High temperature air heater

A high-temperature air and heater technology, used in air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of shortening the service life of heaters, increasing the temperature of electric heating elements, and inability to air heating, and achieve temperature control. Convenience, small resistance to air circulation, prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

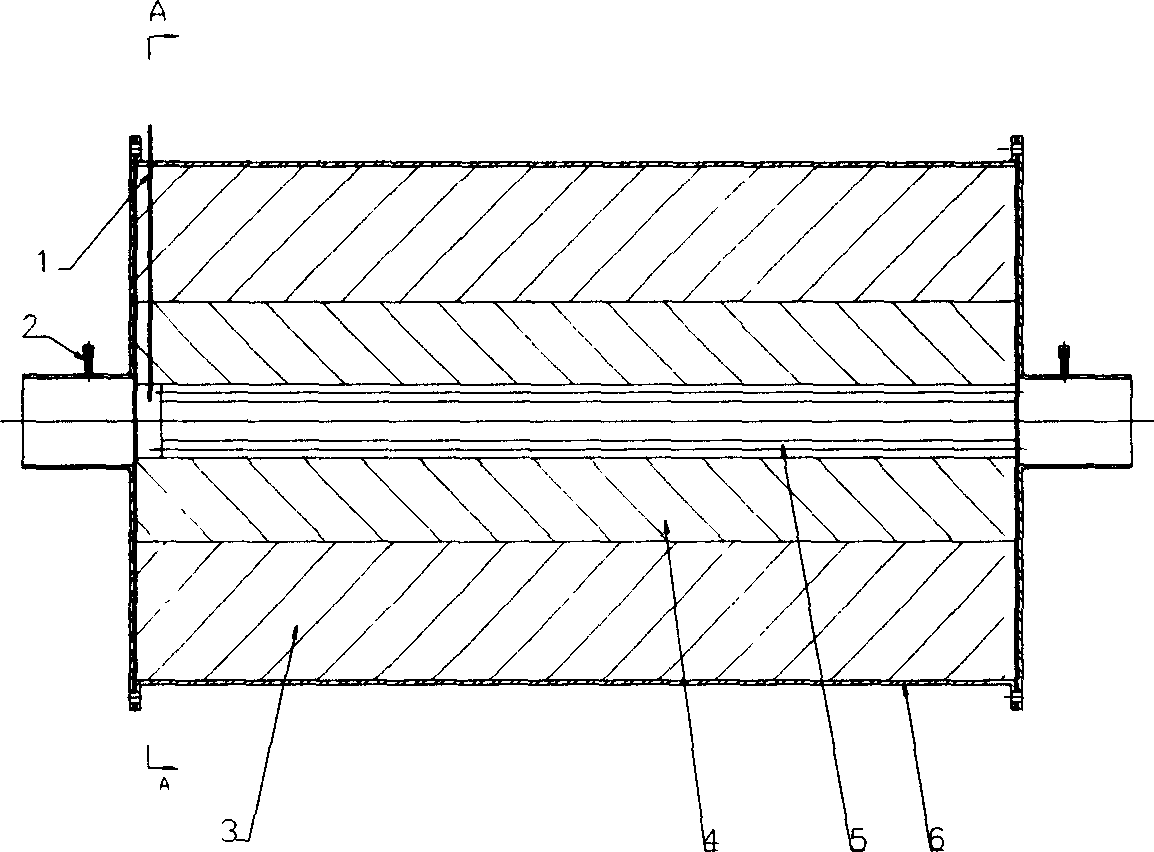

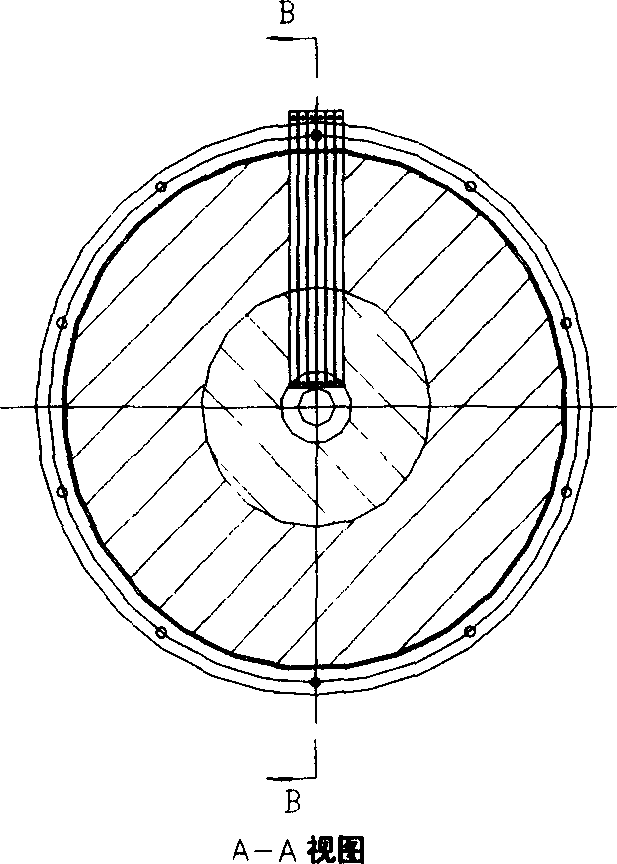

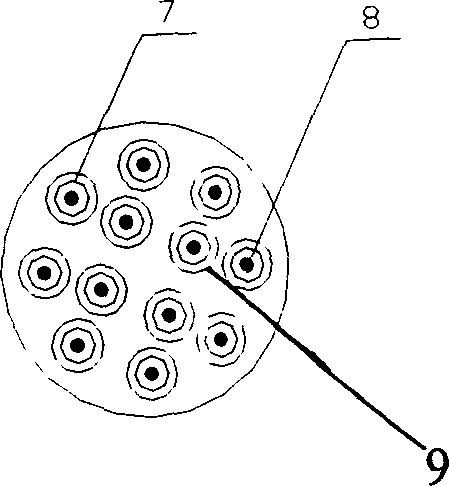

[0015] 20Nm 3 The air in / h is heated from 20°C to 1000°C as an example, the diameter of the lotus root-shaped ceramic body 5 is 70-85mm, and there are 12 inner through-holes 9, which are evenly distributed, and each through-hole diameter is 8-12mm. The total length of the lotus root-shaped ceramic body is 850-1100 mm. 12 thin ceramic rods with a diameter of 5-7 mm are wound with heating wires with a diameter of 0.8-1.2 mm, and placed in the through hole of the lotus root-shaped ceramic body. Each heating wire passes through one end of the lotus root-shaped ceramic body into the through hole, and passes back through another through hole at the other end, forming a U-shaped loop. The rated power of each heating wire is 2kW, and there are six in total. Two kinds of thermal insulation material layers 3 and 4 are arranged outside the lotus root shape ceramic body 5, to improve thermal insulation effect. The required high-temperature air heater is obtained after being packaged b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com