Gas distributor for gas-liquid dispersion

A gas distributor and gas distribution technology, applied in chemical instruments and methods, chemical/physical/physical chemical processes, chemical/physical processes, etc., can solve problems such as fermentation failure, material accumulation, poor dispersion effect, etc., and it is not easy to achieve The effect of blocking, ensuring uniformity, and small gas flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

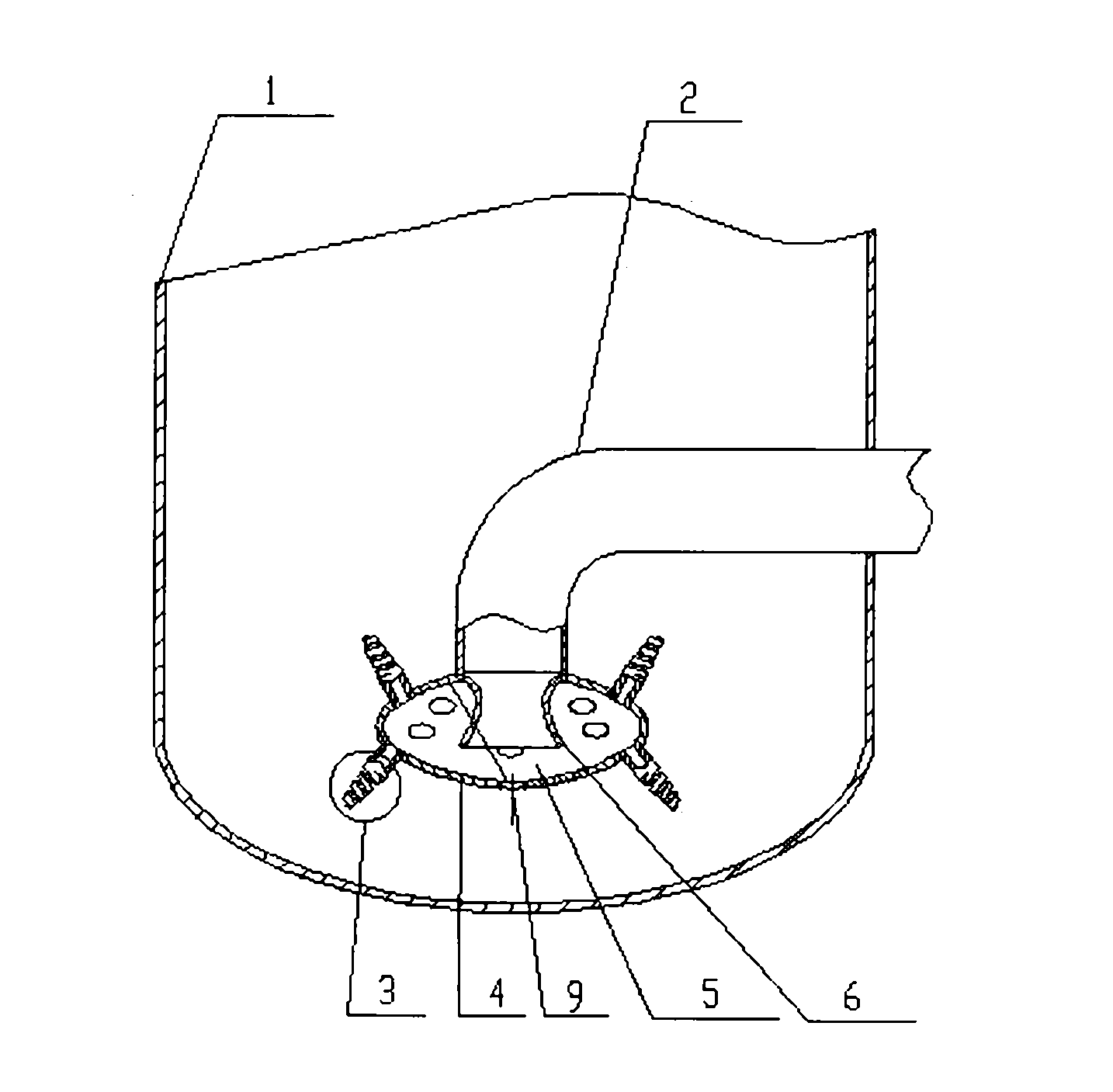

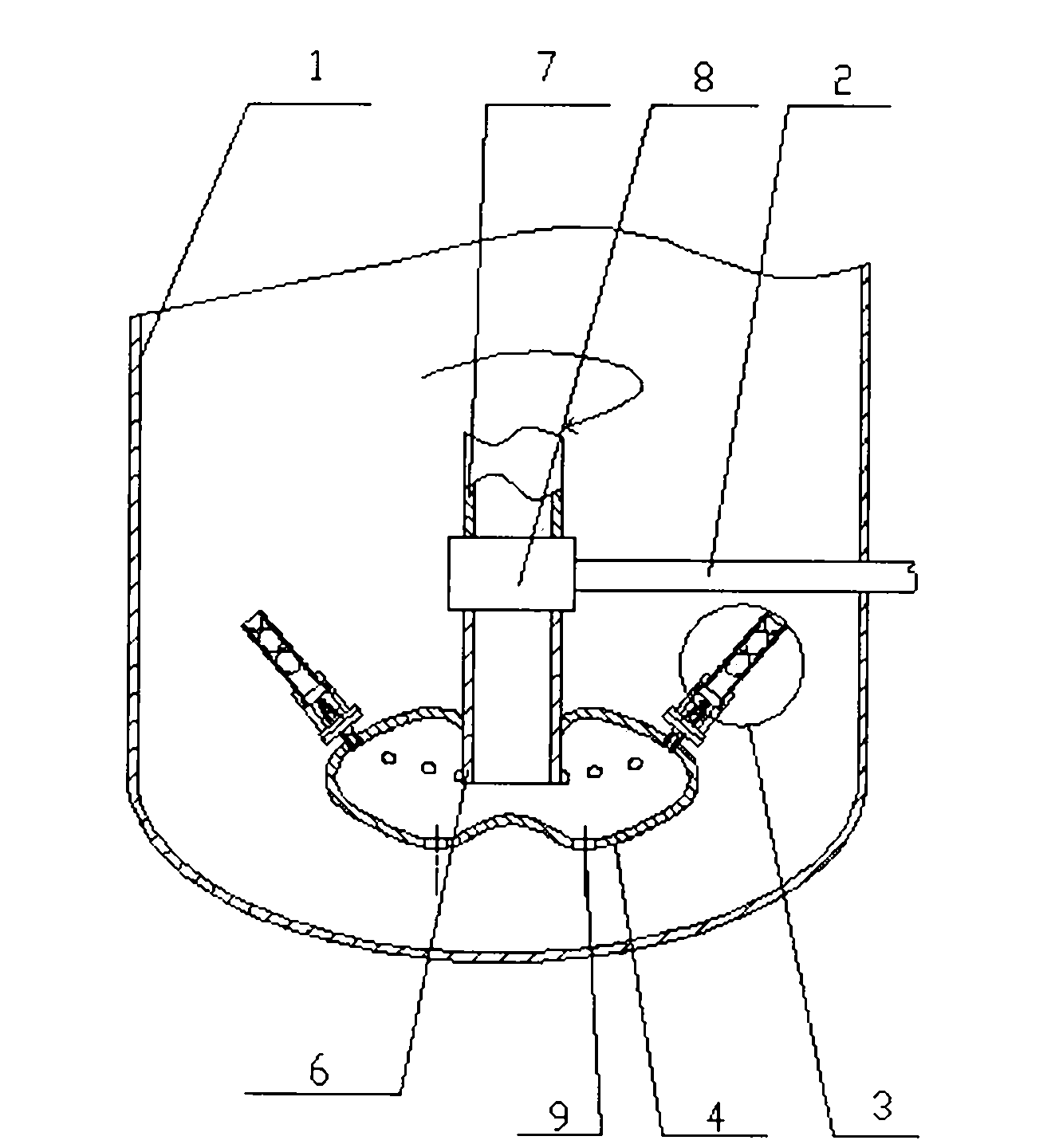

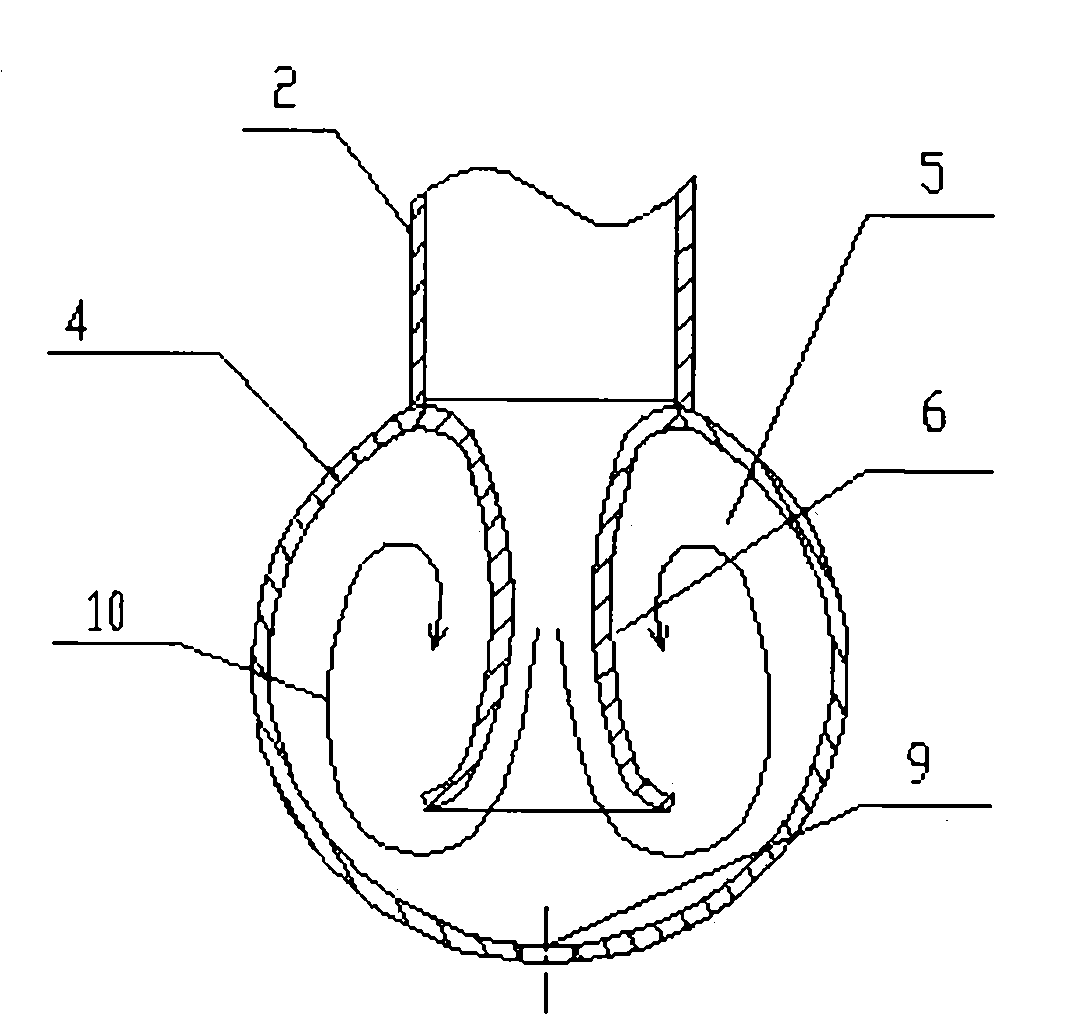

[0033] See attached image 3 , attached Figure 4 , attached Figure 5 , which is a schematic diagram (longitudinal section) of the gas distribution chamber 5 with a hyperbolic draft tube and the gas flow patterns inside it. Its structure is: in the gas distribution chamber 5, there is a guide tube 6 with a hyperbolic longitudinal section. The gas outlet end of the guide cylinder 6 is open and arranged in the cavity of the gas distribution chamber 5, and the outer wall of the guide cylinder 6 and the inner wall of the shell 4 of the gas distribution chamber 5 form a volute-like case with a smooth surface and no dead ends. Shaped gas distribution space, a drain hole 9 is opened at the lowest point of the gas distribution chamber 5 . When working, the gas directly enters the guide tube 6 from the intake pipe 2, and then enters the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com