Coke oven carbonization chamber structure capable of reducing smoke emission

A carbonization chamber and coke oven technology, applied in the field of coke ovens, can solve the problems of raw gas, high air pressure, environmental pollution, etc., and achieve the effects of reducing pressure, reducing gas flow resistance, and reducing escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings:

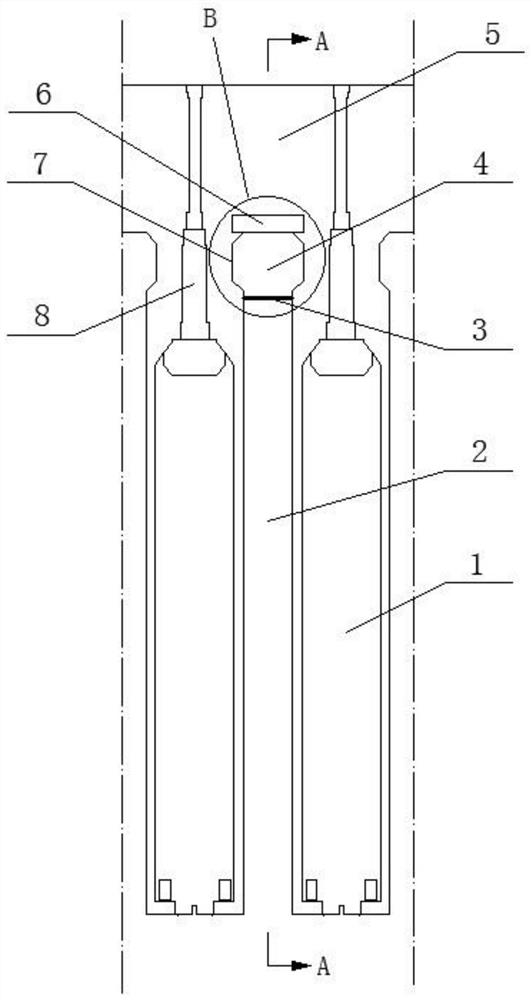

[0021] like Figure 2- Figure 4 As shown, the present invention has reduced the coke oven carbon chamber structure of the soot emission, and the top of the carbonized chamber 2 is formed across the top brick 6, and the top of the carbonization chamber 2 between the top brick 6 and the coal line 3 is the top space. Space 4; sides of the root space 4 extends extends to form a groove structure 7, respectively, so that the width of the head space 4 is greater than the width of the carbonization chamber 2.

[0022] The groove structure 7 is formed by a furr masonry when the coke oven masonry, the upper portion of the groove structure 7, and the lower portion of the lower part of the cattle leg 11, and the bull leg 11 uses a layer-by-layer chart.

[0023] The inner side of the bull leg 11 is a straight or curved surface.

[0024] The single-side distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com