Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

168 results about "Gas dispersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

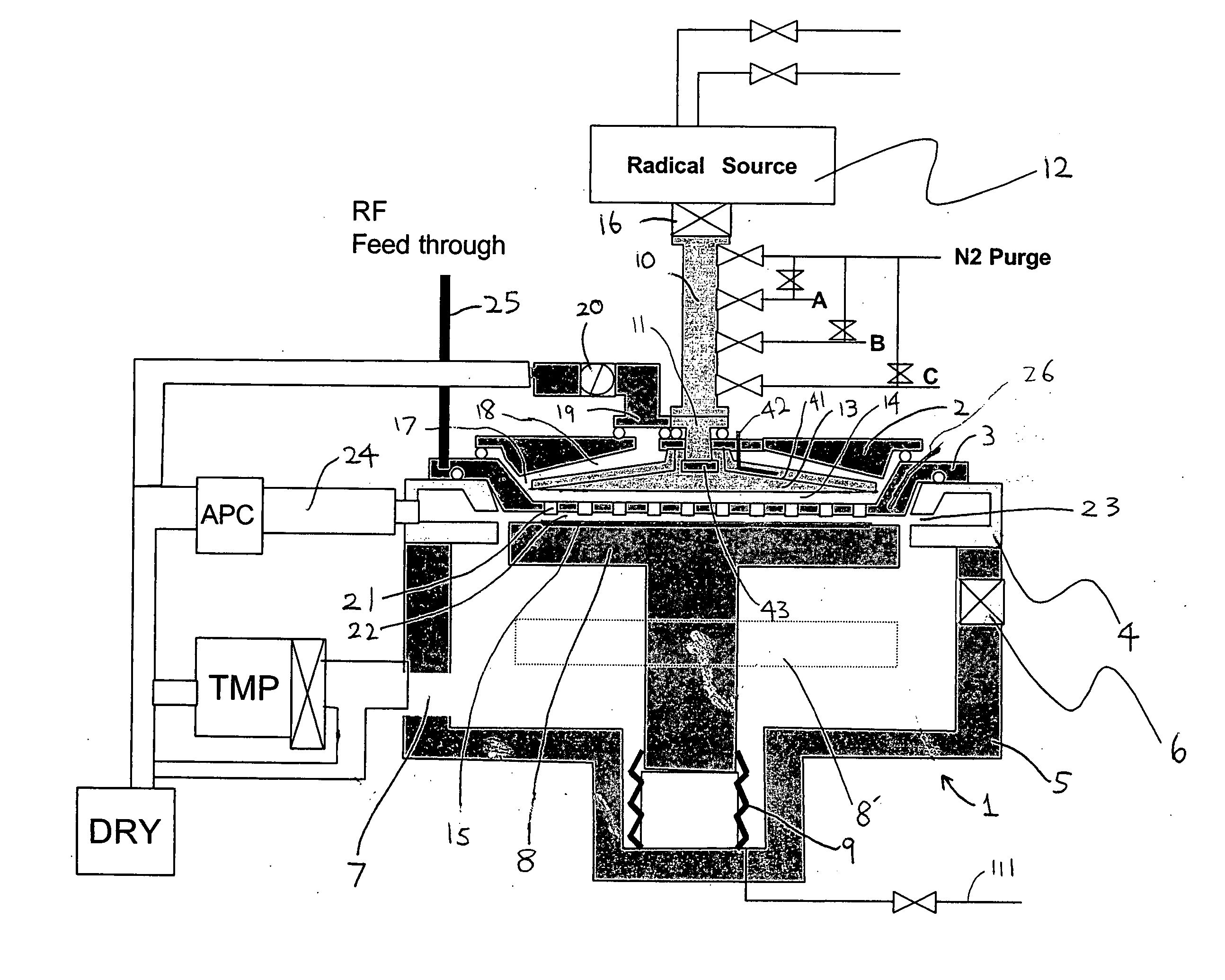

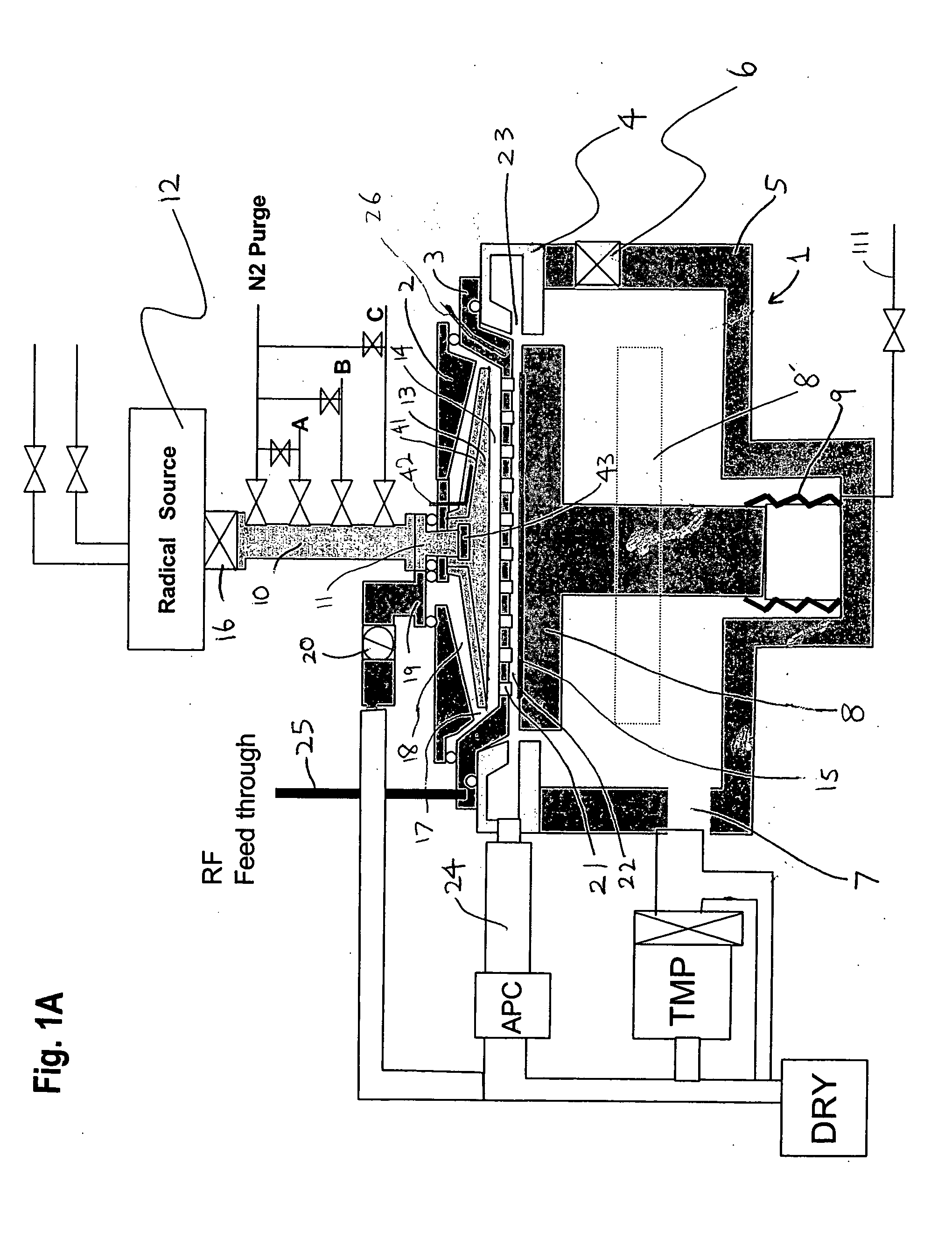

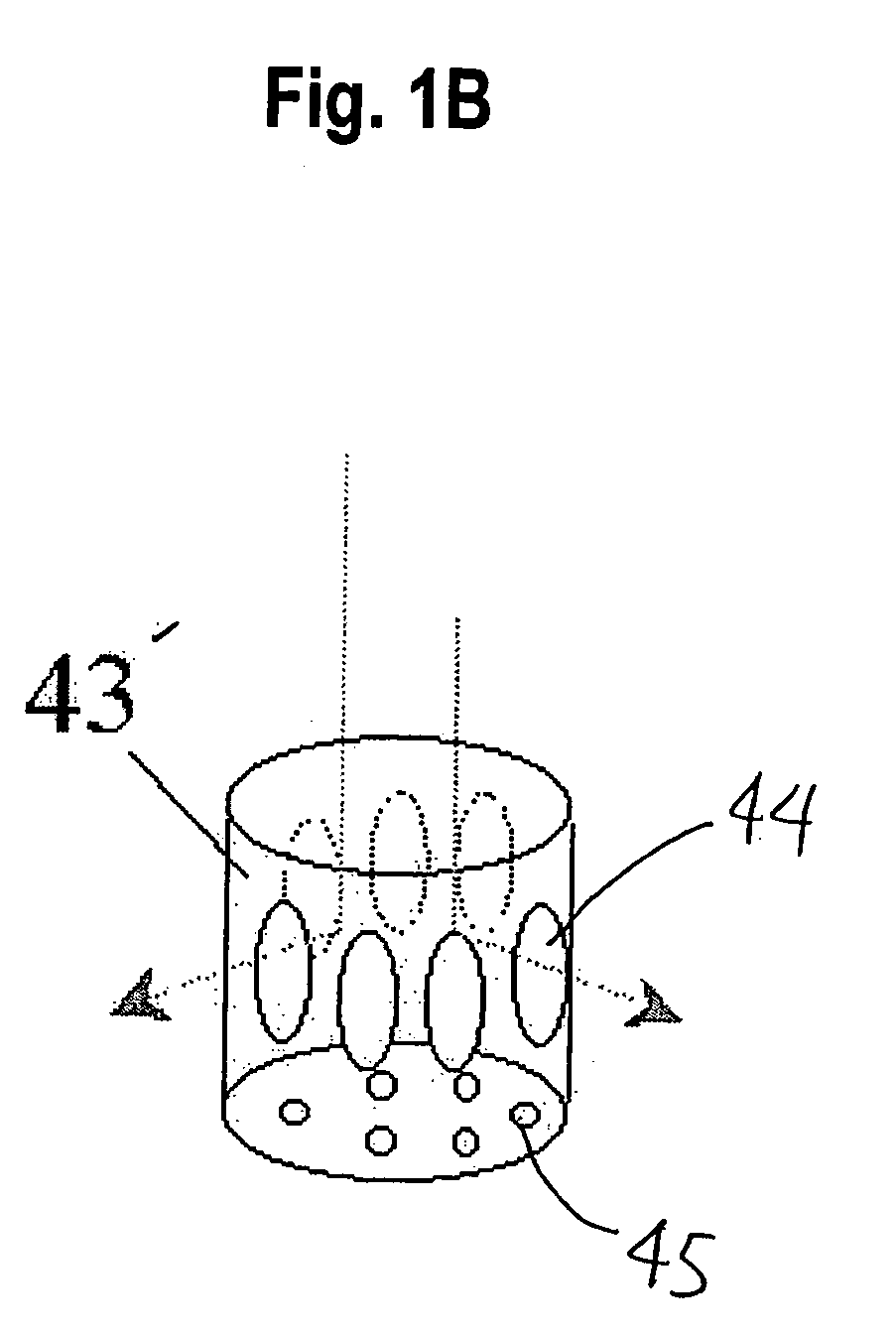

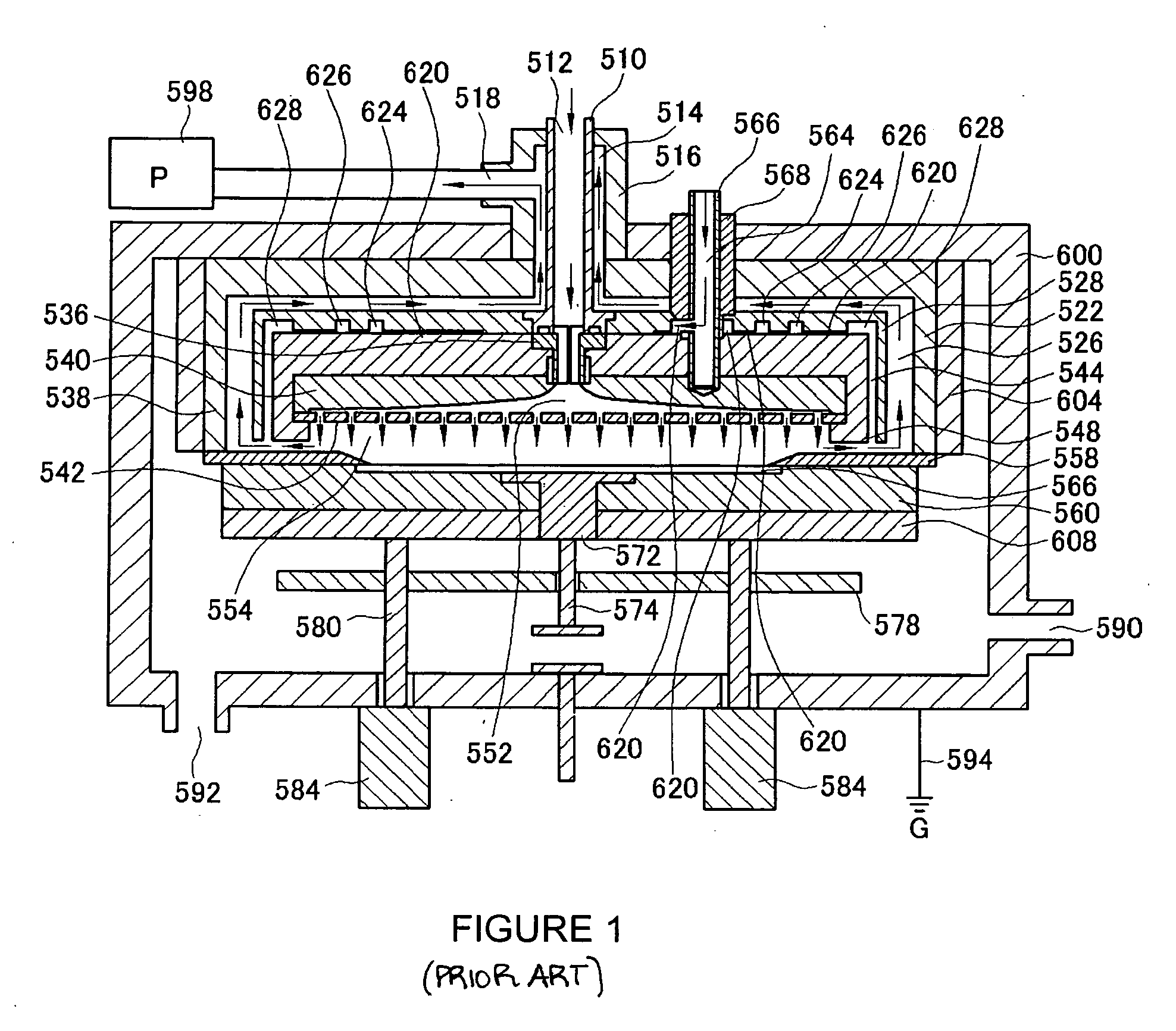

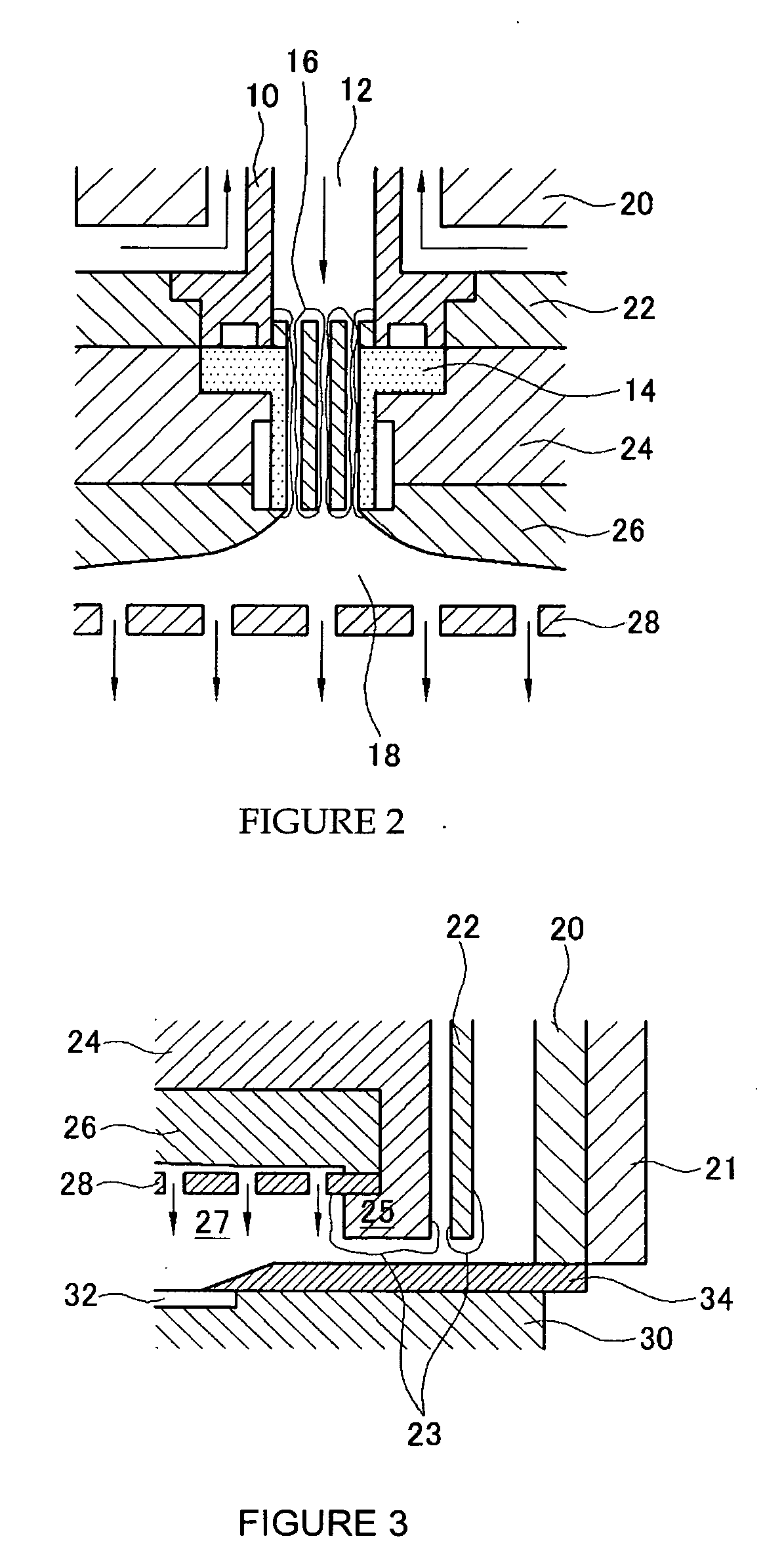

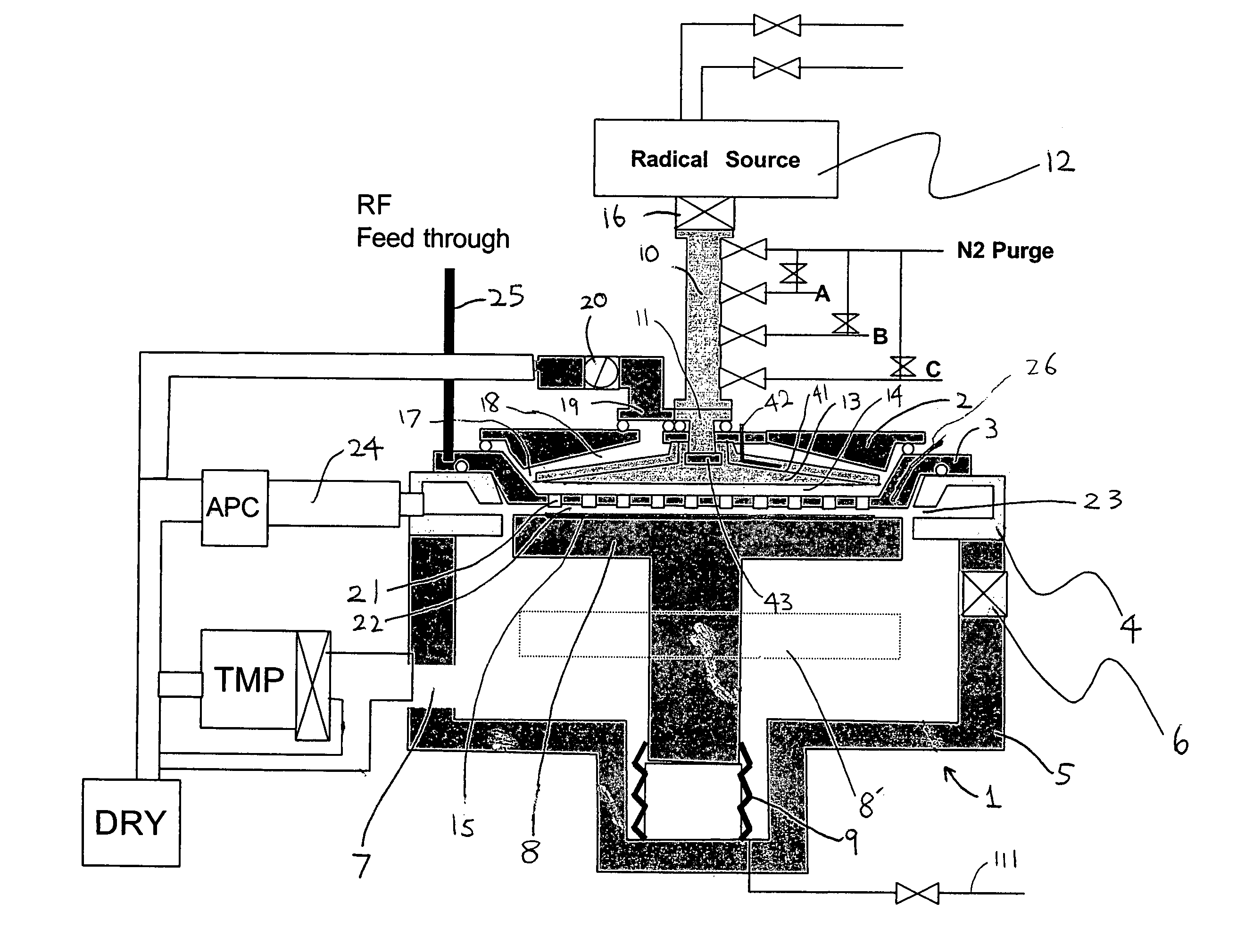

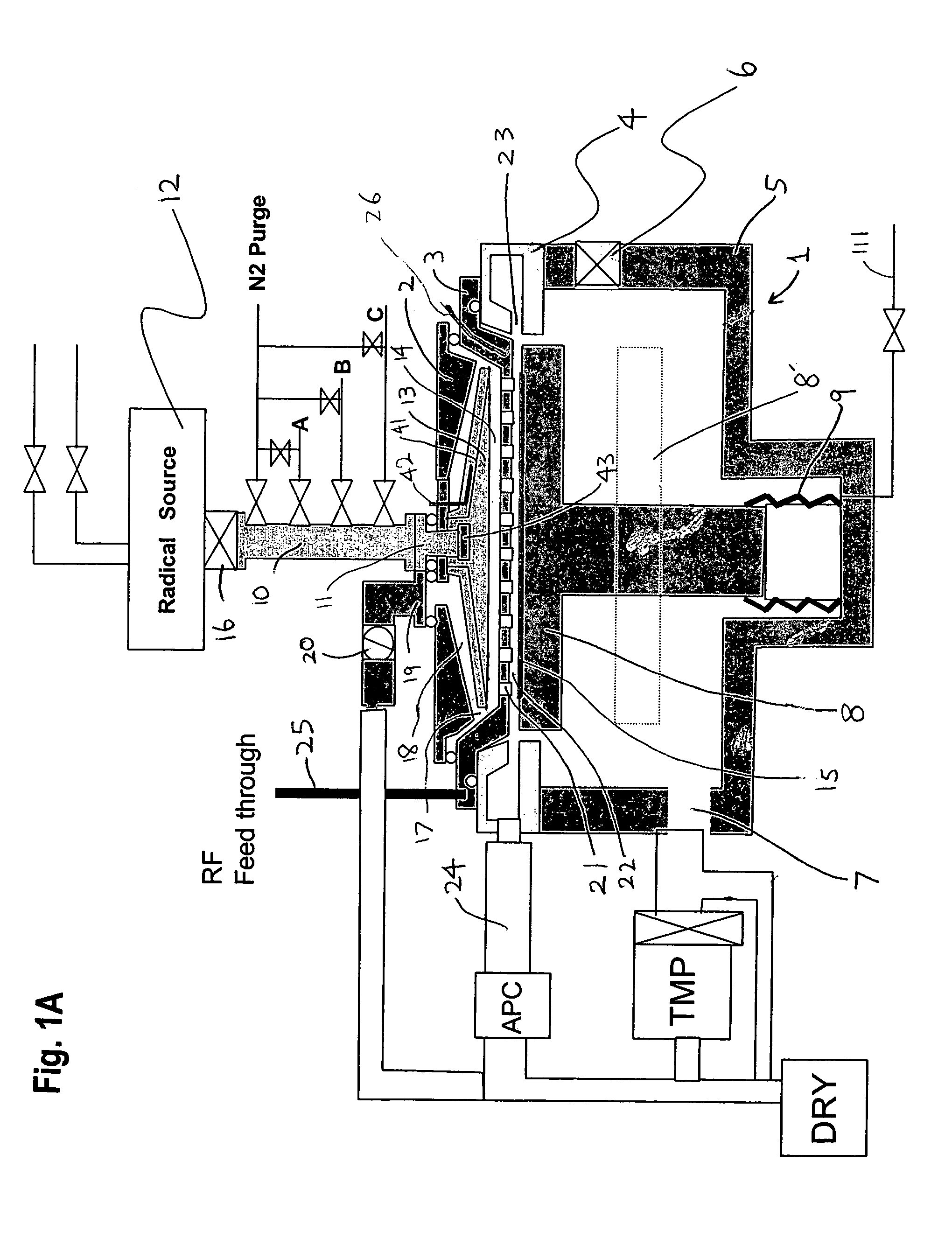

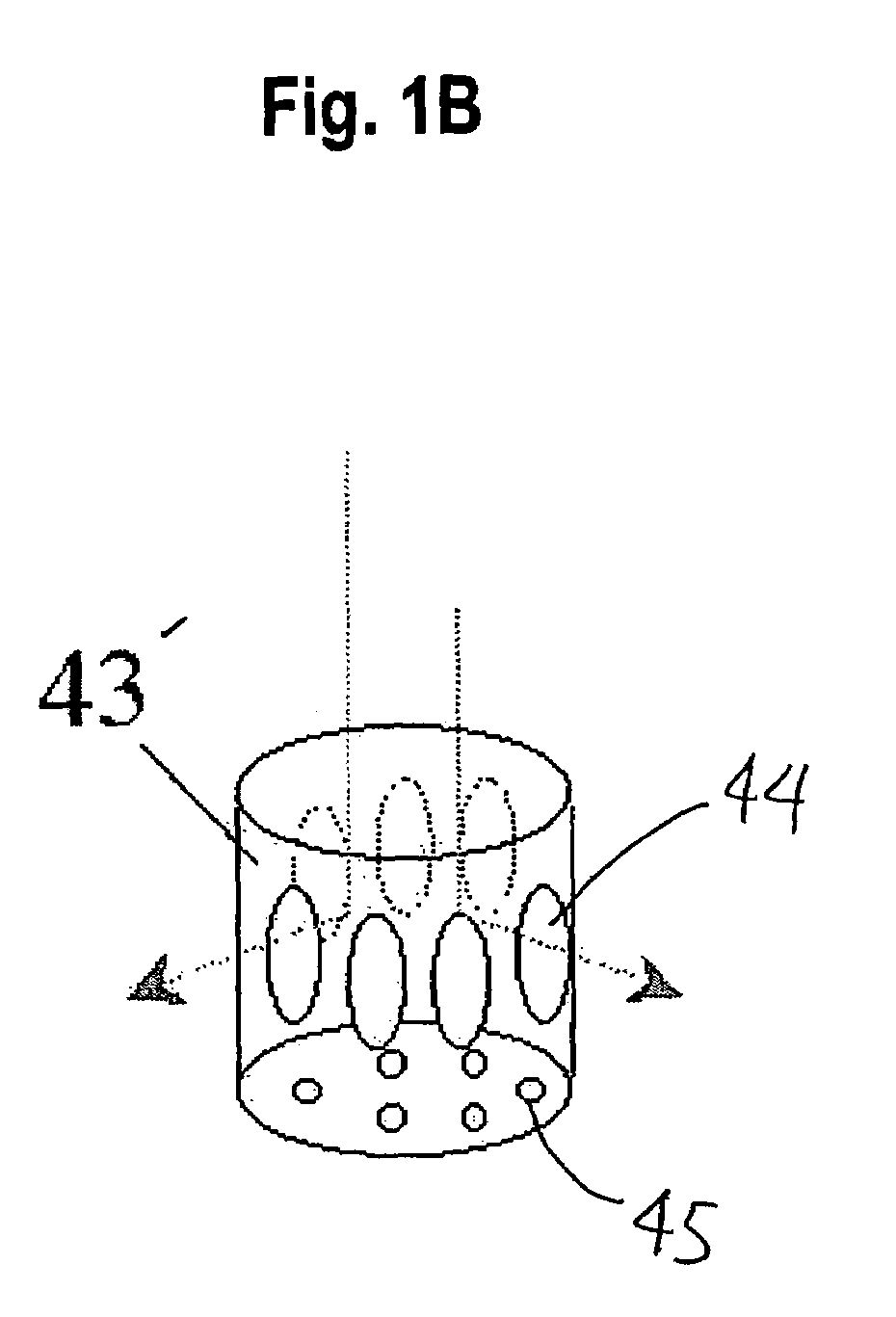

Apparatus and method for forming thin film using upstream and downstream exhaust mechanisms

ActiveUS20050208217A1Improve throughputUniform supplyElectric discharge tubesSemiconductor/solid-state device detailsGas supplySubstrate surface

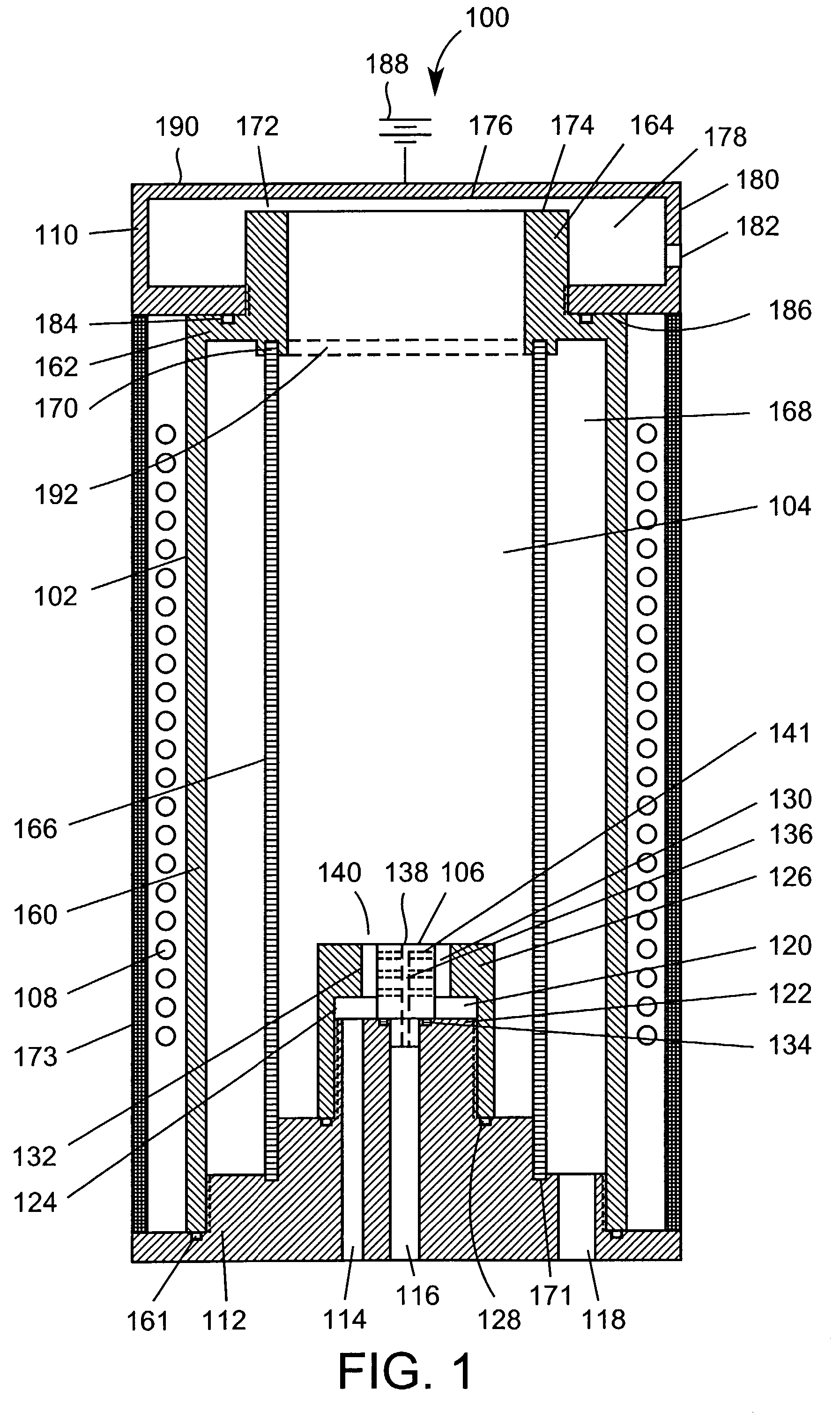

A thin-film formation apparatus possesses a reaction chamber to be evacuated, a placing portion on which a substrate is placed inside the reaction chamber, a gas-dispersion guide installed over the placing portion for supplying a gas onto a substrate surface, a gas-supply port for introducing the gas into the gas-dispersion guide, a gas-dispersion plate disposed on the side of the substrate of the gas-dispersion guide and having multiple gas-discharge pores, a first exhaust port for exhausting, downstream of the gas-dispersion plate, the gas supplied onto the substrate surface from the gas-dispersion plate, and a second exhaust port for exhausting, upstream of the gas-dispersion plate, a gas inside the gas-dispersion guide via a space between the gas-dispersion guide and the gas-dispersion plate.

Owner:ASM JAPAN

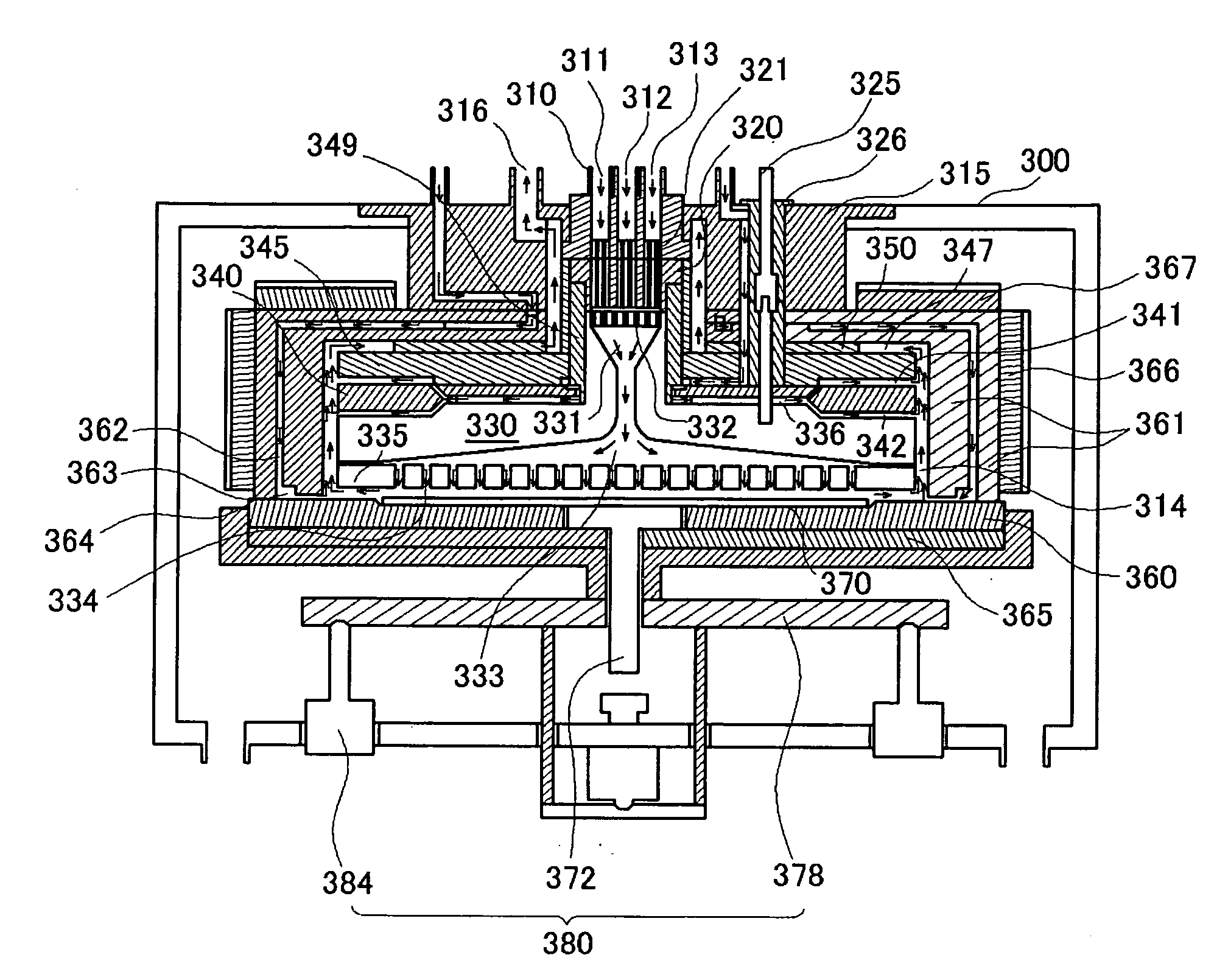

Atomic layer deposition apparatus

InactiveUS20060137608A1Uniform thicknessEasy to controlChemical vapor deposition coatingEngineeringAtomic layer deposition

An atomic layer deposition (ALD) apparatus is, suitable for thermal ALD and plasma-enhanced ALD of conductive and non-conductive films. The ALD apparatus can maintain electrical insulation of a gas dispersion structure, such as a showerhead assembly, which acts as an RF electrode to generate plasma inside a reaction chamber while depositing electrically conductive films in the reaction chamber. Fine tubules of micro-feeding tube assembly prevents plasma generation in them and reactive gases each have separate flow paths through the micro-feeding tube assembly. Process gases out of the micro-feeding tube assembly enter narrow grooves of a helical flow inducing plate and form helical flows which mix well each other. Symmetrically mounted pads on showerhead assembly and flow guiding plate maintain a symmetrical gap through which an inert gas flows continuously to keep reactive gases outside the gap and unwanted film deposition in the gap. Longer operating time before maintenance (cleaning) and thus higher productivity can be achieved.

Owner:ASM GENITECH KOREA

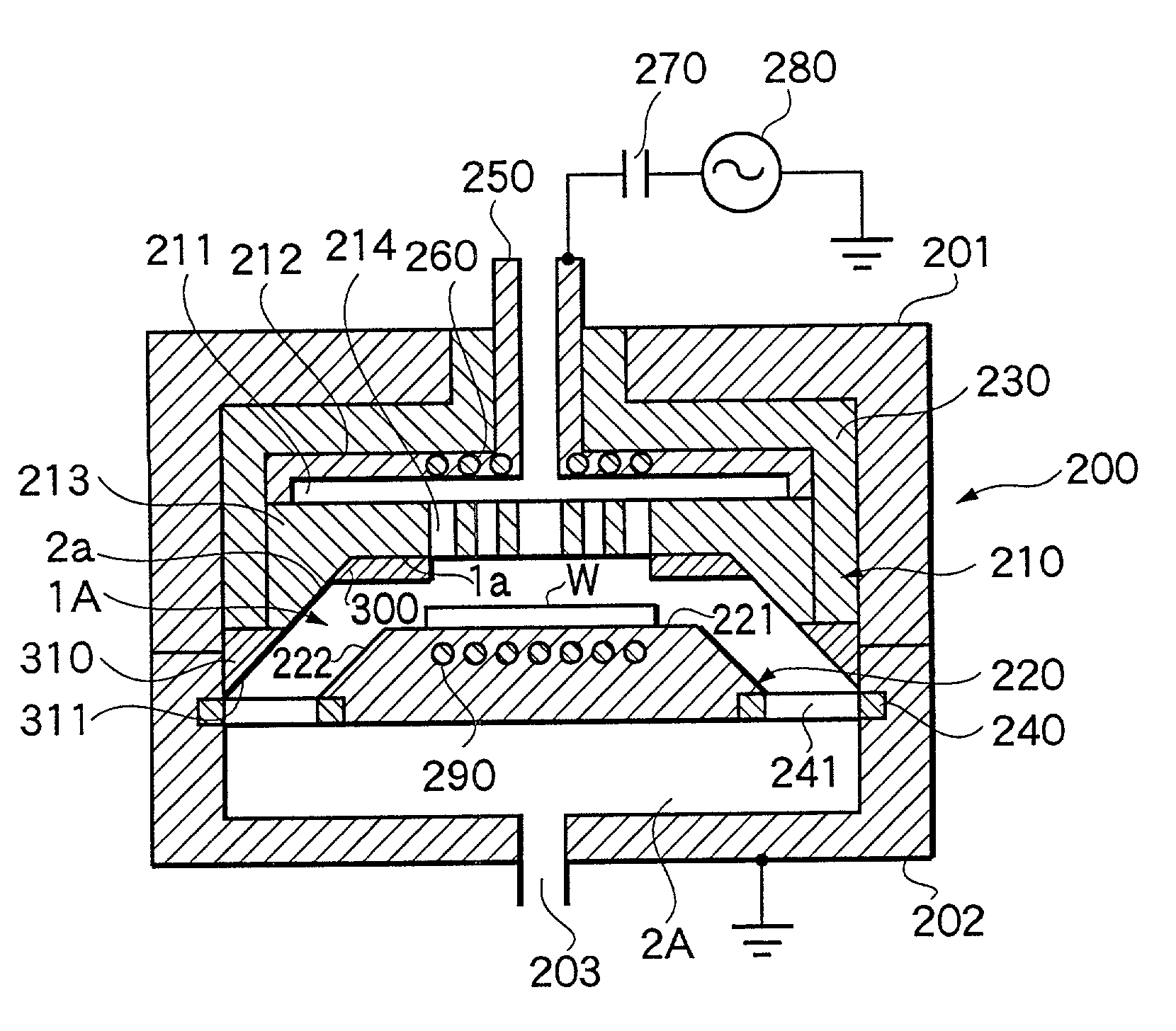

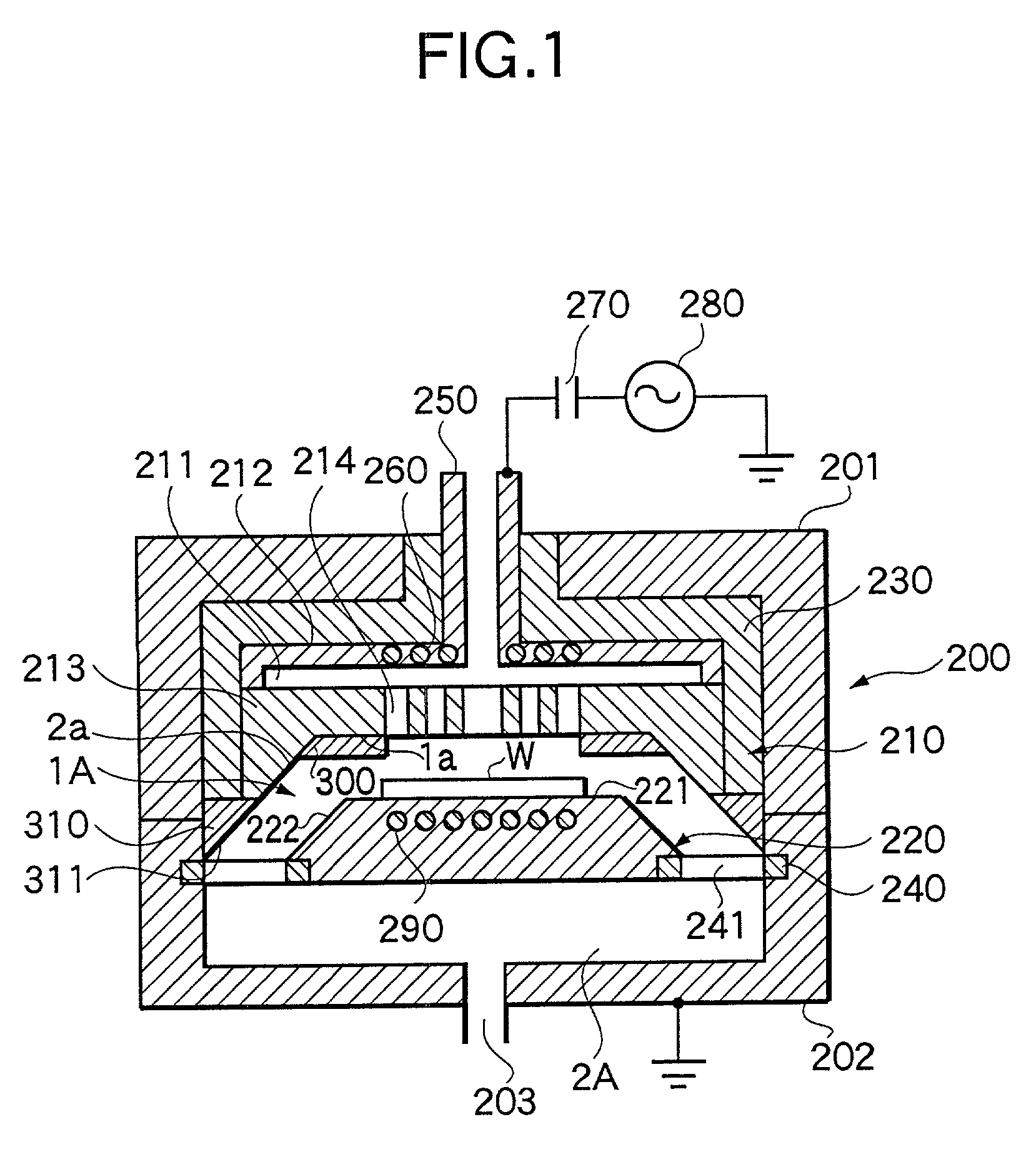

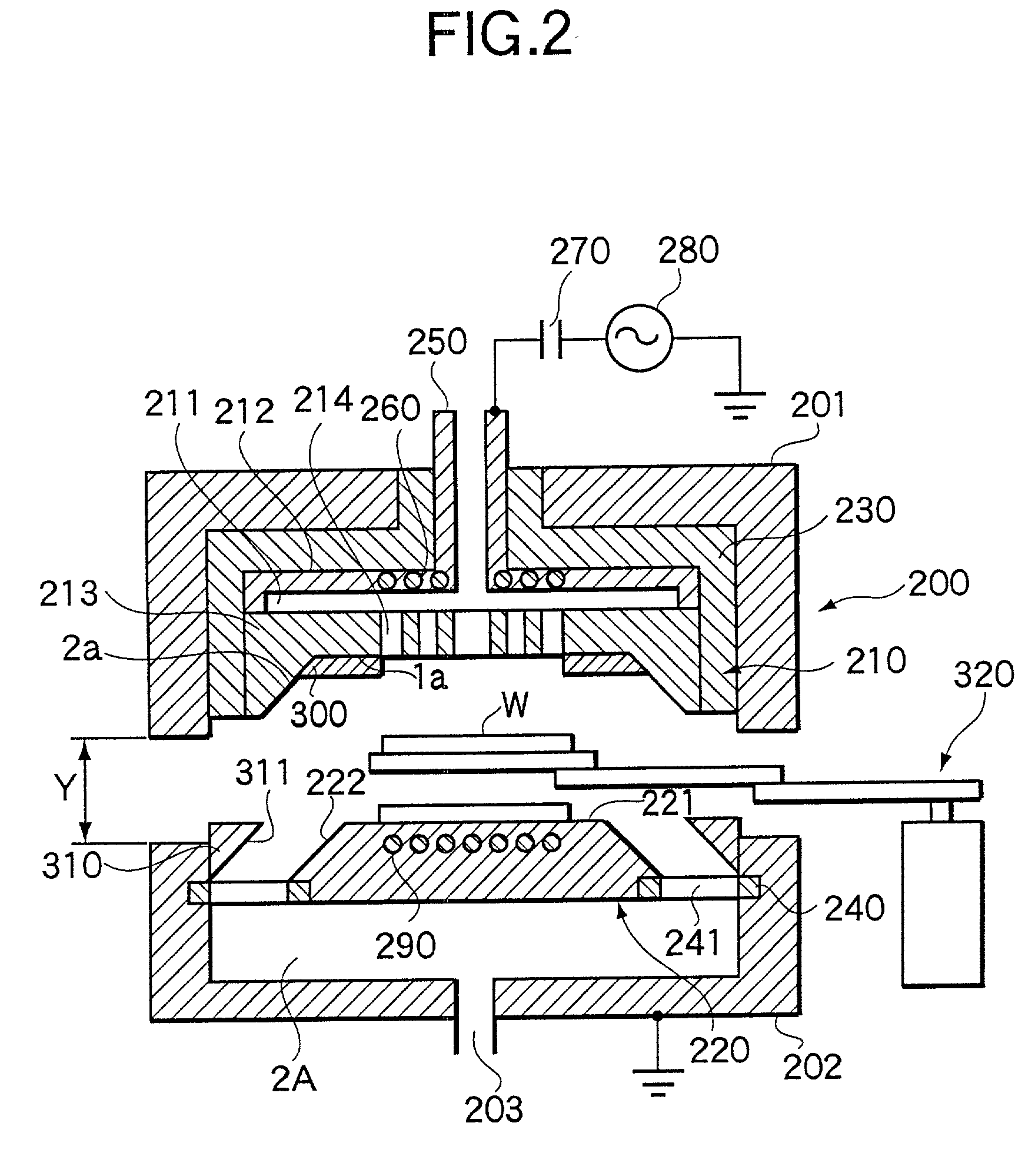

Plasma CVD device

InactiveUS20030205202A1Reduce the amount requiredIncrease productionElectric discharge tubesSemiconductor/solid-state device manufacturingSurface mountingEngineering

It is an object of the present invention to provide a plasma CVD device in which it is possible to inhibit the formation of particles resulting from the adhesion of reaction by-products of poor adhesive strength around the upper electrode. The plasma CVD device has a vacuum container 200, an upper electrode 210 and a lower electrode 220. The edge of the gas dispersion plate 213 of the upper electrode 210 is formed in the shape of an upturned bowl, the edge of which extends below the upper surface of the treatment substrate W mounted on the substrate-mounting surface 221 of the lower electrode 220.

Owner:KOKUSA ELECTRIC CO LTD

Apparatus and method for forming thin film using upstream and downstream exhaust mechanisms

ActiveUS7408225B2Reduce impactEvenly distributedElectric discharge tubesSemiconductor/solid-state device detailsGas supplySubstrate surface

A thin-film formation apparatus possesses a reaction chamber to be evacuated, a placing portion on which a substrate is placed inside the reaction chamber, a gas-dispersion guide installed over the placing portion for supplying a gas onto a substrate surface, a gas-supply port for introducing the gas into the gas-dispersion guide, a gas-dispersion plate disposed on the side of the substrate of the gas-dispersion guide and having multiple gas-discharge pores, a first exhaust port for exhausting, downstream of the gas-dispersion plate, the gas supplied onto the substrate surface from the gas-dispersion plate, and a second exhaust port for exhausting, upstream of the gas-dispersion plate, a gas inside the gas-dispersion guide via a space between the gas-dispersion guide and the gas-dispersion plate.

Owner:ASM JAPAN

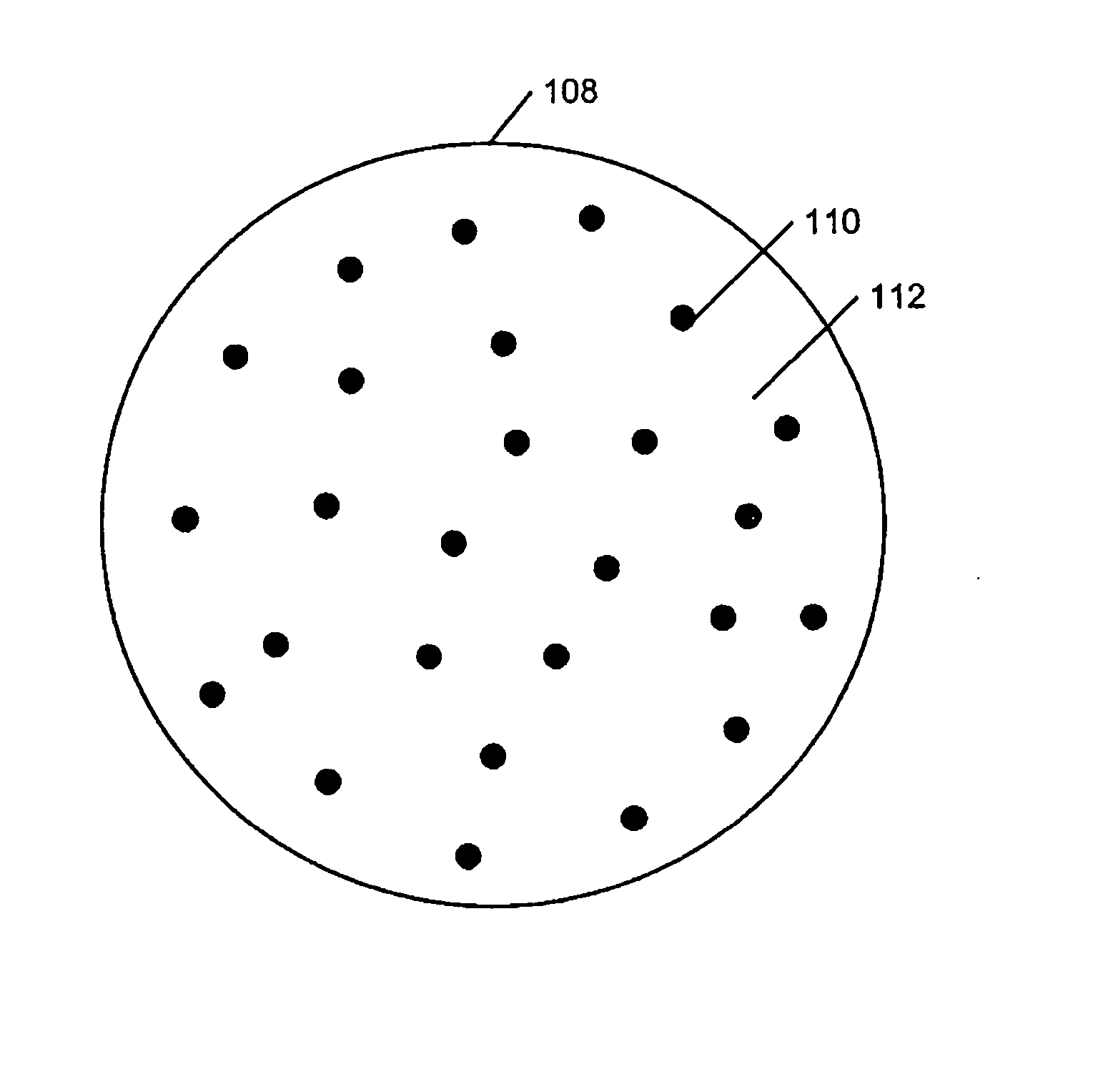

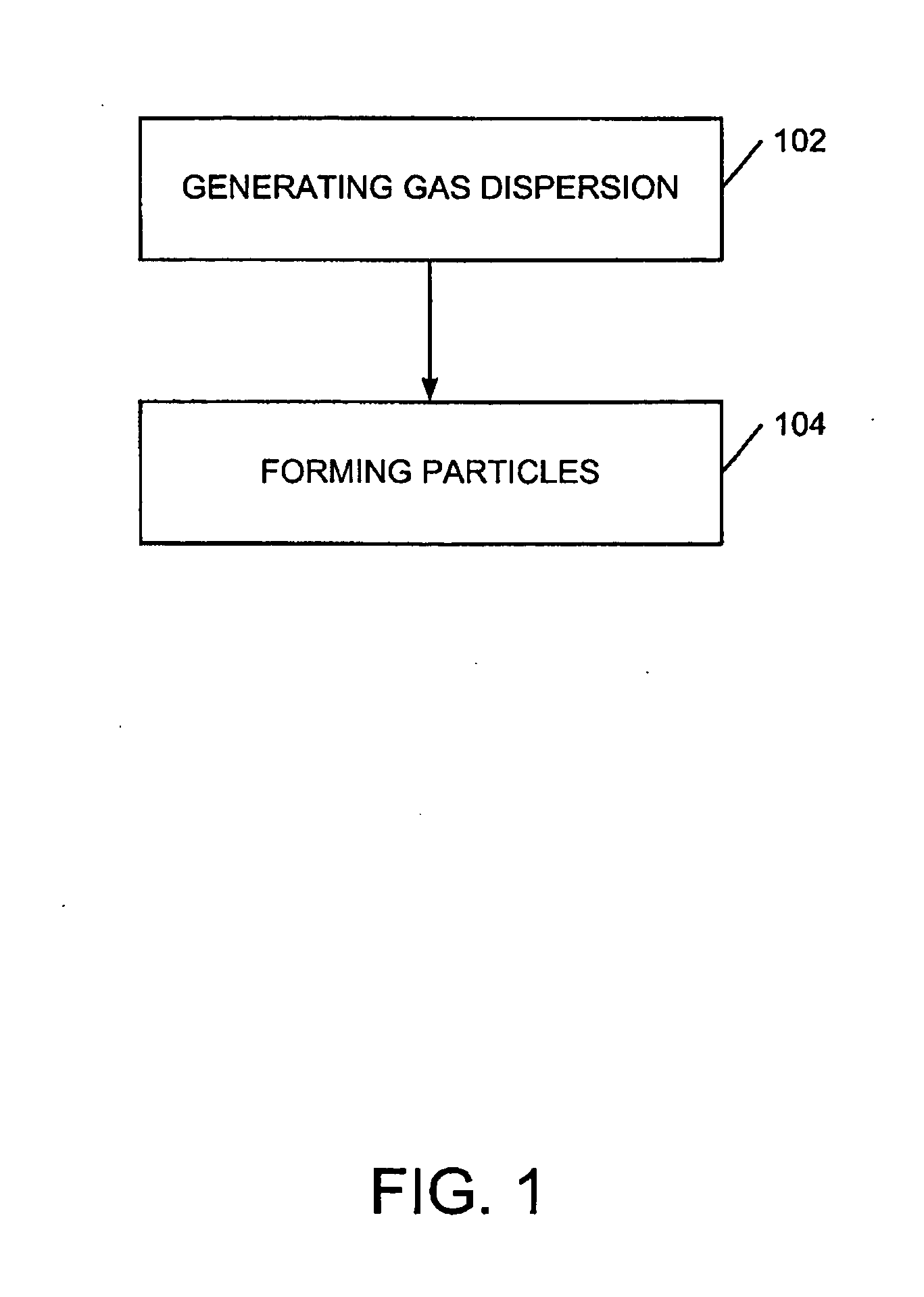

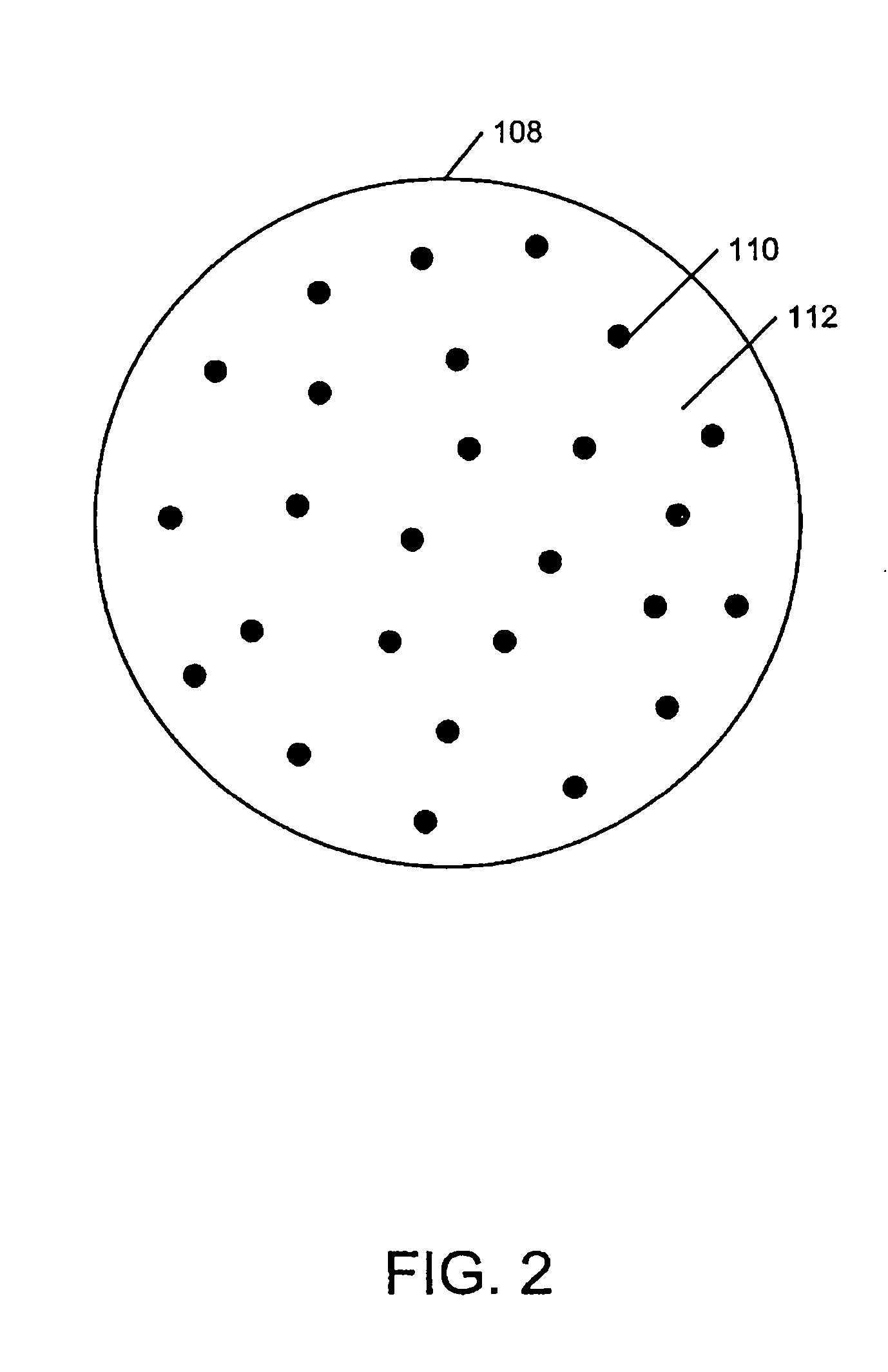

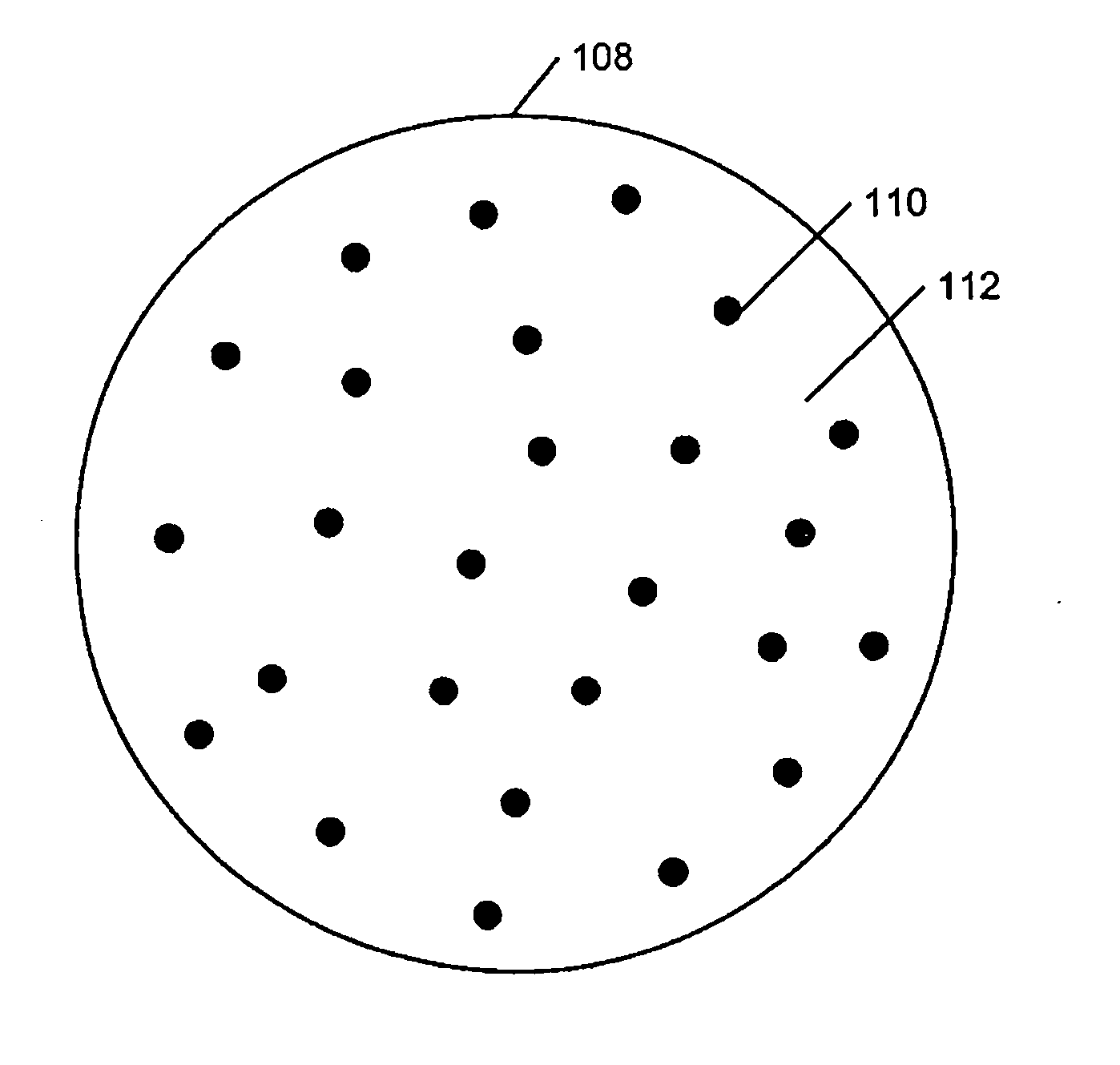

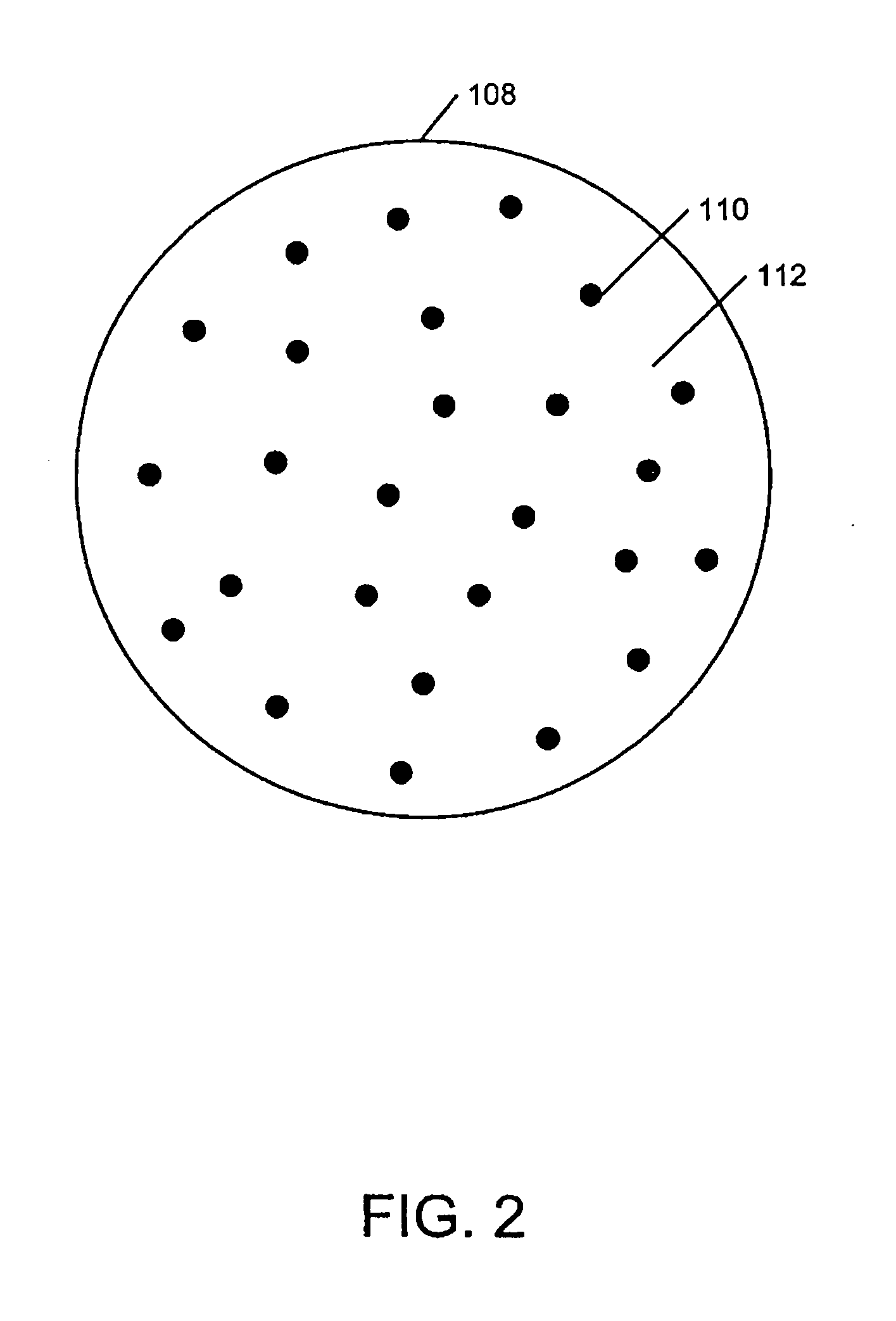

Gas dispersion manufacture of nanoparticulates, and nanoparticulate-containing products and processing thereof

In one aspect, the present invention relates to a method of making multi-phase particles that include nanoparticulates and matrix, which maintains the nanoparticulates in a dispersed state. A flowing gas dispersion is generated that includes droplets of a precursor medium dispersed in a gas phase. The precursor medium contains liquid vehicle and at least a first precursor to a first material and a second precursor to a second material. The multi-phase particles are formed from the gas dispersion by removing at least a portion of the liquid vehicle from the droplets of precursor medium. The nanoparticulates in the multi-phase particles include the first material and the matrix in the multi-phase particles includes the second material.

Owner:SICPA HLDG SA

Apparatus and method for vaporizing a liquid chemical

InactiveUS20030021595A1Steam generation heating methodsCombustible gas purificationParticulatesGas phase

Provided are apparatuses and methods for vaporizing a liquid chemical to form a vapor phase product. One exemplary apparatus includes: a vaporization chamber, which includes a first annular wall having a plurality of openings and enclosing a vaporization space and a second annular wall disposed within the first annular wall, the first and second annular walls forming an annular space therebetween; a first conduit connected to the vaporization chamber for introducing thereto a liquid chemical to be vaporized; a second conduit connected to the vaporization chamber for introducing a carrier gas to the annular space, wherein the carrier gas flows from the annular space through the first annular wall to the vaporization space; and a third conduit connected to the vaporization chamber for supplying the vapor phase product to a point of use. Other exemplary features of the vaporization apparatuses include a gas dispersion jet for forming liquid chemical droplets in the vaporization chamber, a separation chamber for removing particulates in the vaporized chemical, and a solvent cleaning system for cleaning the vaporization apparatus. The apparatuses and methods allow for vaporization without decomposition, liquid re-condensation, chemical channel blockage or impurity contamination, while being easy to control for a desired flow rate, temperature and pressure to provide a precursor vapor excellent in quality. The apparatuses and methods have particular applicability to the semiconductor manufacturing industry for supplying chemicals to semiconductor processing tools, for example, to chemical vapor deposition (CVD) tools.

Owner:AIR LIQUIDE AMERICA INC

Gas dispersion manufacture of nanoparticulates, and nanoparticulate-containing products and processing thereof

In one aspect, the present invention relates to a method of making multi-phase particles that include nanoparticulates and matrix, which maintains the nanoparticulates in a dispersed state. A flowing gas dispersion is generated that includes droplets of a precursor medium dispersed in a gas phase. The precursor medium contains liquid vehicle and at least a first precursor to a first material and a second precursor to a second material. The multi-phase particles are formed from the gas dispersion by removing at least a portion of the liquid vehicle from the droplets of precursor medium. The nanoparticulates in the multi-phase particles include the first material and the matrix in the multi-phase particles includes the second material.

Owner:CABOT CORP

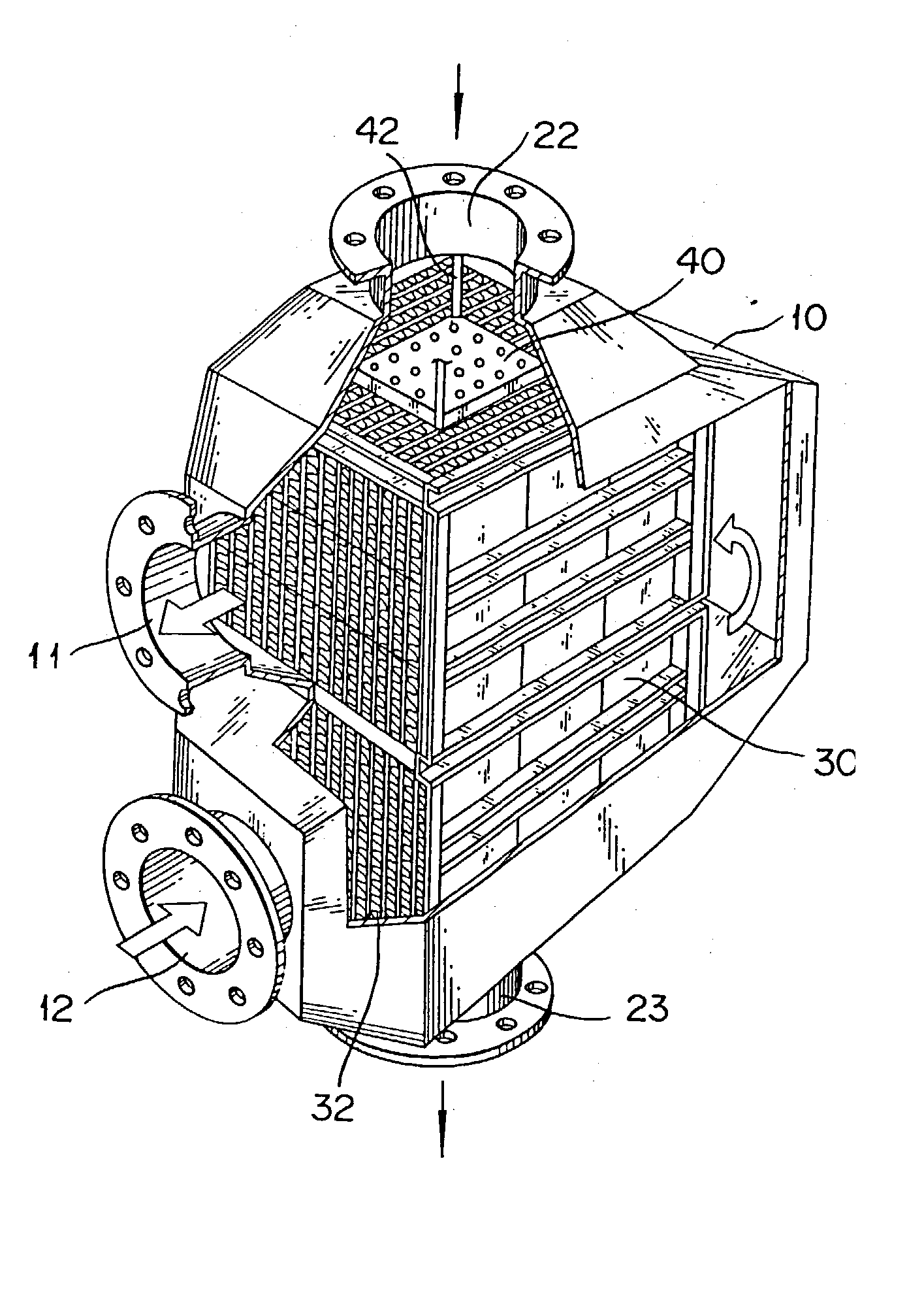

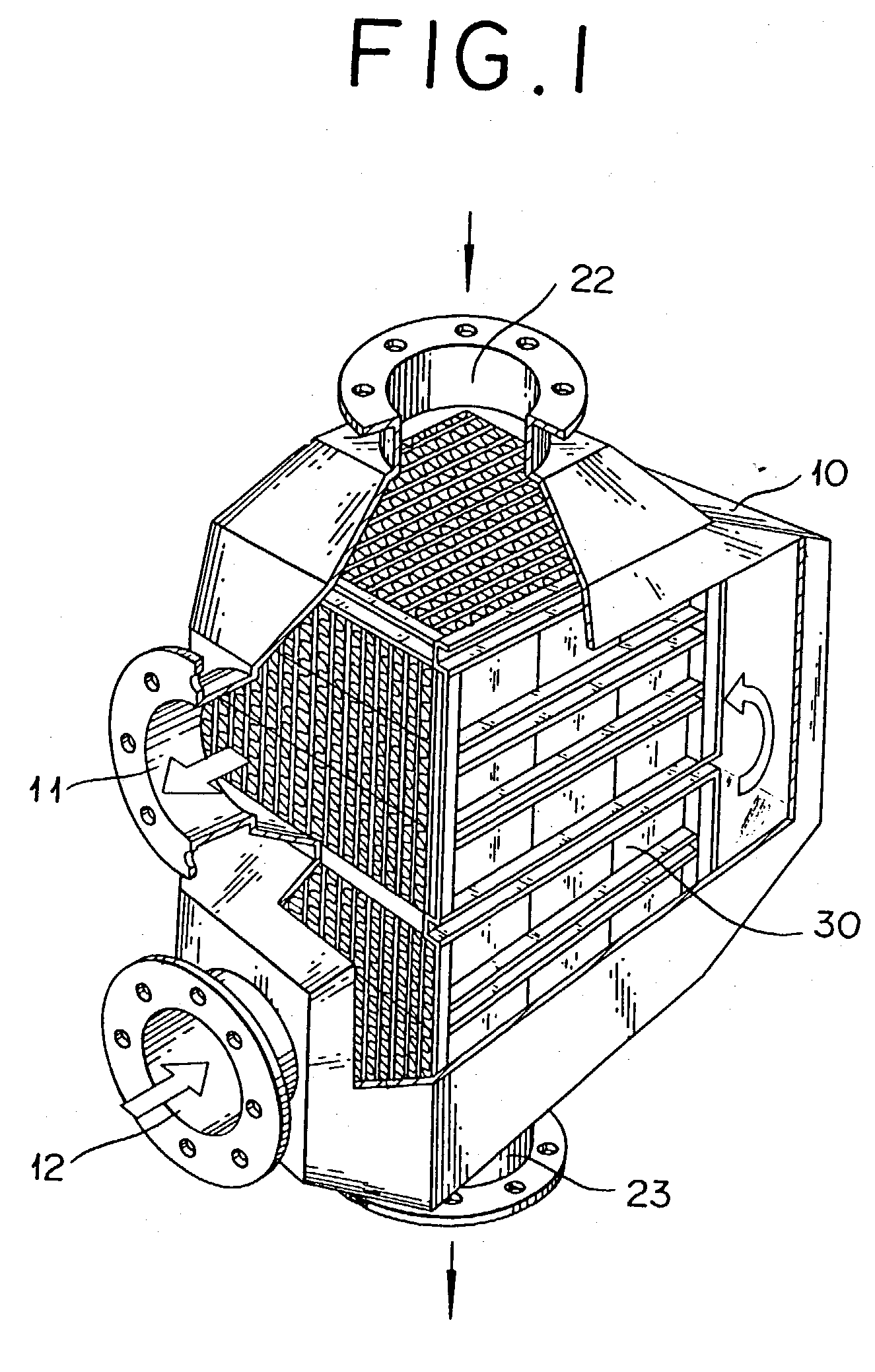

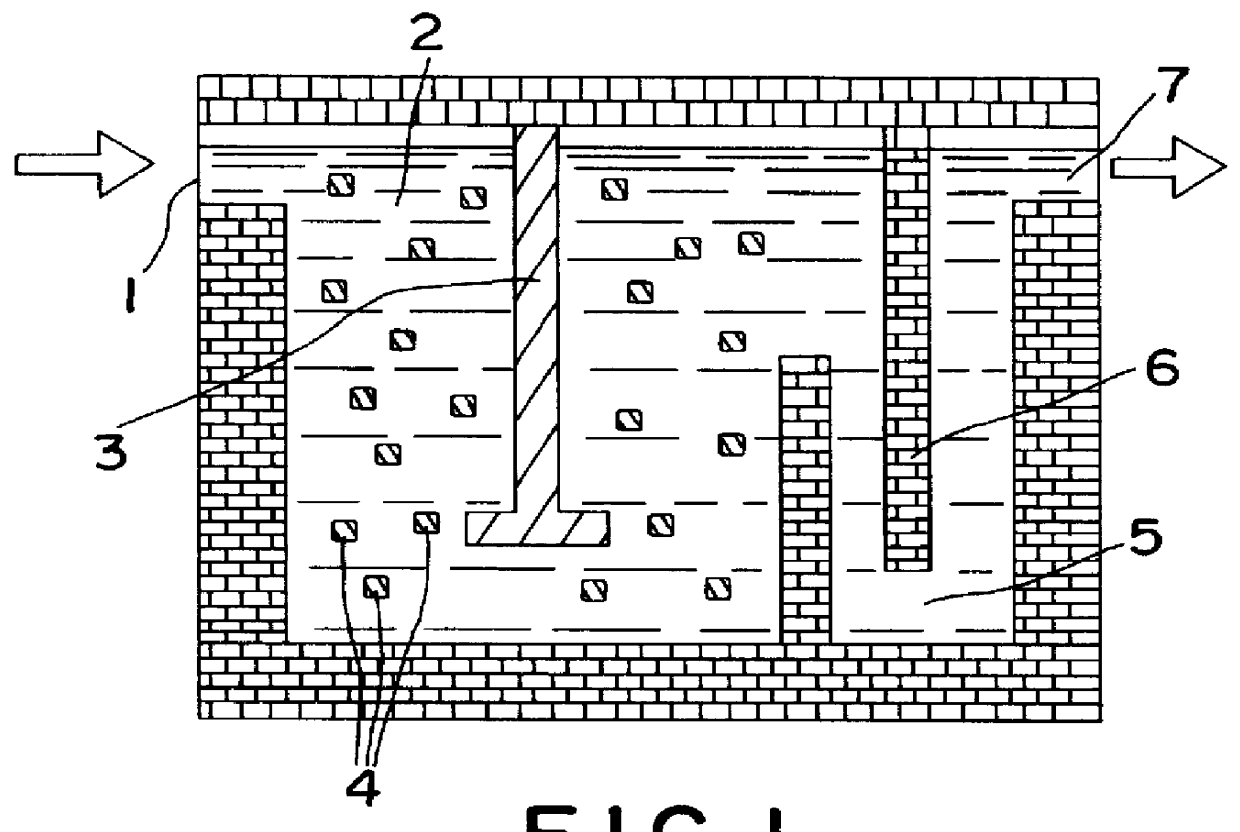

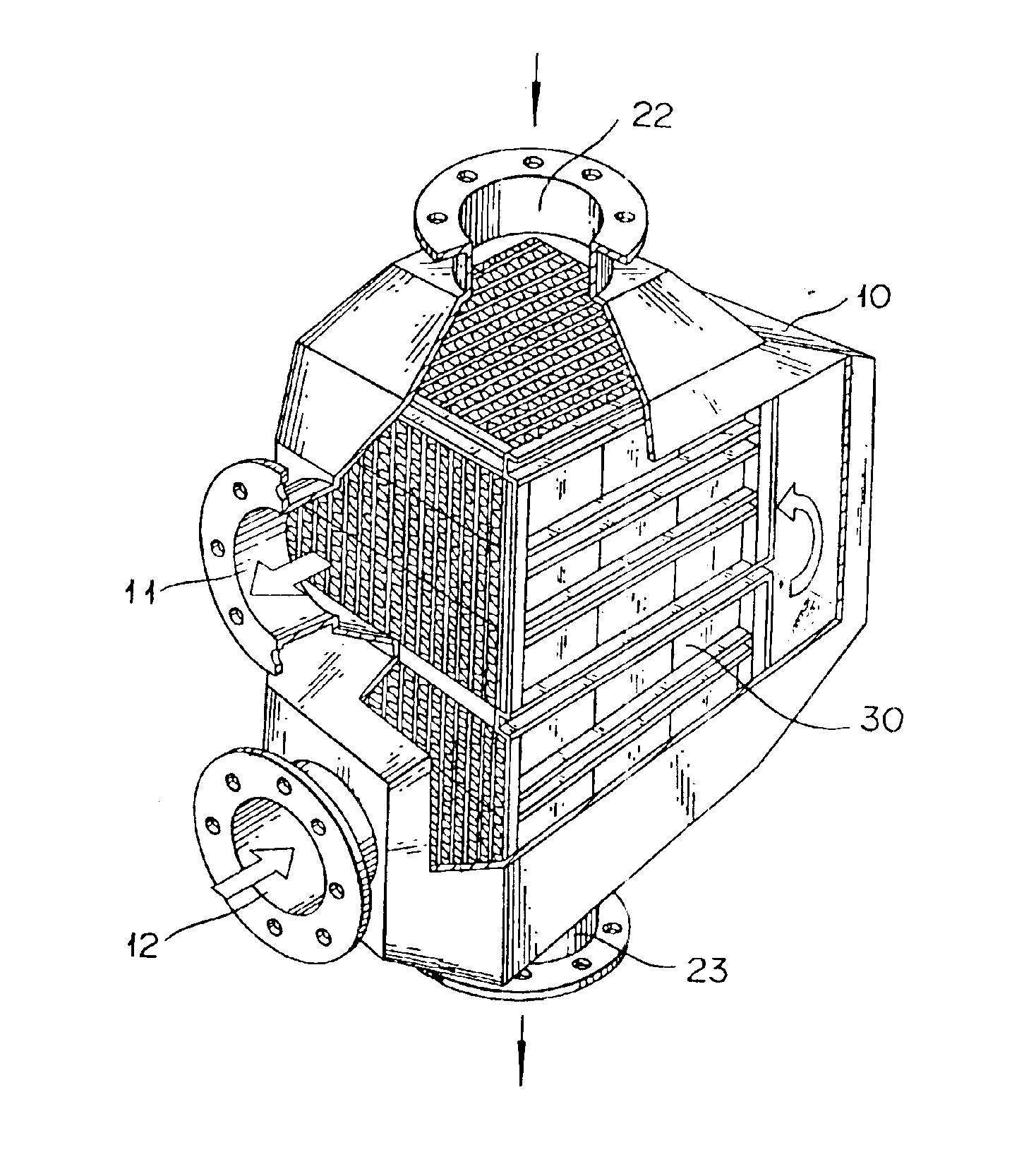

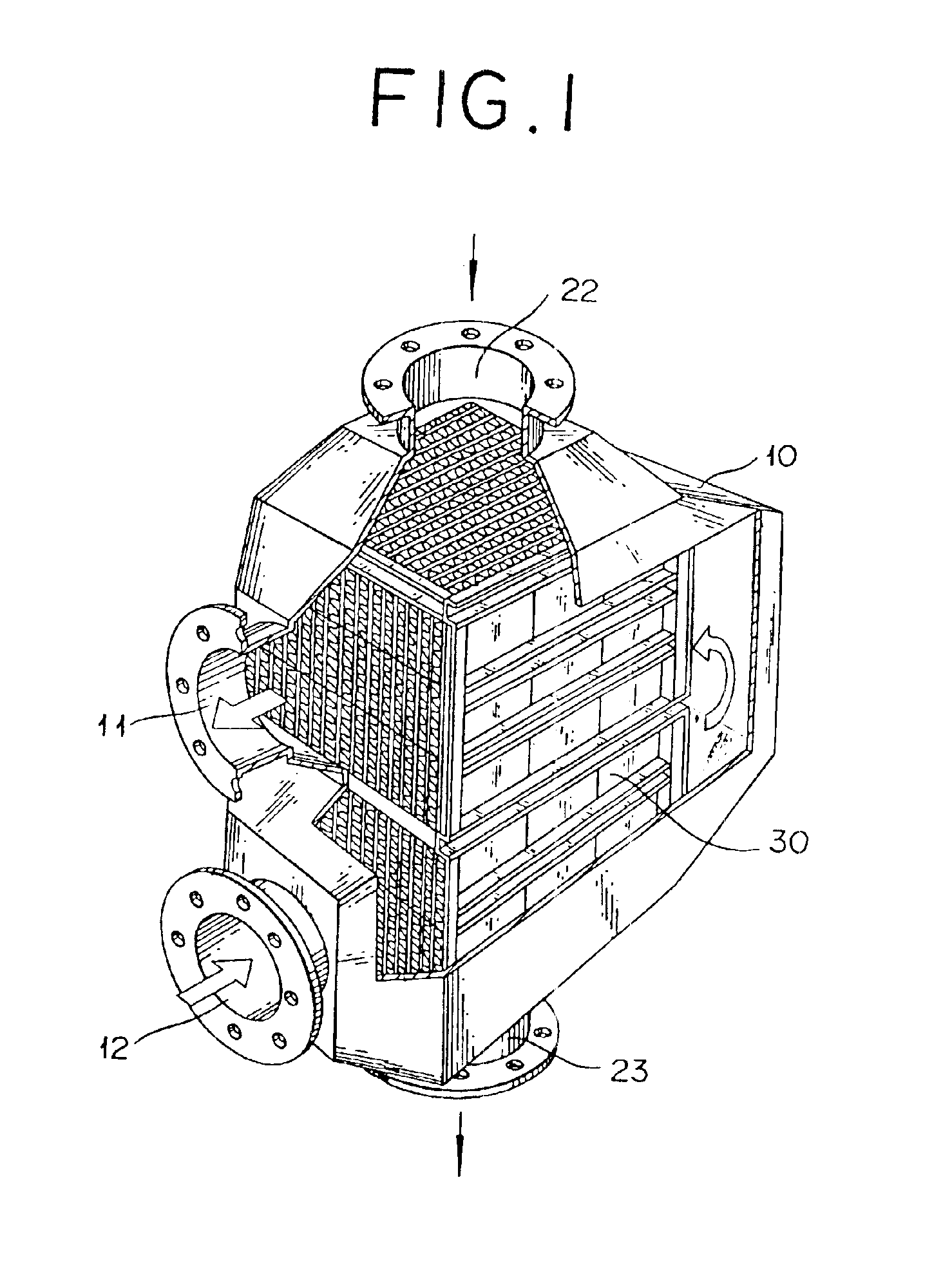

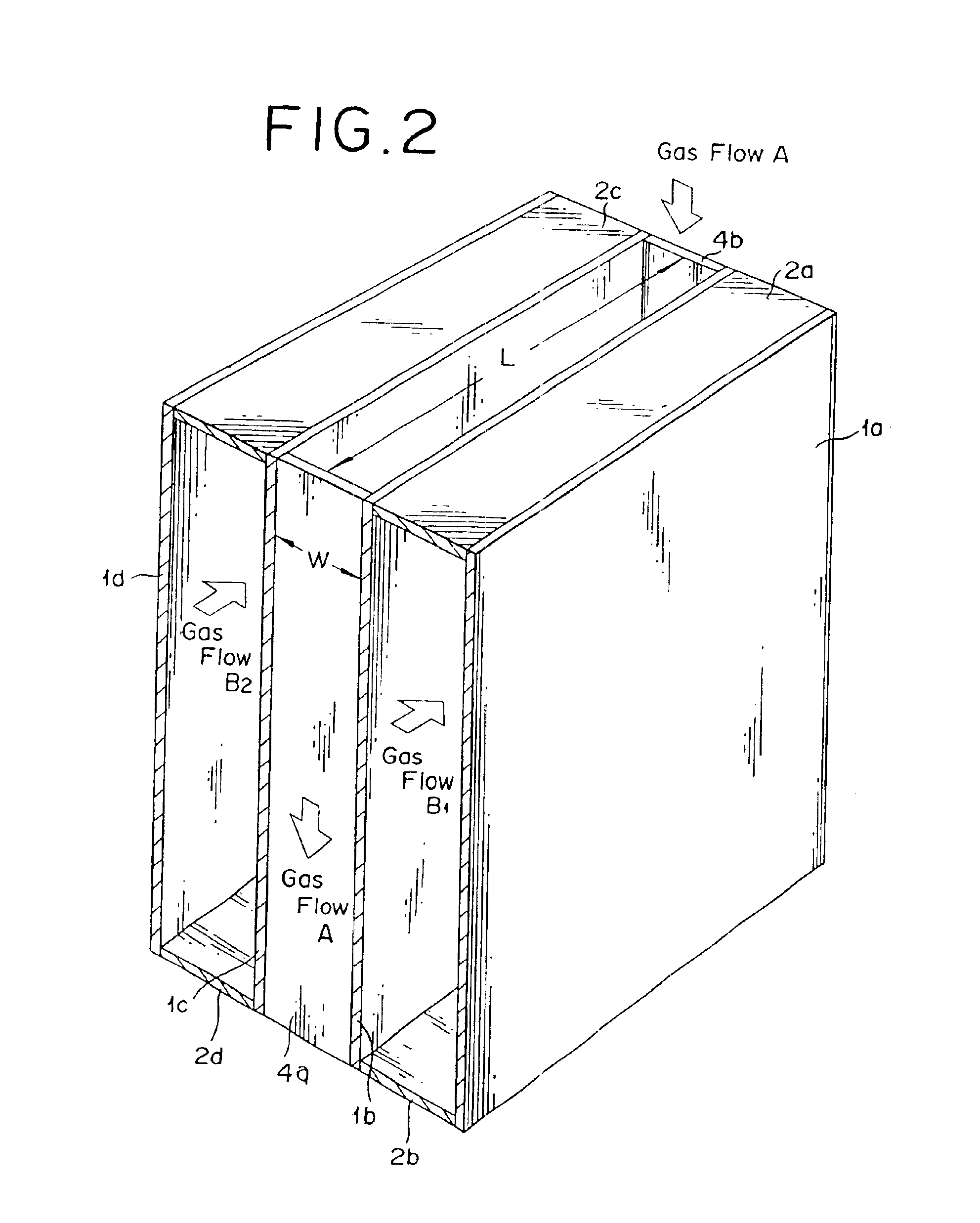

Method for preventing plate type heat exchanger from blockage

InactiveUS20030111216A1Evenly dispersedEasy to blockProcess control/regulationCorrosion preventionGas passingProduct gas

In an apparatus provided with a plate type heat exchanger as a heater and / or a cooler and operated to treat a gas containing an easily blocking substance, a method for preventing the plate type heat exchanger from being blocked is disclosed which is characterized by i) setting the width of a flow path on a plate of the plate type heat exchanger in the apparatus in a range of 6-25 mm and ii) setting the average flow rate of the gas passing the plate type heat exchanger in the apparatus per unit cross-sectional area of the flow path on the plate in the range of 3-15 m / s. In the exchange of heat of an easily blocking substance by the use of a plate type heat exchanger, a method for preventing the plate type heat exchanger from blockage is disclosed which has the plate type heat exchanger provided in the port for introducing a gas containing an easily blocking substance with a gas dispersion plate. This invention, in the heat exchange of an effluent gas emanating from a process for the production of (meth)acrylic acid or an ester thereof or the disposal of the gas, significantly allays blockage of the interior of the plate type heat exchanger.

Owner:NIPPON SHOKUBAI CO LTD

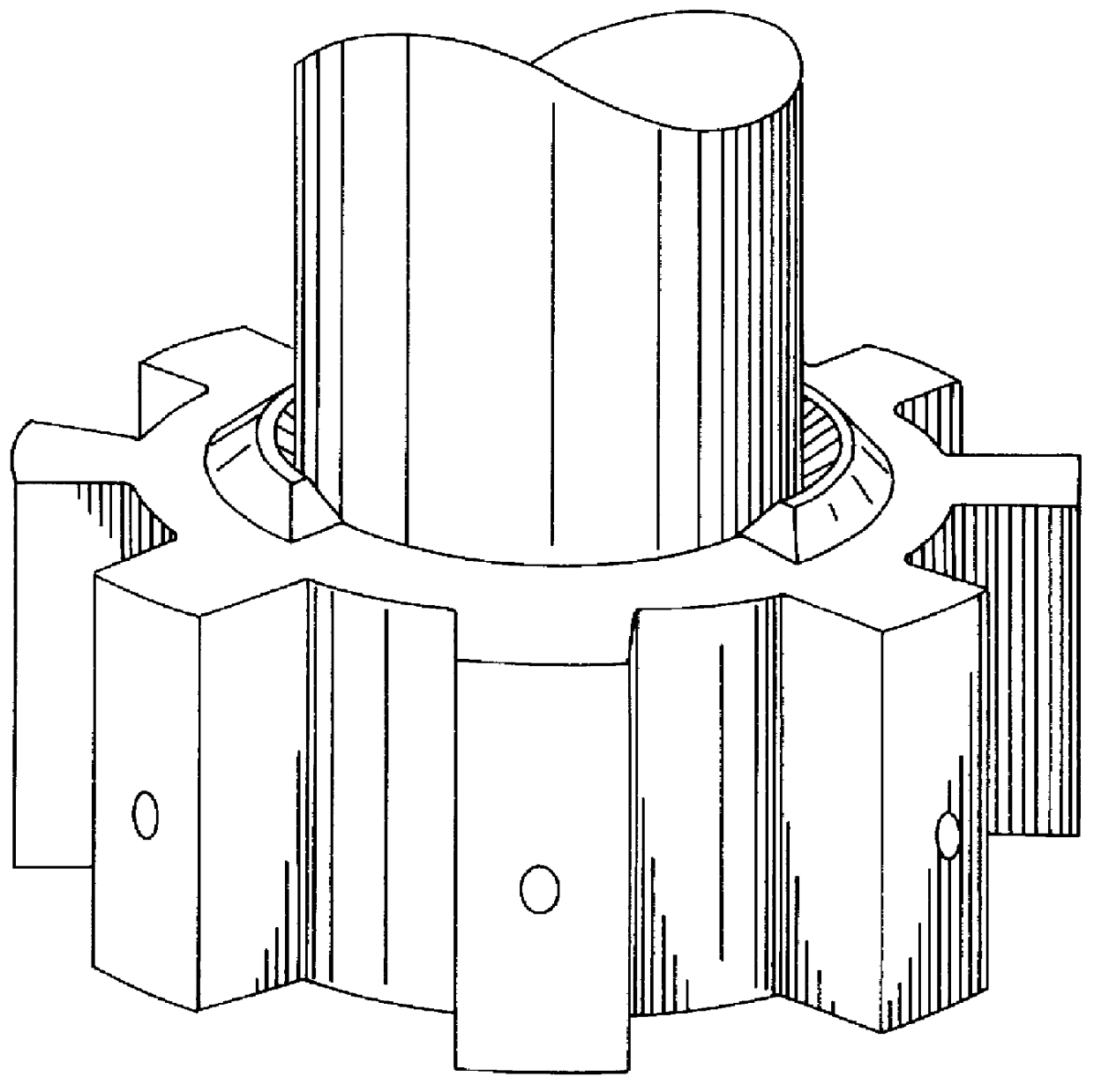

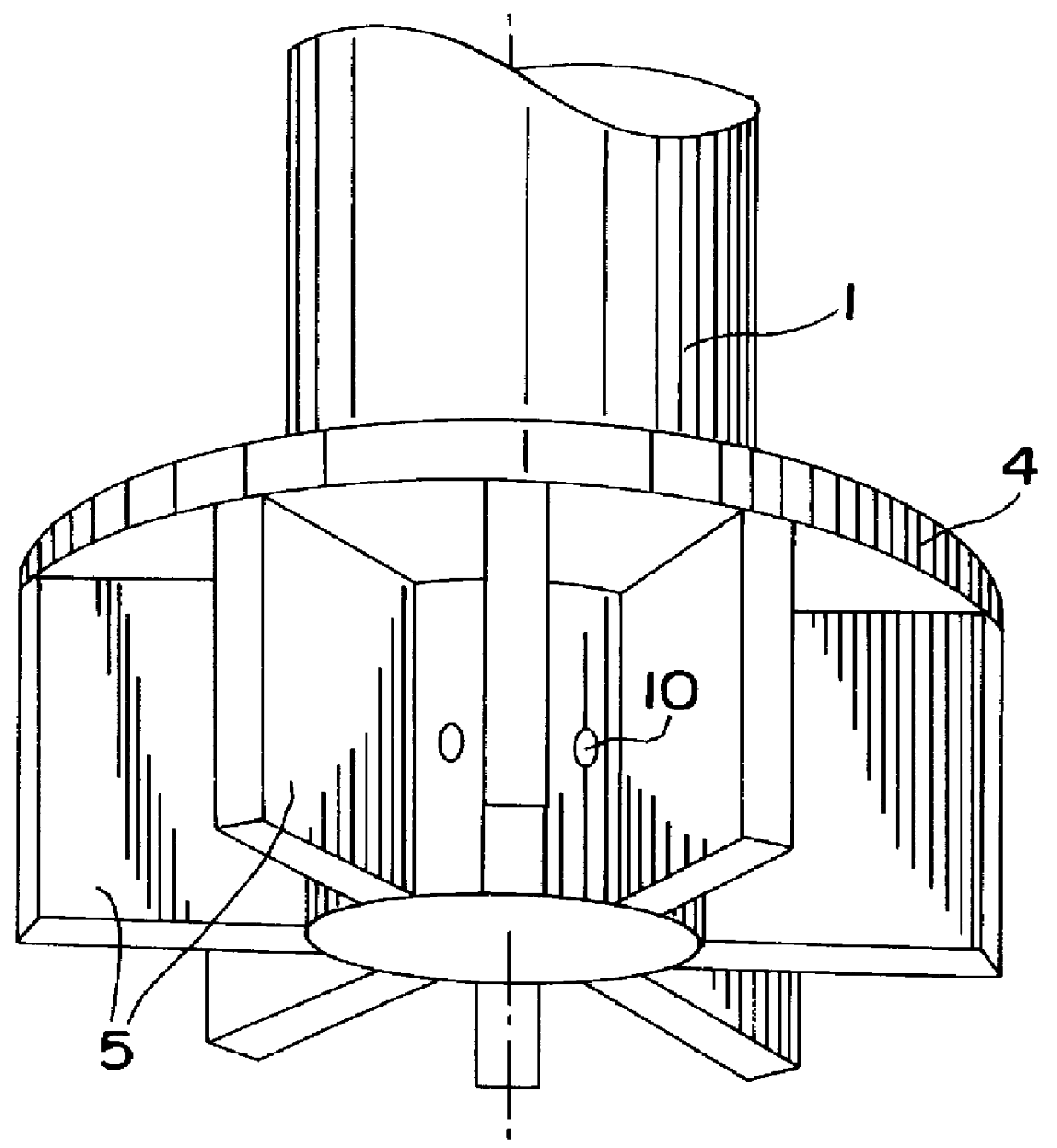

Rotary gas dispersion device for treating a liquid aluminium bath

InactiveUS6060013AHigh blade lift ratioDifficult to manufactureMechanical apparatusStirring devicesEngineeringLiquid aluminium

PCT No. PCT / FR97 / 01367 Sec. 371 Date Mar. 8, 1999 Sec. 102(e) Date Mar. 8, 1999 PCT Filed Jul. 23, 1997 PCT Pub. No. WO98 / 05915 PCT Pub. Date Feb. 12, 1998A rotary gas dispersion device for use in a liquid aluminium treatment vessel is disclosed. The device is useful for reducing surface disturbance, splashing and vortices while maintaining the effectiveness of the treatment. Said device includes a rotor (1) consisting of a set of blades (5) and a substantially flat disc (4) thereabove. Gas is injected through the central hub and side ports (10) between the blades. The ratio of the outer diameter of the rotor to the diameter of the central hub thereof is of 1.5-4.

Owner:NOVELIS INC

Sewage treatment process by activated-sludge method comprising line atomizing treatment

InactiveUS7105092B2Improve efficiencyIncrease ratingsTreatment using aerobic processesMixing methodsActivated sludgeWater treatment system

Disclosed is a waste water disposal process in the biosolid method according to a line atomizing treatment in which a reactive gas containing oxygen or oxygen and ozone as hardly soluble gases is dissolved / stored in water as being converted into ultrafine bubbles. The characteristic feature is that, by forming a gas-dispersion liquid in which the reactive gas containing oxygen or oxygen and ozone is dispersed in the form of ultrafine bubbles in returned biosolid water or in clean water at outside of the vessels (pools) of the waste water treatment system and by introducing the aforementioned gas-dispersion liquid into a reaction vessel (aerobic or anaerobic), oxygen is supplied to the microorganisms. Alternatively, the aforementioned gas-dispersion liquid is introduced into a vessel in the step preceding the reaction vessel or succeeding the reaction vessel. Further, the kind, concentration and volume of the reactive gas, the vessel (pool) for returning and the duration of introduction are set in accordance with the proceeding conditions of the waste water treatment and unitarily controlled.

Owner:RICH WHITNEY +3

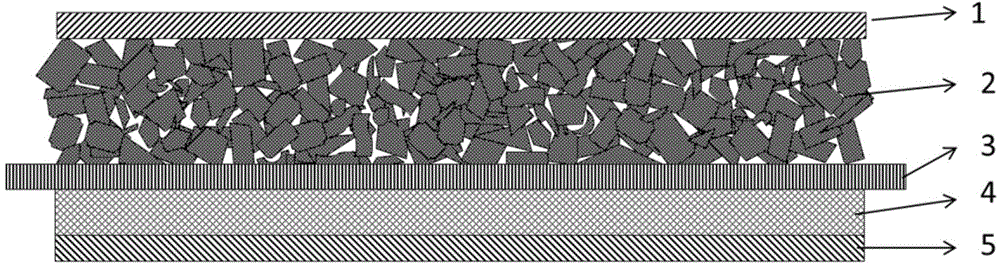

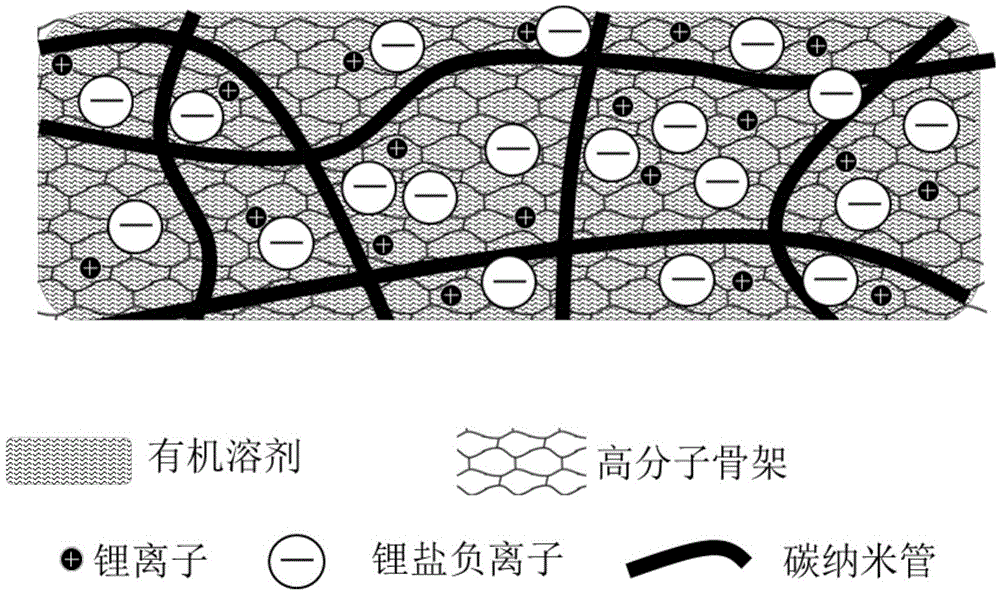

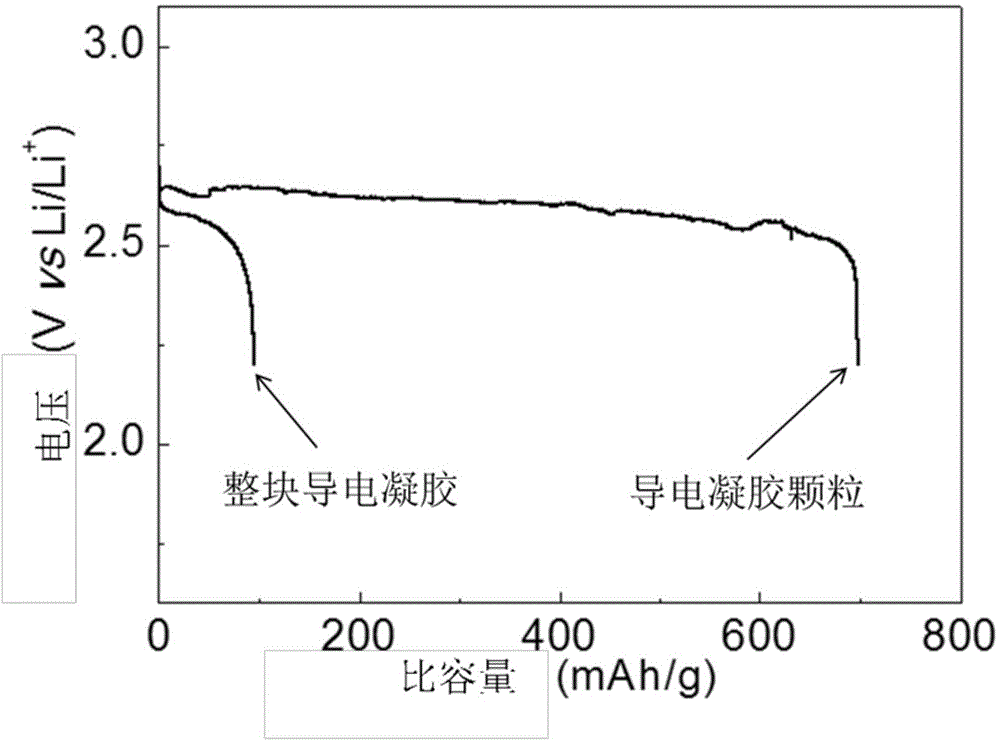

Air positive electrode constructed by conductive gel particles and lithium air battery

ActiveCN104659375AEasy and quick passFast deliveryFuel and primary cellsCell electrodesSolid structureLithium–air battery

The invention discloses an air positive electrode constructed by conductive gel particles and a lithium air battery. The air positive electrode is characterized by being of a full-solid structure and comprising particles with arbitrary shapes, wherein the particles are prepared from conductive gel, gaps are formed among the particles, electrons and ions can be simultaneously conducted by conductive gel, and the size range of the particle sizes of the particles is 10-500 microns; the particles are stacked to form a laminated structure, and the thickness of the laminated structure is 50 microns to 5 millimeters. A battery cell of the lithium air battery is of a multi-layer winding type structure or a multi-layer laminating type structure and is formed by winding and laminating a plurality of repetitive units, and each repetitive unit comprises the air positive electrode. A rapid gas dispersion channel is formed in the air positive electrode and can be prepared to be relatively thick, so that the problem that oxygen is difficult to diffuse is effectively solved, and the air positive electrode can be truly input into actual application.

Owner:HUAZHONG UNIV OF SCI & TECH

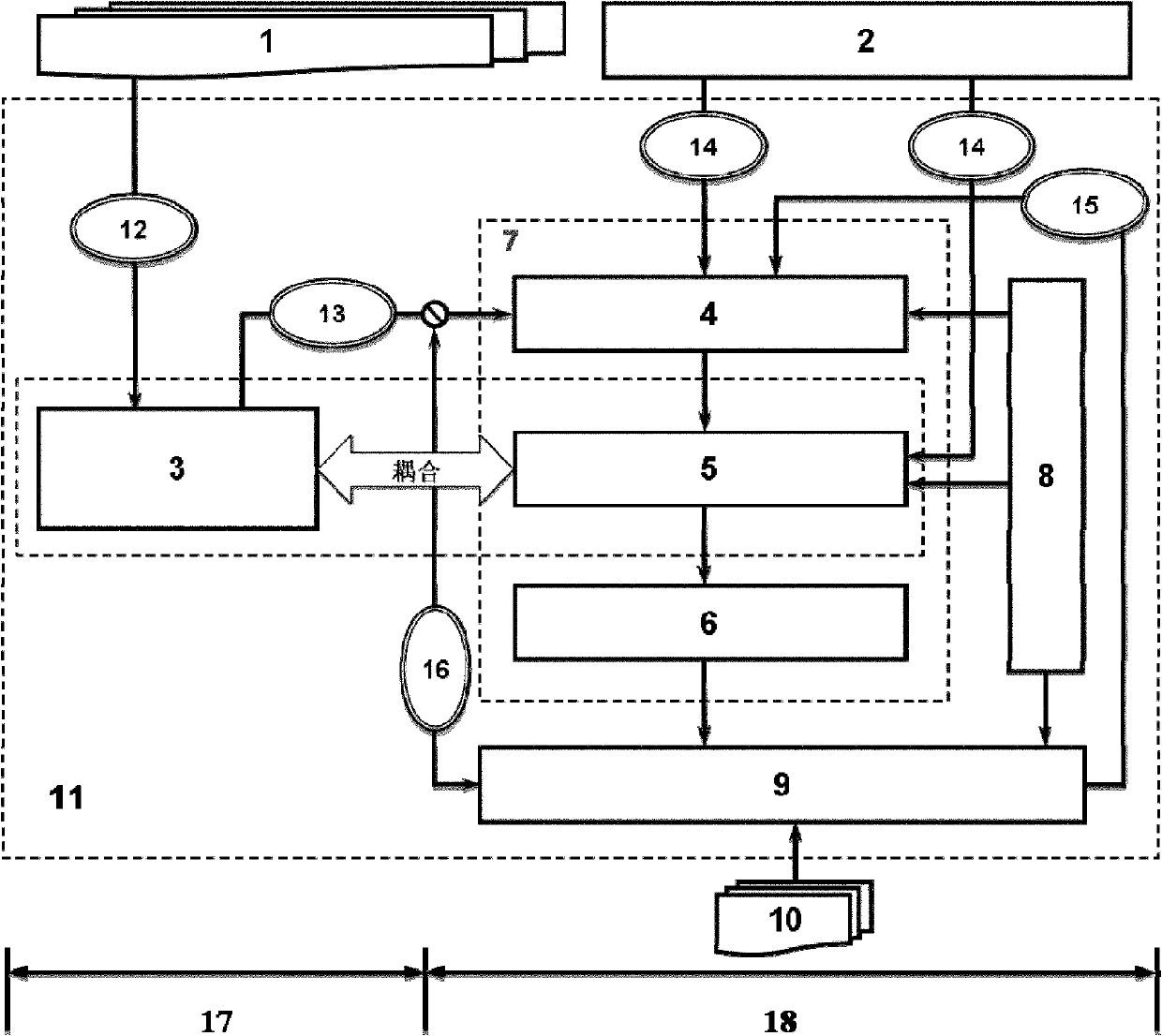

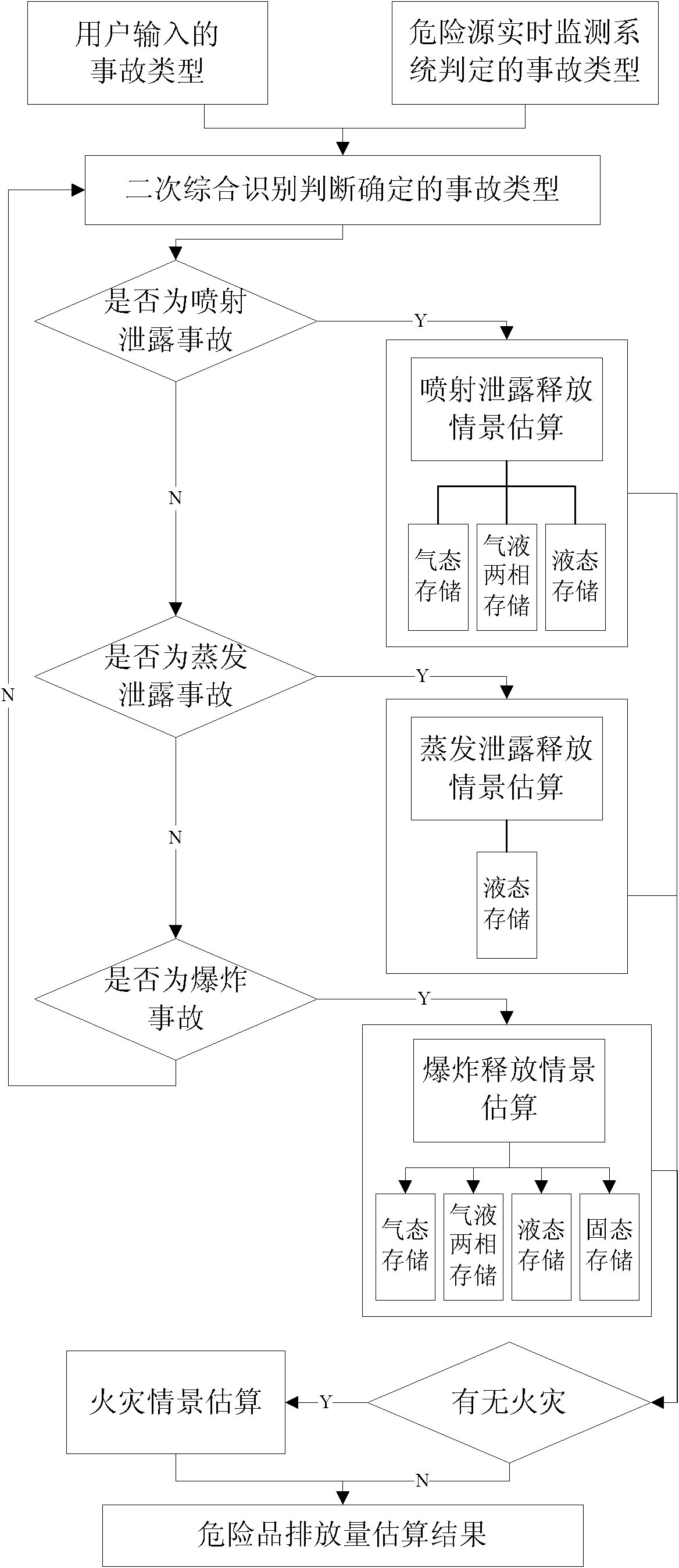

Method for forecasting and warning accident consequence of major hazard installation by combining with real-time meteorological information

InactiveCN102567808AOvercoming serious drawbacks of bindingImprove accuracyForecastingHuman bodyTemporal resolution

The invention discloses a method for forecasting and warning an accident consequence of a major hazard installation by combining with real-time meteorological information. The accident of the hazard installation is simulated by combining a high-spatial and temporal resolution atmospheric circulation numerical simulation and forecasting method with a gas dispersion simulation method, simultaneously adding an integrated forecasting method of a danger emission estimation method and a simulated data result post-processing method and combining with the real-time meteorological information and the real-time monitoring information of the hazard installation to obtain the quantitative three-dimensional spatial and temporal distribution result of hazardous gas after the accident occurs and the influence scope and the duration of the accident on an ambient environment; the hazard level and the like on a human body is analyzed and forecasted to obtain the three-dimensional spatial distribution condition of the poisonous and hazardous gas after the accident occurs and the quantitative pollutant concentration number of every target point. The invention provides a method which can be used for forecasting the accident consequence and an automatic evaluation method for hazard level of the accident. The method for forecasting and warning the accident consequence of the major hazard installation by combining with the real-time meteorological information has the characteristics that spatial and temporal spacing, such as the meteorological information, results and the like can be read in real time, the computing speed is high, the real-time performance is strong and the like.

Owner:BEIJING UNIV OF TECH

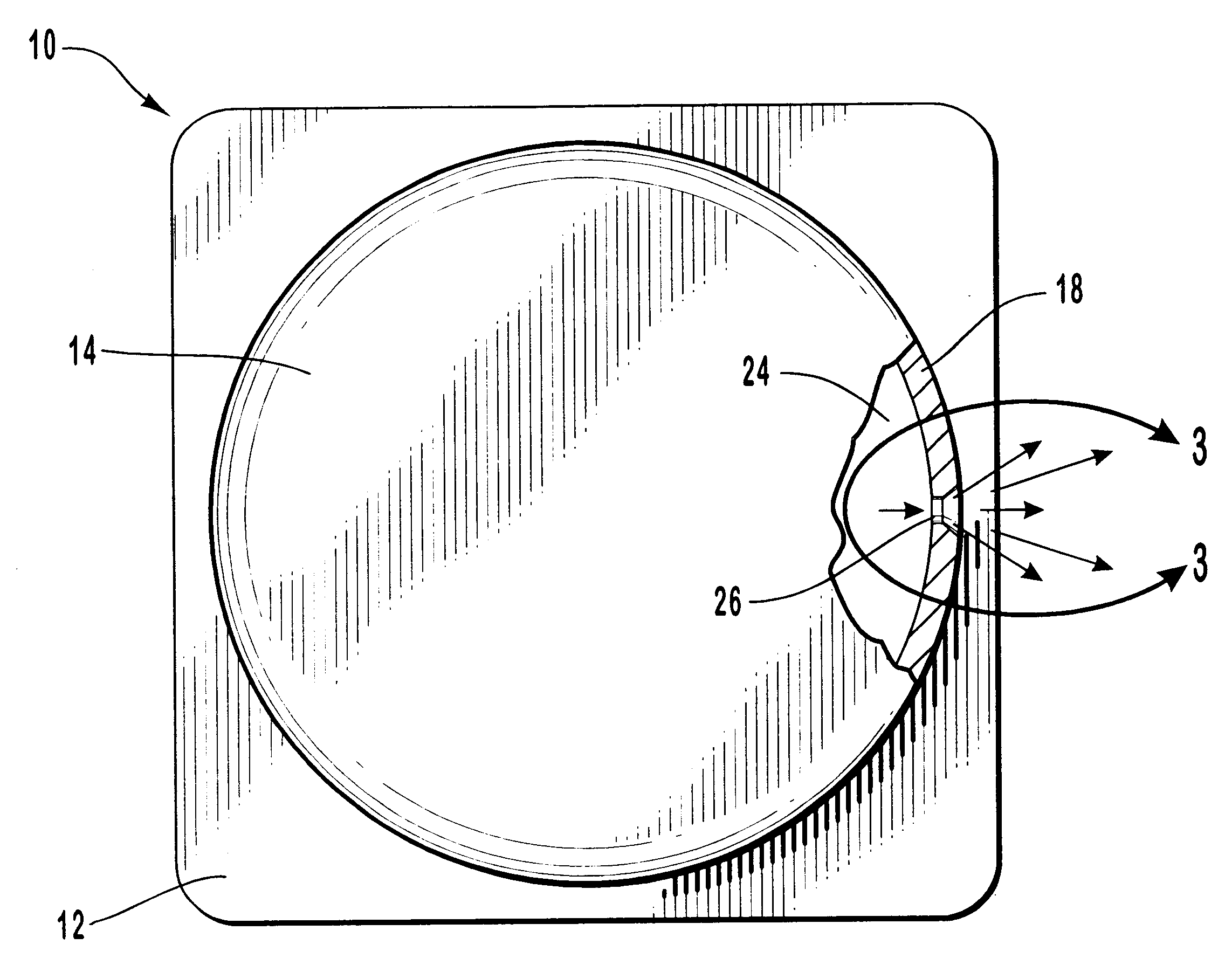

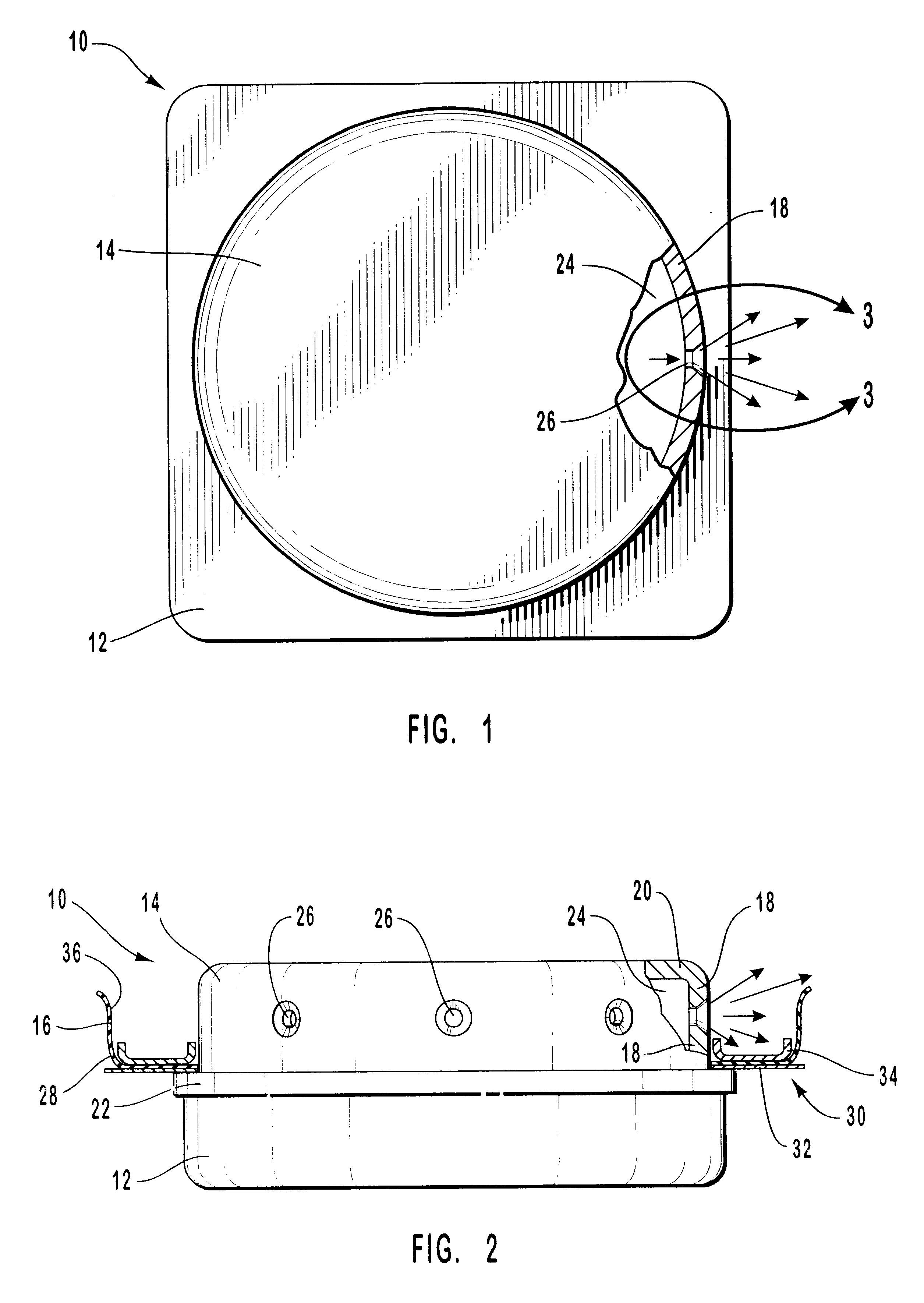

Air bag inflator exit gas dispersion features

InactiveUS6206417B1Reduce thicknessReduce gas concentrationPedestrian/occupant safety arrangementInterior spaceEngineering

An air bag device that includes an air bag cushion, a diffuser canister, and a gas generation inflator. The diffuser canister is attached to the air bag cushion and has walls configured to define an interior space therein. The walls of the diffuser canister have an interior surface, an exterior surface, and a wall thickness t. At least one of the walls has an aperture formed therethrough in communication with the interior of the air bag cushion. The gas generation inflator is configured to rapidly create a gas that exists the diffuser canister through the aperture so as to fill the air bag cushion. The aperture is defined by an edge extending between the interior and said exterior surfaces of the wall that is configured to diffuse the gas exiting the diffuser canister through the aperture. The edge of the aperture is configured such that the cross-sectional area of the aperture that is proximate to the exterior surface of the wall is larger than the cross-sectional area of the aperture proximate to the interior surface of wall. The edge includes an angled portion configured such that opposing sides of the aperture have an angle alpha therebetween in the range of about 20 degrees to about 145 degrees. The aperture has a diameter d1 proximate to the interior surface of the wall and is configured so that the diameter d1 and wall thickness t have a ratio d1 to t in the range of about 0.5 to about 4.

Owner:AUTOLIV ASP INC

Gas dispersion nozzle for a fire arm silencer

A gas dispersion nozzle for a gun silencer having a nozzle portion with a front end and a rear end and walls enclosing a hollow interior therein. The rear end of the nozzle portion is attached to the gun silencer and the nozzle portion extends into the interior of the gun silencer. The rear end also attaches to a firearm. The walls have channels which direct flow of propellant gases out of the hollow interior and into the interior of the gun silencer at an angle to a path along which the projectile passes when the firearm is discharged. The channels cause the flow of propellant gases to become turbulent or rotational or both and can cause the flow rate of said propellant gases to decrease. The gas dispersion nozzle reduces the report and / or flash produced by the discharge of a firearm.

Owner:WHITE MARK

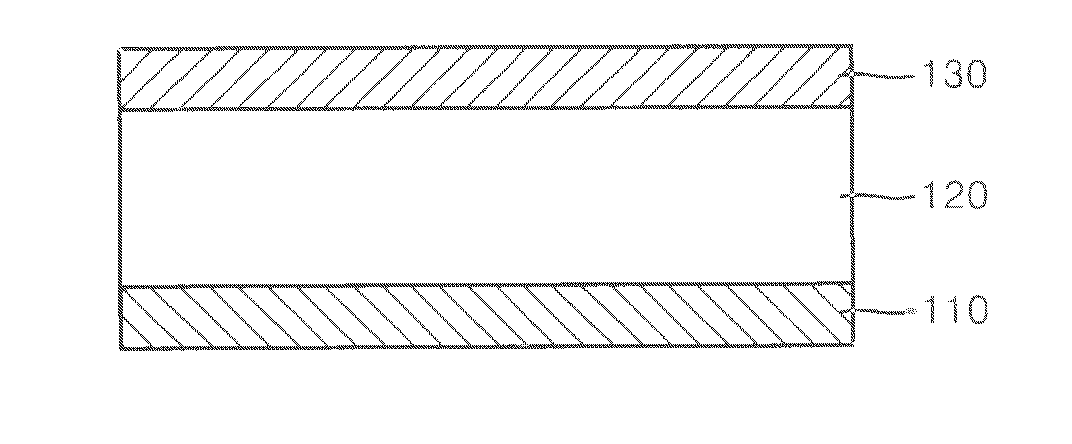

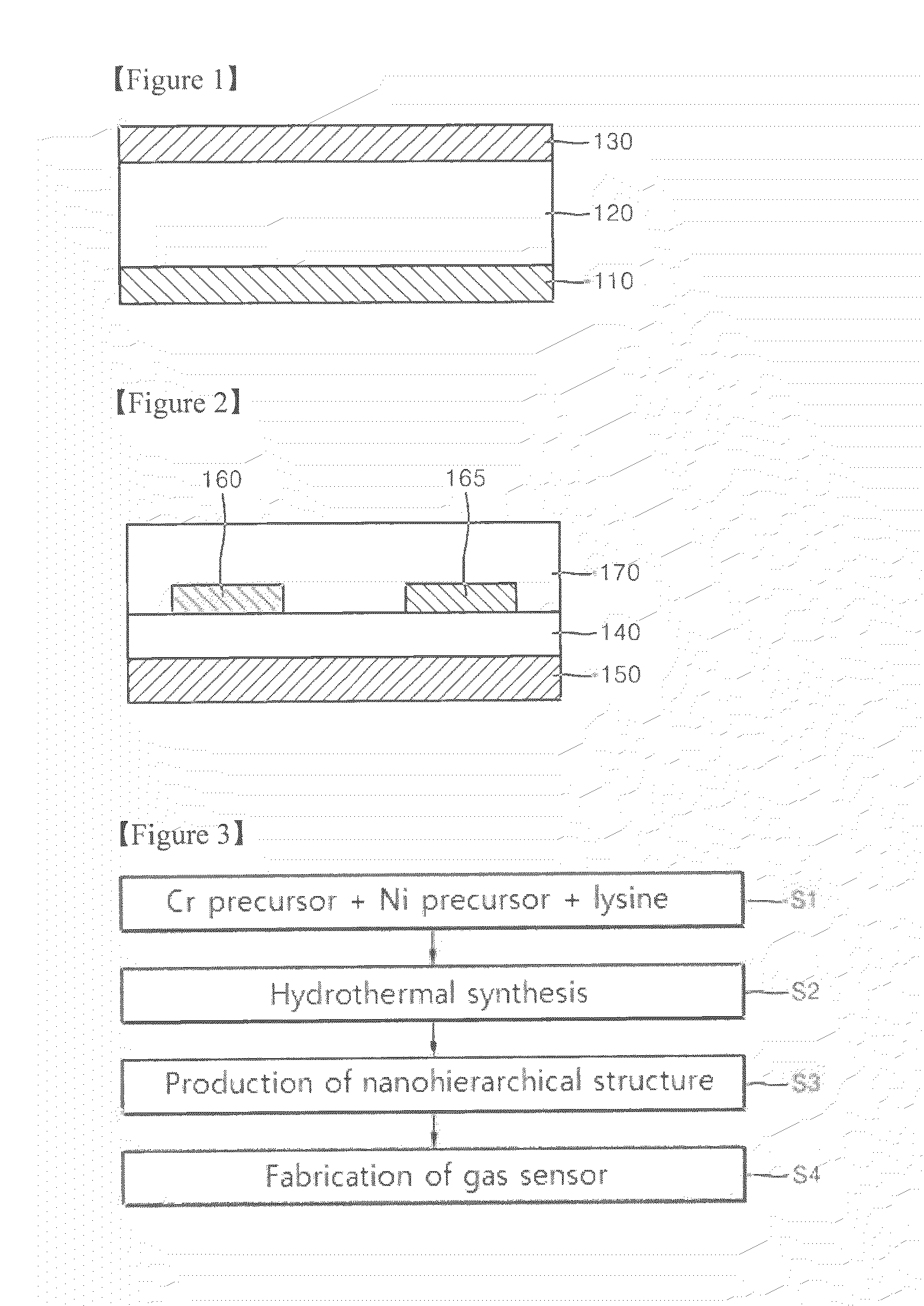

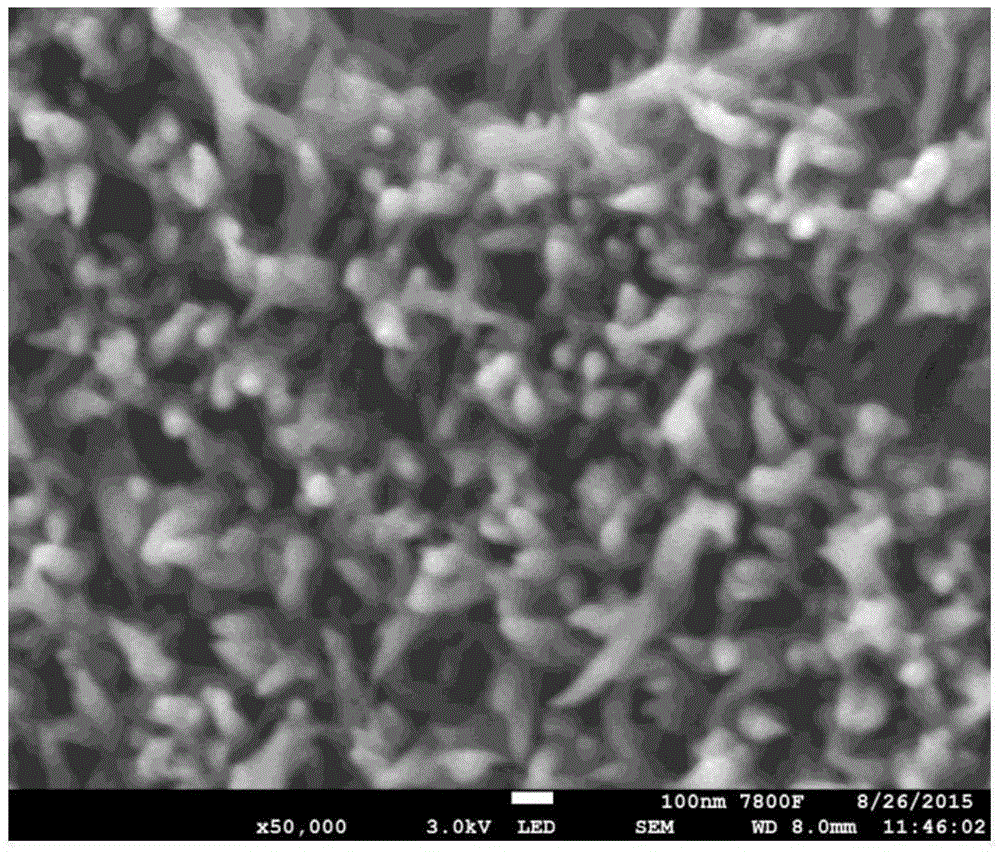

Methylbenzene gas sensor using chrome-doped nickel oxide nanostructures and method for producing same

ActiveUS20160025695A1Reduce cross sensitivityImprove responseNanostructure manufactureConductive materialSensor materialsNanostructure

Provided is a gas sensor comprising a gas-sensitive layer consisting of nickel oxide (NiO) doped with chrome (Cr) so as to selectively detect methylbenzene gas. The gas sensor, according to the present invention, has a gas-sensitive layer consisting of Cr-doped NiO. The gas sensor exhibits superior selectivity for methylbenzene gas when compared to other gases. The gas sensor can be easily and mass produced according to the production method of the present invention and is not affected by the microstructures of the material forming the gas-sensitive layer. The present invention relates to a gas sensor exhibits a negligible sensitivity of benzene, formaldehyde, and alcohol and exhibits significantly high selectivity and sensitivity of methylbenzene gas such as xylene and toluene when the NiO sensor material with a hierarchical structure favorable to gas dispersion and response is doped with Cr.

Owner:KOREA UNIV RES & BUSINESS FOUND

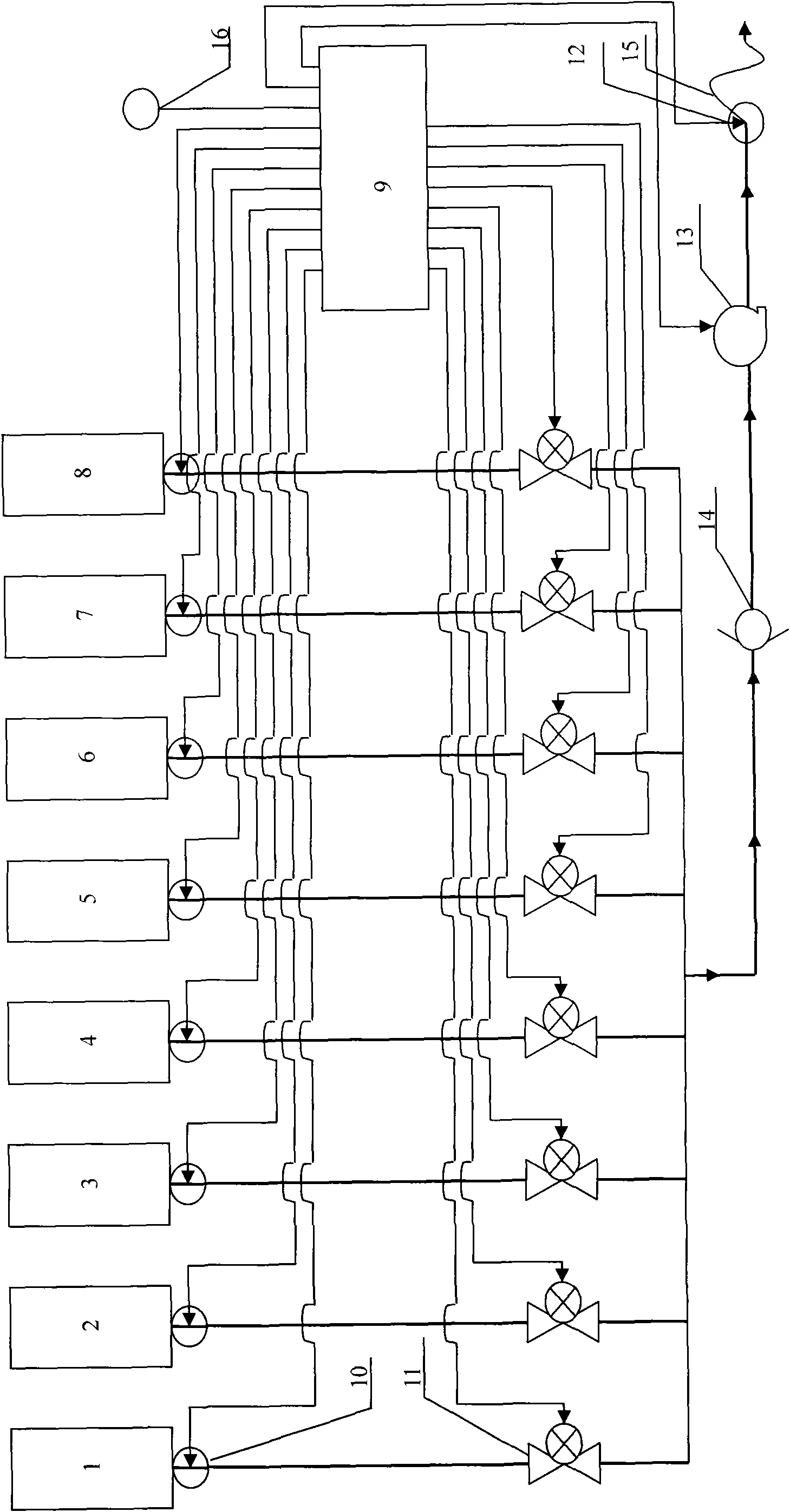

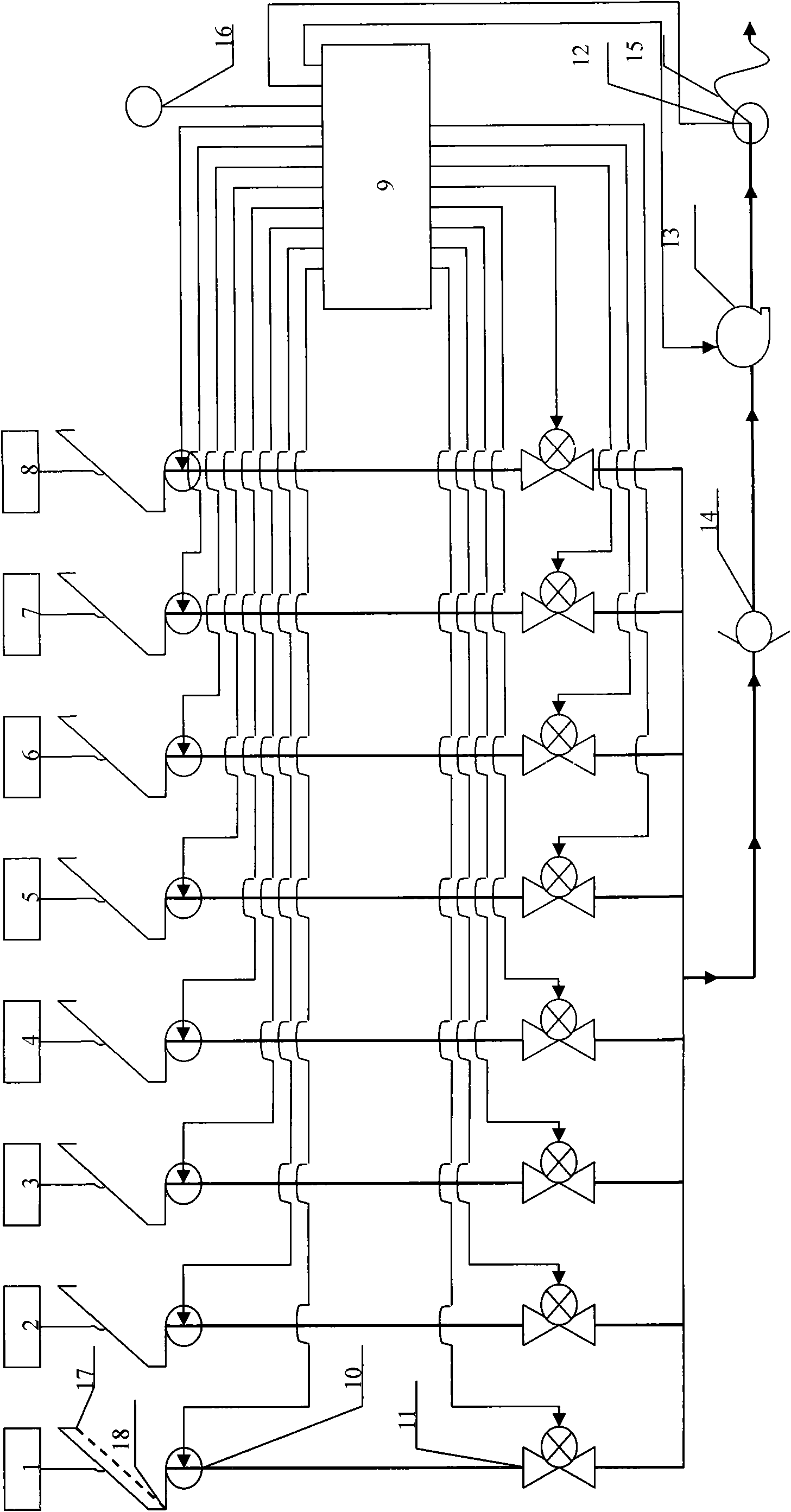

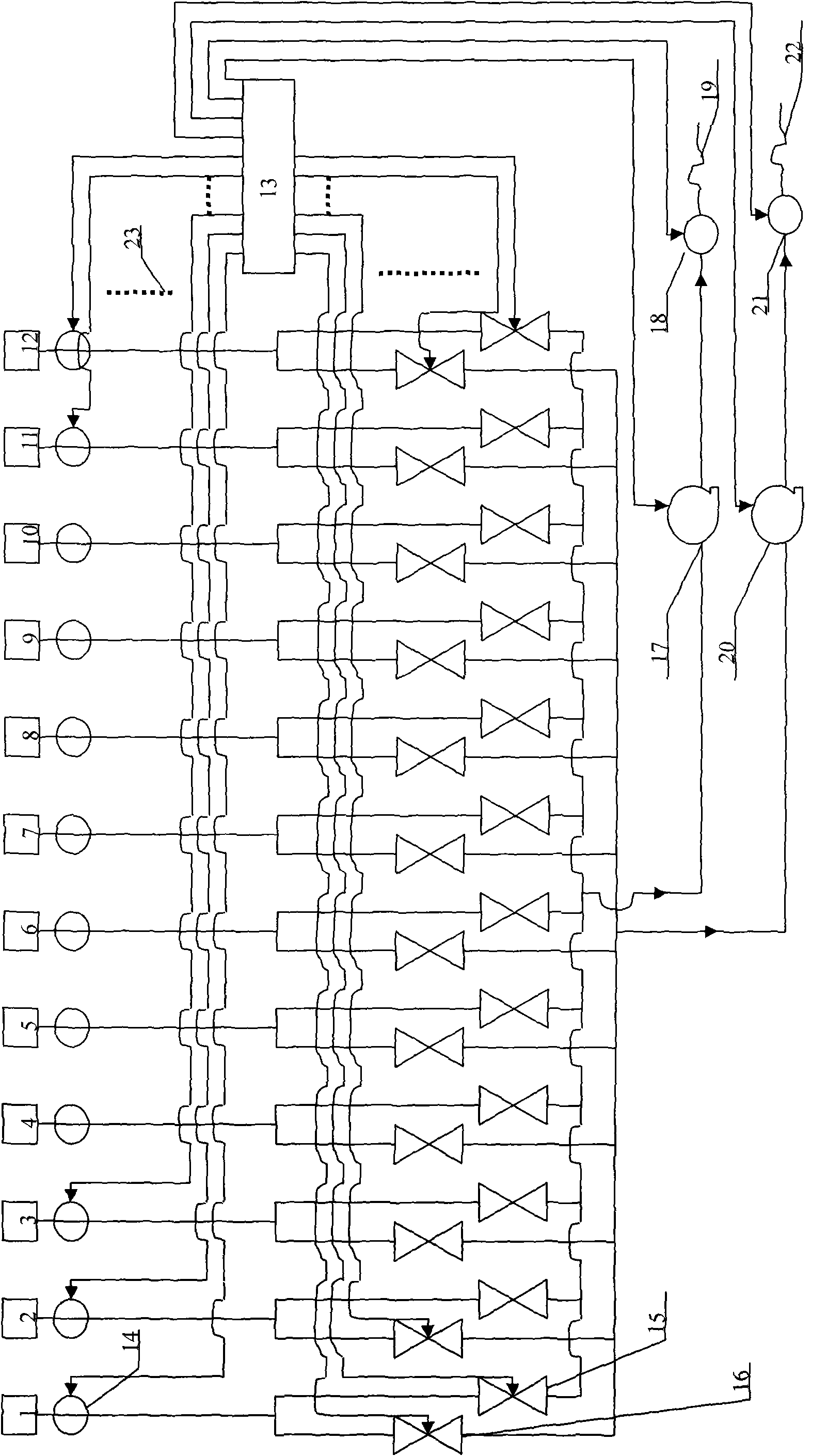

Gas dispenser and gas station composed of the same

ActiveCN101566277ASimple structureVersatileVessel mounting detailsFluid transferredGas cylinderMechanical wear

A gas dispenser is technically characterized in that a PLC firstly collects the pressure value of a pressure sensor in a gas dispersion gun, namely the pressure value in a vehicular gas cylinder. Then the pressure value is added with a preset value, wherein 0<the preset value <20. The summation is compared with the pressure value of each pressure sensor under a plurality of gas cylinder openings. The valve corresponding with the pressure value which is most approximative to and larger than the summation is opened for dispensing the gas through pressure difference. The steps are adopted again before balancing or after balancing. The steps are repeated until the value of the pressure sensor in the gas dispersion gun is the rated pressure value of the vehicular gas cylinder, wherein the rated pressure value is smaller than or equal to 20MPa. Then the valve is closed and the gas dispensation is finished. The gas station of the invention is composed of a plurality of gas cylinders and gas dispensers. The gas station is technically characterized in that the plurality of gas cylinders are used circularly for providing the high-pressure gas for satisfying the using amount of continuous gas dispensation of a single gun or a plurality of guns to the vehicular gas cylinder. The invention changes the technical route of prior gas substation. The matching of large-scale power devices of compressor and hydraulic pump is not required. The gas dispenser has no mechanical wear and extraordinarily low current consumption. The gas dispenser of the invention is the developing direction of the future.

Owner:沈军

Sewage treatment process by activated-sludge method comprising line atomizing treatment

InactiveUS20050258094A1Improve efficiencyIncrease ratingsTreatment using aerobic processesMixing methodsActivated sludgeWater treatment system

Disclosed is a waste water disposal process in the biosolid method according to a line atomizing treatment in which a reactive gas containing oxygen or oxygen and ozone as hardly soluble gases is dissolved / stored in water as being converted into ultrafine bubbles. The characteristic feature is that, by forming a gas-dispersion liquid in which the reactive gas containing oxygen or oxygen and ozone is dispersed in the form of ultrafine bubbles in returned biosolid water or in clean water at outside of the vessels (pools) of the waste water treatment system and by introducing the aforementioned gas-dispersion liquid into a reaction vessel (aerobic or anaerobic), oxygen is supplied to the microorganisms. Alternatively, the aforementioned gas-dispersion liquid is introduced into a vessel in the step preceding the reaction vessel or succeeding the reaction vessel. Further, the kind, concentration and volume of the reactive gas, the vessel (pool) for returning and the duration of introduction are set in accordance with the proceeding conditions of the waste water treatment and unitarily controlled.

Owner:RICH WHITNEY +3

Gas atomization toxicant exposure box

The invention relates to a gas atomization toxicant exposure box which is characterized by comprising a transparent box body, wherein the inner space of the box body is divided into a plurality of compartments by a spacing plate; a gas dispersion plate is arranged above the compartments, and breather holes are overspread on the gas dispersion plate; a box cover is arranged at the top of the box body; a gas inlet and a gas outlet are respectively arranged in the center position and the corner position of the box cover; the gas inlet is connected with an ultrasonic atomizer arranged outside the box body; a carbon dioxide sensor and an oxygen sensor are arranged in the box cover; the output ends of the carbon dioxide sensor and the oxygen sensor are connected with a signal amplification system; the output end of the signal amplification system is connected with a signal collector; the output end of the signal collector is connected with a computer; and a gas concentration monitoring module is prearranged in the computer. The invention has artful structural design and low cost, the prepared related animal models are scientific and reasonable and closer to the changes in human diseases, and the invention can be widely used in the preparation processes of various animal models.

Owner:BEIJING CHAOYANG HOSPITAL CAPITAL MEDICAL UNIV

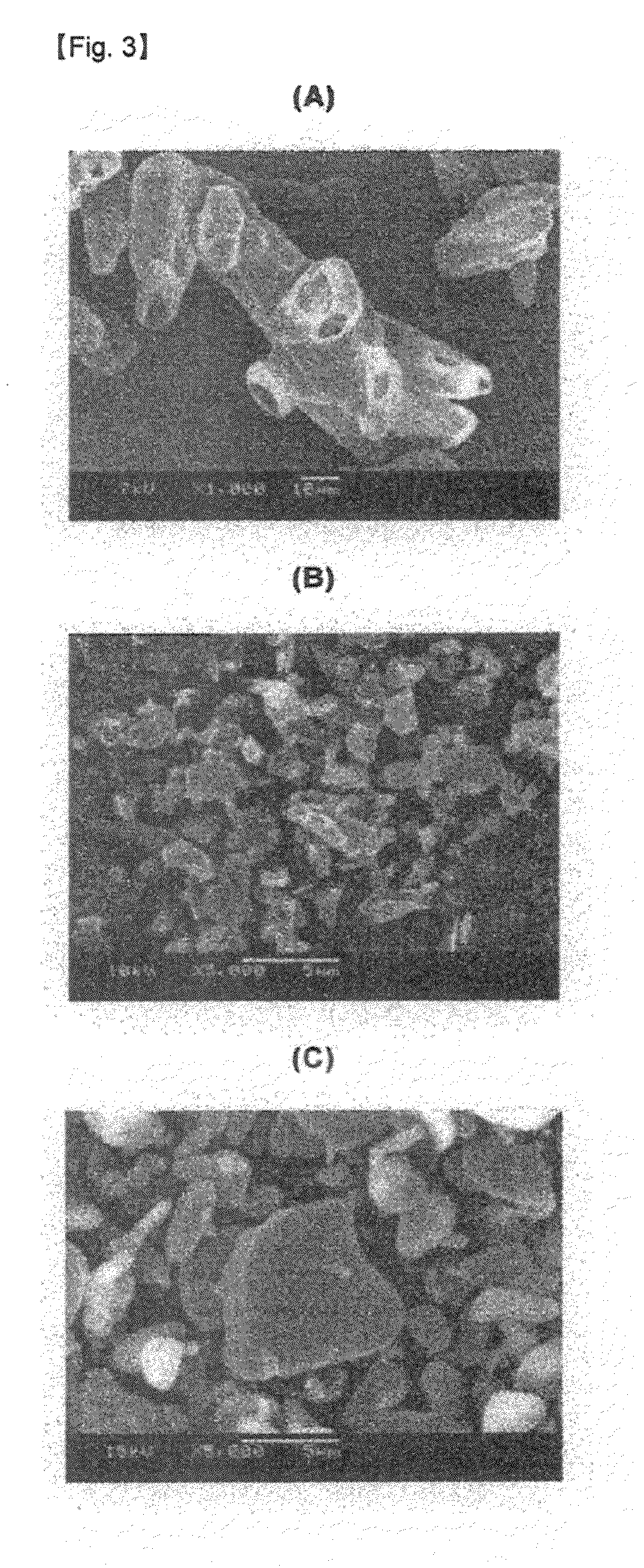

Method for producing fine powder and the fine powder produced by the same

ActiveUS20120289559A1Inhibit aggregationImprove distinguishabilityBiocideCarbon compoundsMetallurgyDry ice

Disclosed is a manufacturing method for a fine powder exhibiting improved solubility, little impurity contamination, and a high recovery rate. Material to be ground and a grinding medium are suspended and stirred in a liquefied inert gas dispersion medium such as dried ice, and the material to be ground is made into a sub-micron or nano-sized fine powder. A uniform fine powder can be obtained when the material to be ground is a mixture having two or more components. Impurity contamination can be reduced by using granular dry ice as the grinding medium.

Owner:MORIROKU CHEM

Fuel cell membrane electrode using polymer superbhort fiber as hydrophobic agent and its preparing method

InactiveCN101071874AImprove drainageWell Reactive Gas Diffusion ChannelsCell electrodesFuel cell detailsFiberPolymer electrolytes

A fuel cell membrane electrode using polymer ultra-short fiber as water repellent and it's the preparation method, in which the catalyst layer is dopped with polymer ultra-short fiber. The preparation method is that: coat the catalyst pulp containing load-type catalyst, solid polymer electrolyte, polymer ultra short fiber and the solvent on to gas diffusion layer surface to get a gas diffusion layer electrode, hot press this electrode and the proton exchange membrane to prepare the membrane electrode; Or transfer solidified catalyst onto two sides of the proton exchange membrane to prepare the catalyst / membrane central assembly. Advantages : raised water discharge function comparing with grain-like polymer water repellent, having good reaction gas dispersion path, raised structure and catalyst size stability and simple preparation process of membrane electrode.

Owner:WUHAN UNIV OF TECH

Method for preventing plate type heat exchanger from blockage

InactiveUS6848501B2Avoid heat exchangeAvoid cloggingProcess control/regulationCorrosion preventionMeth-Gas passing

In an apparatus provided with a plate type heat exchanger as a heater and / or a cooler and operated to treat a gas containing an easily blocking substance, a method for preventing the plate type heat exchanger from being blocked is disclosed which is characterized by i) setting the width of a flow path on a plate of the plate type heat exchanger in the apparatus in a range of 6-25 mm and ii) setting the average flow rate of the gas passing the plate type heat exchanger in the apparatus per unit cross-sectional area of the flow path on the plate in the range of 3-15 m / s. In the exchange of heat of an easily blocking substance by the use of a plate type heat exchanger, a method for preventing the plate type heat exchanger from blockage is disclosed which has the plate type heat exchanger provided in the port for introducing a gas containing an easily blocking substance with a gas dispersion plate. This invention, in the heat exchange of an effluent gas emanating from a process for the production of (meth)acrylic acid or an ester thereof or the disposal of the gas, significantly allays blockage of the interior of the plate type heat exchanger.

Owner:NIPPON SHOKUBAI CO LTD

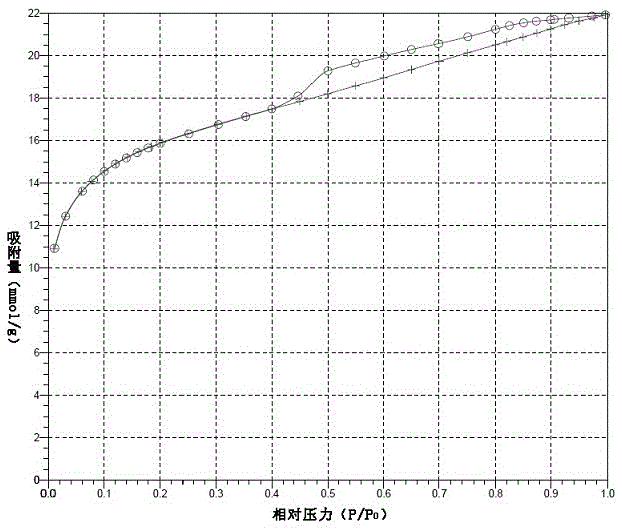

Catalyst for ethyne hydrochlorination for synthesis of chloroethylene and preparation method thereof

ActiveCN105521801AHigh activityLess side effectsPreparation by halogen halide additionMetal/metal-oxides/metal-hydroxide catalystsDispersitySorbent

The invention discloses a catalyst for ethyne hydrochlorination for synthesis of chloroethylene and a preparation method thereof. The catalyst of the invention is prepared by impregnation of an active carbon carrier, metallic compound active components and a hydroxyl-containing water-soluble carboxylic acid competitive adsorbent. The active components contain at least one component selected from chloride, nitrate, sulfate or phosphate of cobalt, copper, manganese, zinc, bismuth, barium and potassium. The competitive adsorbent contains citric acid, malic acid, salicylic acid, oxalic acid, tartaric acid and lactic acid. The prepared catalyst has characteristics of high activity, good selectivity, simple production method and low cost. By adding the hydroxyl-containing water-soluble carboxylic acid competitive adsorbent, the active components are greatly fixed to the carrier, and high temperature transfer of the active components is reduced; by roasting decomposition of the competitive adsorbent, rich pore structures are generated, and gas dispersion in the reaction process is improved; and dispersity of the active components is improved, catalyst poisoning is alleviated, and life of the catalyst is prolonged.

Owner:XINJIANG CORPS MODERN GREEN CHLOR ALKALI CHEM ENG RES CENT LTD

Method for preparing porous silicon-based one-dimensional nanowire gas sensitive element

InactiveCN103245696AHigh responseImprove responseMaterial nanotechnologyVacuum evaporation coatingGas dispersionSilicon based

The invention discloses a method for a preparing porous silicon-based one-dimensional nanowire gas sensitive element, wherein a silicon-based porous silicon composite one-dimensional tungsten oxide nano-structure which has the bore diameter in the range from 1 to 2 microns and also has highly orderly arranged ducts is taken as a gas sensitive element for the first time; due to huge specific surface area and high surface activity, lots of gas absorption positions and gas dispersion channels can be provided so that the gas sensitive element is easy to react with gas. The gas sensitive sensor element provided by the invention has high response value and good sensitivity and selectivity for low-concentration oxynitride gas at a low temperature (100 DEG C), and further is small in size, simple in structure, mature in fabrication process, convenient to use and low in price; as a result, the gas sensitive sensor element is expected to be popularized and applied to the field of the gas sensitive sensor.

Owner:TIANJIN UNIV

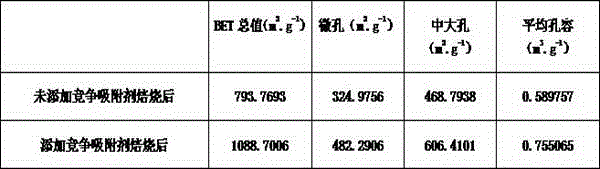

Preparation method for ozone catalytic oxidation catalyst and device using catalyst

ActiveCN102091619ASolve the friction shedding problemSolution flows to a singleMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationCatalytic oxidationFixed bed

The invention discloses a preparation method for an ozone catalytic oxidation catalyst and a device using the catalyst. The preparation method comprises the processes of adsorbing and precipitating an active component by active carbon and drying, washing and roasting; the active carbon adopts an adsorption-precipitation method on the active component; and saturated ferric chloride and manganous nitrate active components and a solution formed by compounding the saturated ferric chloride and manganous nitrate active components are adsorbed by pore channels inside the active carbon, and a proper amount of alkali is added to form hydroxide sediments. The method overcomes the defect of releasing a great quantity of nitric oxide pollutants into environment in the roasting process by a chloride or nitrate soaking method and prevents the condition that the active component is just deposited on the surface of the active carbon in the traditional one-step precipitating method; and an air chamber of the device using the catalyst separately carries out gas inlet and water discharge, and the invention follows the advantages of a reverse-flow type fixed bed, improves the utilization ratio of catalyst on the basis of ensuring gas-liquid-solid efficient mass transfer, has uniform gas dispersion and realizes the industrialized application of an ozone catalytic oxidation treatment technology.

Owner:GUANGDONG UNIV OF TECH +1

Chemical precursor ampoule for vapor deposition processes

Owner:APPLIED MATERIALS INC

Gas dispersion nozzle for a fire arm silencer

A gas dispersion nozzle for a gun silencer having a nozzle portion with a front end and a rear end and walls enclosing a hollow interior therein. The rear end of the nozzle portion is attached to the gun silencer and the nozzle portion extends into the interior of the gun silencer. The rear end also attaches to a firearm. The walls have channels which direct flow of propellant gases out of the hollow interior and into the interior of the gun silencer at an angle to a path along which the projectile passes when the firearm is discharged. The channels cause the flow of propellant gases to become turbulent or rotational or both and can cause the flow rate of said propellant gases to decrease. The gas dispersion nozzle reduces the report and / or flash produced by the discharge of a firearm.

Owner:WHITE MARK

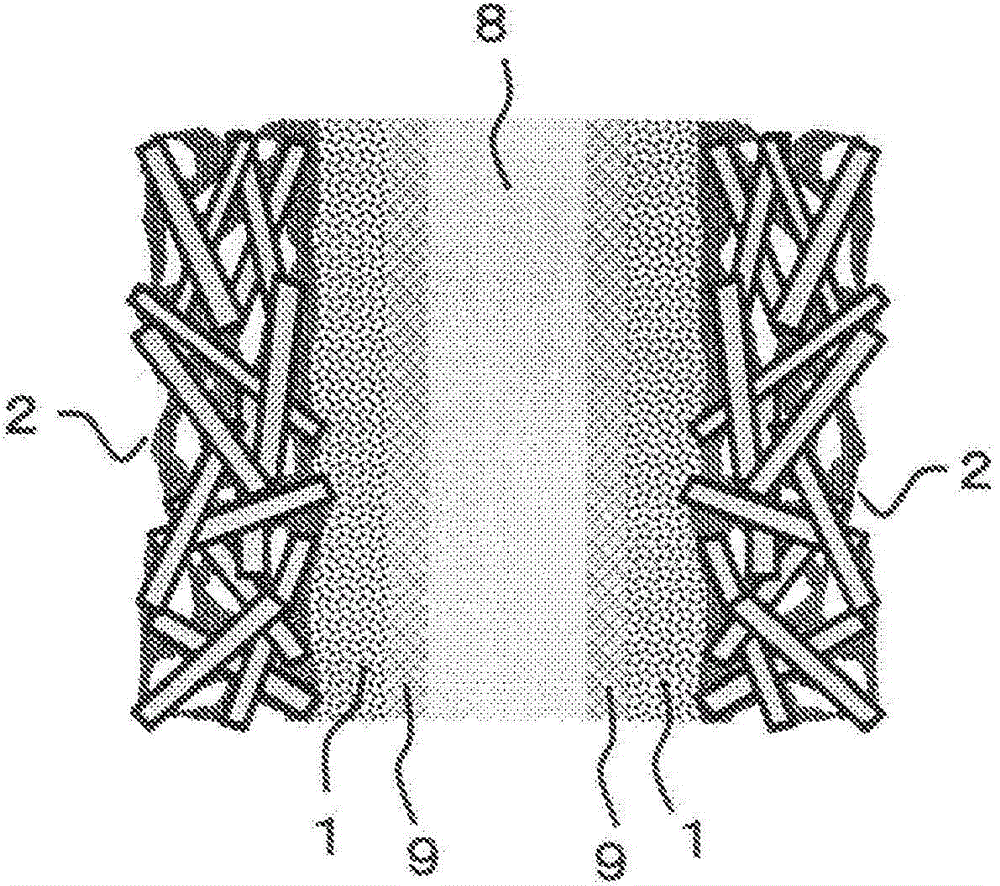

Ordered membrane electrode and preparation and application thereof

ActiveCN106887598AEnhanced mass transferReduce loadMaterial nanotechnologyFinal product manufactureElectrical conductorProton

The invention discloses an ordered membrane electrode. The ordered membrane electrode comprises an ordered array carrier and a catalyst nanoparticle layer which is microscopically attached to the surface of the ordered array carrier, wherein the ordered array carrier vertically grows on the surface of a gas dispersion layer in situ or vertically grows on the surface of a metal layer attached to the surface of an electrolyte membrane in situ; the ordered array carrier is constructed by a conductive high-molecular polymer, or is constructed by a mixture of a conductive high-molecular polymer and an ionic conductor; the ordered array carrier microscopically has a conical structure or a stick-shaped structure. An ordered electrode catalyst layer is prepared by the following steps: (1) preparing an ordered array carrier; (2) preparing a catalyst nanoparticle layer through a magnetron sputtering method. Compared with the prior art, the membrane electrode has the advantages that an ordered conductive array is prepared on the gas dispersion layer or an electrolyte membrane, thereby contributing to mass transfer of gas, protons and electrons; a nano-thickness catalyst layer formed by the magnetron sputtering method has a small carrying amount and a high catalyst utilization rate; the ordered membrane electrode is simple and controllable in a preparation process, is easy to amplify, and is suitable for batch production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

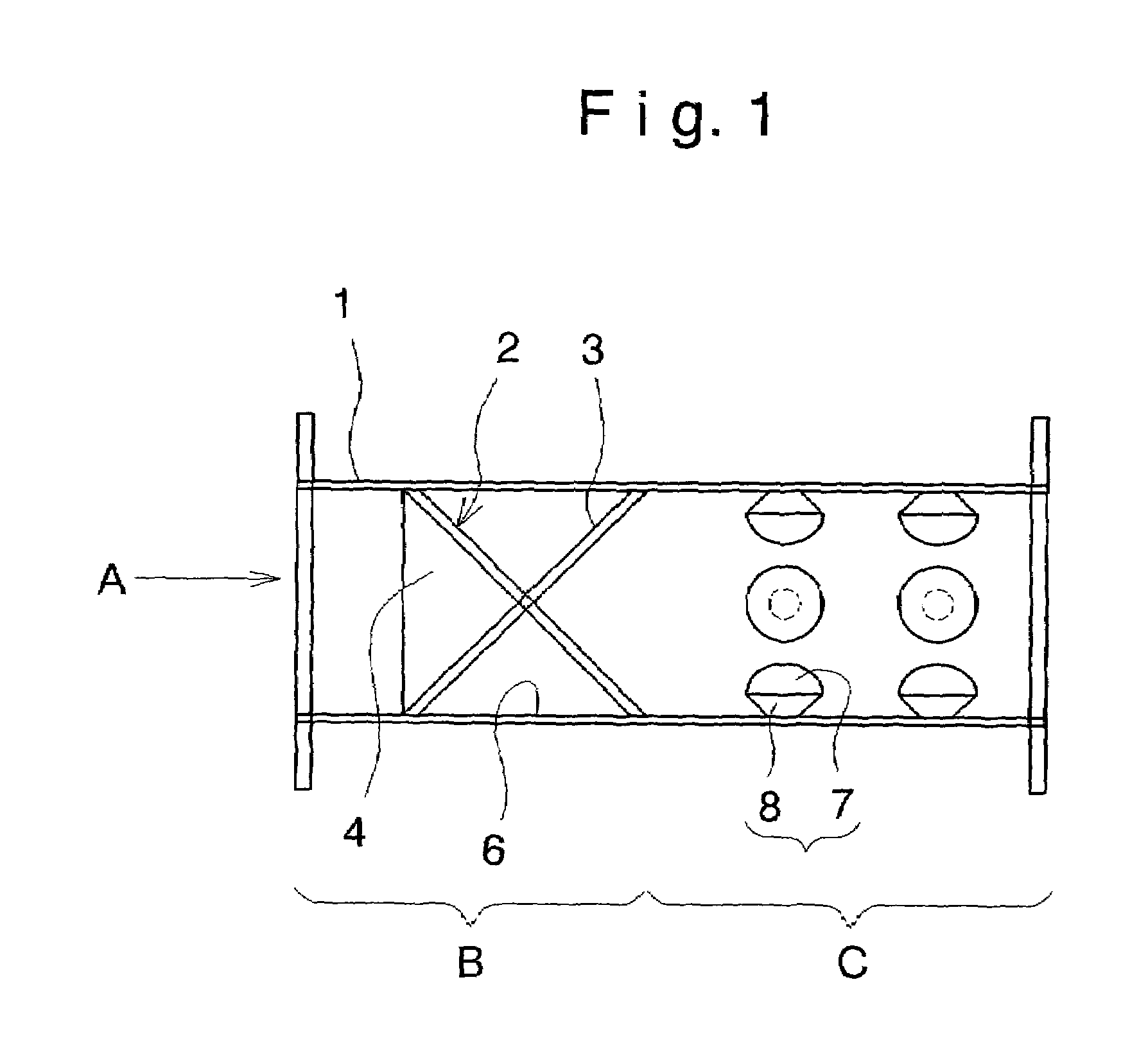

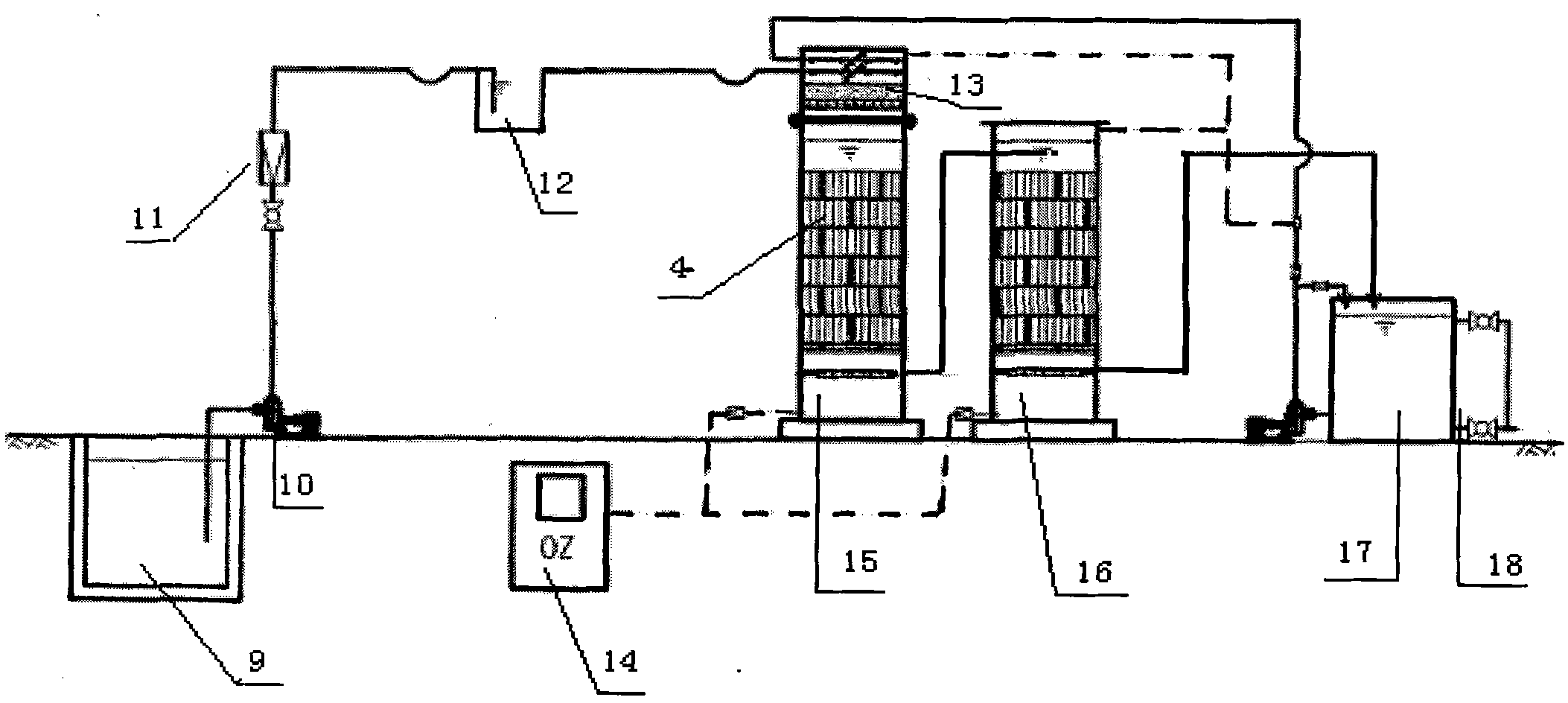

Enclosed switchboard

ActiveCN106030943ASwitchgear arrangementsSubstation/switching arrangement casingsCircuit breakerGas dispersion

The present invention discloses an enclosed switchboard (1) in which the inside of a housing (2) is partitioned into a plurality of compartments (a breaker compartment (3), a bus compartment (4), and a cable compartment (5)). A chamber (8) for alleviating arc-gas dispersion / pressure discharge is arranged above the breaker compartment (3), the bus compartment (4), and the cable compartment (5); and exhaust ducts (9, 10, 11) each of which communicates with the chamber (8) for alleviating arc-gas dispersion / pressure discharge are provided in ceiling sections of the breaker compartment (3), the bus compartment (4), and the cable compartment (5). Flappers (12, 13, 14) are provided in the upper-end sections of the exhaust ducts (9, 10, 11), and a pressure-alleviation shield tank (15) is provided in an opening section (8a) formed in the upper section of the chamber (8) for alleviating arc-gas dispersion / pressure discharge. Ventilation sections (12a, 13a, 14a) for providing communication between the exhaust ducts (9, 10, 11) and the chamber (8) for alleviating arc-gas dispersion / pressure discharge are formed on a primary surface of the flappers (12, 13, 14), and mesh members (12b, 13b, 14b) are provided in the ventilation sections (12a, 13a, 14a).

Owner:MEIDENSHA ELECTRIC MFG CO LTD

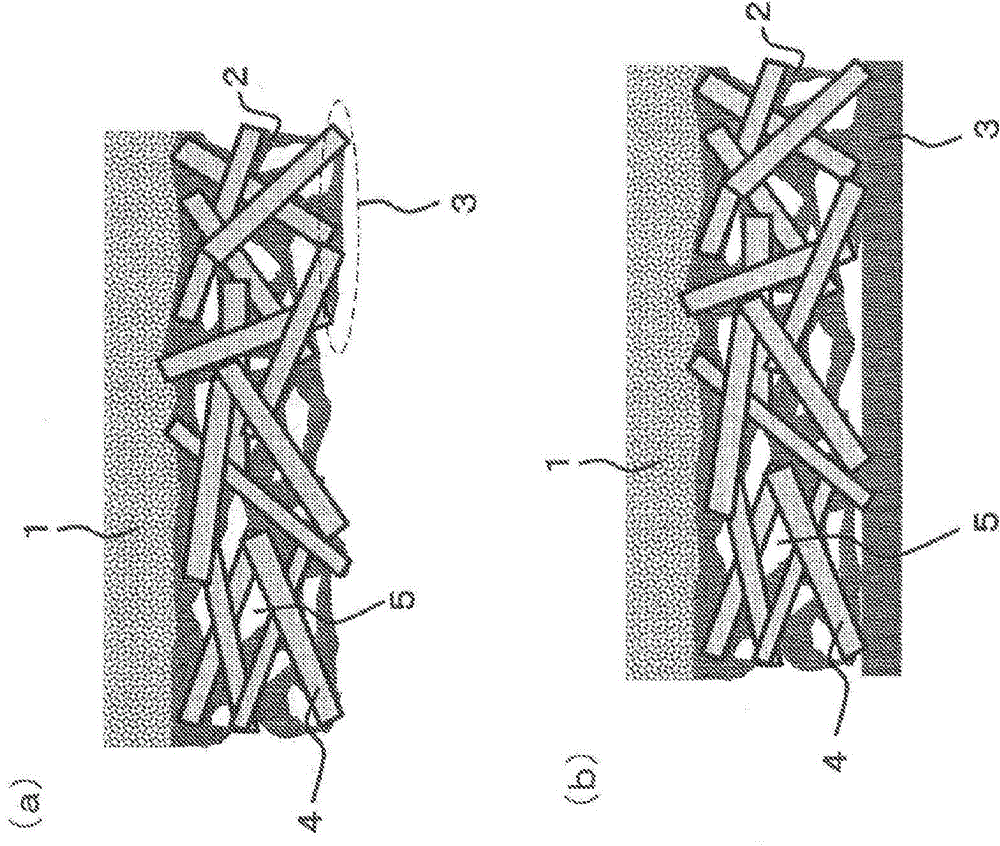

Fuel-cell gas dispersion layer, and method for producing same

ActiveCN104981929ASuppress short circuitImprove smoothnessCell electrodesSolid electrolyte fuel cellsFiberCarbon fibers

A fuel-cell gas dispersion layer configured from a porous carbon fiber substrate obtained by binding discontinuous carbon fibers using a carbide, and a porous layer containing at least carbonaceous particles, wherein: a porous layer (A) is disposed on one surface (A) of the porous carbon fiber substrate so as to have an average thickness (t1) of 10-55μm; a porous layer (J) is inserted into the interior of the porous carbon fiber substrate in a manner such that at least a portion thereof is present on the opposite surface (B); the proportion of the cross-sectional area in the thickness direction of openings in the interior of the porous carbon fiber substrate is 5-40%; the proportion of openings in the porous layer (A) and / or the porous layer (J) is 50-85%; the thickness of the porous carbon fiber substrate is 60-300μm; and the bulk density of the porous carbon fiber substrate is 0.20-0.45g / cm3.

Owner:TORAY IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com