Dehumidification method for main cable of suspension bridge

A suspension bridge and main cable technology, applied in the direction of suspension bridges, bridges, bridge forms, etc., can solve the problems of large gas flow resistance, narrow wire gap, and high cost, and achieve the effect of reducing resistance, reducing electricity costs, and simplifying the dehumidification system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

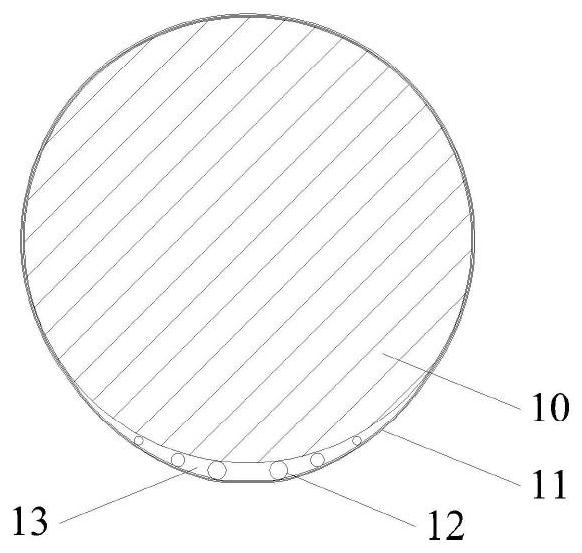

[0044] What is shown in this embodiment is that the main cable has a cavity at the bottom, and there is a connecting pipe connecting two adjacent cavities across the cable clamp to form a bottom airflow channel. see figure 1 — Figure 7 ,and Figure 14 .figure 1 The cross-sectional schematic diagram of the main cable, the steel wire bundle 10 of the main cable is wound with round steel wires on the surface after the cable is tightened. The transparent stainless steel pipe 12 forms a supporting member, which clings to the steel wire at the bottom of the steel wire bundle 10 , and then wraps the wrapping tape 11 to form a cavity 13 at the bottom. The schematic diagram of transparent stainless steel pipe 12 is shown in Figure 5 , there are holes 15 on the pipe wall, the diameter of the holes 15 is equal to the radius of the transparent stainless steel pipe 12, the longitudinal spacing of the holes 15 is the diameter of the transparent stainless steel pipe 12, these holes 15 a...

Embodiment 2

[0048] This embodiment is a modification of Embodiment 1, the connecting pipe 14 is removed, and the installation work and maintenance work of the connecting pipe 14 are avoided. See Figure 8 and Figure 9 . The schematic diagram of the left end face of the cable clamp is shown in Figure 8 , in order to ensure that the bottom cavities 13 on both sides of the cable clamp are connected, a longitudinal through hole 19 is added in the cable clamp. See Figure 9 , The appearance of the main cable is simple, the airflow channel at the bottom is smoother, and the resistance is smaller.

Embodiment 3

[0050] This embodiment is a kind of improved form of embodiment 2, and the top of main cable has increased cavity, see Figure 10 A cross-sectional schematic diagram of the main cable, the main cable has a bottom cavity 13 and a top cavity 20, and the top cavity 20 has a cavity support member composed of transparent stainless steel pipes 12. Figure 11 It is a schematic diagram of the left end face of the cable clamp, considering that the end slot 8 in the conventional cable clamp has no practical value in this program and has been cancelled. Figure 12 It is a schematic diagram of the connection between the two ends of the cable clamp and the wrapping belt 11. For the convenience of the top cavity 20 to form the top air flow channel, the cavity at the two ends of the cable clamp is communicated with the connecting pipe 14. There is an air valve 28 at the farthest end of the top air flow passage from the corresponding blower, see Figure 16 ; During the day, after the humidit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com