Mixer

A technology of mixer and mixing section, which is applied in the direction of machines/engines, noise reduction devices, engine components, etc., and can solve problems such as unfavorable mixing of exhaust gas and urea solution, large exhaust resistance, and poor noise reduction ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The core of this specific embodiment is to provide a mixer, which can optimize the post-processing mixer and achieve good acoustic performance, which solves the current problems in this field.

[0032] Hereinafter, an embodiment will be described with reference to the drawings. In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solution of the invention described in the claims.

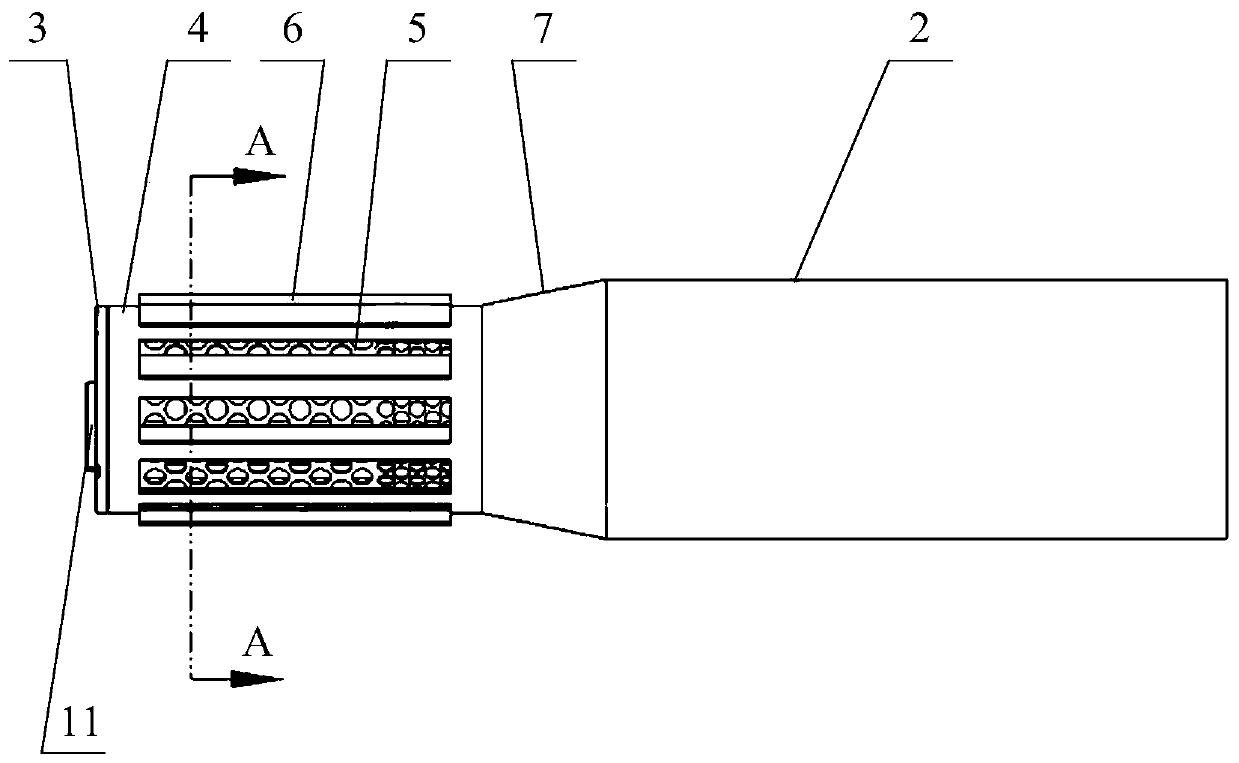

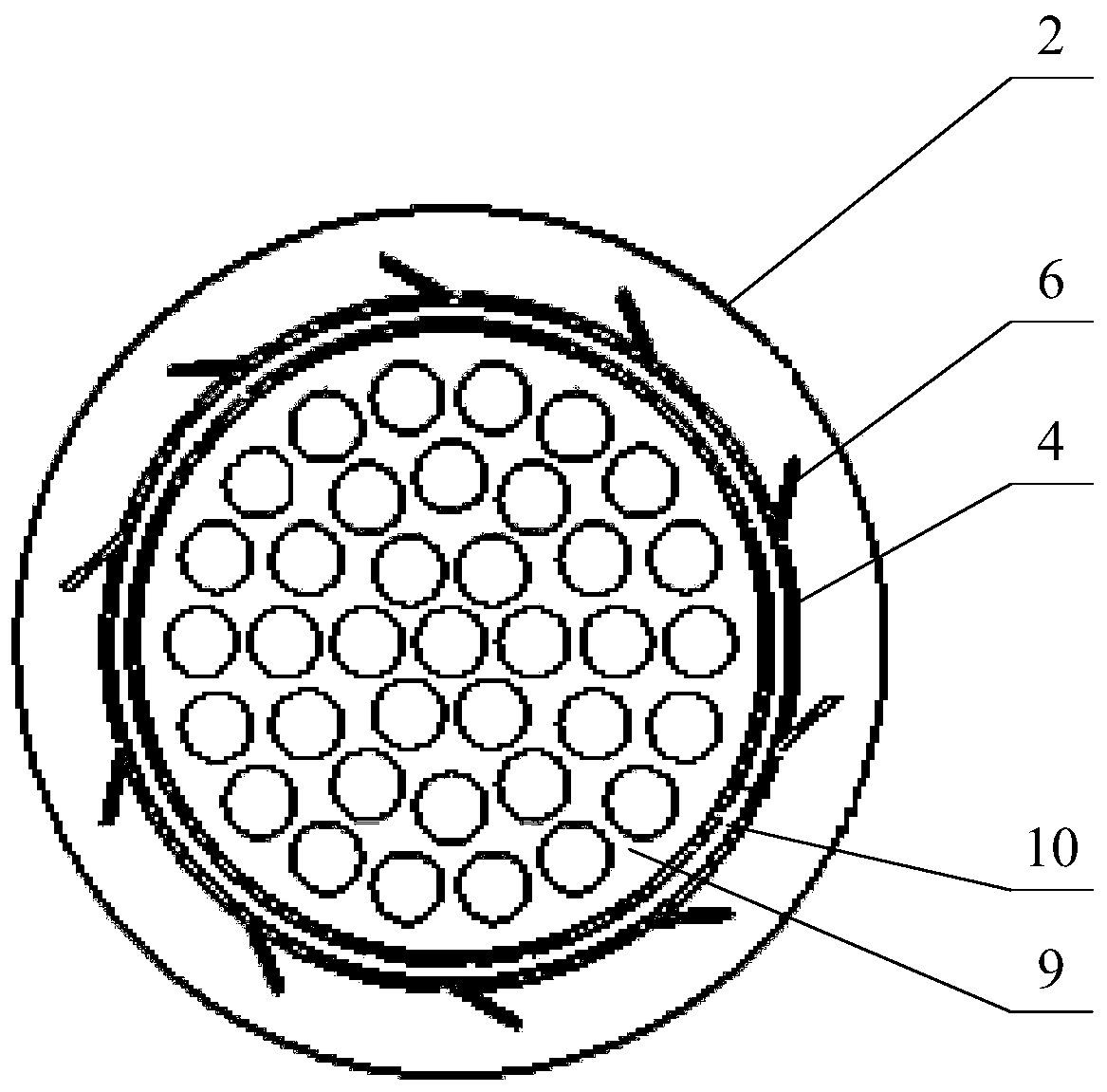

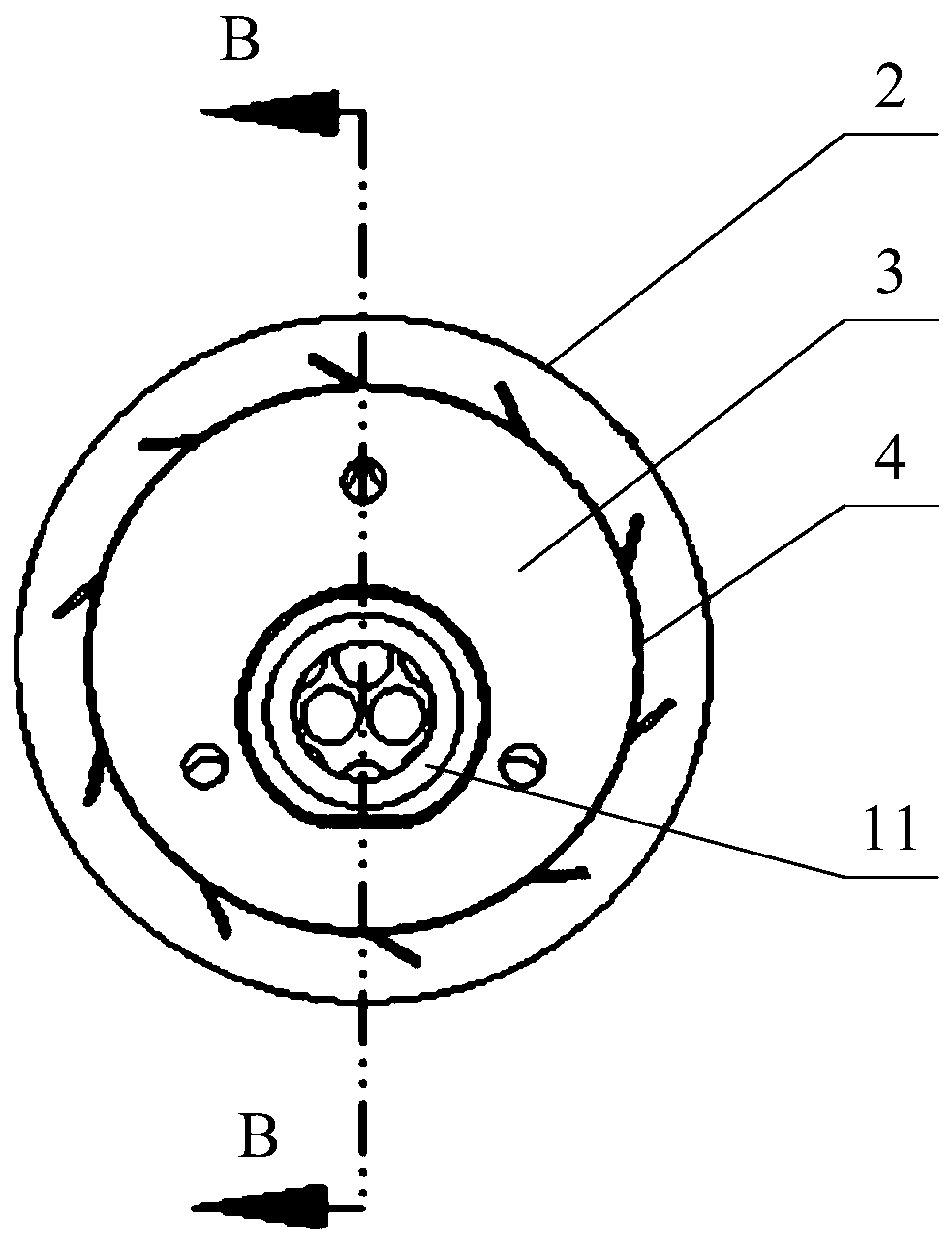

[0033] For the mixer provided in this specific embodiment, please refer to Figure 1-5 ; Including mixing section 1 and expansion section 2; wherein, one end of mixing section 1 is provided with urea nozzle base 3 for mixing exhaust gas and urea entering the mixer; the pipe diameter of expansion section 2 is larger than the pipe diameter of mixing section 1, expanding One end of the section 2 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com