavities at the top and the bottom, thereby facilitating the flowing of dry gas. The principle that moisture in the main cable circularly rises and falls day and nightis ingeniously utilized, and when the moisture is gathered in the cavity, dry gas is introduced to discharge the moisture. Dry gas flow resistance is small, required operation time is short, energy consumption is low, an air feeder does not need to be installed on the upper portion of the bridge tower, and investment is saved; moreover, dry gas can flow at low pressure, the wrapping tape is not easy to break, a special gas inlet cable clamp, a special gas outlet cable clamp and a corresponding pipeline system are not required to be mounted, high-altitude operation in system maintenance is reduced, and the maintenance cost is reduced.

Owner:ZHENGZHOU UNIV

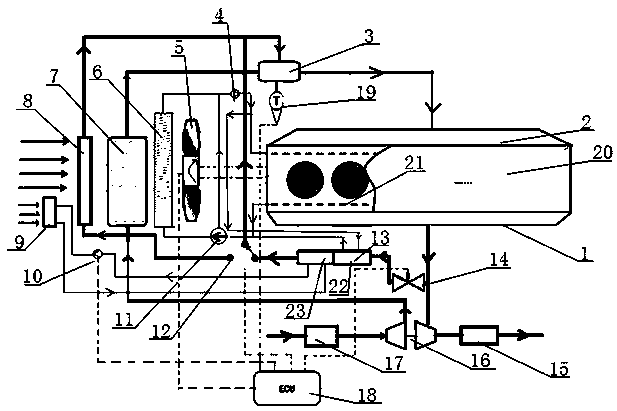

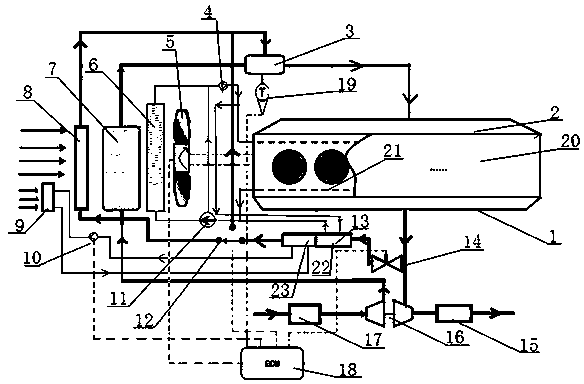

An intelligent cooling device for a supercharged diesel engine egr system

ActiveCN103775252BImprove dynamic response performanceSpeed up the warm-up processInternal combustion piston enginesExhaust gas recirculationIntercoolerElectric control

The invention discloses a supercharged diesel engine EGR (Exhaust Gas Recirculation) system intelligent cooling device, comprising an EGR mixer (3), a mechanical water pump (4), an electric control fan (5), a radiator (6), a thermolator (11), an EGR cooler (13), an electric control EGR valve (14), an engine ECU (Electronic Control Unit) (18), a temperature sensor (19), an exhaust gas intercooler (8) and an electric control two-position three-way valve (12), wherein an inlet of the electric control two-position three-way valve (12) is communicated with a gas outlet of the EGR cooler (13); outlets in two ends of the electric control two-position three-way valve (12) are respectively communicated with an exhaust gas inlet of the EGR mixer (3) and a gas inlet of the exhaust gas intercooler (8); a gas outlet of the exhaust gas intercooler (8) is communicated with the exhaust gas inlet of the EGR mixer (3); the electric control EGR valve (14), the electric control fan (5), the temperature sensor (19) and the electric control two-position three-way valve (12) are respectively connected with the engine ECU (18) electrically.

Owner:DONGFENG COMML VEHICLE CO LTD

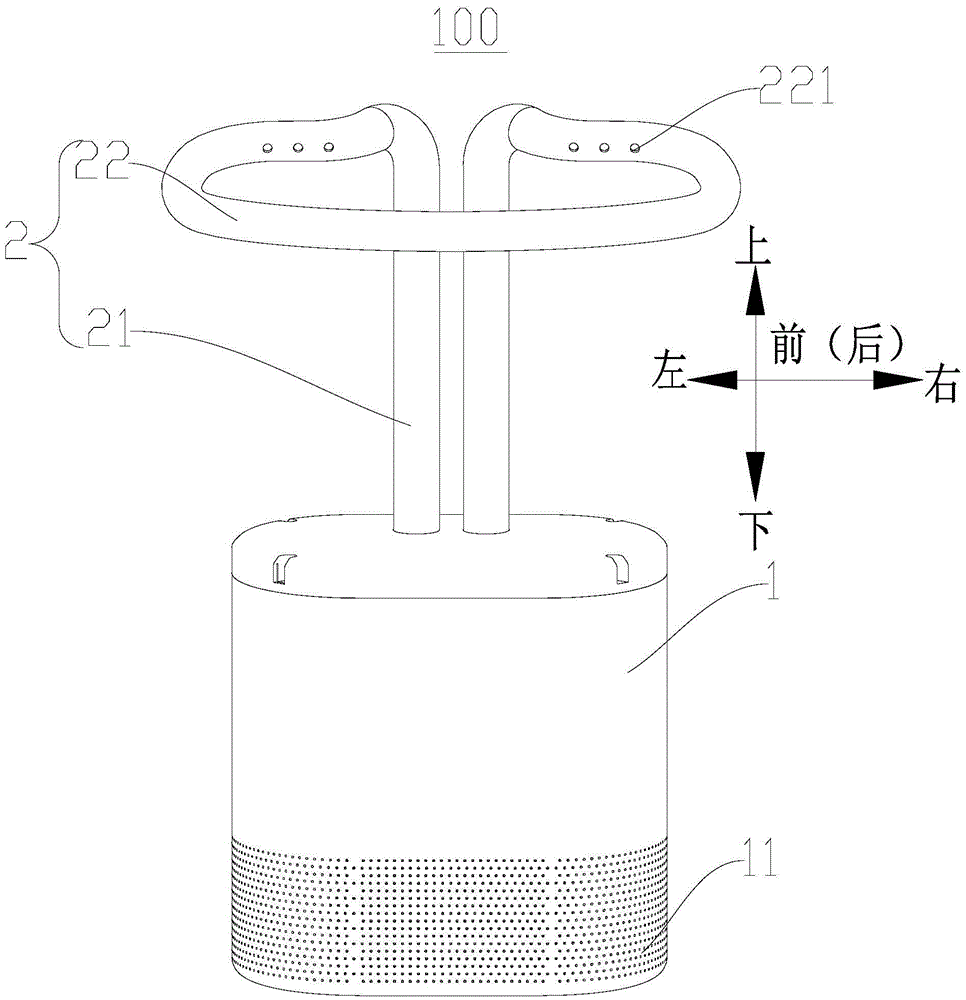

Hand drier

InactiveCN105615757AImprove experienceReduce the sense of experienceDomestic applicationsEngineeringDrying time

The invention discloses a hand drier, which comprises a shell, an air guide duct and a dynamical structure, wherein the shell is provided with an air inlet; the air guide duct is arranged on the shell and comprises two induced pipes and an annular discharge pipe; the two end parts of the discharge pipe extend towards each other; the lower ends of the two induced pipes are respectively communicated with the inner part of the shell; the upper ends of the two induced pipes are respectively connected with the two end parts of the discharge pipe; a plurality of air outlets are formed in the inner peripheral wall of the discharge pipe and comprise left side air outlets and right side air outlets; the dynamical structure is formed in the shell, operates to guide air into the shell from the air inlet and guides the air in the shell to each induced pipe. According to the hand drier provided by the invention, the hand drying area is roomier, the phenomenon that hands of a user touch the discharge pipe when being dried can be avoided, the air speed of the air outlet is improved favorably, and the hand drying time of the user is reduced.

Owner:MIDEA GRP CO LTD

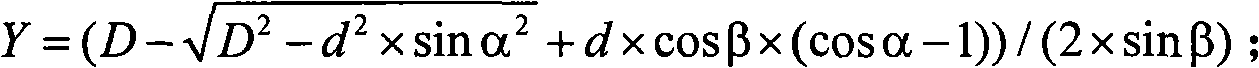

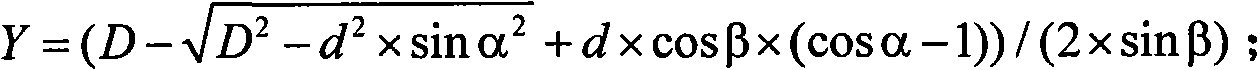

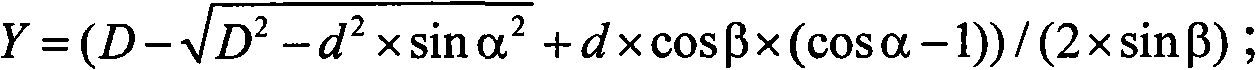

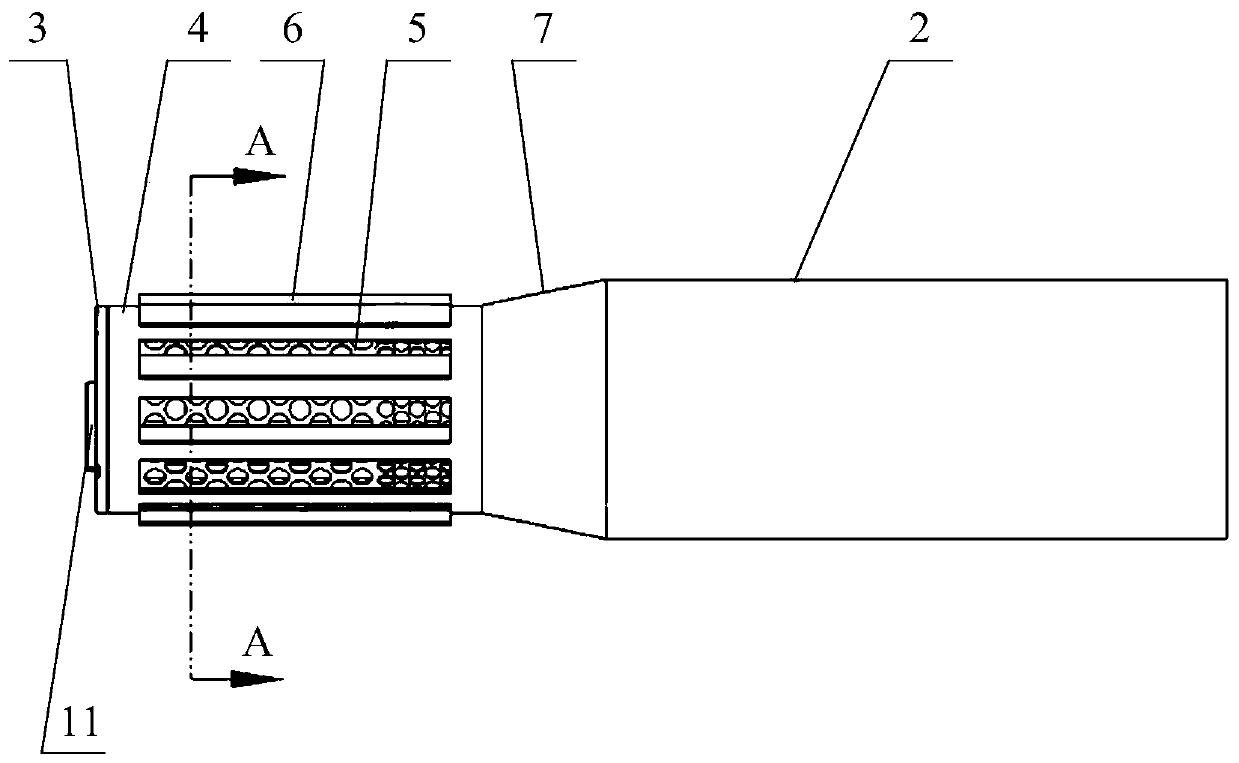

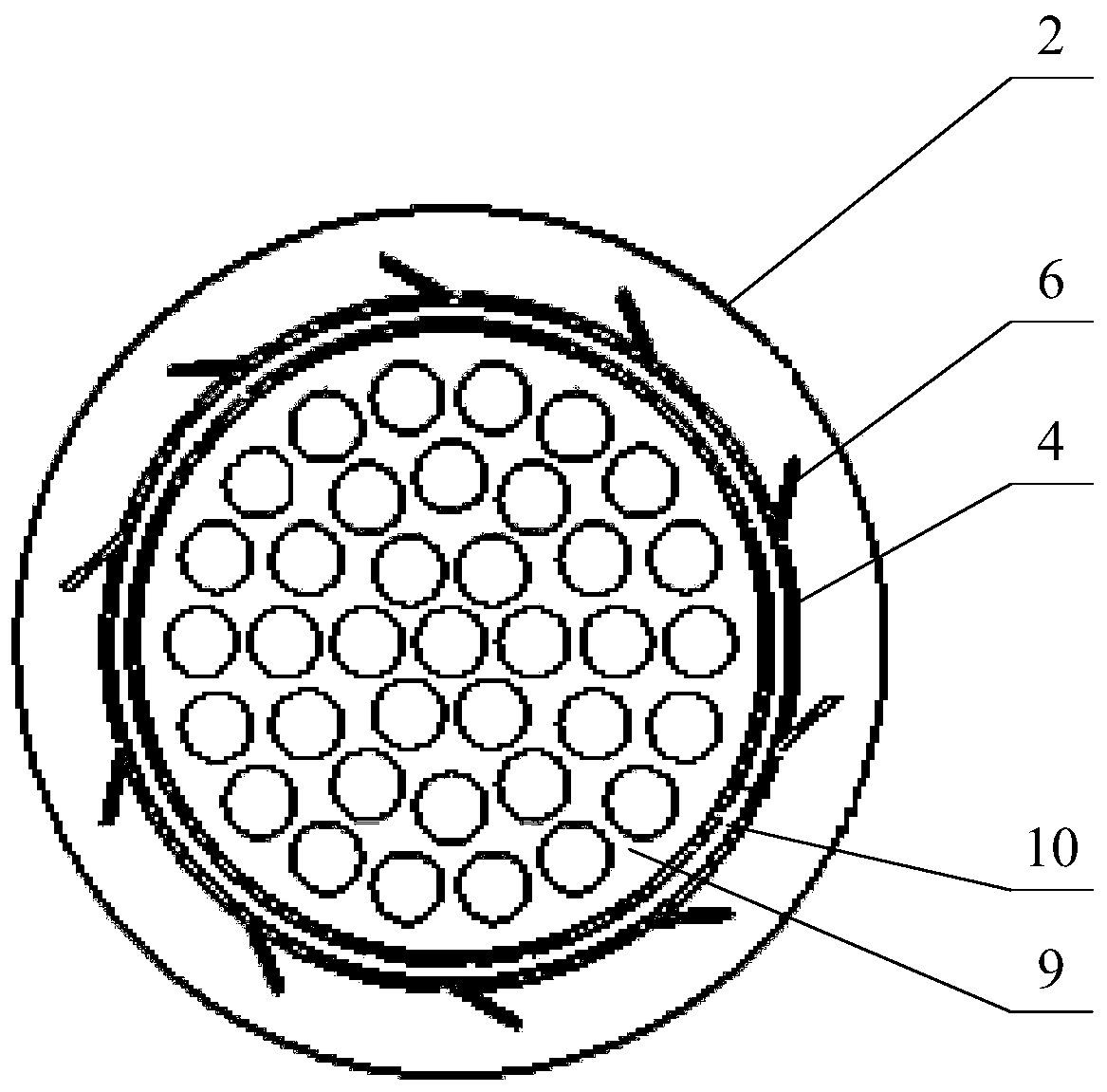

Pipeline three-way computer automatic lofting computation method

InactiveCN101261652ASmall circulation resistanceNice appearanceSpecial data processing applicationsGraphicsMathematical model

The invention discloses an automatic lofting calculation method used for a pipeline three-way computer. The method includes the following steps: a first step, a math model is firstly established; a second step, VB language is adopted for programming; a third step, the line outspread drawing of pipe three-way joints can be drawn in form2 after data is input into a form1window, and a template can be manufactured according to the drawing. The invention is established on the basis of relevant math models, and adopts the VB language programming and a lip-read operation interface to input relevant origin parameters, and after the automatic analysis of the computer, the line outspread drawing of pipe three-way joints is drawn finally. With the method, not only the technical requirement to workers can be reduced, the labor intensity of workers is simplified, work efficiency is enhanced, materials are saved and the resistance of pipeline flow is reduced, but also the manufactured three-way has an elegant appearance, which reaches the design requirement.

Owner:泰州口岸船舶有限公司

Mixer

PendingCN109838293ASmall circulation resistanceImprove acoustic performanceExhaust apparatusSilencing apparatusSound sourcesEngineering

The invention discloses a mixer. The mixer comprises a mixing section and an expanding section, wherein one end of the mixing section is provided with a urea nozzle base, and the mixing section is used for mixing waste gas with urea in the mixer; and the pipe diameter of the expanding section is larger than that of the mixing section, one end of the expanding section is provided with a port matched with the pipe diameter of the mixing section, and the other end of the mixing section is connected with the port. According to the mixer, the mixing section and the expanding section of the mixer are directly connected, and thus, after mixing is completed, the waste gas and the urea directly enter the expanding section; and the pipe diameter of the expanding section is larger than that of the mixing section, thus, when the mixed gas enters the expanding section, the pipe diameter is suddenly changed, the circulation resistance is reduced, acoustic impedance change is caused, accordingly, part of sound waves spreading along a pipeline is reflected back to a sound source, and the gas flow generates the capacity for reducing the sound at the specific frequency band. Thus, through the mixedprovided by the invention, an aftertreatment mixer can be optimized, the good acoustic performance is achieved, and the problems in the field at the present stage are solved.

Owner:WEICHAI POWER CO LTD

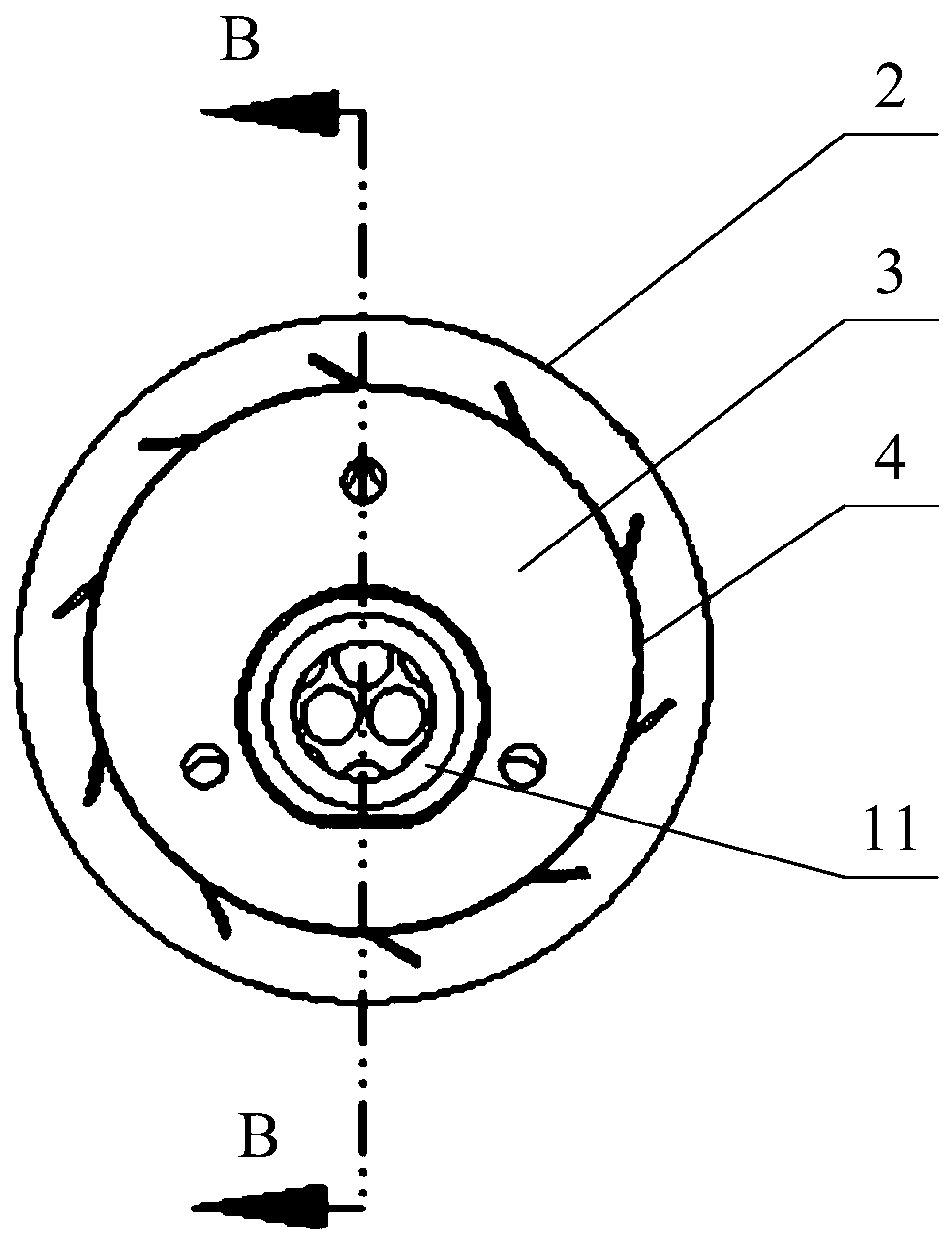

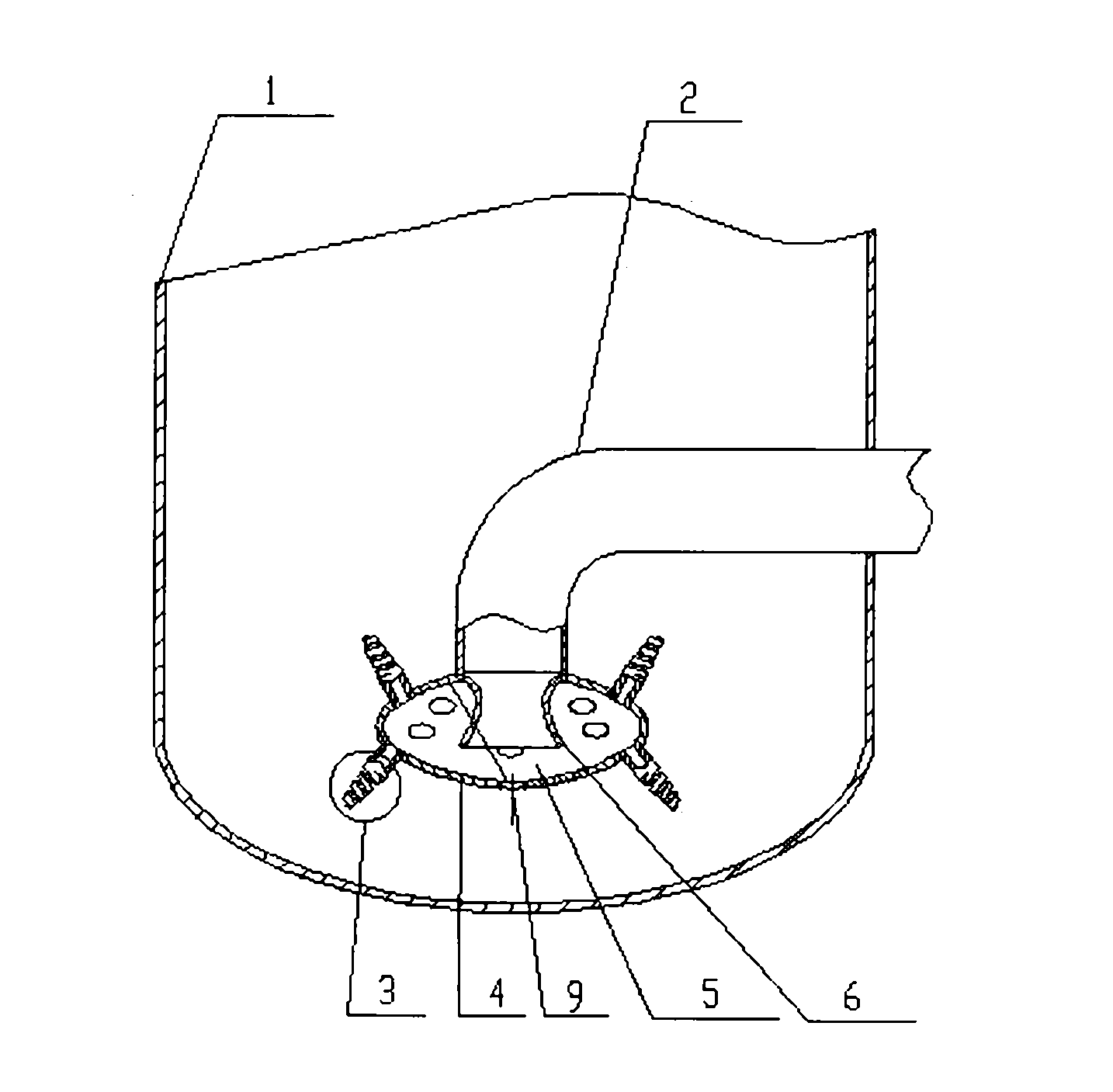

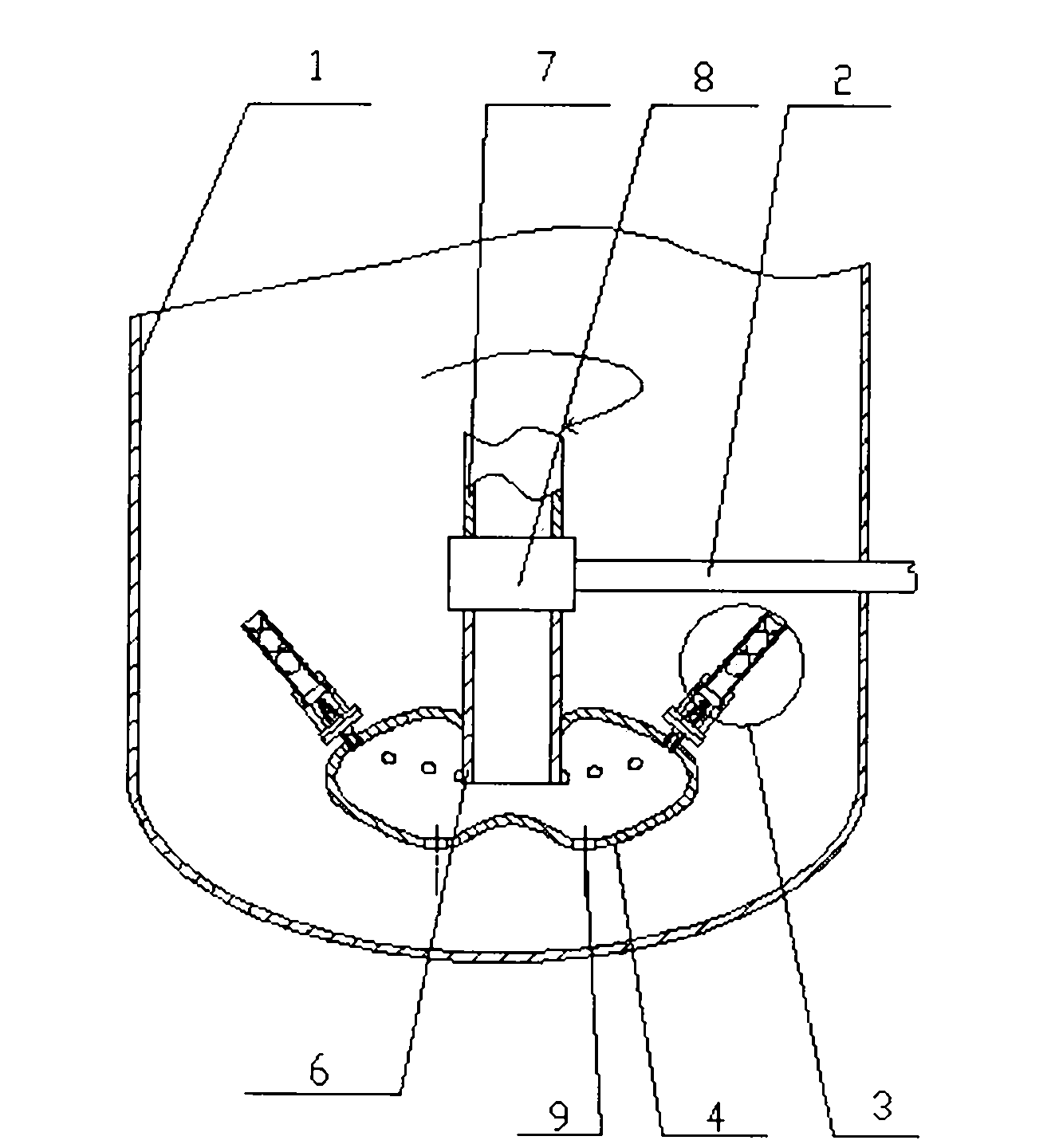

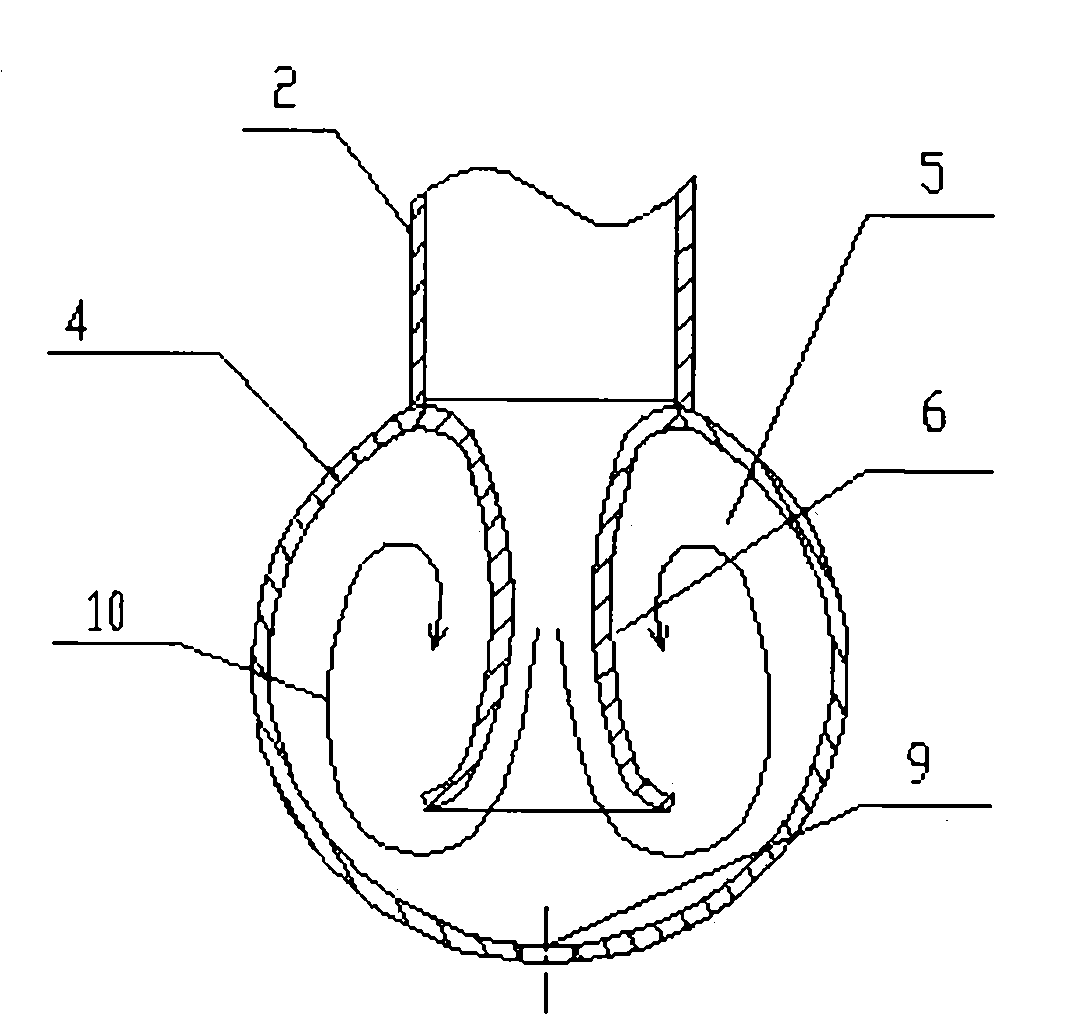

Gas distributor for gas-liquid dispersion

InactiveCN101912759AReduce gas flow resistanceNot easy to blockChemical/physical/physico-chemical processesProduct gasEngineering

The invention discloses a gas distributor for gas-liquid dispersion, which can efficiently disperse gas into liquid. The gas distributor comprises a gas distribution chamber, a gas outflow element arranged on a shell of the gas distribution chamber, and a guide flow cylinder which is arranged in the gas distribution chamber and communicated with a gas inlet pipe, wherein the gas distribution chamber is in the conventional shape or in an apple-shaped bottom structured spherical shape, oblate spheroid shape or flying saucer shape; a longitudinal section of the guide flow cylinder is in a hyperbolic shape or a cylindrical shape; and the gas outflow element is a spiral nozzle, a kerf conical nozzle, a straight pipe or conical pipe with a built-in spinning disk, a jet mixer or a micropore blind pipe. The gas distributor has the advantages of good dispersion effect, less possibility of blockage, high suitability for liquid materials and simple structure.

Owner:方民

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com