Internal threaded heat-transfer copper pipe

A technology of internal thread and copper tube, applied in the field of internal thread heat transfer copper tube, can solve the problems of increased flow resistance of refrigerant and low heat exchange rate of refrigerant, and achieve the effect of reducing flow resistance of refrigerant and increasing heat exchange rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

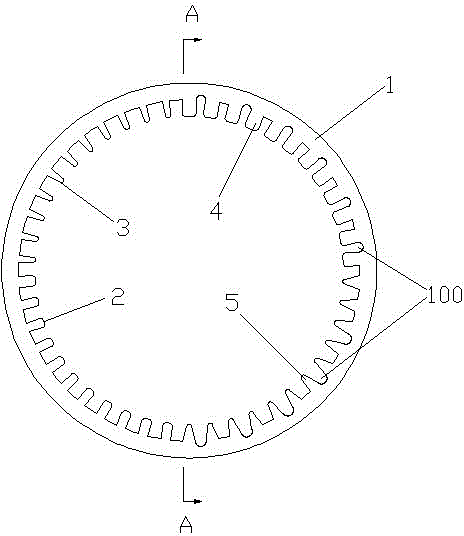

[0025] Embodiment 1: as figure 1 The shown internally threaded heat-transfer copper tube includes a copper tube body 1, and the inner wall of the copper tube body is provided with four sets of spirally distributed ribs along the circumferential direction, which are tooth ribs A2, tooth ribs B3, and tooth ribs a4 , tooth rib b5, on any section of the copper pipe body, the arc surfaces of tooth rib A, tooth rib B, tooth rib a, and tooth rib b each occupy a central angle of 90°, and the cross-sections of tooth rib A and tooth rib a are rectangular structure, the cross-sections of rib B and rib b are triangular, the ratio of the tooth width of rib A to the width of rib a is 1:1.2, the tooth tip angle of rib B is 8°, and the tooth width of rib b is The top angle is 25°, and the inner wall of the copper pipe body corresponding to tooth rib a and tooth rib b is also provided with heat dissipation grooves 100. The heat dissipation grooves are helically distributed along the direction ...

Embodiment 2

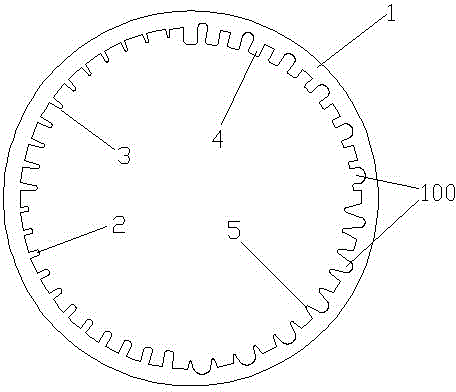

[0026] Embodiment 2: as figure 2The shown internal thread heat transfer copper tube includes a copper tube body 1, and the inner wall of the copper tube body is provided with four sets of spirally distributed tooth ribs along the circumferential direction, respectively tooth rib A2, tooth rib B3, and tooth rib a4 , tooth rib b5, on any section of the copper pipe body, the arc surfaces of tooth rib A, tooth rib B, tooth rib a, and tooth rib b each occupy a central angle of 90°, and the cross-sections of tooth rib A and tooth rib a are rectangular structure, the cross-sections of rib B and rib b are triangular, the ratio of the tooth width of rib A to the width of rib a is 1:1.6, the tooth tip angle of rib B is 20°, and the tooth width of rib b is The top angle is 40°, and the inner wall corresponding to the copper pipe body and tooth ribs a and tooth rib b is also provided with heat dissipation grooves 100. The heat dissipation grooves are helically distributed along the direc...

Embodiment 3

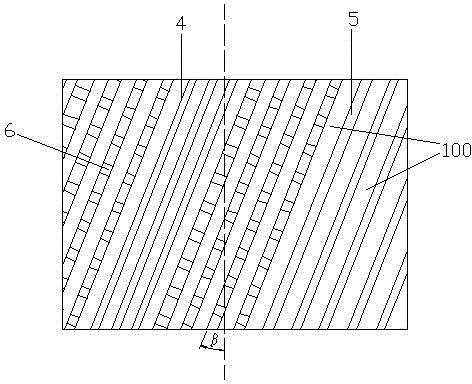

[0027] Embodiment 3: as Figure 4 The shown internal thread heat transfer copper tube includes a copper tube body 1, and the inner wall of the copper tube body is provided with four sets of spirally distributed tooth ribs along the circumferential direction, respectively tooth rib A2, tooth rib B3, and tooth rib a4 , tooth rib b5, on any section of the copper pipe body, the arc surfaces of tooth rib A, tooth rib B, tooth rib a, and tooth rib b each occupy a central angle of 90°, and the cross-sections of tooth rib A and tooth rib a are rectangular structure, the cross-sections of rib B and rib b are triangular, the ratio of the tooth width of rib A to the width of rib a is 1:1.4, the tooth tip angle of rib B is 14°, and the tooth width of rib b is The top angle is 32°, and the inner wall corresponding to the copper pipe body and tooth rib a and tooth rib b is also provided with heat dissipation grooves 100. The heat dissipation grooves are helically distributed along the direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com