Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Good dimensional stability at high temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

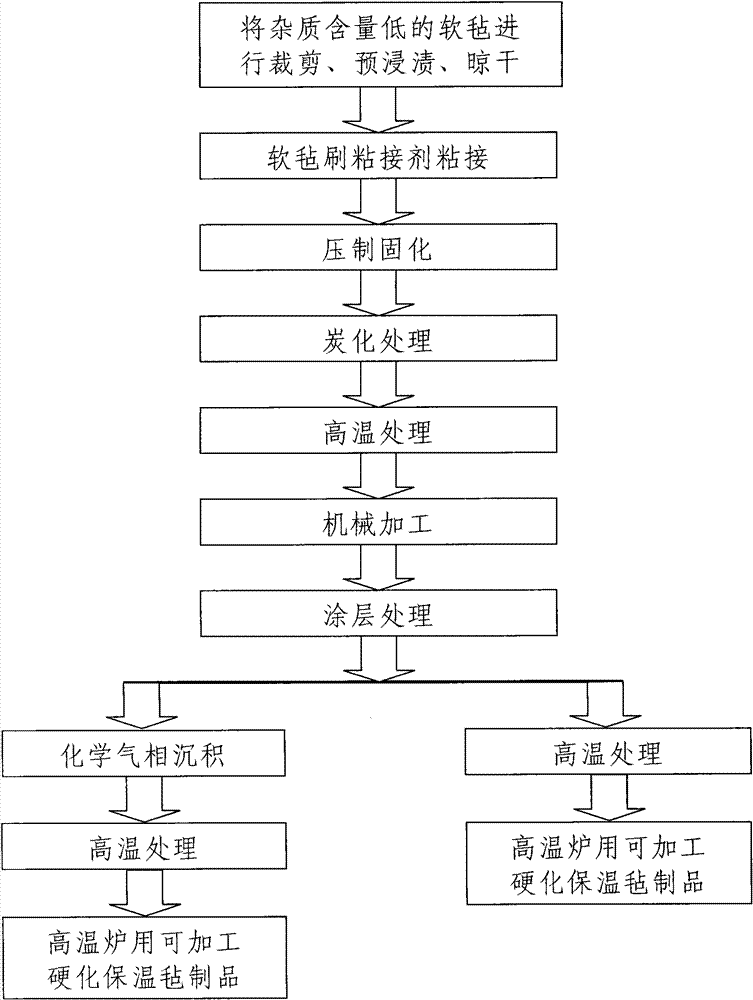

Method for preparing work hardening insulation quilt for high temperature furnace

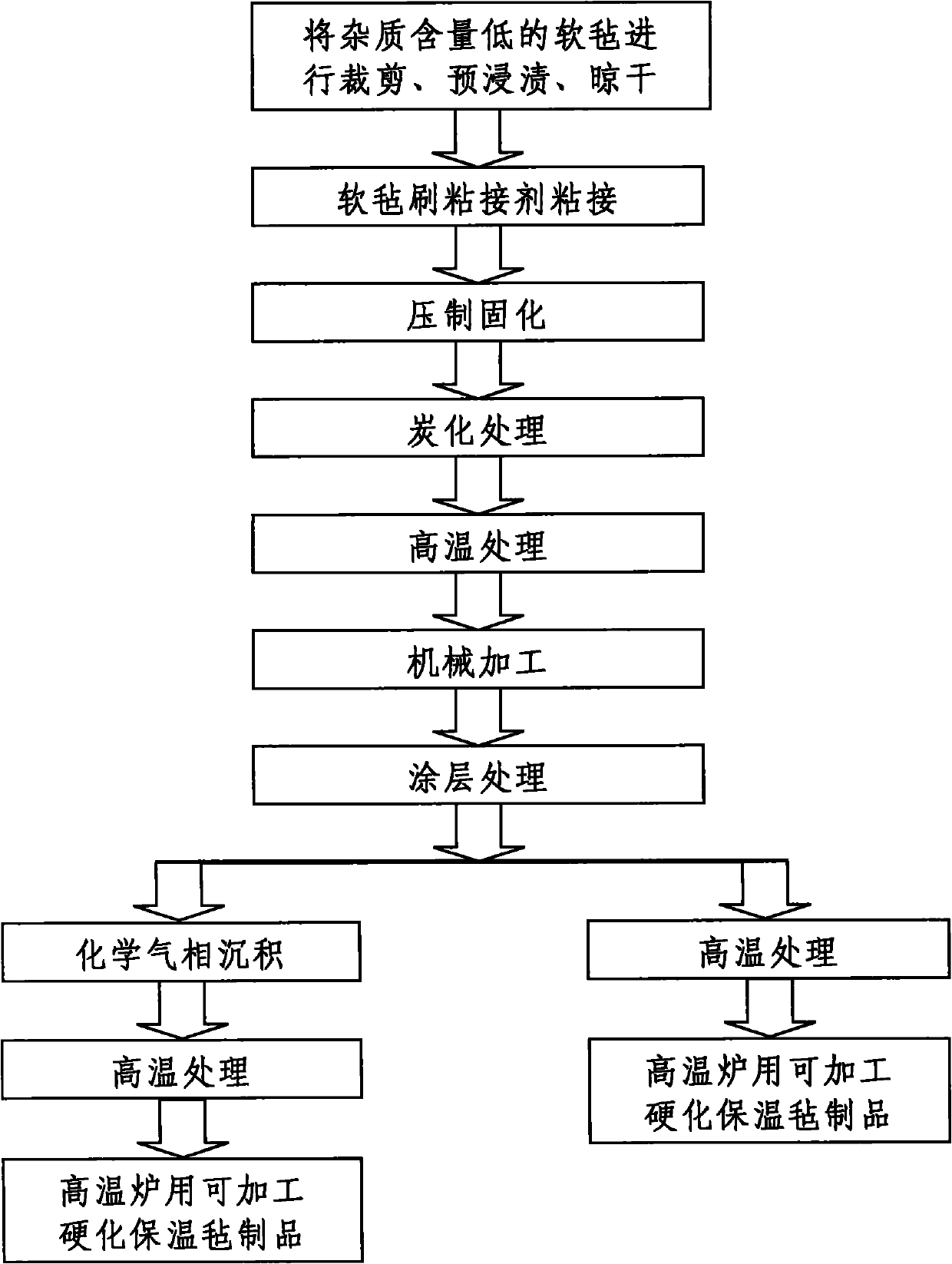

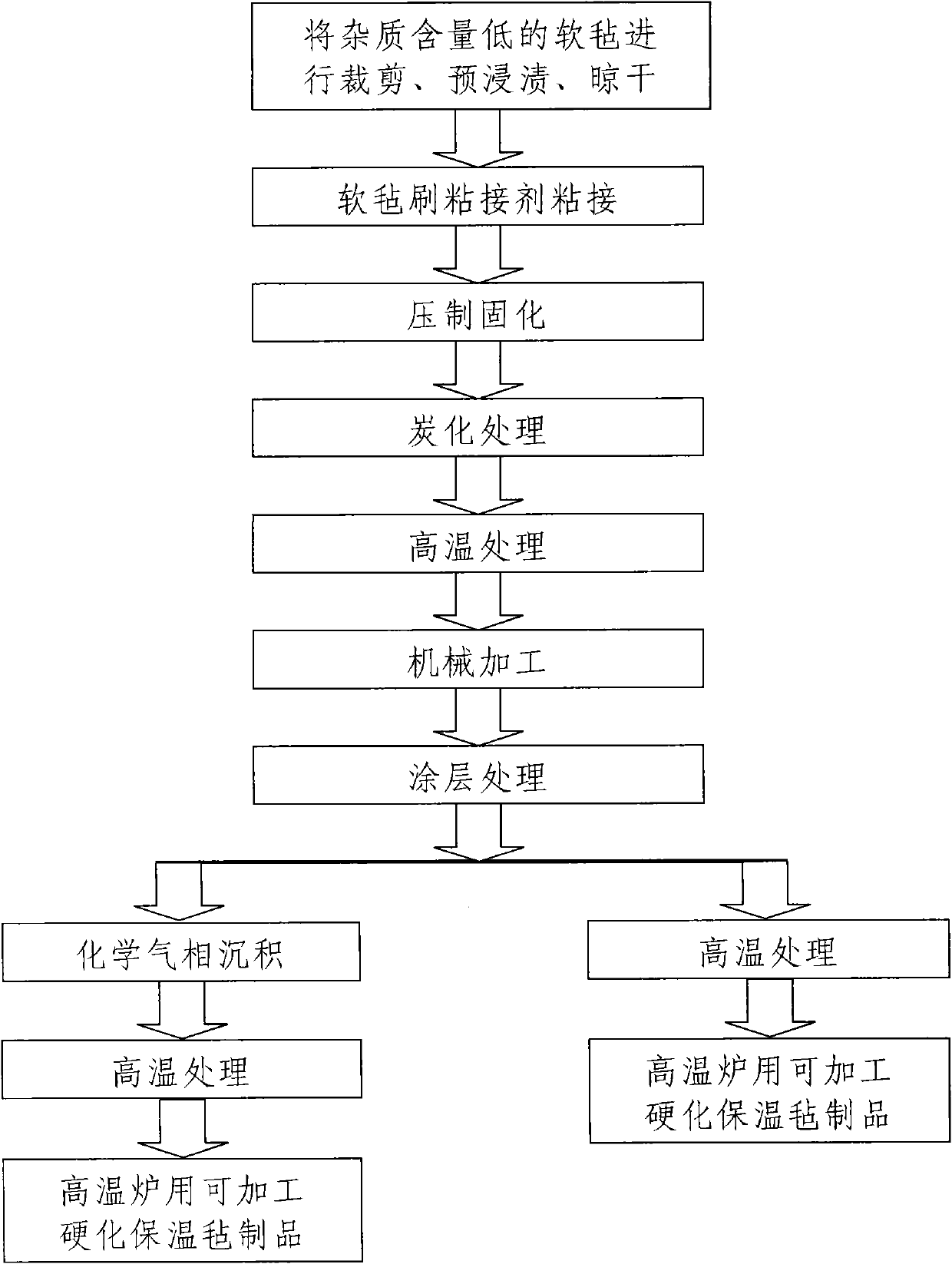

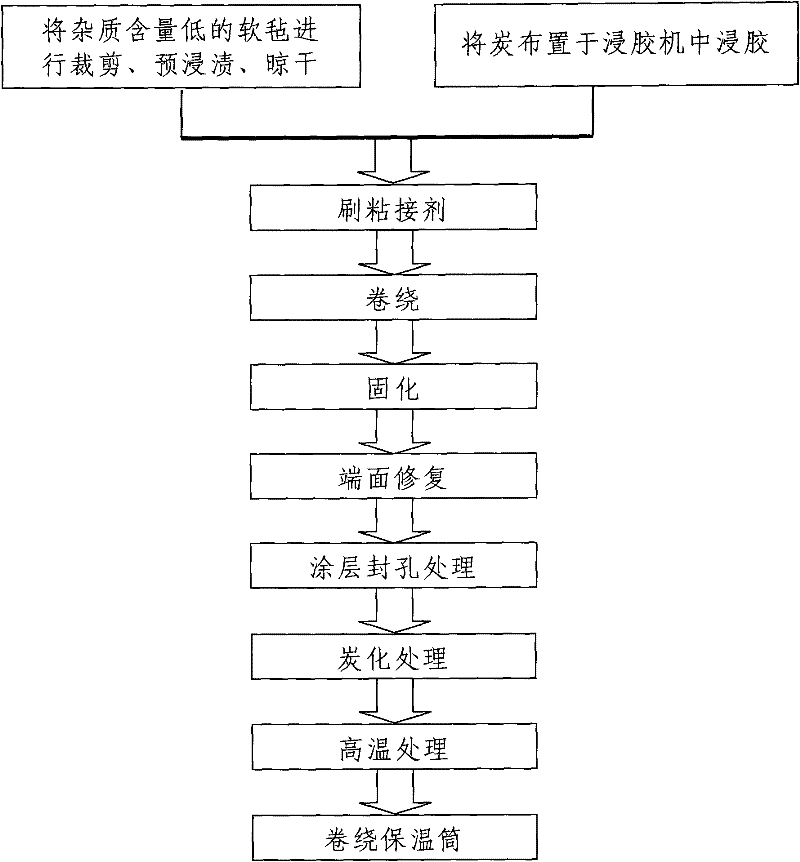

The invention relates to a method for preparing a work hardening insulation quilt for a high temperature furnace, which comprises the following steps of: 1, cutting, pre-impregnating and airing a soft quilt; 2, adhering the soft quilt by using an adhesive; 3, pressing and curing for forming; 4, performing carbonization treatment; 5, performing high temperature treatment; 6, machining; 7, performing coating treatment; and 8, performing chemical vapor deposition treatment and high temperature treatment, or directly performing high temperature treatment to obtain the work hardening insulation quilt for the high temperature furnace. The method has the advantages of simple technological process and suitability for mass production; and the prepared work hardening insulation quilt has the heat conductivity of less than or equal to 0.5W / m.K, the ash content of less than or equal to 2,000ppm, high mechanical properties and high-temperature dimensional stability and excellent processability, does not generate volatile matters when used in the high temperature furnace, cannot pollute the product, and has important significance for prolonging the service life of the insulation quilt in the high temperature furnace.

Owner:XIAN CHAOMA SCI TECH

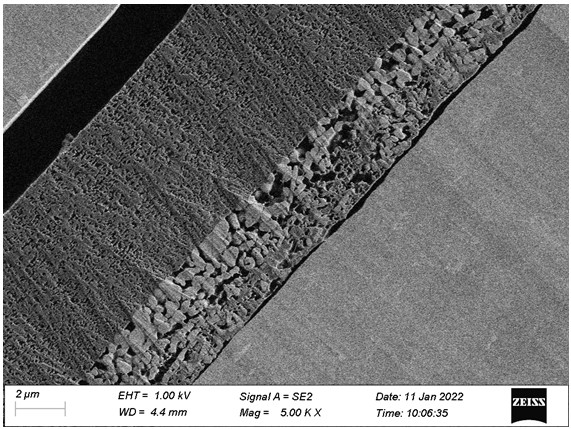

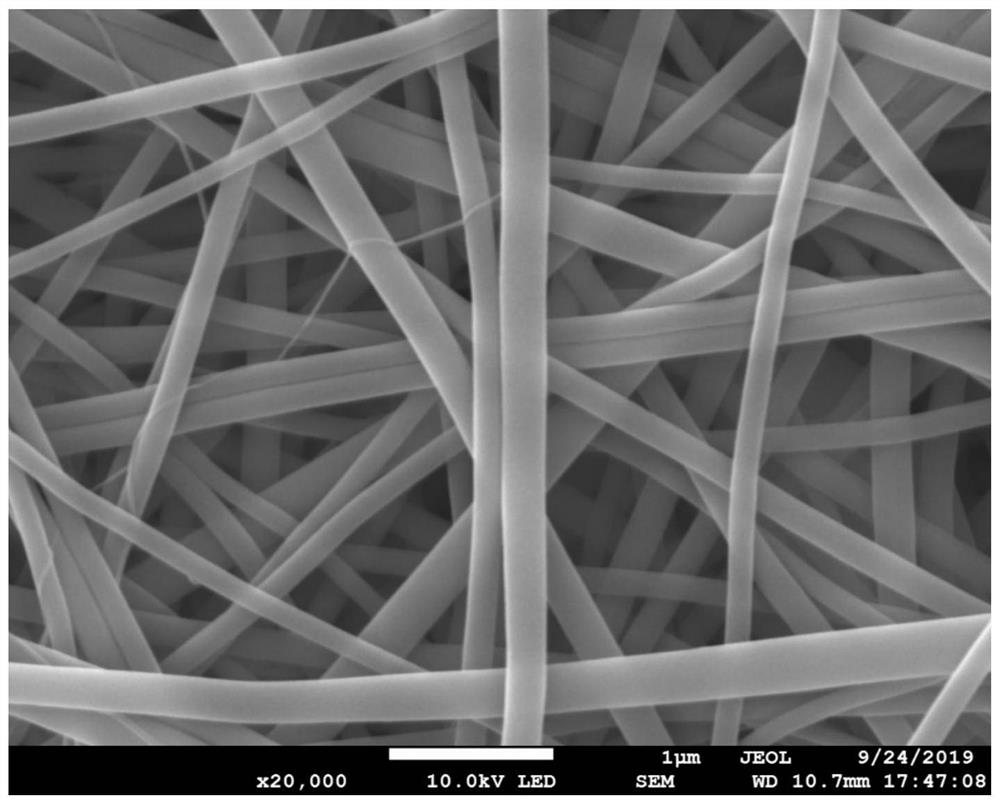

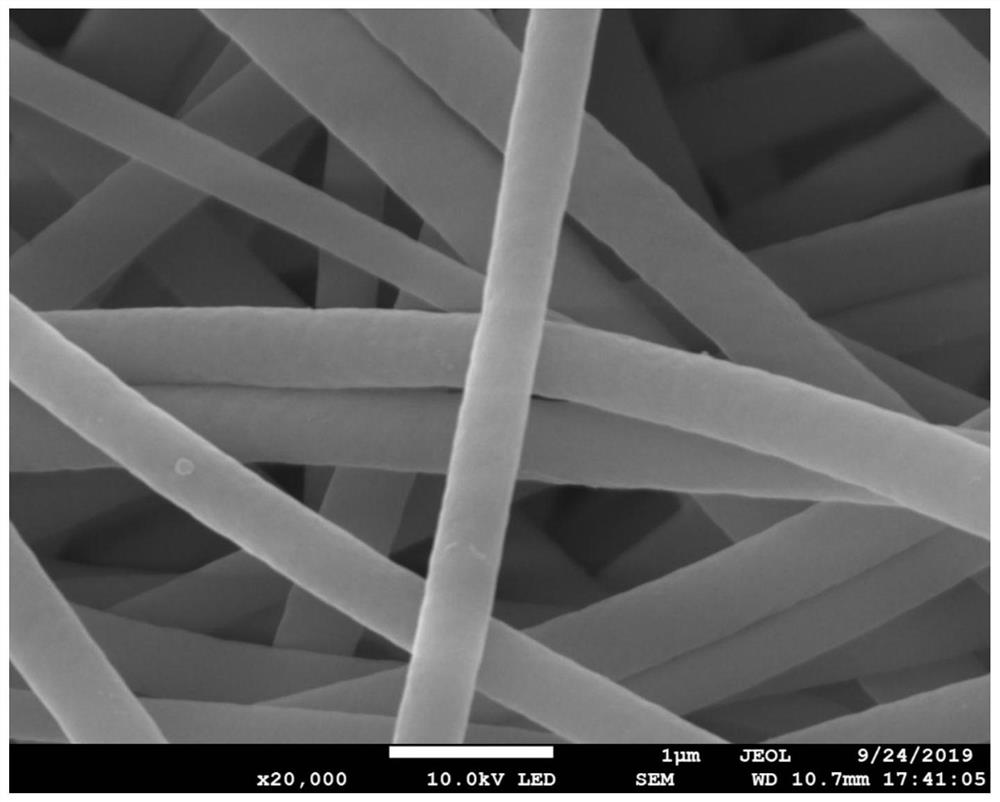

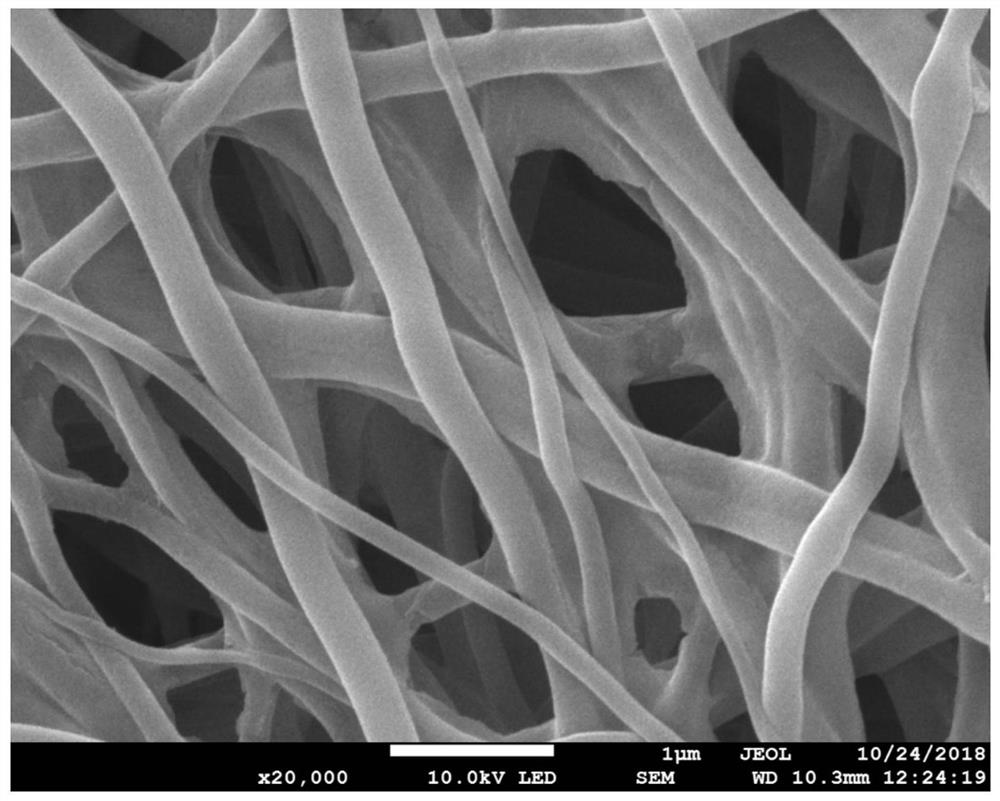

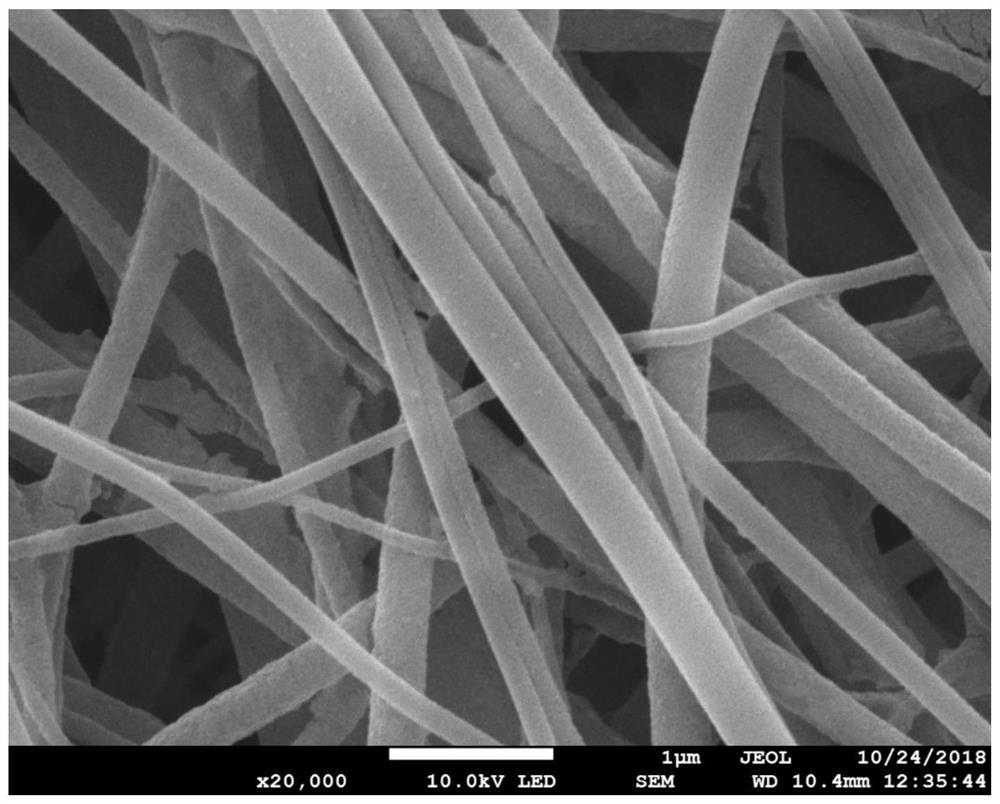

Polyimide-zirconium dioxide composite nanofiber membrane and preparation method thereof

ActiveCN105970485AHigh porosityHigh temperature resistantFibre typesNon-woven fabricsFiberComposite nanofibers

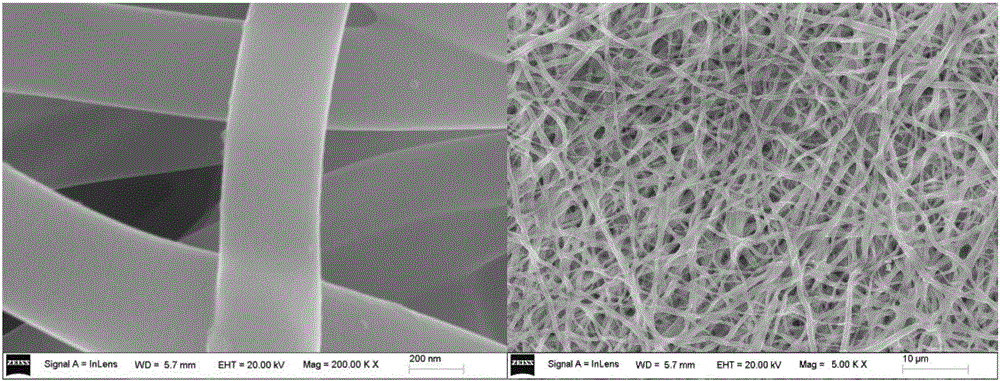

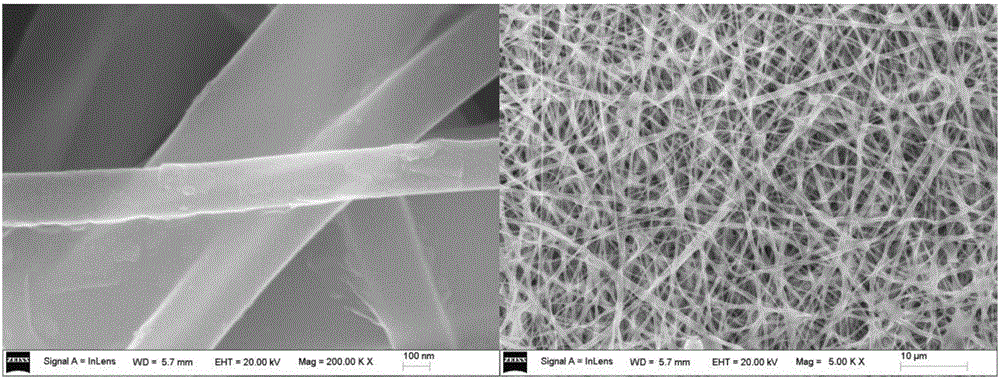

The invention discloses a polyimide-zirconium dioxide composite nanofiber membrane and a preparation method thereof. The preparation method comprises the steps that a polyamide acid nanofiber membrane is prepared through electrostatic spinning, then the polyamide acid nanofiber membrane is put into zirconium dioxide sol to enable the nanofiber surfaces to be uniformly coated with the zirconium dioxide sol, gradient temperature increasing thermal imidization processing is conducted, and then the polyimide nanofiber membrane of which the surface is coated with a nano-zirconium dioxide layer is prepared. The polyimide-zirconium dioxide composite nanofiber membrane prepared through the method is composed of the zirconium dioxide nanometer layers coating the surfaces of the polyimide nanofibers, the thickness of the zirconium dioxide layer is 10-100 nm, and the diameter of the polyimide fibers is 30-600 nm. Accordingly, through coating of the zirconium dioxide nanometer layers, the surface wettability, the size stability, the mechanical property and the temperature resistance of the polyimide fiber membrane are improved; in addition, the implementing process is easy, processing is easy to achieve, and the application prospect is good.

Owner:启鼎技术(北京)有限公司

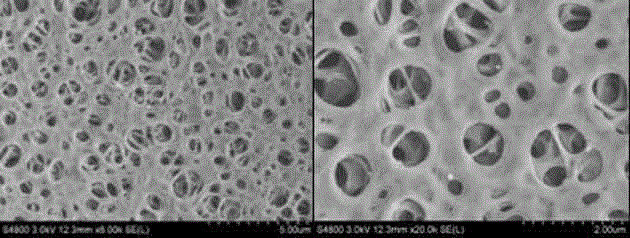

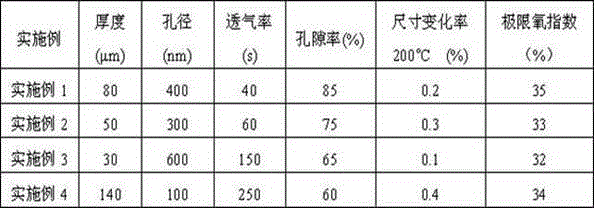

Polyarylsulfone amido porous membrane, and preparation method and application thereof

The invention belongs to the field of polymeric membrane materials, and particularly relates to a polyarylsulfone amido porous membrane, and a preparation method and an application thereof. The porous membrane is provided with a porous eyed structure, the hole diameter range is 50 nm-5 mum, and the porosity is 50-90%. The invention further discloses the preparation method of the porous membrane. The polyarylsulfone amido porous membrane is prepared from a solution containing polyarylsulfone amide, an additive, a pore-foaming agent and a solvent with a phase inversion method. The preparation technology is good in controllability; the preparation method is simple; the production cost is low; the obtained porous membrane is adjustable in hole diameter, good in penetrability and higher in membrane air permeability; the dimension shrinkage rate at 200 DEG C is less than 1%; the thermal stability is excellent; and the flame resistance is good. The porous membrane can be used in the fields of high-temperature filter materials, adsorbing materials, air-permeability packaging materials, parting materials, lithium ion battery diaphragms and the like.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Vitrifiable flame-retardant silicone rubber foam material and preparation method thereof

The invention relates to a vitrifiable flame-retardant silicone rubber foam material and a preparation method thereof. The vitrifiable flame-retardant silicone rubber foam material is prepared from the following raw materials in parts by mass: 100 parts of silicone rubber, 1-10 parts of foaming agent, 1-8 parts of foaming aid, 1-5 parts of vulcanizing agent, 1-40 parts of reinforcing agent, 1-10 parts of structure controller, 1-40 parts of combustion improver, 0-20 parts of vitrification filler and 0-15 parts of vitrification aid. The silicone rubber foam material provided by the invention has the advantages of favorable flame retardancy and favorable high-temperature dimensional stability, and is vitrifiable at low temperature.

Owner:QINGDAO UNIV OF SCI & TECH

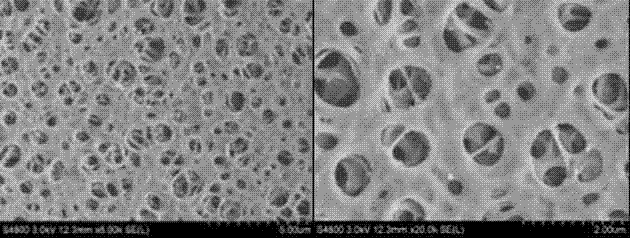

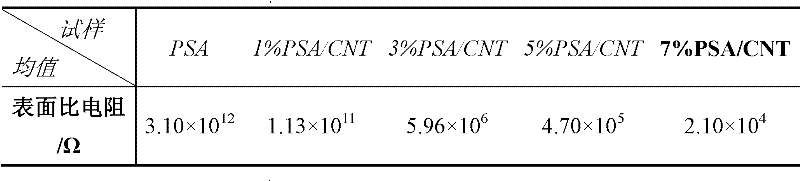

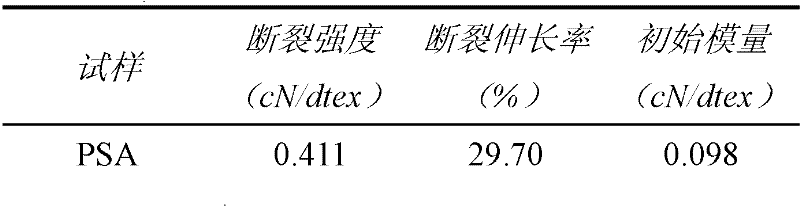

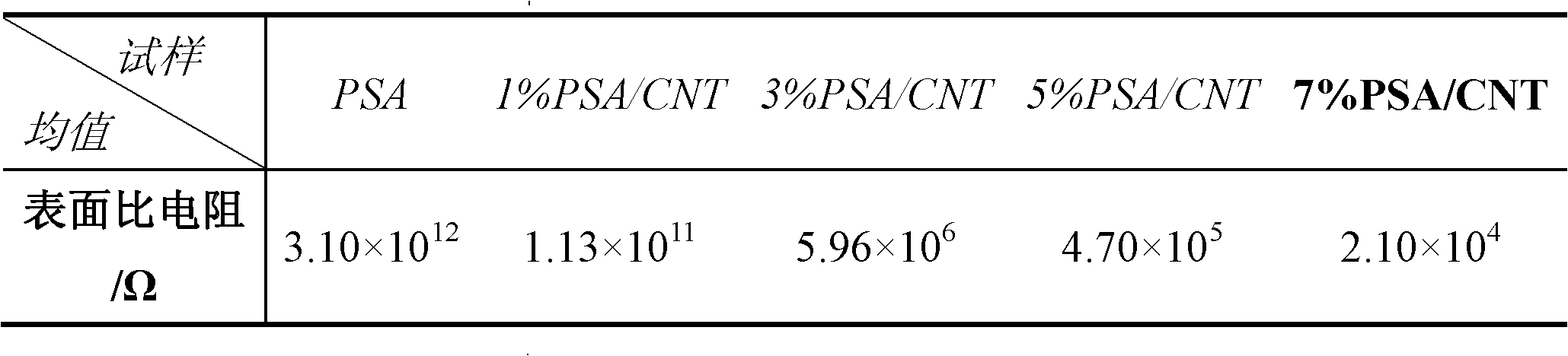

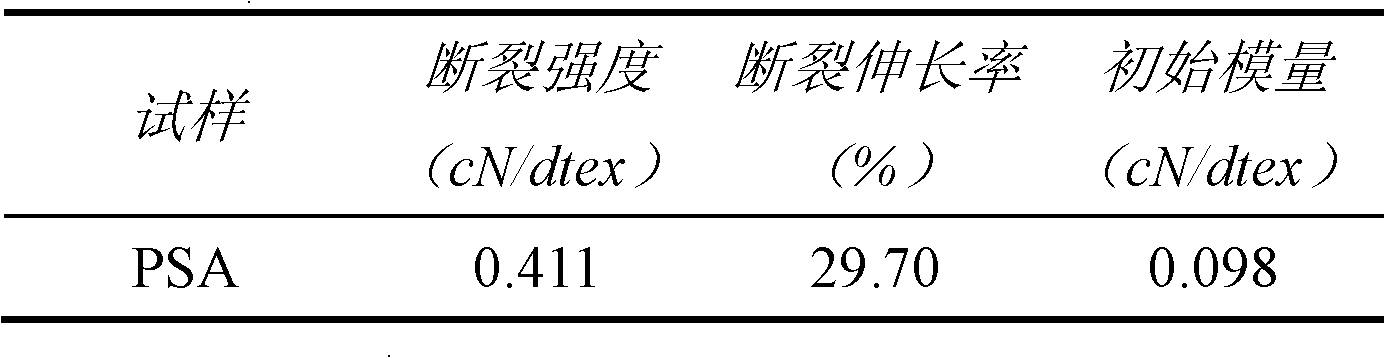

Antistatic polysulfonamide/carbon nano-tube composite material and preparation method thereof

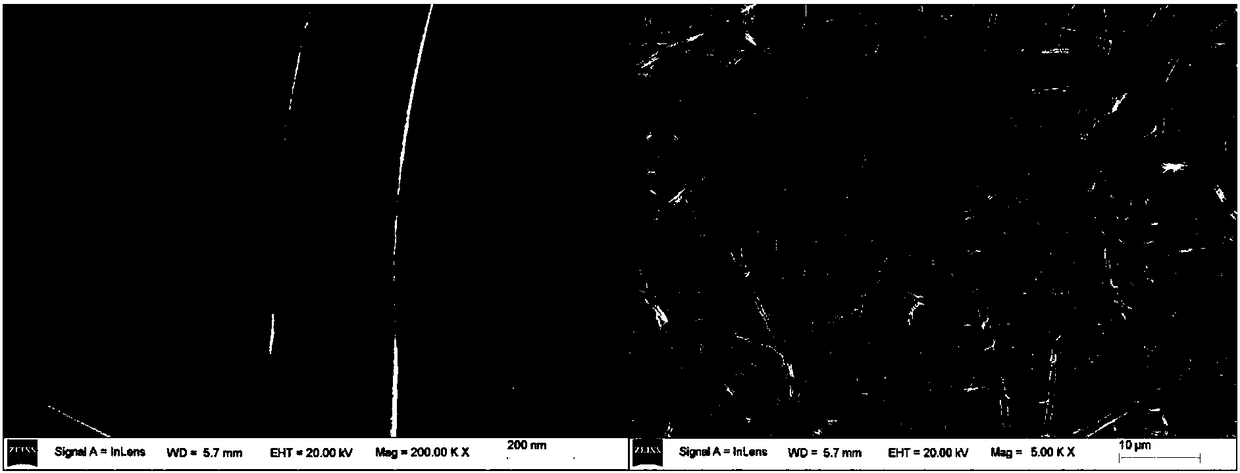

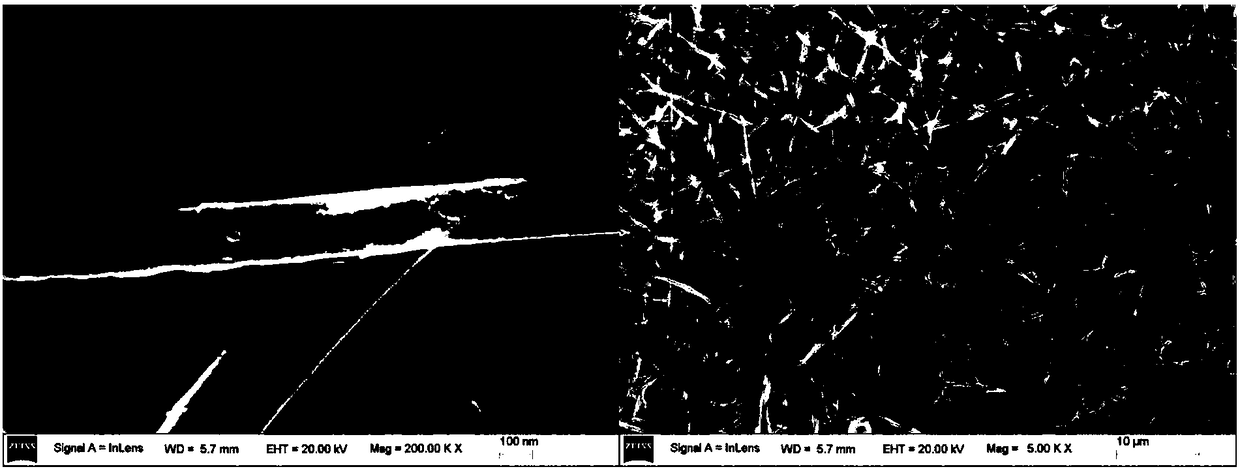

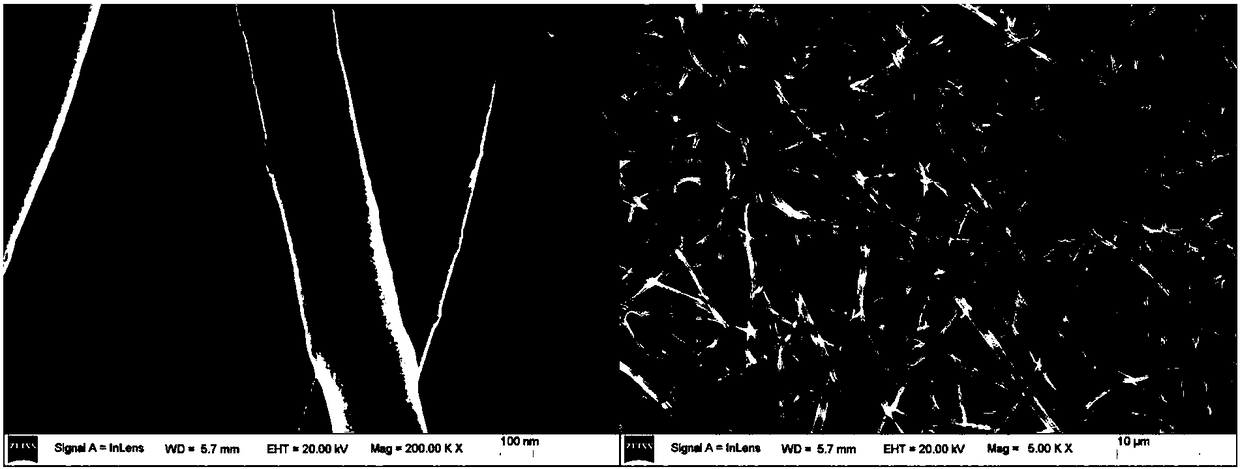

InactiveCN102418164AGood dimensional stability at high temperatureImprove heat resistanceElectroconductive/antistatic filament manufactureMonocomponent copolyamides artificial filamentFiberComposite film

The invention provides an antistatic polysulfonamide / carbon nano-tube composite material and a preparation method thereof. The polysulfonamide / carbon nano-tube composite material is prepared by adopting a solution blending method in a physical blending technology, taking polysulfonamide as a matrix and adding carbon nano-tubes with different mass fractions, and is prepared into composite fibers or composite films. According to the invention, an ultrasonic blending technology is utilized so that a small amount of the carbon nano-tubes can be uniformly dispersed in the polysulfonamide matrix in nano-scale; as nano particles with excellent electric conductivity, the carbon nano-tubes ensure that the prepared antistatic polysulfonamide / carbon nano-tube composite material has good antistatic properties, and the specific surface resistivity of the composite material reaches 104 to 1,011 omega; moreover, the rigidity and excellent high-temperature dimensional stability, heat resistance and the like of the carbon nano-tubes can be perfectly combined with the tenacity and processability of an organic polymer. The preparation method provided by the invention is simple and convenient in process, strong in operability and low in cost.

Owner:SHANGHAI UNIV OF ENG SCI

Multilayer micro-porous polyolefin diaphragm and production method thereof

ActiveCN107808943AHigh porosityImprove uniformitySecondary cellsCell component detailsPolyolefinHeat resistance

The invention provides a production method of a multilayer micro-porous polyolefin diaphragm. The method comprises the following steps: 1, respectively carrying out melt extrusion on polypropylene andinorganic composite polyethylene through adopting three extrusion casting machines, and carrying out multilayer bush die casting to obtain a multilayer composite cast film, wherein the polypropyleneis positioned at the outer layer, and the inorganic composite polyethylene is positioned at the middle layer; 2, carrying out heat treatment on the multilayer composite cast film at 125 DEG C for 0.5h to obtain a multilayer heat-treated film; 3, carrying out cold drawing on the multilayer heat-treated film at -20 DEG C under a drawing ratio of 50% to obtain a heat-treated film having initial porous nucleuses; 4, carrying out hot drawing on the heat-treated film having initial porous nucleuses at 125 DEG C under a drawing ratio of 90%; and 5, fixing the micro-porous film obtained in step 4 at125 DEG C for 20 min in order to obtain the multilayer micro-porous polyolefin diaphragm. The produced micro-porous diaphragm has the advantages of uniform aperture, good heat resistance and good stability.

Owner:GUANGDONG UNIV OF TECH

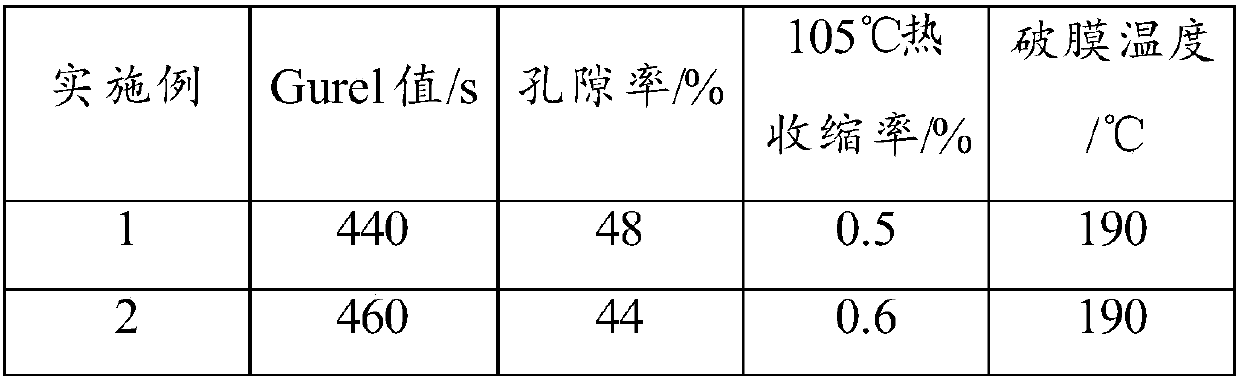

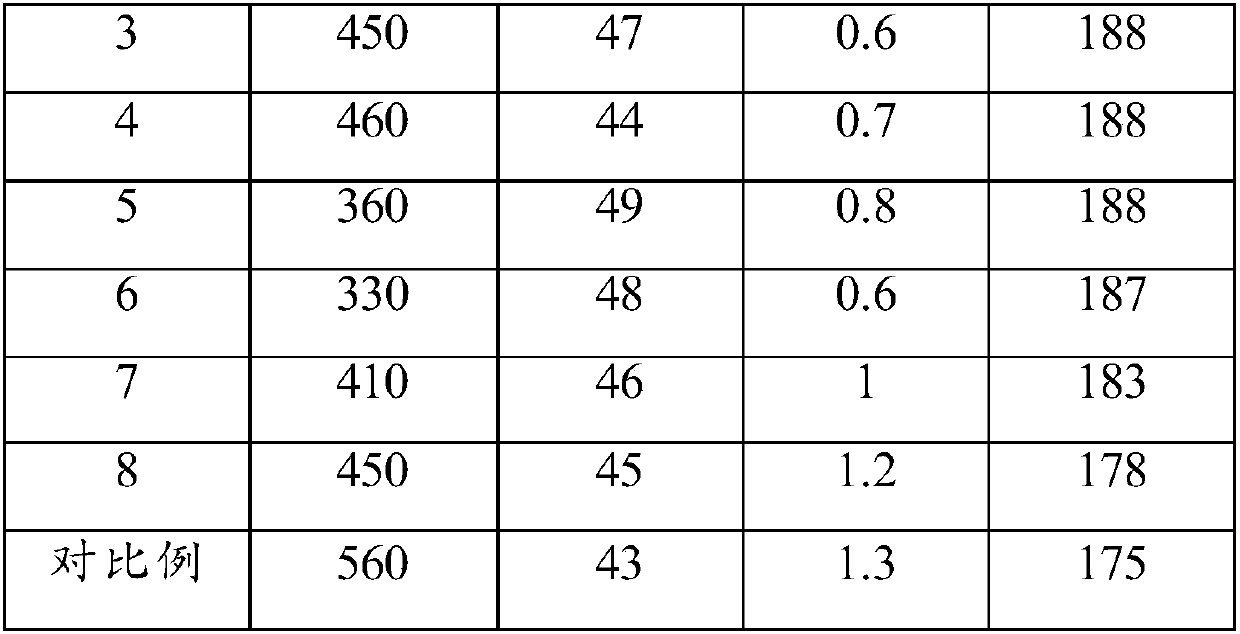

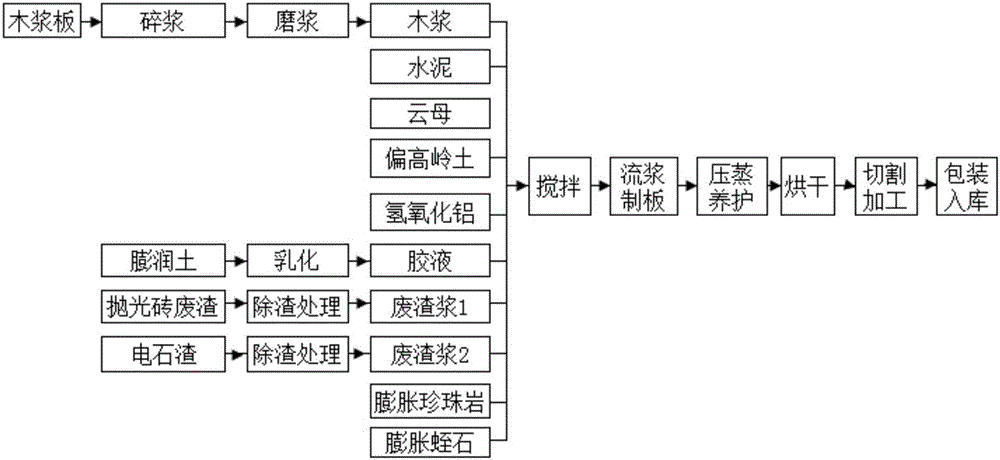

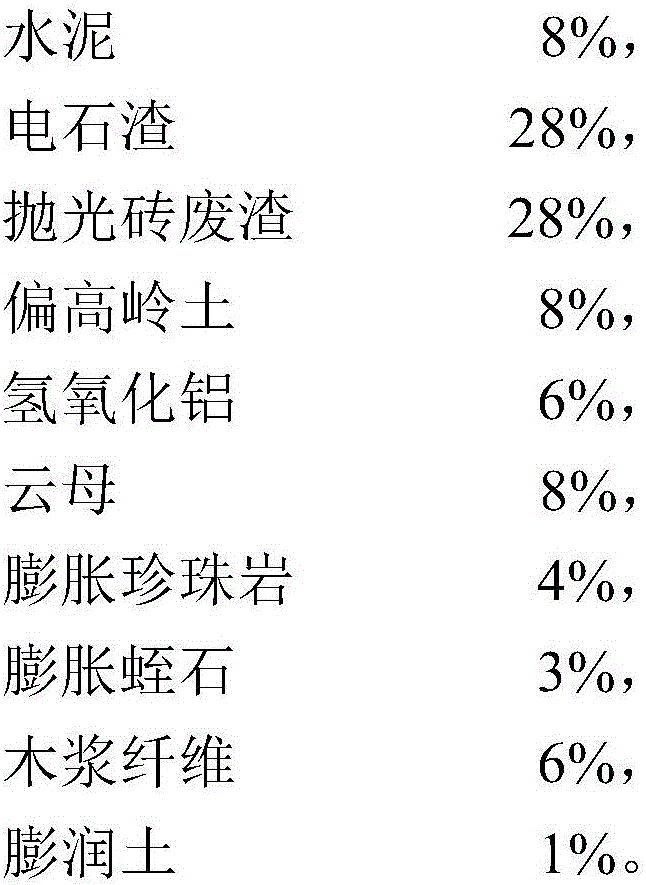

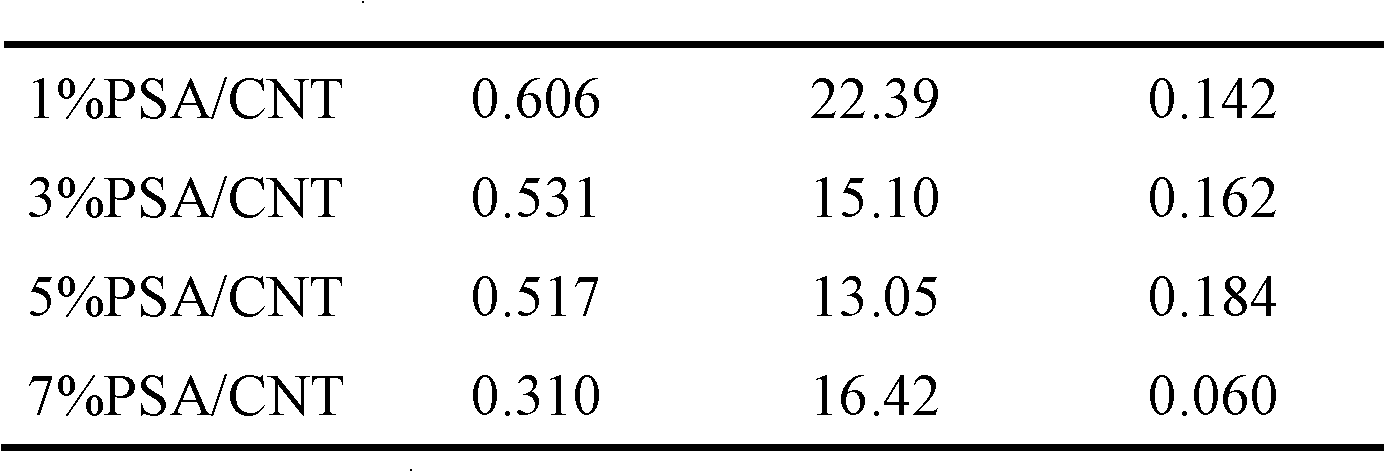

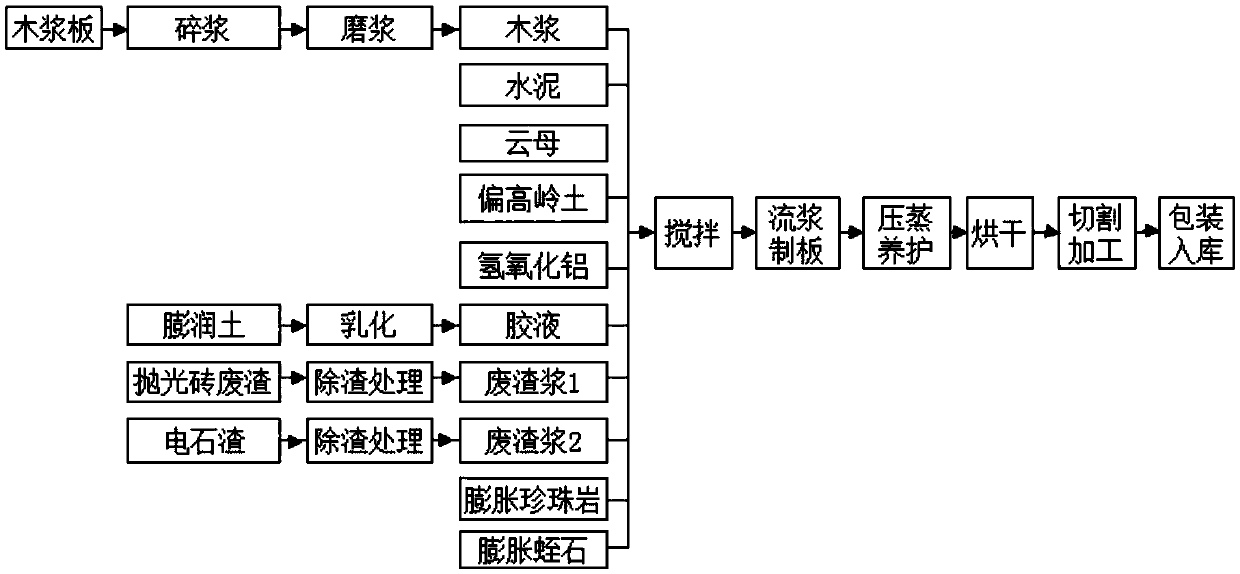

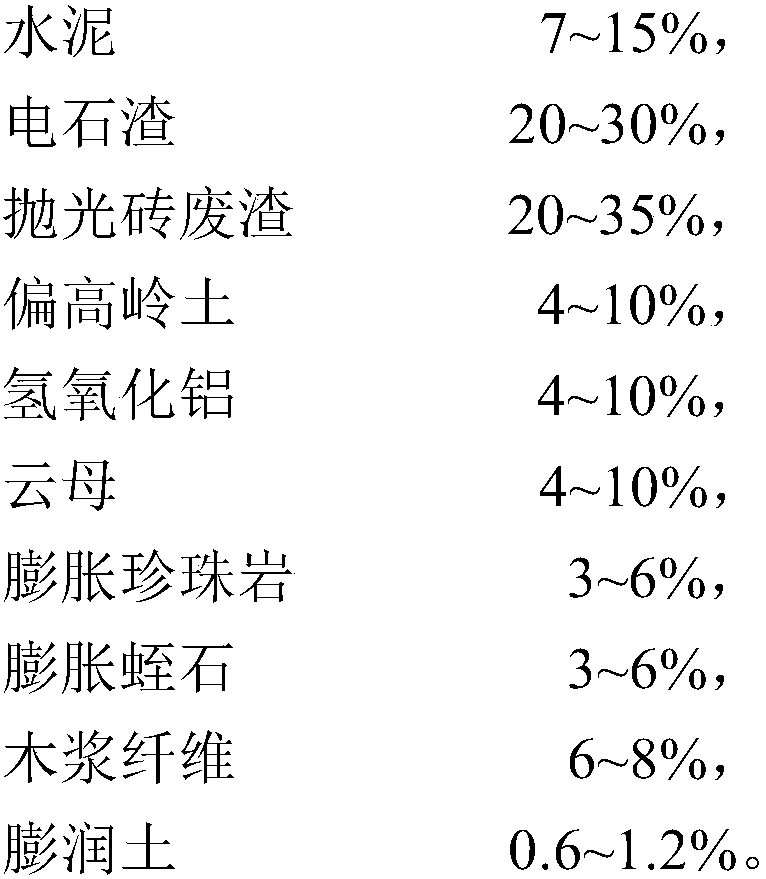

Fiber reinforced silicate fireproof board produced by doping industrial waste residue and preparation method and application thereof

ActiveCN106810156AThe total usage ratio is largeThe purpose of recycling is goodFiberHeat conducting

The invention discloses a fiber reinforced silicate fireproof board produced by doping industrial waste residue. The fiber reinforced silicate fireproof board comprises, by mass, 7-15% of cement, 20-30% of carbide slag, 20-35% of polished tile waste residue, 4-10% of metakaolin, 4-10% of aluminum hydroxide, 4-10% of mica, 3-6% of expanded perlite, 3-6% of expanded vermiculite, 6-8% of wood pulp fiber and 0.6-1.2% of bentonite. The polished tile waste residue is utilized to produce the fiber reinforced silicate fireproof board, so that a new path is provided for using the polished tile waste residue, production cost is low, the process is easy to realize, and the fiber reinforced silicate fireproof board has remarkable substantial effect on utilization of the polished tile waste residue and environment protection. The fiber reinforced silicate fireproof board has low heat conducting coefficient and high high-temperature size stability and can be used for face boards of passive fireproof system of various buildings.

Owner:金强(福建)建材科技股份有限公司

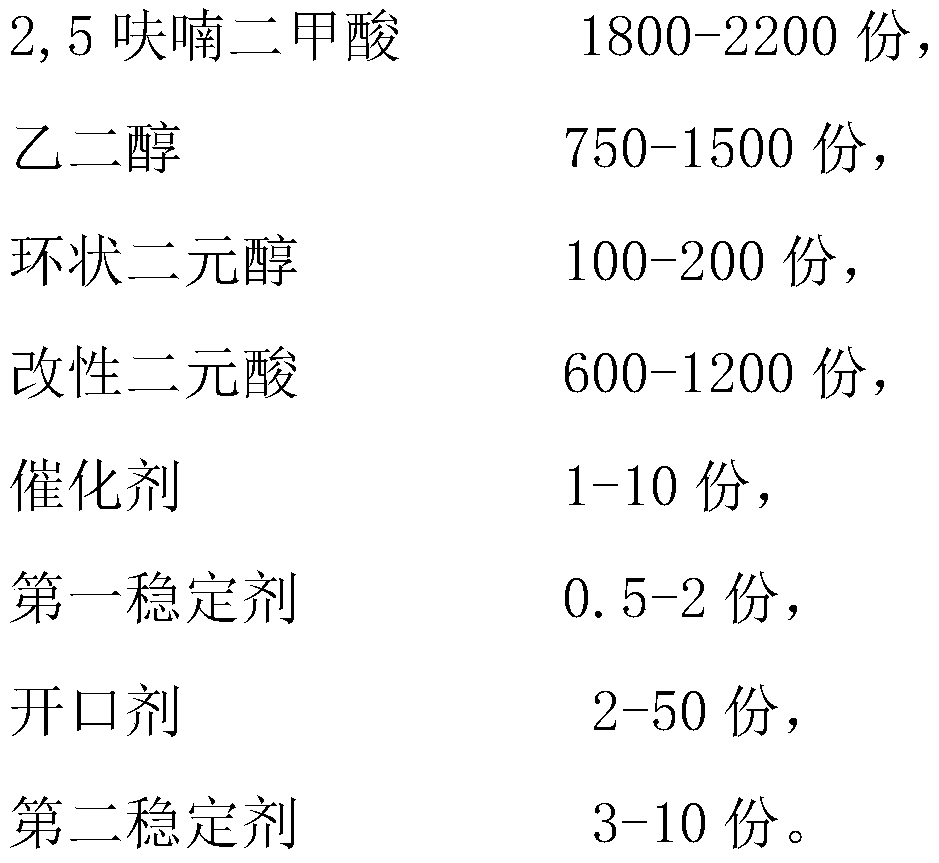

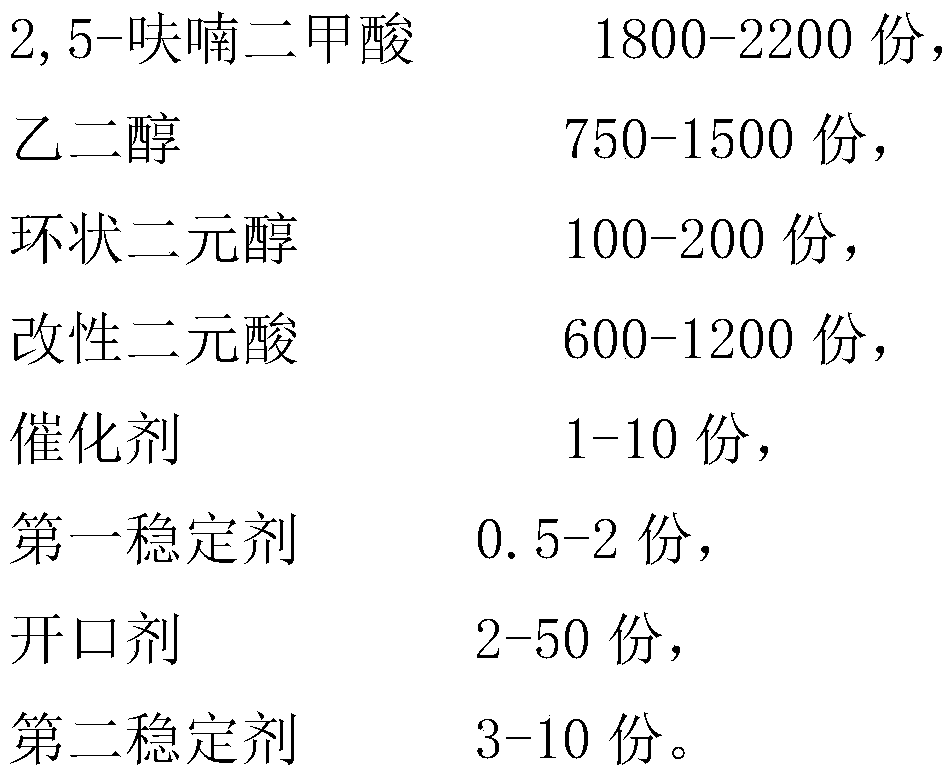

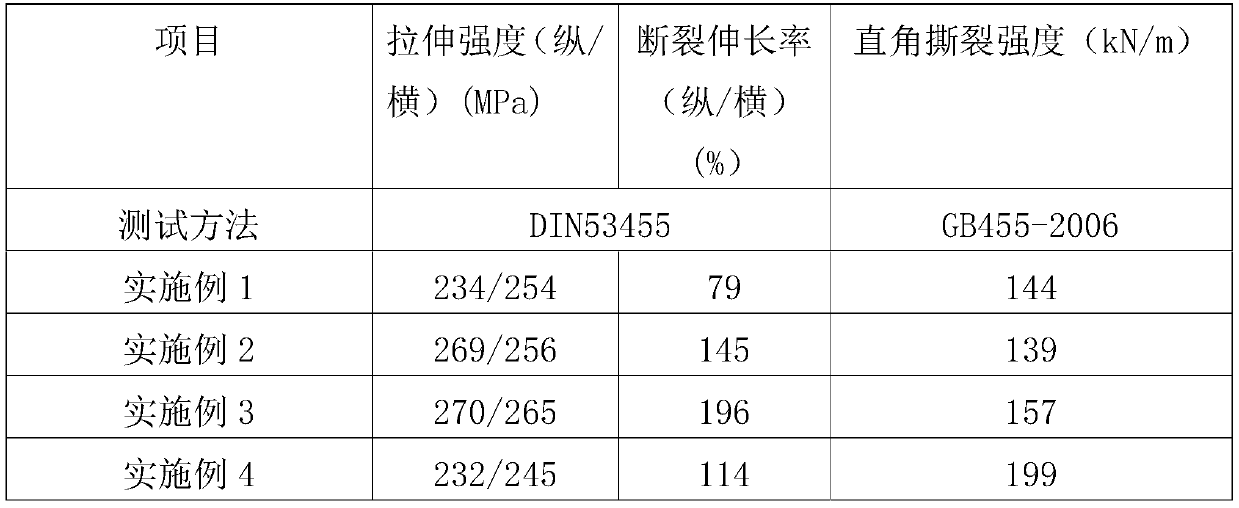

Biaxially oriented polyester film with excellent dimensional stability at high temperature, and production method thereof

InactiveCN110128797AGood dimensional stability at high temperatureGlass transition temperature risePolyesterHeat resistance

The invention discloses a biaxially oriented polyester film with an excellent dimensional stability at a high temperature, and a production method thereof. The biaxially oriented polyester film is prepared from, by weight, 1800-2200 parts of 2,5-furandicarboxylic acid, 750-1500 parts of ethylene glycol, 100-200 parts of cyclic diol, 600-1200 parts of a modified diacid, 1-10 parts of a catalyst, 0.5-2 parts of a first stabilizer, 2-50 parts of an anti-blocking agent and 3-10 parts of a second stabilizer. The biaxially oriented polyester film with the excellent dimensional stability at the hightemperature has a good heat resistance, a good toughness and a good high temperature dimensional stability, and can fully meet the performance requirements of film capacitors for the film material.

Owner:无锡风鹏新材料科技有限公司

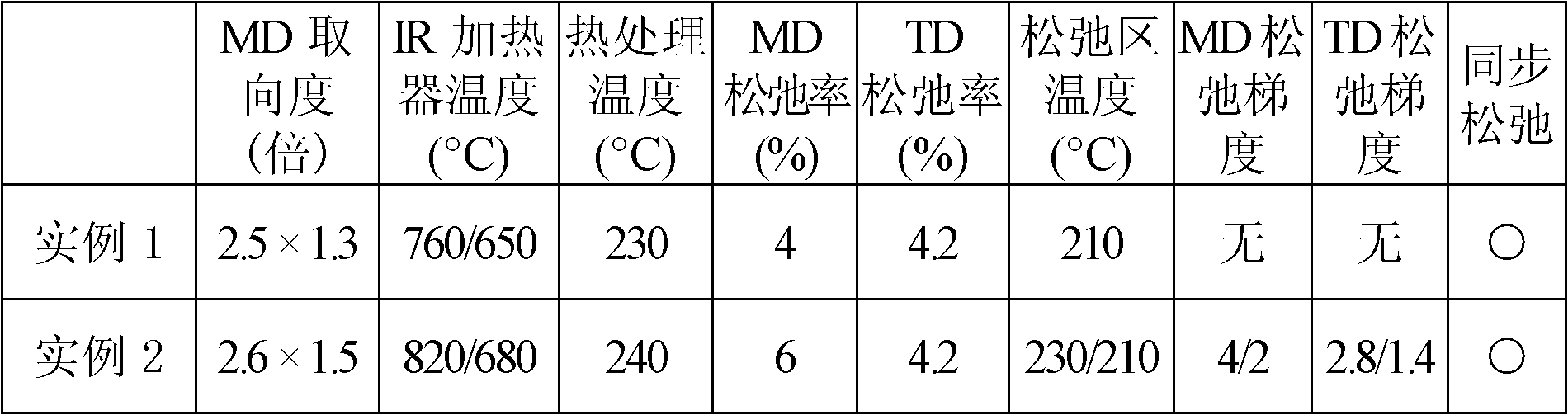

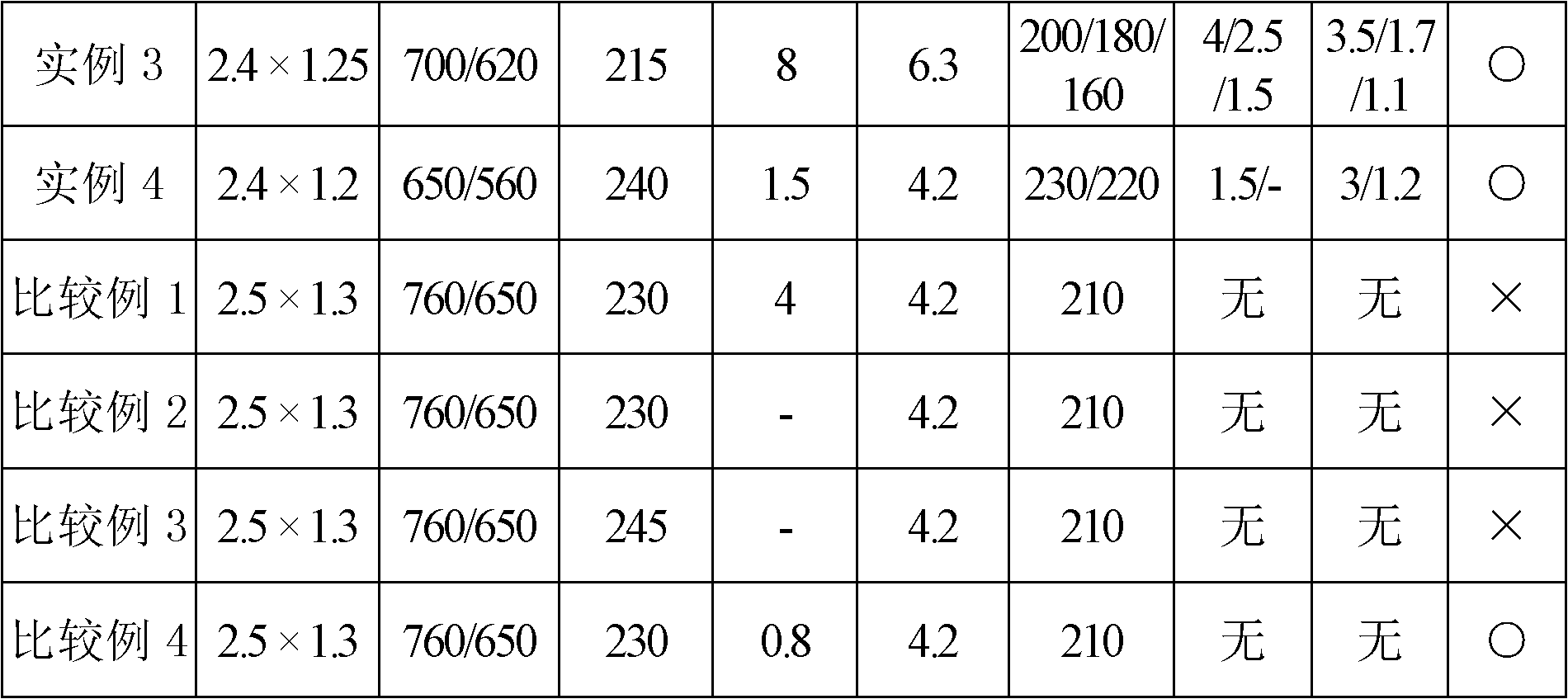

Polyester film and manufacturing method thereof

InactiveCN102143993AReduced machine direction (MD) shrinkageGood dimensional stability at high temperatureSynthetic resin layered productsFlat articlesPolyester resinEngineering

Provided is a polyester film having excellent high-temperature dimensional stability. More particularly, provided is a method for producing a polyester film, including: a) extruding and cooling a polyester resin to provide a non-oriented sheet; b) orienting the sheet in the machine direction (MD); c) orienting the MD oriented sheet in the transverse direction (TD); d) heat treating the sheet; and e) carrying out simultaneous relaxation by subjecting the heat treated sheet to MD relaxation at a ratio of 1 % or higher, while subjecting it to TD relaxation in a tenter. Provided also is a polyester film obtained by the method.

Owner:KOLON IND INC

Method for preparing work hardening insulation quilt for high temperature furnace

Owner:XIAN CHAOMA SCI TECH

Preparation and application methods of calcium zirconate ceramic core

InactiveCN109574662AImprove room temperature strengthHigh temperature strengthFoundry mouldsFoundry coresAlcoholTurbine blade

The invention relates to the technical field of ceramic cores, particularly to preparation and application methods of a calcium zirconate ceramic core. The preparation method of the calcium zirconateceramic core comprises the following steps of mixing acrylamide, crosslinking agent and absolute ethyl alcohol to obtain a premixed solution; mixing the premixed solution, dispersion, calcium zirconate and mineralizer to obtain a calcium zirconate pulp; mixing the calcium zirconate pulp, initiator and catalysts for mold casting to obtain a calcium zirconate ceramic core blank; powder-sintering thecalcium zirconate ceramic core blank to obtain the calcium zirconate ceramic core. The calcium zirconate ceramic core prepared through the method is high in strength and more applicable to at high temperature casting Nb-Si-based alloy turbine blades, and meanwhile, achieves high-temperature chemical stability, avoids sharp reaction with chemical elements of Nb-Si-based alloy and effectively ensures the quality of the inner cavity of Nb-Si alloy hollow blades.

Owner:沃尔曼科技张家港有限公司

Aromatic polyester polyol, raw material composition, polyurethane foam and preparation methods

The invention discloses aromatic polyester polyol, a raw material composition, polyurethane foam and preparation methods. The aromatic polyester polyol comprises the following raw materials: phthalicanhydride, diethylene glycol, aliphatic diol and a catalyst, wherein aliphatic diol is linear diol with a carbon number of 6 to 7; a molar ratio of phthalic anhydride to diethylene glycol is 1: (1.8-2.1); and a molar ratio of diethylene glycol to aliphatic diol is (8.0-13.0): 1. The aromatic polyester polyol of the invention uses cheap raw materials and has low cost; the preparation methods are simple in process, mild in reaction conditions, convenient to operate, reduced in energy consumption and friendly to environment; the aromatic polyester polyol prepared by adding aliphatic diol has goodcompatibility with cyclopentane and good thermal stability; and the polyurethane foam of the invention has high compressive strength, excellent flame retardancy and high dimensional stability at hightemperature.

Owner:SHANGHAI DONGDA CHEM

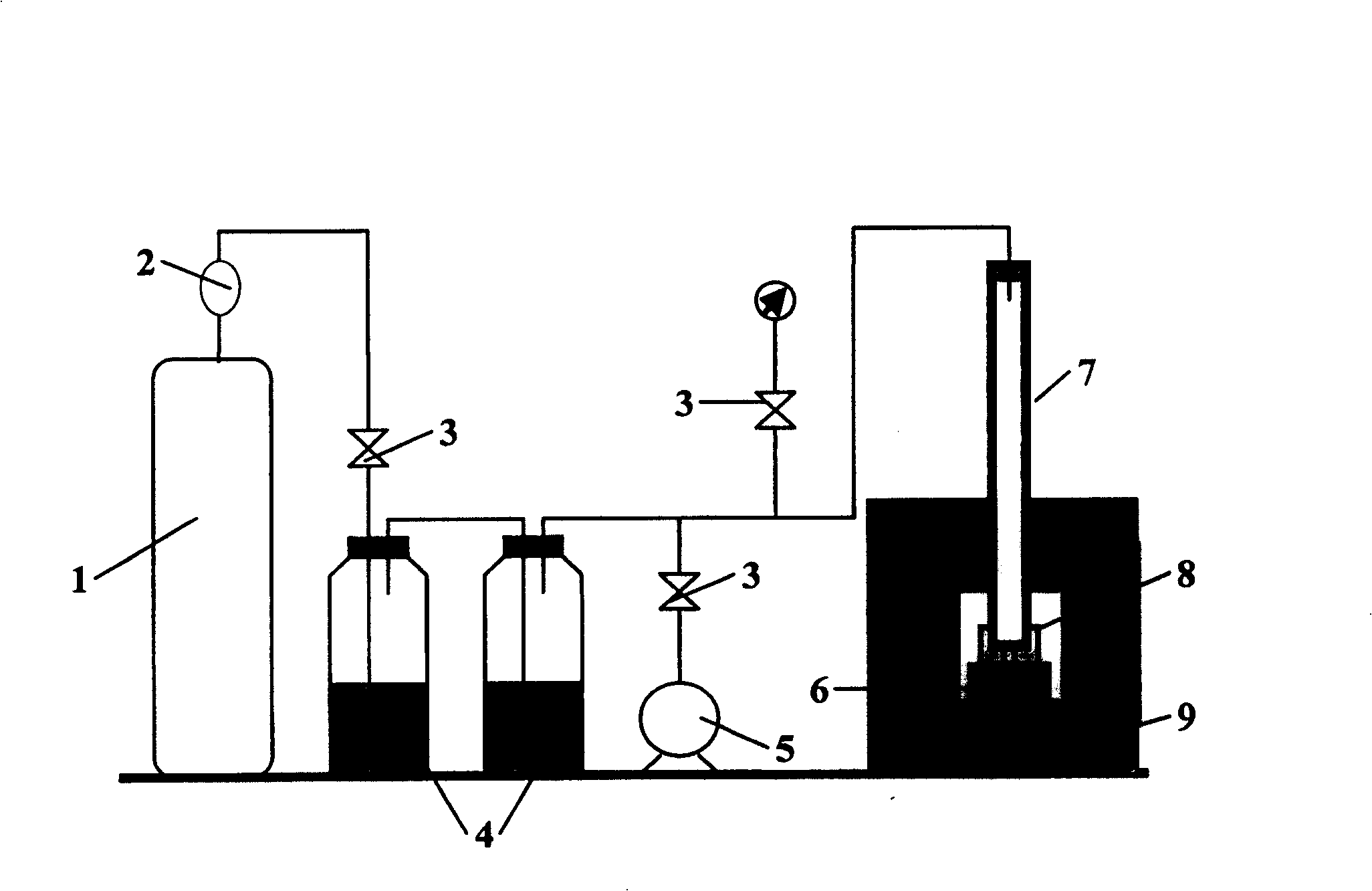

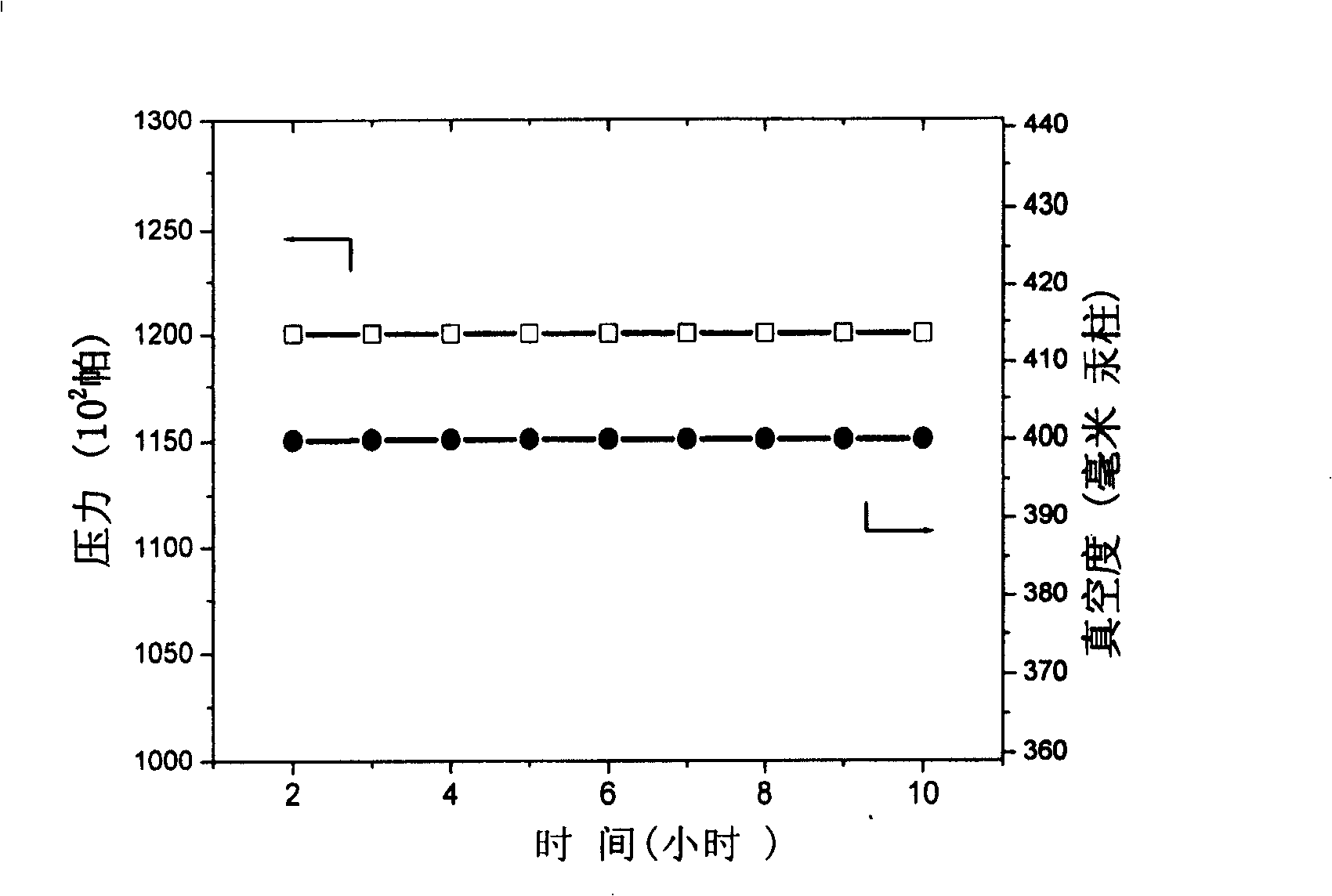

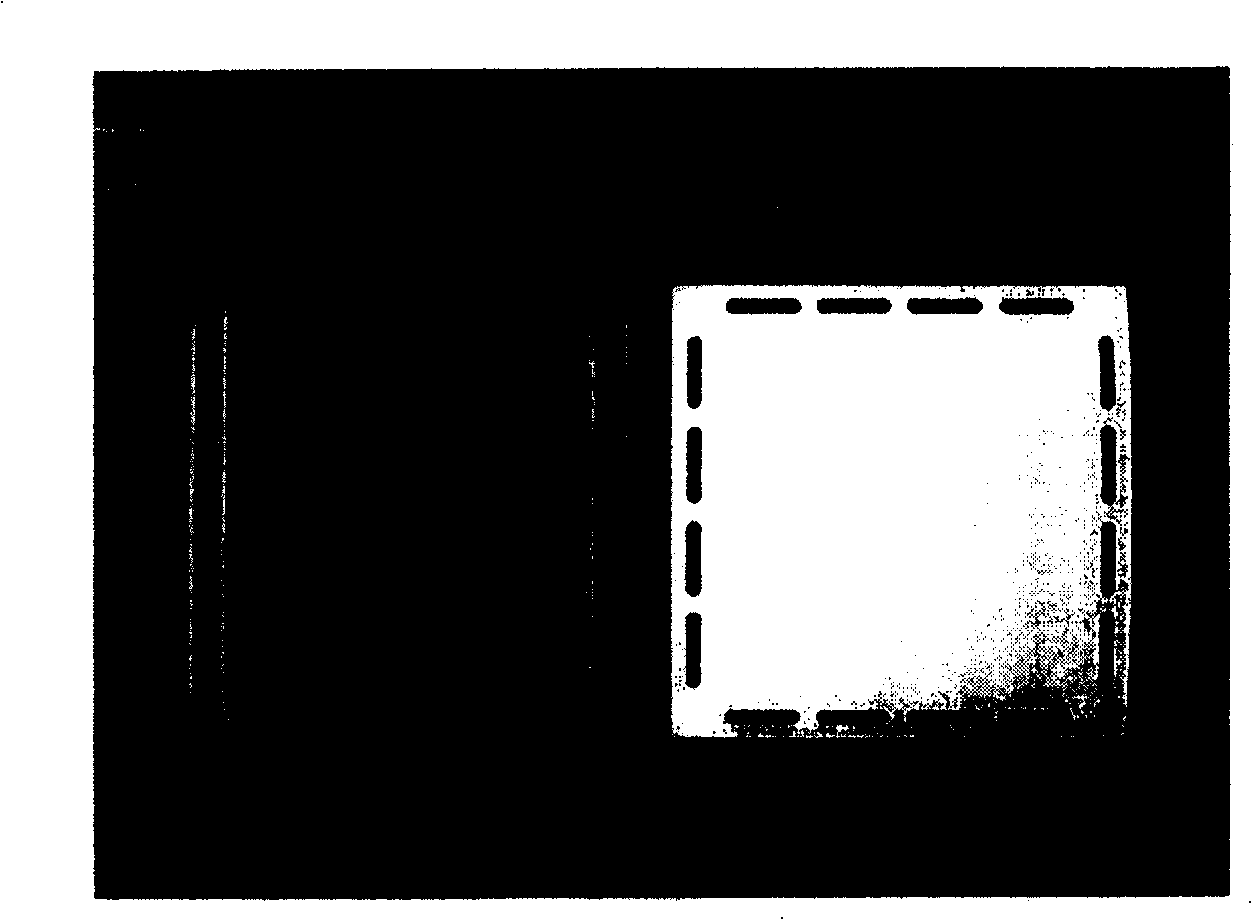

Medium and high temperature sealing method of plate type solid oxide fuel battery and its sealing material

InactiveCN100438183CImprove sealingImprove wettabilityOther chemical processesFinal product manufactureThermal expansionSealant

A series of sealant materials suitable to 800-1000 deg.C are prepared by using microcrystalline glass in system of CaO-Al2O3-SiO2-B2O3. Range of softening temperature of the series of microcrystalline glass is 750-850 deg.C, and range of crystallizatino is 800-1000 deg.C. In warming up procedure, pristine glass softened at 750-850 deg.C is drenched and adhered with ZrO2 electrolyte and Ni-Cr material of bipolar plate. When temperature goes up continuously, integral recrystallization is occurred, and intensity of material is enhanced. Experiments prove that the material suits to sealing use at temperature 800-1000 deg.C: certain mechanical strength and size, wettability, coefficient of thermal expansion, chemical stability and good matching to materials of batteries. The invention possesses advantages of wide range of sealing temperature, easy manufacturing and sealing technique and high cost performance ratio.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

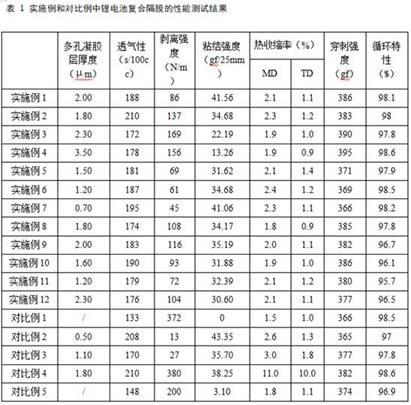

A lithium battery composite separator and its preparation method and application

ActiveCN114335904BIncrease energy densityPromote circulationFinal product manufactureLi-accumulatorsAdhesivePhysical chemistry

The invention provides a lithium battery composite separator and its preparation method and application. The lithium battery composite separator of the present invention includes a polymer base film, a ceramic layer and a porous gel layer. The porous gel layer includes inorganic ceramic particles, PVDF resin and acrylate adhesive. Any of the lithium battery composite separators The peeling force between the two interfaces is not less than 60N / m; compared with the existing technology, the present invention sets a porous gel layer mainly composed of PVDF resin, and adds inorganic ceramic particles and acrylic esters to the porous gel layer. The adhesive can not only improve the positive electrode bonding performance, thermal stability and ion conductivity of the composite separator, reduce the thermal shrinkage rate of the composite separator, but also effectively improve the peel strength between the layers of the composite separator and reduce the material cost of the composite separator. Composite separators have excellent comprehensive performance, which can improve the performance of lithium batteries.

Owner:中材锂膜(宁乡)有限公司

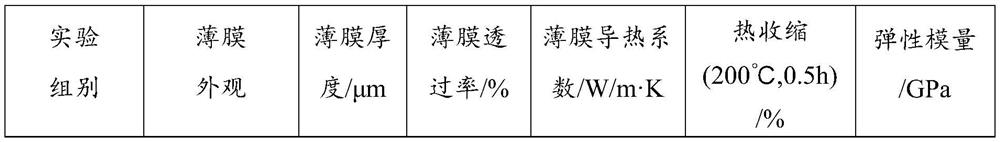

Colorless transparent polyimide film, preparation method thereof and LED film screen

The invention provides a colorless transparent polyimide film, a preparation method thereof and an LED film screen, and relates to the technical field of films. The colorless transparent polyimide film is mainly prepared from polyimide resin, a heat-conducting filler and other raw materials, the prepared colorless transparent polyimide film has high transmittance and excellent heat-conducting property, the appearance of a building wall cannot be affected after the colorless transparent polyimide film is made into an LED film screen, meanwhile, heat generated when an LED emits light can be rapidly conducted, the heat cannot be gathered to cause temperature rise, so that the luminous efficiency of the LED film screen cannot be influenced; in addition, the colorless transparent polyimide film also has the characteristics of high elastic modulus, good heat resistance, low possibility of deformation at high temperature, namely good high-temperature dimensional stability and the like, so that the LED film screen applying the colorless transparent polyimide film has corresponding characteristics. The invention also provides a preparation method of the colorless transparent polyimide film.

Owner:NINGBO CHANGYANG TECH

A kind of polyimide/zirconia composite nanofiber film and preparation method thereof

ActiveCN105970485BHigh porosityHigh temperature resistantFibre typesNon-woven fabricsFiberComposite nanofibers

The invention discloses a polyimide-zirconium dioxide composite nanofiber membrane and a preparation method thereof. The preparation method comprises the steps that a polyamide acid nanofiber membrane is prepared through electrostatic spinning, then the polyamide acid nanofiber membrane is put into zirconium dioxide sol to enable the nanofiber surfaces to be uniformly coated with the zirconium dioxide sol, gradient temperature increasing thermal imidization processing is conducted, and then the polyimide nanofiber membrane of which the surface is coated with a nano-zirconium dioxide layer is prepared. The polyimide-zirconium dioxide composite nanofiber membrane prepared through the method is composed of the zirconium dioxide nanometer layers coating the surfaces of the polyimide nanofibers, the thickness of the zirconium dioxide layer is 10-100 nm, and the diameter of the polyimide fibers is 30-600 nm. Accordingly, through coating of the zirconium dioxide nanometer layers, the surface wettability, the size stability, the mechanical property and the temperature resistance of the polyimide fiber membrane are improved; in addition, the implementing process is easy, processing is easy to achieve, and the application prospect is good.

Owner:启鼎技术(北京)有限公司

High-temperature-resistant wear-resistant brake pad

InactiveCN106009497AImprove wear performanceImprove mechanical propertiesOther chemical processesFriction liningInsulation layerWear resistant

The invention discloses a high-temperature-resistant wear-resistant brake pad which comprises a steel plate, a heat-insulation layer and a friction block. The friction block is prepared from a phenolic resin, biphenyl polyimide powder, superfine total vulcanized powder rubber, octaanilino POSS (polyhedral oligomeric silsesquioxane), polyurethane powder, an epoxy resin, silicon carbide whiskers, high silica fibers, potassium titanate whiskers, aluminum borate whiskers, basic magnesium sulfate whiskers, nano paligorskite, barium carbonate, aluminum nitride powder, calcined coke, zinc sulfide, titanium carbide, vermiculite, mica, molybdenum disulfide, natural graphite, zirconium dioxide microspheres, multi-wall carbon nanotubes, polyboron azane, boron carbide and epoxy soybean oil. The high-temperature-resistant wear-resistant brake pad disclosed by the invention has the advantages of excellent high temperature resistance, excellent wear resistance, excellent heat stability, favorable braking property and long service life.

Owner:WUHU DONGZHENG AUTOMOTIVE IND

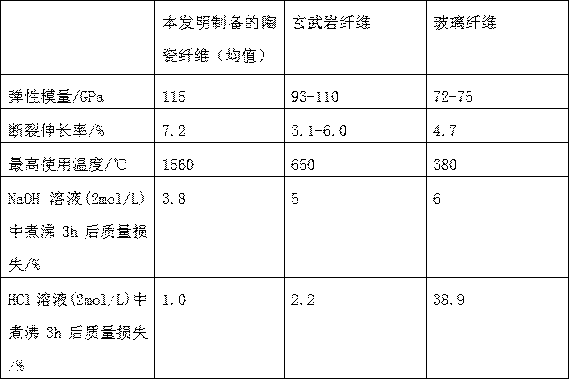

Ceramic fiber-reinforced polyimide electric insulation composite material

The invention discloses a ceramic fiber-reinforced polyimide electric insulation composite material, which relates to the technical field of ceramic-based composite materials. The ceramic fiber-reinforced polyimide electric insulation composite material is prepared by the following steps: (1) polyacrylamide is adopted to modify nano-sericite, so that polyacrylamide-modified nano-sericite is obtained; (2) the polyacrylamide-modified nano-sericite is dispersed into absolute ethyl alcohol, polyimide powder is dispersed into the absolute ethyl alcohol, and thereby mixed dispersion is prepared; (3)the mixed dispersion is agitated at high speed under an ultrasonic field, grinding is then carried out, and after drying under high temperature, a mixed material is obtained; (4) the mixed material and ceramic fibers are mixed, and by die-pressing, the ceramic fiber-reinforced polyimide electric insulation composite material is obtained. According to the ceramic fiber-reinforced polyimide electric insulation composite material provided by the invention, not only can the high temperature resistance and acid and alkali resistance of the material be remarkably improved, but also the elongation of the material is improved.

Owner:郭平

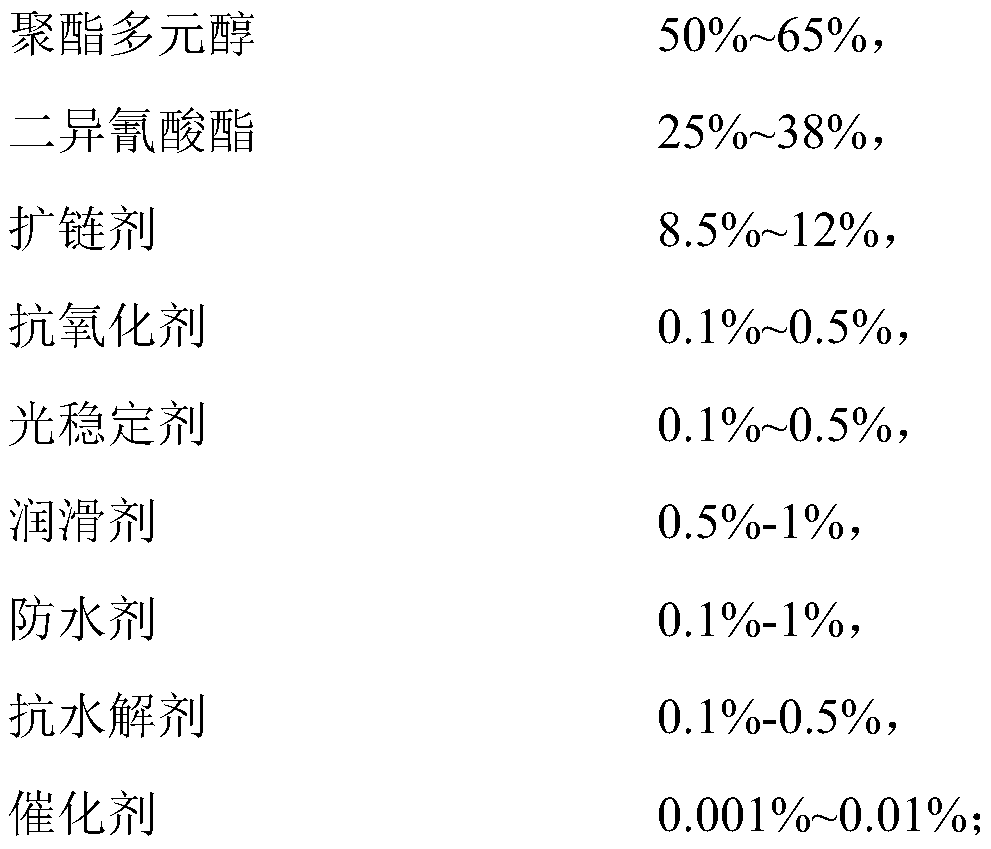

Thermoplastic polyurethane elastomer for mining sieve as well as preparation method thereof

InactiveCN110591045AGood dimensional stability at high temperatureImprove hydrolysis resistanceBulk chemical productionPolyesterPolyol

The invention relates to a thermoplastic polyurethane elastomer for a mining sieve as well as a preparation method thereof, and belongs to the technical field of thermoplastic polyurethane. The thermoplastic polyurethane elastomer for the mining sieve comprises the following raw materials: polyester polyol, diisocyanate, a chain extender, an antioxidant, a light stabilizer, a lubricating agent, awater-proofing agent, an anti-hydrolysis agent and a catalyst, wherein the molecular weight of the polyester polyol is 1000 to 3000 and the functionality degree of the polyester polyol is 2.001 to 2.02. The thermoplastic polyurethane elastomer for the mining sieve has excellent high-temperature dimensional stability, high modulus, low abrasion and hydrolysis resistance, can be formed rapidly and can perform processing by an extruding or injection molding mode; meanwhile, the invention provides a simple and practicable preparation method.

Owner:SHANDONG INOV POLYURETHANE

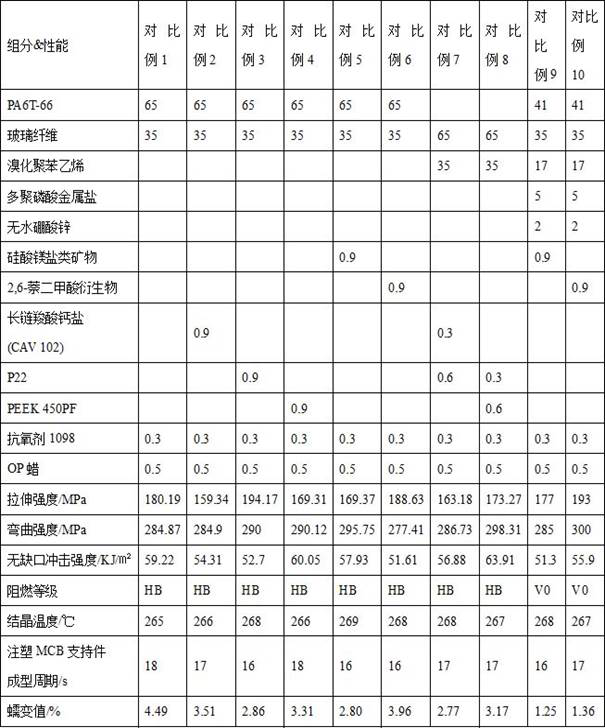

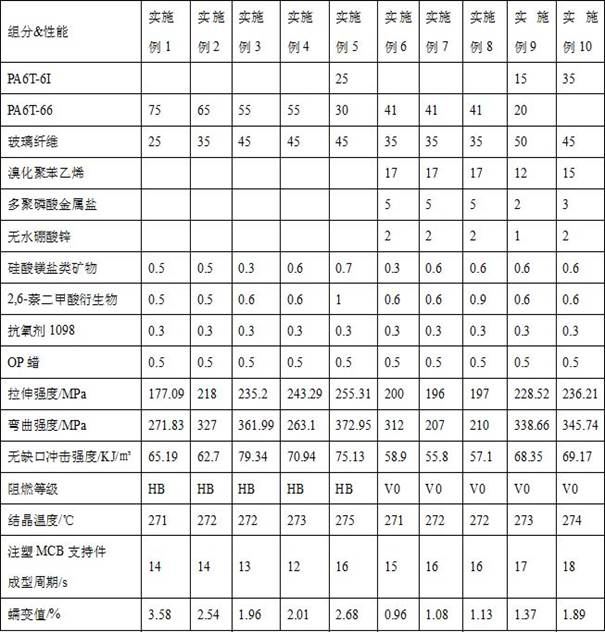

Semi-aromatic nylon composition and preparation method thereof

PendingCN112521749AImprove heat resistanceGood dimensional stability at high temperatureFiberPolymer science

The invention discloses a semi-aromatic nylon composition which comprises the following components in parts by weight: 35-75 parts of semi-aromatic nylon resin, 25-50 parts of reinforced fibers, 0.3-1part of an inorganic nucleating agent, 0.5-1 part of 2,6-naphthalic acid and derivatives thereof, 0-24 parts of a flame retardant and 0-7 parts of a synergistic flame retardant. The semi-aromatic nylon composition disclosed by the invention is high in crystallization temperature and short in molding period; the invention solves the problems that the existing modified semi-aromatic nylon compositematerial is difficult to mold and demold, the size shrinkage of a molded product needs post-treatment and the like. The product has excellent high-temperature creep resistance and comprehensive mechanical properties and can be widely applied to the fields of electronics, automobiles, war industry and the like.

Owner:BENSONG ENG PLASTICS HANGZHOU

A kind of high temperature resistant al-si-b-o ceramic airgel material and its synthesis method

ActiveCN110436953BGood heat insulationGood dimensional stabilityCeramicwareSupercritical dryingNanoparticle

The invention provides a high-temperature-resistant Al-Si-B-O ceramic airgel material, which uses a sol-gel process to uniformly disperse an aluminum precursor, a silicon precursor, and a boron precursor in a solvent, and then undergoes hydrolysis and polycondensation After the reaction, co-gel, and then synthesize a high-temperature-resistant Al-Si-B-O ceramic airgel material through a supercritical drying process. The present invention is passed in Al 2 o 3 The introduction of Si and B elements into the airgel can not only significantly delay Al 2 o 3 The sintering and phase transformation of nanoparticles can also form an aluminoborosilicate glass phase film covering the surface of the aerogel at a high temperature of 1500 ° C, effectively blocking the continuous transfer of heat from the outside of the aerogel to the inside, thereby improving the performance of the aerogel. al 2 o 3、 Al 2 o 3 ‑SiO2 2 The high-temperature thermal stability and high-temperature heat insulation performance of the base airgel can significantly increase the service temperature of the aerogel, and can be used as a high-temperature heat-insulation protective material for aerospace vehicles.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Antistatic polysulfonamide/carbon nano-tube composite material and preparation method thereof

InactiveCN102418164BGood dimensional stability at high temperatureImprove heat resistanceElectroconductive/antistatic filament manufactureMonocomponent copolyamides artificial filamentFiberComposite film

The invention provides an antistatic polysulfonamide / carbon nano-tube composite material and a preparation method thereof. The polysulfonamide / carbon nano-tube composite material is prepared by adopting a solution blending method in a physical blending technology, taking polysulfonamide as a matrix and adding carbon nano-tubes with different mass fractions, and is prepared into composite fibers or composite films. According to the invention, an ultrasonic blending technology is utilized so that a small amount of the carbon nano-tubes can be uniformly dispersed in the polysulfonamide matrix in nano-scale; as nano particles with excellent electric conductivity, the carbon nano-tubes ensure that the prepared antistatic polysulfonamide / carbon nano-tube composite material has good antistatic properties, and the specific surface resistivity of the composite material reaches 104 to 1,011 omega; moreover, the rigidity and excellent high-temperature dimensional stability, heat resistance and the like of the carbon nano-tubes can be perfectly combined with the tenacity and processability of an organic polymer. The preparation method provided by the invention is simple and convenient in process, strong in operability and low in cost.

Owner:SHANGHAI UNIV OF ENG SCI

Fiber-reinforced silicate fireproof board produced by mixing industrial waste residue, and preparation method and application thereof

The invention discloses a fiber reinforced silicate fireproof board produced by doping industrial waste residue. The fiber reinforced silicate fireproof board comprises, by mass, 7-15% of cement, 20-30% of carbide slag, 20-35% of polished tile waste residue, 4-10% of metakaolin, 4-10% of aluminum hydroxide, 4-10% of mica, 3-6% of expanded perlite, 3-6% of expanded vermiculite, 6-8% of wood pulp fiber and 0.6-1.2% of bentonite. The polished tile waste residue is utilized to produce the fiber reinforced silicate fireproof board, so that a new path is provided for using the polished tile waste residue, production cost is low, the process is easy to realize, and the fiber reinforced silicate fireproof board has remarkable substantial effect on utilization of the polished tile waste residue and environment protection. The fiber reinforced silicate fireproof board has low heat conducting coefficient and high high-temperature size stability and can be used for face boards of passive fireproof system of various buildings.

Owner:金强(福建)建材科技股份有限公司

Industrial canvas

The invention aims at providing industrial canvas. Warp yarns and weft yarns adopt activated polyester industrial filaments, wherein an external layers of polyester industrial filaments are processed by epoxy compound activation oil agents; density of warps is 136 warps / cm; density of wefts is 56 wefts / cm; the warp yarns and the weft yarns adopt activated polyester industrial filaments; the filaments have the advantages of high modulus, high orientation and good size stability under high temperature; the external layers of the polyester industrial filaments are processed by the epoxy compound activation oil agents, consequently, the performance of high modulus and low shrinkage of the polyester yarns can be ensured; impregnation through one bath process is used in a subsequent impregnation process, so that the production cost is reduced.

Owner:WUHU SHZ IND FABRIC

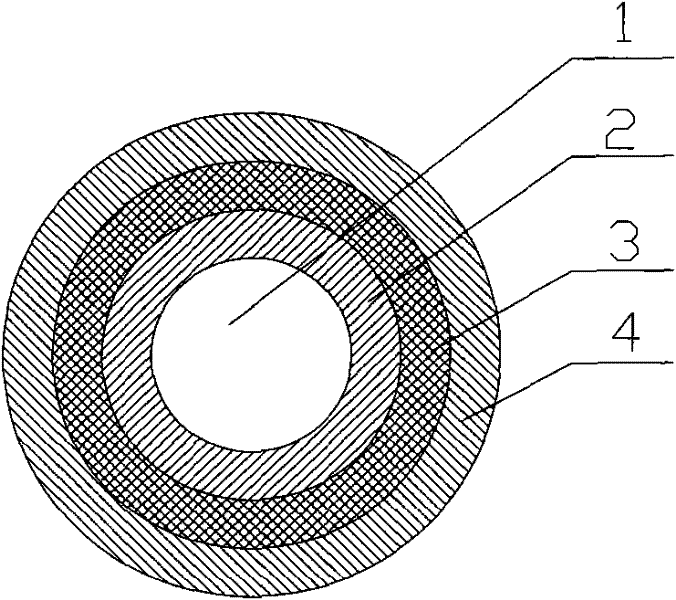

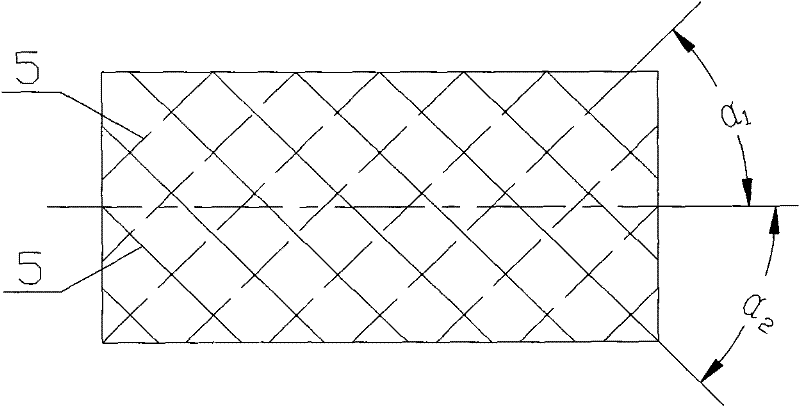

Method for preparing wound heat-insulating drum

ActiveCN101949481BReduce manufacturing costShorten the production cycleThermal insulationPipe protection by thermal insulationAdhesiveCarbonization

Owner:XIAN CHAOMA SCI TECH

Polyimide/magnesium oxide composite lithium ion battery diaphragm and preparation method thereof

PendingCN113725554AGood dimensional stability at high temperatureImprove flame retardancySecondary cellsCell component detailsPolyamideLithium electrode

The invention provides a preparation method of a polyimide / magnesium oxide composite lithium ion battery diaphragm. According to the method, Mg < 2 + > metal ions are introduced onto polyamide acid fibers by adopting an ion exchange method, and subsequent heat treatment is carried out to simultaneously realize imidization of polyamide acid and formation of MgO nanoparticles. The method comprises the following steps of: firstly, synthesizing polyamide acid serving as a spinning solution by taking diamine and dianhydride as monomers, and obtaining a polyamide acid nanofiber membrane through electrostatic spinning; then preparing a magnesium salt solution with a certain concentration, immersing the polyamide acid nanofiber membrane into the magnesium salt solution for a period of time to perform ion exchange, performing cleaning and drying; and finally performing thermal imidization to obtain the polyimide / magnesium oxide composite nanofiber membrane. The method disclosed by the invention is simple and low in cost; the surface of the polyimide nanofiber membrane is coaxially coated withmagnesium oxide, and therefore, the wettability of a diaphragm electrolyte is increased, the flame retardance of the diaphragm electrolyte is improved; and the method has a wide application prospect in the field of novel lithium ion battery diaphragms.

Owner:北京宇程科技有限公司

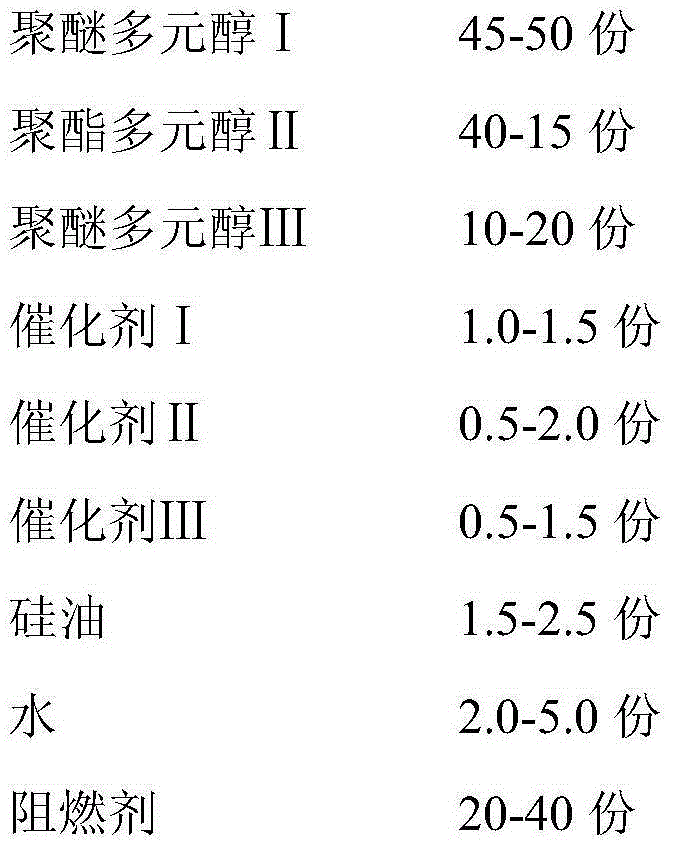

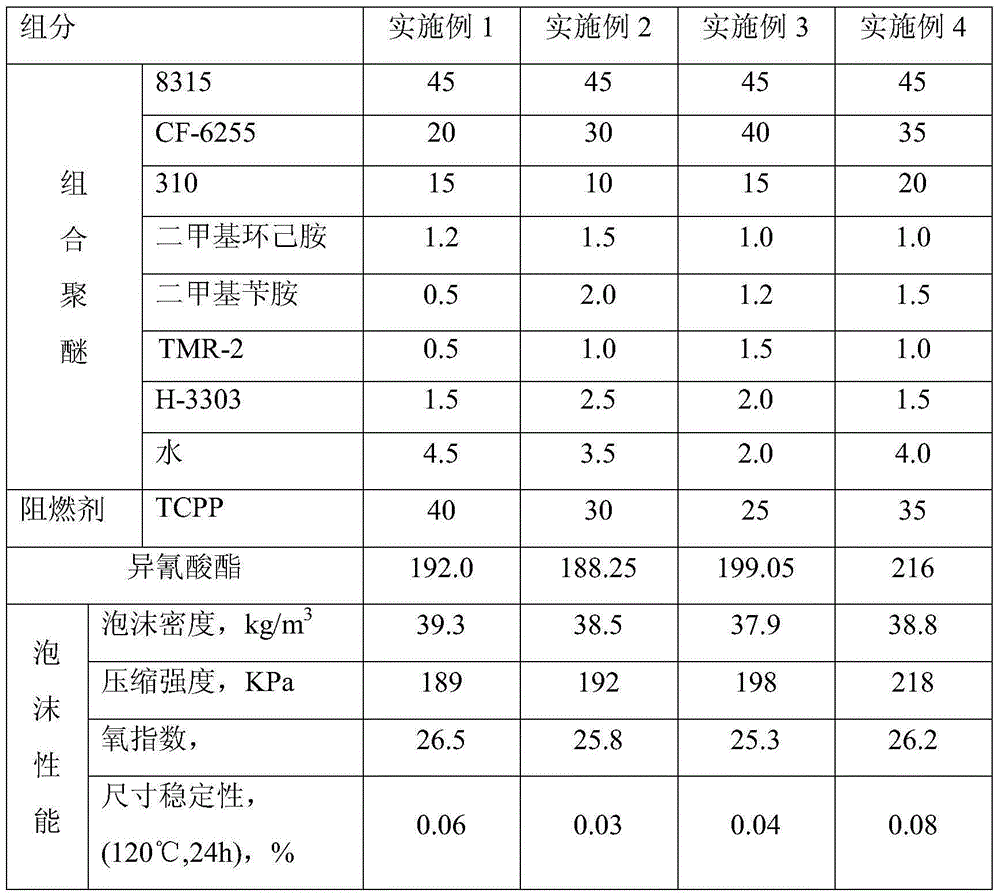

Foaming material for split solar thermal insulation board and preparation method thereof

ActiveCN103665297BHigh compressive strengthGood dimensional stability at high temperaturePolyesterPolyol

The invention belongs to the technical field of polyurethane foaming plastics, and in particular relates to a foaming material for a split solar heat-insulation board and a preparation method of the foaming material. Polyether polyol I, polyether polyol II, polyether polyol III, a catalyst I, a catalyst II, a catalyst III, silicone oil and a fire retardant are mixed uniformly to obtain the foaming material. Foam generated during the reaction process of the prepared foaming material and isocyanate has high compression strength, therefore the foam generated by the foaming material for the split solar heat-insulation board has high high-temperature size stability, and the foam is prevented from deforming at high temperature. Meanwhile, fire-retardant polyester is adopted to be matched with the fire retardant for use, so that the split solar heat-insulation board is ensured to have B2-grade fire-retardant performance. The method has the advantages of being scientific and reasonable, simplicity and easiness in operation and low production cost.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

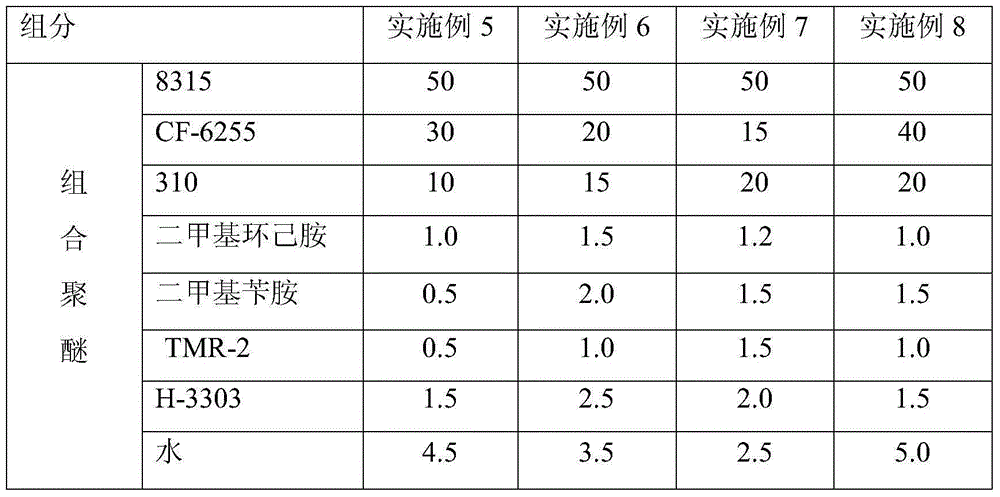

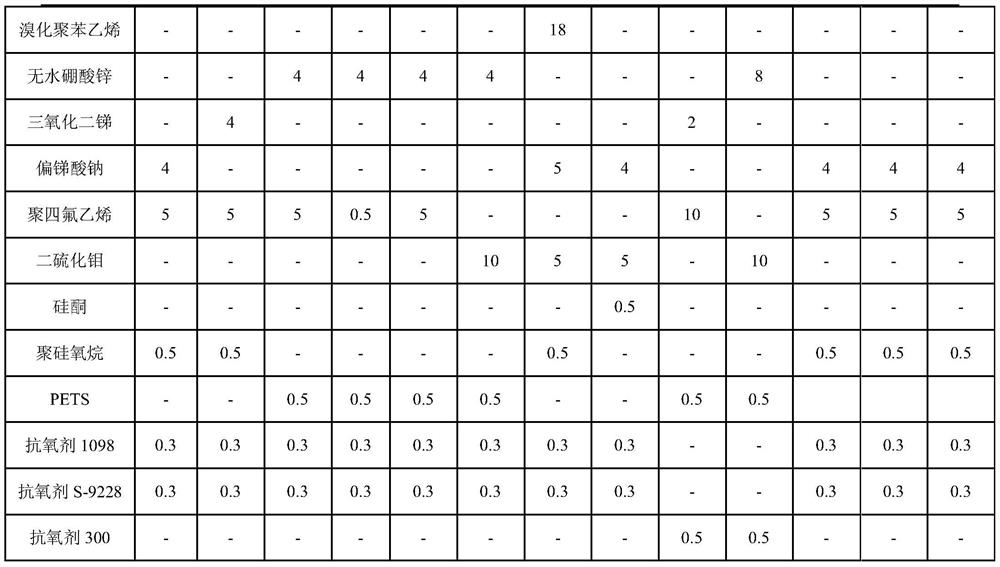

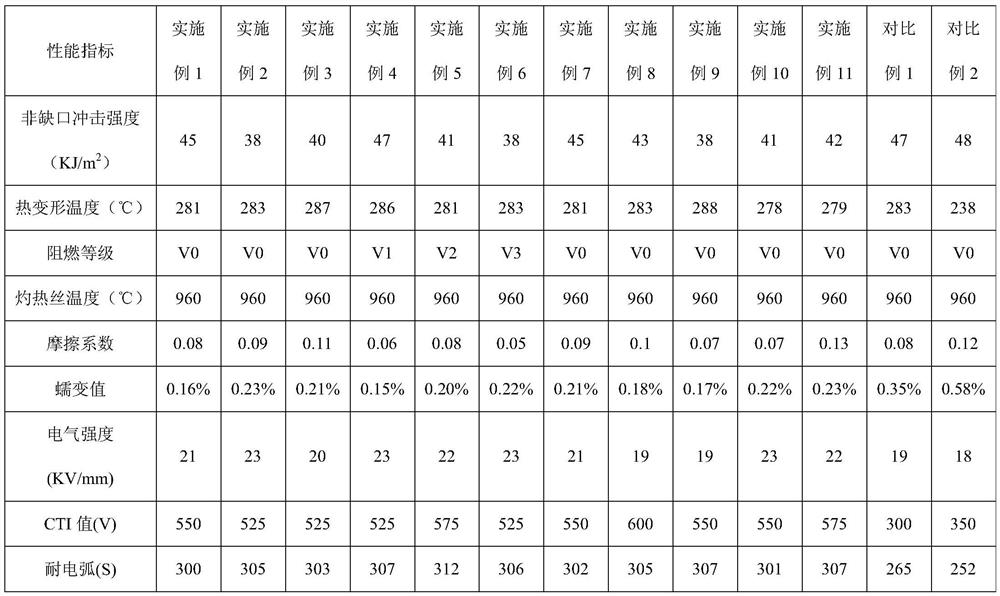

a thermoplastic composition

The invention relates to a thermoplastic composition which can replace thermosetting plastic and cross-linked nylon when used as a contact supporting part for a medium-and-high-grade alternating current contactor. According to the invention, a specific resin matrix is selected and used, and a specific fire retardant is rationally compounded with a reinforcing agent and a wear-resisting agent, so a reinforced flame-retardant wear-resistant synergistic system is formed, and the effect each component is made full use of. Compared with the prior art, the thermoplastic composition provided by the invention has the characteristics of high impact strength, high heat resistance, excellent flame resistance, good wear resistance, good dimensional stability at high temperature, superior arc resistance and good insulating properties, and completely satisfy performance requirements of a contact supporting material.

Owner:BENSONG ENG PLASTICS HANGZHOU

Polyimide/zinc oxide composite lithium ion battery diaphragm and preparation method thereof

PendingCN113725553AGood dimensional stability at high temperatureImprove wettabilitySecondary cellsCell component detailsElectrolytic agentOxide composite

The invention provides a preparation method of a polyimide / zinc oxide composite lithium ion battery diaphragm. According to the method,Zn < 2 + > metal ions are introduced onto polyamide acid (PAA) fibers by adopting an ion exchange method, and subsequent heat treatment is performed to simultaneously realize the imidization of the PAA and the formation of ZnO nanoparticles. The method comprises the following steps of: synthesizing PAA by taking diamine and dianhydride as monomers, and carrying out electrostatic spinning by taking the PAA as a spinning solution to obtain a PAA nanofiber membrane; then preparing a zinc salt solution with a certain concentration, immersing the PAA nanofiber membrane into the zinc salt solution for a period of time for ion exchange, and performing cleaning; and finally, carrying out thermal imidization to obtain a polyimide / zinc oxide composite nanofiber membrane. The method is simple and low in cost; the surface of the polyimide nanofiber membrane is coaxially coated with zinc oxide, so that the wettability of a diaphragm electrolyte is improved, and the flame retardance of the diaphragm electrolyte is effectively improved; and the method has a wide application prospect in the field of novel lithium ion battery diaphragms.

Owner:BEIJING YUCHENG TECH CO LTD

A kind of polyaryl sulfone amide-based porous membrane and its preparation method and application

The invention belongs to the field of polymeric membrane materials, and particularly relates to a polyarylsulfone amido porous membrane, and a preparation method and an application thereof. The porous membrane is provided with a porous eyed structure, the hole diameter range is 50 nm-5 mum, and the porosity is 50-90%. The invention further discloses the preparation method of the porous membrane. The polyarylsulfone amido porous membrane is prepared from a solution containing polyarylsulfone amide, an additive, a pore-foaming agent and a solvent with a phase inversion method. The preparation technology is good in controllability; the preparation method is simple; the production cost is low; the obtained porous membrane is adjustable in hole diameter, good in penetrability and higher in membrane air permeability; the dimension shrinkage rate at 200 DEG C is less than 1%; the thermal stability is excellent; and the flame resistance is good. The porous membrane can be used in the fields of high-temperature filter materials, adsorbing materials, air-permeability packaging materials, parting materials, lithium ion battery diaphragms and the like.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com